Bock Water heaters 32E, 32PPC, 50ES, 51EC, 33E Installation, Operation & Maintenance Instructions Manual

...

TO THE INSTALLER:

Please attach these in -

struc tions next to the

water heater.

TO THE CONSUMER:

Read these and all com -

po nent in struc tions.

Please keep for fu ture

reference. Pleas e re mem ber to return the

registration card.

Waranty, regist ration

card & parts list in clud ed.

INSTALLATION, OPERATION &

MAINTENANCE IN STRUC TIONS

BOCK RESIDENTIAL OIL-FIRED

WATER HEATERS

Model numbers: 32E, 32PPC, 33E, 50ES,

51EC, 51PPC, 120E

WARNING:

Improper installation, adjustment, alteration, ser vice

or maintenance can cause serious in ju ry or prop erty damage. Refer to this man u al. For as sis tance

or additional in for ma tion, con sult a qual i fied in stall er

or service agency.

WARNING:

If the information in these instructions is not fol lowed exactly, fire or explosion may result and can

cause property damage, personal in ju ry or death.

WARNING:

Follow minimum combustible clearance as noted

on wa ter heater label. Do not in stall on com bus ti ble flooring (see Figure 2, Page 3). In stall in ac cor dance with all lo cal codes. In the ab sence of local

codes, re fer to NFPA 31.

CAUTION:

The recommended temperature for normal residen tial use is 120°F. The dial on the aquastat does not

always reflect the outcoming water tem per a ture,

which could occasionally exceed 120°F. The vari a tion in outcoming tem per a ture could be based on

factors including but not limited to us age pat terns

and type of installation. Test your water at the tap

nearest to the water heater. (See page 5 for mea sur ing the outcoming water tem per a ture).

WARNING:

Hotter water increases the risk of scald injury. Be fore changing the temperature setting, read the

in struc tion manual. Tem per a tures at which injury oc curs vary with the in di vid u al’s age and length of

ex po sure.

The slower reaction times of children, elderly and

physically or mentally impaired persons in creas es

the scald ing hazard to them. It is rec om mend ed low er

wa ter temperatures be used where these sit u a tions

exist.

Households with small children or invalids may re quire a tem per a ture setting less than 120°F to pre vent

accidental contact with hot water.

To lower water temperature use point-of-use tem per a ture limiting devices.

WARNING:

Flammable vapors may be drawn to this wa ter heat er from other areas of the struc ture by air currents.

Do not store or use any flam ma ble liquids in the

vicinity of this heater.

WARNING:

Water heater blankets may not be used on the

heater and may cause fire, asphyxiation, per son al

injury or death.

23420 Rev 10 (9/17)

110 South Dickinson Street • Madison, WI 53703

Phone: 608/257-2225 • Fax: 608/257-5304 • www.bockwaterheaters.com

Bock Water Heaters, Inc.

CONSUMER

RE SPON SI BIL I TIES

THIS MANUAL HAS BEEN PREPARED TO ACQUAINT YOU WITH THE IN STAL LA TION, OP ER A TION, AND MAINTENANCE OF YOUR WATER HEATER AND

TO PRO VIDE IM POR TANT SAFETY INFORMATION.

FAILURE TO FOLLOW

THESE INSTRUCTIONS

OR ALL APPLICABLE

BUILD ING CODES AND

REG U LA TIONS VOIDS

THE WAR RAN TY ON THIS

WATER HEAT ER.

MULTIPLE BURNER

INSTALLATION

Read all instructions thoroughly before attempting installation or operation of the

water heat er. Keep these and all component instructions for future ref er ence.

The manufacturer of this water heater will not be liable for any damages caused

by failure to comply with the installation and operating instructions outlined on the

fol low ing pages. These instructions are a guide for the correct installation of the

water heater.

If the installer lacks the necessary skills or has difficulty following the

di rec tions, do not pro ceed but get help from a qualified person for that part of the

installation that is not un der stood.

Local plumbing and electrical codes must be followed in the installation of this

water heater. In the absence of a local code use the UNIFORM PLUMBING CODE

and the NFPA Code. Local codes may supersede instructions in this installation

manual.

When two or more burners are used, each unit should have a separate

supply line to the fuel pump to prevent nuisance lockouts caused by one or both

pumps starving for oil. If this is not possible, the use of a priority

control is recommended.

Check new equip ment to see if all com po nents are in good con di tion.

