Bock Water heaters 30SK, 50SK, 40SK, 80SK, 119SK Instruction Manual

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause serious

injury or property damage. Refer to this

manual. For assistance or additional

information, consult a qualified installer or

service agency.

CAUTION

The recommended temperature for normal

residential use is 120°F. The dial on the

aquastat does not always reflect the outcoming water temperature, which could

occasionally exceed 120°F. The variation in outcoming temperature could be based on factors

including but not limited to usage patterns and

type of installation. Test your water at the tap

nearest to the water heater.

WARNING

Hotter water increases the risk of scald injury.

Before adjusting the water temperature setting,

read this instruction manual. Temperatures at

which injury occurs vary with the person’s age

and the length of exposure.

The slower reaction time of children, elderly,

and physically or mentally challenged persons

increases the scalding hazard to them. It is

recommended that lower water temperatures

be used where these exposure hazards exist.

Such households may require a temperature

setting less than 120°F to prevent accidental

contact with hot water.

To lower water temperature use point-of-use

temperature limiting devices.

WARNING

Water heater blankets are not recommended

and will void the warranty.

THIS MANUAL HAS BEEN PREPARED

TO ACQUAINT YOU WITH THE INSTALLATION,

OPERATION, AND MAINTENANCE OF

YOUR WATER HEATER AND TO PROVIDE

IMPORTANT SAFETY INFORMATION.

INSTALLER RESPONSIBILITIES

Please read all instructions thoroughly before

installing or placing the heater into service.

This unit must be installed by licensed or

authorized installers, or technical personnel

that service water heating equipment. The

heater must be installed in accordance with all

local codes and ordinances.

These instructions are a guide for the correct

installation of the water heater. The

manufacturer will not be liable for damages

caused by failure to comply with the installation

and operating instructions outlined on the

following pages.

CAUTION

The recommended water temperature setting for

normal residential use is 120°F/49°C.

HANDLING

Before uncrating, check for shipping damage.

Report any damage to your carrier. Note damage

on bill of lading or delivery receipt and file a

claim.

FAILURE TO FOLLOW THESE INSTRUCTIONS

OR ALL APPLICABLE BUILDING CODES AND

REGULATIONS VOIDS THE WARRANTY

ON THIS WATER HEATER.

Read all instructions thoroughly before

attempting installation or operation of your

water heater. Keep these instructions for future

reference.

Local plumbing and electrical codes must be

followed in the installation of this water

heater. In the absence of a local code use the

UNIFORM PLUMBING CODE and the NFPA

Code. Local codes may supersede instructions

in this installation manual.

These instructions are a guide for the correct

installation of the water heater. The

manufacturer will not be liable for damages

caused by failure to comply with the

installation and operating instructions

outlined on the following pages.

Warranty, Registration Card and Parts List are included.

Homeowner: Please remember to return

the Registration Card!

To the Consumer:

Please read these and all component

instructions and keep for future reference.

To the Installer:

Please attach these instructions

next to the water heater.

Indirect Water Heater

Instruction Manual

Rev 8 6

/16

23955

Page 2

TABLE OF CONTENTS

Section I: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section II: General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Section III: Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Section IV: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Section V: Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Section VI: Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Section VII: Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Section VIII: Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Page 3

