Page 1

AIR-COOLED CONDENSERS

Technical Guide

BN-ACCTB

November 2015

Replaces BN-ACCTB, May 2014

Page 2

TABLE OF CONTENTS

Overview.................................................................................. 2, 3

Features & Options............................................................... 3, 4

Three Solutions............................................................................5

Nomenclature..............................................................................6

Condenser Selection Procedure........................................7-9

Fixed Speed A/C Series

540 RPM .............................................................................10-12

830 RPM (1.0 HP)..............................................................13-15

830 RPM (1.5 HP)..............................................................16-18

1140 RPM ...........................................................................19-21

VSEC Information

ECCSelection ....................................................................... 22

Sound Data .......................................................................... 22

Energy Comparison .......................................................... 23

OVERVIEW

The Bohn VSEC and 3-Phase A/C Series of direct drive

air-cooled condensers incorporate the latest condenser

technology to provide the quietest and most ecient

condensers in the industry.

VSEC Series

Optimized sound and energy performance.

The VSEC Series of condensers by Bohn oers the

optimum solution for sound and energy performance.

The VSEC Series utilizes variable speed EC (VSEC)

motor technology, which provides unmatched sound

and energy performance and is the perfect solution

for those applications where low noise levels and

signicant energy savings are essential for success.

VSEC Series

830 RPM (Rail Mounted) ............................................... 24-26

1140 RPM (Rail Mounted)...............................................27-29

Venturi Mounted...............................................................30-32

Additional Information

Dimensions................................................................................ 33

Fan Cycling ..........................................................................34-35

Condenser Refrigerant Charge ....................................36-38

Calculate Refrigerant Charge ............................................. 38

Typical Condenser Wiring Diagrams ..........................39-40

Sound Data ............................................................................... 41

3-Phase A/C Series

Excellence in sound, energy

and capacity solutions.

The 3-Phase A/C Series of condensers by Bohn is

designed specically with the growing needs of the

supermarket and grocery industry in mind. This series

utilizes 830 and 540 RPM motors and incorporates

advanced features that further improve sound levels

and energy eciencies, as well as provide increased

capacity in a smaller footprint. In addition, there are

new features designed to improve serviceability,

resulting in reduced maintenance costs.

The 3-Phase A/C Series is a perfect t for applications

requiring low sound and energy levels and

optimized capacities.

Since product improvement is a continuing eort, we reserve the

right to make changes in specications without notice.

2

1140 Series

Bohn continues to oer the 1140 RPM Series for

customers seeking the most economical solution for

their capacity requirements.

Bohn condensers now incorporate a broader product

range with capacities ranging from 11 to 265 nominal

tons to address all applications.

All Bohn condenser coils incorporate the Floating Tube

coil design, which virtually eliminates the possibility

of tube sheet leaks. Condenser coils are designed for

maximum heat transfer and are designed to operate

with most common refrigerants.

© 2015, Heatcraft Refrigeration Products LLC

Page 3

OVERVIEW (continued)

As with all Bohn products, extensive testing of the

condenser ensures long and trouble-free service life.

The condensers are designed for outdoor application

with housings available in aluminum nish and painted

or unpainted galvanized steel.

The condensers are available in either single or double

wide fan congurations.

The condenser design incorporates the features most

desired in air-cooled condensers. An extensive list of

options and fan cycle control panels complement the

condenser design and allow the condenser to match the

most rigid application requirements.

The Floating Tube Coil Design

Dramatically Reduces Tube Sheet Leaks

FEATURES

The Bohn air-cooled condenser is available in multiple

product tiers and is designed with features to meet

specic customer requirements.

Bohn Venturi Mounted VSEC Series of Condensers

Customers seeking optimum sound and energy

performance can select the Bohn VSEC Series of

condensers with variable speed EC motor technology.

VSEC motors provide unparalleled sound and energy

performance.

Features include:

• VSEC motor, swept fan blade and Venturi

incorporating integrated variable speed technology

• Broad capacity range from 16 to 264 tons

• Aluminum housing for an attractive appearance and

corrosion protection, with painted galvanized steel,

or galvanized steel available as an option

• Side access panels allow for ease of cleaning coils

Venturi Mounted VSEC Series with VSEC Motor Technology

3

Page 4

Bohn 3-Phase A/C Series of Condensers

The 3-Phase A/C Series by Bohn is designed

specically with the growing needs of the

supermarket and grocery industry in mind.

This series utilizes 830 and 540 RPM motors and

incorporates advanced features that further improve

sound levels and energy eciencies, as well as provide

increased capacity in a smaller footprint. In addition,

there are new features designed to improve serviceability,

resulting in reduced maintenance costs. The 3-Phase A/C

Series is a perfect t for applications requiring low sound

and energy levels and optimized capacities.

Features include:

• Direct drive fan motors in 830 or 540 RPM

• The patented QuietEdge fan blade provides an

unprecedented sound level of 49.6 dBA (540 RPM @ 10 ft.)

• The Bohn patented (#7, 210, 661) ServiceEase motor

mount feature allows for ease of motor service and

reduces likelihood of damage to the coils during

servicing

• Bohn condenser coils incorporate the latest coil

technology to provide maximum capacity

• Broader product range to address all applications

capacities ranging from 11 to 225 nominal tons

• Galvanized steel cabinet with the option for

aluminum or painted galvanized steel

• High eciency, three-phase fan motors with ball

bearings and internal overload protection

1140 Series

For customers seeking an economical solution to

their capacity needs, Bohn now oers the 1140 RPM

Series with enhancements to improve capacity and

serviceability.

Bohn's Patented QuietEdge Fan Blade for

Improved Sound Performance

Features include:

• Direct drive fan motors

• The Bohn patented (#7, 210, 661) ServiceEase™ motor

mount

• New, high eciency condenser coil designed for

optimum performance

• Expanded product range from 15 to 249 nominal tons

• Galvanized steel as a standard housing, with an option

for aluminum or painted galvanized steel

• High eciency, three-phase fan motors with ball

bearings and internal overload protection

All Standard Condensers

• 10 ns per inch spacing

• Modular design with models in both single and

double wide fan congurations

• All Bohn condensers incorporate the Floating Tube

coil design, which virtually eliminates tube sheet leaks

• Internal baes provided between all fan cells

• Condensers up to 3 fans in length use 3/8” diameter

tube to minimize refrigerant charge. Condensers

4 or more fans in length use 1/2" diameter tube to

minimize refrigerant pressure drop

• Coated steel fan guards

• Weatherproof control panel with factory-mounted

door interrupt disconnect switch

• UL and UL listed for Canada

Available Options:

• Multi-circuiting at no additional charge

• Optional 8, 12 or 14 FPI spacing

• Fan-cycle control panels

• Alternate coil construction including BohnGuard coated

ns, epoxy or phenolic coated ns and copper ns

• Hinged fan panels for ease of servicing (3-Phase A/C

and 1140 Series only)

• Side access panels

• Extended condenser legs for increased ground clearance

• Sealtite wiring

• Frame for shipping

ServiceEase Motor Mount System

4

Page 5

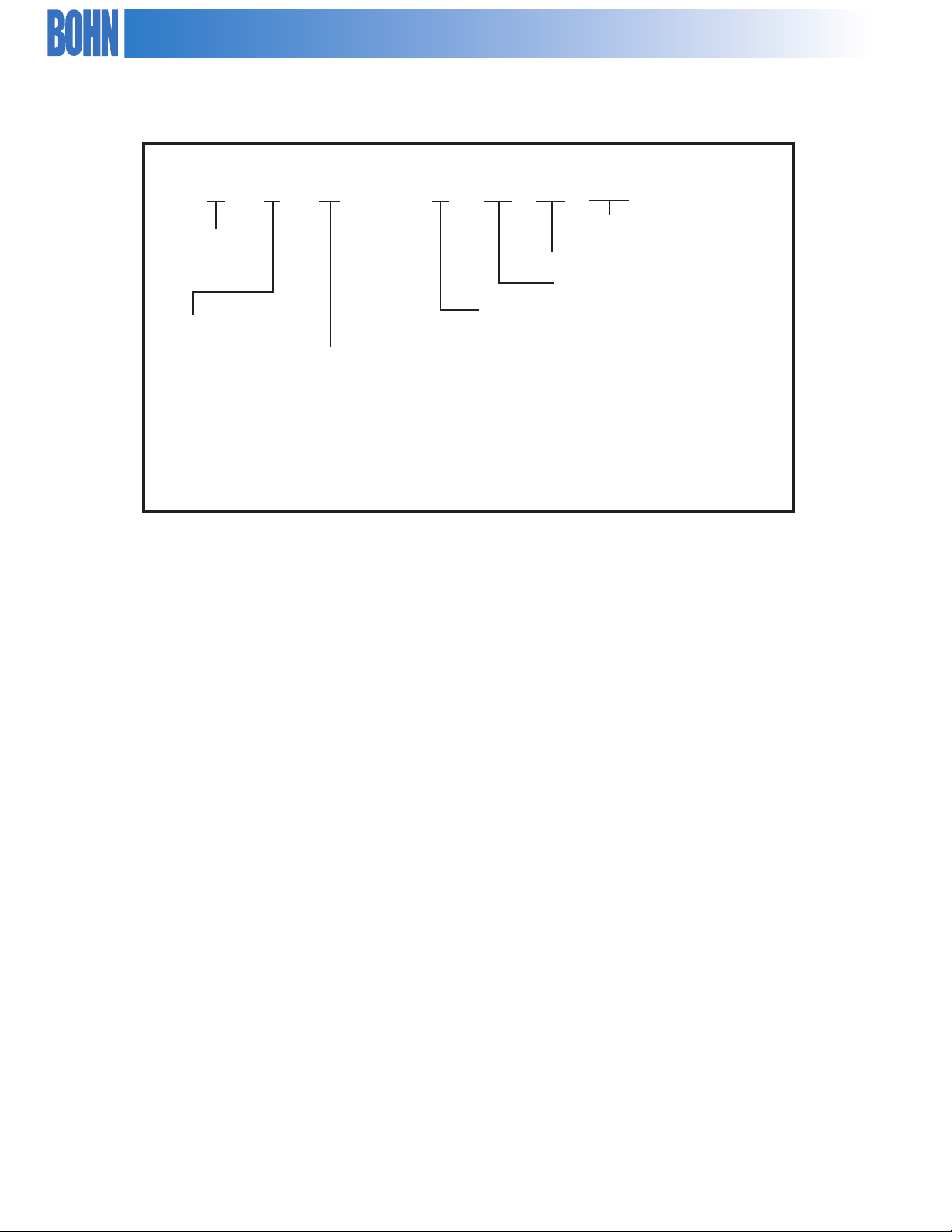

Three Solutions Tailored To Fit Your Unique Needs

Choose from Fixed Speed, Rail Mounted VSEC, or Venturi Mounted VSEC series of

air-cooled condensers by Bohn. Choosing the Venturi Mounted VSEC Series means that

you are selecting the ultimate in capacity, sound, and eciency. The Rail Mounted VSEC

option oers all of the benets of variable speed in a conventional condenser package,

while the xed speed options continue to provide proven performance and capacity.

FEATURE

1140 RPM

FIXED SPEED

830 & 540 RPM

FIXED SPEED

RAIL MOUNTED

VSEC

VENTURI

MOUNTED VSEC

Motors

Standard Motor 1140 RPM 830, 540 RPM

P66 Motor Option

Cabinet

Standard Cabinet Galvanized Galvanized Galvanized Aluminum

Galvanized Option (standard) (standard) (standard)

Pre-Painted Galvanized Option

Aluminum Option

Venturi Cover

Standard Venturi Removable Removable Removable

Hinged Option

Fan Blades

Standard Blade Standard QuietEdge™ Standard/QuietEdge

Motor Mounted

p p

p p p p

p p p

p p p

Variable Speed

EC Motors

TM

Variable Speed

EC Motors

(standard)

EC Tall

Optimized

EC Optimized

p

-

Standard Motor Mounted Service Ease™ Service Ease™ Service Ease™ EC Optimized

Warranty

Two-Year Warranty

Two-Year Warranty - Rail Mounted VSEC Motors - -

Three-Year Warranty - Venturi Mounted VSEC Motors - - -

Five-Year Warranty - Floating TUBE ™ Coil Design

p p p p

p

p

p p p p

-

5

Page 6

NOMENCLATURE

B N H – S 04 A 050

B - Bohn

N – Vintage

Model Identier

Fans

Width

S – Single Wide

Motor

H - 1140 RPM 1.5 HP

L - 830 RPM, 1.5 HP

X - 830 RPM, 1.0 HP

Q - 540 RPM, 0.5 HP

E - Venturi Mounted VSEC, 2.0 HP

J - Rail Mounted VSEC, 830 RPM, 2.5 HP

K - Rail Mounted VSEC, 1140 RPM, 2.25 HP

D – Double Wide

01-14

Standard Capacity

(MBH/°TD, R-22 @ 10 FPI)

6

Page 7

Condenser Selection

Capacity for air-cooled condensers are based on Total Heat of Rejection (THR)

at the condenser. Total heat of rejection is equal to net refrigeration at the

evaporator (compressor capacity) plus the energy input into the refrigerant

by the compressor (heat of compression). The heat of compression will

vary depending on the compressor manufacturer, type of compressor

and the operating conditions of the compressor. Whenever possible, it is

recommended that you obtain the heat of compression value from the

compressor manufacturer.

If this is not available, the THR can be estimated using the following formula:

THR = (Compressor Capacity) * (Heat of Compression Factor, Tables 1 & 2)

Table 1 contains heat of compression factors for suction cooled compressors

and Table 2 contains factors for open drive compressors. For refrigeration

systems beyond the range of Tables 1 and 2, use the following equations to

estimate THR:

Open Compressors:

THR = Compressor Capacity (BTUH) + (2545) * (Break Horsepower, BHP)

Suction Cooled Compressors:

THR = Compressor Capacity (BTUH) + (3413 * KW)

The compressor capacity is eected by its altitude. If the condenser location

is above sea level, an additional correction is required to the THR, as follows:

THR (altitude) = THR * Altitude Correction Factor, Table 3

Selection Example

Compressor capacity: 350,000

Evaporator temperature: +25° F

Condensing temperature: 115° F

Ambient temperature 95° F

Refrigerant: R-22

Compressor type: Semi-hermetic, suction cooled

Condenser type: 540 RPM, one row of fans

Condenser altitude: 1,000 feet

Step 1: Estimate Condenser THR

From Table 1 for suction cooled compressors, at +25° F suction, we need to

determine the heat of compression factor for 115° F condensing temperature

(NOT shown in table).

Therefore, select the condensing temperatures and heat of compression

factor for +25° F suction temperatures as follows:

100° 115° 110° (Condensing Temperature)

1.31 X 1.36 (Heat of Compression Factor)

To determine X: (Heat of Compression Factor)

((1.36-X) / (1.36-1.31)) = ((120-115) / (120-110)) = ((1.36-X)/0.05) = (5/10)

X = 1.36 – (0.05 * 0.5) = 1.335

Therefore heat of compression factor at 115° F condensing temperature is

1.335

THR = Compressor Capacity * Heat of Compression Factor

= 350,000 * 1.335

= 467,250

Step 2: Correct for Altitude

From Table 3 obtain an altitude correction factor of 1.02 for 1,000 feet.

THR = THR (from step 1) * Altitude Correction Factor (design)

= 467,250 * 1.02

= 476,595

Step 3: Calculate Design Condenser T.D.

Design Condenser T.D. = Condensing Temp — Ambient Temp

= 115 - 95

= 20° T.D.

Step 4: Condenser Selection

Condenser capacities for condensers at 540 RPM are located in Table 7. These

capacities are given in MBH/°TD. Convert the THR calculated in step 2 to

MBH/°TD by dividing by 1,000 to get THR in MBH. Then divide the THR by the

design TD to get MBH/°TD.

THR (MBH) = 476,595 / 1,000 = 476.6

THR (MBH/°TD) = 476.6 / 20 = 23.83

Locate the 10 FPI column for R-22 refrigerant and read down until you locate a

value equal to or just larger than 23.83. This value is 25.9. Read horizontally to

the left to obtain a condenser model of BNQ-S05-A026.

Step 5: Calculate Actual T.D. and Condensing Temperature

The actual condenser T.D. can be calculated by dividing the design THR by

the condenser rating.

Actual T.D. = THR (Design) / (Rating @ 1° T.D.)

= 476.6 / 25.9

= 18.4°F. T.D.

The actual condensing temperature is the actual T.D. plus the ambient

temperature. Actual Condensing Temperature = (Actual T.D.) + (Ambient)

= 18.4 + 95

= 113.4°F.

