S P E C I FI C AT I ON S

E lec tric al R atings :

E nvironmen tal R atings :

Ambient Temperature: -40F to 130F

Humidity: 0-95% non-condensing

Wiring C onnections :

Screw clamp terminals for #22AWG up to #8AWG wire.

Use #8 AWG wire with 90C rating for 40A loads.

Use #10 AWG wire with 90C rating for 30A loads.

E nclos ures :

Plastic NE MA 3R R aintight Indoor/Outdoor

Metal NEMA 1 Indoor

L ED Indic ation: G reen LE D when in refrigeration mode

Red L ED when in defrost mode

A P PL I CA T IO N

The DTS X Defros t Timer is identical in function, termina l identifi-

cation, and wiring to the Paragon 8140 a nd Prec ision 6140

series Defrost Timers. The DTSX ma y als o be us ed to replac e

Paragon 8040 and Precision 6040 series time terminated defros t

timers. With the addition of a remote pressure switch, the DTSX

can replac e the Paragon 8240 series and Prec ision 6240 s eries

pressure terminated defros t timers.

Defrosts will be initiated at the times set on the timer, which will

ac cept from 1 to over 24 defros t initiation s ettings per da y at 15

minute interva ls (8:00AM, 8:15AM, 8: 30AM, etc.) Defros t duration is settable in 15 minute interva ls from a minimum of 15 minutes up to s everal hours (15 minutes, 30 minutes , 45 minutes, 1

hour, 1 hour-15 minutes, etc.) The defrost duration determines

the termina tion time.

In standard configuration, the c ontac ts between terminals 1 and

3 are normally open and close during a defros t to energize

defrost heaters; the contacts between terminals 2 and 4 are normally c losed (when timer is energized) a nd open during a

defrost to de-energiz e refrigeration and fans .

DT S X T ime Initiated, R emote Temperature, P res s ure or

Time Terminated: Is us ed in electric or hot gas defrost applic ations where the defrost is terminated when the c oil is frost free,

as sens ed by a temperature or pressure switch, even though

the defros t progra mmed termination time has not been rea ched.

The time termination functions as a fail-sa fe and will terminate

the defros t if the temperature or pre ssure switc h fails to do so.

The temperature or pres sure switch on the refrigeration coil

have contacts which c lose on a temperature or pres s ure ris e to

above the freezing level, indic ating that frost and ic e have melted from the c oil. Typic ally a wide differential SPDT temperature

switc h is used, with it's normally c los ed contacts wired to the

fans , s o that the fans are delayed from turning on a fter defros t

termination, until the coil temperature has dropped ba c k to

below freezing. In most applic ations, the contac ts at terminals

2-4 a re normally c los ed (when timer is energized) and c ontrol

the fans a nd refrigera tion equipment or c ompres sor. For hot ga s

defrost, or for double pole switc hing, the 2-4 contacts may be

configured as normally open by moving jumper S 1 to the "B"

pos ition. Refer to wiring diagrams 1 thru 12.

ÒFÓ T erminal: The DTS X c ontains a normally c los ed contact

between terminals 1-F. This terminal may be used for switching

the fans off during a defros t rather than the 2-4 terminals . For

hot ga s defros t applications, with S1 in the "B" position, the fans

may be connec ted to the "F" terminal.

I NS T A L L AT I ON

Note: For outdoor locations, Raintight

, or wet loc ation conduit

hubs that c omply with requirements of U L 514B (standard for fittings for conduit and outlet boxes ) are to be used.

1. R emove 2 s crews retaining the interior cover panel and

remove panel by prying out with a thin blade (NE MA3R ).

2. S elec t knoc kouts to be used. R emove the inner (1/2") knock-

out by ins erting a s crewdriver in the s lot and c arefully punc h

knoc kout loose. R emove s lug. If the 3/4" knoc kout is

required, remove the outer ring with pliers after removing the

1/2" knoc kout. Smooth edges with knife if nec essary.

3. P lace enc losure in desired mounting location a nd mark the

three mounting holes.

