Page 1

DIRECT DRIVE FLUID COOLERS

Technical Guide

Models DFT and BFH

BNFCTB

April 2007

(Replaces 10108.1, 06/02)

Page 2

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Direct-Drive Design Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Selection Formulas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Given Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Correction Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Model DFT Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Model DFT Specications and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Model BFH Capacity Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-13

Model BFH Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Model BFH Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2

© 2007 Heatcraft Refrigeration Products LLC

Page 3

Overview

Our engineers have carefully selected and matched components to provide excellent performance, long service life

and a wide range of performance selections. Specically engineered for outdoor installations, the DFT and BFH uid

coolers are constructed of aluminum and heavy gauge galvanized steel to resist corrosion in all climates.

Fluid coolers are available in a wide range of sizes. Each model is available with several circuit options to ensure

the exact uid cooler for your requirements. Our uid coolers are designed to reduce the cost of time required for

installation. Each unit is completely assembled and tested at the factory. All motor leads are wired to a junction box

providing a single point for eld wiring.

Direct-Drive Design Features

• Cabinets are heavy-duty construction and designed for outdoor

applications; tube sheets and all structural members are fabricated from

galvanized steel

• Cabinet panels are fabricated from heavy-gauge aluminum for an

attractive appearance and corrosion protection

• Coils are fabricated with corrugated aluminum ns with staggered

copper tubes for optimum heat transfer; all units are pressure-tested,

dehydrated and pressurized prior to shipment

• Alternate coil constructions are available — copper ns, BohnGuard™

ns and coated coils

• BFH models incorporate the Floating Tube™ coil design that reduces the

possibility of tube sheet leaks

• DFT models available in either horizontal or vertical air ow; BFH models

available in vertical air ow only

• Fully baed fan sections provide structural strength and prevent fan wind-milling in the o cycle

• Energy ecient fan motors with direct-drive fans available at 1140 RPM; fan motors have thermal overload

protection and permanently lubricated ball bearings

• DFT models are available in 208-230 V single-phase, 208-230/460 dual-voltage, three-phase or 575 V three-phase

motors; BFH models are available in 208-230/460 dual voltage, three-phase or 575 V three-phase motors

• Statically and dynamically balanced fan blades are aluminum and riveted to painted steel spider and hubs

• Fan guards are PVC coated steel for optimum corrosion protection

• All fan motor leads are wired to a weatherproof electrical enclosure for single-point eld wiring

• Fan cycling controls are available that cycle all fans in response to BFH only; DFT fan cycling is ambient air

• All controls are factory mounted and wired; control circuit voltage is 230 V standard, 24 and 115 V controls are

also available

Dramatically Reduces Tube Sheet Leaks

The Floating Tube™ Coil Design

• A wide selection of circuit options maximizes performance at minimal cost

• Sizes available from 10 GPM through 500 GPM

• Units are UL listed for US and Canada

3

Page 4

Selection Procedure

Selection Formulas

Design Capacity = GPM x (Entering Fluid Temperature - Leaving Fluid Temperature) x Fluid Constant, Table 1

Average Fluid Temperature = (Entering Fluid Temperature + Leaving Fluid Temperature)/2

Initial Temperature Dierence, I TD = Entering Fluid Temperature - Entering Air Temperature

Base Capacity = Design Capacity/(1,000 x ITD x Capacity Correction, Table 2 x Altitude Correction Factor, Table 3)

Pressure Drop, Fluid = Pressure Drop, Catalog x Correction Factor, Table 4

Given Conditions

Direct Drive 120˚F Leaving Fluid Temperature

50 GPM 100˚F Entering Air Temperature

20% Ethylene glycol solution 20 feet maximum uid pressure drop

130˚F Entering Fluid Temperature 1,000 feet altitude

Solution

1. Calculate design capacity. From Table 1, select the uid constant for 20% of 484.

Design Capacity = 50 x (130-120) x 484

Design Capacity = 242,000 BTUH

2. Calculate average uid temperature

= (130 +120)/2

= 125˚F

3. Calculate the initial temperature dierence, ITD

ITD = 130 - 100

ITD = 30˚F

4. Calculate Base capacity. From Table 2, for a 20% solution and an average uid temperature of 125˚ F, interpolate

to obtain a correction factor of 1.035. From Table 3, obtain an attitude correction factor at 1000 feet of 0.98.

Base Capacity = 242,000/(1,000 x 30 x 1.035 x 0.98)

Base Capacity = 7.95 MBH / ˚TD

4

Page 5

Correction Factors

5. Select the model and circuiting required. From the capacity tables, locate the GPM you desire and read down

until you nd a base capacity equal to or greater than your calculated base capacity. Read horizontally to the

left to obtain the model and circuiting (Feeds) for your application.

The selection is a DFT 16, with 32 feeds, with a base capacity of 8.34 MBH/1˚ TD and a uid loss of 15.1 feet

of water.

6. Calculate the pressure drop of the uid. From Table 4, using 20% glycol solution and a 125˚F average uid

temperature, interpolate to get a correction factor of 0.86.