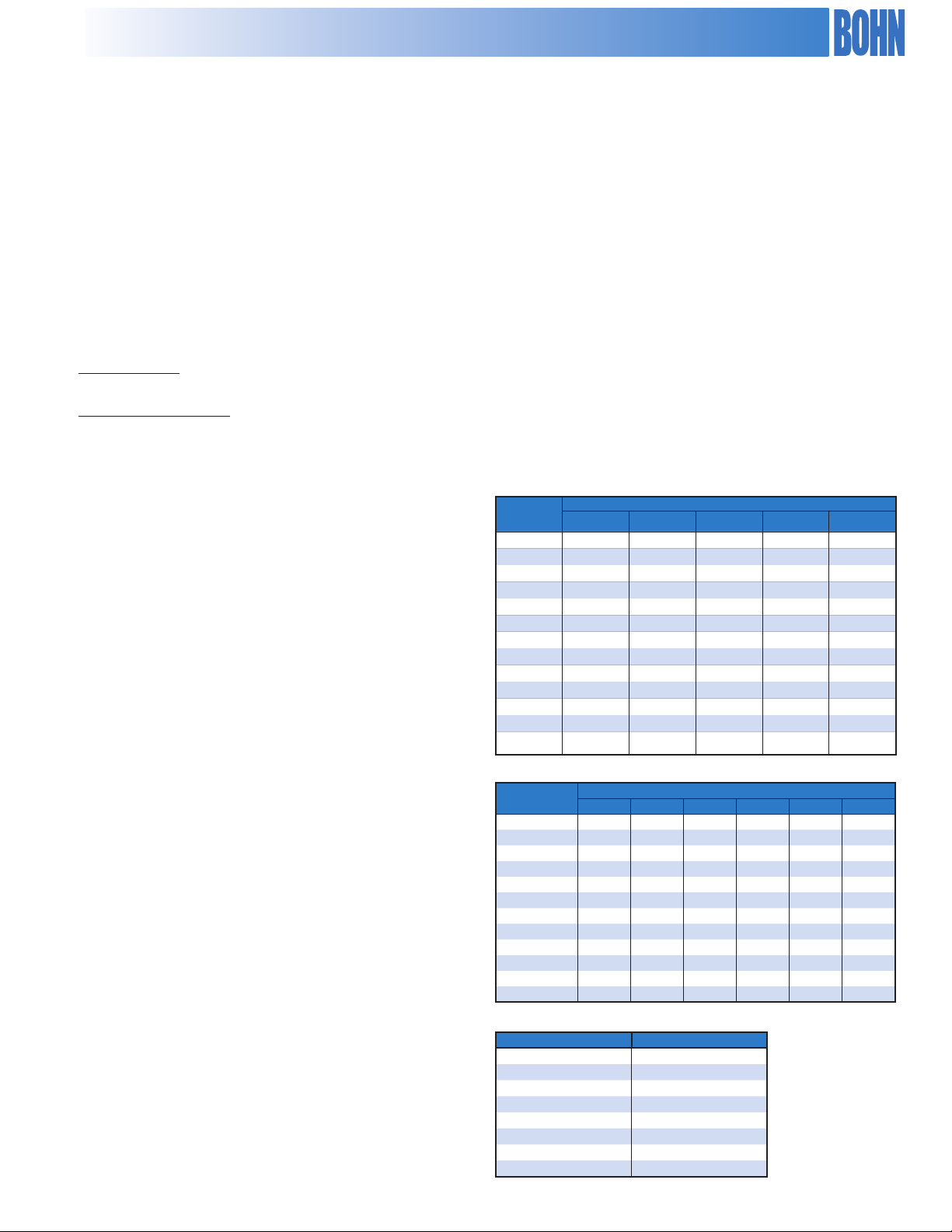

Table 1. Heat of Compression Factor for Suction Cooled Compressors.

Suction

Temp. °F

-40° 1.56 1.63 1.72 1.81 1.94

-30° 1.49 1.55 1.62 1.7 1.8

-20° 1.43 1.49 1.55 1.62 1.7

-10° 1.38 1.43 1.49 1.55 1.63

0° 1.34 1.38 1.43 1.49 1.56

5° 1.31 1.36 1.41 1.48 1.55

10° 1.29 1.34 1.39 1.44 1.52

15° 1.26 1.31 1.36 1.41 1.48

20° 1.24 1.28 1.33 1.38 1.44

25° 1.22 1.26 1.31 1.36 1.42

30° 1.2 1.24 1.28 1.33 1.39

40° 1.17 1.2 1.24 1.28 1.33

50° 1.13 1.16 1.2 1.24 1.28

90° 100° 110° 120° 130°

Condensing Temp erature °F

Table 2. Heat of Compression Factor for Open Drive Compressors.

Evaporator

Temp. °F

-30° 1.37 1.42 1.47 — — —

-20° 1.33 1.37 1.42 1.47 — —

-10° 1.28 1.32 1.37 1.42 1.47 —

0° 1.24 1.28 1.32 1.37 1.41 1.47

5° 1.23 1.26 1.3 1.35 1.39 1.45

10° 1.21 1.24 1.28 1.32 1.36 1.42

15° 1.19 1.22 1.26 1.3 1.34 1.4

20° 1.17 1.2 1.24 1.28 1.32 1.37

25° 1.16 1.19 1.22 1.26 1.3 1.35

30° 1.14 1.17 1.2 1.24 1.27 1.32

40° 1.12 1.15 1.17 1.2 1.23 1.28

50° 1.09 1.12 1.14 1.17 1.2 1.24

90° 100° 110° 120° 130° 140°

Condensing Temperature °F

Table 3. Altitude Correction Factors.

Altitude Correction Factor

0 1

1,000 1.02

2,000 1.05

3,000 1.07

4,000 1.1

5,000 1.12

6,000 1.15

7,000 1.17

7

Page 8

Multi-Circuiting Selection

Multi-Circuiting Selection Procedure

The air-cooled condensers are available with more than one

refrigerant circuit. The condenser will be factory assembled with the

condenser coil divided into individual refrigerant circuits, each sized

Multi-Circuit Condenser Selection

Given four suction cooled compressors with conditions shown in Table

4. The condenser shall have 830 RPM, 1.0 HP fan motors,

Selection Procedure

Step 1: Input customer data in Table 4 in columns 1, 2, 3, 4

and 5.

Step 2: From Table 1, select the heat of compression factor

for suction cooled compressors and input into

Column #6.

Step 3: From Table 3 obtain the altitude correction factor

and input into Column #7.

Step 4: From Table 5 obtain the refrigerant capacity factor and

input into Column #8.

for its own specic application. Each circuit is supplied with its own

inlet and outlet connections, individually labeled.

with two rows of fans. The condenser location is at 3,000 ft. and the

design ambient is 95°F.

Step 5: Calculate the design T.D. for each circuit by

subtracting the ambient temperature from the circuit

design condensing temperature and input into

Column #9.

T.D. = Design Condensing Temperature - Ambient Temperature

Step 6: Calculate the design THR / °T.D. for each circuit.

Multiply Column #5 by Column #6 and Column #7 to

calculate the THR for each circuit. Divide the result by

the refrigerant correction factor, Column #8 to convert

the capacities to a common refrigerant. Divide the

result by the design T.D., Column #9 to calculate the

design THR / °T.D. and input into Column #10.

Design THR / °T.D. = Compressor Capacity (#5) * Heat of Compressor Factor (#6) x Altitude Factor (#7)

Refrigerant Capacity Factor (#8) * Design T.D. (#9)

Example for Circuit #1:

Design THR / °T.D. = 235,000 * 1.31 * 1.07

1.02 x 15

= 21,529 BTUH / °T.D.

Step 7: Add the design THR / °T.D. for each circuit in column

#10, to get a total of 39,578 BTUH / °T.D. Divide this

total by 1,000 to get 39.6 MBH / °T.D.

Step 8: From Table 10 for two rows of condenser fans with

830 RPM, 1.0 HP fan motors, locate the column for

R-404A capacity with 10 FPI. Read down the column

until you get to a capacity equal to or greater than 39.6

MBH / °T.D. This value is 44.5 which corresponds to a

BNX-D06-A045. From Table 12 obtain the total

number of feeds available as 56.

8

Page 9

Multi-Circuiting Condenser

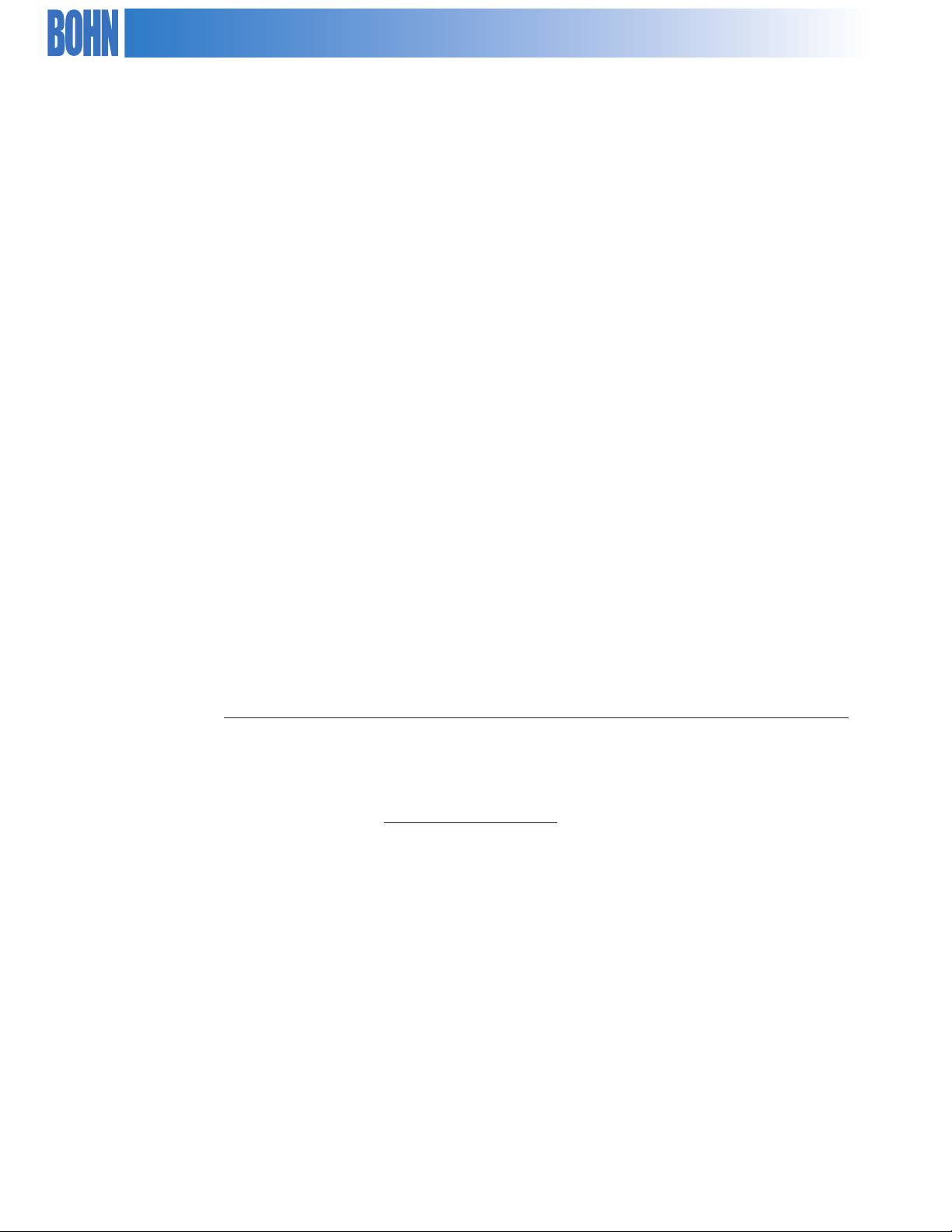

Table 4. Condenser Multi-Circuit Selection

1 2 3 4 5 X 6 X 7 ÷ 8 ÷ 9 = 10 11 12 13

X

Heat of

Com-

press.

Factor

X

Alti-

tude

Factor

÷

Refrig.

Cap.

Factor

Design

÷

Cond.

T.D .

TOTAL = 39,578 56

39,578 / 1,000 = 39.6 MBH/°TD

=

Design

THR/°TD

No. of

Feeds

Per Circ.

Actual

Cond.

Circuit

Name

Step 9: Determine the number of feeds per circuit. Divide the design THR / °T.D. in Column #10 by the total capacity required (39,578) and

Evap.

Temp.°F

1 25 110 22 235,000 X 1.31 X 1.07 ÷ 1.02 ÷ 15 = 21,529 31 13.1 108.1

2 20 110 134a 61,000 X 1.33 X 1.07 ÷ .97 ÷ 15 = 5,966 8 14.1 109.1

3 -10 105 22 31,000 X 1.46 X 1.07 ÷ 1.02 ÷ 10 = 4,748 7 8.5 103.5

4 -20 105 22 46,000 X 1.52 X 1.07 ÷ 1.02 ÷ 10 = 7,335 10 9.2 104.2

multiply this result by the number of feeds available, which is 56. Round this value to the nearest integer and place in Column #11

Add the individual feeds per circuit to get a total number of feeds for the condenser. This total must equal the total number of

feeds available for the condenser (56).

Design

Cond.

Temp.°F

Comp.

Refrig.

Type

Cap.

BTUH

T.D .

Actual

Cond.

Temp.

°F

Number of = Design THR / °T.D.(#10) * Number of Circuits Available (56)

feeds/circuit Total Capacity Required (39,578)

Step 10: Calculate actual condensing T.D., (ATD):

ATD = Design T.D. (#9) * Design THR/°T.D. (#10) * Number of Feeds Available (56)

Number Feeds / CIR (#11) * Condenser Capacity / °T.D. (Step #8) * 1,000

Example for Circuit #1:

ATD = 15 * 21,529 x 56

= 13.1°F.

31 * 44.5 * 1,000

Input these T.D. values in column #12.

Step 11: Calculate the actual condensing temperature. Actual condensing temperature is equal to the actual condensing T.D., Column #12

plus the design ambient (95°). Input these values in Column #13. If the actual condensing temperature for each circuit is too high,

it may be necessary to adjust the number of feeds per circuit or to select the next larger condenser size and recalculate the number

of feeds per circuit.

Table 5. Refrigerant Capacity Factor.

Refrigerant Capacity Factor

R-22 1.02

R-134a 0.99

R-404A 1

R-407A 0.98*

R-407C 0.94*

R-407F 0.98*

R-410A 1.02

R-507 1

Table 6. Voltage Frequency

Capacity Factor

Frequency Capacity Factor

60 Hz 1.0

50 Hz (H, L, X, Q) 0.92

50 Hz (E) 1.0

*Correction factors based on midpoint condensing temperature.