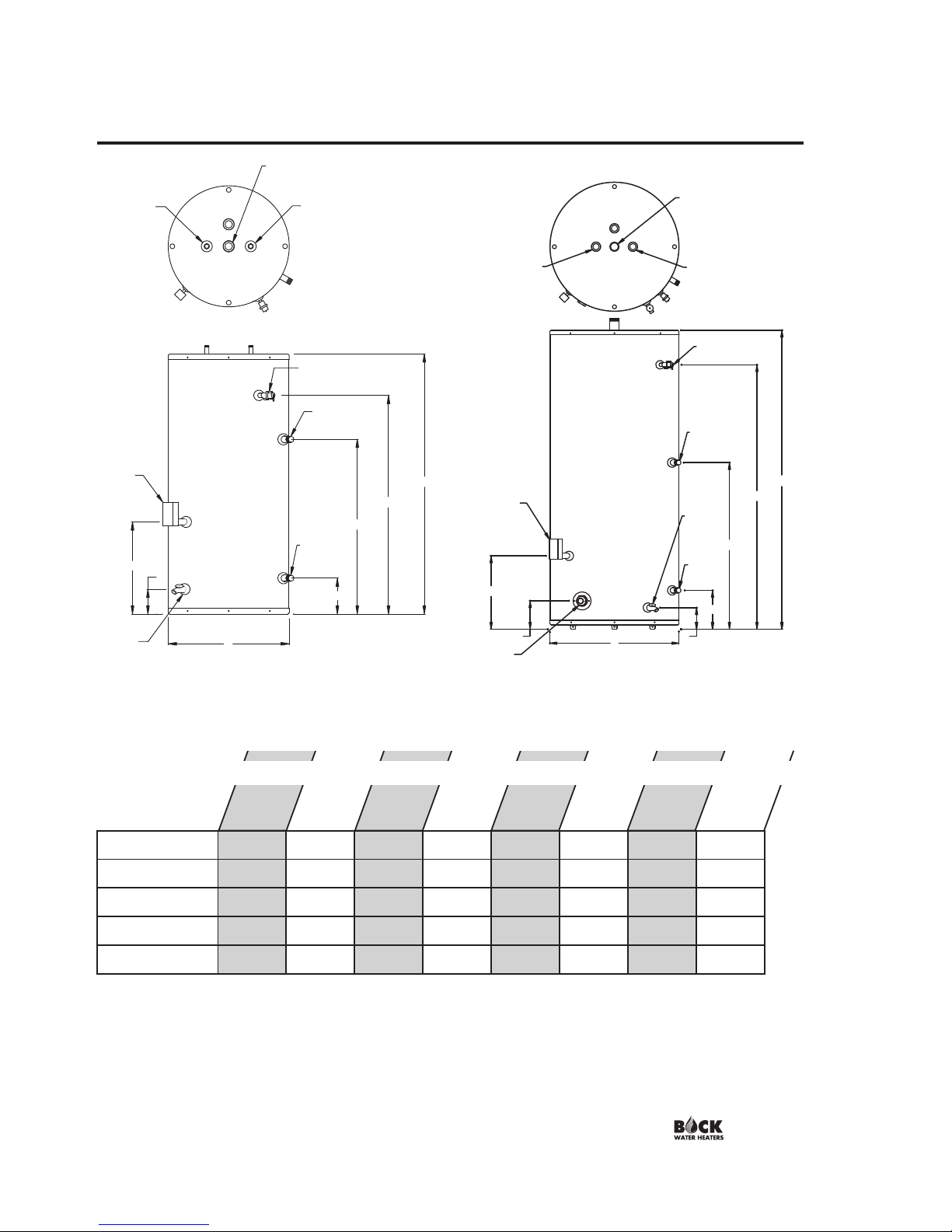

G

Cold Inlet,

3/4" NPT

Hot Outlet/

Anode Rod,

3/4" NPT

Anode

Rod

Aquastat

T&P Relief

Valve

From Boiler

Supply, 1" NPT

To Boiler

Return, 1"

NPT

Drain

Valve

F

D

C

E

B

A

SECTION I: SPECIFICATIONS

Foam insulation standard on Indirect models. Pressures, all: Test pressure, 300 PSI Working pressure, 150 PSI

Standard voltage, all: 120V, 60Hz, 1P. T&P valve installed; nipples supplied for top connection.

WARNING: Installation should be in accordance with all national and/or local codes.

CAUTION: The recommended water temperature setting for normal residential use is 120°F. Bock recommends a tempering

valve or anti-scald valve be installed and used according to the manufacturer's directions to prevent scalding.