Actual Fluid Loss = 15.1 x 0.86

Actual Fluid Loss = 13.0 feet of water

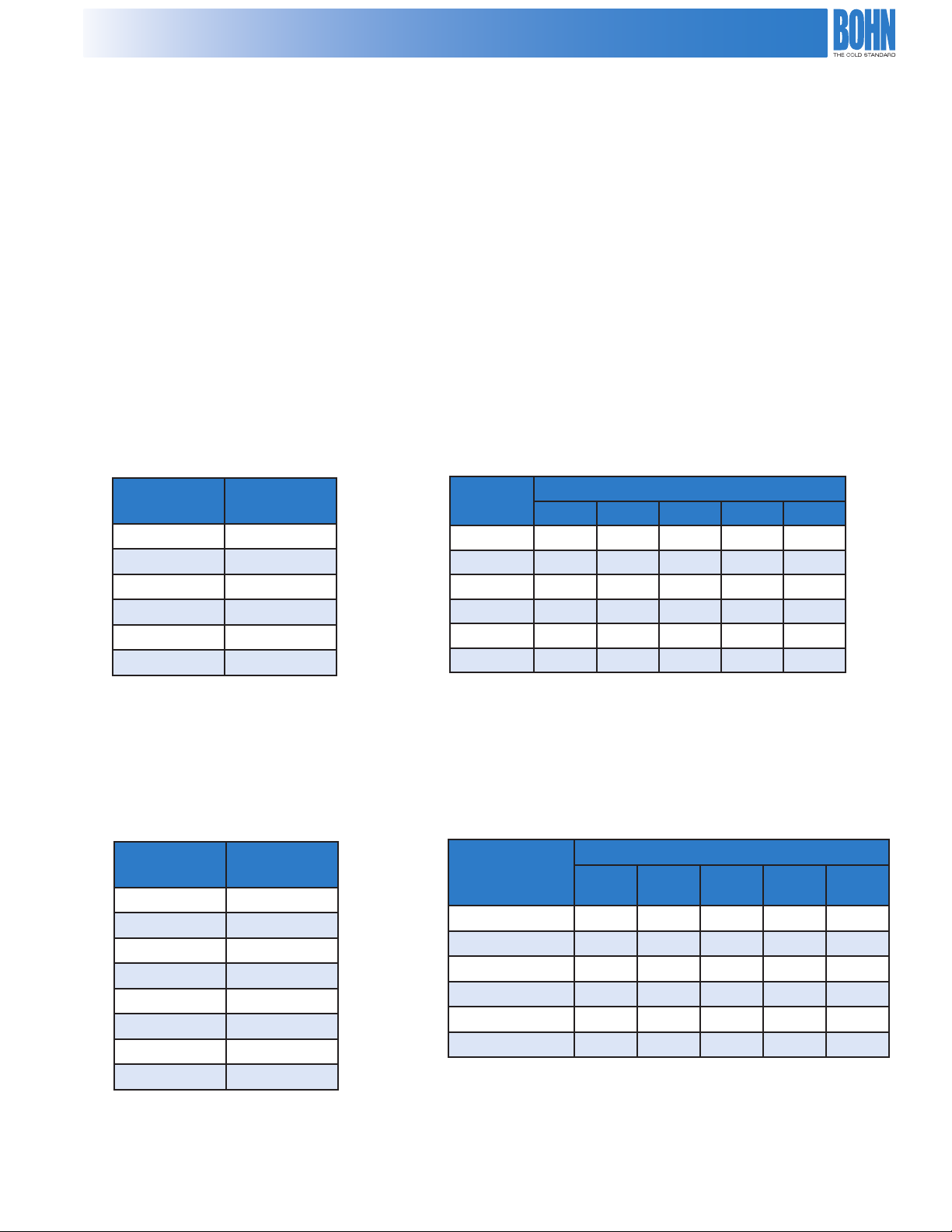

Table 1. Fluid Constraints

Percent

Glycol

Fluid

Constant

0 500

10 493

20 484

30 470

40 453

50 435

Table 3. Altitude Correction Factor

Altitude

(Feet)

Correction

Factor

0 1.00

1,000 0.98

2,000 0.95

3,000 0.93

4,000 0.90

5,000 0.88

6,000 0.85

7,000 0.83

Table 2. Capacity Correction Factor

Percent

Glycol

0 0.97 1.01 1.03 1.05 1.07

10 0.96 1.00 1.02 1.04 1.06

20 0.94 0.98 1.00 1.02 1.04

30 0.92 0.96 0.98 1.00 1.02

40 0.90 0.94 0.96 0.98 1.00

50 0.87 0.91 0.94 0.96 0.98

Note: For average uid temperature less than 50˚F or greater than 130˚F, consult

the factory

Average Fluid Temperature ˚F

50 70 90 110 130

Table 4. Correction Factor for Fluid Loss

Percent

Average Fluid Temperature ˚F

Ethylene

Glycol

50 70 90 110 130

0 0.88 0.82 0.78 0.75 0.71

10 0.97 0.90 0.86 0.82 0.78

20 1.05 0.98 0.94 0.89 0.85

30 1.15 1.07 1.02 0.98 0.93

40 1.24 1.15 1.10 1.05 1.00

50 1.33 1.23 1.18 1.12 1.07

5

Page 6

Capacity Ratings

Table 5. Capacity Ratings MBH / oTD, 40% Ethylene Glycol at 130oF Average Fluid Temperature

