Page 1

Air Cooled

Condenser

Installation

Bulletin No. H-IM-65B December 1999 Part Number 90800701

Replaces H-IM-65A, August 1996

Angle Leg Models

Channel Legs Models

Air-Cooled

Condensers

21 - 212 Tons

Installation and

Maintenance Data

Table of Contents

Inspection

System Warranty

Installation

Unit Location

Sound Vibration . . . . . . . . . . . . . . . . . . . . . . . . 2

Rigging Instructions . . . . . . . . . . . . . . . . . . . . . 3

Space and Location Requirements . . . . . . . . . 4

Typical Arrangements

Installation, Refrigerant Piping . . . . . . . . . . . . . 5

Line Sizing

Discharge Lines

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . 6

Typical Wiring Diagrams . . . . . . . . . .. . . . . . . 7-8

Start-Up

Discharge Gas Pulsation

Operation

Winter Operation Head Pressure Control

Fan Cycling . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Fan Cycling Head Pressure Controls

Flooding Head Pressure Controls

Refrigerant Charge . . . . . . . . . . . . . . . . . . . . . . 10

Minimum Ambient for Fan Cycling

Mechanical Fan Cycling Thermostat Settings. . 11

Electronic Fan Cycling Thermostat Settings

Pressure Chart . . . . . . . . . . . . . . . . . . . . . . . . . 12

Additional Refrigerant Charges

Maintenance

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . 13

In-Warranty Return Material Procedure

Replacement Parts . . . . . . . .. . . . . . . . . . . . . 14

Installation Check List . . . . . . . . . . . . . . . . . 15

1

Page 2

Inspection

Responsibility should be assigned to a dependable individual

at the job site to receive material. Each shipment should

be carefully checked against the bill of lading. The shipping

receipt should not be signed until all items listed on the bill of

lading have been accounted for.

Check carefully for concealed damage. Any shortage or

damages should be reported to the delivering carrier.

Damaged material becomes the delivering carrier's

responsibility, and should not be returned to the manufacturer

unless prior approval is given to do so. When uncrating, care

should be taken to prevent damage. Heavy equipment should

be left on units shipping base until it has been moved to the

nal location.

System Warranty

This equipment is designed to operate properly and produce

rated capacity when installed in accordance with accepted

industry standards. Failure to meet the following conditions

may result in voiding of the system warranty:

1. System piping must be installed following industry

standards for good piping practices.

2. Inert gas must be charged into piping during

welding.

3. System must be thoroughly leak checked and

evacuated before initial charging. High vacuum

gauge capable of reading microns is mandatory.

Dial indicating pressure gauges are not acceptable.

4. Power supply to system must meet the

following conditions:

a. Voltage for 208/230 motors not less than

195 volts or more than 253 volts.

b. All other voltages must not exceed +/- 10%

of nameplate ratings.

c. Phase imbalance not to exceed 2%.

5. All controls and safety switch circuits properly

connected per wiring diagram.

6. Factory installed wiring must not be changed without

written factory approval.

Installation

Note: Installation and maintenance to be performed

onlybyqualiedpersonnelwhoarefamiliarwith

local codes and regulations, and experienced

withthistypeofequipment.

Caution: Sharp edges and coil surfaces are a

potential injury hazard.

Avoidcontactwiththem.

Unit Location

Units are designed for outdoor application and may be

mounted on a roof or concrete slab (ground level installation).

Roof mounted units should be installed level on steel

channels or an I-beam frame to support the unit above the

roof. Use of vibration pads or isolators is recommended. The

roof must be strong enough to support the weight of the unit.

Concrete slabs used for unit mounting should be installed

level and be properly supported to prevent settling. A onepiece concrete slab with footings extending below the frost

line is recommended.

The condenser should be located far enough away from any

wall or other obstruction to provide sufcient clearance for air

entrance. Do not attach ductwork to the coil inlet or fan outlet.

Care should be taken to avoid air recirculation conditions that

can be caused by sight screening, walls, etc. Also keep unit

fan discharge away from any building air intakes. See page 4

for space and location requirements.

Sound Vibration

Units should be installed away from occupied spaces and

above or outside of utility areas, corridors and auxiliary

spaces to reduce the transmission of sound and vibration to

occupied spaces. The refrigerant piping should be exible

enough to prevent the transmission of noise and vibration

from the unit into the building. If the refrigerant lines are to

be suspended from the structure of the building, isolation

hangers should be

used to prevent the transmission of vibration. Where piping

passes through a wall, it is advisable to pack berglass and

sealing compound around the lines to minimize vibration and

retain exibility in the lines.

The unit needs to be secured in its nal location. Holes are

provided in the base runner for this purpose.

Warning: This equipment may contain a substance

whichharmsthepublichealthand

environment by destroying ozone in the

upper atmosphere. Venting of certain

refrigerants to the atmosphere is illegal.

Refrigerant recovery devices must be used

wheninstallingorservicingthisproduct.

Consult your local codes for requirements

in your location.