4. Drill holes for #10 screws, start s crews in holes .

5. P lace enc losure over screws a nd tighten scre ws.

6. C onnec t conduit hubs to c onduit before connec ting the hubs

to the enc los ure. After ins erting hubs into enclosure, c arefully

tighten hub loc k nut. Do not over-torque.

7. If us ing NE MA 1 Metal E nc los ur e c onnec t grou nd wires

to grou nd lug on bottom of enclos ur e.

(Not applicable for NE MA3R plas tic enc los ure).

8. Wire in accordance with National and Local C odes .

9. R epla ce interior cover panel and 2 s crews (NE MA3R).

G ro unding: NE MA 3R enc los ure is of plastic construc tion

and does not require a ground connec tion or bonding.

N E M A 3 R e nc lo s ure doe s no t p r o v ide groundi n g be t w ee n

c on d u its . W he n u s in g n o n-m e ta ll i c c o nduit o r c a b le ,

c onne c t th e gro und w ir es of a ll c a ble s to ge the r w it h

a w ire n u t. W h e n m e ta l lic c o n d uit is u s e d , u s e

ground in g ty pe bu s hi n gs a nd a ju mpe r w ir e be tw e e n

e a c h c on du it.

C A U T IO N : Do not c he c k c irc uit s by Òs pa r k in g Ó w i r e s

to te rm in a ls . Da m age t o the d e fr os t tim e r m a y r es ult.

DT S X T im e I nitia t e d, T e m pe ra t ure , P r e s s ure o r

T im e Te r m in a te d 4 0 A De fr os t T im e rs

DTSX-IM-120

Defrost Timer Synchronous Drive: 40A

Blank: Plastic NEMA 3R

IM: Indoor Metal NEMA 1

M: Mechanism Only

P: Panel Mount w/standoff

B: Bracket Mount

120 VAC

240 VAC

[2] & [4] Contacts

30A Resistive

@120~240VAC

1HP @ 120VAC

2HP @ 240VAC

}

[1] & [3] Contacts

40A Resistive

@120~240VAC

1HP @ 120VAC

2HP @ 240VAC

}

[1] & [F] Contacts

30A Resistive

@120~240VAC

1HP @ 120VAC

2HP @ 240VAC

THE R MO S TAT

COM PR E S S OR

OR

SO LE NO ID VA LVE

OR

CON TAC TO R C OIL

DE FR O ST

HE ATE R

L1

L2

TIME R

TIME R

RE L EA S E

RE L AY

TE R MIN ATIO N

TH ER MO S TAT

W/FAN DE LAY

1

2

X

DT S X T ime/Temp. - E lectric D efrost W iring Dia gram

814 1 R eplac ement

S 1 P osition A with 814 1 La bel A pplied

7

8141

LAB E L

3

LIN E

FA N

N

4

L1

L2

TE R MIN ATION

TH ER MO S TAT

W/FA N D EL AY

2

4

X

N

DT S X T ime/Temp. - H ot G as Defros t Wiring D iagram

814 3 R eplac ement

S 1 P osition B with 81 43 L abel Applied

8

8143

LAB E L

TIME R

RE L EA S E

RE L AY

TIME R

LIN E

CO NN E C T AC R O S S

CO MP RE S S OR

TH ER MO S TAT

FA N

HOT

GA S

VA LV E

1

NO TE : R emove Bridge Betwee n 3-4

*S ee N ote 1

3

L1

L2

TE R MIN ATION

TH ER MO S TAT

2

X

DT S X T ime/Temp. - E lec tric Defros t Wiring D iagram

814 3 R eplac ement - Double P ole Switching

S 1 P osition B with 81 43 L abel Applied

9

8143

LAB E L

TIME R

RE L EA S E

RE L AY

TIME R

NO TE : R emove Bridge Betwee n 3-4

NO TE : Conne ct B ridge B etween 2 -X

3

DE FR O ST

HE ATE R

LIN E

SO LE NO ID

VA LV E

OR

CO NTAC TO R

1

4

N

P R O GR A M M IN G (S ync hronous and Qua rtz

E lec tromechanical Models )

S etting the Time:

Turn the minute hand c lockwise until the time of day (and AM

or PM) on the outer dial is aligned with the triangle marker on

the inner dial.