GPM

Model Feeds

DFT

005

8

12

16

12

DFT

Model DFT

008

16

21

32

DFT

010

DFT

012

DFT

014

DFT

016

DFT

021

DFT

023

DFT

026

* PD is glycol uid loss in feet of water at 130˚F uid temperature

12

16

24

12

16

24

12

16

24

12

21

32

16

24

48

24

48

21

32

64

10 15 20 25 30 40 50 60

MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD*

2.36

14.0

2.71

28.7

2.23

3.07 7.4 3.67

3.46 7.5 4.32

3.62 7.5 4.62

3.92 9.4 5.12

4.7

2.58

2.47

3.55

4.16

4.45

4.96

9.7

2.80

4.5

2.70

15.1

4.04

7.0

3.92

3.79

15.5

4.88

7.1

4.73

4.46

15.5

5.30

7.1

5.12

4.81

19.3

8.9 5.78

5.49

16.1

7.5

25.2

11.6

5.6

25.7

11.9

4.0

25.7

11.9

4.0

14.7

5.0

2.95

24.0

2.85

11.2 2.97 15.5

4.17

17.3

4.05

5.13

4.86

5.61

5.30

6.39

6.08

8.4

17.6

6.0

17.6

6.0

21.9

7.4 6.53 10.2 7.19 16.9 7.64 25.2

4.35

4.24

4.02

5.42

5.17

5.99

5.68

23.8

11.5

3.8

4.49

4.30

19.2

6.4

24.3

8.3 5.60 13.8 5.89 20.4 6.10 28.2

24.3

8.3 6.23 13.8 6.60 20.4 6.88 28.2

4.17 12.4 5.57 25.4

7.27 9.2 8.44

5.93 12.3 7.22

6.93

6.99 6.8 7.98 10.2 8.78 14.0 9.96

7.65 12.9 8.81

20.5

6.8 7.90 10.2 8.68 14.0 9.83

6.57

8.44

13.7

4.4

19.1

6.1

9.43

7.09

9.73

9.33

18.9

6.1 7.84 10.2 8.34 15.1 8.70 20.9

23.3

8.97

3.7 9.78 5.5 10.41 7.5

23.3

9.25

3.7 10.14 5.5 10.82 7.5

26.3

8.4 10.66 14.0 11.58

4.66

4.49

10.63

28.5

9.4 4.62 13.0

20.8

3.3

12.25

11.33

28.7

4.5

Table 6. Capacity Ratings MBH / ˚TD, 40% Ethylene Glycol at 130˚F Average Fluid Temperature

GPM

Model Feeds

DFT

48 10.89 9.9 11.29 12.6 11.61 15.5 11.88 18.6 12.12 22.1 12.31 25.7

021

DFT

48 11.36 9.9 11.80 12.6 12.16 15.5 12.46 18.6 12.72 22.1 12.94 25.7

023

DFT

64 11.88 6.0 12.33 7.5 12.69 9.3 12.98 11.2 13.24 13.3 13.46 15.5 13.64 17.8 13.81 20.3 13.95 23.0 14.08 25.7