9

Page 10

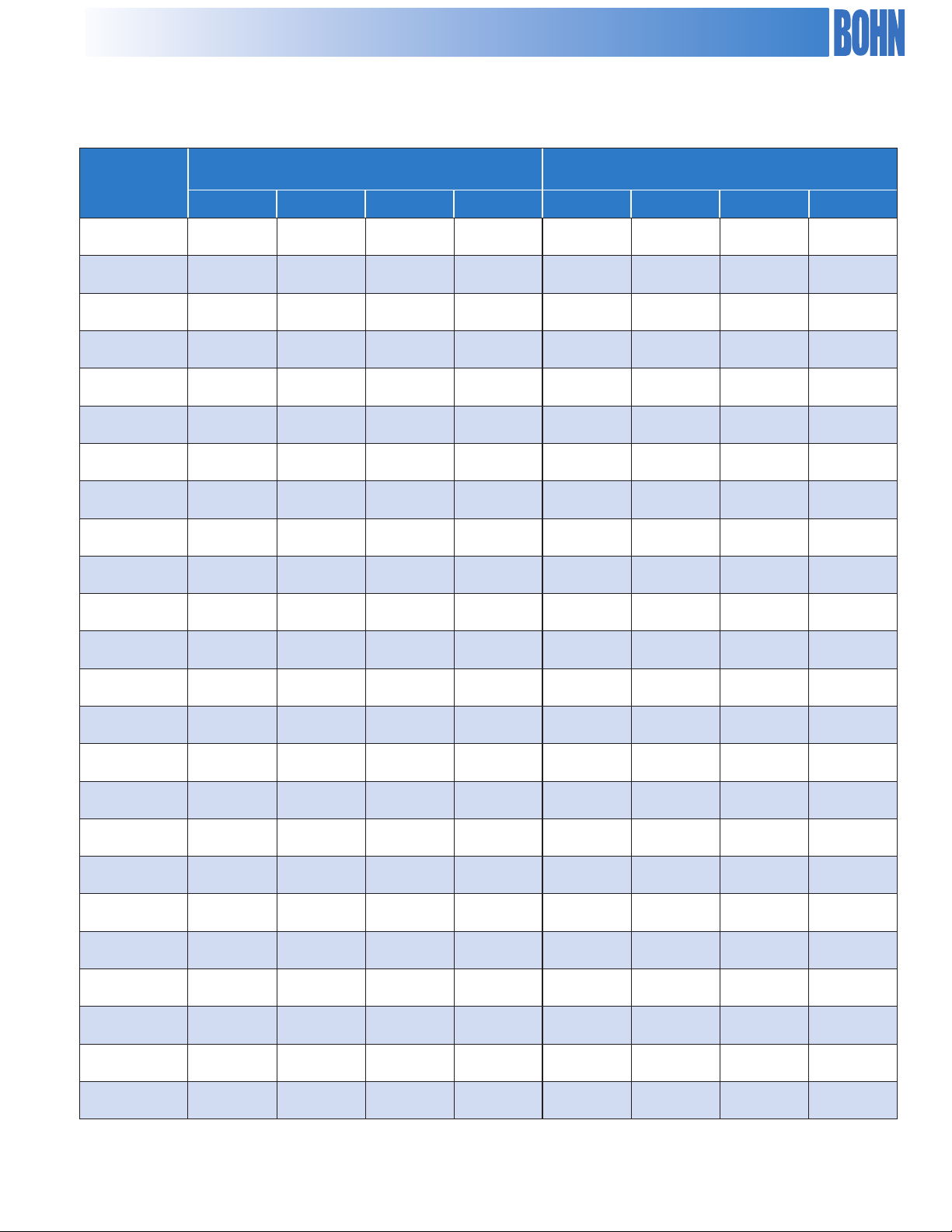

CONDENSER CAPACITY

Table 7. BNQ Models, 540 RPM, 0.5 HP, 30" Fan Diameter

R22 / R410A

Model

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

MBH / 1° TD

BNQ 540 830 VSEC 1140

R404A/R507

MBH / 1° TD

BNQ-S01-A005

BNQ-S01-A006

BNQ-S02-A008

BNQ-S02-A010

BNQ-S02-A011

BNQ-S03-A016

BNQ-S03-A017

BNQ-S04-A021

BNQ-S04-A023

BNQ-S05-A026

BNQ-S05-A029

BNQ-S06-A034

BNQ-S07-A042

4.6 5.2 5.6 5.9 4.6 5.1 5.5 5.8

5.5 6.1 6.4 6.6 5.4 5.9 6.2 6.5

7.2 8.0 8.7 9.1 7.0 7.8 8.5 8.9

9.4 10.3 10.8 11.8 9.2 10.1 10.6 11.6

10.8 11.5 11.9 12.3 10.6 11.2 11.7 12.0

14.1 15.6 16.2 16.9 13.8 15.2 15.9 16.6

16.2 17.2 17.9 19.8 15.9 16.9 17.5 19.4

18.8 20.7 21.6 23.5 18.4 20.3 21.2 23.0

21.6 22.9 23.8 24.5 21.2 22.4 23.3 24.0

23.5 25.9 27.0 29.3 23.1 25.4 26.4 28.8

27.0 28.6 29.8 30.7 26.5 28.1 29.2 30.1

32.4 34.4 35.7 36.8 31.8 33.7 35.0 36.1

38.4 41.6 42.8 44.3 37.7 40.7 41.9 43.4

BNQ-D04-A016

BNQ-D04-A021

BNQ-D04-A023

BNQ-D06-A031

BNQ-D06-A034

BNQ-D08-A041

BNQ-D08-A046

BNQ-D10-A052

BNQ-D10-A057

BNQ-D12-A069

BNQ-D14-A083

BOLD indicates standard model capacity.

* Data based on mid point condensing temperature

14.3 16.0 17.3 18.2 14.0 15.6 16.9 17.9

18.8 20.7 21.6 23.6 18.4 20.3 21.2 23.2

21.6 22.9 23.8 24.5 21.2 22.4 23.3 24.0

28.2 31.0 32.4 33.8 27.6 30.4 31.8 33.1

32.4 34.4 35.7 39.5 31.8 33.7 35.0 38.7

37.6 41.4 43.2 47.0 36.9 40.6 42.3 46.1

43.2 45.8 47.6 49.0 42.4 44.9 46.7 48.1

47.0 51.8 54.0 58.7 46.1 50.7 52.9 57.5

54.0 57.3 59.5 61.3 53.0 56.1 58.3 60.1

64.8 68.7 71.4 73.6 63.6 67.3 70.0 72.1

76.8 83.1 85.5 88.6 75.3 81.5 83.8 86.8

10

Page 11

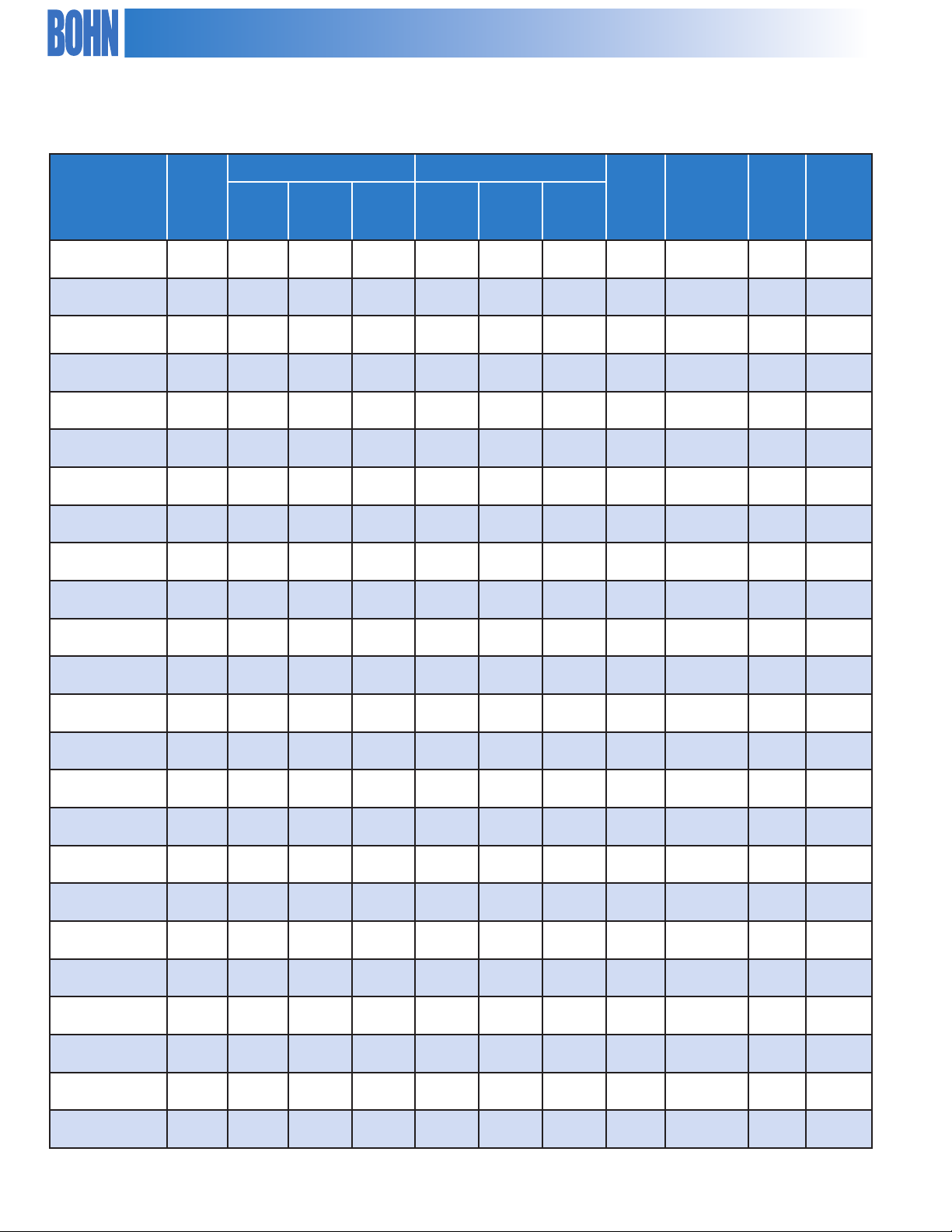

CONDENSER CAPACITY

Table 8. BNQ Models, 540 RPM, 0.5 HP, 30" Fan Diameter

R407A / R407F*

Model

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

MBH / 1° TD

BNQ 540 830 VSEC 1140

R407C*

MBH / 1° TD

BNQ-S01-A005

BNQ-S01-A006

BNQ-S02-A008

BNQ-S02-A010

BNQ-S02-A011

BNQ-S03-A016

BNQ-S03-A017

BNQ-S04-A021

BNQ-S04-A023

BNQ-S05-A026

BNQ-S05-A029

BNQ-S06-A034

BNQ-S07-A042

4.5 5.0 5.4 5.7 4.3 4.8 5.2 5.5

5.3 5.8 6.1 6.3 5.1 5.6 5.9 6.1

6.9 7.6 8.3 8.7 6.6 7.3 8.0 8.4

9.0 9.9 10.4 11.3 8.7 9.5 10.0 10.9

10.4 11.0 11.4 11.8 10.0 10.6 11.0 11.3

13.5 14.9 15.6 16.2 13.0 14.3 14.9 15.6

15.6 16.5 17.1 19.0 14.9 15.8 16.4 18.2

18.1 19.9 20.8 22.6 17.3 19.1 19.9 21.6

20.8 22.0 22.9 23.6 19.9 21.1 21.9 22.6

22.6 24.9 25.9 28.2 21.7 23.8 24.9 27.0

25.9 27.5 28.6 29.5 24.9 26.4 27.4 28.3

31.1 33.0 34.3 35.3 29.9 31.7 32.9 33.9

36.9 39.9 41.1 42.5 35.4 38.3 39.4 40.8

BNQ-D04-A016

BNQ-D04-A021

BNQ-D04-A023

BNQ-D06-A031

BNQ-D06-A034

BNQ-D08-A041

BNQ-D08-A046

BNQ-D10-A052

BNQ-D10-A057

BNQ-D12-A069

BNQ-D14-A083

BOLD indicates standard model capacity.

* Data based on mid point condensing temperature

13.8 15.3 16.6 17.5 13.2 14.7 15.9 16.8

18.1 19.9 20.7 22.7 17.3 19.1 19.9 21.8

20.8 22.0 22.9 23.6 19.9 21.1 21.9 22.6

27.1 29.8 31.1 32.5 26.0 28.6 29.9 31.1

31.1 33.0 34.3 38.0 29.9 31.7 32.9 36.4

36.1 39.8 41.5 45.1 34.6 38.1 39.8 43.3

41.5 44.0 45.7 47.1 39.8 42.2 43.9 45.2

45.2 49.7 51.9 56.4 43.3 47.7 49.7 54.1

51.9 55.0 57.2 58.9 49.8 52.8 54.8 56.5

62.3 66.0 68.6 70.7 59.7 63.3 65.8 67.8

73.8 79.9 82.2 85.1 70.8 76.6 78.8 81.6

11

Page 12

CONDENSER SPECIFICATIONS

BNQ 540 830 VSEC 1140

Table 9. BNQ Models, 540 RPM, 0.5 HP, 30" Fan Diameter

208-230/3/60 460/3/60

Model CFM

FLA MCA MOPD FLA MCA MOPD

BNQ-S01-A005 5,400 3.5 15.0 15 1.8 15.0 15 0.4 1 3/8 7 330

BNQ-S01-A006 5,200 3.5 15.0 15 1.8 15.0 15 0.4 1 3/8 14 360

BNQ-S02-A008 11,200 7.0 15.0 15 3.6 15.0 15 0.9 1 3/8 14 580

BNQ-S02-A010 10,800 7.0 15.0 15 3.6 15.0 15 0.9 1 5/8 21 630

BNQ-S02-A011 10,400 7.0 15.0 15 3.6 15.0 15 0.9 2 1/8 28 680

BNQ-S03-A016 16,100 10.5 15.0 20 5.4 15.0 15 1.3 2 1/8 21 930

BNQ-S03-A017 15,600 10.5 15.0 20 5.4 15.0 15 1.3 2 1/8 28 1,000

BNQ-S04-A021 21,500 14.0 15.0 20 7.2 15.0 15 1.7 2 1/8 21 1,210

Unit

kW

Conn.

(in.)

Max.

No.

of

Feeds

prox.

Weight

(lbs)

Ap-

Net

BNQ-S04-A023 20,800 14.0 15.0 20 7.2 15.0 15 1.7 2 5/8 28 1,310

BNQ-S05-A026 26,900 17.5 20.0 25 9.0 15.0 15 2.2 2 5/8 21 1,510

BNQ-S05-A029 26,000 17.5 20.0 25 9.0 15.0 15 2.2 2 5/8 28 1,640

BNQ-S06-A034 31,200 21.0 21.9 30 10.8 15.0 15 2.6 2 5/8 28 1,950

BNQ-S07-A042 36,400 24.5 25.4 35 12.6 15.0 15 3.1 2 @ 2 5/8 28 2,240

BNQ-D04-A016 22,300 14.0 15.0 20 7.2 15.0 15 1.7 2 @ 1 3/8 28 1,240

BNQ-D04-A021 21,500 14.0 15.0 20 7.2 15.0 15 1.7 2 @ 1 5/8 42 1,340

BNQ-D04-A023 20,800 14.0 15.0 20 7.2 15.0 15 1.7 2 @ 2 1/8 56 1,440

BNQ-D06-A031 32,300 21.0 21.9 30 10.8 15.0 15 2.6 2 @ 2 1/8 42 1,990

BNQ-D06-A034 31,200 21.0 21.9 30 10.8 15.0 15 2.6 2 @ 2 1/8 56 2,140

BNQ-D08-A041 43,000 28.0 28.9 35 14.4 15.0 20 3.5 2 @ 2 1/8 42 2,630

BNQ-D08-A046 41,600 28.0 28.9 35 14.4 15.0 20 3.5 2 @ 2 5/8 56 2,830

BNQ-D10-A052 53,700 35.0 35.9 45 18.0 20.0 20 4.4 2 @ 2 5/8 42 3,290

BNQ-D10-A057 52,100 35.0 35.9 45 18.0 20.0 20 4.4 2 @ 2 5/8 56 3,540

BNQ-D12-A069 62,500 42.0 42.9 50 21.6 22.1 25 5.2 2 @ 2 5/8 56 4,230

BNQ-D14-A083 72,900 49.0 49.9 60 25.2 25.7 30 6.1 4 @ 2 5/8 56 4,910

12

Page 13

CONDENSER CAPACITY

BNX 540 830 VSEC 1140

Table 10. BNX Models, 830 RPM, 1.0 HP, 30" Fan Diameter

R22/R410A

Model

MBH / 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNX-S01-A006 5.6 6.4 7.0 7.4 5.5 6.2 6.8 7.3

BNX-S01-A008 6.8 7.5 8.0 8.4 6.6 7.4 7.9 8.3

BNX-S02-A010 8.8 9.8 10.6 11.2 8.6 9.6 10.4 11.0

BNX-S02-A013 12.0 13.1 13.8 14.8 11.8 12.8 13.6 14.5

BNX-S02-A015 14.0 15.1 15.7 16.0 13.7 14.8 15.3 15.7

BNX-S03-A020 18.0 19.7 20.8 21.8 17.7 19.3 20.4 21.4

BNX-S03-A023 21.0 22.7 23.5 25.3 20.5 22.3 23.0 24.8

BNX-S04-A026 24.1 26.3 27.7 29.3 23.6 25.7 27.1 28.7

R404A/R507

MBH / 1° TD

BNX-S04-A030 27.9 30.3 31.3 32.0 27.4 29.7 30.7 31.4

BNX-S05-A033 30.1 32.8 34.6 36.7 29.5 32.1 33.9 36.0

BNX-S05-A038 34.9 37.8 39.2 40.1 34.2 37.1 38.4 39.3

BNX-S06-A045 41.9 45.4 47.0 48.1 41.1 44.5 46.0 47.1

BNX-S07-A052 47.7 52.0 54.8 56.1 46.8 51.0 53.7 55.0

BNX-D04-A020 17.5 19.6 21.2 22.5 17.2 19.2 20.8 22.0

BNX-D04-A026 24.1 26.2 27.7 29.7 23.6 25.7 27.1 29.1

BNX-D04-A030 27.9 30.3 31.3 32.0 27.4 29.7 30.7 31.4

BNX-D06-A039 36.1 39.4 41.5 43.7 35.4 38.6 40.7 42.8

BNX-D06-A045 41.9 45.4 47.0 50.6 41.1 44.5 46.0 49.6

BNX-D08-A052 48.1 52.5 55.4 58.6 47.1 51.4 54.3 57.5

BNX-D08-A061 55.9 60.6 62.7 64.1 54.8 59.3 61.4 62.8

BNX-D10-A066 60.1 65.6 69.2 73.5 58.9 64.3 67.8 72.0

BNX-D10-A076 69.9 75.7 78.3 80.1 68.4 74.2 76.8 78.5

BNX-D12-A091 83.8 90.8 94.0 96.1 82.1 89.0 92.1 94.2

BNX-D14-A104 95.5 104.1 109.6 112.2 93.6 102.0 107.5 110.0

BOLD indicates standard model capacity.

