Bock Water heaters 541E, 361E, 72E, 73E, 241E User Manual

TO THE INSTALLER:

Please attach these in-

structions next to the

water heater.

TO THE CONSUMER:

Read these and all

component instructions. Please keep for

future reference.

INSTALLATION, OPERATION

& MAINTENANCE INSTRUCTIONS

Waranty, registration card

OIL-FIRED WATER HEATERS

& parts list included.

72E • 73E • 190E • 241E • 361E • 541E

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause serious injury or

property damage. Refer to this manual. For assistance

or additional information, consult a qualified installer or

service agency.

WARNING: If the information in these instructions is not

followed exactly, fire or explosion may result and can

cause property damage, personal injury or death.

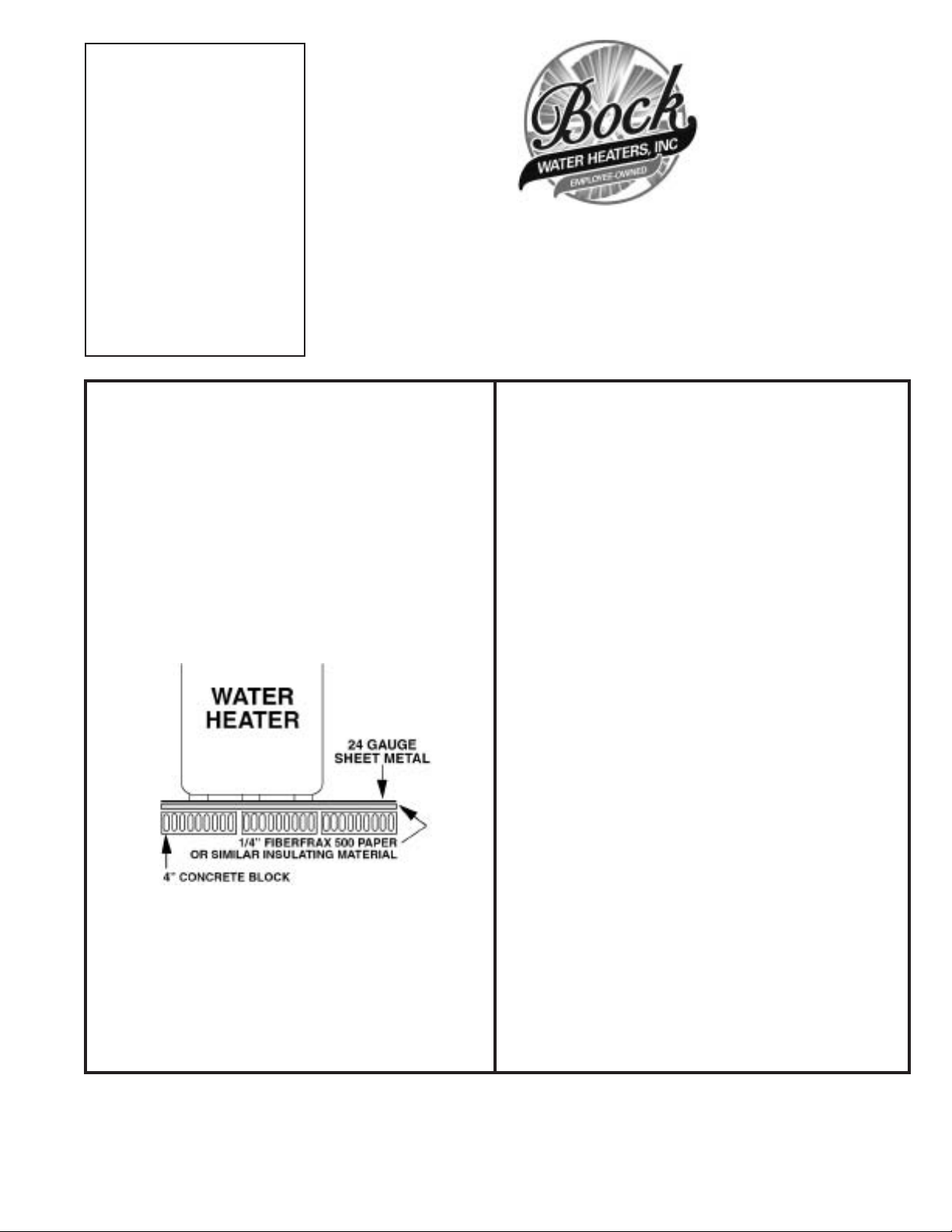

DO NOT INSTALL THE WATER HEATER ON COMBUSTIBLE FLOORING.

codes. In the absence of local codes, refer to NFPA 31

or ANSI Z21.10.1,

questions concerning proper flooring materials.

