Boge base control Operating Instructions Manual

Operating Instructions

base control

for Scroll Compressors

Operating Instructions

base

control

for Scroll Compressors

BOGE KOMPRESSOREN

Otto Boge GmbH & Co. KG

Postfach 10 07 13

33507 Bielefeld

Otto-Boge-Straße 1-7

33739 Bielefeld

Tel: +49-520-660-10

Fax: +49-520-660-1200

Email: info@boge.com

Web: www.boge.com

Version: 11 / 2016

No. 596.1454.18

Nominal price: €5.00

BOGE base control for scroll compressors Page I

Table of Contents

Table of Contents

Part 1: About these Operating Instructions

Part 2: Safety

1.1 Who are these Operating Instructions aimed at?........................ 1

1.2 Content of these Instructions........................................................ 1

1.3 Other Important Documents .......................................................... 2

1.4 Guide for Reading........................................................................... 2

Symbols and Typographic Aids ........................................................ 2

Structure of Warning Notices............................................................ 3

2.1 General Safety Information............................................................ 5

Prior to Commissioning and Operation............................................. 5

Intended Use .................................................................................... 5

Reasonably Foreseeable Misuse ..................................................... 5

2.2 Special Safety Information............................................................. 6

Switch Cabinet.................................................................................. 6

Emergency Stop Function / Main Switch .......................................... 6

Changing Parameters / Settings....................................................... 7

Data Security .................................................................................... 7

Damage to the Control Unit .............................................................. 7

2.3 Operator and Personnel................................................................. 7

Personnel Requirements .................................................................. 7

Obligations of the Operator............................................................... 8

Obligations of Personnel................................................................... 8

Part 3: Layout and Function

BOGE base control for scroll compressors Page III

3.1 Operating Principle of the Control ................................................ 9

Basic Tasks of the Control................................................................ 9

Use as a Lower-level Control in the Compressor Network ............... 9

3.2 Layout of the Control Unit ........................................................... 10

LCD Display (1) .............................................................................. 11

"Fault" and "Ready" Indicator Lamps (2 and 3) .............................. 11

Info and Enter Keys (4 and 5)......................................................... 11

On and Off Keys (6 and 7).............................................................. 12

Table of Contents

Part 4: Display and Operation

Part 5: Setting Parameters

Part 6: Troubleshooting

4.1 Description of Display Symbols .................................................. 13

4.2 Description of the Displays and Navigation............................... 14

Main Display ................................................................................... 14

Additional Displays ......................................................................... 16

5.1 Unlocking Code-protected Parameters ...................................... 19

5.2 Changing Individual Parameters................................................. 20

Parameter Codes............................................................................ 20

Compressor Servicing Interval: Restart the Counter / Change the Start

Value............................................................................................... 20

Motor Servicing Interval: Restart the Counter / Change the Start Value

21

Change Target Pressure Values (p

Activating / Deactivating the Auto-Restart Function ....................... 23

Activating / Deactivating the External Output Release ................... 25

Performing Leakage Measurement (without code release) ............ 27

6.1 Message Types ............................................................................. 31

6.2 Processing Messages .................................................................. 31

max

and p

) ........................... 22

min

Part 7: Servicing

6.3 List / Meaning of Message Codes ............................................... 32

6.4 Acknowledging Messages ........................................................... 33

7.1 Cleaning the Display .................................................................... 35

7.2 Updating the Software.................................................................. 35

Page IV BOGE base control for scroll compressors

About these Operating Instructions

1.1 Who are these Operating Instructions aimed at?

Part 1: About these Operating Instructions

1.1 Who are these Operating Instructions aimed at?

These operating instructions are aimed at end customers of BOGE who have

purchased a scroll compressor and wish to operate it using the compressor

base control.

In addition to reading these instructions, the user must meet the following prerequisites in order to ensure professional operation of the control. S/he must:

– have an understanding of the compressor

– have an understanding of the accompanying operating instructions

– be classified as qualified personnel or trained personnel with technical

background knowledge in the field of compressed air technology (see also

"Personnel Requirements", page 7).

1.2 Content of these Instructions

These operating instructions deal exclusively with the functionality, operation

and parametrization of the base control.