Warning: There may be more than one source of

electrical current in this unit. Do not

servicebeforedisconnectingallpower

supplies.

2

© 2004, Heatcraft Refrigeration Products LLC

Page 3

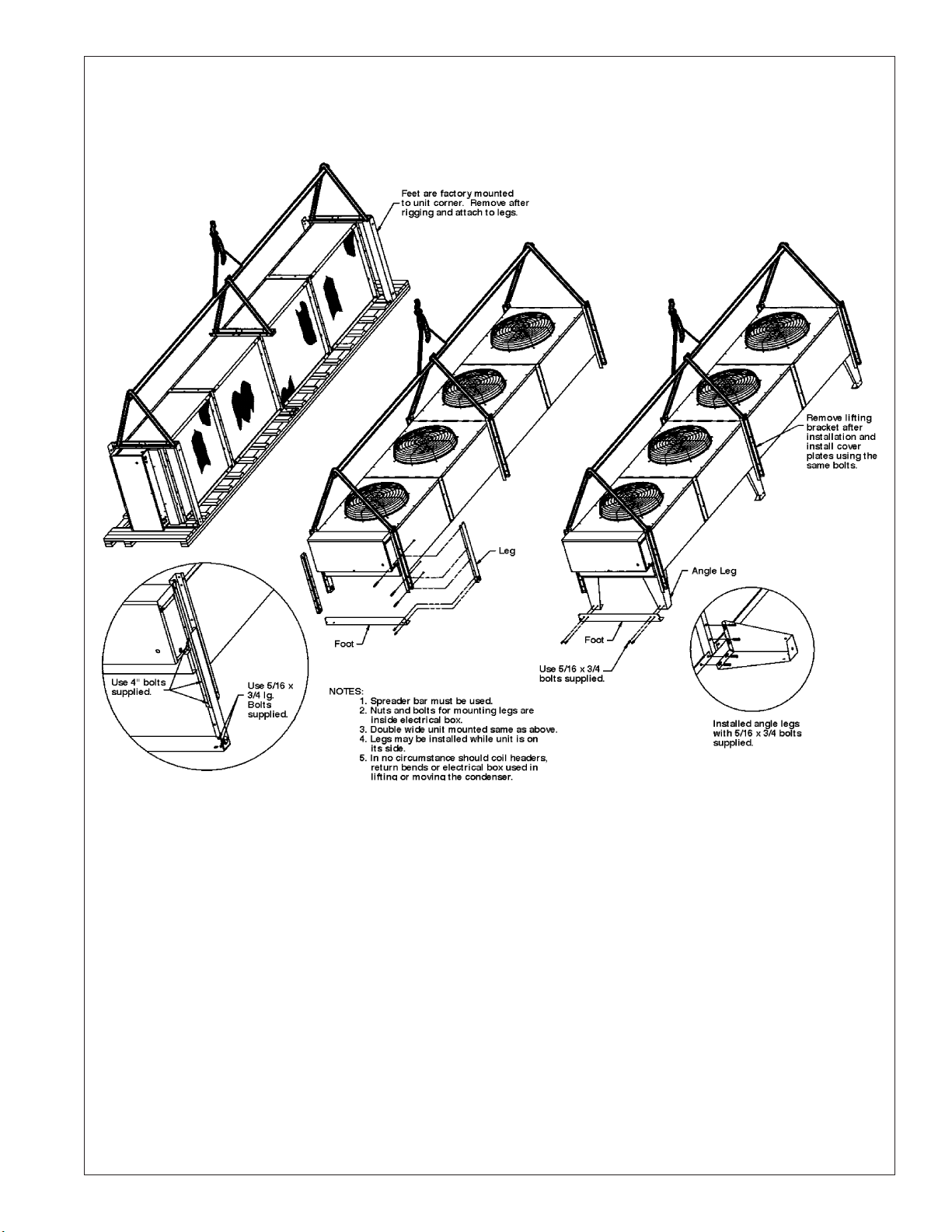

Drawing1.RiggingInstructions

3

Page 4

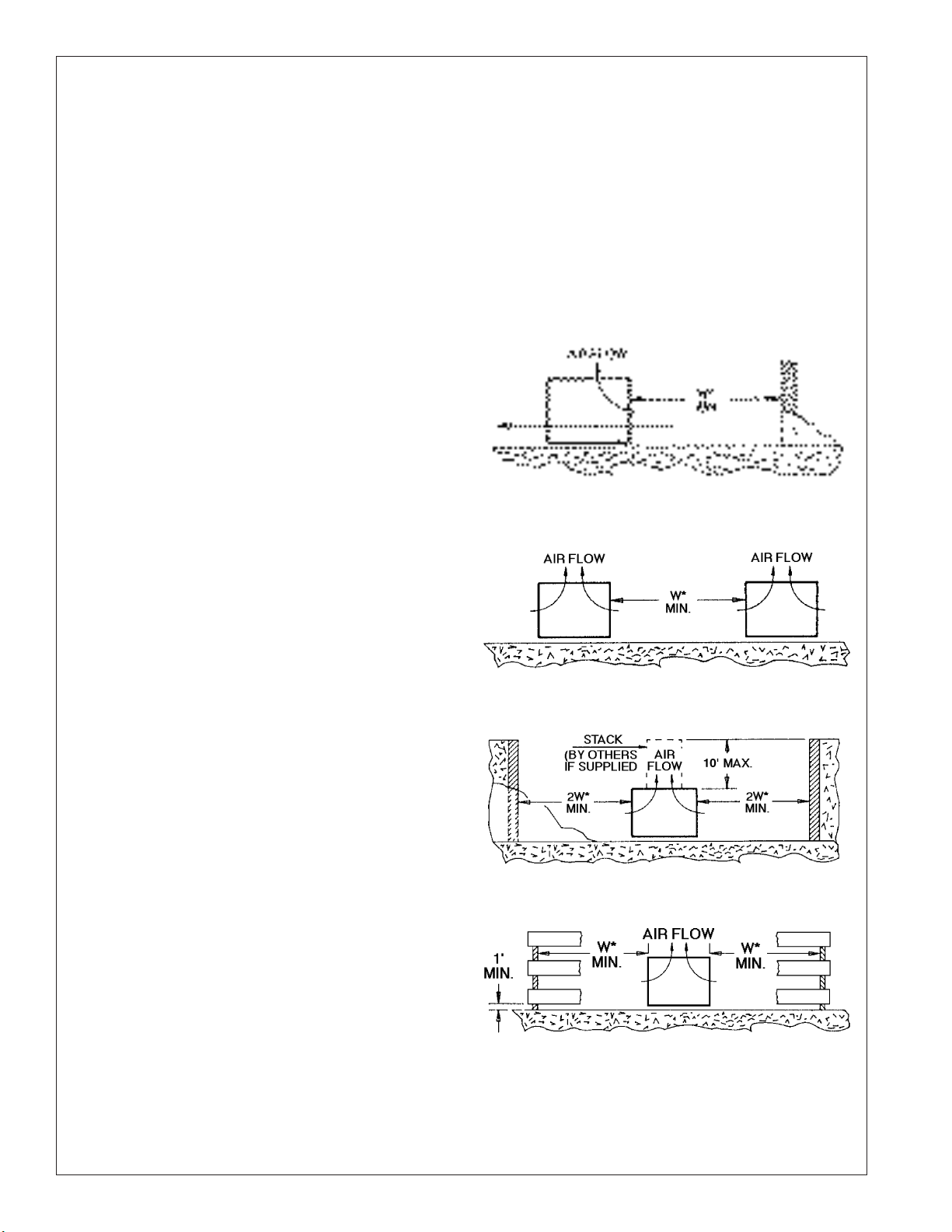

Space and Location Requirements

The most important consideration which must be taken

into account when deciding upon the location of air-cooled

equipment is the provision for a supply of ambient air to the

condenser, and removal of heated air from the condenser

area. Where this essential requirement is not adhered to,

it will result in higher head pressures, which cause poor

operation and possible eventual failure of equipment. Units

must not be located in the vicinity of steam, hot air or fume

exhausts.

Walls or Obstructions

The unit should be located so that air may circulate freely and

not be recirculated. For proper air ow and access all sides

of the unit should be a minimum of “W” away from any wall

or obstruction. It is preferred that this distance be increased

whenever possible. Care should be taken to see that ample

room is left for maintenance work through access doors and

panels. Overhead obstructions are not permitted. When the

unit is in an area where it is enclosed by three walls the unit

must be installed as indicated for units in a pit.

Another consideration which must be taken is that the unit

should be mounted away from noise sensitive spaces and

must have adequate support to avoid vibration and noise

transmission into the building. Units should be mounted

over corridors, utility areas, rest rooms and other auxiliary

areas where high levels of sound are not an important factor.

Sound and structural consultants should be retained for

recommendations.

Multiple Units

For units placed side by side, the minimum distance between

units is the width of the largest unit. If units are placed end to

end, the minimum distance between units is 4 feet.

Units in Pits

The top of the unit should be level with the top of the pit, and

side distance increased to “2W”.

If the top of the unit is not level with the top of pit, discharge

cones or stacks must be used to raise discharge air to the top

of the pit. This is a minimum requirement.

Decorative Fences

Fences must have 50% free area, with 1 foot undercut, a “W”

minimum clearance, and must not exceed the top of unit.

If these requirements are not met, unit must be installed as

indicated for “Units in pits”.

* “W” = Total width of the condenser.