The wa ter heater and oil burner may be shipped as sep a rate units. The aquastat

and im mer sion well may be packed with the oil burner.

SELECT THE RIGHT

LOCATION

Check for exhaust fans in

the heater room or ad ja cent ar eas which draw

com bus tion air away from

heater. THE HEATER

MUST HAVE COM BUS TION AIR TO OP ER ATE.

The new water heater re quires fuel (#I or #2 heat ing oil), electricity and should be

close to the chim ney and water supply. Lo cate the heater near a floor drain if pos si ble for easy main te nance and protection if trouble should occur. Allow ample

space around the heater for servicing (see combustible clearance warning, page

1). Ad e quate air for com bus tion must be available. NOTE: Locate the heater so it

is not subject to physical damage by moving vehicles or possible flood ing.

DO NOT INSTALL THE WATER HEATER ON COM BUS -

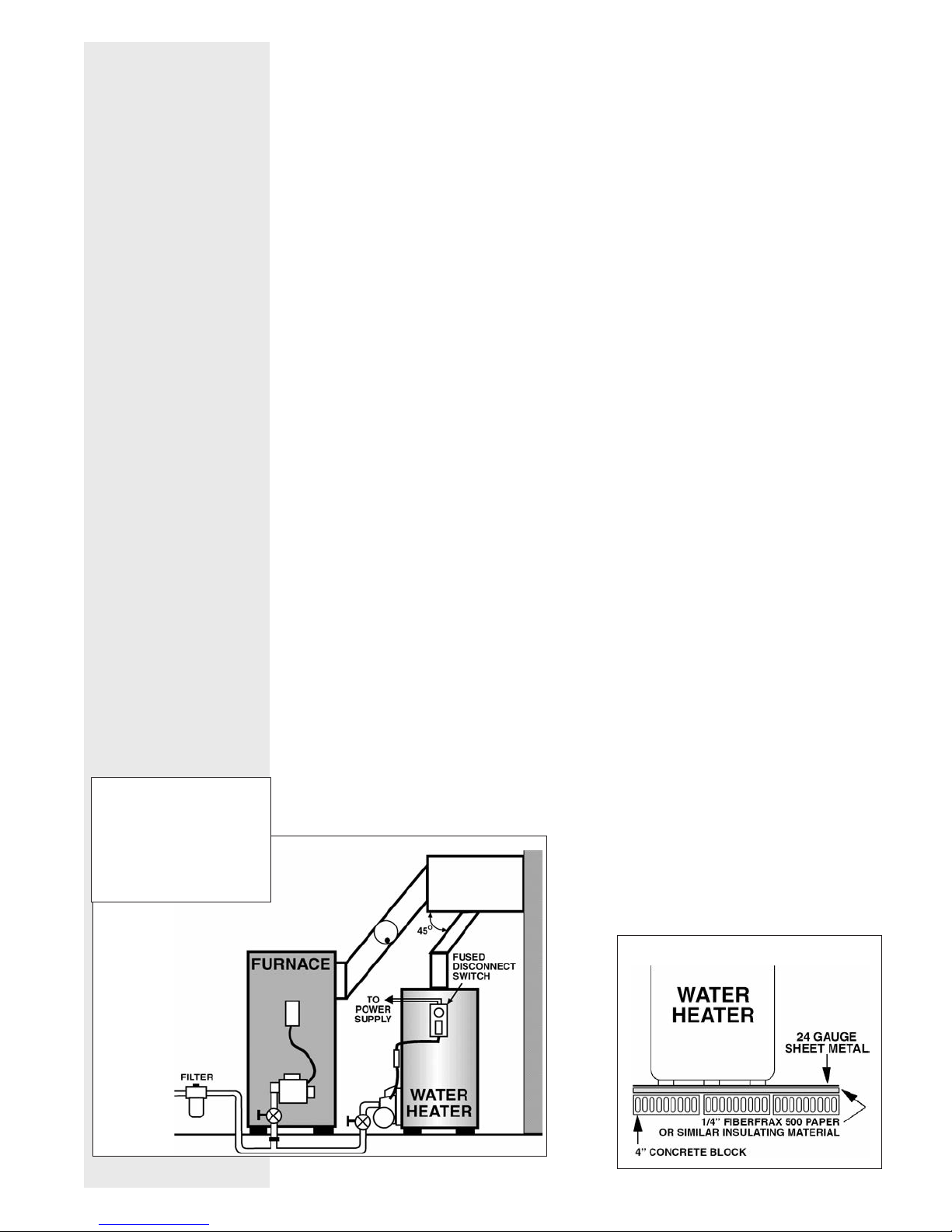

FIGURE 1

TI BLE FLOORING (see Figure 2).

con tact Bock Wa ter Heat ers with questions con cern ing

prop er floor ing ma te ri als.