* Data based on mid point condensing temperature

13

Page 14

CONDENSER CAPACITY

BNX 540 830 VSEC 1140

Table 11. BNX Models, 830 RPM, 1.0 HP, 30" Fan Diameter

R407A / R407F*

Model

MBH / 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNX-S01-A006 5.4 6.1 6.7 7.1 5.2 5.9 6.4 6.8

BNX-S01-A008 6.5 7.2 7.7 8.1 6.2 6.9 7.4 7.8

BNX-S02-A010 8.4 9.4 10.2 10.8 8.1 9.0 9.8 10.4

BNX-S02-A013 11.6 12.6 13.3 14.3 11.1 12.1 12.7 13.7

BNX-S02-A015 13.4 14.5 15.0 15.4 12.9 13.9 14.4 14.8

BNX-S03-A020 17.3 18.9 19.9 21.0 16.6 18.1 19.1 20.1

BNX-S03-A023 20.1 21.8 22.5 24.3 19.3 20.9 21.6 23.3

BNX-S04-A026 23.1 25.2 26.6 28.2 22.2 24.2 25.5 27.0

R407C*

MBH / 1° TD

BNX-S04-A030 26.8 29.1 30.1 30.8 25.7 27.9 28.9 29.5

BNX-S05-A033 28.9 31.5 33.2 35.3 27.7 30.2 31.9 33.9

BNX-S05-A038 33.5 36.3 37.6 38.5 32.2 34.8 36.1 36.9

BNX-S06-A045 40.2 43.6 45.1 46.1 38.6 41.8 43.3 44.3

BNX-S07-A052 45.9 50.0 52.7 53.9 44.0 47.9 50.5 51.7

BNX-D04-A020 16.8 18.8 20.4 21.6 16.1 18.0 19.6 20.7

BNX-D04-A026 23.1 25.2 26.6 28.5 22.2 24.2 25.5 27.3

BNX-D04-A030 26.8 29.1 30.1 30.8 25.7 27.9 28.9 29.5

BNX-D06-A039 34.7 37.8 39.9 41.9 33.2 36.3 38.3 40.2

BNX-D06-A045 40.2 43.6 45.1 48.6 38.6 41.8 43.3 46.6

BNX-D08-A052 46.2 50.4 53.2 56.3 44.3 48.4 51.0 54.0

BNX-D08-A061 53.7 58.1 60.2 61.5 51.5 55.8 57.7 59.0

BNX-D10-A066 57.8 63.0 66.5 70.6 55.4 60.4 63.8 67.7

BNX-D10-A076 67.1 72.7 75.2 76.9 64.3 69.7 72.1 73.8

BNX-D12-A091 80.5 87.2 90.3 92.3 77.2 83.7 86.6 88.5

BNX-D14-A104 91.7 100.0 105.3 107.8 88.0 95.9 101.0 103.4

BOLD indicates standard model capacity.

* Data based on mid point condensing temperature

14

Page 15

CONDENSER SPECIFICATIONS

BNX 540 830 VSEC 1140

Table 12. 3-Phase A/C BNX Models, 830 RPM, 1.0 HP, 30" Fan Diameter

208-230/3/60 460/3/60

Model CFM

BNX-S01-A006 7,600 4.8 15.0 15 2.4 15.0 15 1.1 1 3/8 7 330

BNX-S01-A008 7,300 4.8 15.0 15 2.4 15.0 15 1.1 1 3/8 14 360

BNX-S02-A010 15,900 9.6 15.0 20 4.8 15.0 15 2.2 1 3/8 14 580

BNX-S02-A013 15,200 9.6 15.0 20 4.8 15.0 15 2.2 1 5/8 21 630

BNX-S02-A015 14,700 9.6 15.0 20 4.8 15.0 15 2.2 2 1/8 28 680

BNX-S03-A020 22,900 14.4 20.0 25 7.2 15.0 15 3.4 2 1/8 21 930

BNX-S03-A023 22,000 14.4 20.0 25 7.2 15.0 15 3.4 2 1/8 28 1,000

BNX-S04-A026 29,800 19.2 20.4 30 9.6 15.0 15 4.5 2 1/8 21 1,210

FLA MCA MOPD FLA MCA MOPD

Unit

kW

Conn.

(in.)

Max.

No.

of

Feeds

Approx.

Net Wt.

(lbs)

BNX-S04-A030 28,400 19.2 20.4 30 9.6 15.0 15 4.5 2 5/8 28 1,310

BNX-S05-A033 37,300 24.0 25.2 35 12.0 15.0 15 5.6 2 5/8 21 1,510

BNX-S05-A038 35,500 24.0 25.2 35 12.0 15.0 15 5.6 2 5/8 28 1,640

BNX-S06-A045 42,600 28.8 30.0 40 14.4 15.0 20 6.7 2 5/8 28 1,950

BNX-S07-A052 49,700 33.6 34.8 45 16.8 20.0 20 7.8 2 @ 2 5/8 28 2,240

BNX-D04-A020 31,700 19.2 20.4 30 9.6 15.0 15 4.5 2 @ 1 3/8 28 1,240

BNX-D04-A026 30,500 19.2 20.4 30 9.6 15.0 15 4.5 2 @ 1 5/8 42 1,340

BNX-D04-A030 29,300 19.2 20.4 30 9.6 15.0 15 4.5 2 @ 2 1/8 56 1,440

BNX-D06-A039 45,700 28.8 30.0 40 14.4 15.0 20 6.7 2 @ 2 1/8 42 1,990

BNX-D06-A045 44,000 28.8 30.0 40 14.4 15.0 20 6.7 2 @ 2 1/8 56 2,140

BNX-D08-A052 59,700 38.4 39.6 50 19.2 20.0 25 8.9 2 @ 2 1/8 42 2,630

BNX-D08-A061 56,800 38.4 39.6 50 19.2 20.0 25 8.9 2 @ 2 5/8 56 2,830

BNX-D10-A066 74,600 48.0 49.2 60 24.0 24.6 30 11.2 2 @ 2 5/8 42 3,290

BNX-D10-A076 71,000 48.0 49.2 60 24.0 24.6 30 11.2 2 @ 2 5/8 56 3,540

BNX-D12-A091 85,200 57.6 58.8 70 28.8 29.4 35 13.4 2 @ 2 5/8 56 4,230

BNX-D14-A104 99,400 67.2 68.4 80 33.6 34.2 40 15.6 4 @ 2 5/8 56 4,910

15

Page 16

CONDENSER CAPACITY

BNL 540 830 VSEC 1140

Table 13. BNL Models, 830 RPM, 1.5 HP, 30" Fan Diameter

R22 / R410A

Model

MBH / 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNL-S01-A007 5.9 6.7 7.3 7.9 5.8 6.6 7.2 7.7

BNL-S01-A008 7.2 8.0 8.6 9.0 7.0 7.8 8.4 8.8

BNL-S02-A010 9.1 10.1 11.0 11.7 8.9 9.9 10.8 11.4

BNL-S02-A014 12.6 13.9 14.9 15.7 12.4 13.6 14.6 15.4

BNL-S02-A016 15.0 16.1 16.8 17.6 14.7 15.8 16.5 17.3

BNL-S03-A021 18.9 20.9 22.3 23.4 18.6 20.5 21.8 23.0

BNL-S03-A024 22.5 24.2 25.2 26.9 22.0 23.8 24.7 26.3

BNL-S04-A028 25.3 27.8 29.7 31.2 24.8 27.3 29.1 30.6

BNL-S04-A032 30.0 32.3 33.6 35.2 29.4 31.7 32.9 34.5

R404A/R507

MBH / 1° TD

BNL-S05-A035 32.1 35.5 37.4 39.0 31.4 34.7 36.6 38.2

BNL-S05-A042 38.4 41.6 43.4 44.7 37.7 40.8 42.5 43.8

BNL-S06-A050 46.1 49.9 52.1 53.6 45.2 48.9 51.0 52.6

BNL-S07-A055 50.5 55.0 58.0 60.2 49.5 53.9 56.8 59.0

BNL-D04-A020 18.1 20.2 22.0 23.3 17.7 19.8 21.5 22.9

BNL-D04-A028 25.3 27.8 29.7 31.4 24.8 27.3 29.1 30.7

BNL-D04-A032 30.0 32.3 33.6 35.2 29.4 31.7 32.9 34.5

BNL-D06-A042 37.9 41.8 44.5 46.9 37.2 40.9 43.7 45.9

BNL-D06-A048 45.0 48.4 50.4 53.7 44.1 47.5 49.4 52.7

BNL-D08-A056 50.6 55.7 59.4 62.4 49.6 54.6 58.3 61.1

BNL-D08-A065 60.0 64.6 67.2 70.4 58.8 63.3 65.8 69.0

BNL-D10-A071 64.2 70.9 74.7 78.0 62.9 69.5 73.2 76.5

BNL-D10-A083 76.9 83.1 86.8 89.4 75.3 81.5 85.0 87.6

BNL-D12-A100 90.4 99.8 104.1 107.3 92.2 97.8 102.0 105.1

BNL-D14-A110 101.1 110.0 116.0 120.3 99.1 107.9 113.7 117.9

BOLD indicates standard model capacity.

* Data based on mid point condensing temperature

16

Page 17

CONDENSER CAPACITY

BNL 540 830 VSEC 1140

Table 14. BNL Models, 830 RPM, 1.5 HP, 30" Fan Diameter

R407A / R407F*

Model

MBH / 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNL-S01-A007 5.7 6.5 7.0 7.6 5.5 6.2 6.8 7.2

BNL-S01-A008 6.9 7.7 8.2 8.6 6.6 7.3 7.9 8.3

BNL-S02-A010 8.7 9.7 10.6 11.2 8.3 9.3 10.1 10.8

BNL-S02-A014 12.1 13.4 14.3 15.1 11.6 12.8 13.7 14.4

BNL-S02-A016 14.4 15.5 16.1 16.9 13.8 14.9 15.5 16.2

BNL-S03-A021 18.2 20.1 21.4 22.5 17.5 19.2 20.5 21.6

BNL-S03-A024 21.6 23.3 24.2 25.8 20.7 22.3 23.2 24.8

BNL-S04-A028 24.3 26.7 28.5 30.0 23.3 25.6 27.4 28.7

BNL-S04-A032 28.8 31.0 32.3 33.8 27.6 29.8 31.0 32.4

R407C*

MBH / 1° TD

BNL-S05-A035 30.8 34.0 35.9 37.5 29.6 32.7 34.4 35.9

BNL-S05-A042 36.9 39.9 41.7 42.9 35.4 38.3 40.0 41.2

BNL-S06-A050 44.3 47.9 50.0 51.5 42.5 45.9 48.0 49.4

BNL-S07-A055 48.5 52.8 55.7 57.8 46.6 50.7 53.4 55.4

BNL-D04-A020 17.4 19.4 21.1 22.4 16.7 18.6 20.2 21.5

BNL-D04-A028 24.3 26.7 28.5 30.1 23.3 25.6 27.4 28.9

BNL-D04-A032 28.8 31.0 32.3 33.8 27.6 29.8 30.9 32.4

BNL-D06-A042 36.4 40.1 42.8 45.0 34.9 38.5 41.0 43.2

BNL-D06-A048 43.2 46.5 48.4 51.6 41.4 44.6 46.4 49.5

BNL-D08-A056 48.6 53.5 57.1 59.9 46.6 51.3 54.8 57.5

BNL-D08-A065 57.6 62.1 64.5 67.6 55.3 59.5 61.9 64.8

BNL-D10-A071 61.6 68.1 71.8 74.9 59.1 65.3 68.9 71.9

BNL-D10-A083 73.8 79.8 83.3 85.8 70.8 76.6 79.9 82.3

BNL-D12-A100 90.4 95.8 99.9 103.0 86.7 91.9 95.9 98.8

BNL-D14-A110 97.1 105.7 111.4 115.6 93.1 101.4 106.9 110.9

BOLD indicates standard model capacity.

* Data based on mid point condensing temperature

17

Page 18

CONDENSER SPECIFICATIONS

Table 15. BNL Models, 830 RPM, 1.5 HP, 30" Fan Diameter

BNL 540 830 VSEC 1140

208-230/3/60 460/3/60 575/3/60

Model CFM

UnitkWConn.

(in.)

FLA MCA MOPD FLA MCA MOPD FLA MCA MOPD

BNL-S01-A007 8,400 6.6 15.0 25 3.3 15.0 15 2.6 15.0 15 1.4 1 3/8 7 330

BNL-S01-A008 8,000 6.6 15.0 25 3.3 15.0 15 2.6 15.0 15 1.4 1 3/8 14 360

BNL-S02-A010 17,500 13.2 15.0 30 6.6 15.0 15 5.2 15.0 15 2.7 1 3/8 14 580

BNL-S02-A014 16,700 13.2 15.0 30 6.6 15.0 15 5.2 15.0 15 2.7 1 5/8 21 630

BNL-S02-A016 16,100 13.2 15.0 30 6.6 15.0 15 5.2 15.0 15 2.7 2 1/8 28 680

BNL-S03-A021 25,100 19.8 21.5 35 9.9 15.0 15 7.8 15.0 15 4.1 2 1/8 21 930

BNL-S03-A024 24,100 19.8 21.5 35 9.9 15.0 15 7.8 15.0 15 4.1 2 1/8 28 1,000

BNL-S04-A028 32,800 26.4 28.1 45 13.2 15.0 20 10.4 15.0 15 5.4 2 1/8 21 1,210

BNL-S04-A032 31,200 26.4 28.1 45 13.2 15.0 20 10.4 15.0 15 5.4 2 5/8 28 1,310

BNL-S05-A035 41,000 33.0 34.7 50 16.5 20.0 25 13.0 15.0 20 6.8 2 5/8 21 1,510

Max.

No.

of

Feeds

Approx.

Net

Weight

(lbs)