S etting Defrost Initiation T ime:

Move a white tab (tripper) on the outer dial outward a t eac h

desired initiation time. For exa mple, to s et defrost initiation

times at 6: 00AM, 11:30AM, 4: 30PM a nd 11:00P M, move the

tab adjacent to the "M" in AM on the dial (6:00AM), the tab

that lies between 11:30AM a nd 11:45 AM, the tab between

4:30PM and 4:45PM, and the tab a djacent to the

11:00-11:15P M marks . (See note for 8243/6243 replac ement.)

DO N O T R O T AT E M IN U T E H A N D C OU N T E R -C L O C K W IS E

S etting Maximum Defros t Duration:

Different defrost durations may be s et for each defros t initiation

setting. Each white tab (tripper) provides a 15 minute interva l.

The tabs that set the initiation time provide a minimum of 15

minutes of defrost. F or longer defros t duration, move additional

tabs (following in time) from the initiation tab. For example, if a

45 minute defrost is to s tart at 7:00AM,

move the tab outward that lies between

7:00 and 7:15 on the AM side of the dial,

and the tabs a djacent to 7:15-7:30 and

7:30-7:45. (3 tabs moved outward). The

defrost will initiate at 7:00AM a nd time terminate at 7:45AM (if temperature termination does not occur firs t.)

For electronic models , refer to separate progr amming

ins truc tions .

M

IMP OR TA NT INFOR MATION: T he Normally C los ed c ontacts between term inals 2 and 4 a re only c los ed wh en the defros t

timer is energized . T he 2-4 c ontacts a re the Normally O pen c ontacts of rela y K 2. (Normal Open relay conta c ts a re more

relia ble than Normally Closed). When chec k ing c ontinuity o f the c ontro l with no voltage applied, the 2-4 c ontacts will

appear as o pen ; th is is normal. T he 1-3 c onta cts will appear as open and the 1-F contac ts will a ppears as c los ed. We

recommen d that the c ontrol be te sted by u sing a v oltmeter, with rated voltage a pplied.

Note: A definite purpose contac tor must be us ed to switch loads grea ter than the following maximum loads:

Max. Fan & C ompressor L oad: 120V: 1HP

208/240V: 2HP

Max. Fan Load on Terminal "F" 120V: 1HP

208/240V: 2HP

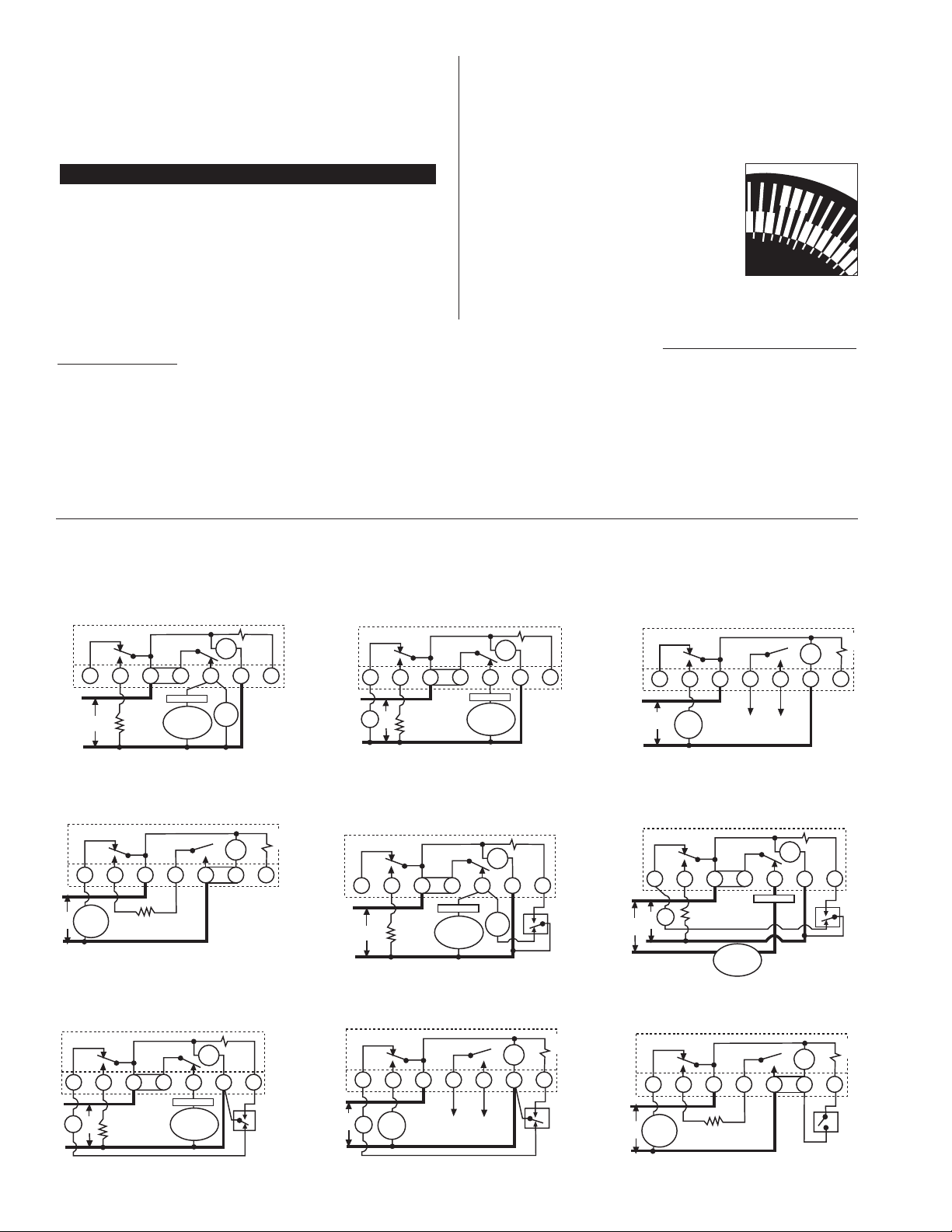

T Y P I C A L W I R I N G DI A G R A MS

All switc h pos itions a re s hown in refrigeration cyc le operation, and change position upon initiation of a defros t.

COM PR E S S OR

OR

SO LE NO ID VA LV E

OR

CON TAC TO R CO IL

FA N

MOT OR

DE FR O ST

HE ATE R

L1

L2

TIME R

TIME R

RE L EA S E

RE L AY

F

3

1-N

2

4 X

LIN E

DT S X T ime/Time - E lec tric Defros t Wiring D iagram

804 5 R eplac ement

S 1 P osition A with 804 5 La bel A pplied

1

THE R MO S TAT

8045

LAB E L

THE R MO S TAT

COM PR E S S OR

OR

SO LE NO ID VA LVE

OR

CON TAC TO R C OIL

DE FR O ST

HE ATE R

L1

L2

TIME R

TIME R

RE L EA S E

RE L AY

1

2

4 X

DT S X T ime/Time - E lec tric Defros t Wiring D iagram

804 1 R eplac ement

S 1 P osition A with 804 1 La bel A pplied

2

8041

LAB E L

3

LIN E

FA N

N

L1

L2

2

4

N

3

DT S X T ime/Time - H ot Ga s D efrost W iring Dia gram

804 3 R eplac ement

S 1 P osition B with 80 43 L abel Applied

3

8043

LAB E L

TIME R

RE L EA S E

RE L AY

TIME R

LIN E

CO NN E C T AC R O S S

CO MP RE S S OR

TH ER MO S TAT

HOT

GA S

VA LV E

F

NO TE : R emove Bridge Betwee n 1-4

1

L1

L2

2

2

DT S X T ime/Time - E lec tric Defros t Wiring D iagram

804 7 R eplac ement - Double P ole Switching

S 1 P osition B with 80 47 L abel Applied

4

8047

LAB E L

TIME R

RE L EA S E

RE L AY

TIME R

NO TE : Move Bridge to 2-2

NO TE :