Minimum clearance to combustible construction is:

SIDES 6"; BACK 6"; FRONT 24". The installation of this

water heater must conform with local codes and ordinances. In the absence of local codes, the installation

must comply with the National Fire Protection Association (NFPA 31) Code.

WARNING: The recommended temperature for normal

residential use is 120oF. The dial on the aquastat does

not always reflect the outcoming water temperature,

Install in accordance with all local

or contact Bock Water Heaters with

which could occasionally exceed 120oF

outcoming temperature could be based on factors in

cluding but not limited to usage patterns and type of

installation. Test your water at the tap nearest to the water heater.

WARNING: Hotter water increases the risk of scald injury. Before changing the temperature setting, read the

instruction manual. Temperatures at which injury occurs

vary with the individual’s age and length of exposure.

The slower reaction times of children, elderly and physically or mentally impaired persons increases the

scalding hazard to them. It is recommended lower water temperatures be used where these situations exist.

To lower water temperature use point-of-use temperature limiting devices.

WARNING:

water heater from other areas of the structure by air currents.

the vicinity of this heater

WARNING: Water heater blankets may restrict air flow

to the heater and cause fire, asphyxiation, personal injury or death.

ARNING:

W

water system that has not been used for an extended

period–generally, two weeks or longer. To prevent possible injury under this situation, we recommend that a

hot water faucet be wide open for several minutes

before you use

ed to the hot water system. If hydrogen is present, an

unusual sound – such as air escaping – will come from

the open faucet as the hot water begins to flow

Hydrogen gas is extremely flammable – there must

be no open flame near this open faucet.

Flammable vapors may be drawn to this

Do not store or use any flammable liquids in

.

Hydrogen gas can be produced in a hot

electrical appliance that is connect

ANY

. The variation in

-

-

.

Bock Water Heaters, Inc.

110 S. Dickinson St. • P.O. Box 8632 • Madison, WI 53708-8632

Phone: 608/257-2225 • Fax: 608/257-5304 • www.bockwaterheaters.com

PERFORMANCE SPECIFICATIONS

AND ROUGHING-IN DIMENSIONS

CAUTION:

The recommended

water temperature

setting for normal

residential use is

O

120

F.

72E CARLIN EZ-2HP/9833222J72E 1.25X70OB 150 PSI

WAYNE MSR/371-019B 1.50X80OB 100 PSI

IELLO R35.5/C8512221 1.25X60

R

RIELLO 40F10/ 1.25X60

Leave ample room for servicing when the water heater is installed – do not block access to the burner, inspection door,

handholes or controls. Leave room to pipe the unit and connect

the fuel and electricity.