BNL-S05-A042 39,100 33.0 34.7 50 16.5 20.0 25 13.0 15.0 20 6.8 2 5/8 28 1,640

BNL-S06-A050 46,900 39.6 41.3 50 19.8 20.6 25 15.6 20.0 20 8.1 2 5/8 28 1,950

BNL-S07-A055 54,700 46.2 47.9 60 23.1 23.9 30 18.2 20.0 25 9.5

BNL-D04-A020 35,000 26.4 28.1 45 13.2 15.0 20 10.4 15.0 15 5.4

BNL-D04-A028 33,500 26.4 28.1 45 13.2 15.0 20 10.4 15.0 15 5.4

BNL-D04-A032 32,100 26.4 28.1 45 13.2 15.0 20 10.4 15.0 15 5.4

BNL-D06-A042 50,200 39.6 41.3 50 19.8 20.6 25 15.6 20.0 20 8.1

BNL-D06-A048 48,200 39.6 41.3 50 19.8 20.6 25 15.6 20.0 20 8.1

BNL-D08-A056 65,600 52.8 54.5 70 26.4 27.2 35 20.8 21.5 25 10.8

BNL-D08-A065 62,500 52.8 54.5 70 26.4 27.2 35 20.8 21.5 25 10.8

BNL-D10-A071 82,000 66.0 67.7 80 33.0 33.8 40 26.0 26.7 30 13.5

BNL-D10-A083 78,100 66.0 67.7 80 33.0 33.8 40 26.0 26.7 30 13.5

BNL-D12-A100 93,700 79.2 80.9 90 39.6 40.4 45 31.2 31.9 35 16.2

BNL-D14-A110 109,300 92.4 94.1 110 46.2 47.0 50 36.4 37.1 40 18.9

2@2

5/8

2 @ 1

3/8

2 @ 1

5/8

2 @ 2

1/8

2 @ 2

1/8

2 @ 2

1/8

2 @ 2

1/8

2 @ 2

5/8

2 @ 2

5/8

2 @ 2

5/8

2 @ 2

5/8

4 @ 2

5/8

28 2,240

28 1,240

42 1,340

56 1,440

42 1,990

56 2,140

42 2,630

56 2,830

42 3,290

56 3,540

56 4,230

56 4,910

18

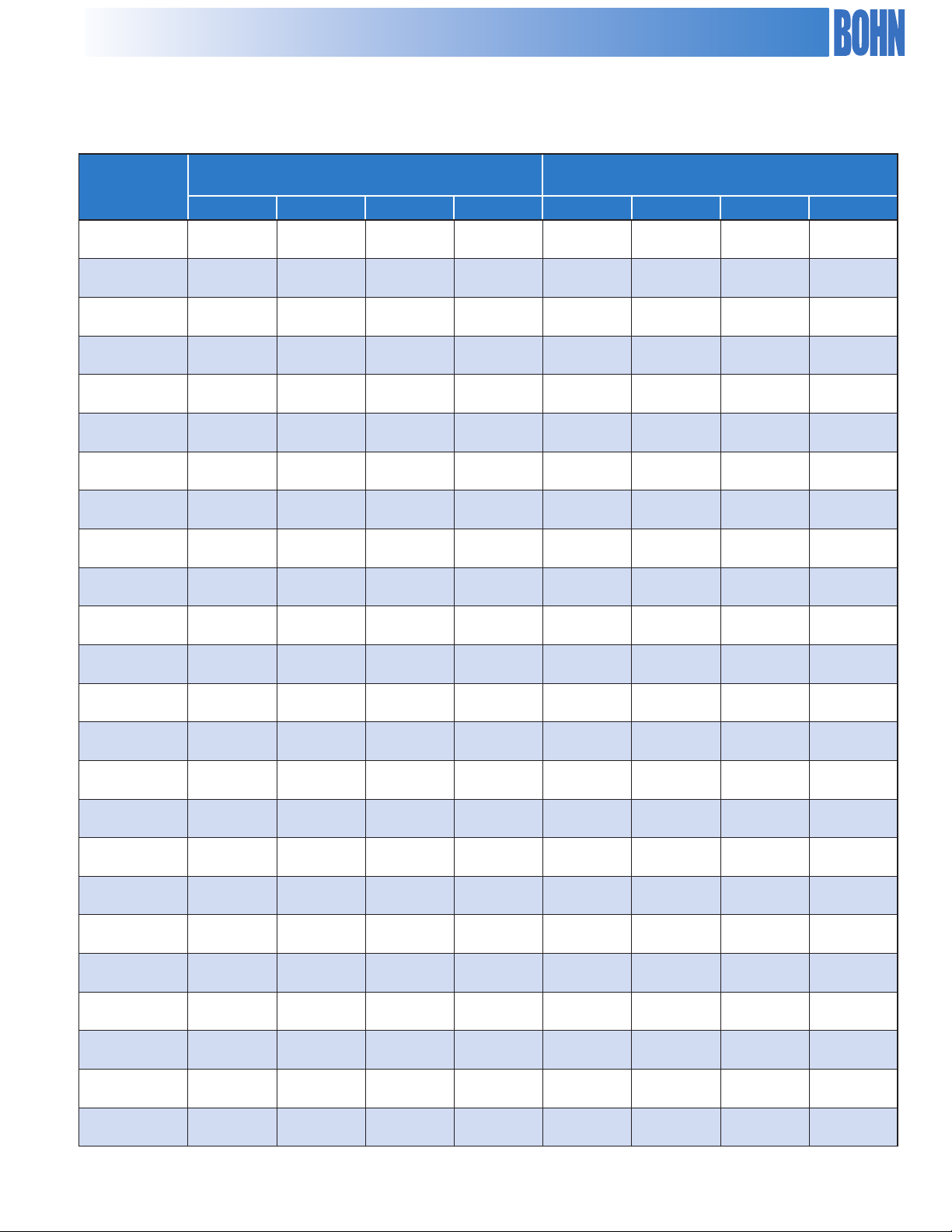

Page 19

CONDENSER CAPACITY

BNH 540 830 VSEC 1140

Table 16. Bohn 1140 Series BNH Models, 1140 RPM, 1.5 HP, 30" Fan Diameter

R22 / R410A

Model

MBH / 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNH-S01-A007 6.4 7.3 8.0 8.6 6.3 7.2 7.9 8.5

BNH-S01-A009 7.8 8.7 9.5 10.0 7.6 8.6 9.3 9.8

BNH-S02-A011 9.6 10.7 11.7 12.4 9.4 10.5 11.5 12.1

BNH-S02-A015 13.1 14.5 15.6 16.3 12.8 14.2 15.3 16.0

BNH-S02-A017 15.7 17.1 18.1 19.2 15.3 16.7 17.7 18.8

BNH-S03-A022 19.7 21.8 23.4 24.5 19.3 21.4 22.9 24.0

BNH-S03-A026 23.5 25.7 27.1 29.9 23.1 25.2 26.6 29.3

BNH-S04-A029 26.2 29.1 31.2 32.6 25.7 28.5 30.5 32.0

R404A/R507

MBH / 1° TD

BNH-S04-A034 31.4 34.2 36.1 38.3 30.7 33.5 35.4 37.6

BNH-S05-A037 33.6 37.1 39.3 41.3 32.9 36.4 38.5 40.5

BNH-S05-A044 40.5 44.0 46.1 48.6 39.7 43.1 45.1 47.6

BNH-S06-A053 48.6 52.8 55.3 58.3 47.7 51.7 54.1 57.1

BNH-S07-A061 55.4 61.0 64.7 67.5 54.3 59.8 63.5 66.2

BNH-D04-A021 19.2 21.4 23.4 24.8 18.8 21.0 22.9 24.3

BNH-D04-A029 26.2 29.1 31.2 32.6 25.7 28.5 30.6 32.0

BNH-D04-A034 31.4 34.2 36.1 38.3 30.7 33.5 35.4 37.6

BNH-D06-A044 39.4 43.6 46.7 48.9 38.6 42.8 45.8 47.9

BNH-D06-A051 47.0 51.3 54.2 59.8 46.1 50.3 53.1 58.7

BNH-D08-A058 52.5 58.2 62.3 65.3 51.4 57.0 61.1 63.9

BNH-D08-A068 62.7 68.4 72.3 76.7 61.5 67.1 70.8 75.1

BNH-D10-A074 67.1 74.2 78.5 82.6 65.7 72.7 76.9 80.9

BNH-D10-A088 81.0 88.0 92.1 97.2 79.4 86.2 90.2 95.2

BNH-D12-A106 97.2 105.6 110.5 116.6 95.3 103.5 108.3 114.2

BNH-D14-A122 110.8 121.9 129.5 135.0 108.6 119.5 126.9 132.4

BOLD indicates standard model capacity.

19

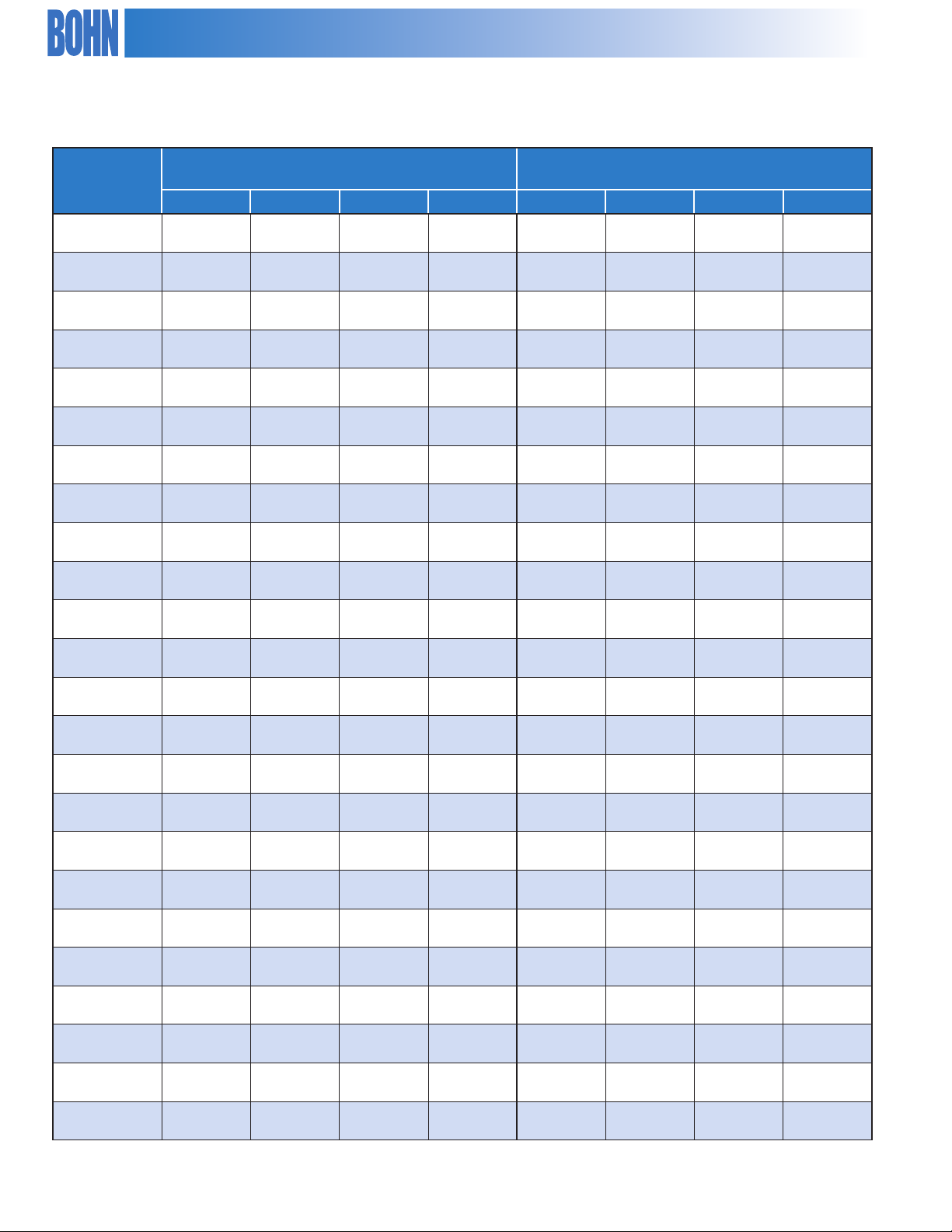

Page 20

CONDENSER CAPACITY

BNH 540 830 VSEC 1140

Table 17. Bohn 1140 Series BNH Models, 1140 RPM, 1.5 HP, 30" Fan Diameter

Model

R407A/R407F*

MBH / 1° TD

R407C*

MBH / 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNH-S01-A007 6.1 7.0 7.7 8.3 5.9 6.7 7.4 8.0

BNH-S01-A009 7.5 8.4 9.1 9.6 7.2 8.1 8.7 9.2

BNH-S02-A011 9.2 10.3 11.2 11.9 8.8 9.9 10.8 11.4

BNH-S02-A015 12.6 14.0 15.0 15.7 12.1 13.4 14.4 15.0

BNH-S02-A017 15.0 16.4 17.4 18.4 14.4 15.7 16.6 17.6

BNH-S03-A022 18.9 21.0 22.4 23.5 18.1 20.1 21.5 22.5

BNH-S03-A026 22.6 24.6 26.0 28.8 21.7 23.6 25.0 27.6

BNH-S04-A029 25.2 28.0 29.9 31.3 24.1 26.8 28.7 30.1

BNH-S04-A034 30.1 32.9 34.7 36.8 28.9 31.5 33.3 35.3

BNH-S05-A037 32.2 35.6 37.7 39.7 30.9 34.2 36.2 38.0

BNH-S05-A044 38.9 42.3 44.2 46.7 37.3 40.5 42.4 44.8

BNH-S06-A053 46.7 50.7 53.1 56.0 44.8 48.6 50.9 53.7

BNH-S07-A061 53.2 58.6 62.2 64.9 51.1 56.2 59.7 62.2

BNH-D04-A021 18.4 20.5 22.4 23.8 17.7 19.7 21.5 22.8

BNH-D04-A029 25.2 28.0 29.9 31.3 24.1 26.8 28.7 30.1

BNH-D04-A034 30.1 32.9 34.7 36.8 28.9 31.5 33.3 35.3

BNH-D06-A044 37.8 41.9 44.9 47.0 36.3 40.2 43.1 45.1

BNH-D06-A051 45.2 49.3 52.0 57.5 43.3 47.3 49.9 55.2

BNH-D08-A058 50.4 55.9 59.9 62.7 48.3 53.6 57.4 60.1

BNH-D08-A068 60.2 65.7 69.4 73.6 57.8 63.0 66.6 70.6

BNH-D10-A074 64.4 71.2 75.4 79.3 61.8 68.3 72.3 76.0

BNH-D10-A088 77.8 84.5 88.4 93.3 74.6 81.1 84.8 89.5

BNH-D12-A106 93.4 101.4 106.1 112.0 89.6 97.3 101.8 107.4

BNH-D14-A122 106.5 117.1 124.4 129.7 102.1 112.3 119.3 124.4

BOLD indicates standard model capacity.

20

Page 21

CONDENSER SPECIFICATIONS

BNH 540 830 VSEC 1140

Table 18. 1140 Series BNH Models, 1140 RPM, 1.5 HP, 30" Fan Diameter

208-230/3/60 460/3/60 575/3/60

Model CFM

UnitkWConn.

(in.)

FLA MCA MOPD FLA MCA MOPD FLA MCA MOPD

BNH-S01-A007 9,900 7.0 15.0 25 3.5 15.0 15 2.8 15.0 15 1.9 1 3/8 7 330

BNH-S01-A009 9,500 7.0 15.0 25 3.5 15.0 15 2.8 15.0 15 1.9 1 3/8 14 360

BNH-S02-A011 20,500 14.0 20.0 35 7.0 15.0 15 5.6 15.0 15 3.8 1 3/8 14 580

BNH-S02-A015 19,800 14.0 20.0 35 7.0 15.0 15 5.6 15.0 15 3.8 1 5/8 21 630

BNH-S02-A017 19,000 14.0 20.0 35 7.0 15.0 15 5.6 15.0 15 3.8 2 1/8 28 680

BNH-S03-A022 29,700 21.0 22.8 40 10.5 15.0 20 8.4 15.0 15 5.8 2 1/8 21 930

BNH-S03-A026 28,500 21.0 22.8 40 10.5 15.0 20 8.4 15.0 15 5.8 2 1/8 28 1,000

BNH-S04-A029 38,600 28.0 29.8 45 14.0 15.0 20 11.2 15.0 15 7.7 2 1/8 21 1,210

BNH-S04-A034 37,000 28.0 29.8 45 14.0 15.0 20 11.2 15.0 15 7.7 2 5/8 28 1,310

Max.

No.

of

Feeds

Ap-

prox.

Net

Wt.

(lbs)

BNH-S05-A037 48,300 35.0 36.8 50 17.5 20.0 25 14.0 15.0 20 9.6 2 5/8 21 1,510

BNH-S05-A044 46,200 35.0 36.8 50 17.5 20.0 25 14.0 15.0 20 9.6 2 5/8 28 1,640

BNH-S06-A053 55,400 42.0 43.8 60 21.0 21.9 30 16.8 20.0 25 11.5 2 5/8 28 1,950

BNH-S07-A061 64,700 49.0 50.8 70 24.5 25.4 35 19.6 20.3 25 13.5

BNH-D04-A021 41,000 28.0 29.8 45 14.0 15.0 20 11.2 15.0 15 7.7

BNH-D04-A029 39,600 28.0 29.8 45 14.0 15.0 20 11.2 15.0 15 7.7

BNH-D04-A034 38,100 28.0 29.8 45 14.0 15.0 20 11.2 15.0 15 7.7

BNH-D06-A044 59,400 42.0 43.8 60 21.0 21.9 30 16.8 20.0 25 11.5

BNH-D06-A051 57,100 42.0 43.8 60 21.0 21.9 30 16.8 20.0 25 11.5

BNH-D08-A058 77,200 56.0 57.8 70 28.0 28.9 35 22.4 23.1 30 15.4

BNH-D08-A068 73,900 56.0 57.8 70 28.0 28.9 35 22.4 23.1 30 15.4

BNH-D10-A074 96,500 70.0 71.8 90 35.0 35.9 45 28.0 28.7 35 19.2

BNH-D10-A088 92,400 70.0 71.8 90 35.0 35.9 45 28.0 28.7 35 19.2

BNH-D12-A106 110,900 84.0 85.8 100 42.0 42.9 50 33.6 34.3 40 23.1

BNH-D14-A122 129,400 98.0 99.8 110 49.0 49.9 60 39.2 39.9 45 26.9

2 @

2 5/8

2 @

1 3/8

2 @

1 5/8

2 @

2 1/8

2 @

2 1/8

2 @

2 1/8

2 @

2 1/8

2 @

2 5/8

2 @

2 5/8

2 @

2 5/8

2 @

2 5/8

4 @

2 5/8

28 2,240

28 1,240

42 1,340

56 1,440

42 1,990

56 2,140

42 2,630

56 2,830

42 3,290

56 3,540

56 4,230

56 4,910

21

Page 22

Bohn Venturi Mounted VSEC Series

BNE (1030 RPM) BNE (830 RPM) BNE (630 RPM) BNE (420 RPM)

Selection Tables

The Bohn Venturi Mounted VSEC Series of air-cooled

condensers incorporates Venturi Mounted VSEC motor

technology to provide the quietest and most ecient

condensers in the industry, using integrated variable speed

technology.

we are providing an unprecedented 3-year warranty on

the VSEC motor (2-year warranty on the unit) so you can be

assured of worry-free operation.