The following content and work descriptions do not form part of these operating instructions:

– All safety information on the compressor. This is part of the compressor

operating instructions.

– Work such as electrical commissioning or repairs to the control.

– Work on the control that requires the switch cabinet to be opened, for

example installing updates.

– Work on the compressor and its accessories (e.g. installation or commis-

sioning).

The above-mentioned work must only be carried out by an authorized, qualified electrician or BOGE Service personnel.

BOGE recommends having the control, compressor and accessories set up

and commissioned by BOGE Service personnel. Maintenance and repair work

on the control should also be carried out by BOGE Service personnel.

Should you have any questions about this product, please contact

Product Support on:

Telephone: +49-520-660-1140

If you require Service assistance, please contact BOGE Service on:

Telephone: +49-520-660-1100

BOGE base control for scroll compressors Page 1

About these Operating Instructions

1.3 Other Important Documents

1.3 Other Important Documents

The following documents are required for any work not described in these

operating instructions:

– the compressor operating instructions;

– the operating instructions for the connected accessories.

Pay particular attention to the safety information in this document!

The following pages contain a guide for reading these instructions as well as

information on the design of warning notices.

1.4 Guide for Reading

These operating instructions are designed to help you to operate the compressor control quickly and easily.

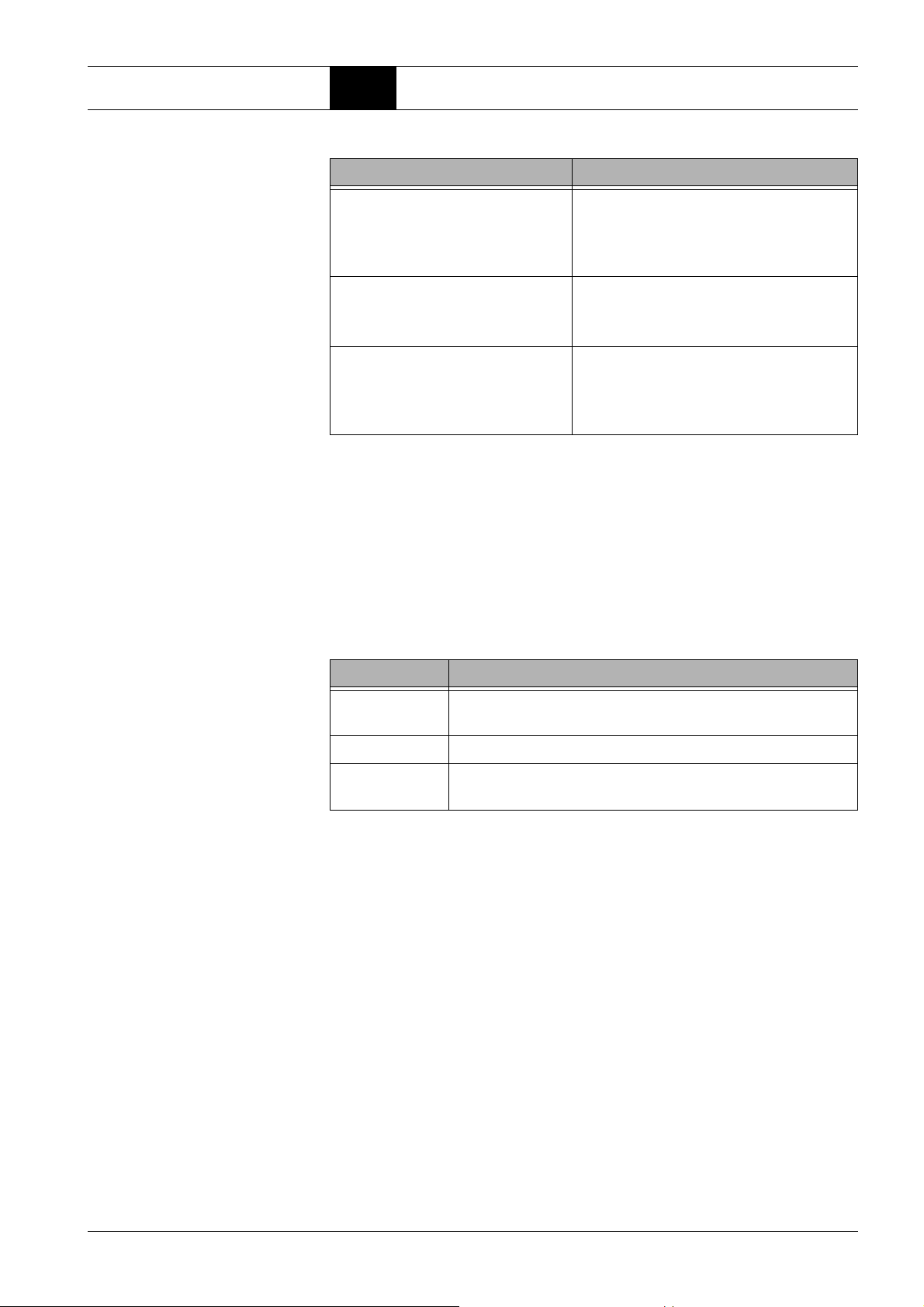

Symbols and Typographic Aids

The following table contains an overview of all the symbols and typographic

aids used to simplify the content:

Symbol

– Information 1

– Information 2

– Information 3

● Action Directions for Use I

Meaning

Setup Mode

In this area, settings can only be

changed if a code has been issued.

Tips and additional information on

optimum operation

Tips and information that help you

to use the control in an optimum

manner are indicated by the symbol

shown.

List

Important information is listed clearly.

Directions for use with one action are

indicated by the symbol shown.

Page 2 BOGE base control for scroll compressors

About these Operating Instructions

1.4 Guide for Reading

Structure of Warning Notices

Symbol

1. Action 1

2. Action 2

3. Action 3

Result of action Result

(1)

(2)

(3)

Tab. 1.1: Overview of all design elements that simplify the content of these

instructions

The warning notices in these instructions indicate dangers that may occur

when carrying out certain tasks. They also indicate how a dangerous situation

can be avoided. Warning notices follow a fixed structure which is described

below.

Signal Words

The following signal words are used:

Meaning

Directions for Use II

Directions for use with several actions

are numbered and must be carried out

in the specified sequence.

The outcome that will follow an action is indicated by the arrow shown.

Screenshots

The screenshots of the operating unit

display may be divided into areas.

The individual areas are numbered.

Signal Word Meaning

WARNING Warns of dangers to persons that could lead to serious

injury or death.