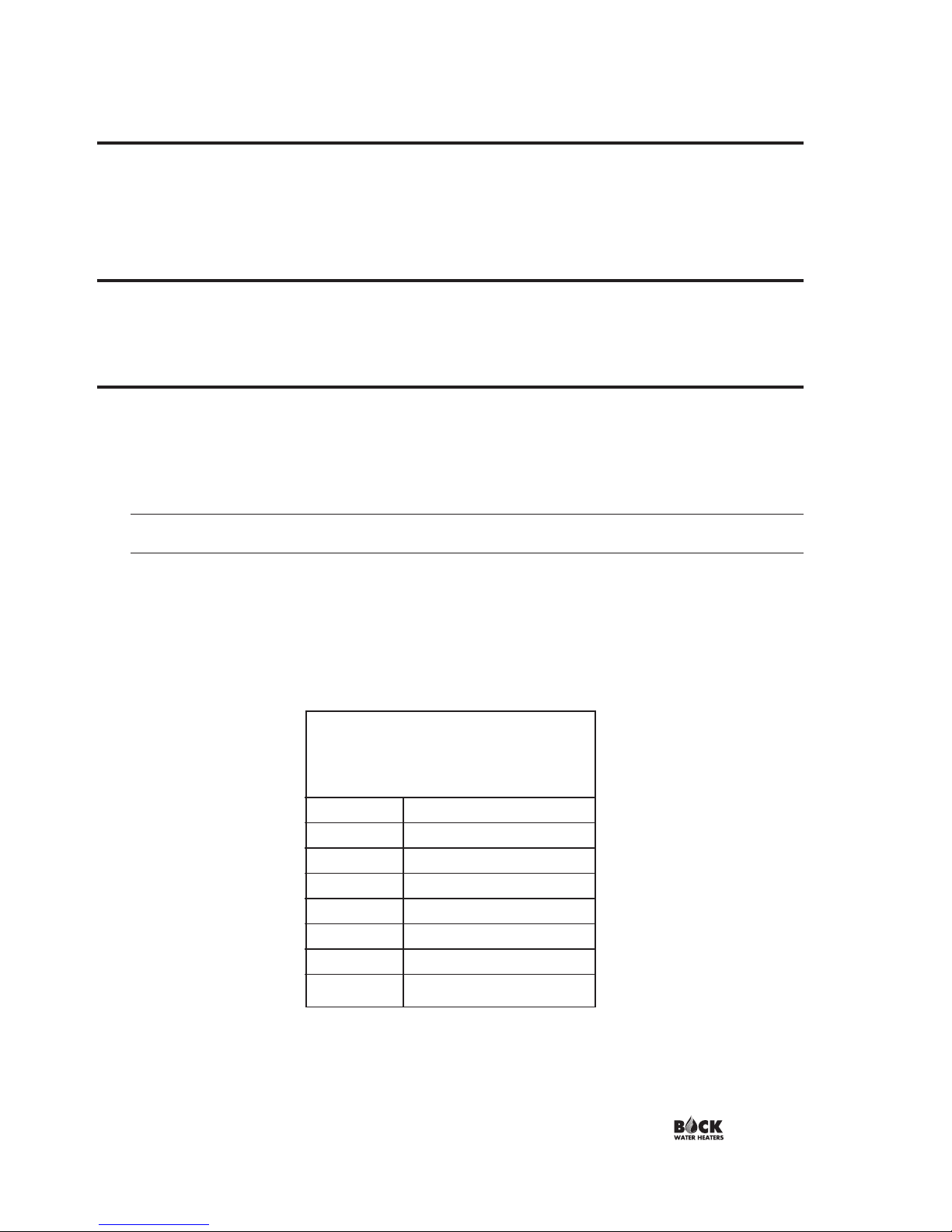

30SK

22

35 1⁄4 27 3⁄4 19 1⁄2 11 3⁄4 6 1⁄2 4 1⁄2 n/a

40SK 22 42 1⁄4 34 3⁄4 31 1⁄2 16 3⁄4 6 1⁄2 4 1⁄2 n/a

50SK 22 48 1⁄4 39 3⁄4 31 1⁄2 16 3⁄4 6 1⁄2 4 1⁄2 n/a

80SK 24 64 57 1⁄8 33 19 1⁄4 8 5 5

119SK 28 65 57 3⁄4 33 3⁄4 16 1⁄4 8 3⁄4 5 6 1⁄2

Model

A

B

C

D

E

F

G

H

Table 1: Dimensions

G

H

A