4

Page 5

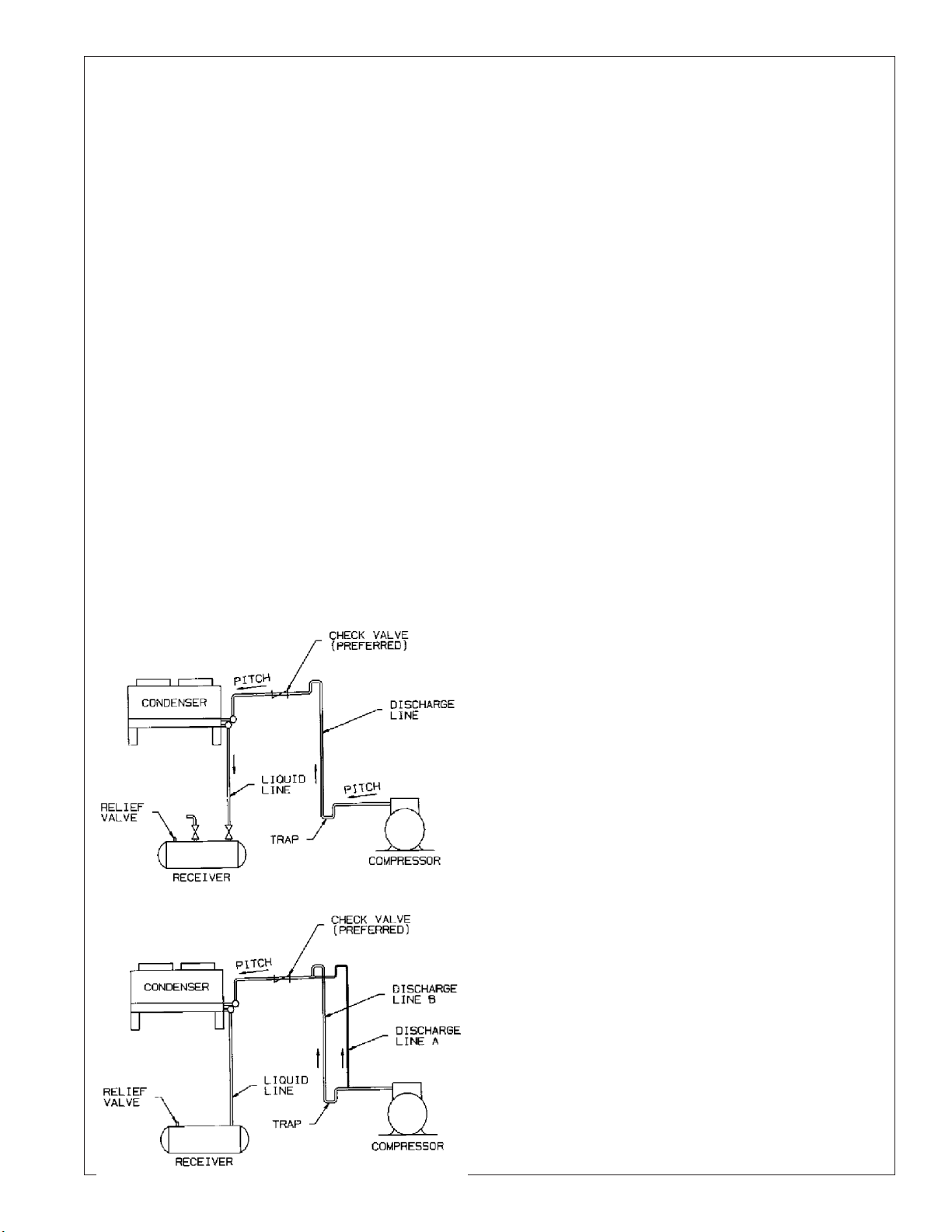

Typical Arrangements

Notes:

Figure 1 illustrates a typical piping arrangement involving a

remote condenser located at a higher elevation, as commonly

encountered when the condenser is on a roof and the

compressor and receiver are on grade level or in a basement

equipment room.

In this case, the design of the discharge line is very critical.

If properly sized for full load condition, the gas velocity

might be too low at reduced loads to carry oil up through the

discharge line and condenser coil. Reducing the discharge

line size would increase the gas velocity sufciently at

reduced load conditions; however, when operating at full load,

the line would be greatly undersized, and thereby create an

excessive refrigerant pressure drop. This condition can be

overcome in one of two following ways:

1.The discharge line may be properly sized for the desired

pressure drop at full load conditions and an oil separator

installed at the bottom of the trap in the discharge line

from the compressor.

2. A double riser discharge line may be used as shown in

Figure 2. Line “A” should be sized to carry the oil at mini mum load conditions and the line “B” should be sized so

that at the full load conditions both lines would have suf cient ow velocity to carry the oil to the condenser.

For more complete information, refer to the ASHRAE

Handbook on Systems.

Figure 1

1. All oil traps are to be as short in radius as

possible. Common practice is to fabricate the

trap using three 90 degrees ells.

2. Pressure relief valves are recommended at the

condenser for protection of the coil.

3. A drain line check valve is recommended for

applications where the condenser may be at a

lower temperature than the receiver.

Installation, Refrigerant Piping

Install piping according to standard accepted

refrigeration practice. The following recommendations

should be adhered to:

1. See Tables 1 and 2 for discharge and liquid

drain line sizes for remote condenser

connections.

