Page 1

BNMPTB

April 2008

Replaces BN-MPTB, June 2007

MEDIUM PROFILE UNIT COOLERS

Technical Guide

Models BMA | Air Defrost • BME/BML | Electric Defrost • BMG/BMF | Hot Gas Defrost

www.thecoldstandard.com

Page 2

Table of Contents

Nomenclature .........................................................................................................................................................................................................2

Features & Benets ...............................................................................................................................................................................................3

Performance Data & Specications

Air Defrost ............................................................................................................................................................................................................4-5

Electric Defrost ................................................................................................................................................................................................... 6-7

Hot Gas Defrost .................................................................................................................................................................................................. 8-9

Physical Data .................................................................................................................................................................................................. 10-11

Dimensional Data ................................................................................................................................................................................................12

Replacement Parts by InterLink™ ..................................................................................................................................................................13

Standard Nozzle Selection ...............................................................................................................................................................................

We have made a commitment to customer needs, innovation and environmental stewardship and have dedicated

ourselves to delivering energy-ecient choices. PSC and EC motors will reduce costs, improve the bottom line and

enhance equipment performance and service life.

14

Choose the most energy-ecient motor available for evaporators.

The EC motor is an Energy Solutions® option on new Bohn Medium Prole

evaporators. Available on all new equipment or as an easy-to-install,

drop-in replacement aftermarket part from InterLink™ Commercial

Refrigeration Parts. Because they’re a drop-in replacement for existing

PSC motors, installation is quick and easy. It’s a high impact, quick

payback solution for reducing costs and achieving green initiatives

without replacing the entire system.

EC motors by InterLink are up to 75% ecient - that’s a 30-35%

increase over permanent-split capacitor (PSC) motors. With all of

this added eciency, you can count on more energy savings and lower

operational costs while taking a step in the right direction toward

conserving our planet’s resources.

To learn more about EC motors, visit www.interlinkparts.com/ec.

Nomenclature

BM A 130 B A

Model Series Model Type Capacity Electrical Code Design Revision

Bohn Medium

Prole Unit Coolers

2

A = Air defrost

E = Electric defrost, 6 FPI

L = Electric defrost, 4 FPI

G = Hot gas defrost, 6 FPI

F = Hot gas defrost, 4 FPI

# BTUH x 100 A = 115/1/60

B = 208-230/1/60

C = 208-230/3/60

D = 460/3/60

M = 460/1/60

E = 575/3/60

L = 575/1/60

N = 110/1/50

Q = 220/1/50

R = 380/1/50

V = 380/3/50

AE = 115/1/60 (EC)

BE = 208-230/1/60 (EC)

CE = 208-230/3/60 (EC)

©2008 Heatcraft Refrigeration Products LLC

Page 3

Features & Benefits

Cabinet

Schrader valve provided for suction pressure measurement

•

External equalizer connection

•

Heavy-guage textured aluminum cabinet

•

All electrical components factory wired to terminal board

•

and identified, making it easy to field wire the unit

Sweat connections to reduce potential for leaks

•

Internal panels are isolated for quiet operation

•

Liquid line solenoid wire harness is factory-installed for

•

quick installation

Drain Pan

Front hinged drain pan for easy access

•

Large diameter drain fitting (3/4" ID)

•

Motors

Motors plug into wiring harness for easier servicing

•

Single phase EC motors available factory-installed or as

•

a drop-in replacement through InterLink™ Commercial

Refrigeration Parts in 115 and 208-230 voltages

Thermally protected, lifetime-lubricated single phase

•

PSC motors

Coil

Patented Thermo-Flex™ coil design allows the coil to

•

“flex” during periods of defrost resulting in expansion of

the coil surface. By eliminating the possibility of wear at

critical stress areas, the integrity and longevity of the unit

are dramatically increased (Patent Number 5,584,340)

Coil heater slots have been enlarged for easier

•

installation and replacement

Electric defrost models have fixed defrost termination /

•

fan delay and heater limit thermostats

Reliable nickel steel alloy defrost heater elements

•

Heaters are coil face mounted for easy access

•

Factory-installed liquid line

solenoid wiring harness for

faster installation

Innovative Thermo-Flex™ coil

Options

Totally enclosed single phase PSC motors available as an option for 208-230 and 460 voltages

•

Unit Configurations: mounted components, pre-assembled, pre-charged and Beacon II™

•

- Units available with mounted TXV and mounted TXV / solenoid valve

- Pre-assembled units come with mounted TXV, liquid line solenoid valve and room thermostat

- Pre-charged units come with mounted TXV, liquid line solenoid valve, room thermostat and quick connect fittings

(limited availability)

- Room thermostat option mounted on the back of unit

- Beacon II units come with electronic expansion valves, pressure transducer, temperature sensors and Beacon control board

Most models available with glycol circuiting (see glycol product brochure)

•

Units available with stainless steel housing and drain pan

•

Units available with copper fins. Air defrost units also available with polyester coated fins or various coil coatings options

•

Units available with insulated drain pan

•

Ship-loose air sock collar available

•

Wire fan guards for air diffusion

•

Adjustable defrost termination / fan delay thermostat

•

Bohn oers a ve-year limited guarantee against leaks at tube sheets and center supports for all medium prole unit coolers

3

Page 4

Performance Data

Model BMA Air Defrost | 60 Hz

†

Diused

(Optional)

Model

Capacity Fan Data

10°F TD

25°F SST

BTUH Watts in. mm ft. m ft. m

6°C TD

- 4°C SST

No. CFM m3h

Diameter

Air Throw*

Extended

(Standard)

BMA130 13,000 3,810 1 2,300 3,910 18 457 65 20 50 15

BMA155 15,500 4,540 1 2,200 3,740 18 457 65 20 50 15

BMA245 24,500 7,180 2 4,600 7,820 18 457 65 20 50 15

BMA300 30,000 8,790 2 4,400 7,480 18 457 65 20 50 15

BMA365 36,500 10,690 3 6,900 11,730 18 457 65 20 50 15

BMA450 45,000 13,180 3 6,600 11,220 18 457 65 20 50 15

BMA510 51,000 14,940 4 9,200 15,640 18 457 65 20 50 15

BMA600 60,000 17,570 4 8,800 14,960 18 457 65 20 50 15

BMA710 71,000 20,790 5 10,500 17,850 18 457 65 20 50 15

Model BMA Air Defrost | 50 Hz

Capacity Fan Data

Model

10°F TD

25°F SST

BTUH Watts in. mm ft. m ft. m

6°C TD

- 4°C SST

‡

No. CFM m3h

Diameter

Air Throw*

Extended

(Standard)

