Bock Water heaters 32PPC, 51EC, 50ES, 32E, 50ESC User Manual

...

TO THE INSTALLER:

Please attach these in-

structions next to the

w

ater heater.

TO THE CONSUMER:

Read these and all com-

ponent instructions.

Please keep for future

reference. Please remember to return the

registration card.

Waranty, registration

card & parts list included.

INSTALLATION, OPERATION &

MAINTENANCE INSTRUCTIONS

BOCK RESIDENTIAL OIL-FIRED

WATER HEATERS

Model numbers: 20e, 20pp, 32E, 32EC, 32PP,

32PPC, 33E, 33PP, 40E, 40PP, 50ES, 50ESC,

51E, 51EC, 51PP, 51PPC, 71E, 120E

WARNING:

Improper installation, adjustment, alteration, service

or maintenance can cause serious injury or property damage. Refer to this manual. For assistance

or additional information, consult a qualified installer

or service agency.

WARNING:

If the information in these instructions is not followed exactly, fire or explosion may result and can

cause property damage, personal injury or death.

WARNING:

Follow minimum combustible clearance as noted

on water heater label. Do not install on combustible

flooring (see Figure 2, Page 3). Install in accordance with all local codes. In the absence of local

codes, refer to NFPA 31 or ANSI Z21.10.1.

CAUTION:

The recommended temperature for normal residen-

The dial on the aquastat does not

.

F

tial use is 120

always reflect the outcoming water temperature,

which could occasionally exceed 120

tion in outcoming temperature could be based on

factors including but not limited to usage patterns

and type of installation. Test your water at the tap

nearest to the water heater. (See page 5 for measuring the outcoming water temperature).

°

The varia

.

F

°

ARNING:

W

Hotter water increases the risk of scald injury. Before changing the temperature setting, read the

instruction manual. Temperatures at which injury occurs vary with the individual’s age and length of

exposure.

The slower reaction times of children, elderly and

physically or mentally impaired persons increases

the scalding hazard to them. It is recommended lower

water temperatures be used where these situations

exist.

Households with small children or invalids may require a temperature setting less than 120°F to prevent

accidental contact with hot water

To lower water temperature use point-of-use temperature limiting devices.

WARNING:

Flammable vapors may be drawn to this water heat

from other areas of the structure by air currents.

er

Do not store or use any flammable liquids in the

vicinity of this heater.

-

WARNING:

Water heater blankets may restrict air flow to the

heater and cause fire, asphyxiation, personal injury

or death.

.

-

Bock Water Heaters, Inc.

110 South Dickinson Street • P.O. Box 8632 • Madison, WI 53708-8632

Phone: 608/257-2225 • Fax: 608/257-5304 • www.bockwaterheaters.com

CONSUMER

RESPONSIBILITIES

THIS MANUAL HAS BEEN PREPARED TO ACQUAINT YOU WITH THE INSTALLATION, OPERATION, AND MAINTENANCE OF YOUR WATER HEATER AND

T

O PROVIDE IMPORTANT SAFETY INFORMATION.

FAILURE TO FOLLOW

THESE INSTRUCTIONS

OR ALL APPLICABLE

BUILDING CODES AND

REGULATIONS VOIDS

HE WARRANTY ON THIS

T

WATER HEATER.

MULTIPLE BURNER

INSTALLATION

Read all instructions thoroughly before attempting installation or operation of the

water heater. Keep these and all component instructions for future reference.

The manufacturer of this water heater will not be liable for any damages caused

by failure to comply with the installation and operating instructions outlined on the

following pages. These instructions are a guide for the correct installation of the

water heater.

If the installer lacks the necessary skills or has difficulty following the

directions, do not proceed but get help from a qualified person for that part of the

installation that is not understood.

Local plumbing and electrical codes must be followed in the installation of this

water heater. In the absence of a local code use the UNIFORM PLUMBING

CODE and the NFPA Code. Local codes may supersede instructions in this installation manual.