BURNER SPECIFICATIONS

ODEL/OEM # NOZZLE PRESSURE

M

O

B

O

B 150 PSI

150 PSI

73E CARLIN EZ-2HP/9833222J73E 1.50X70OB 150 PSI

WAYNE MSR/371-022B 1.75X80

RIELLO 40F10/C8514109 1.50X60

190E WAYNE MSR/371-129B 1.35X70OB 100 PSI

CARLIN EZ-1/9682811J190E 1.35X70

O

B 100 PSI

O

B 150 PSI

O

B 100 PSI

BECKETT AF 1.35X70OB 100 PSI

241E CARLIN EZ-2HP/9833111J241E 1.65X70OB 150 PSI

WAYNE 371-024B 2.0X80

O

B 100 PSI

361E CARLIN 201CRD/98285000B361E 2.50X70OB 150 PSI

WAYNE EH/371-026 3.00X80OA 100 PSI

541E CARLIN 201CRD/98285000B541E 4.00X70OB 130 PSI

WAYNE EH/371-028 4.50X80OB 100 PSI

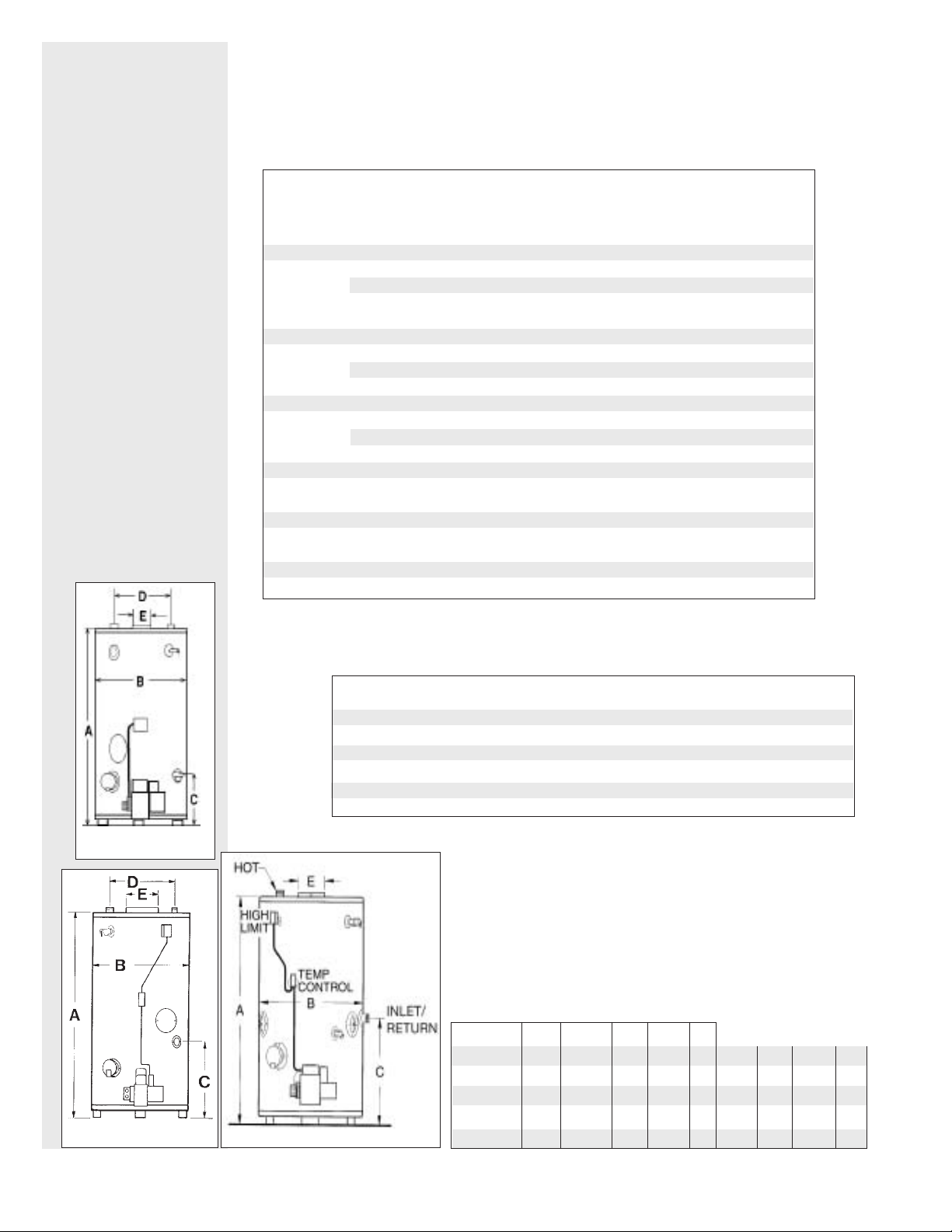

SIZES AND CAP

ACITIES

(shipping weights are complete assembly, including burners and controls)

MODEL

72E 67 GAL. 199,000 1.50 GPH 120V 60HZ 1/7 HP 550 LBS. ––

73E 67 GAL. 242,000 1.75 GPH 120V 60HZ 1/7 HP 550 LBS. ––

190E 113 GAL. 190,000 1.35 GPH 120V 60HZ 1/7 HP 690 LBS. ––

241E 109 GAL. 277,000 2.00 GPH 120V 60HZ 1/7 HP 925 LBS. 950 LBS.

361E 91 GAL. 415,000 3.00 GPH 120V 60HZ 1/4 HP 1105 LBS. 1125 LBS.

541E 83 GAL. 623,000 4.50 GPH 120V 60HZ 1/4 HP 1330 LBS. 1340 LBS.

STORAGE

CAPACITY

BTUH

INPUT

FIRING

RATE

STANDARD

VOLTAGE

MOTOR

SHIPPING WEIGHT

STANDARD ASME

72E

73E, 190E, 241E, 361E

– 2 –

541E

MODEL A B C D E

16”

20”

72E & 73E58”

190E 66

241E

361E

541E

28”

1

1

/

4

”31

67”31

67” 31

66” 34” 30

* Nipple not furnished ** Under drain valve

1

/

/

2

”20

2

” 19” 6” 2”* 1” 3/4” 2”

1

/

2

”

1

/

2

” 26” 23” 9” 2”* 1” 3/4” 2”

19” 8” 2”* 1” 3/4” 2”

22”

1

/

2

” NA 10” 2”* 2”* 3/4” 2”

HOT

1

/

1

8”

OUTLET *

COLD

DRAIN

INLET

3/4”

1”

2

”*

on 72E & 73E only

ALT INLET/

RETURN **

1

/

1

2

”

COMBUSTION &

VENTILATION AIR

NOTE: All ducts

must have the same

cross sectional area

as the free area of

each opening to

which they connect.