†

Diused

(Optional)

BMA130 11,960 3,500 1 2,070 3,520 18 457 60 18.5 45 13.5

BMA155 14,260 4,180 1 1,980 3,370 18 457 60 18.5 45 13.5

BMA245 22,540 6,600 2 4,140 7,040 18 457 60 18.5 45 13.5

BMA300 27,600 8,080 2 3,960 6,730 18 457 60 18.5 45 13.5

BMA365 33,580 9,840 3 6,210 10,560 18 457 60 18.5 45 13.5

BMA450 41,400 12,130 3 5,940 10,100 18 457 60 18.5 45 13.5

BMA510 46,920 13,740 4 8,280 14,080 18 457 60 18.5 45 13.5

BMA600 55,200 16,170 4 7,920 13,460 18 457 60 18.5 45 13.5

BMA710 65,320 19,130 5 9,450 16,070 18 457 60 18.5 45 13.5

* Standard molded fan guards allow for extended air throw; optional wire guards promote air diusion

†

Air throw data based on 12-ft. high ceilings with no obstructions where velocity drops to 50 FPM

‡

For EC motors, use 60 Hz capacity and airow values (Units with EC motors operating at 50 Hz will not see a reduction in performance due to the

electronic control of the motor)

4

Page 5

Specifications

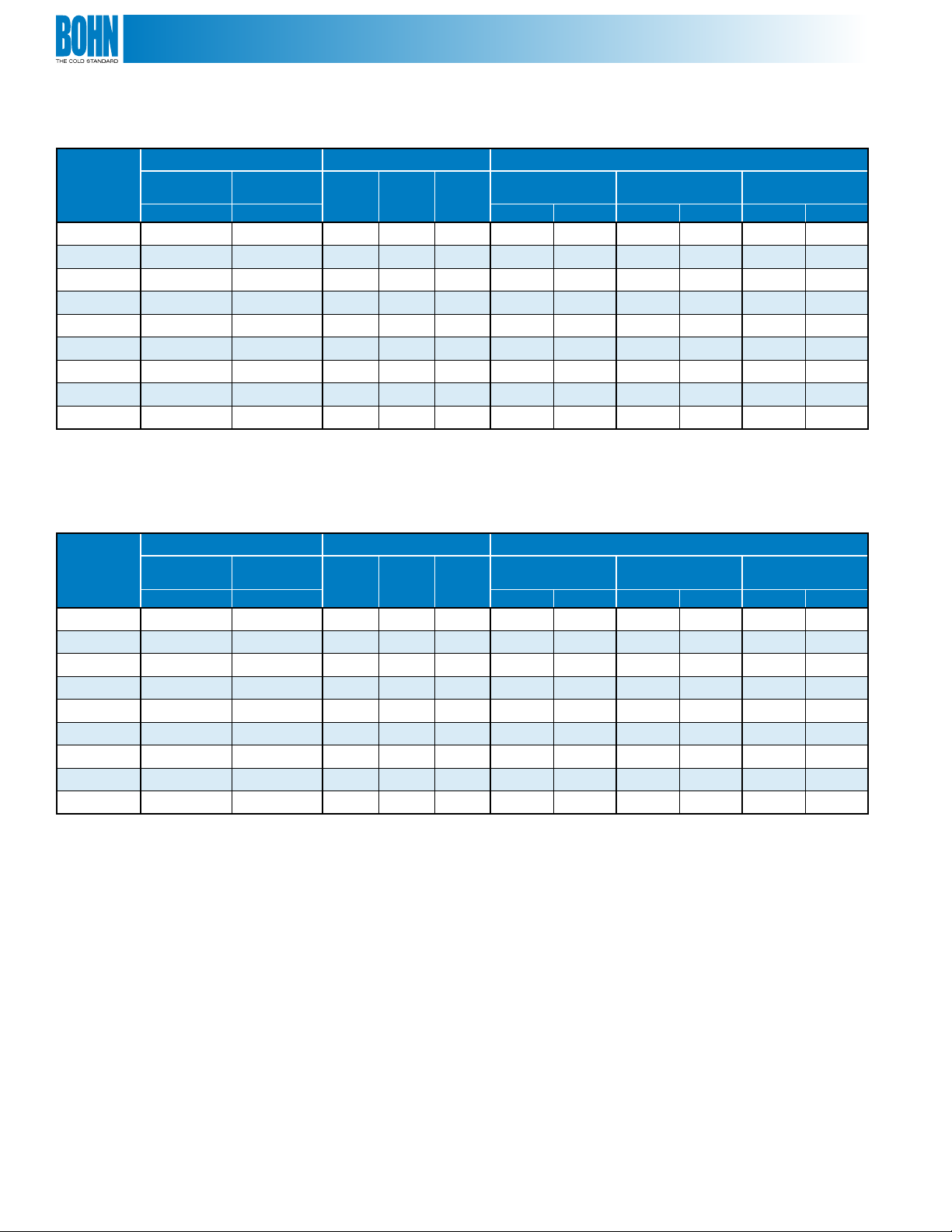

Model BMA Air Defrost | 60 Hz

PSC Motor EC Motor

Model

BMA130 1/4 4.0 300 1.8 305 1.0 305 0.7 310 2.8 210 1.4 205

BMA155 1/4 4.0 300 1.8 305 1.0 305 0.7 310 2.8 210 1.4 205

BMA245 1/4 8.0 600 3.6 610 2.0 610 1.4 620 5.6 420 2.8 410

BMA300 1/4 8.0 600 3.6 610 2.0 610 1.4 620 5.6 420 2.8 410

BMA365 1/4 12.0 900 5.4 915 3.0 915 2.1 930 8.4 630 4.2 615

BMA450 1/4 12.0 900 5.4 915 3.0 915 2.1 930 8.4 630 4.2 615

BMA510 1/4 16.0 1,200 7.2 1,220 4.0 1,220 2.8 1,240 11.2 840 5.6 820

BMA600 1/4 16.0 1,200 7.2 1,220 4.0 1,220 2.8 1,240 11.2 840 5.6 820

BMA710 1/4 - 1,500 9.0 1,525 5.0 1,525 3.5 1,550 14.0 1,050 7.0 1,025

HP*

Model BMA Air Defrost | 50 Hz

Model

BMA130 1/4 4.0 1.8 1.0 2.8 1.4

BMA155 1/4 4.0 1.8 1.0 2.8 1.4

BMA245 1/4 8.0 3.6 2.0 5.6 2.8

BMA300 1/4 8.0 3.6 2.0 5.6 2.8

BMA365 1/4 12.0 5.4 3.0 8.4 4.2

BMA450 1/4 12.0 5.4 3.0 8.4 4.2

BMA510 1/4 16.0 7.2 4.0 11.2 5.6

BMA600 1/4 16.0 7.2 4.0 11.2 5.6

BMA710 1/4 - 9.0 5.0 14.0 7.0

HP

115/1/60 208-230/1/60 460/1/60 575/1/60 115/1/60 208-230/1/60

Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts Amps Watts

PSC Motor EC Motor

110/1/50 220/1/50 380/1/50 110/1/50 220/1/50

Amps Amps Amps Amps Amps

* 575/1/60 motors are 1/3 HP

5

Page 6

Performance Data

Model BME/BML Electric Defrost | 60 Hz

Capacity Fan Data

Model

10°F TD

-20°F SST

BTUH Watts in.

6°C TD

-29°C SST

No.

CFM m3h

Diameter

BME101 10,100 2,960 1 2,350 4,000 18 457 65 20 50 15