CAUTION Warns of property damage and data loss

NOTE Warns of faults in the operating sequence /

communication

Tab. 1.2: Signal words

BOGE base control for scroll compressors Page 3

About these Operating Instructions

1.4 Guide for Reading

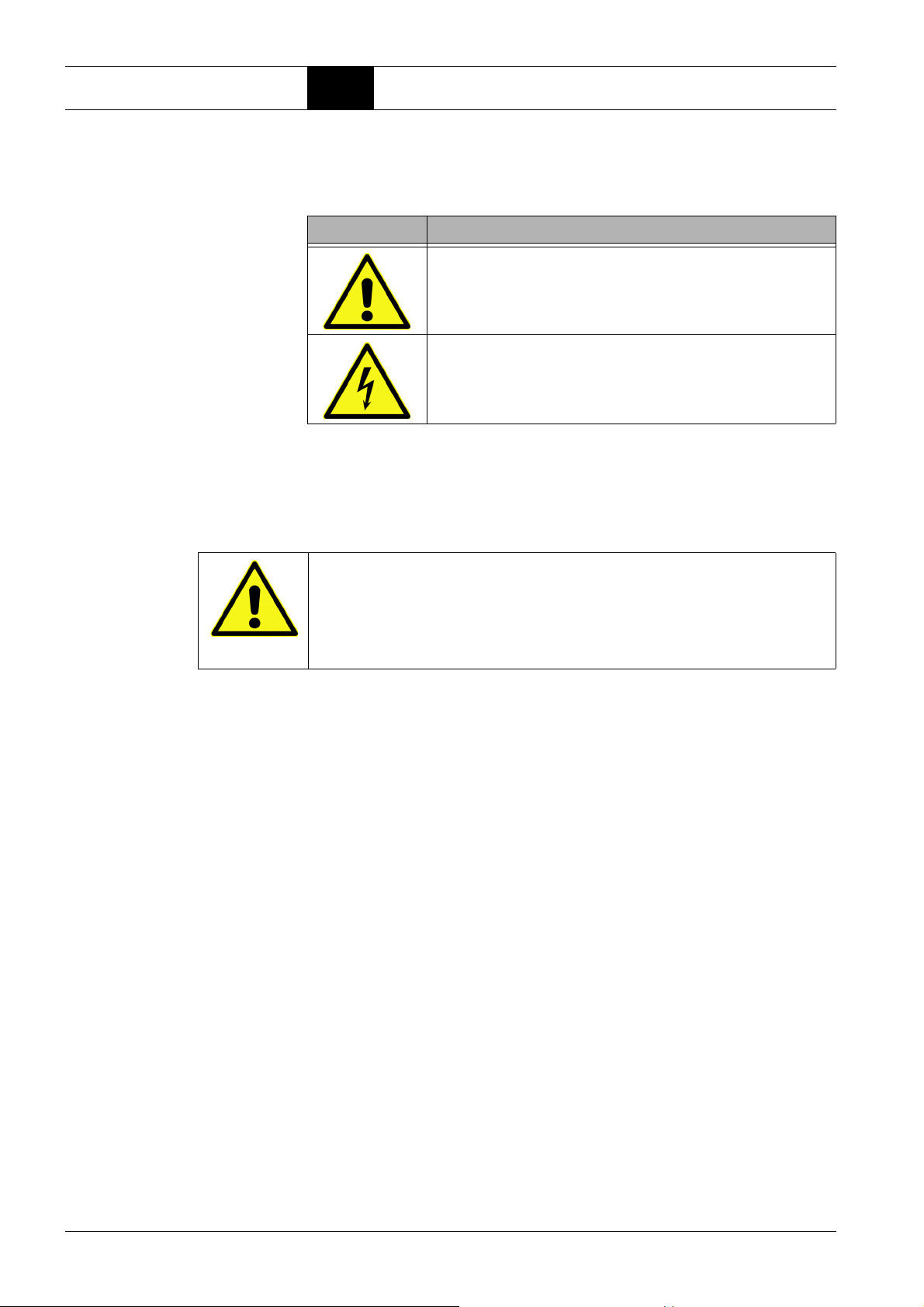

Warning Signs

The following warning signs are used:

Warning Sign Meaning

Warns of a hazardous area

Warns of life-threatening electrical voltage

Tab. 1.3: Warning signs

Design of Warning Notices

Warning notices are a combination of signal words, warning signs and information. They are structured as follows:

SIGNAL WORD

Type of Danger

Source of the danger and consequences if the warning notice is not observed.

How to avoid the danger.

Page 4 BOGE base control for scroll compressors

Safety 2.1 General Safety Information

Part 2: Safety 2.1 General Safety Information

Prior to Commissioning and Operation

Intended Use

Reasonably Foreseeable Misuse

The following must be observed prior to commissioning and operation of the

base control:

– These instructions must be read thoroughly and understood before com-

missioning / operating the control.

– These instructions must be available at all times at the place of operation

of the control.

– Changes to parameters and settings may only be carried out by authorized,

qualified personnel, see also "Personnel Requirements".

– Work on the control that requires the switch cabinet to be opened may only

be carried out by an authorized, qualified electrician, see also "Personnel

Requirements".

– Prior to initial commissioning of the control unit, check for visible transport

damage.

– Damage to the control that affects safe operation of the machine must be

rectified immediately.

The control is intended exclusively for the correct operation of a BOGE scroll

compressor and its connected accessories.

The control is not suitable for use with other types of compressed air generators or compressors from other manufacturers.

BOGE base control for scroll compressors Page 5

Safety 2.2 Special Safety Information

2.2 Special Safety Information

Switch Cabinet

Emergency Stop Function / Main Switch

The control is housed in a switch cabinet.

The control unit of the control can be found at the front of the switch cabinet.