The minimum side

dimension of a rectangular duct must

be no smaller than

three (3) inches.

Caution: Operation

of exhaust fans, ventilating systems,

power burners, induced draft systems,

clothes dryers, or

fireplaces may create conditions that

require special

attention to avoid

unsatisfactory operation of installed

equipment.

T&P RELIEF VALVE

ATTACH BURNER

& OIL LINES

Care must be taken to insure an adequate air supply for the water heater.

. Install equipment only where the water heater will have satisfactory combustion, proper venting,

A

and the maintenance of temperature at safe limits all around the unit under normal operating conditions. Free circulation of air around the water heater is essential. If the air supply is inadequate,

introduce outside air. Any temperature above 90°F around the heater indicates a need for additional air (see NFPA 31 for air requirements).

B. In addition to air needed for combustion, air may be required for draft control; cooling off; controlling

ew point; heating; drying; oxidation or dilution; safety exhaust; odor control; and compressors.

d

C. Make sure air around the water heater is adequate for personnel comfort and working conditions.

D. Check for proper draft. Place a draft gauge in the chimney above the draft diverter. Drafts should

be at least -0.02" W. C. and less than -0.05” W.C. while the water heater is in operation.

nconfined space: No additional combustion and ventilation air is required if the volume of the

U

space is greater than 50 cubic feet per 1,000 BTUH of the combined total input of all equipment installed in that space. Rooms leading directly to the space through openings which cannot be closed

are considered part of the unconfined space.

Confined space: When the unit will be installed in a space with a volume of less than 50 cubic feet

per 1,000 BTUH, the space must be vented at the floor for combustion air and at the ceiling for ventilation. This air can be supplied from either inside or outside of the building as conditions allow (refer

to NFPA 31 or local codes).

A. Inside air supply: Provide two permanent openings; one within 12" of the top of the enclosure and

one within 12" of the bottom, leading directly to room(s) of sufficient volume so that the combined

volume of all the space meets the criteria for unconfined space. Each opening requires a mini-

mum free area of one (1) square inch (two square inches total) per 1,000 BTUH of the combined

total input of all equipment installed in the enclosure, but not less than 100 square inches.

B. Outside air supply: Provide two permanent openings; one within 12" of the top of the enclosure

and one within 12" of the bottom. These openings must lead directly to crawl and attic spaces

leading directly to the outside of the building.

Leading directly to outside or through vertical ducts: Each opening (top and bottom)

1.

requires a minimum free area of one (1) square inch (two square inches total) per 4,000 BTUH

of the combined total input of all equipment installed in the enclosure.

2.

Leading to the outside through horizontal ducts: Each opening (top and bottom) requires

a minimum free area of one (1) square inch (two square inches total) per 2,000 BTUH of the

combined total input of all equipment installed in the enclosure.

Louvers and grilles: In calculating the “free” area in Equipment Located in Confined Spaces,

consider the blocking effects of louvers, grilles, or screens protecting openings. The screens cannot

be smaller than one (1) inch of mesh. If the “free” area of a louver or grille is known, it should be

used in calculating the size opening required to provide the “free” area specified. If the design and

“free” area is not known, assume wood louvers have 20% to 25% “free” area, and metal louvers and

grilles 60% to 75%. Fix louvers and grilles in the open position or interlock with the equipment so

they are opening automatically during equipment operation.

ATER PIPING:

W

sweat fittings, do not apply heat to the nipples. Pipe hot and cold lines with a union and valve on

each line.

If backflow preventers and pressure regulators are installed or if the heater is installed in a closed

system, allow for water expansion by installing either a thermal expansion valve or an expansion

tank in the system. Contact the local water supplier or plumbing inspector to correct the situation.

The Bock factory has installed the properly rated temperature and pressure (T&P) relief valve.

To prevent water damage when relief occurs, install a discharge line from the relief valve outlet to a

place for water disposal. Do not install reducing coupling or other restriction in the discharge line.

Arrange the line to allow complete drainage of both the relief valve and the discharge line. If the T&P

relief valve discharges periodically, service to the water system is required.

Do not place the shut-off valve between the relief valve and the water heater.

Check handholes for tightness.

The operating thermostat and high limit are packed with the burner

1.

provided. Burners are shipped with all settings at the approximate start point. Check inside the

combustion chamber to verify that the burner tube is not obstructed or protruding into the chamber. Swing back the hinged transformer and rotate the blower wheel by hand a few turns to loosen

the pump seal.

Models 72E, 73E, 190E, 241E and 361E have polysulfone dip tubes. When using

. Mount the burner with bolts

– 3 –

Loading...

Loading...