BME140 14,000 4,100 1 2,250 3,830 18 457 65 20 50 15

BME190 19,000 5,570 2 4,700 7,990 18 457 65 20 50 15

BME260 26,000 7,620 2 4,500 7,650 18 457 65 20 50 15

BME310 31,000 9,080 3 7,050 11,990 18 457 65 20 50 15

BME390 39,000 11,420 3 6,750 11,480 18 457 65 20 50 15

6 Fins Per Inch

BME430 43,000 12,590 4 8,800 14,960 18 457 65 20 50 15

BME520 52,000 15,230 4 8,400 14,280 18 457 65 20 50 15

BME620 62,000 18,160 5 10,000 17,000 18 457 65 20 50 15

BML100 10,000 2,930 1 2,325 3,950 18 457 65 20 50 15

BML165 16,500 4,830 2 4,900 8,330 18 457 65 20 50 15

BML220 22,000 6,440 2 4,650 7,910 18 457 65 20 50 15

BML250 25,000 7,320 3 7,350 12,500 18 457 65 20 50 15

BML330 33,000 9,670 3 6,975 11,860 18 457 65 20 50 15

BML370 37,000 10,840 4 9,100 15,470 18 457 65 20 50 15

4 Fins Per Inch

BML440 44,000 12,890 4 8,700 14,790 18 457 65 20 50 15

BML530 53,000 15,520 5 10,350 17,600 18 457 65 20 50 15

Air Throw*

Extended

(Std.)

mm

ft. m ft. m

†

Diused

(Opt.)

Capacity Correction

Factors For Electric and

Hot Gas Defrost Units

Saturated

Suction

Temperature °F

Saturated

Suction

Temperature °C

Multiply

Capacity By

+20 -10 -20 -30 -40

-7 -23 -29 -34 -40

1.15 1.02 1.00 0.90 0.80

Model BME/BML Electric Defrost | 50 Hz

Capacity Fan Data

Model

10°F TD

-20°F SST

BTUH Watts in. mm ft. m ft. m

6°C TD

-29°C SST

No.

CFM m3h

‡

Diameter

Air Throw*

Extended

(Std.)

BME101 8,832 2,590 1 2,115 3,600 18 457 60 18.5 45 13.5

BME140 12,236 3,580 1 2,025 3,440 18 457 60 18.5 45 13.5

BME190 16,652 4,880 2 4,230 7,190 18 457 60 18.5 45 13.5

BME260 22,724 6,660 2 4,050 6,890 18 457 60 18.5 45 13.5

BME310 27,140 7,950 3 6,345 10,790 18 457 60 18.5 45 13.5

BME390 34,132 10,000 3 6,075 10,330 18 457 60 18.5 45 13.5

6 Fins Per Inch

BME430 37,628 11,020 4 7,920 13,460 18 457 60 18.5 45 13.5

BME520 45,448 13,310 4 7,560 12,850 18 457 60 18.5 45 13.5

BME620 54,188 15,870 5 9,000 15,300 18 457 60 18.5 45 13.5

BML100 8,740 2,560 1 2,093 3,560 18 457 60 18.5 45 13.5

BML165 14,444 4,230 2 4,410 7,500 18 457 60 18.5 45 13.5

BML220 19,228 5,630 2 4,185 7,120 18 457 60 18.5 45 13.5

BML250 21,896 6,410 3 6,615 11,250 18 457 60 18.5 45 13.5

BML330 28,888 8,460 3 6,278 10,670 18 457 60 18.5 45 13.5

BML370 32,384 9,490 4 8,190 13,920 18 457 60 18.5 45 13.5

4 Fins Per Inch

BML440 38,456 11,260 4 7,830 13,310 18 457 60 18.5 45 13.5

BML530 46,368 13,580 5 9,315 15,840 18 457 60 18.5 45 13.5

†

Diused

(Opt.)