E

F

D

C

B

Cold Inlet,

1 1/2" NPT

Hot Outlet,

1 1/2" NPT

Anode

Rod

Anode

Rod

T&P Relief

Valve

From Boiler

Supply, 1" NPT

To Boiler

Return,

1"NPT

Drain

Valve

Aquastat

Figure 2: 80SK, 119SK

D i m e n s i o n s

Figure 1: 30SK, 40SK, 50SK

Page 4

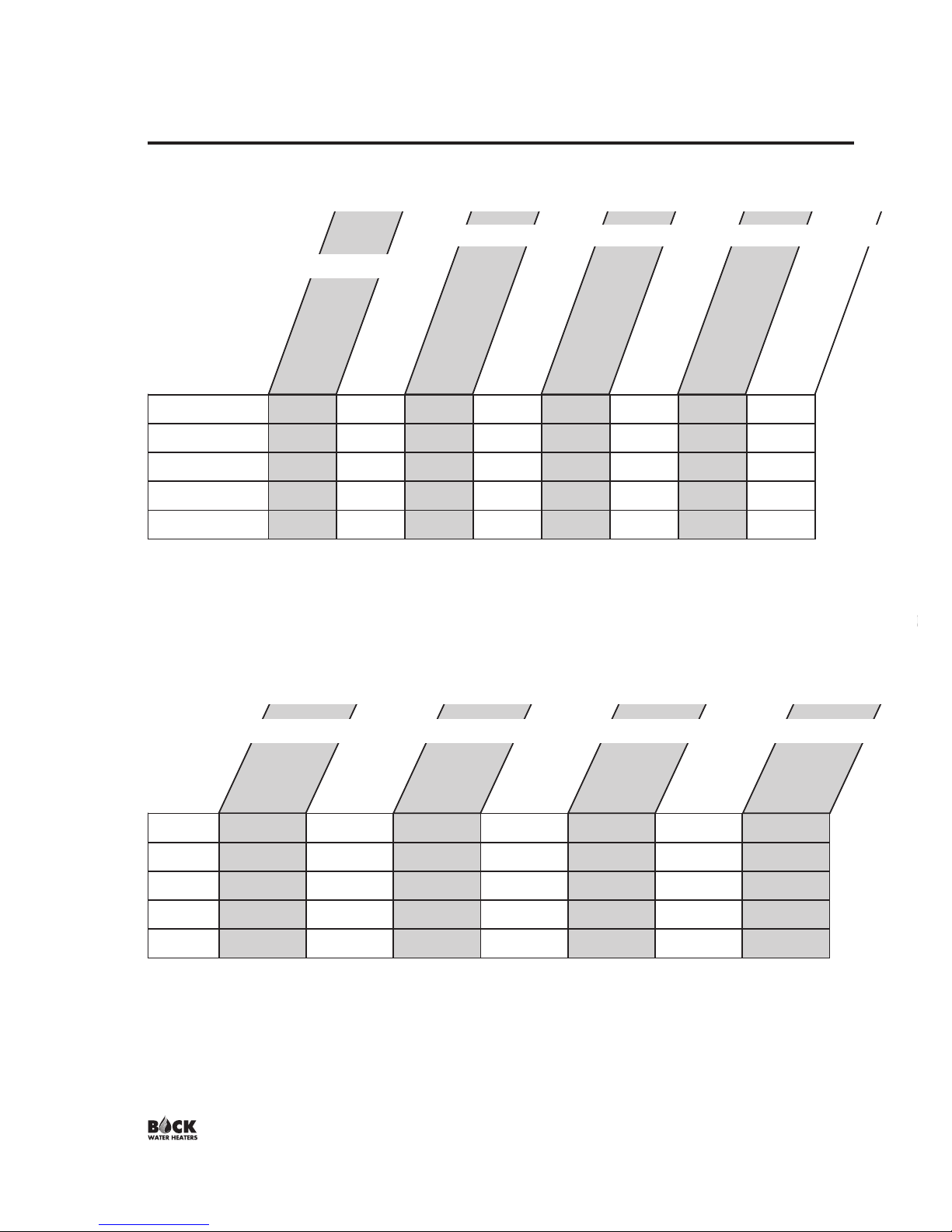

SECTION I: SPECIFICATIONS (cont.)