Protection at every level

The VSEC motors have several built-in features that protect

against locked-rotors, under-voltage and phase failure.

Simplicity: Variable speed without the complexity

The Bohn VSEC Series is a complete system that incorporates

an VSEC motor, integrated drive and control electronics,

optimized swept motor blade and venturi panel in one

simple package. Variable speed is accomplished without the

complexities typically associated with Variable Frequency

Drives (VFD).

Flexibility: Maximum eciency, minimum sound,

capacity when you need it

The Venturi Mounted VSEC Series condensers’ integrated

variable speed capability allows optimization to your

operating conditions; at higher speeds on hot summer

afternoons to maintain capacity or at lower speeds at night to

meet a local sound ordinance. Whatever your requirements,

the Bohn VSEC Series can be selected and programmed to

your specic needs; whether it is lower energy costs, lower

sound or both.

Reliability: The highest quality backed

by industry-leading warranties

We are so condent in the reliability of the VSEC motor that

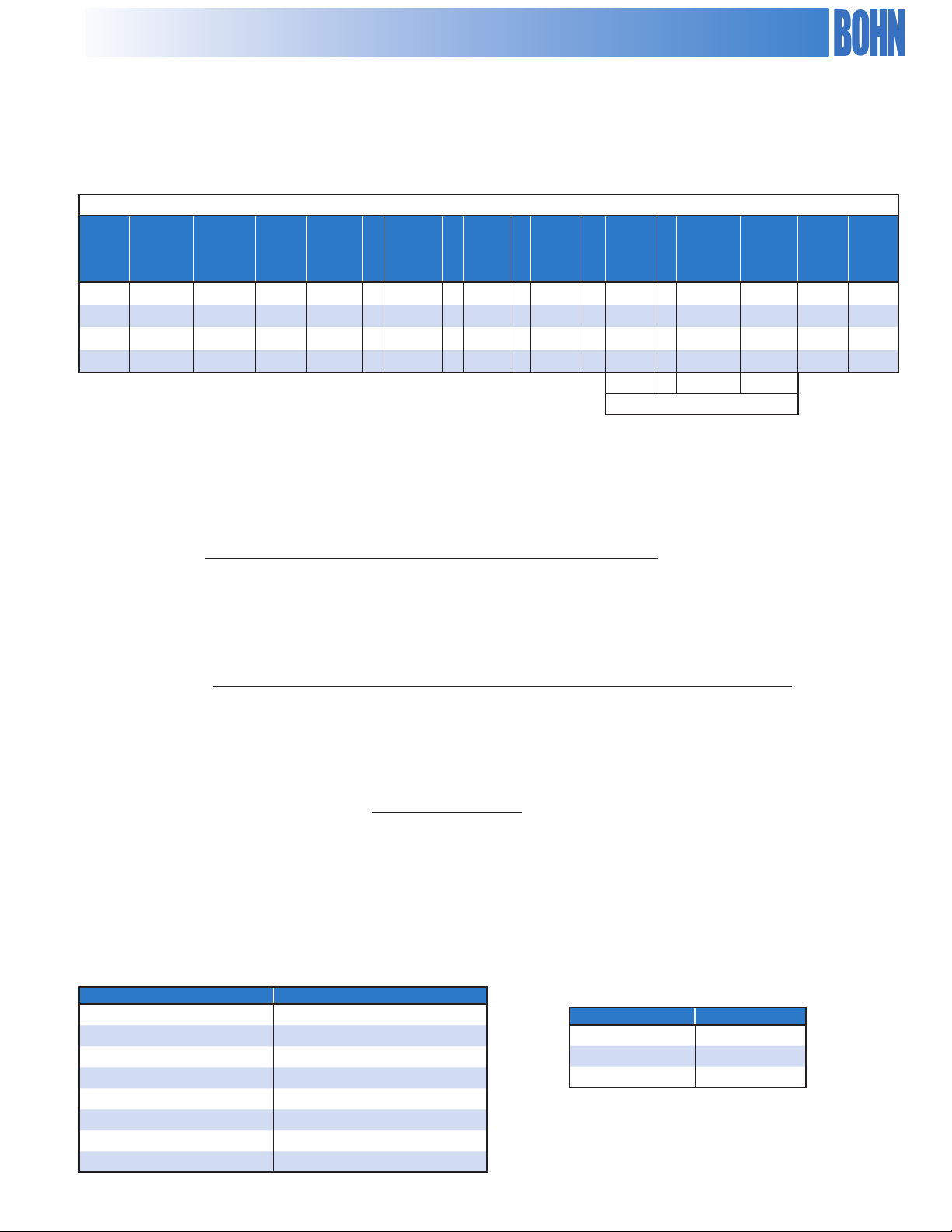

EC Sound Data (dBA @ 10 ft.)

Variable Speed Operation

The Venturi Mounted VSEC Series condensers provide variable

speed operation automatically; providing dramatically lower

sound and energy levels than would be observed with

condensers using traditional AC motors.

Typical performance of a Venturi Mounted VSEC Series

condenser at various loads versus a 540 RPM or 1140 RPM

condenser is shown in the charts on the next page.

Model Selection

Selecting the right Bohn VSEC Series unit for your needs

is easier than you think, and is just as easy as selecting a

standard unit.

Simply use Table 25 & 26 to nd the model and ns per inch

required to meet your capacity needs.

Selecting condensers with specic sound or energy levels

The variable speed nature allows selection to meet maximum

sound or energy usage levels.

To select condensers with these goals in mind, please contact

your sales representative. They will be able to help you select

the appropriate model for your specic requirements.

85

80

75

70

65

60

dBA @ 10 ft.

55

50

45

0 2 4 6 8 10 12 14

Number of Fans

22

BNE

Fans

1030

RPM

BNE

RPM

830

BNE

630

RPM

BNE

420

RPM

1 66.9 62.0 52.9 45.3

2 69.9 65.0 55.9 48.3

3 71.7 66.8 57.7 50.1

4 72.9 68.0 58.9 51.3

5 73.9 69.0 59.9 52.3

6 74.7 69.8 60.7 53.1

7 75.4 70.5 61.4 53.8

8 75.9 71.0 61.9 54.3

10 76.9 72.0 62.9 55.3

12 77.7 72.8 63.7 56.1

14 78.4 73.5 64.4 56.8

Page 23

Power Consumption & Variable Speed Operation

Bohn VSEC vs. 540 and 1140 Series

10 Fan EC Motor Sound Production at Various Loads

Percent of Max. Load 30% 40% 50% 60% 70% 80% 90% 100%

RPM 215 313 407 511 630 748 892 1030

dBA @ 10 ft 49.5 51.8 55 58.4 62.9 67.8 74.8 76.9

23

Page 24

CONDENSER CAPACITY

Table 19. BNJ Models, 830 RPM, 1.1 Kw, 30" Fan Diameter

BNJ 540 830 VSEC 1140

Model

R22/R410A

MBH / 1° TD

R404A / R507

MBH / 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNJ-S01-A007 5.9 6.7 7.3 7.9 5.8 6.6 7.2 7.7

BNJ-S01-A008 7.2 8.0 8.6 9.0 7.0 7.8 8.4 8.8

BNJ-S02-A010 9.1 10.1 11.0 11.7 8.9 9.9 10.8 11.4

BNJ-S02-A014 12.6 13.9 14.9 15.7 12.4 13.6 14.6 15.4

BNJ-S02-A016 15.0 16.1 16.8 17.6 14.7 15.8 16.5 17.3

BNJ-S03-A021 18.9 20.9 22.3 23.4 18.6 20.5 21.8 23.0

BNJ-S03-A024 22.5 24.2 25.2 26.9 22.0 23.8 24.7 26.3

BNJ-S04-A028 25.3 27.8 29.7 31.2 24.8 27.3 29.1 30.6

BNJ-S04-A032 30.0 32.3 33.6 35.2 29.4 31.7 32.9 34.5

BNJ-S05-A035 32.1 35.5 37.4 39.0 31.4 34.7 36.6 38.2

BNJ-S05-A042 38.4 41.6 43.4 44.7 37.7 40.8 42.5 43.8

BNJ-S06-A050 46.1 49.9 52.1 53.6 45.2 48.9 51.0 52.6

BNJ-S07-A055 50.5 55.0 58.0 60.2 49.5 53.9 56.8 59.0

BNJ-D04-A020 18.1 20.2 22.0 23.3 17.7 19.8 21.5 22.9

BNJ-D04-A028 25.3 27.8 29.7 31.4 24.8 27.3 29.1 30.7

BNJ-D04-A032 30.0 32.3 33.6 35.2 29.4 31.7 32.9 34.5

BNJ-D06-A042 37.9 41.8 44.5 46.9 37.2 40.9 43.7 45.9

BNJ-D06-A048 45.0 48.4 50.4 53.7 44.1 47.5 49.4 52.7

BNJ-D08-A056 50.6 55.7 59.4 62.4 49.6 54.6 58.3 61.1

BNJ-D08-A065 60.0 64.6 67.2 70.4 58.8 63.3 65.8 69.0

BNJ-D10-A071 64.2 70.9 74.7 78.0 62.9 69.5 73.2 76.5

BNJ-D10-A083 76.9 83.1 86.8 89.4 75.3 81.5 85.0 87.6

BNJ-D12-A100 90.4 99.8 104.1 107.3 92.2 97.8 102.0 105.1

BNJ-D14-A110 101.1 110.0 116.0 120.3 99.1 107.9 113.7 117.9

BOLD indicates standard model capacity.

* Data based on mid point condensing temperature

24

Page 25

CONDENSER CAPACITY

Table 20. BNJ Models, 830 RPM, 1.1 Kw, 30" Fan Diameter

BNJ 540 830 VSEC 1140

Model

R407A / R407F*

MBH / 1° TD

R407C*

MBH / 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNJ-S01-A007 5.7 6.5 7.0 7.6 5.5 6.2 6.8 7.2

BNJ-S01-A008 6.9 7.7 8.2 8.6 6.6 7.3 7.9 8.3

BNJ-S02-A010 8.7 9.7 10.6 11.2 8.3 9.3 10.1 10.8

BNJ-S02-A014 12.1 13.4 14.3 15.1 11.6 12.8 13.7 14.4

BNJ-S02-A016 14.4 15.5 16.1 16.9 13.8 14.9 15.5 16.2

BNJ-S03-A021 18.2 20.1 21.4 22.5 17.5 19.2 20.5 21.6

BNJ-S03-A024 21.6 23.3 24.2 25.8 20.7 22.3 23.2 24.8

BNJ-S04-A028 24.3 26.7 28.5 30.0 23.3 25.6 27.4 28.7

BNJ-S04-A032 28.8 31.0 32.3 33.8 27.6 29.8 31.0 32.4

BNJ-S05-A035 30.8 34.0 35.9 37.5 29.6 32.7 34.4 35.9

BNJ-S05-A042 36.9 39.9 41.7 42.9 35.4 38.3 40.0 41.2

BNJ-S06-A050 44.3 47.9 50.0 51.5 42.5 45.9 48.0 49.4

BNJ-S07-A055 48.5 52.8 55.7 57.8 46.6 50.7 53.4 55.4

BNJ-D04-A020 17.4 19.4 21.1 22.4 16.7 18.6 20.2 21.5

BNJ-D04-A028 24.3 26.7 28.5 30.1 23.3 25.6 27.4 28.9

BNJ-D04-A032 28.8 31.0 32.3 33.8 27.6 29.8 30.9 32.4

BNJ-D06-A042 36.4 40.1 42.8 45.0 34.9 38.5 41.0 43.2

BNJ-D06-A048 43.2 46.5 48.4 51.6 41.4 44.6 46.4 49.5

BNJ-D08-A056 48.6 53.5 57.1 59.9 46.6 51.3 54.8 57.5

BNJ-D08-A065 57.6 62.1 64.5 67.6 55.3 59.5 61.9 64.8

BNJ-D10-A071 61.6 68.1 71.8 74.9 59.1 65.3 68.9 71.9

BNJ-D10-A083 73.8 79.8 83.3 85.8 70.8 76.6 79.9 82.3

BNJ-D12-A100 90.4 95.8 99.9 103.0 86.7 91.9 95.9 98.8

BNJ-D14-A110 97.1 105.7 111.4 115.6 93.1 101.4 106.9 110.9

BOLD indicates standard model capacity.

* Data based on mid point condensing temperature

25

Page 26

BNJ 504 830 VSEC 1140

CONDENSER SPECIFICATIONS

Table 21. BNJ Models, 1.1 kW, 30" Fan Diameter

Model

CFM

230/3/60 460/3/60

Unit kWConn.

(in)

Max.

No. of

Feeds

Approx.

Net. Wt.

(lbs)

FLA MCA MOPD FLA MCA MOPD

BNJ-S01-A007 8400.0 6.6 15.0 25.0 3.3 15.0 15.0 1.1 1 3/8 7 340

BNJ-S01-A008 8000.0 6.6 15.0 25.0 3.3 15.0 15.0 1.1 1 3/8 14 370

BNJ-S02-A010 17500.0 13.2 15.0 30.0 6.6 15.0 15.0 2.1 1 3/8 14 600

BNJ-S02-A014 16700.0 13.2 15.0 30.0 6.6 15.0 15.0 2.1 1 5/8 21 650

BNJ-S02-A016 16100.0 13.2 15.0 30.0 6.6 15.0 15.0 2.1 2 1/8 28 700

BNJ-S03-A021 25100.0 19.8 21.5 35.0 9.9 15.0 15.0 3.2 2 1/8 21 960

BNJ-S03-A024 24100.0 19.8 21.5 35.0 9.9 15.0 15.0 3.2 2 1/8 28 1030

BNJ-S04-A028 32800.0 26.4 28.1 45.0 13.2 15.0 20.0 4.2 2 1/8 21 1250

BNJ-S04-A032 31200.0 26.4 28.1 45.0 13.2 15.0 20.0 4.2 2 5/8 28 1350

BNJ-S05-A035 41000.0 33.0 34.7 50.0 16.5 20.0 25.0 5.2 2 5/8 21 1570

BNJ-S05-A042 39100.0 33.0 34.7 50.0 16.5 20.0 25.0 5.2 2 5/8 28 1700

BNJ-S06-A050 46900.0 39.6 41.3 50.0 19.8 20.6 25.0 6.3 2 5/8 28 2020

BNJ-S07-A055 54700.0 46.2 47.9 60.0 23.1 23.9 30.0 7.3 2 @ 2 5/8 28 2320

BNJ-D04-A020 35000.0 26.4 28.1 45.0 13.2 15.0 20.0 4.2 2 @ 1 3/8 28 1280

BNJ-D04-A028 33500.0 26.4 28.1 45.0 13.2 15.0 20.0 4.2 2 @ 1 5/8 42 1380

BNJ-D04-A032 32100.0 26.4 28.1 45.0 13.2 15.0 20.0 4.2 2 @ 2 1/8 56 1480

BNJ-D06-A042 50200.0 39.6 41.3 50.0 19.8 20.6 25.0 6.3 2 @ 2 1/8 42 2060

BNJ-D06-A048 48200.0 39.6 41.3 50.0 19.8 20.6 25.0 6.3 2 @ 2 1/8 56 2210

BNJ-D08-A056 65600.0 52.8 54.5 70.0 26.4 27.2 35.0 8.4 2 @ 2 1/8 42 2720

BNJ-D08-A065 62500.0 52.8 54.5 70.0 26.4 27.2 35.0 8.4 2 @ 2 5/8 56 2920

BNJ-D10-A071 82000.0 66.0 67.7 80.0 33.0 33.8 40.0 10.4 2 @ 2 5/8 42 3400

BNJ-D10-A083 78100.0 66.0 67.7 80.0 33.0 33.8 40.0 10.4 2 @ 2 5/8 56 3650

BNJ-D12-A100 93700.0 79.2 80.9 90.0 39.6 40.4 45.0 12.5 2 @ 2 5/8 56 4360

BNJ-D14-A110 109300.0 92.4 94.1 110.0 46.2 47.0 50.0 14.6 4 @ 2 5/8 56 5060

26

Page 27

BNK 504 830 VSEC 1140

CONDENSER CAPACITY

Table 22. BNK Models, 1140 RPM, 2.0 kW, 30" Fan Diameter

Model

R22/R410A

MBH / 1° TD

R404A / R507

MBH/ 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNK-S01-A007 6.4 7.3 8.0 8.6 6.3 7.2 7.9 8.5

BNK-S01-A009 7.8 8.7 9.5 10.0 7.6 8.6 9.3 9.8

BNK-S02-A011 9.6 10.7 11.7 12.4 9.4 10.5 11.5 12.1

BNK-S02-A015 13.1 14.5 15.6 16.3 12.8 14.2 15.3 16.0

BNK-S02-A017 15.7 17.1 18.1 19.2 15.3 16.7 17.7 18.8

BNK-S03-A022 19.7 21.8 23.4 24.5 19.3 21.4 22.9 24.0

BNK-S03-A026 23.5 25.7 27.1 29.9 23.0 25.1 26.6 29.3

BNK-S04-A029 26.2 29.1 31.2 32.6 25.7 28.5 30.5 32.0

BNK-S04-A034 31.4 34.2 36.1 38.3 30.7 33.5 35.4 37.6

BNK-S05-A037 33.6 37.1 39.3 41.3 32.9 36.4 38.5 40.5

BNK-S05-A044 40.5 44.0 46.0 48.6 39.7 43.1 45.1 47.6

BNK-S06-A053 48.6 52.8 55.2 58.3 47.7 51.7 54.1 57.1

BNK-S07-A061 55.4 61.0 64.7 67.5 54.3 59.8 63.5 66.2

BNK-D04-A021 19.2 21.4 23.4 24.8 18.8 21.0 22.9 24.3

BNK-D04-A029 26.2 29.1 31.2 32.6 25.7 28.5 30.6 32.0

BNK-D04-A034 31.4 34.2 36.1 38.3 30.7 33.5 35.4 37.6

BNK-D06-A044 39.4 43.6 46.7 48.9 38.6 42.8 45.8 47.9

BNK-D06-A051 47.0 51.3 54.2 59.8 46.1 50.3 53.1 58.7

BNK-D08-A058 52.5 58.2 62.3 65.3 51.4 57.0 61.1 63.9

BNK-D08-A068 62.7 68.4 72.3 76.7 61.5 67.1 70.8 75.1

BNK-D10-A074 67.1 74.2 78.5 82.6 65.7 72.7 76.9 80.9

BNK-D10-A088 81.0 88.0 92.1 97.2 79.4 86.2 90.2 95.2

BNK-D12-A106 97.2 105.6 110.5 116.6 95.3 103.5 108.3 114.2

BNK-D14-A122 110.8 121.9 129.5 135.0 108.6 119.5 126.9 132.4

BOLD indicates standard model capacity.