026

* PD is glycol uid loss in feet of water at 130˚F uid temperature

70 80 90 100 110 120 130 140 150 160

MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD*

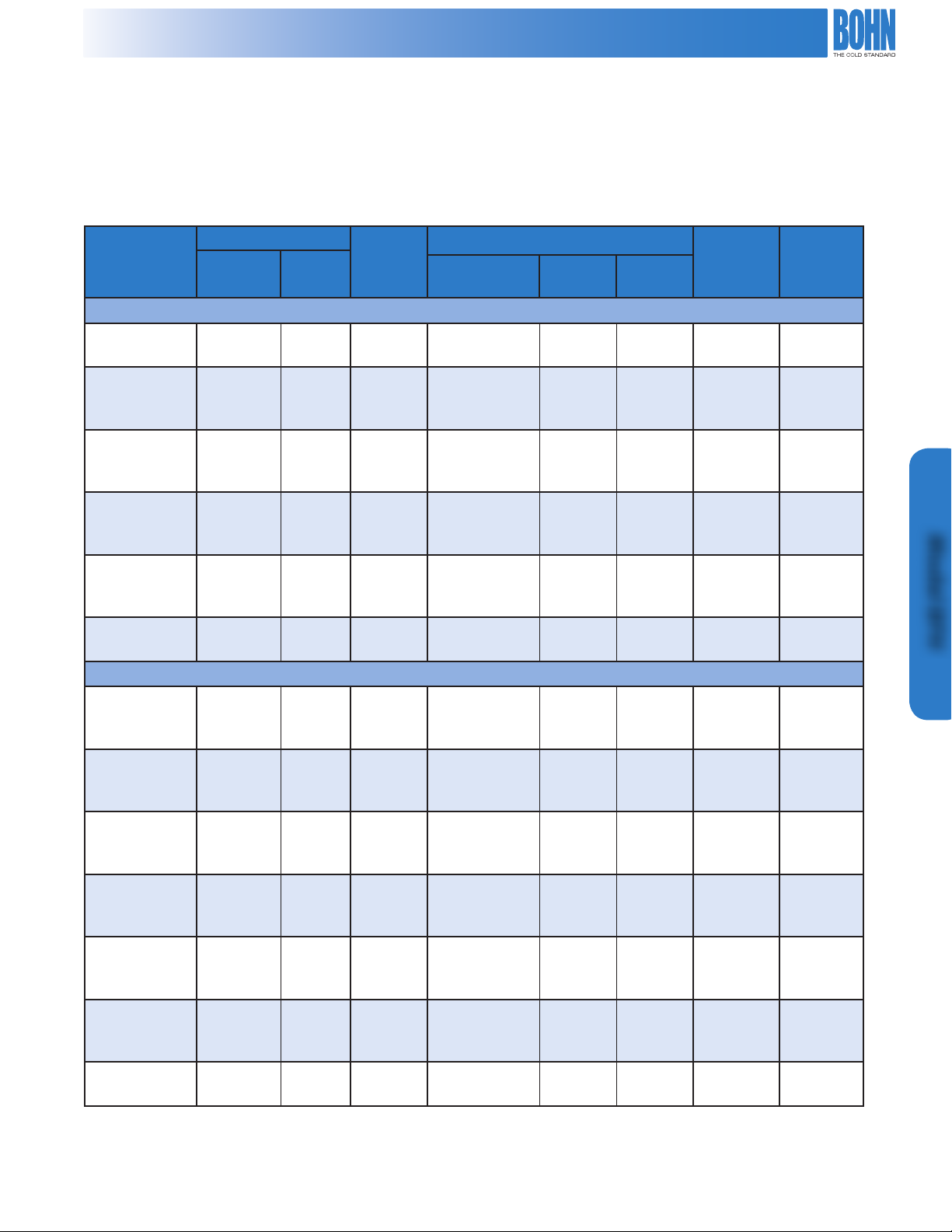

Table 7. Model DFT Connection Sizes, based on the number of feeds

Feeds Inlet/Outlet

8 1-1/8” ODS

12 1-3/8” ODS

16 1-3/8” ODS

21 1-5/8” ODS

Feeds Inlet/Outlet

24 2-1/8” ODS

32 2-1/8” ODS

48 2-5/8” ODS

64 2-5/8” ODS

6

Page 7

Specications and Dimensions

Diagram 1. Model DFT Dimensions, 5 through 26 Tons with Vertical Air Flow

Diagram 2. Model DFT Dimensions, 5 through 26 Tons with Horizontal Air Flow

Model DFT

Table 8. Model DFT Specications

Dimensions

Model

DFT005

DFT008

DFT010

DFT012

DFT014

DFT016

DFT021

DFT023

DFT026

1

Motor voltage 208-230/1/60; 1075 RPM

2

Motor voltage 208-230-460/3/60; 1140 RPM

(in.)

A B No. Dia. HP1FLA1HP

39-3/4

49-3/4

69-3/4

69-3/4

89-3/4

89-3/4

129-3/4

129-3/4

129-3/4

120

120

120

30

40

60

60

80

80

CFM

5,050

6,450

10,100

12,400

13,700

12,900

20,500

19,900

19,400

Fan Motor Data

1

24

1/3

1

26

1/2

2

24

1/3

2

26

1/2

2

26

1/2

2

26

1/2

3

26

1/2

3

26

1/2

3

26

1/2

3.4

3.9

6.8

7.8

7.8

7.8

11.7

11.7

11.7

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

Approx.

Net Wt.

2

FLA

2.6/1.3

2.6/1.3

5.2/2.6

5.2/2.6

5.2/2.6

5.2/2.6

7.8/3.9

7.8/3.9

7.8/3.9

2

(Lbs.)

205

260

330

348

420

436

565

580

610

7

Page 8

Capacity Ratings

Table 9. Capacity Ratings MBH / ˚TD, 40% Ethylene Glycol at 130˚F Average Fluid Temperature

Model Feeds

BFH

0231428

BFH

027

BFH

031

BFH

035

BFH

041

BFH

Model BFH

045

BFH

046

BFH

049

* PD is glycol uid loss in feet of water at 130˚F uid temperature

Fan

Cong.

1 x 2

14

21421 x 2

14

21421 x 2

18

28561 x 2

14

21421 x 3

14

21421 x 3

18

28562 x 2

18

28561 x 3

20 30 40 50 60 70 80 90 100

MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD*

6.4 3.2 8.04 6.5 9.18

8.08

7.01 4.8 8.85

7.42 4.8 9.56

8.19 7.0 10.99

9.9

10.1

8.39

3.2

9.60

9.9

11.04

9.02

3.2

10.45

10.2 6.6 11.88

11.2

14.3

13.04

10.54

4.6

12.52

11.62

14.3

14.03

11.15

4.6

13.43

11.24 6.6 13.63

12.8

11.92 9.5 14.49

13.85

10.8

10.01

16.1

10.64

1.5

8.9

2.3

9.55

16.5

10.99

24.4

5.3

10.49

16.5

5.3

11.51

11.0

13.08

3.2

12.38

23.8

7.7 14.02 11.4 15.19

23.8

7.7 15.21 11.4 16.61

11.0

15.54

3.2

15.9

16.45

4.6

15.73

7.9 11.17

10.06

12.1

24.4

7.9 12.32

10.99

16.3

13.98

4.7

13.29

13.83

14.99

16.3

17.08

14.6

4.7

16.08

23.5

6.9 17.22 9.5 18.41 12.4 19.37

GPM

22.2

3.1 10.07 4.1 10.51 5.2 10.87 6.4 11.18 7.8

10.8

11.7

14.2

12.13

18.0

12.48

22.2

1.5

10.62

2.0

10.8

1.5

22.5

6.5

15.8

2.3

15.8

2.3

22.5

6.5

12.95

11.64

14.66

13.99

16.13

14.76

17.74

16.09

18.35

17.31

11.08

14.2

13.47

2.0

12.19

29.5

8.6 14.55

13.16

20.7

16.90

3.0

15.54

20.7

18.66

3.0

17.01

29.5

8.6 18.35

16.17

17.69

2.6

11.47

3.1 11.8 3.8

18.0

13.89

22.2

2.6

12.65

3.1 13.05 3.8

10.8

15.01

13.4

15.39

1.5

13.67

1.9

14.1

26.2

3.7 16.19 4.6 16.76 5.6

26.2

3.7 17.79 4.6 18.46 5.6

10.8

19.24

13.4

20.01

1.5

17.04

1.9

17.81

15.8

20.18

19.4

20.85

2.3

18.51

2.8

19.22

16.1

2.3

16.1

2.3

23.4

3.3

8

Page 9

Capacity Ratings

Table 10. Capacity Ratings MBH / ˚TD, 40% Ethylene Glycol at 130˚F Average Fluid Temperature

Model Feeds

BFH

0542842

BFH

053

BFH

0602842

BFH

0612142

BFH

0663656

BFH

065

BFH

0703656

BFH

071

BFH

0752142

BFH

079

BFH

0802842

BFH

0862842

BFH

0902842

BFH

089

BFH

0972856

BFH

0983656

BFH

1072856

* PD is glycol uid loss in feet of water at 130˚F uid temperature

Fan

Cong.