Minimum clearance to combustible con struc tion is:

SIDES 6"; BACK 6"; FRONT 24". The in stal la tion of

this water heater must con form with local codes and

or di nanc es. In the absence of local codes, the in stal la tion must comply with the Na tion al Fire Pro tec tion

As so ci a tion (NFPA 31) Code.

Refer to NFPA 31 or

FIGURE 2

– 2 –

CONNECT WA TER

NOTE: INDEX LINE ON INLET NIPPLE

MUST BE ALIGNED WITH ARROW ON

DECAL. HOLD INLET NIPPLE WH EN

TIGHTENING FITTINGS. ROTATI NG

NIPPLE COULD DRASTICALLY REDUCE

PERFORMANCE.

PIPING

Connect the water piping, being careful not to apply heat to the heater

nipples. Install di elec tric unions and shut off valves on both hot and cold water

lines.

Model 33E is equipped with an inlet flow diverter installed

in the tank. This model contains decal next to the inlet

(shown to the left). The purpose of this diverter is to help

keep the tank bottom free of sediment by aiding tank

flushing. The index line on the diverter nipple must be

aligned with the arrow on the decal (left) to function

properly. Do not allow the diverter to rotate out of position

when tightening the inlet fittings.

CAUTION!! Scalding injury and/or water dam age can

occur from ei ther the manual lifting of the lever or the

normal op er a tion of the T&P valve if it is not piped to a

proper drain. If the valve fails to flow water or reseat, call a

plumb er.

CONNECT TO

CHIMNEY

MOUNT THE OIL

BURN ER

Inspect the incoming water line for check valves or water pres sure re duc ing

valves. Any type of check valve may cause pres sure to build up in the heater and

cause tank failure. If the heat er is in stalled in a closed system or if backflow

preventers and pressure reg u la tors are in stalled, add an ex pan sion tank. Do not

try to heat hard water. Install a water soft en er if the heat er is being used in a hard

wa ter area (water hardness more than 7 grains).

An ap proved temperature and pressure (T&P) relief valve is factory installed in the

opening provided in the upper right hand side of the heater. Pipe the T&P to within

6" of the floor or to a floor drain with a free flowing drain pipe.

Install a vent connector between the chimney and the water heater. The size of

the vent connector shall be acceptable based on the rise in height of the connector and the water heater input.

If it is necessary to connect to an existing vent connector, be sure the connector

utilized is large enough to ac com mo date the products of com bus tion of all units

at tached to it. When utilizing an oth er connector, run in at 45° angle (see Figure 1).

Install a draft regulator con trol only if nec es sary. Overfire draft should not be pos i tive. Breech draft should be -.03” W.C. min i mum to -.05” W.C. maximum; CO2

should be a minimum of 11% with zero smoke on the Bacharach scale.

The oil burner is equipped with a primary relay. An aquastat with immersion

well is packed with the burner. The thermostat is factory set at 120°F for residential use (see caution on page 1 regarding temperature vari a tions). Install the

immersion well with the aquastat and check the bulb length (see “Burner &

Controls” section, page 10).

Remove the cardboard core from the burner opening. Mount the burner on stud

bolts and place the gasket (sup plied) between the burner flange and the heater.

Secure the burner to the heater with 1/4 -20 nuts (supplied). Open the inspection

door on the heater and check the burner tube with a mirror before firing to

– 3 –

be sure the open ing is not blocked (see Maintenance and Service sections on

pages 6 and 7 for troubleshooting).

CONNECT THE

ELECTRICITY

All wiring must comply with applicable codes and ordinances. The primary relay is

wired to the burner at the factory. Install the aquastat well in the 3/4" tapping at

the front of the heater. Be sure the sensing bulb is inserted all the way into the

well. For Honeywell aquastats, tighten the screw on top of the aquastat to secure

the control to the well. For Carlin EZ-Temp aquastats, refer to the pre-packaged

installation guide for proper set-up procedure. Refer to drawings for correct

models. Connect the power supply to the aquastat and run through a fused dis con nect switch (attached to heater in field). See Figure 1.