* Standard molded fan guards allow for extended air throw; optional wire guards promote air diusion

†

Air throw data based on 12-ft. high ceilings with no obstructions where velocity drops to 50 FPM

‡

For EC motors, use 60 Hz capacity and airow values (Units with EC motors operating at 50 Hz will

not see a reduction in performance due to the electronic control of the motor)

6

Page 7

Specifications

Model BME/BML Electric Defrost | 60 Hz

PSC Motor EC Motor Defrost Heater

Model

BME101 1/4 1.8 275 1.0 275 0.7 310 1.4 275 2,730 11.9 8.2 5.9 4.1 3.3

BME140 1/4 1.8 275 1.0 275 0.7 310 1.4 275 2,730 11.9 8.2 5.9 4.1 3.3

BME190 1/4 3.6 550 2.0 550 1.4 620 2.8 550 5,350 23.3 16.0 11.6 8.3 6.6

BME260 1/4 3.6 550 2.0 550 1.4 620 2.8 550 5,350 23.3 16.0 11.6 8.3 6.6

BME310 1/4 5.4 825 3.0 825 2.1 930 4.2 825 7,750 33.7 23.2 16.8 12.0 9.6

BME390 1/4 5.4 825 3.0 825 2.1 930 4.2 825 7,750 33.7 23.2 16.8 12.0 9.6

6 Fins Per Inch

BME430 1/4 7.2 1,100 4.0 1,100 2.8 1,240 5.6 1,100 10,200 - 30.5 22.2 15.8 12.6

BME520 1/4 7.2 1,100 4.0 1,100 2.8 1,240 5.6 1,100 10,200 - 30.5 22.2 15.8 12.6

BME620 1/4 9.0 1,375 5.0 1,375 3.5 1,550 7.0 1,375 11,600 - 34.7 25.2 18.1 14.4

BML100 1/4 1.8 275 1.0 275 0.7 310 1.4 275 2,730 11.9 8.2 5.9 4.1 3.3

BML165 1/4 3.6 550 2.0 550 1.4 620 2.8 550 5,350 23.3 16.0 11.6 8.3 6.6

BML220 1/4 3.6 550 2.0 550 1.4 620 2.8 550 5,350 23.3 16.0 11.6 8.3 6.6

BML250 1/4 5.4 825 3.0 825 2.1 930 4.2 825 7,750 33.7 23.2 16.8 12.0 9.6

BML330 1/4 5.4 825 3.0 825 2.1 930 4.2 825 7,750 33.7 23.2 16.8 12.0 9.6

BML370 1/4 7.2 1,100 4.0 1,100 2.8 1,240 5.6 1,100 10,200 - 30.5 22.2 15.8 12.6

4 Fins Per Inch

BML440 1/4 7.2 1,100 4.0 1,100 2.8 1,240 5.6 1,100 10,200 - 30.5 22.2 15.8 12.6

BML530 1/4 9.0 1,375 5.0 1,375 3.5 1,550 7.0 1,375 11,600 - 34.7 25.2 18.1 14.4

HP*

208-

230/1/60

Amps Watts Amps Watts Amps Watts Amps Watts

460/1/60 575/1/60

208-

230/1/60

Watts

208-

230/1/60

208-

230/3/60

460/1/60 460/3/60 575/3/60

Total Amps

Model BME/BML Electric Defrost | 50 Hz

PSC Motor EC Motor Defrost Heater

Model

BME101 1/4 1.8 1.0 1.4

BME140 1/4 1.8 1.0 1.4

BME190 1/4 3.6 2.0 2.8

BME260 1/4 3.6 2.0 2.8

BME310 1/4 5.4 3.0 4.2

BME390 1/4 5.4 3.0 4.2

6 Fins Per Inch

BME430 1/4 7.2 4.0 5.6

BME520 1/4 7.2 4.0 5.6

BME620 1/4 9.0 5.0 7.0

BML100 1/4 1.8 1.0 1.4

BML165 1/4 3.6 2.0 2.8

BML220 1/4 3.6 2.0 2.8

BML250 1/4 5.4 3.0 4.2

BML330 1/4 5.4 3.0 4.2

BML370 1/4 7.2 4.0 5.6

4 Fins Per Inch

BML440 1/4 7.2 4.0 5.6

BML530 1/4 9.0 5.0 7.0

220/1/50 380/1/50 220/1/50

HP

Amps Amps Amps

220/1/50 380/3/50

Watts

2,510

2,510

4,910

4,910

7,090

7,090

9,340

9,340

10,620

2,510

4,910

4,910

7,090

7,090

9,340

9,340

10,620

Total Amps

11.4 3.4

11.4 3.4

22.3 6.9

22.3 6.9

32.2 9.9

32.2 9.9

- 13.1

- 13.1

- 15.0

11.4 3.4

22.3 6.9

22.3 6.9

32.2 9.9

32.2 9.9

- 13.1

- 13.1

- 15.0

* 575/1/60 motors are 1/3 HP

7

Page 8

Performance Data

Model BMG/BMF Hot Gas Defrost | 60 Hz

Capacity Fan Data

Model

10°F TD

-20°F SST

BTUH Watts in. mm ft. m ft. m

6°C TD

-29°C SST

No. CFM m3h

Diameter

BMG190 19,000 5,570 2 4,700 7,990 18 457 65 20 50 15

BMG260 26,000 7,620 2 4,500 7,650 18 457 65 20 50 15

BMG310 31,000 9,080 3 7,050 11,990 18 457 65 20 50 15

BMG390 39,000 11,420 3 6,750 11,480 18 457 65 20 50 15

BMG430 43,000 12,590 4 8,800 14,960 18 457 65 20 50 15

6 Fins Per Inch

BMG520 52,000 15,230 4 8,400 14,280 18 457 65 20 50 15

BMF165 16,500 4,830 2 4,900 8,330 18 457 65 20 50 15

BMF220 22,000 6,440 2 4,650 7,910 18 457 65 20 50 15

BMF250 25,000 7,320 3 7,350 12,500 18 457 65 20 50 15

BMF330 33,000 9,670 3 6,975 11,860 18 457 65 20 50 15

BMF370 37,000 10,840 4 9,100 15,470 18 457 65 20 50 15

4 Fins Per Inch

BMF440 44,000 12,890 4 8,700 14,790 18 457 65 20 50 15

Air Throw*

Extended

(Std.)

†

Diused

(Opt.)