2. Use only refrigeration grade copper tubing.

3. Soft solder joints are not acceptable.

4. Put dry nitrogen through lines while brazing.

5. Do not leave dehydrated piping or components

open to the atmosphere any longer than is

absolutely necessary.

Figure 2

5

Page 6

Discharge Lines

The proper design of discharge lines involves two objectives:

1. To minimize refrigerant pressure drop, since high

pressure losses cause increased compressor

horsepower per ton of refrigerant.

2. To maintain sufciently high gas velocity to carry oil

through to the condenser coil and receiver at all loading

conditions.

Table 1. Tons of Refrigeration

Line Size

Type L R-22 R-404A/R-507 Velocity 100 FPM

Copper Sat. Suction Temp (°F) Sat. Suction Temp (°F) Refrigerant

OD -40 0 40 -40 0 40 R-22 R-502

1/2 0.75 0.8 0.85 0.56 0.63 0.7 2.3 1.5

5/8 1.4 1.5 1.6 1.0 1.2 1.3 3.7 2.3

7/8 3.7 4.0 4.2 2.7 3.1 3.4 7.8 4.9

1 1/8 7.5 8.0 8.5 5.5 6.3 7.0 13.2 8.3

1 3/8 13.1 14.0 14.8 9.6 10.9 12.1 20.2 12.6

1 5/8 20.7 22.0 23.4 15.2 17.2 19.1 28.5 17.9

2 1/8 42.8 45.7 48.5 31.4 35.6 39.5 49.6 31.1

2 5/8 75.4 80.4 85.4 55.3 62.8 69.5 76.5 48.0

3 1/8 120.2 128.2 136.2 87.9 99.8 110.5 109.2 68.4

3 5/8 178.4 190.3 202.1 130.5 148.1 164.0 147.8 92.6

4 1/8 251.1 267.8 284.4 183.7 208.4 230.9 192.1 120.3

Discharge Line

Drain Line

Table 2. Condensing

Temperature Correction Factor

Condensing Discharge Line

Temperature R-22 R-404A/R-507

90 0.88 0.91

100 0.95 0.97

110 1.04 1.02

120 1.10 1.08

130 1.18 1.16

Source: ASHRAE Refrigeration Handbook:

1. Line sizes based on pressure drop equivalent to 1°F per 100

equivalent feet.

2. Values in Table are based on 105°F condensing temperature.

Multiply Table capacities by the factors in Table 2 for other

condensing temperatures.

Electrical Wiring

The electrical installation should be in accordance with

National Electrical Code, local codes and regulations. Proper

overcurrent protection should be provided for the fan motors.

All standard motors have internal inherent overload

protectors. Therefore, contactors can be used instead of

starters requiring thermal protectors, eliminating the problem

of furnishing the proper heating elements.

All air-cooled condensers are furnished with either single-

phase or three-phase fan motors which are identied by the

unit dataplate.

3. If subcooling is substantial or the line is short, a smaller line

size may be used. Applications with very little subcooling or

very long lines may require larger sizes

Electrical leads from each motor terminate at the unit junction

box. Field connections must be made from these leads in

accordance with local, state and national codes.

Three-phase motors must be connected to three-phase

power of voltage to agree with motor and unit dataplate.

The motors are wired into a common junction box. Where

fan cycling is furnished and factory installed, the motors are

completely wired through the control and to the contactors.

The motors must be checked for proper rotation. Be sure to

check that motor voltage and control connection agree with

electric services furnished.

WARNING: There may be more than one source of electrical current in this unit. Do not service before

disconnectingallpowersupplies.

6

Page 7

Diagram 1. Typical Wiring Diagram for Standard Fan Cycling.

7

Page 8

Diagram2.TypicalWiringDiagramforVariableSpeedMotorwithFanCycling.

8

Page 9

Start-Up

Check for proper fan rotation. Air is drawn through the coil on

all units. Be sure the fans turn freely.

Rotation of the motors and blades should be in a “CW”

direction looking at the unit from the blade side. On three

phase units, it may be necessary to reverse two of the three

power leads to the unit.

NOTE: The manifold assembly is not designed to

supporteldpiping.Anydamagestothe

condenserduetoexcessiveweight,

pressureorvibrationwillnotbecovered

byourstandardwarranty.

Discharge Gas Pulsation

Gas pulsations in a refrigeration system are most commonly

associated with the compressor and connecting discharge

piping. Variations in the system piping conguration, line

sizing, operating pressures and compressor and component

mounting all contribute to the presence and magnitude of

these pulsations.

The vibration and movement of components caused by the

pulsations may result in line breakage or damage to the

condenser. In order to eliminate discharge pulsations and the

potential for related condenser damage, it is recommended

that a discharge mufer be installed in the refrigeration piping.

In all cases, the recommendations of the compressor or

mufer manufacturer must be followed when selecting these

components.

Operation

Winter Operation Head Pressure Control

The capacity of an air-cooled condenser varies with the

difference between the entering air dry bulb temperature

and the condensing temperature of the refrigerant. Since

air temperature in some regions varies as much as 100°

from summer to winter, some means must be employed to

keep the condensing temperature sufciently high to insure

proper operation of the refrigerant expansion valve during

low ambient operation, and also allow sufcient capacity so

that excessively high condensing temperatures do not result

during high ambient conditions.