2 x 2

14

21421 x 4

2 x 2

1 x 4

2 x 2

18

28561 x 4

2 x 2

18

28561 x 4

1 x 5

18

28561 x 5

2 x 3

2 x 3

2 x 3

18

28561 x 5

1 x 6

2 x 3

1 x 6

20 30 40 50 60 70 80 90 100

MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD*

14.03 4.8 16.06 7.2 17.70

8.71 9.2 12.20

18.4

11.86

6.1 14.50 10.1 16.62 15.0 18.32

14.84 4.8 17.18 7.2 19.12

12.34 6.1 15.34 10.1 17.80 15.0 19.81

12.88 12.5 16.23

13.04 12.5 16.53

12.97 7.5 16.52 12.5 19.56 18.5 22.14

13.20 15.4 16.90

13.40 15.4 17.39

20.7

15.71

6.1 18.31 9.0 20.44 12.4 22.21 16.3 23.68

20.7

16.01

6.1 18.76 9.0 21.04 12.4 22.93 16.3 24.50

25.6

16.51

7.5 19.53 11.1 22.08 15.4 24.23 20.2 26.06

16.38 7.0 19.38 10.4 21.97

16.69 7.0 19.89 10.4 22.67

16.93 7.0 20.29 10.4 23.23

2.56

17.03

7.5 20.38 11.1 23.27 15.4 25.75 20.2 27.87

17.22 8.9 20.70 13.3 23.74 18.3 26.38 24.1

17.59 8.9 21.37 13.3 24.76 18.3 27.76 24.1

GPM

9.9

19.06

13.0

20.19

16.78

3.2

18.10

4.2

19.21

20.7

19.71

27.1

16.85

3.0

18.18

3.9 19.30 4.9 20.27 6.1 21.10 7.3

9.9

20.73

13.0

22.09

18.05

3.2

19.60

4.2

20.92

20.7

21.47

27.2

18.12

3.0

19.68

3.9 21.01 4.9 22.15 6.1 23.14 7.4

17.77 4.8 19.84 6.6 21.55 8.7 22.99

21.71

21.80

18.21 4.8 20.41 6.6 22.24 8.7 23.78

22.41

22.50

25.6

20.53

3.7 22.54 4.9 24.28 6.1 25.80 7.6 27.13 9.1

24.27

14.3

24.18

18.8

26.08

21.09

4.6

23.21

6.1

25.04

14.3

25.07

18.8

27.16

21.76

4.6

24.04

6.1

26.03

14.3

25.81

18.8

28.05

22.30

4.6

24.73

6.1

26.86

25.84

26.92 4.4 28.78 5.4 30.43 6.5

20.73 6.9 23.84 9.5 26.58 12.5 28.97

27.70

28.48 4.4 30.61 5.4 32.50 6.5

16.5

21.15

20.3

21.97

24.4

5.3

20.16

16.5

23.24

5.3

22.05

11.0

24.21

3.2

22.90

20.7

24.91

3.0

23.00

11.0

25.08

3.2

23.68

20.7

25.82

3.0

23.78

25.6

3.7 25.76 4.5 27.06 5.5

23.8

27.73

7.7

26.64

23.8

28.97

7.7

27.78

23.8

30.01

7.7

28.74

25.6

3.7 27.55 4.5 29.04 5.5

15.9

31.07

4.6

29.70

6.5

20.99

20.3

24.22

24.4

6.5

23.03

13.5

25.25

16.3

3.9

23.94

25.5

3.7 24.04 4.4

13.5

26.19

16.3

3.9

24.78

25.5

3.7 24.88 4.4

29.4

9.5 28.05 11.4

29.4

9.5 29.32 11.4

29.4

9.5 30.41 11.4

19.5

32.91

23.5

5.7

31.46

7.9

7.9

Model BFH

4.7

4.7

6.9

9

Page 10

Capacity Ratings

Table 11. Capacity Ratings MBH / ˚TD, 40% Ethylene Glycol at 130˚F Average Fluid Temperature

Fan

Model Feeds

BFH

1062842

BFH

1202842

BFH

1323656

BFH

1403656

BFH

152

BFH

1623656

BFH

1683656

Model BFH

BFH

178

BFH

194

BFH

202

BFH

212

* PD is glycol uid loss in feet of water at 130˚F uid temperature

42

56

56

56

56

Con-

g.

2 x 4

2 x 4

2 x 4

2 x 4

2 x 5

2 x 5

2 x 5

2 x 5

2 x 6

2 x 6

2 x 6

20 30 40 50 60 70 80 90 100

MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD*

17.42 9.2 21.10 13.6 24.41

17.74 9.2 21.70 13.6 25.35

GPM

18.7

27.35

24.6

23.71

6.1

26.51

8.0 29.01 10.1 31.24 12.4 33.23 15.0

18.7

28.68

24.6

24.67

6.1

27.83

8.0 30.68 10.1 33.26 12.4 35.60 15.0

21.96 9.0 25.77 12.5 29.27 16.4 32.45

31.41

22.13 9.0 26.06 12.5 29.71 16.4 33.07

32.02

25.94 7.5 29.62 9.9 33.03 12.5 36.20 15.4 39.11 18.5

22.33 11.2 26.41 15.4 30.24 20.2 33.81

33.03

22.45 11.2 26.64 15.4 30.62 20.2 34.62

33.61

34.06 7.5 37.53 9.2 40.76 11.1

34.44 8.9 38.03 11.0 41.39 13.3

34.86 8.9 38.61 11.0 42.15 13.3

35.17 8.9 39.05 11.0 42.74 13.3

20.7

35.34

25.6

37.94

30.8

6.1

34.14

7.5

36.61

9.0

20.7

36.12

25.6

6.1

34.90

7.5 37.52 9.0

25.6

7.5 36.17 9.2 39.06 11.1

25.6

7.5 36.92 9.2 40.00 11.1

10

Page 11

Capacity Ratings

Table 12. Capacity Ratings MBH / ˚TD, 40% Ethylene Glycol at 130˚F Average Fluid Temperature

Model Feeds

Fan

Cong.