Capacity Correction

Factors For Electric and

Hot Gas Defrost Units

Saturated

Suction

Temperature °F

Saturated

Suction

Temperature °C

Multiply

Capacity By

+20 -10 -20 -30 -40

-7 -23 -29 -34 -40

1.15 1.02 1.00 0.90 0.80

Model BMG/BMF Hot Gas Defrost | 50 Hz

Capacity Fan Data

Model

10°F TD

-20°F SST

BTUH Watts in. mm ft. m ft. m

6°C TD

-29°C SST

No.

CFM m3h

‡

Diameter

Air Throw*

Extended

(Std.)

†

Diused

(Opt.)

BMG190 16,652 4,880 2 4,230 7,190 18 457 60 18.5 45 13.5

BMG260 22,724 6,660 2 4,050 6,890 18 457 60 18.5 45 13.5

BMG310 27,140 7,950 3 6,345 10,790 18 457 60 18.5 45 13.5

BMG390 34,132 10,000 3 6,075 10,330 18 457 60 18.5 45 13.5

BMG430 37,628 11,020 4 7,920 13,460 18 457 60 18.5 45 13.5

6 Fins Per Inch

BMG520 45,448 13,310 4 7,560 12,850 18 457 60 18.5 45 13.5

BMF165 14,444 4,230 2 4,410 7,500 18 457 60 18.5 45 13.5

BMF220 19,228 5,630 2 4,185 7,120 18 457 60 18.5 45 13.5

BMF250 21,896 6,410 3 6,615 11,250 18 457 60 18.5 45 13.5

BMF330 28,888 8,460 3 6,278 10,670 18 457 60 18.5 45 13.5

BMF370 32,384 9,490 4 8,190 13,920 18 457 60 18.5 45 13.5

4 Fins Per Inch

BMF440 38,456 11,260 4 7,830 13,310 18 457 60 18.5 45 13.5

* Standard molded fan guards allow for extended air throw; optional wire guards promote air diusion

†

Air throw data based on 12-ft. high ceilings with no obstructions where velocity drops to 50 FPM

‡

For EC motors, use 60 Hz capacity and airow values (Units with EC motors operating at 50 Hz will

not see a reduction in performance due to the electronic control of the motor)

8

Page 9

Specifications

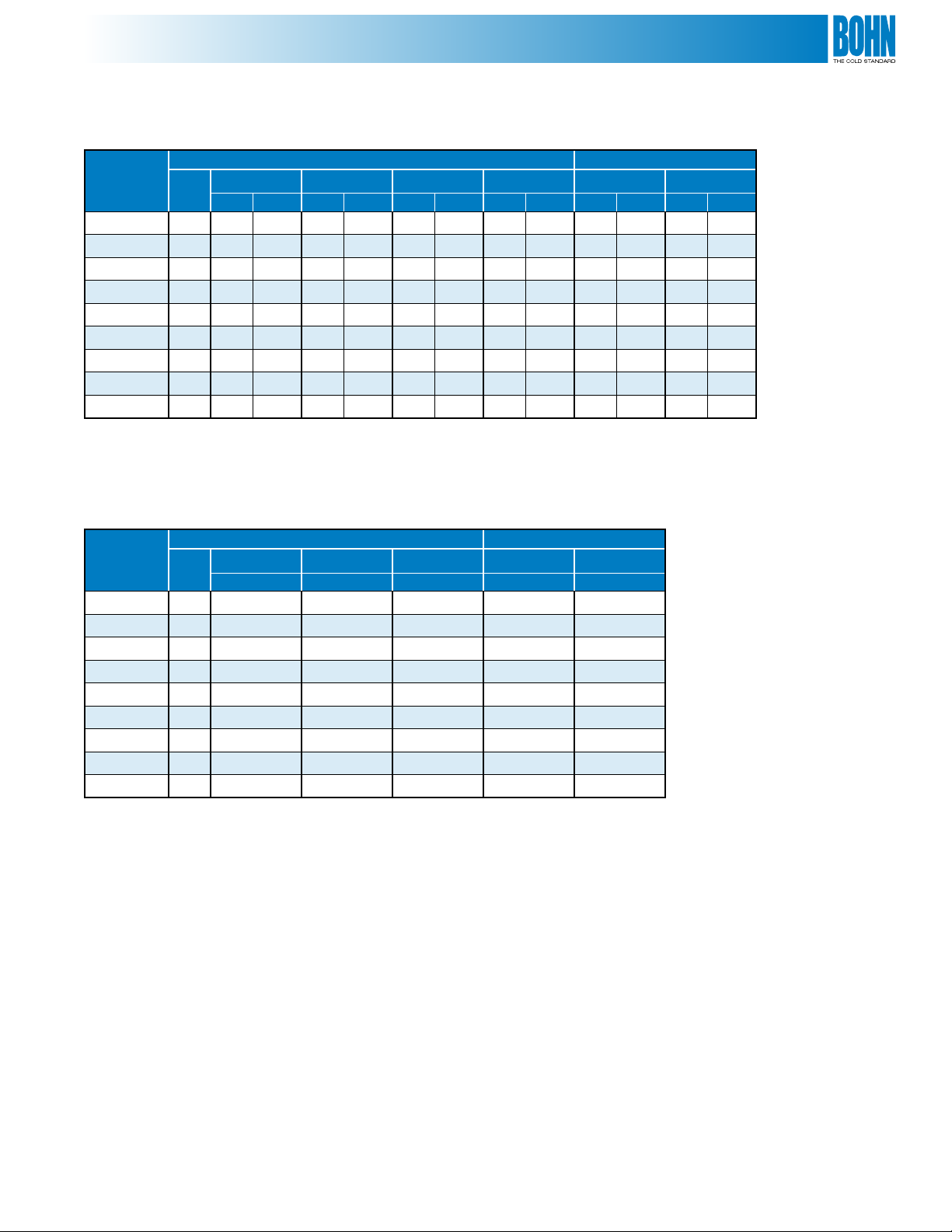

Model BMG/BMF Hot Gas Defrost | 60 Hz

PSC Motor EC Motor Drain Pan Heater (Std.)