The low limit of the head pressure is dependent upon the

required pressure drop across the thermostatic expansion

valve. For normal air conditioning applications, head

pressure should be maintained above a condensing

temperature corresponding to 90° F. This, in effect,

corresponds to a normal lower limit of about 60° F ambient

air. Since air conditioning is not normally required at these

lower ambient temperatures, condenser head pressure

control may not always be necessary. However for those

applications which are of such a nature that operation is

required below 60° F ambient air temperature, additional

head pressure control will be required.

Fan Cycling

A decrease in ambient air temperature results in a capacity

increase in the air-cooled condenser. This capacity increase

is directly proportional to the temperature difference between

the condensing temperature and the temperature of the ambient air entering the condenser. Since air-cooled condensers

are often required to operate over a wide range of ambient

air temperatures and variable loading conditions, provisions

must be made to maintain the overall system balance. Any

air-cooled condenser tends to run at a low head pressure

when operating in a low ambient air temperature. Low head

pressures could result in poor expansion valve operation and

poor system operation.

The cycling of condenser fans provides an automatic means

of maintaining head pressure control, within reasonable limits,

at lower ambient air temperatures. A fan cycling control system allows fans to cycle in sequence by sensing either ambient temperature or condensing pressures. However, care

must be used by the engineer or installing contractor in making adjustments to prevent short cycling of the fan motors.

Short cycling is normally caused by too close a differential in

the control settings or set points. If ooding valves are used

with fan cycling, they must be set to follow the fan cycling.

Recommended differential settings for ambient sensing

thermostats are 5° F and a minimum of 35 PSIG differential

for pressure switches. However, system or climate conditions

vary and the controls may require further eld adjustment

to provide optimum system performance and prevent short

cycling.

Any fan cycle that is less than three minutes is considered

short cycling, and could be detrimental to the system. Adjust

controls accordingly. It is also recommended that the fan closest to the header end of the condenser be wired to run continuously, whenever the compressor(s) is (are) operational.

Cycling all of the fans off usually results in rapid, short cycling

of the fans and erratic head pressure control.

If additional head pressure control is necessary beyond letting the lead fan run, we recommend adding variable speed

or ooding controls. If cycling the header fan is necessary

for adequate head pressure control, we recommend cycling

on pressure. Ambient sensing thermostats should never be

used to cycle the lead fan.

Fans must not cycle in multiples except on double wide single

circuit condensers where they may cycle in pairs (one motor

on each side). Do not cycle more than two fans at a time on

double wide condensers and only one fan at a time on single

wide condensers.

9

Page 10

Fan Cycling Head Pressure Controls

Condenser fans are cycled to maintain adequate

head pressure. Ambient and pressure fan cycling are

available as optional equipment.

Ambient fan cycling cycles fans in response to the

ambient air temperature. This control is ideal for multicircuited condensers or for systems operating in mild

ambient conditions. See table 3 for minimum ambient

temperatures for fan cycling. Set points for thermostats

will vary depending on the number of fans and

condenser design T.D. See table 4 for recommended

set points.

Pressure fan cycling cycles fans in response to

condenser pressure. This style of control is more

appropriate where the load on the condenser will vary

due to multiple compressor operation or stages of

unloading or systems incorporating heat reclaim or hot

gas defrost.

Variable Speed

Condenser head pressure control is provided by

varying the air ow through the condenser by changing

the RPM of the condenser fan. This control package

is offered in combination with ambient fan cycling. The

fan motor next to the header end of the condenser is

the variable speed fan.

The remainder of the fans are constant speed and are

cycled separately using ambient sensing thermostats.

On condensers with two rows of fans, two variable

speed fans are provided (one per unit) and the

remainder of the fans are constant speed and are

cycled in pairs.

Splitting Controls

Additional head pressure can be provided by valving

off a portion of the condenser circuit and removing

that portion from the refrigeration circuit. This is

often referred to as splitting a condenser. In addition

to providing a means of head pressure control, this

control will reduce the amount of refrigerant required

to operate the condenser with a ooded head pressure

control.

Condenser splitting is recommended as a seasonal

adjustment controlled by ambient temperature. An

initial setting of 50° to 55° F with a 20° F differential is

recommended. A pressure switch is also provided as

a backup control to prevent high head pressures from

occurring during heavy load conditions.

On condensers with a single row of fans the control

package consists of an ambient sensing thermostat,

a pressure switch sensing condensing pressure and

a splitting relay. The splitting relay provides a set of

dry contacts to control the valves required to split the

condenser (valves supplied by others).

On condensers with double rows of fans, additional

controls and contactors are provided to cycle all of the

fans on the side of the condenser which has been split

off.

Except as noted above, the splitting packages do not

control fan cycling. It is recommended that fan cycling

be controlled by combining the splitting package with

pressure fan cycling.