3

DE FR O ST

HE ATE R

LIN E

SO LE NO ID

VA LV E

OR

CO NTAC TO R

N

4

1

COM PR E S S OR

OR

SO LE NO ID VA LV E

OR

CON TAC TO R CO IL

FA N

MOT OR

DE FR O ST

HE ATE R

L1

L2

TIME R

TIME R

RE L EA S E

RE L AY

TE R MIN ATION

TH ER MO S TAT

W/FA N D EL AY

F

3

1 2

4

X

N

LIN E

DT S X T ime/Temp. - E lectric Defros t Wiring Dia gram

814 5 R eplac ement

S 1 P osition A - N o La bel R equire d

5

THE R MO S TAT

THE R MO S TAT

COM PR E S S OR

OR

SO LE NOI D VA LVE

OR

CON TAC TO R C OIL

DE FR O ST

HE ATE R

L1

N

120V

TIME R

TIME R

RE L EA S E

RE L AY

TE R MIN ATIO N

TH ER MO S TAT

W/FA N D EL AY

1

2

4

X

DT S X T ime/Temp. - E lectric D efrost W iring Dia gram

120 V F an & D efrost H eater; 240 V C ompres sor

S 1 P osition A - N o La bel R equire d

6

3

N

F

FA N

120V

240V

L2

Max. Defros t Heater Load: 120V: 4800Watts

208V: 8320Watts

240V: 9600Watts

8

7

A

N

1

X

N O

C ON N E C T I O N

N

1

3

4

2

2

N O

C ON N E C T I O N

F

3

1

4

2

N

N O

C ON N E C T I O N

F

3

1

2

4

N

X

F

3

1 -N

2

4

X p

p

N

1

3

2

4

X p

p

F

3

1 -N

2

4

X p

p

N

1

3

2

4

X

1

N

3

4

2

X

F

3

1 -N

2

4

X

3

2

4

TE R MINA L IDE NTIF IC ATION

The s tandard DTS X terminal identific ation is identic al to the Pa ragon

8145 with the addition of the "F" terminal. T ermina l identification labels

are provided for the other models to be pla ced over the printed numbers on the printed c irc uit board. From the table below, selec t the

proper labe l, apply to printed c irc uit boa rd, a nd wire per the original

wiring or the wiring diagrams indic ated.

MODE S E LE CT ION (B lue J umperS 1)

The mode selec tor jumper S1 (located at lower

right s ide of the board) de termines the configuration of c ontac ts 2-4. In pos ition "A" the contacts

are normally closed (only when the timer is energized), and will open during a defrost. In position

"B" the 2-4 c ontacts a re normally open, and will

close during a defrost. S elec t proper pos ition

from table below, a nd wiring diagrams indic ated.

To move jumper, pull straight away from board,

and reinsert over the top two pins for position

"B" or the bottom two pins for position "A".

N ote : When S 1 jumper is in "B" pos ition the DTSX will operate as follows. R efrigeration Mode- R E D & G R E E N LED's will turn ON (1&3

and 2&4 bre ak while 1&F make) Defros t Mode- R ED & G RE EN LE D's

will turn O FF (1&3 a nd 2&4 make while 1&F brea k)

8 04 5 R E P L A C E M E N T :

The DTS X with 8045 terminal ID label applied differs from the 8045 in

that terminals 1 and N are combined. This means that the DTSX

model mus t be the same voltage as the defros t c ircuit (defros t he ater,

contactor coil, or hot gas valve). If being us ed in an applic ation where

the defros t c ircuit is 120V and the refrigera tion c ircuit is 240V, the

DTSX must be configured for 120V applic ation (all red jumpe rs ins ert-

ed) with 120V power connec ted to 1 -N and X , a nd the bridge

jumper be tween 1 -N and 2 mus t be removed .

N O T E 1 :8143 R eplacement:

When replac ing a P aragon 8143 or

Precision 6143, wire the termination thermos tat to terminal X of the DTS X and the adja c ent blank terminal. The

Pa ragon and Prec is ion timers are wired to terminal N and the

blank te rmin al . If the termination thermos tat is wired to terminal N

of the DTSX (with the 8143 label attac hed), tempera ture termination

will not oc cur and may res ult in burnout of the DTMV. S ee wiring diagra ms 8 & 9.