Model

115/1/60

HP*

Amps Watts Amps Wat ts Amps Watts Amps Watts Amps Watts Amps Wat ts

208-

230/1/60

460/1/60

575/1/60

115/1/60

BMG190 1/4 8.0 550 3.6 550 2.0 550 1.4 620 5.6 420 2.8 410 950 8.3 4.1 2.1 1.7

BMG260 1/4 8.0 550 3.6 550 2.0 550 1.4 620 5.6 420 2.8 410 950 8.3 4.1 2.1 1.7

BMG310 1/4 12.0 825 5.4 825 3.0 825 2.1 930 8.4 630 4.2 615 1,350 11.7 5.9 2.9 2.3

BMG390 1/4 12.0 825 5.4 825 3.0 825 2.1 930 8.4 630 4.2 615 1,350 11.7 5.9 2.9 2.3

BMG430 1/4 16.0 1,100 7.2 1,100 4.0 1,100 2.8 1,240 11.2 840 5.6 820 1,800 15.7 7.8 3.9 3.1

6 Fins Per Inch

BMG520 1/4 16.0 1,100 7.2 1,100 4.0 1,100 2.8 1,240 11.2 840 5.6 820 1,800 15.7 7.8 3.9 3.1

BMF165 1/4 8.0 550 3.6 550 2.0 550 1.4 620 5.6 420 2.8 410 950 8.3 4.1 2.1 1.7

BMF220 1/4 8.0 550 3.6 550 2.0 550 1.4 620 5.6 420 2.8 410 950 8.3 4.1 2.1 1.7

BMF250 1/4 12.0 825 5.4 825 3.0 825 2.1 930 8.4 630 4.2 615 1,350 11.7 5.9 2.9 2.3

BMF330 1/4 12.0 825 5.4 825 3.0 825 2.1 930 8.4 630 4.2 615 1,350 11.7 5.9 2.9 2.3

BMF370 1/4 16.0 1,100 7.2 1,100 4.0 1,100 2.8 1,240 11.2 840 5.6 820 1,800 15.7 7.8 3.9 3.1

4 Fins Per Inch

BMF440 1/4 16.0 1,100 7.2 1,100 4.0 1,100 2.8 1,240 11.2 840 5.6 820 1,800 15.7 7.8 3.9 3.1

208-

230/1/60

Watts

115/1/60

208-

230/1/60

Total Amps

460/1/60 575/1/60

Model BMG/BMF Hot Gas Defrost | 50 Hz

PSC Motor EC Motor Drain Pan Heater (Std.)

Model

BMG190 1/4 3.6 2.0 2.8 860 3.9 1.7

BMG260 1/4 3.6 2.0 2.8 860 3.9 1.7

BMG310 1/4 5.4 3.0 4.2 1,230 5.6 2.4

BMG390 1/4 5.4 3.0 4.2 1,230 5.6 2.4

BMG430 1/4 7.2 4.0 5.6 1,650 7.5 3.2

6 Fins Per Inch

BMG520 1/4 7.2 4.0 5.6 1,650 7.5 3.2

BMF165 1/4 3.6 2.0 2.8 860 3.9 1.7

BMF220 1/4 3.6 2.0 2.8 860 3.9 1.7

BMF250 1/4 5.4 3.0 4.2 1,230 5.6 2.4

BMF330 1/4 5.4 3.0 4.2 1,230 5.6 2.4

BMF370 1/4 7.2 4.0 5.6 1,650 7.5 3.2

4 Fins Per Inch

BMF440 1/4 7.2 4.0 5.6 1,650 7.5 3.2

* 575/1/60 motors are 1/3 HP

220/1/50 380/1/50 220/1/50

HP

Amps Amps Amps

220/1/50 380/1/50

Watts

Total Amps

9

Page 10

Physical Data

Model BMA Air Defrost

No.

Model

BMA130 1 1/2 7/8 1/4 3/4 115 52

BMA155 1 1/2 1-1/8 1/4 3/4 123 56

BMA245 2 7/8 1-1/8 1/4 3/4 134 61

BMA300 2 7/8 1-1/8 1/4 3/4 148 67

BMA365 3 7/8 1-3/8 1/4 3/4 200 91

BMA450 3 1-1/8* 1-3/8 1/4 3/4 227 103

BMA510 4 1-1/8* 1-5/8 1/4 3/4 230 104

BMA600 4 1-1/8* 1-5/8 1/4 3/4 255 116

BMA710 5 1-1/8* 1-5/8 1/4 3/4 285 129

* Supplied with adapter to 7/8 ODF

of

Fans

Coil Inlet

ODF

Model BME/BML Electric Defrost

No.

Model

BME101 1 1/2 7/8 1/4 3/4 118 54

BME140 1 1/2 7/8 1/4 3/4 126 57

BME190 2 7/8 1-1/8 1/4 3/4 138 63

BME260 2 1-1/8* 1-3/8 1/4 3/4 153 69

BME310 3 1-1/8* 1-3/8 1/4 3/4 210 95

BME390 3 1-1/8* 1-3/8 1/4 3/4 237 108

6 Fins Per Inch

BME430 4 1-1/8* 1-5/8 1/4 3/4 267 121

BME520 4 1-1/8* 1-5/8 1/4 3/4 300 136

BME620 5 1-1/8* 1-5/8 1/4 3/4 338 153

BML100 1 1/2 7/8 1/4 3/4 125 56

BML165 2 7/8 1-1/8 1/4 3/4 136 62

BML220 2 1-1/8* 1-3/8 1/4 3/4 151 68

BML250 3 1-1/8* 1-3/8 1/4 3/4 207 94

BML330 3 1-1/8* 1-3/8 1/4 3/4 234 106

BML370 4 1-1/8* 1-5/8 1/4 3/4 262 119

4 Fins Per Inch

BML440 4 1-1/8* 1-5/8 1/4 3/4 295 134

BML530 5 1-1/8* 1-5/8 1/4 3/4 332 151

* Supplied with adapter to 7/8 ODF

of

Fans

Coil Inlet

ODF

Connections (in.) Approx. Net Weight

Suction

ODF

Suction

ODF

External Equalizer

ODF

Connections (in.) Approx. Net Weight

External Equalizer

ODF

Drain

FPT

Drain

FPT

lbs. kg

lbs. kg

10

Page 11

Physical Data

Model BMG/BMF Hot Gas Defrost

No.