120 140 160 180 200 220 240 260 280

MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD*

GPM

BFH023

BFH027

BFH

BFH

BFH

BFH

BFH

BFH

BFH

BFH

BFH

BFH

BFH

BFH

BFH

BFH

28 1 x 2 11.69 10.7

42 1 x 2 12.33 5.2 12.74 6.9 13.07 8.7 13.34 10.7

031 42 1 x 2 13.68 5.2 14.17 6.9 14.57 8.7 14.89 10.7

28

035

56

041 42 1 x 3 17.67 7.7 18.39 10.1 18.96 12.8 19.40 15.7

045 42 1 x 3 19.56 7.7 20.42 10.1 21.10 12.8 21.66 15.7

049 56 1 x 3 20.36 4.6 21.24 6.1 21.95 7.7 22.52 9.5 22.99 11.4 23.39 13.5 23.74 15.7

28

046

56

42

054

84

053 42 1 x 4 22.45 10.1 23.53 13.3 24.39 16.9 25.09 20.8

42

060

84

061 42 1 x 4 24.77 10.1 26.05 13.3 27.08 16.9 27.93 20.8

0663656

112

065 56 1 x 4 25.75 6.1 27.08 8.0 28.15 10.1 29.02 12.5 29.75 15.0 30.36 17.8 30.89 20.8

0703656

112

071 56 1 x 4 26.70 6.1 28.12 8.0 29.25 10.1 30.17 12.5 30.94 15.0 31.58 17.8 32.13 20.8

1 x 2

2 x 2

2 x 2

2 x 2

2 x 2

2 x 2

15.98

22.2

14.79

3.1 15.32 4.1 15.74 5.2 16.07 6.4 16.35 7.8 16.59 9.2 16.79 10.7

21.27

22.2

19.10

3.1 20.15 4.1 21.01 5.2 21.74 6.4 22.37 7.8 22.91 9.2 23.38 10.7

22.34

10.8

23.40

14.2

24.26

18.0

24.96

20.12

24.65

21.98

26.92

25.63

27.98

26.59

1.5

10.8

1.5

22.5

6.5

22.5

6.5

21.24

25.93

23.30

28.21

26.96

29.34

28.00

2.0

22.16

14.2

26.95

2.0

24.40

29.5

8.6 28.03

25.43

29.5

8.6 29.13

26.34

2.6

18.0

2.6

10.8

1.5

10.8

1.5

22.2

22.93

3.1 23.59 3.8 24.16 4.5 24.66 5.2 25.10 6.0 25.49 6.9

27.80

22.2

25.32

3.1 26.11 3.8 26.79 4.5 27.39 5.2 27.91 6.0 28.37 6.9

28.90

13.4

29.62

16.1

26.38

30.05

27.36

1.9

13.4

1.9

27.20

30.81

28.22

2.3

16.1

2.3

30.23

27.90

31.45

28.96

19.1

2.7

19.1

2.7

30.75

28.51

32.00

29.60

Model BFH

22.2

3.1 29.04 3.6 29.51 4.1

22.2

3.1 30.17 3.6 30.67 4.1

* PD is glycol uid loss in feet of water at 130˚F uid temperature

* PD is glycol uid loss in feet of water at 130˚F uid temperature

11

Page 12

Capacity Ratings

Table 13. Capacity Ratings MBH / ˚TD, 40% Ethylene Glycol at 130˚F Average Fluid Temperature

42

56

56

56

56

Fan

Cong.

1 x 5

1 x 5

2 x 3

2 x 3

1 x 5

2 x 3

1 x 6

2 x 3

1 x 6

2 x 4

2 x 4

2 x 4

2 x 4

2 x 5

2 x 5

2 x 5

2 x 5

2 x 6

2 x 6

2 x 6

120 140 160 180 200 220 240 260 280

MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD* MBH PD*

29.34 12.6 31.09 16.5 32.52 20.9 33.69 25.8

29.21 7.6 30.92 9.9 32.30 12.6 33.44 15.5 34.39 18.7 35.20 22.1 35.89 25.8

30.40

15.8

32.27

20.7

27.66

2.3

29.52

3.0

31.91

15.8

33.98

20.7

28.91

2.3

30.94

3.0

31.52 7.6 33.49 9.9 35.06 12.6 36.36 15.5 37.43 18.7 38.34 22.1 39.12 25.8

33.21

15.8

35.47

20.7

29.98

2.3

32.17

3.0

33.19 9.0 35.40 11.9 37.20 15.0 38.69 18.5 39.95 22.3 41.02 26.4

34.43 9.5 36.81 12.4 38.75

35.68 9.0 38.23 11.9 40.31 15.0 42.02 18.5 43.45 22.3 44.66 26.4

36.64

20.7

39.42

27.1

33.71

3.0

36.37

3.9 38.62 4.9 40.54 6.1 42.20 7.3 43.64 8.7 44.92 10.1 46.05 11.7 47.06 13.3

39.62

20.7

42.95

27.1

36.24

3.0

39.36

3.9 42.02 4.9 44.30 6.1 46.28 7.3 48.01 8.7 49.54 10.1 50.89 11.7 52.10 13.3

40.89 12.4 44.42 16.3 47.35

42.08 12.4 45.85 16.3 49.00

44.27

25.6

41.05

3.7 45.08 4.9 48.56 6.1 51.59 7.6 54.25 9.1 56.59 10.8 58.66 12.6 60.51 14.5 62.17 16.5