* Data based on mid point condensing temperature

27

Page 28

CONDENSER CAPACITY

Table 23. BNK Models, 1140 RPM, 2.0 Kw, 30" Fan Diameter

BNK 504 830 VSEC 1140

Model

R407A/407F*

MBH / 1° TD

407C*

MBH/ 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNK-S01-A007 6.1 7.0 7.7 8.3 5.9 6.7 7.4 8.0

BNK-S01-A009 7.5 8.4 9.1 9.6 7.2 8.1 8.7 9.2

BNK-S02-A011 9.2 10.3 11.2 11.9 8.8 9.9 10.8 11.4

BNK-S02-A015 12.6 14.0 15.0 15.7 12.1 13.4 14.4 15.0

BNK-S02-A017 15.0 16.4 17.4 18.4 14.4 15.7 16.6 17.6

BNK-S03-A022 18.9 21.0 22.4 23.5 18.1 20.1 21.5 22.5

BNK-S03-A026 22.6 24.6 26.0 28.8 21.7 23.6 25.0 27.6

BNK-S04-A029 25.2 28.0 29.9 31.3 24.1 26.8 28.7 30.1

BNK-S04-A034 30.1 32.9 34.7 36.8 28.9 31.5 33.3 35.3

BNK-S05-A037 32.2 35.6 37.7 39.7 30.9 34.2 36.2 38.0

BNK-S05-A044 38.9 42.3 44.2 46.7 37.3 40.5 42.4 44.8

BNK-S06-A053 46.7 50.7 53.1 56.0 44.8 48.6 50.9 53.7

BNK-S07-A061 53.2 58.6 62.2 64.9 51.1 56.2 59.7 62.2

BNK-D04-A021 18.4 20.5 22.4 23.8 17.7 19.7 21.5 22.8

BNK-D04-A029 25.2 28.0 29.9 31.3 24.1 26.8 28.7 30.1

BNK-D04-A034 30.1 32.9 34.7 36.8 28.9 31.5 33.3 35.3

BNK-D06-A044 37.8 41.9 44.9 47.0 36.3 40.2 43.1 45.1

BNK-D06-A051 45.2 49.3 52.0 57.5 43.3 47.3 49.9 55.2

BNK-D08-A058 50.4 55.9 59.9 62.7 48.3 53.6 57.4 60.1

BNK-D08-A068 60.2 65.7 69.4 73.6 57.8 63.0 66.6 70.6

BNK-D10-A074 64.4 71.2 75.4 79.3 61.8 68.3 72.3 76.0

BNK-D10-A088 77.8 84.5 88.4 93.3 74.6 81.1 84.8 89.5

BNK-D12-A106 93.4 101.4 106.1 112.0 89.6 97.3 101.8 107.4

BNK-D14-A122 106.5 117.1 124.4 129.7 102.1 112.3 119.3 124.4

BOLD indicates standard model capacity.

* Data based on mid point condensing temperature

28

Page 29

BNK 504 830 VSEC 1140

CONDENSER SPECIFICATIONS

Table 24. BNK Models, 1140 RPM, 2.0 kW, 30" Fan Diameter

Model

CFM

230/3/60 460/3/60

Unit kWConn.

(in)

Max.

No. of

Feeds

Approx.

Net. Wt.

(lbs)

FLA MCA MOPD FLA MCA MOPD

BNK-S01-A007 9900.0 6.6 15.0 25.0 3.3 15.0 15.0 2.0 1 3/8 7 340

BNK-S01-A009 9500.0 6.6 15.0 25.0 3.3 15.0 15.0 2.0 1 3/8 14 370

BNK-S02-A011 20500.0 13.2 15.0 30.0 6.6 15.0 15.0 3.9 1 3/8 14 600

BNK-S02-A015 19800.0 13.2 15.0 30.0 6.6 15.0 15.0 3.9 1 5/8 21 650

BNK-S02-A017 19000.0 13.2 15.0 30.0 6.6 15.0 15.0 3.9 2 1/8 28 700

BNK-S03-A022 29700.0 19.8 21.5 35.0 9.9 15.0 15.0 5.9 2 1/8 21 960

BNK-S03-A026 28500.0 19.8 21.5 35.0 9.9 15.0 15.0 5.9 2 1/8 28 1030

BNK-S04-A029 38600.0 26.4 28.1 45.0 13.2 15.0 20.0 7.8 2 1/8 21 1250

BNK-S04-A034 37000.0 26.4 28.1 45.0 13.2 15.0 20.0 7.8 2 5/8 28 1350

BNK-S05-A037 48300.0 33.0 34.7 50.0 16.5 20.0 25.0 9.7 2 5/8 21 1570

BNK-S05-A044 46200.0 33.0 34.7 50.0 16.5 20.0 25.0 9.7 2 5/8 28 1700

BNK-S06-A053 55400.0 39.6 41.3 50.0 19.8 20.6 25.0 11.7 2 5/8 28 2020

BNK-S07-A061 64700.0 46.2 47.9 60.0 23.1 23.9 30.0 13.6 2 @ 2 5/8 28 2320

BNK-D04-A021 41000.0 26.4 28.1 45.0 13.2 15.0 20.0 7.8 2 @ 1 3/8 28 1280

BNK-D04-A029 39600.0 26.4 28.1 45.0 13.2 15.0 20.0 7.8 2 @ 1 5/8 42 1380

BNK-D04-A034 38100.0 26.4 28.1 45.0 13.2 15.0 20.0 7.8 2 @ 2 1/8 56 1480

BNK-D06-A044 59400.0 39.6 41.3 50.0 19.8 20.6 25.0 11.7 2 @ 2 1/8 42 2060

BNK-D06-A051 57100.0 39.6 41.3 50.0 19.8 20.6 25.0 11.7 2 @ 2 1/8 56 2210

BNK-D08-A058 77200.0 52.8 54.5 70.0 26.4 27.2 35.0 15.5 2 @ 2 1/8 42 2720

BNK-D08-A068 73900.0 52.8 54.5 70.0 26.4 27.2 35.0 15.5 2 @ 2 5/8 56 2920

BNK-D10-A074 96500.0 66.0 67.7 80.0 33.0 33.8 40.0 19.4 2 @ 2 5/8 42 3400

BNK-D10-A088 92400.0 66.0 67.7 80.0 33.0 33.8 40.0 19.4 2 @ 2 5/8 56 3650

BNK-D12-A106 110900.0 79.2 80.9 90.0 39.6 40.4 45.0 23.3 2 @ 2 5/8 56 4360

BNK-D14-A122 129400.0 92.4 94.1 110.0 46.2 47.0 50.0 27.2 4 @ 2 5/8 56 5060

29

Page 30

CONDENSER CAPACITY

BNE 540 830 VSEC 1140

Table 25. BNE Models, 2.0 kW, 31.5" Fan Diameter

R22 / R-410A

Model

MBH / 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNE-S01-A008 6.8 7.7 8.5 9.1 6.6 7.6 8.3 9.0

BNE-S01-A009 8.3 9.3 10.0 10.6 8.1 9.1 9.8 10.4

BNE-S02-A011 10.2 11.3 12.4 13.1 10.0 11.1 12.1 12.9

BNE-S02-A015 13.9 15.4 16.5 17.3 13.6 15.1 16.2 17.0

BNE-S02-A018 16.6 18.1 19.2 20.3 16.3 17.8 18.8 19.9

BNE-S03-A023 20.9 23.1 24.8 25.9 20.4 22.7 24.3 25.4

BNE-S03-A027 24.9 27.2 28.7 31.7 24.4 26.7 28.2 31.1

BNE-S04-A031 27.8 30.8 33.0 34.6 27.2 30.2 32.4 33.9

R404/R507

MBH / 1° TD

BNE-S04-A036 33.2 36.3 38.3 40.6 32.6 35.5 37.5 39.8

BNE-S05-A039 35.6 39.3 41.6 43.8 34.9 38.5 40.8 42.9

BNE-S05-A047 43.0 46.6 48.8 51.5 42.1 45.7 47.8 50.5

BNE-S06-A056 51.6 56.0 58.6 61.8 50.5 54.8 57.4 60.5

BNE-S07-A065 58.7 64.6 68.6 71.6 57.6 63.3 67.3 70.2

BNE-D04-A023 20.4 22.7 24.8 26.2 19.9 22.2 24.3 25.7

BNE-D04-A031 27.8 30.8 33.1 34.6 27.2 30.2 32.4 33.9

BNE-D04-A036 33.2 36.3 38.3 40.6 32.6 35.5 37.5 39.8

BNE-D06-A046 41.7 46.2 49.5 51.9 40.9 45.3 48.6 50.8

BNE-D06-A054 49.8 54.4 57.4 63.4 48.8 53.3 56.3 62.2

BNE-D08-A062 55.6 61.7 66.1 69.2 54.5 60.5 64.7 67.8

BNE-D08-A073 66.5 72.5 76.6 81.3 65.2 71.1 75.1 79.7

BNE-D10-A079 71.1 78.6 83.2 87.5 69.7 77.0 81.6 85.8

BNE-D10-A093 85.9 93.3 97.6 103.0 84.2 91.4 95.7 100.9

BNE-D12-A112 103.1 111.9 117.1 123.6 101.0 109.7 114.8 121.1

BNE-D14-A129 117.5 129.2 137.2 143.1 115.2 126.7 134.5 140.3

BOLD indicates standard model capacity.

30

Page 31

CONDENSER CAPACITY

BNE 540 830 VSEC 1140

Table 26. BNE Models, 2.0 kW, 31.5" Fan Diameter

R407A/R407F*

Model

MBH / 1° TD

8 FPI 10 FPI 12 FPI 14 FPI 8 FPI 10 FPI 12 FPI 14 FPI

BNE-S01-A008 6.5 7.4 8.2 8.8 6.2 7.1 7.8 8.4

BNE-S01-A009 7.9 8.9 9.6 10.2 7.6 8.5 9.2 9.7

BNE-S02-A011 9.8 10.9 11.9 12.6 9.4 10.4 11.4 12.1

BNE-S02-A015 13.3 14.8 15.9 16.6 12.8 14.2 15.2 15.9

BNE-S02-A018 15.9 17.4 18.4 19.5 15.3 16.7 17.6 18.7

BNE-S03-A023 20.0 22.2 23.8 24.9 19.2 21.3 22.8 23.9

BNE-S03-A027 23.9 26.1 27.6 30.5 23.0 25.1 26.5 29.2

BNE-S04-A031 26.7 29.6 31.7 33.2 25.6 28.4 30.4 31.9

R407C*

MBH / 1° TD

BNE-S04-A036 31.9 34.8 36.8 39.0 30.6 33.4 35.3 37.4

BNE-S05-A039 34.2 37.8 40.0 42.0 32.8 36.2 38.3 40.3

BNE-S05-A047 41.3 44.8 46.9 49.5 39.6 43.0 45.0 47.5

BNE-S06-A056 49.5 53.8 56.2 59.3 47.5 51.6 53.9 56.9

BNE-S07-A065 56.4 62.1 65.9 68.8 54.1 59.5 63.2 66.0

BNE-D04-A023 19.5 21.8 23.8 25.2 18.8 20.9 22.8 24.2

BNE-D04-A031 26.7 29.6 31.7 33.2 25.6 28.4 30.5 31.9

BNE-D04-A036 31.9 34.8 36.8 39.0 30.6 33.4 35.3 37.4

BNE-D06-A046 40.1 44.4 47.6 49.8 38.4 42.6 45.6 47.8

BNE-D06-A054 47.9 52.2 55.2 61.0 45.9 50.1 52.9 58.5

BNE-D08-A062 53.4 59.2 63.4 66.4 51.2 56.8 60.9 63.7

BNE-D08-A073 63.9 69.7 73.6 78.1 61.3 66.8 70.6 74.9

BNE-D10-A079 68.3 75.5 79.9 84.0 65.5 72.4 76.7 80.6

BNE-D10-A093 82.5 89.6 93.7 98.9 79.1 85.9 89.9 94.9

BNE-D12-A112 99.0 107.5 112.5 118.7 94.9 103.1 107.9 113.8

BNE-D14-A129 112.8 124.1 131.9 137.5 108.2 119.1 126.5 131.9

BOLD indicates standard model capacity.

31

Page 32

CONDENSER SPECIFICATIONS

Table 27. BNE Models, 2.0 kW, 31.5" Fan Diameter

BNE 540 830 VSEC 1140

208-230/3/60 460/3/60

Model CFM

FLA MCA MOPD FLA MCA MOPD

BNE-S01-A008 11,000 7.0 15.0 25 3.5 15.0 15 2.0 1 3/8 7 330

BNE-S01-A009 10,500 7.0 15.0 25 3.5 15.0 15 2.0 1 3/8 14 360

BNE-S02-A011 23,400 14.0 20.0 35 7.0 15.0 15 4.0 1 3/8 14 590

BNE-S02-A015 22,000 14.0 20.0 35 7.0 15.0 15 4.0 1 5/8 21 640

BNE-S02-A018 20,900 14.0 20.0 35 7.0 15.0 15 4.0 2 1/8 28 690

BNE-S03-A023 33,100 21.0 22.8 40 10.5 15.0 20 6.0 2 1/8 21 930

BNE-S03-A027 31,400 21.0 22.8 40 10.5 15.0 20 6.0 2 1/8 28 1,010

BNE-S04-A031 42,600 28.0 29.8 45 14.0 15.0 20 8.0 2 1/8 21 1,220

BNE-S04-A036 40,000 28.0 29.8 45 14.0 15.0 20 8.0 2 5/8 28 1,320

BNE-S05-A039 53,200 35.0 36.8 50 17.5 20.0 25 10.0 2 5/8 21 1,520

UnitkWConn.

(in.)

Max.

Number

of Feeds

Approx.