8 24 0/6 24 0 S E R I E S R E P L A C E M E N T :

The DTS X may be used to replac e the Pa ragon 8240 or Prec is ion

6240 series defrost timers with integral pres sure termination by the

addition of a remote pressure s witch wired to termina ls X p a nd p of

the DTS X (with an 8240 series terminal label applied). There mus t be

no external voltage connec ted to the pressure s witch. Set pre ssure

switc h cut-in to the s ame value a s s et on the Paragon or P recis ion

defrost timer be ing replac ed. Set c ut-out 6 to 14psi below c ut-in. See

wiring diag rams 10, 11, and 12.

R e c o m m e n de d P r e s s u r e S w i tc hes :Johnson/Penn P170,

Ranc o 010 s eries , or Danfoss K P1 s eries . Pres sure range approximately 35-110ps i, C U T -I N O N P R E S S U R E R I S E .

N O T E 2 :8243 R eplacement:

When replac ing a P aragon 8243 or

Precision 6243, the DTS X white tabs (trippers ) for setting defrost

time and defrost duration must be revers ed. Pull AL L tabs outward.

Press the tabs inward at the des ired defros t initiation times, and for

desire d duration.

COM PR E S S OR

OR

SO LE NOI D VA LV E

OR

CON TAC TOR CO IL

FA N

MOT OR

DE FR O ST

HE ATE R

L1

L2

TIME R

TIME R

RE L EA S E

RE L AY

PR E S S UR E

SW IT CH

F

3

1-N

2

4

LIN E

DT S X Time /Pres sure -E lectric D efrost W iring Dia gram

824 5 R eplac ement

S 1 P osition A with 824 5 La bel A pplied

1 0

THE R MO S TAT

Xp

p

LAB E L

8245

NO TE : R emove B ridge Betwee n 1-N -2

*S ee N ote 2

CO MP RE S S OR

L1

L2

TIME R

TIME R

RE L EA S E

RE L AY

F

3

2

4

LIN E

DT SX T ime/P ress ure-C ompress or S hutdown

824 3 R eplac ement

S 1 P osition B with T rippers R evers ed

1 1

PR E S S UR E

SW IT CH

1-N

p

Xp

LAB E L

8243

DT S X T

L1

L2

4

ime/P res sure-E lec tric De frost W iring Diagra m

824 7 R eplac ement-Double Po le S witching

S 1 P osition B with 82 47 L abel Applied

1 2

8247

LAB E L

TIME R

RE L EA S E

RE L AY

TIME R

NO TE : R emove B ridge Betwee n 3-4

NO TE : Conne ct B ridge B etween 4 -Xp

3

DE FR O ST

HE ATE R

LIN E

SO LE NO ID

VAL V E

OR

CON TAC TO R

N

2

1

p

PR E S S UR E

SW IT CH

Xp

R E P L A C I N G E X I S T I N G D E F R O S T T I M E R S

I MP O R T A N T : When replacing a Gras s lin DT-040 model with a DTS X, the power c onnections must be made to terminals N and 1 on the

DTSX. No c onnection must be made to the X terminal or damage to the unit will result. Disc onnect the power wire from terminal X on the DT-040

and c onnect it to terminal N on the DTSX. Dis c onnect the other power wire from terminal N on the DT-040 and c onnec t it to terminal 1 on the

DTSX. All other wires s hould be connec ted to the DTS X the same as on the DT-040.

The DTSX will replace a ll models of Paragon 8040, 8140, 8240 Series or P recision 6040, 6140, 6240 S eries

1

2

3

4

5 , 6

7

8 , 9

S ee N ote 1

1 0

1 1

S ee N ote 2

1 2

NO TE : In "Terminal La yout," the c onnec ting lines between termina ls indic ate the corre ct positions of the bridges for each model. The heavy line

indic ates the bridg e mus t be ins talled as s hown. T he light line indic ates the bridg e may be removed if different voltage s are us ed at ea ch switc h.