When two or more burners are used, each unit should have a separate

supply line to the fuel pump to prevent nuisance lockouts caused by one or both

pumps starving for oil. If this is not possible, the use of a priority

control is recommended.

Check new equipment to see if all components are in good condition.

The water heater and oil burner may be shipped as separate units. The aquastat

and immersion well may be packed with the oil burner

.

SELECT THE RIGHT

LOCATION

Check for exhaust fans in

the heater room or adjacent areas which draw

combustion air away from

.

heater

MUST HAVE COMBUSTION AIR TO OPERATE.

THE HEA

TER

The new water heater requires fuel (#I or #2 heating oil), electricity and should be

close to the chimney and water supply. Locate the heater near a floor drain if pos

sible for easy maintenance and protection if trouble should occur

. Allow ample

space around the heater for servicing (see combustible clearance warning, page

1). Adequate air for combustion must be available. NOTE: Locate the heater so it

is not subject to physical damage by moving vehicles or possible flooding.

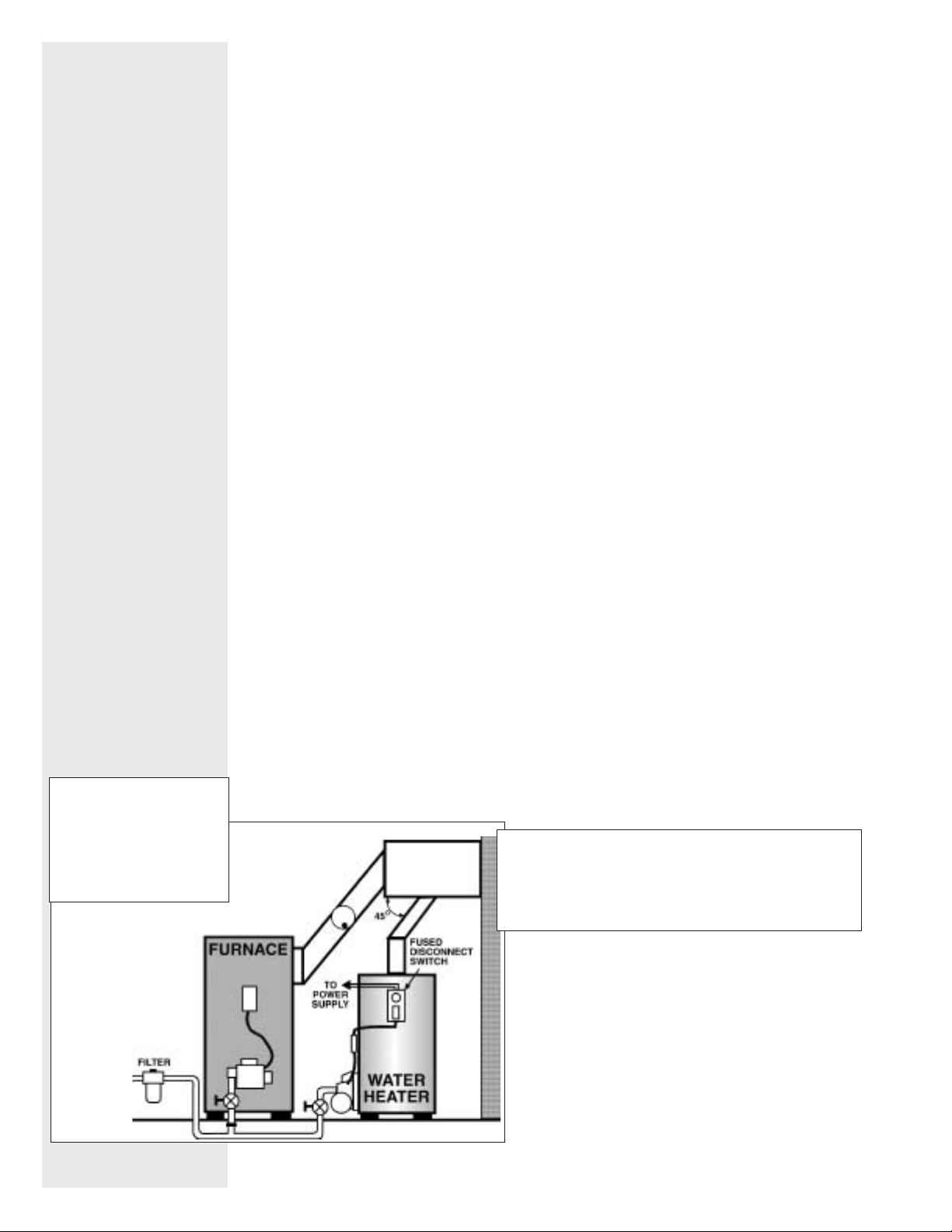

FIGURE 1

TER HEA

WHEN THE W

BINED APPLIANCE

CONTACT THE LOCAL DISTRIBUTOR OR THE FACTORY FOR INSTALLATION INSTRUCTIONS ON

“SYSTEM PLUS”.

DO NOT INSTALL THE WATER HEATER ON COMBUSTIBLE FLOORING (see Figure 2).

contact Bock Water Heaters with questions concerning proper flooring materials.

Minimum clearance to combustible construction is:

SIDES 6"; BACK 6"; FRONT 24". The installation of

this water heater must conform with local codes and

ordinances. In the absence of local codes, the installation must comply with the National Fire Protection

Association (NFP

A

TER IS USED IN A

APPLICATION, PLEASE

Refer to NFP

A 31) Code.

COM-

A

-

31 or

– 2 –

CONNECT WATER

PIPING

Connect the water piping, being careful not to apply heat to the heater

nipples. Install dielectric unions and shut off valves on both hot and cold water

l

ines.

Hot water outlet

(“HOT”) is on tank

top. Cold water inlet

is on right front

bottom of 33E and

40E. On all other

models, cold water

inlet is on tank top.