Flooding Head Pressure Controls

Another means of head pressure control is to change

the condenser capacity by lling the inside of the

condenser with liquid refrigerant. Flooding controls

are ideal for condensers operating in low ambient

conditions (beyond the limits of fan cycling controls) or

under partial load conditions. These controls require

additional refrigerant charge to ood the condenser.

This additional refrigerant charge can often be reduced

by incorporating the ooded control with one of the fan

cycle controls previously described.

Several styles of ooding valves or combinations of

valves are available. Contact the valve manufacturer

for specic recommendations.

Refrigerant Charge

The refrigerant charge for summer operation can be

found in table 8. This table also contains the additional

charge required by ooding style controls.

Table 7 contains the recommended ooding charge

required when combining fan cycling with ooding

valves.

10

Page 11

Table 3. Minimum Ambient for Fan Cycling

Number of Fans

Single Double Design T.D.*

Row Row 30 25 20 15 10

2 4 35 45 55 60 70

3 6 15 30 40 55 65

4 8 0 15 30 45 60

5 10 0 10 20 35 55

6 12 0 0 10 30 50

* Based on maintaining 90°F minimum condensing temperature.

Table 4. Mechanical Fan Cycling Thermostat Settings

Number of Fans

Single Double Design Thermostat Setting

Row Rows T.D. 1 2 3 4 5

2 4 30 60

25 65

20 70

15 75

10 80

3 6 30 60 40

25 65 55

20 70 60

15 75 65

10 80 65

4 8 30 60 50 30

25 65 55 40

20 70 65 50

15 75 70 60

10 80 75 70

5 10 30 60 55 45 30

25 65 60 50 35

20 70 65 60 40

15 75 70 65 55

10 80 75 70 65

6 12 30 55 50 40 30 25

25 65 60 55 45 35

20 70 65 60 50 40

15 75 70 65 60 50

10 80 75 70 65 60

11

Page 12

Table 5. Electronic Fan Cycling Thermostat Settings *

Number of Fans A350 S350 Temperature Stage Modules

Single Double Design Set Offset Settings

Row Rows T.D. Point 2 3 4 5

30 60

25 65

2 4 20 70

15 75

10 80

30 60 20

25 65 10

3 6 20 70 10

15 75 10

10 80 15

30 60 10 30

25 65 10 25

4 8 20 70 5 20

15 75 5 15

10 80 5 10

30 60 5 15 30

25 65 5 15 30

5 10 20 70 5 10 30

15 75 5 10 20

10 80 5 10 15

30 55 5 15 25 30

25 65 5 10 20 30

6 12 20 70 5 10 20 30

15 75 5 10 15 25

10 80 5 10 15 20

* Johnson Controls Style S350 operation.

5° differential set on all modules. All modules set in the “heating” mode.

Table 6. Pressure Chart

Number of Fans Control Settings

Single Double Design PressureSwitchCut-InSettings

Row Rows T.D. Refrigerant PC1 PC2 PC3 PC4 PC5

R134a 147

2 4 20 R22 215

R404A 220

R134a 147 155

3 6 20 R22 215 245

R404A 220 247

R134a 147 155 160

4 8 20 R22 215 231 247

R404A 220 238 255

R134a 147 153 156 160

5 10 20 R22 215 225 236 247

R404A 220 238 250 260

R134a 147 150 153 157 160

6 12 20 R22 215 223 230 239 247

R404A 220 238 245 255 265

Based on 20º T.D.;

For (R404A/R507) set cutout 35 PSIG below cutin; for (R134A) set cutout 25 PSIG below cutin.

Fan on header end to remain on whenever compressor is operating.

12

Page 13

Table 7. Additional Charge for Fan Cycling and Flooded Condenser, R-22*

Standard 25° TD 20° TD 15° TD 10° TD

No. No. Chg. for Minimum Minimum Minimum Minimum

of of Summer Condenser Ambient Condenser Ambient Condenser Ambient Condenser Ambient

Fans Rows Operation 40 20 0 -20 40 20 0 -20 40 20 0 -20 40 20 0 -20

2 2 8 3 10 14 17 8 14 17 19 13 17 20 28 18 21 22 23

3 12 4 15 20 25 12 21 25 28 20 26 30 32 27 32 34 35

4 15 5 20 28 34 17 28 34 38 26 34 40 42 36 42 45 47

3 3 19 0 7 20 28 0 19 28 35 17 30 38 42 32 41 46 50

4 22 0 9 26 37 0 25 38 47 22 40 50 56 42 54 61 66

4 3 22 0 0 14 26 0 11 28 38 9 30 42 57 34 49 56 61

4 27 0 0 18 35 0 15 38 51 11 40 56 67 45 65 75 81

5 3 35 - - 5 31 - - 34 58 - 38 70 83 49 79 98 112

4 43 - - 8 41 - - 46 77 - 51 94 111 65 106 130 149

6 4 50 - - - 25 - - 28 74 - 37 85 116 51 111 144 165

Table 8. Additional Refrigerant Charge for Flooded Condenser, No Fan Cycling R-22 *