30SK 30 1.4 119 92 27 59,000 1.5 2.3

40SK 38 2.3 198 165 33 105,000 1.5 3.4

50SK 45 2.3 205 165 40 105,000 1.1 3.4

80SK 75 2.8 259 189 70 120,000 0.8 3.5

119SK 110 2.8 291 189 102 120,000 1.2 3.5

Model

Actual Tank

Volume (gal)

Coil Volume

(gal)

First Hour

Rating (gal)*

Continuous Draw

Rating (GPH)*

First Draw

Rating (gal)*

Minimum Coil

Output (BTU/Hr)**

Standby Loss

Rating (°F/hr)

Heat Source Friction

Loss (ft. w.c.)

Table 2: Capacity & Performance

Capacities

P e r f o r m a n c e

30SK

115 @ 56,000 117 @ 57,000 118 @ 58,000 138 @ 71,000 144 @ 75,000 149 @ 78,000 154 @ 81,000

40SK

173 @ 89,000 183 @ 96,000 191 @ 101,000 214 @ 115,000 226 @ 123,000 235 @ 129,000 243 @134,000

50SK

180 @ 89,000 190 @ 96,000 198 @ 101,000 221 @ 115,000 233 @ 123,000 242 @ 129,000 250 @134,000

80SK

233 @ 104,000 245 @ 111,000 254 @ 117,000 277 @ 132,000 292 @141,000 304 @ 149,000 314 @155,000

119SK

265 @ 104,000 277 @ 111,000 286 @ 117,000 309 @ 132,000 324 @ 141,000 336 @149,000 346 @155,000

Model

180°F

8 GPM*

180°F

10 GPM*

200°F

8 GPM*

200°F

12 GPM*

FIRST HOUR RATING (gal) @ Coil Output (Btu/hr)

Table 3: Performance (cont.)

NOTES:

* Based on 77°F rise with 58°F potable water inlet temperature at 14 GPM heat source flow rate. Heat source temperature was 180°F.

** Minimum Coil output based on continuous boiler operation over 30 minutes. See Section III for additional considerations.

All data obtained through testing in accordance with GAMA INDIRECT-FIRED WATER HEATER TESTING STANDARD IWH-TS-1_MARCH 2003

200°F

14 GPM*

200°F

10 GPM*

180°F

12 GPM*

NOTES:

First Hour Rating = First Draw + Continuous Draw

* Coil Input (temperature, flow rate). Ratings based on 77°F rise with 58°F inlet potable water.

All data obtained through testing in accordance with GAMA INDIRECT-FIRED WATER HEATER TESTING STANDARD IWH-TS-1_MARCH 2003

Page 5

SECTION II: GENERAL INFORMATION

LOCATION

The indirect water heater should be located in a central location to the piping system, as

close as practical to the boiler and in an area not subject to freezing temperatures. Leave

sufficient space for servicing and maintaining the heater.

Note: Long heating supply runs can lengthen recovery times.

WATER TREATMENT/FILTRATION

In areas where poor water conditions are suspected (i.e. lime, iron, and other minerals), it is

essential that the water be tested and appropriate action taken to prevent damage to the

indirect heater and ensure the quality of the water.

TEMPERATURE CONTROL

Water temperature from the heat source / boiler to the indirect water heater is controlled by

an immersion aquastat. This control operates the circulator, and provides limited control for

domestic hot water temperature. The proper temperature setting for domestic hot water use is

120°F/49°C. If hotter water is required a tempering device or anti-scald device must be

installed at the domestic hot water outlet of the heater or at the point of use.

CAUTION: Hot water in excess of 120°F

can cause scalding!

Bock recommends a tempering valve or anti-scald valve be installed and used according to

the manufacturer’s directions to prevent scalding. Many state and local codes now require

installation of these devices. The tempering valve or anti-scald valve will ensure potable

water temperatures at the desired set point with a higher degree of accuracy.