The 40E and all “C” models (example: 32EC, 51PPC) have a 1” NPT tapping located on the front left side of the tank. This is an alternate outlet for use with combined

appliance applications. If this fitting is not used, plug it with a fitting suitable for

potable water.

A 1” NPT fitting is also located behind the drain valve on the 40E and all

“C” models. This is for use as an alternate inlet or a combined appliance return.

Your heater is shipped with a reducer in this location to mount

the drain valve.

NOTE: INDEX MARK ON INLET BUSING MUST

OINT TOWARD ARROW ON DECAL. HOLD

P

USHING OR NIPPLE WHEN TIGHTENING

B

INLET

FITTINGS. ROTATING BUSHING COULD DRASTI-

ALLY REDUCE PERFORMANCE.

C

INDEX MARK

INLET BUSHING

The 33E and 40E models are equipped with a

brass inlet bushing installed in the tank. Heat-

equipped with this bushing are marked next

ers

to the inlet by the decal shown on the left. The

purpose of this bushing is to help keep the tank

bottom free of sediment by aiding tank flushing.

This bushing must be located as shown on the

decal to function properly. Do not allow the bushing to rotate out of position when tightening the

inlet fittings. In installations requiring high flow

rates, contact the factory.

The drain valve fitting may be used as an alternate cold water inlet on heaters

equipped with a dip tube, as shown in Figure 3. By plumbing a “T” into the drain

fitting, the cold water inlet can be relocated to this point. The dip tube

must be

removed and its fitting plugged. Figure 3 also shows a copper loop heat trap

installed on the hot water outlet to reduce standby losses.

FIGURE 2

The drain valve fitting may be used as

an alternate cold water inlet on heaters

equipped with a dip tube, as shown in

Figure 3. By plumbing a “T” into the drain

fitting, the cold water inlet can be

relocated to this point. The dip tube

must

be removed and its fitting plugged.

Figure 3 also shows a copper loop heat

trap installed on the hot water outlet to

reduce standby losses.

Note: When converting to this configuration on an existing heater

inspect the heater and make certain it

does not have scale buildup on the

bottom of the tank. Scale can restrict the flow

of water into the tank.