Std. 30°TD Minimum 25°TD Minimum 20°TD Minimum 15°TD Minimum 10°TD Minimum

No. No. Chg. for Condenser Condenser Condenser Condenser Condenser

of of Summer Ambient Ambient Ambient Ambient Ambient

Fans Rows Oper. +60 +40 +20 0 -20 +60 +40 +20 0 -20 +60 +40 +20 0 -20 +60 +40 +20 0 -20 +60 +40 +20 0 -20

2 2 8 - 9 14 18 19 3 13 17 19 20 7 16 19 21 22 12 19 21 22 23 17 22 24 24 25

3 12 - 14 21 27 30 4 19 25 29 32 11 24 28 32 34 19 29 32 34 36 27 34 35 37 38

4 15 - 18 29 36 40 6 25 33 39 42 15 31 38 43 45 26 37 43 46 47 37 43 48 4: 51

3 3 19 - 21 33 40 45 6 28 38 44 47 17 35 43 48 51 2: 42 49 51 54 42 49 54 56 58

4 22 - 28 43 54 59 8 38 50 58 62 22 47 57 64 67 38 56 64 68 70 54 66 71 74 76

4 3 22 - 28 43 54 59 8 38 50 58 62 22 48 57 64 67 38 57 64 68 70 54 67 71 74 76

4 27 - 37 59 71 79 11 50 68 77 84 29 63 77 85 90 50 75 87 91 95 71 88 96 99 102

5 3 35 - 53 83 101 112 27 71 96 110 119 41 89 108 121 128 71 106 122 130 135 101 124 135 140 144

4 43 - 71 111 135 149 35 95 128 147 158 54 118 144 161 170 95 141 163 173 180 135 166 180 187 192

6 4 50 - 85 133 162 179 43 114 153 176 190 65 142 173 193 205 114 170 196 207 216 162 199 216 224 230

* NOTE: Values are shown for single fan wide condensers. Double these values for condensers that are two fans wide.

For R134a multiply charge by 0.99; For R404A multiply charge by 0.91; For R502 multiply charge by 1.04.

Maintenance

Air-cooled condensing units require a minimum of maintenance. The unit coil will require a periodic cleaning and this

can be accomplished by a brush, vacuum cleaner, pressurized air stream or a commercially available coil clean-

Cleaning Instructions

Heatcraft recommends that the nned surface of this unit

be cleaned approximately every six months; more frequent

cleaning may be required if extreme conditions cause clogging or fouling of air passages through the nned surface.

Calgon Corporation's CalClean 41352 (or equal) should be

acceptable for cleaning this unit. CalClean should be

ing foam. All of the condenser fan motors have sealed ball

bearings. The only acceptable service to these bearings is

replacement.

applied liberally to entering air and leaving air surfaces of the

nned area in accordance with the label directions.

CAUTION: Under no circumstances should this unit

becleanedwithanacid-basedcleaner.

13

Page 14

In-Warranty Return Material Procedure

Material may not be returned except by permission

of authorized factory service personnel of Heatcraft

Inc. Refrigeration Products Division in Stone Mountain, Georgia. A “Return Goods” tag will be sent to be

included with the returned material. Enter the required

information on the tag in order to expedite handling at

our factories and prompt issuance of credits. All parts

shall be returned to the factory designated on the “Return Goods” tag, transportation charges prepaid.

The return of a part does not constitute an order for

replacement. Therefore, a purchase order must be

entered through your nearest Heatcraft Refrigeration

Products representative. The order should include part

number, model number and serial number of the unit

involved.

Following our careful inspection of the returned part

and if it is determined that the failure is due to faulty

material or workmanship, credit will be issued on

customer's purchase order.

Replacement Parts

When writing to the factory for service or replacement

parts, refer to the model number and serial number of

the unit as stamped on the serial plate attached to the

unit. If replacement parts are required, mention the

date of installation of the unit and date of failure, along

with an explanation of the malfunctions and a description of the replacement parts required.

Table 9. Replacement Parts List

Fan RPM 1140 1140 830 830 (X Models) 540 (Q Models)

Motor HP 1-1/2 3/4 Var. Speed 1-1/2 1 1/2

Fan Motor Part No. 25301801 2530174 25301701 2538000 25302401

Fan Blade Part No. 22900401 2292625 22900301 2293030 2293030

Fan Guard Part No. 23100301 23100301 23100301 23100301 23100301

Contact Customer Service Department for parts to specic condenser models.

14

Page 15

Start Up Date

Model #

Serial #

Electrical

Voltage

Amperage

Installation Check List

Condenser

Installer: Name & Address

Telephone:

Pleaseretainthisinformationwiththecondenser.

15

Page 16

Since product improvement is a continuing effort, we reserve the right to make changes in specications without notice.

Heatcraft Refrigeration Products LLC

2175 West Park Place Blvd., Stone Mountain, GA 30087

Ph.: 770.465.5600 • Fax: 770.465.5990 • www.heatcraftrpd.com

16

Loading...

Loading...