Net

Weight

(lbs)

BNE-S05-A047 50,000 35.0 36.8 50 17.5 20.0 25 10.0 2 5/8 28 1,650

BNE-S06-A056 60,000 42.0 43.8 60 21.0 21.9 30 12.0 2 5/8 28 1,960

BNE-S07-A065 70,000 49.0 50.8 70 24.5 25.4 35 14.0 2 @ 2 5/8 28 2,260

BNE-D04-A023 46,700 28.0 29.8 45 14.0 15.0 20 8.0 2 @ 1 3/8 28 1,290

BNE-D04-A031 44,100 28.0 29.8 45 14.0 15.0 20 8.0 2 @ 1 5/8 42 1,390

BNE-D04-A036 41,800 28.0 29.8 45 14.0 15.0 20 8.0 2 @ 2 1/8 56 1,490

BNE-D06-A046 66,100 42.0 43.8 60 21.0 21.9 30 12.0 2 @ 2 1/8 42 2,060

BNE-D06-A054 62,700 42.0 43.8 60 21.0 21.9 30 12.0 2 @ 2 1/8 56 2,210

BNE-D08-A062 85,100 56.0 57.8 70 28.0 28.9 35 16.0 2 @ 2 1/8 42 2,730

BNE-D08-A073 80,000 56.0 57.8 70 28.0 28.9 35 16.0 2 @ 2 5/8 56 2,930

BNE-D10-A079 106,400 70.0 71.8 90 35.0 35.9 45 20.0 2 @ 2 5/8 42 3,410

BNE-D10-A093 100,100 70.0 71.8 90 35.0 35.9 45 20.0 2 @ 2 5/8 56 3,660

BNE-D12-A112 120,100 84.0 85.8 100 42.0 42.9 50 24.0 2 @ 2 5/8 56 4,370

BNE-D14-A129 140,100 98.0 99.8 110 49.0 49.9 60 28.0 4 @ 2 5/8 56 5,070

32

Page 33

CONDENSER DIMENSIONS

End Views

Single Row of Fans

Double Row of Fans

Side Views

1 x 1

1 x 3

2 x 3

1 x 2

2 x 2

1 x 4

2 x 4

1 x 5

2 x 5

1 x 6

2 x 6

1 x 7

2 x 7

33

Page 34

Fan Cycle Control Panels

Fan cycling panels are available to cycle fans on ambient

temperature or condensing pressure or custom built control

panels can be factory installed to interface with electronic

refrigeration controllers.

• All fans are cycled with contactors.

• Condensers with a single row of fans cycle fans separately

with one contactor per fan.

• Condensers with two rows of fans cycle fans in pairs, with

one contactor for every pair of fans.

• Fans closest to the header end of the unit run continuously.

Ambient Fan Cycle

Condenser fans are controlled by ambient temperature

using electronic temperature controls. Ambient fan cycling is

recommended for multi-circuited condensers or single circuit

condensers where there is little variation in condenser load.

Ambient fan cycling is limited in its ability to control head pressure

to mild ambient conditions, see Table 28 for minimum ambients

for fan cycling. Full year head pressure control can be obtained

by combining ambient fan cycling with another means of head

Pressure Fan Cycling

• Standard control circuit voltage is 230 volts. Control

circuits with 24 or 115 volts are available on request.

• Control circuits are factory wired to a control circuit

terminal board for convenient single point eld wiring.

• Standard control circuits require an external power supply

for powering control circuit (by others).

• A control circuit transformer is available on 460 volt

condensers as a factory mounted option to provide

power to the control circuit.

pressure control, such as condenser ooding controls or variable

speed. Combining these controls with ambient fan cycling has the

additional advantage of reducing the amount of refrigerant required

to ood the condenser.

See Table 29 for typical settings for ambient thermostats.

Condenser fans are controlled by pressure switches which

monitor condenser pressure. Pressure fan cycling is ideal for

those condensers which see a signicant change in condenser

load. Since the controls sense condensing pressure, they can

cycle fans at any ambient temperature, in response to a change in

condensing pressure.

An additional pressure switch is available as an option to cycle the

fan closest to the header end of the condenser. This option is only

recommended for condensers with large variations in condenser

load caused by heat reclaim, hot gas defrost or a high percentage of

compressor unloading.

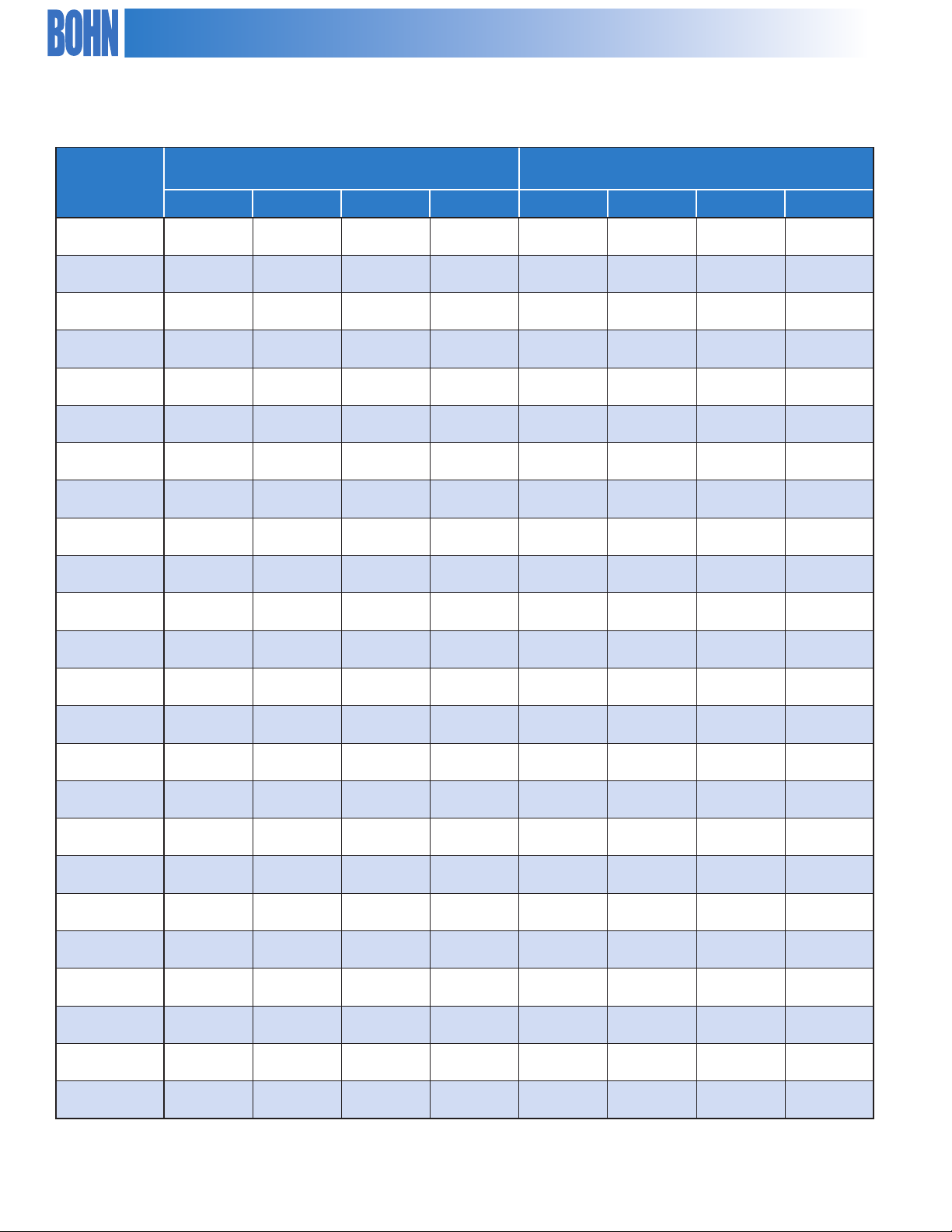

Table 28. Minimum Ambient for Fan Cycling

Number of Fans Design T.D.*

Single Row Double Row 30 25 20 15 10

2 4 35 45 55 60 70

3 6 15 30 40 55 65

4 8 0 15 30 45 60

5 10 0 10 20 35 55

6/7 12/14 0 0 10 30 50

*Based on maintaining 90° F minimum condensing temperature.

34

Page 35

Table 29. Fan Cycling Thermostat Settings

Number of Fans Design Thermostat Setting

Single Row Double Rows T.D. 1 2 3 4 5

2 4 30 60

25 65

20 70

15 75

10 80

3 6 30 60 40

25 65 55

20 70 60

15 75 65

10 80 75

4 8 30 60 50 30

25 65 55 40

20 70 65 50

15 75 70 60

10 80 75 70

5 10 30 60 55 45 30

25 65 60 50 35

20 70 65 60 40

15 75 70 65 55

10 80 75 70 65

6/7 12/14 30 55 50 40 30 25

25 65 60 55 45 35

20 70 65 60 50 40

15 75 70 65 60 50

10 80 75 70 65 60

Variable Speed

Condenser head pressure control is provided by varying the air ow through the condenser by changing the RPM of the condenser fan. This

control package is oered in combination with ambient fan cycling. The fan motor next to the header end of the condenser is the variable

speed fan. The remainder of the fans are constant speed and are cycled separately using ambient sensing thermostats. On condensers with

two rows of fans, two variable speed fans are provided (one per row) and the remainder of the fans are constant speed and are cycled in

pairs. The variable speed control package consists of a special variable speed motor (1140 RPM, single phase) and an electronic speed control

which controls the speed of the motor in response to condensing pressure. Fan motor, speed control and all related components are all

factory mounted and wired. Two speed controls are provided on units with two rows of fans to allow for separate control of each fan motor.

Splitting Controls

Additional head pressure can be provided by valving o a portion of the condenser circuit and removing that portion from the refrigeration

circuit, or splitting the condenser. In addition to providing a means of head pressure control, this control will reduce the amount of refrigerant

required to operate the condenser with a ooded head pressure control. Condenser splitting is recommended as a seasonal adjustment

controlled by ambient temperature. A pressure switch is also provided as a backup control to prevent high head pressures from occurring

during heavy load conditions. On condensers with a single row of fans the control package consists of an ambient sensing thermostat, a

pressure switch sensing condensing pressure and a splitting relay. The splitting relay provides a set of dry contacts to control the valves

required to split the condenser (valves supplied by others). On condensers with double rows of fans, additional controls and contactors are

provided to cycle all of the fans on the side of the condenser which has been split o. Except as noted above, the splitting packages do not

control fan cycling. It is recommended that fan cycling be controlled by combining the splitting package with pressure fan cycling.

Control Panels for Electronic Controllers

Custom control panels can often be fabricated to interface with many of the microprocessor based electronic refrigeration controls.

These panels often include individual motor fusing, individual fan motor contactors, splitting relays and printed circuit boards to

interface with the microprocessor control. Contact the factory with your specic requirements.

35

Page 36

Condenser Refrigerant Charge

The normal summer operating charge for condensers is shown

in Table 30. This charge can also be used in condensers with fan

cycling kits, since added refrigerant is not required for mild weather

control. Table 30 also contains the additional refrigerant charge

required when using ooded style head pressure controls.

Combining fan cycling with ooded head pressure controls

signicantly reduces the amount of winter charge required to ood

the condenser. Table 32 shows the refrigerant charge required

when fan cycling is used in conjunction with a ooded style head

pressure control.

Table 30. Refrigerant Charge, Lbs. R22 for Flooded Condenser

Refrigerant R22

Model*

1 8 7 10 11 11 11

2 10 10 13 15 15 16

3 10 10 13 14 15 15

4 15 15 19 21 22 23

5 20 19 26 29 30 31

6 22 22 29 32 34 35

7 30 29 38 42 44 46

8 51 50 66 74 77 80

9 70 66 87 96 100 105

10 64 62 83 92 95 99

11 86 83 110 122 127 132

12 102 100 132 147 153 159

13 118 117 155 172 179 186

14 19 20 27 29 31 32

15 29 30 39 44 46 47

16 40 39 51 57 59 62

17 44 44 58 64 67 70

18 58 59 78 86 90 94

19 104 99 131 146 152 158

20 140 131 174 193 201 209

21 125 126 168 186 194 201

22 172 165 219 243 253 263

23 201 201 267 296 308 320

24 236 233 310 343 357 372

Charge

for summer

Operation, Lbs.

+60 +40 +20 +0 -20

Additional Refrigerant R22 Charge Required

for Flooded Condenser Operation

Lbs. For 20°F TD

Minimum Ambient at Condenser

* See Model Cross Reference Table #33.

Table 31. Flooded Charge Temperature Dierence Factor

Design T.D.

Ambient, °F 30 25 20 15 10

+60 0.38 1.0 1.74 2.46

+40 0.59 0.80 1.0 1.19 1.40

+20 0.76 0.88 1.0 1.13 1.25

0 0.84 0.91 1.0 1.07 1.16

-20 0.88 0.93 1.0 1.05 1.13

----

36

Page 37

Table 32. Refrigerant Charge for Fan Cycling plus Flooded Condenser (lbs. R-22)

Model*

Summer

Charge

1 8 7 8 9 9 8 9 10 10 9 10 11 11 13 12 12 12

2 10 9 12 13 14 11 13 14 15 13 14 15 16 17 18 17 18

3 10 1 6 8 10 4 8 10 11 7 10 12 13 10 13 14 14

4 15 2 9 12 15 7 12 15 17 12 16 18 19 17 19 21 22

5 20 3 11 16 19 9 16 20 22 15 21 24 25 21 25 27 28

6 22 0 3 10 15 0 10 16 20 0 17 22 25 0 24 27 29

7 30 0 4 13 20 0 12 20 26 0 21 27 32 0 29 34 38

8 51 0 0 8 22 0 6 23 35 0 22 38 48 0 37 52 61

9 70 0 0 11 29 0 8 31 46 0 29 51 63 0 49 71 80

10 64 0 0 0 15 0 0 17 33 0 0 39 52 0 0 60 70

11 86 0 0 0 19 0 0 22 44 0 0 50 69 0 0 78 93

40°F 20°F 0°F -20°F 40°F 20°F 0°F -20°F 40°F 20°F 0°F -20°F 40°F 20°F 0°F -20°F

25° TD 20° TD 15° TD 10° TD

12 102 0 0 0 6 0 0 8 37 0 0 37 69 0 0 66 100

13 118 0 0 0 0 0 0 0 29 0 0 0 69 0 0 0 108

14 19 3 12 17 20 9 17 21 23 15 22 25 26 21 27 29 29

15 29 4 17 24 29 13 24 30 34 22 31 36 39 31 38 41 43

16 40 5 22 32 38 17 31 39 44 29 40 46 50 41 49 53 56

17 44 0 5 20 31 0 18 31 40 0 31 42 49 0 44 53 59

18 58 0 7 27 42 0 25 42 54 0 43 57 66 0 61 71 79

19 104 0 0 17 44 0 12 47 69 0 43 77 95 0 74 107 119

20 140 0 0 22 57 0 16 62 91 0 57 102 125 0 99 141 157

21 125 0 0 0 30 0 0 34 67 0 0 77 105 0 0 120 141

22 172 0 0 0 39 0 0 44 88 0 0 100 137 0 0 156 186

23 201 0 0 0 11 0 0 16 74 0 0 74 137 0 0 132 200

24 236 0 0 0 0 0 0 0 57 0 0 0 135 0 0 0 213

* See Model Cross Reference Table #33.

Refrigerant Multiply charge by:

R-134a 0.99

R-404A 0.91

R-407A 0.96

Note: For other refrigerants, use the table at the right. For alternate T.D.s, multiply by

flooded charge T.D. factors in Table 31.

Refrigerant Multiply charge by:

R-407C 0.95

R-410A 0.96

R-507A 0.91

37

Page 38

Table 33. Model Cross Reference

Model

Reference

1 BNH-S01-A007 BNK-S01-A007 BNL-S01-A007 BNJ-S01-A007 BNX-S01-A006 BNQ-S01-A005 BNE-S01-A008

2 BNH-S01-A009 BNK-S01-A009 BNL-S01-A008 BNJ-S01-A008 BNX-S01-A008 BNQ-S01-A006 BNE-S01-A009

3 BNH-S02-A011 BNK-S02-A011 BNL-S02-A010 BNJ-S02-A010 BNX-S02-A010 BNQ-S02-A008 BNE-S02-A011

4 BNH-S02-A015 BNK-S02-A015 BNL-S02-A014 BNJ-S02-A014 BNX-S02-A013 BNQ-S02-A010 BNE-S02-A015

5 BNH-S02-A017 BNK-S02-A017 BNL-S02-A016 BNJ-S02-A016 BNX-S02-A015 BNQ-S02-A011 BNE-S02-A018

6 BNH-S03-A022 BNK-S03-A022 BNL-S03-A021 BNJ-S03-A021 BNX-S03-A020 BNQ-S02-A016 BNE-S03-A023

7 BNH-S03-A026 BNK-S03-A026 BNL-S03-A024 BNJ-S03-A024 BNX-S03-A023 BNQ-S03-A017 BNE-S03-A027

8 BNH-S04-A029 BNK-S04-A029 BNL-S04-A028 BNJ-S04-A028 BNX-S04-A026 BNQ-S04-A021 BNE-S04-A031

9 BNH-S04-A034 BNK-S04-A034 BNL-S04-A032 BNJ-S04-A032 BNX-S04-A030 BNQ-S04-A023 BNE-S04-A036