CAUTION!!

damage can occur from either the manual

lifting of the lever or the normal operation of the

valve if it is not piped to a proper drain. If

T&P

the valve fails to flow water or reseat, call

a plumber

Scalding injury and/or water

.

, visually

FIGURE 3

– 3 –

Inspect the incoming water line for check valves or water pressure reducing

v

alves. Any type of check valve may cause pressure to build up in the heater and

cause tank failure. If the heater is installed in a closed system or if backflow prev

enters and pressure regulators are installed, add an expansion tank. Do not try

to heat hard water. Install a water softener if the heater is being used in a hard

water area (water hardness more than 7 grains).

An approved temperature and pressure (T&P) relief valve is factory installed in

the opening provided in the upper right hand side of the heater. Pipe the T&P to

within 6" of the floor or to a floor drain with a free flowing drain pipe. Do not install

a check valve in the cold water line.

CONNECT TO

CHIMNEY

MOUNT THE OIL

BURNER

Using “L” or “A” type venting, connect the heater to the chimney. Use the same

size smoke pipe as the heater flue pipe (on models 20e, 20pp, 32E, 32PP and

33E, you may use 4" with a reducer if needed).

WARNING:

120E, do not reduce the smoke pipe diameter. Run a separate smoke pipe from

the water heater to the chimney wherever possible.

If it is necessary to tee into an existing smoke pipe, be sure the connector being

teed into is large enough to accommodate the products of combustion of all units

attached to it. When teeing into another connector, run in at 45° angle (see Figure

1). Install a draft regulator control only if necessary. Overfire draft should not be

positive. Stack draft should be -.02” W.C. minimum to -.05” W

should be a minimum of 11%. If a draft control is installed on the chimney,

another one on the heater is not needed.

The oil burner is equipped with a primary relay

well is packed with the burner. The thermostat is factory set at 120°F for residential use (see caution on page 1 regarding temperature variations). Install the

immersion well with the aquastat and check the bulb length (see “Burner &

Controls” section, page 10).

Remove the cardboard core from the burner opening. Mount the burner on stud

bolts and place the gasket (supplied) between the burner flange and the heater.

Secure the burner to the heater with 1/4 -20 nuts (supplied). Open the inspection

door on the heater and check the burner tube with a mirror before firing to

be sure the opening is not blocked (see Maintenance and Service sections on

pages 6 and 7 for troubleshooting).

On Models 40E, 5OES, 50ESC, 51E, 51EC, 51PP, 51PPC. 71E and

.C. maximum; CO2

. An aquastat with immersion

CONNECT THE

ELECTRICITY

CONNECT THE OIL

LINE

WARNING!! WHEN YOU

INSTALL THE BYPASS

PLUG YOU MUST RUN A

TWO-LINE SYSTEM.

– 4 –

All wiring must comply with applicable codes and ordinances. The primary relay

is wired to the burner at the factory. Install the aquastat well in the 3/4" tapping at

the front of the heater. Be sure the sensing bulb is inserted all the way into the

well. For Honeywell aquastats, tighten the screw on top of the aquastat to secure

the control to the well. For Carlin EZ-Temp aquastats, refer to the pre-packaged

installation guide for proper set-up procedure. Refer to drawings for correct models. Connect the power supply to the aquastat and run through a fused disconnect switch (attached to heater in field). See Figure 1.

Gravity System: The oil burner is normally equipped with a single-stage pump

equipped for one line (gravity) flow. Use 1/2" O.D. soft copper tubing and attach

with flared fittings. DO NOT

off valve and oil filter in the oil line. Follow the pump manufacturer’s instructions

(attached to the pump).

Lift System: The burner should be ordered with a 2-stage pump. Run a 2-line

system (suction and return lines). Install the bypass plug according to the

USE COMPRESSION FITTINGS. Install the shut

instructions attached to pump (plug is in a bag with an instruction sheet).

Loading...

Loading...