The control may only be operated via the control unit when the switch cabinet

is closed.

WARNING

Risk of Electric Shock

Live parts are located inside the switch cabinet. There is a risk of electric

shock when the switch cabinet is opened.

Never open the switch cabinet during operation.

Only operate the control when the switch cabinet is closed.

The switch cabinet may only be opened by an authorized and qualified

electrician.

Please note that only settings that can be applied via the control unit of the

control may be changed using these operating instructions.

The emergency stop function serves to avert or prevent a prevailing emergency situation, where such a situation is the result of conduct by individuals

or an event posing an unexpected danger.

The emergency stop function is provided through the main switch. When the

main switch with emergency stop function is pressed, compressor operation

stops immediately and the switch cabinet and control are no longer live.

Dangerous voltage may still be present on the supply terminals even though

the machine is disconnected from the grid.

The main switch is not located on the control unit of the base control; it is instead in a highly visible location on the front of the scroll compressor housing.

Please note:

– Press the main switch to avoid or prevent an emergency situation.

– In normal operation the Off key should be pressed on the control to prop-

erly shut down the compressor.

– In addition, always press the main switch when carrying out inspections

or work on the compressor or switch cabinet.

Page 6 BOGE base control for scroll compressors

Safety 2.3 Operator and Personnel

Changing Parameters / Settings

Data Security

Damage to the Control Unit

The control regulates the compressor using specific parameters / settings.

The individual parameters represent the values that can be used to change

the compressor functions (e.g. switch-on and switch-off pressure) so that the

compressor generates compressed air as required. However, incorrect settings can also lead to operational faults or destruction of the compressor.

CAUTION

Compressor Damage

Changing parameters / operational settings that have an effect on the operation or function of the compressor may damage or destroy the compressor.

Only authorized, qualified personnel may make changes to parameters

or settings.

If in doubt regarding a change to operational settings, contact BOGE

Service.

The base control automatically stores all data – e.g. altered settings – in the

non-volatile memory. The saved data are therefore also available in the event

of a power failure.

All keys on the control unit are operated by tapping on them with a finger. Light

tapping on the interface is sufficient to actuate the keys. Do not use any sharp

or abrasive objects when operating the control unit. BOGE accepts no liability

for damage resulting from improper use.

Personnel Requirements

2.3 Operator and Personnel

Only individuals who are able to carry out the work correctly and reliably and

who meet the following requirements may perform work on the control:

Trained Personnel

Trained personnel are individuals who have been informed in detail by the

operator of the potential dangers concerning the tasks assigned to them and

for whom this training has been documented.

Qualified Personnel

Qualified personnel are individuals who are able to successfully carry out work

assigned to them, recognize potential dangers independently and avoid injury

to individuals or property due to their professional training, knowledge and

experience as well as their knowledge of the relevant regulations.

BOGE base control for scroll compressors Page 7

Safety 2.3 Operator and Personnel

Qualified Electricians

Qualified electricians are individuals who are able to successfully carry out

work assigned to them, recognize potential dangers independently and avoid

injury to individuals or property due to their qualifications, knowledge and experience as well as their knowledge of the relevant regulations.

Prior to descriptions of work requiring specialist knowledge, the requirements that the individual must fulfill in order to be able to carry out the work

described are clearly stated.

Obligations of the Operator

Obligations of Personnel

The operator is subject to the legal obligations concerning occupational safety

and must be familiar with the applicable occupational health and safety regulations. In addition:

– The operator must authorize qualified electricians to carry out work on the

switch cabinet.

– The operator may only provide the key to the switch cabinet to a qualified

electrician who is authorized to carry out work on the switch cabinet.

– The operator must authorize qualified personnel to change parameters or

settings on the control.

Personnel are subject to the legal obligations concerning occupational safety

and must be familiar with the applicable occupational health and safety regulations. In addition:

– Personnel must have read these instructions thoroughly before commis-

sioning / operating the control.

– The same applies to the instructions for the compressor and accessories.

– For all work requiring specific qualifications, personnel must be authorized

by the operator to carry out such work in line with these instructions.

Page 8 BOGE base control for scroll compressors

Loading...

Loading...