CONNECT THE OIL

LINE

WARNING!! WHEN YOU

INSTALL THE BYPASS

PLUG YOU MUST RUN A

TWO-LINE SYSTEM.

A properly sized and rated oil filter shall be installed in the oil supply line

(NFPA 31, 4.5.4).

Gravity System: The oil burner is normally equipped with a single-stage pump

equipped for one line (gravity) flow. Use minimum 3/8" O.D. soft copper tubing and

attach with flared fit tings. DO NOT USE COM PRES SION FITTINGS. Install the

shut off valve and oil filter in the oil line. Follow the pump man u fac tur er’s instructions (attached to the pump).

Lift System: The burner should be ordered with a 2-stage pump. Run a 2-line

system (suc tion and

return lines). Install the bypass plug according to the

instructions attached to pump (plug is in a bag with an instruction sheet).

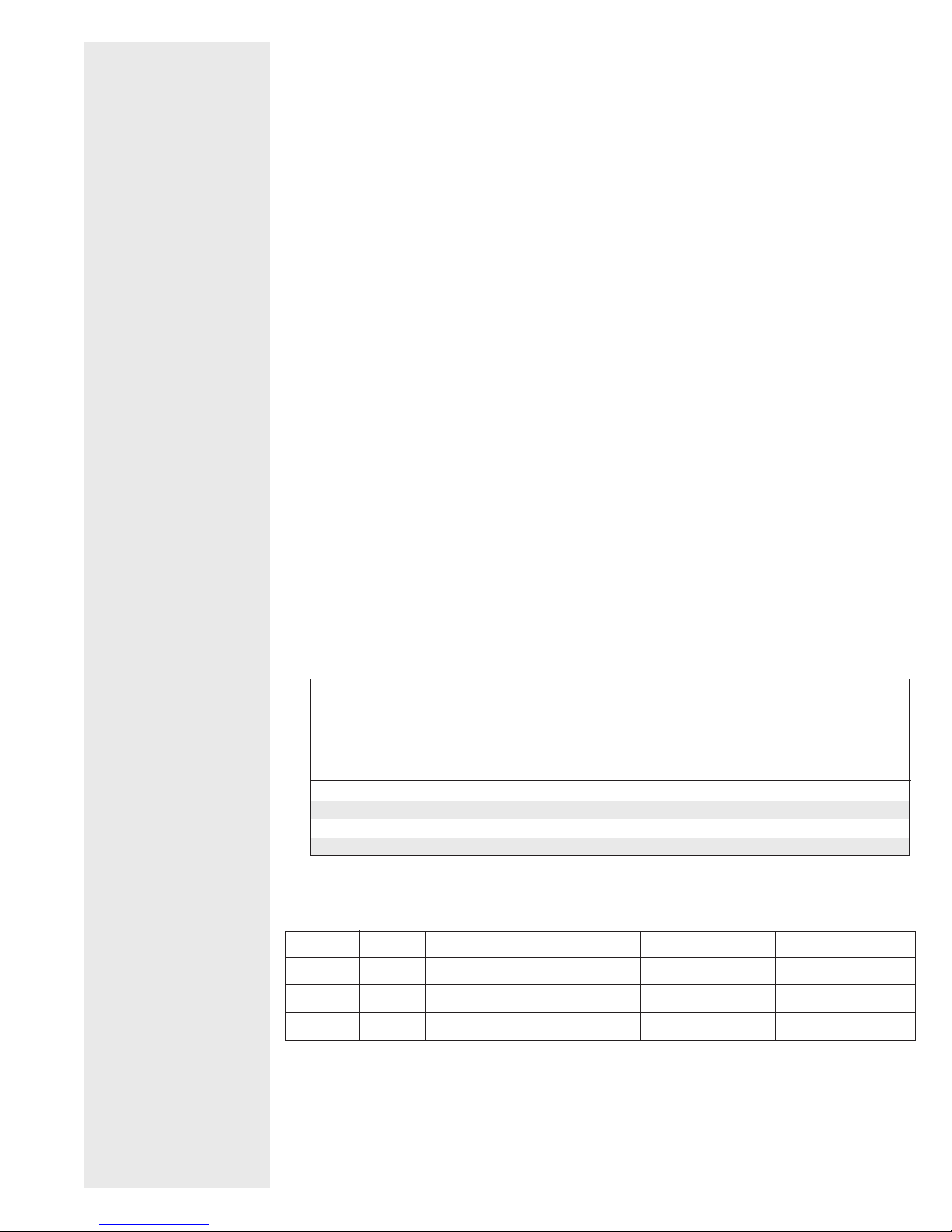

For any horizontal run exceeding the maximum length specified in Figure 3, or any

lift of more than 10 feet, a booster pump must be used. Boost er pumps must be

installed as close to the oil supply tank as possible. Suction and return lines

should be the same diameter and both go within 6” of the bottom of the tank. The

return line should stop slightly above the suction line. Use a minimum of fittings.