Model

BMG190 2 1-1/8* 1-1/8 1/4 3/4 5/8 7/8 175 79

BMG260 2 1-1/8* 1-3/8 1/4 3/4 5/8 7/8 190 86

BMG310 3 1-1/8* 1-3/8 1/4 3/4 5/8 7/8 210 95

BMG390 3 1-1/8* 1-3/8 1/4 3/4 5/8 7/8 237 108

BMG430 4 1-1/8* 1-5/8 1/4 3/4 5/8 7/8 267 121

6 Fins Per Inch

BMG520 4 1-1/8* 1-5/8 1/4 3/4 5/8 7/8 300 136

BMF165 2 1-1/8* 1-1/8 1/4 3/4 5/8 7/8 173 78

BMF220 2 1-1/8* 1-3/8 1/4 3/4 5/8 7/8 188 85

BMF250 3 1-1/8* 1-3/8 1/4 3/4 5/8 7/8 207 94

BMF330 3 1-1/8* 1-3/8 1/4 3/4 5/8 7/8 234 106

BMF370 4 1-1/8* 1-5/8 1/4 3/4 5/8 7/8 262 119

4 Fins Per Inch

BMF440 4 1-1/8* 1-5/8 1/4 3/4 5/8 7/8 295 134

* Supplied with adapter to 7/8 ODF

** Supplied with electric drain pan heater as standard, hot gas pan is optional

of

Fans

Coil Inlet

ODF

Suction

ODF

Connections (in.)

External

Equalizer

ODF

Drain

FPT

Side Port

ODF

Hot Gas

Pan Conns.**

ODF

Approx.

Net Weight

lbs. kg

11

Page 12

Dimensional Data

22-3/4"

578 mm

15-1/2"

390 mm

23 -1/4"

590 mm

2-1/2"

64 mm

24"

608 mm

18-7/8"

480 mm

17-1/2"

444 mm

Electrical

Connection

End

Refrigerant

Connection

End

Air

Flow

All Models Dimensions

All Models Dimensional Data

6 FPI Models 4 FPI Models Dimensions

Model

BMA130 BME101

BMA155 BME140

BMA245 BME190

BMA300 BME260

BMA365 BME310

BMA450 BME390

BMA510 BME430

BMA600 BME520

BMA710 BME620

NOTE: Evaporator mounting brackets accept up to 1/2" hanger rod

Defrosts Defrosts A B C D E F

Elec.

Hot

Gas

-

-

BMG190

BMG260

BMG310

BMG390

BMG430

BMG520

-

Elec.

BML100 - 39-5/16 1,000 30-1/4 770 - - - - - - 4-15/16 125

BML165 BMF165 67-5/16 1,710 58-1/4 1,480 - - - - - - 4-15/16 125

BML220 BMF220 67-5/16 1,710 58-1/4 1,480 - - - - - - 4-15/16 125

BML250 BMF250 95-5/16 2,420 86-1/4 2,190 - - - - - - 4-15/16 125

BML330 BMF330 95-5/16 2,420 86-1/4 2,190 - - - - - - 4-15/16 125

BML370 BMF370 123-5/16 3,130 114-1/4 2,900 56 1,420 58-1/4 1,480 - - 4-15/16 125

BML440 BMF440 123-5/16 3,130 114-1/4 2,900 56 1,420 58-1/4 1,480 - - 4-15/16 125

BML530 - 138-13/16 3,530 129-3/4 3,300 51 1,300 53-1/4 1,350 25-1/2 650 4-15/16 125

Hot

Gas

- - 39-5/16 1,000 30-1/4 770 - - - - - - 4-15/16 125

in. mm in. mm in. mm in. mm in. mm in. mm

12

Page 13

Replacement Parts

Commercial Refrigeration Parts

Right source. Right parts. Right now.

InterLink™ is your link to a complete line of dependable and

certied commercial refrigeration parts, accessories and

innovative electronic controls for all Bohn equipment. At

InterLink, we provide our wholesalers with a comprehensive

selection of product solutions and innovative technologies

for the installed customer base. And every product is built

to ensure the same high performance standards with which

all Heatcraft Refrigeration Products (HRP) brands are built

— backed by a dedicated team to serve every customer

need, delivering at the best lead times in the industry.

Dependable. Versatile. Courteous.

Finally, one simple source for all your replacement needs

from a name you can trust.

For parts, please contact (800) 686-7278 or

visit www.interlinkparts.com.

Motor/Fan/Blade/Guards

Part # Description

5020-S Motor 115V

5020-T Motor 208-230V

4567-T Motor 208-230V Totally Enclosed

25302201 Motor 460V

25304601* Motor 460V Low Temp Totally Enclosed

25308101* Motor 208-230V Low Temp Totally Enclosed

5599-M

5779-G

22511601 Run Capacitor (7.5 MFD) - Used with 25399301

25399301 Motor 575V

5064-E Motor Mount

5130-C Fan Blade

4339-X Fan Guard Molded with Logo

5063-E Fan Guard Beige Wire

* Special motors to be used in room ambients -31°F to -50°F

Cabinet Components

Part # Description No. of Fans

40491902 Drain Pan* 1

40492102 Drain Pan* 2

40492302 Drain Pan* 3

40492502 Drain Pan* 4

40492702 Drain Pan* 5

40830101 Header Side Panel 1-5

40830201 Electrical Side Panel 1-5

40830901 Header Connection Panel 1-5

92864003 Drain Fitting 1-5

* Includes provision to mount drain pan heater

Run Capacitor (5 MFD) - Used with most PSC Motors

Run Capacitor (7.5 MFD) - Used with 25304601

Motor Only

Electrical Components

Part # Description

2891040 Room Thermostat

5709-L

2890109

5708-L Heater Limit Thermostat

NOTE: Contact factory for hot gas defrost components not listed

Defrost Term. / Fan Delay Thermostat Sealed

Bimetal Type

Defrost Term. / Fan Delay Thermostat

Adjustable Type

Drain Pan Defrost Heater (1 per unit)