44.16 15.4 48.47 20.2 52.13

45.46 15.4 50.11 20.2 54.07

46.55 15.4 51.50 20.2 55.74

47.47 18.3 52.75 24.1

48.61 18.3 54.26 24.1

49.52 18.3 55.52 24.1

Model Feeds

BFH

075

BFH

079

BFH

0804284

BFH

0864284

BFH

089

BFH

0904284

BFH

097

BFH

09856112

BFH

Model BFH

107

BFH

1064284

BFH

1204284

BFH

13256112

BFH

14056112

BFH

1524284

BFH

16256112

BFH

16856112

BFH

17856112

BFH

19456112

BFH

20256112

BFH

21256112

* PD is glycol uid loss in feet of water at 130˚F uid temperature

GPM

33.81

26.2

31.08

3.7 32.39 4.6 33.52 5.6 34.50 6.6 35.36 7.7 36.12 8.8 36.79 10.1

35.67

26.2

32.65

3.7 34.09 4.6 35.34 5.6 36.42 6.6 37.36 7.7 38.19 8.8 38.94 10.1

37.31

26.2

34.02

3.7 35.58 4.6 36.93 5.6 38.10 6.6 39.12 7.7 40.03 8.8 40.83 10.1

15.8

40.35

19.4

41.70

23.4

42.84

27.7

35.39

2.3

37.03

2.8

38.43

20.7

49.82

25.5

43.59

3.0

46.00

3.7 48.08 4.4 49.90 5.2 51.50 6.1 52.91 7.0 54.16 8.0

20.7

51.64

25.5

44.99

3.0

47.55

3.7 49.77 4.4 51.70 5.2 53.40 6.1 54.90 7.0 56.24 8.0

25.6

48.54

3.7 51.52 4.5 54.13 5.5 56.42 6.5 58.44 7.6 60.25 8.7 61.86 9.9

25.6

50.23

3.7 53.44 4.5 56.25 5.5 58.72 6.5 60.91 7.6 62.85 8.7 64.59 9.9

25.6

51.69

3.7 55.11 4.5 58.10 5.5 60.74 6.5 63.07 7.6 65.14 8.7 66.99 9.9

53.83 4.4 57.57 5.4 60.86 6.5 63.78 7.8 66.37 9.0 68.70 10.4 70.79 11.9

55.52 4.4 59.53 5.4 63.08 6.5 66.23 7.8 69.04 9.0 71.56 10.4 73.82 11.9

56.95 4.4 61.21 5.4 64.99 6.5 68.36 7.8 71.36 9.0 74.04 10.4 76.46 11.9

3.3

39.65

4.0 40.72 4.6 41.65 5.3 42.48 6.1

12

Page 13

Capacity Ratings

Table 14. Capacity Ratings MBH / ˚TD, 40% Ethylene Glycol at 130˚F Average Fluid Temperature

Model Feeds

Fan

Cong.

300 350 400 450 500

MBH PD* MBH PD* MBH PD* MBH PD* MBH PD*

BFH054 84 2 x 2 25.83 7.8 26.56 10.2

BFH060 84 2 x 2 28.78 7.8 29.65 10.2

BFH066 112 2 x 2 29.94 4.7 30.82 6.1 31.50 7.8 32.06 9.6 32.53 11.5

BFH070 112 2 x 2 31.11 4.7 32.03 6.1 32.75 7.8 33.33 9.6 33.80 11.5

BFH080 84 2 x 3 37.40 11.4 38.66 15.0

BFH086 84 2 x 3 39.60 11.4 40.99 15.0

BFH090 84 2 x 3 41.55 11.4 43.06 15.0

BFH098 112 2 x 3 43.22 6.9 44.77 9.0 45.98 11.4 46.97 14.0 47.77 16.9

BFH106 84 2 x 4 47.96 15.0 49.87 19.8

BFH120 84 2 x 4 53.18 15.0 55.46 19.8

BFH132 112 2 x 4 55.29 9.0 57.63 11.9 59.50 15.0 61.00 18.5 62.24 22.3

BFH140 112 2 x 4 57.43 9.0 59.92 11.9 61.87 15.0 63.45 18.5 64.74 22.3

BFH152 84 2 x 5 63.67 18.7 66.82 24.5

BFH162 112 2 x 5 63.30 11.2 66.36 14.8 68.80 18.7 70.78 23.0 72.42 27.7

BFH168 112 2 x 5 66.15 11.2 69.43 14.8 72.04 18.7 74.16 23.0 75.91 27.7

BFH178 112 2 x 5 68.65 11.2 72.14 14.8 74.90 18.7 77.12 23.0 78.96 27.7

BFH194 112 2 x 6 72.69 13.4 76.69 17.6 79.90 22.3 82.52 27.5 84.70 33.1

BFH202 112 2 x 6 75.87 13.4 80.18 17.6 83.63 22.3 86.45 27.5 88.78 33.1

BFH212 112 2 x 6 78.64 13.4 83.24 17.6 86.90 22.3 89.87 27.5 92.33 33.1

* PD is glycol uid loss in feet of water at 130˚F uid temperature

GPM

Model BFH

Table 15. Model BFH Connection Sizes, based on number of feeds

Single Row of Fans

Feeds Inlet/Outlet

14 2-1/8” ODS

18 2-1/8” ODS

21 2-5/8” ODS

28 2-5/8” ODS

42 3-1/8” ODS

56 3-5/8” ODS

Double Row of Fans

Feeds Inlet/Outlet

18 2 @ 2-1/8” ODS

28 2 @ 2-1/8” ODS

36 2 @ 2-1/8” ODS

42 2 @ 2-5/8” ODS

56 2 @ 2-5/8” ODS

84 2 @ 3-1/8” ODS

112 2 @ 3-5/8” ODS

13

Page 14

Dimensions

127”