Make bends in the tubing with as large a radius as possible. DO NOT USE

COM PRES SION FITTINGS. Caution must be used in the final connection to the

burner so as not to strain the fuel unit. Before attaching the tubing to the burner,

form a coil in the tubing to minimize any vibration. State and local codes must be

followed.

PLACE THE WATER

SYSTEM IN

OPERATION

FIGURE 3: MAXIMUM LIFT & HORIZONTAL RUN

1-Pipe Single Stage Horizontal 2-Pipe Two-Stage Horizontal

System Pump Run System Pump Run

3/8” O.D. 1/2” O.D. 3/8” O.D. 1/2” O.D.

Lift Tube Tube Lift Tube Tube

0’ 65’ 100’ 0’ 75’ 100’

4’ 45’ 100’ 4’ 64’ 100’

7’ 31’ 100’ 7’ 55’ 100’

8’ 16’ 64’ 10’ 47’ 100’

Your log (or one similar to this) must be filled out as follows:

Date Time Test person’s name Set temp. oF Outlet temp. oF

1. Fill the tank with water, opening a hot water faucet to allow trapped air to

escape from the heater. Open the cold water inlet valve. Shut off each faucet as it

delivers water that is free of air. Inspect for leaks. Never operate an empty or

partially full heater.

– 4 –

2. To place burner in operation, follow the instructions provided with the burner.

3. Set the pump pressure to 100 PSI for Wayne, Carlin and Beckett burners and

150 PSI for Riello burners.

Warning: Handhole

cover may loosen

during ship ping –

check for tightness

before putting heater

in operation.

MEASURING

THE

OUTCOMING

WATER

TEMPERATURE

4. Adjust the burner combustion air in accordance with the burner manufacturer’s

instructions. Us ing com bus tion in stru ments, check the C02 and smoke. The C02

should be at least 11% min i mum with zero smoke on the Bacharach scale.

5. While the burner is operating, disconnect one of the yellow cad cell wires.

Check to see that the burner control locks out in the time specified on the control.

Reattach the wire and reset the control. The burner should restart. Note: You may

have to wait a minute before resetting the control.

6. The thermostat is factory set at 120°F for residential use. (See caution on

page 1 re gard ing tem per a ture variations. It is the responsibility of the homeowner

and installer to verify that the installer follows the rec om mend ed quantitative

testing for measuring the outcoming water tem per a ture. To make sure that the

system works properly after installation and in the future, it is rec ommend ed that

the heater’s per for mance be measured and monitored. Run water out of the tap

nearest the heater until it comes out warm. Using a calibrated thermometer, take

a mea sure ment. If the water is not at a suitable tem per a ture for the installation,

have a qual i fied service person adjust the aquastat. Contact Bock for further

information on the ther mom e ter if need ed.

WARNING: Hydrogen gas can be produced in a hot water system served by

a heater that has not been used for a long period of time (generally two

weeks or more.) Hy dro gen gas is ex treme ly flammable. To reduce the risk of

injury, open the hot water faucet at the highest lo ca tion in the house for

several minutes before using any electrical ap pli ance connected to the hot

water system. If hy dro gen is present, there may be an un usu al sound such

as air escaping through the pipe as the water begins to flow. Do not smoke

or allow an open flame near the faucet at the time it is open.

MAINTENANCE

SERVICE

1. Follow the burner manufacturer’s instructions for proper maintenance of the oil

burner.

2. EVERY SIX to 12 MONTHS. Drain water from the heater tank and inspect for

sed i ment or lime ac cu mu la tion. Flush out if necessary. If lime has accumulated,

remove with a com mer cial compound for dissolving lime or by scraping through

the hand hole opening (if supplied). Check water softening equip ment if lime is

found in the tank. DO NOT ATTEMPT TO HEAT HARD WA TER. (See

maintenance label on heater.)

3. Change the magnesium anode rods every six to 12 months or when they

are re duced to 3/8” diameter (see maintenance label on heat er).