DT S X S 1 P os itio n ÒB Ó

Termin al Typic al

P ara gon P rec is ion G R AS S L IN S 1 Mode Iden t. Wiring Termin al L ay out

Model Mod el Model S ele ctor L abel Diagram (s ee note below)

TIME INIT IATE D, TIME T E RMINATE D

8045 6045 DTSX A None

8046 DTSX A None

8041 6041 DTSX A 8041

8043 6043 DTSX B 8043

8047 6047 DTSX B 8047

TIME INIT IATE D, R E MOT E T EMP E RATUR E OR P R E SS UR E TE R MINA TE D

8145 6145 DTSX A None

8141 6141 DTSX A 8141

8143 6143 DTSX B 8143

TIME INIT IATE D, P RE SS UR E TE R MINA TE D

(S eparate P res sure S witch R equired - s ee instructions )

8245 6245 DTSX A 8245

8243 6243 DTSX B 8243

8247 6247 DTSX B 8247

N O

C ON N E C T I O N

NE W S TYL E

1. Disconnec t power.

2. R emove and s ave ins ulator from Paragon timer.

3. Disconnec t wiring.

4. R emove Paragon mec hanism from enclos ure.

5. R emove Gras slin DT model from it's enc losure.

6. If neces sary, move S1 jumper and apply terminal identification label from plastic bag to DT model as per table

on previous page.

7. L ocate metal clip in plastic bag and as semble it to printed c ircuit board at notch in right side.

8. E ngage tabs on left side of printed circuit board in

enc losure, and swing PC B into plac e until tab on metal

clip engages tang on Pa ragon enclosure.

9. R ec onnect wires , tighten terminal s crews s ecurely.

10. As semble insulator from plas tic bag to Paragon ins ula-

tor by interleaving a s shown.

11. Plac e ins ulator assembly over mec hanism, with notch

and tab over retaining clip, and engaging tab in slot in

tang to retain insulator.

OL D S TYL E and B R AC K ET MOUNT

1. Disconnec t power.

2. R emove and s ave ins ulator from Paragon timer.

3. Disconnec t wiring.

4. R emove and s ave the 6-32 screw. R emove a nd disca rd

two metal pos ts retaining Paragon mechanism.

5. R emove Paragon mec hanism from enclos ure.

6. R emove Gras slin DT model from it's enc losure, and with

pliers, break off the 3 tabs on left side of printed circuit

board.

7. R emove contents of plas tic bag.

8. If neces sary, move S1 jumper and apply terminal identification label to DT model as per table on previous

page.

9. L ocate plastic 3/4"long s tandoff with interna l threads,

and using s crew from Paragon timer, as semble standoff

on t o p of

upper center hole in DT board with s c r ew

throu g h ba c k of board.

10. Plac e board in Para gon enclosure with s ta ndo ff

a li gn e d u nd er hole in the e nc los u r e's uppe r

fla ng e.

11. As semble the 6-32 x 1/4" screw through the tapped

hole in the enclos ure's flange and into the tapped hole

in the standoff. (Hold board and standoff firmly up

against the flange while driving the s crew).

12. As semble the two plastic insulator retainer posts with

screwdriver at two locations where metal posts were

removed.

13. Reconnec t wires , tighten terminal s crews s ecurely.

14. As semble insulator from plas tic bag to Paragon ins ula-

tor by interleaving a s shown.

15. Plac e ins ulator assembly over mec hanism and press

onto pla stic pos ts.

I N S T A L L AT I ON I N E X I S T I NG E N C L OS U R E S

Interleave Grass lin

insulator (top) with

Paragon ins ulator

as s hown here

New Style

Old Style

C A U T I O N : I f the D e f r o s t T i m e r boa r d a s s e m bl y i s not

a s s e m bl e d t o t h e b r a c k e t e x a c tly a s s ho w n a bo v e , a

s hort m ay oc c ur w hic h w il l de s troy t he de fr os t t im e r.

G R A S S L I N C ON T R O L S C OR P O R A T IO N

A GE Indus trial S ys tems C ompany

31 Indus trial Ave. Mahwah, New Jersey 07430

Tel.: 201-825-9696 Fax: 201-825-8694

www.gras slin.com

3/4Ó T hreade d S tandoff

Fr om Ba g Ass embly

6-32 S crew F rom

P aragon B rac ket

Time r Module

Nylon Pos ts

Fr om Ba g

As sembly

Defros t T imer

As sembly

P aragon

Br acke t

Bo ard

Loading...

Loading...