20.25”

106”

112”

180”

20.25”

53” 53” 53”

165”

233”

20.25”

106”

218”

106”

286”

20.25”

53” 53” 53” 53” 53”

271”

339”

20.25”

53” 53” 53” 53” 53” 53”

324”

3,223 mm

515 mm

2,692 mm

2,845 mm

515 mm

4,572 mm

1,346 mm 1,346 mm1,346 mm

4,191 mm

1,346 mm 1,346 mm

1,346 mm

1,346 mm

1,346 mm

515 mm

515 mm

1,346 mm 1,346 mm

1,346 mm

1,346 mm

1,346 mm

1,346 mm

515 mm

2,692 mm

2,692 mm

5,918 mm

5,537 mm

7,264 mm

6,883 mm

8,611 mm

8,230 mm

45.43”

42.43”

38.00”

49.13”

88”

85”

49.13”

80.50”

1,154 mm

1,008 mm

965 mm

1,248 mm

2,355 mm

2,159 mm

0.875” [22 mm]

diameter mtg.

0.875” [22 mm]

diameter mtg.

holes typ.

2,045 mm

1,248 mm

Diagram 3. Model BFH Dimensions

End Views

Single

Row

Model BFH

Double

Row

Side Views

1 x 2

2 x 2

1 x 3

2 x 3

1 x 4

2 x 4

14

1 x 5

2 x 5

1 x 6

2 x 6

Page 15

Specications

Table 16. Model BFH Specications

Model

BFH023

BFH027

BFH031

BFH035

BFH041

BFH045

BFH049

BFH053

BFH061

BFH065

BFH071

BFH075

BFH079

BFH089

BFH097

BFH107

BFH046

BFH054

BFH060

BFH066

BFH070

BFH080

BFH086

BFH090

BFH098

BFH106

BFH120

BFH132

BFH140

BFH152

BFH162

BFH168

BFH178

BFH194

BFH202

BFH212

Fan Data

Fan

Cong.

1 x 2

1 x 2

1 x 2

1 x 2

1 x 3

1 x 3

1 x 3

1 x 4

1 x 4

1 x 4

1 x 4

1 x 5

1 x 5

1 x 5

1 x 6

1 x 6

2 x 2

2 x 2

2 x 2

2 x 2

2 x 2

2 x 3

2 x 3

2 x 3

2 x 3

2 x 4

2 x 4

2 x 4

2 x 4

2 x 5

2 x 5

2 x 5

2 x 5

2 x 6

2 x 6

2 x 6

1

No. of

Fans

2

2

2

2

3

3

3

4

4

4

4

5

5

5

6

6

4

4

4

4

4

6

6

6

6

8

8

8

8

10

10

10

10

12

12

12

CFM

208-230/3/60 575/3/60 460/3/60

Single Row of Fans

19,780

19,800

19,110

18,340

29,700

28,660

28,070

38,600

37,250

38,020

35,710

46,610

46,200

44,580

55,400

53,460

Double Row of Fans

39,570

39,600

38,210

37,530

36,770

59,400

58,510

57,320

56,240

77,200

74,500

72,790

71,310

93,120

92,400

91,010

89,170

110,900

109,240

107,020

14.0

14.0

14.0

14.0

21.0

21.0

21.0

28.0

28.0

28.0

28.0

35.0

35.0

35.0

42.0

42.0

28.0

28.0

28.0

28.0

28.0

42.0

42.0

42.0

42.0

56.0

56.0

56.0

56.0

70.0

70.0

70.0

70.0

84.0

84.0

84.0

FLA

2

5.6

5.6

5.6

5.6

8.4

8.4

8.4

11.2

11.2

11.2

11.2

14.0

14.0

14.0

16.8

16.8

11.2

11.2

11.2

11.2

11.2

16.8

16.8

16.8

16.8

22.4

22.4

22.4

22.4

28.0

28.0

28.0

28.0

33.6

33.6

33.6

7.0

7.0

7.0

7.0

10.5

10.5

10.5

14.0

14.0

14.0

14.0

17.5

17.5

17.5

21.0

21.0

14.0

14.0

14.0

14.0

14.0

21.0

21.0

21.0

21.0

28.0

28.0

28.0

28.0

35.0

35.0

35.0

35.0

42.0

42.0

42.0

Operating

Charge

(Gal.)

6.6

9.0

9.0

11.6

12.8

12.8

16.4

16.4

16.4

21.3

21.3

20.0

26.1

26.1

31.0

31.0

13.3

18.2

18.2

23.1

23.1

25.4

25.4

25.4

32.8

32.7

32.7

42.5

42.5

40.0

52.1

52.1

52.1

62.0

62.0

62.0

Approx.

Net Wt.

†

(lbs.)

720

760

780

860

1,170

1,190

1,220

1,550

1,590

1,620

1,730

1,960

1,960

2,200

2,350

2,580

1,560

1,600

1,650

1,670

1,780

2,350

2,400

2,500

2,560

3,080

3,140

3,190

3,450

3,920

3,930

4,070

4,300

4,620

4,800

5,130

Model BFH

Notes:

1

All fan blades are 30" diameter

2

All motors are 1-1/2 HP, 208-230/460/3/60, 1140 RPM

†

Does not include operating charge

15

Page 16

For more information on Bohn refrigeration products, contact

your sales representative or visit us at www.thecoldstandard.com.

A Brand of Heatcraft Refrigeration Products LLC

2175 West Park Place Blvd. • Stone Mountain, GA 30087

800.537.7775 • FAX 770.465.5990

www.thecoldstandard.com

Since product improvement is a continuing eort, we reserve the right to

make changes in specications without notice.

BN-FCTB-0407 | version 000

Loading...

Loading...