Part # Description Voltage Color Code

24710301 1 Fan Unit, 530W 208-230V Black

24710302 2 Fan Unit, 950W 208-230V Black

24710303 3 Fan Unit, 1350W 208-230V Black

24710304 4 Fan Unit, 1800W 208-230V Black

24710305 5 Fan Unit, 2000W 208-230V Black

24710401 1 Fan Unit, 530W 460V Red

24710402 2 Fan Unit, 950W 460V Red

24710403 3 Fan Unit, 1350W 460V Red

24710404 4 Fan Unit, 1800W 460V Red

24710405 5 Fan Unit, 2000W 460V Red

24710502 2 Fan Unit, 950W 115V Black, White

24710503 3 Fan Unit, 1350W 115V Black, White

24710504 4 Fan Unit, 1800W 115V Black, White

24710901 1 Fan Unit, 530W 575V Black, Red

24710902 2 Fan Unit, 950W 575V Black, Red

24710903 3 Fan Unit, 1350W 575V Black, Red

24710904 4 Fan Unit, 1800W 575V Black, Red

24710905 5 Fan Unit, 2000W 575V Black, Red

Coil Defrost Heaters (4 per unit)

Part # Description Voltage

24710201 1 Fan Unit, 550W 230-460V

24710202 2 Fan Unit, 1100W 230-460V

24710203 3 Fan Unit, 1600W 230-460V

24710204 4 Fan Unit, 2100W 230-460V

24710205 5 Fan Unit, 2400W 230-460V

24711101 1 Fan Unit, 550W 575V

24711102 2 Fan Unit, 1100W 575V

24711103 3 Fan Unit, 1600W 575V

24711104 4 Fan Unit, 2100W 575V

24711105 5 Fan Unit, 2400W 575V

23308001 Heater Clip (1-3 fans) 23308101 Heater Clip (4-5 fans) -

13

Page 14

Nozzle Selection

Model BMA Air Defrost

Model

BMA130 1 3/16 21-1/2 3 L-1 L-3/4

BMA155 1 3/16 21-1/2 5 L-1 L-3/4

BMA245 2 3/16 21-1/2 9 G-2-1/2 G-1-1/2

BMA300 2 3/16 21-1/2 9 G-2-1/2 G-1-1/2

BMA365 3 3/16 21-1/2 9 G-3 G-2

BMA450 3 3/16 21-1/2 12 E-4 E-2-1/2

BMA510 4 3/16 21-1/2 13 E-5 E-3

BMA600 4 3/16 21-1/2 18 E-5 E-3

BMA710 5 3/16 21-1/2 18 E-6 E-4

No. of

Fans

Model BME/BML Electric Defrost

Model

BME101 1 3/16 21-1/2 5 L-1-1/2 L-3/4

BME140 1 3/16 21-1/2 6 L-1-1/2 L-1

BME190 2 3/16 21-1/2 9 G-2-1/2 G-1-1/2

BME260 2 3/16 21-1/2 12 E-3 E-2

BME310 3 3/16 21-1/2 13 E-4 E-2-1/2

BME390 3 3/16 21-1/2 18 E-5 E-3

BME430 4 3/16 21-1/2 12 E-5 E-3

6 Fins Per Inch

BME520 4 3/16 21-1/2 17 E-6 E-4

BME620 5 3/16 21-1/2 17 E-8 E-5

BML100 1 3/16 21-1/2 6 L-1-1/2 L-1

BML165 2 3/16 21-1/2 9 G-2-1/2 G-1-1/2

BML220 2 3/16 21-1/2 12 E-3 E-2

BML250 3 3/16 21-1/2 13 E-4 E-2-1/2

BML330 3 3/16 21-1/2 18 E-5 E-3

BML370 4 3/16 21-1/2 12 E-5 E-3

4 Fins Per Inch

BML440 4 3/16 21-1/2 17 E-6 E-4

BML530 5 3/16 21-1/2 17 E-8 E-5

No. of

Fans

Distributor Tube (in.)

OD Length

Distributor Tube (in.)

OD Length

No. of Circuits

No. of

Circuits

R-404A*

Nozzle

R-404A*

Nozzle

R-22

Nozzle

R-22

Nozzle

Model BMG/BMF Hot Gas Defrost

Model

BMG190 2 1/4 21-1/2 9 E-3 E-1-1/2

BMG260 2 1/4 21-1/2 12 E-4 E-2-1/2

BMG310 3 3/16 21-1/2 13 E-4 E-2-1/2

BMG390 3 3/16 21-1/2 18 E-5 E-3

BMG430 4 3/16 21-1/2 13 E-5 E-3

6 Fins Per Inch

BMG520 4 3/16 21-1/2 18 E-6 E-4

BMF165 2 1/4 21-1/2 9 E-3 E-1-1/2

BMF220 2 1/4 21-1/2 12 E-4 E-2-1/2

BMF250 3 3/16 21-1/2 13 E-4 E-2-1/2

BMF330 3 3/16 21-1/2 18 E-5 E-3

BMF370 4 3/16 21-1/2 13 E-5 E-3

6 Fins Per Inch

BMF440 4 3/16 21-1/2 18 E-6 E-4

*Also suitable for R-507, R-502, R-134A, R-401A, R-402A

Nozzles sized for 90° - 100°F liquid temp. at expansion valve. Refer to manual H-IM-64 if liquid temp. is not 90° - 100°F

Consult Bohn Application Engineering if evaporator TD is not 10° - 15ºF, (room temp. - saturated suction temp.)

No. of

Fans

Caution: Refrigeration system will not perform properly without Correct Nozzle!

14

Distributor Tube (in.)

OD Length

No. of

Circuits

R-404A*

Nozzle

Nozzle

R-22

Page 15

Notes

15

Page 16

For more information on Bohn refrigeration products, contact

your Sales Representative or visit us at www.thecoldstandard.com.

A Brand of Heatcraft Refrigeration Products LLC

2175 West Park Place Blvd. • Stone Mountain, GA • 30087

800.537.7775 • FAX 770.465.5990

www.thecoldstandard.com

Since product improvement is a continuing eort, we reserve the right to

make changes in specications without notice.

BN-MPTB-0408 | Version 000

Loading...

Loading...