4. Open the relief valve test lever to flush out the tank. Make sure it reseats itself.

5. If the heater is to be shut off in cold weather, drain the tank to prevent freezing.

1. Check the fuel supply, electrical wiring and fuses, and make sure temperature

control is calling for heat.

2. If the burner fails to operate, call a qualified local service provider.

– 5 –

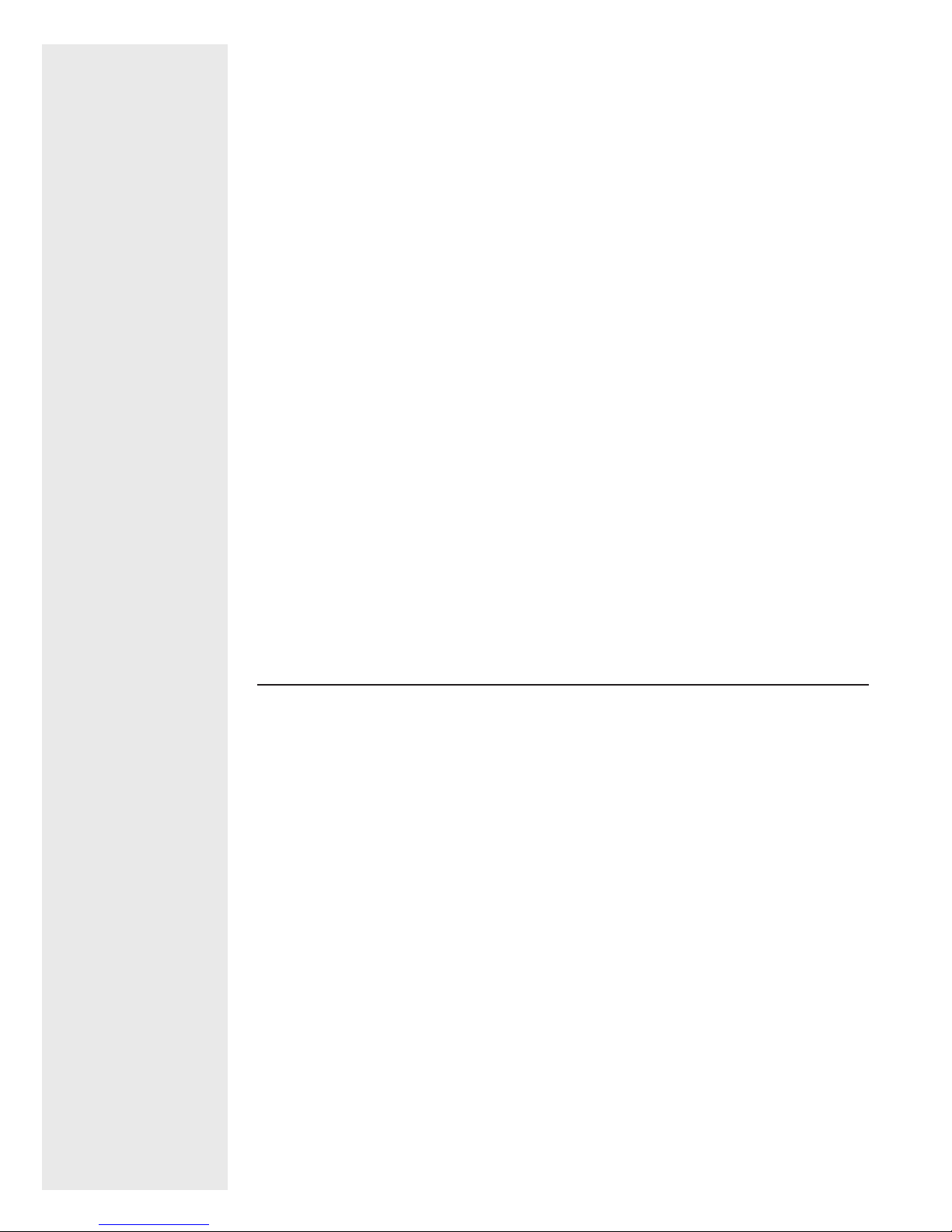

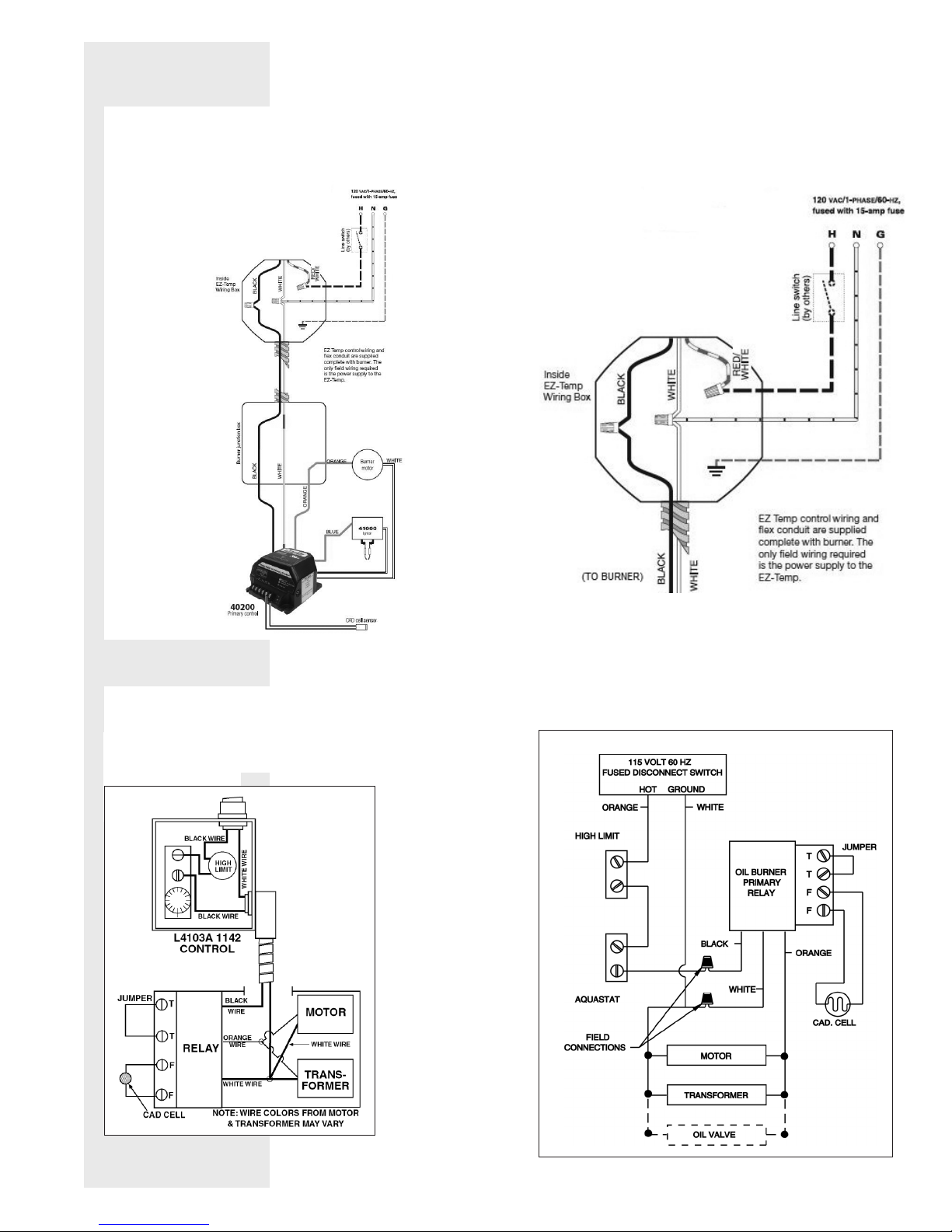

WIRING

FIGURE 4: Carlin burner w/ Carlin EZ-Temp

For Models: 32, 33, 50, 51, 120

(see burner manufacturer’s instructions for 20e;

60200 primary w/ three wire harness)

FIGURE 5: Beckett or Wayne burner w/ Carlin EZ-Temp

For Models: 32, 33, 50, 51, 120

FIGURE 6: Honeywell L4103A-1142

For Models: 32, 33, 51

FIGURE 6 NOTES:

Set point 120°

FIGURE 7: Honeywell L4006A w/ L8080B

For Models: 50, 120E

High limit: 190°

Aquastat:

120° set point

15° differential

L4080B

L4006A

– 6 –

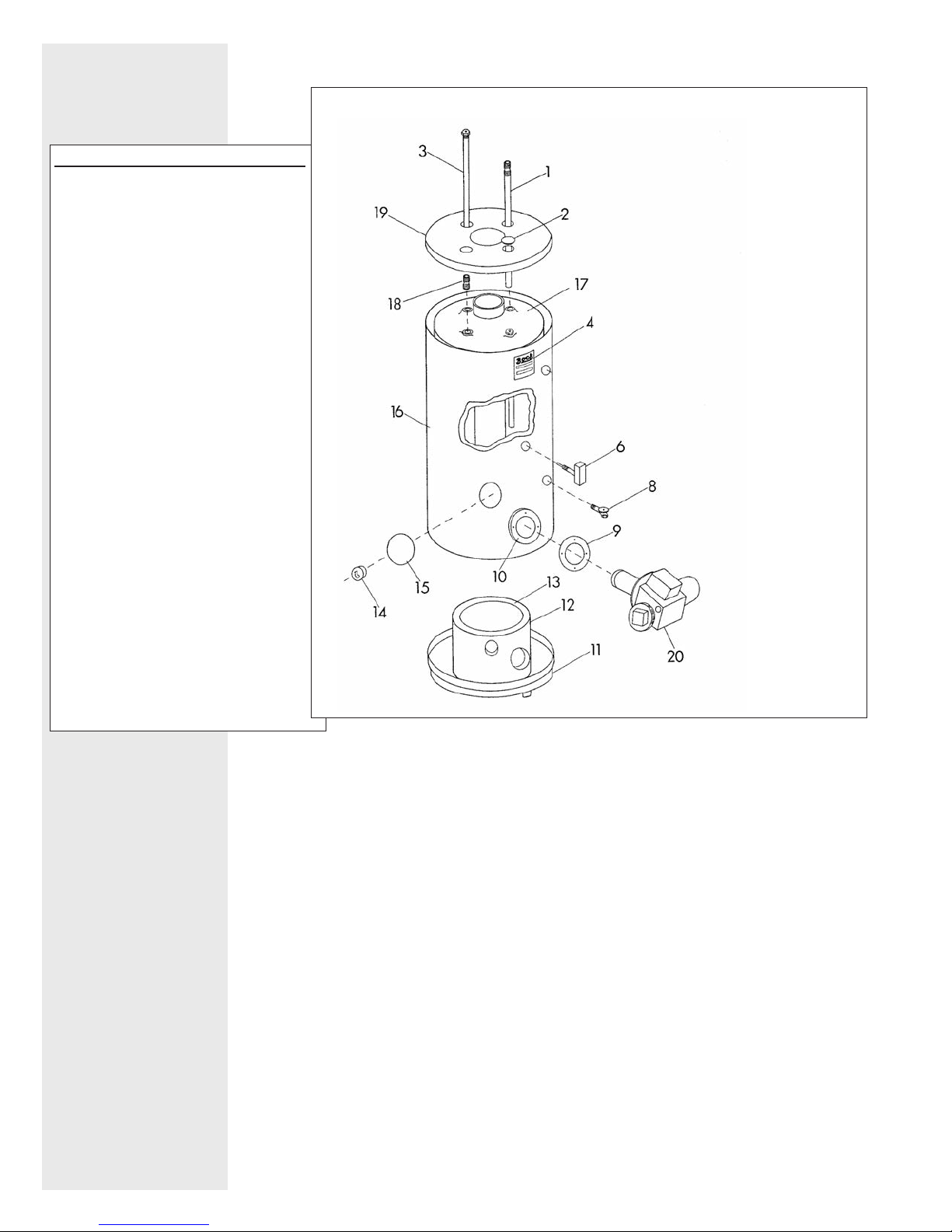

ITEM DESCRIPTION

1. Cold Water Inlet Dip Tube

(N/A 33E)

2. Plastic Cap

3. Magnesium Anode Rod

(aluminum avaliable)

4. Name Plate/Rating Label

6. Immersion Well & Aquastat

8. Drain Valve

9. Mounting Bracket Gasket

10. Burner Mount ing Bracket

(part of jacket assembly on Models

32E through 51 Series; sold

sep a rate ly on 120E)

11. Bottom Pan

12. Combustion Chamber Sleeve

13. Com bus tion Chamber

14. Inspection Block

15. Inspection Door

16. Heater Jacket

17. Tank

18. Hot Out Nipple

51 Series: 1”

AlI others: 3/4”

50ES: N/A

19. Top Pan

20. Burner

OIL FIRED WATER HEATER

BOCK TANK ASSEMBLY

PARTS LIST

When ordering repair parts, always give

the part name, model num ber, size and

serial number.

Handhole cover plate and gasket

(for 50ES only) not shown.

– 7 –

Loading...

Loading...