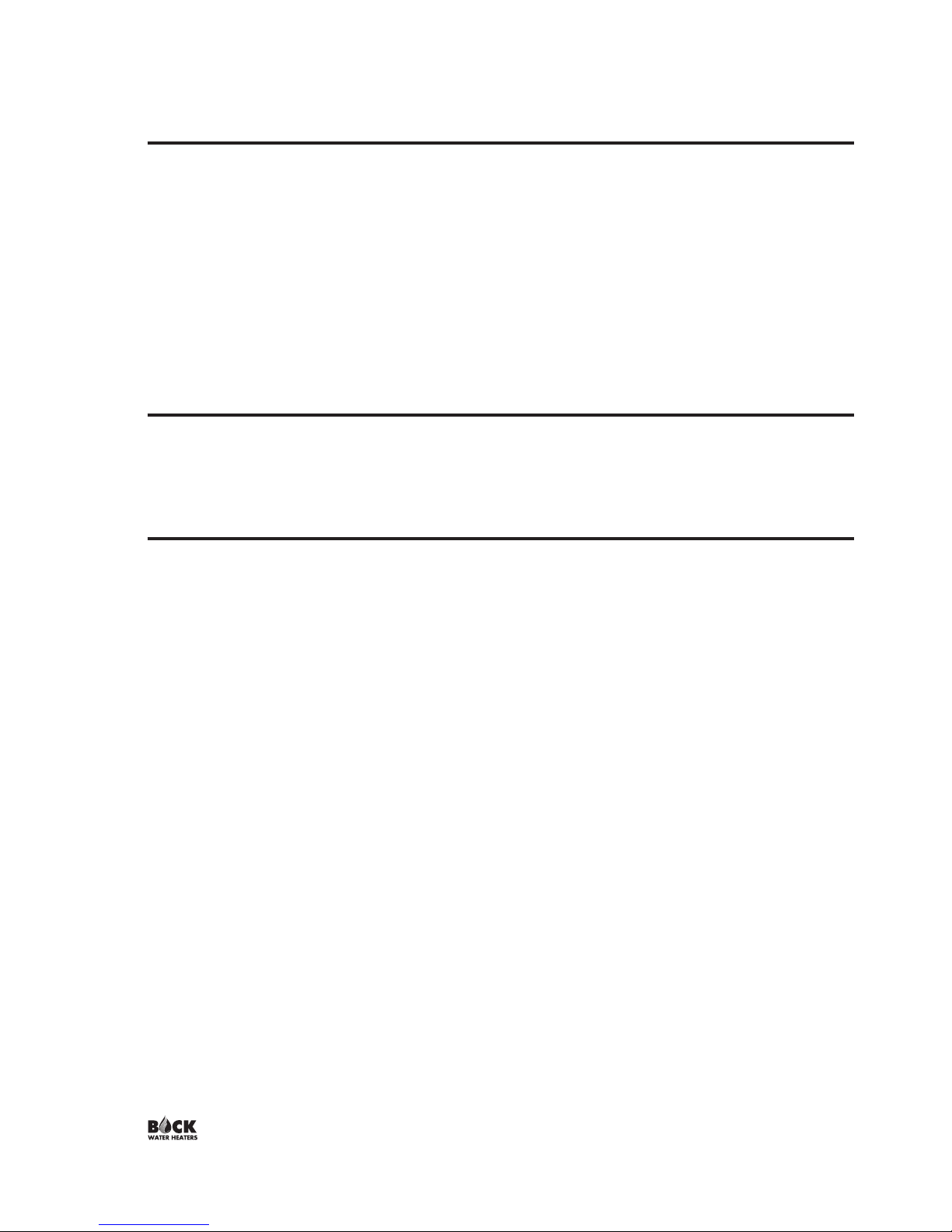

APPROXIMATE

TEMPERATURE/TIME

RELATIONSHIPS TO

SCALDING

120°F More than 5 minutes

125°F 1

1

⁄2 to 2 minutes

130°F About 30 seconds

135°F About 10 seconds

140°F Less than 5 seconds

145°F Less than 3 seconds

150°F About 1

1

⁄2 seconds

155°F About 1 second

Page 6

SECTION II: GENERAL INFORMATION (cont.)

ANODE RODS

The anode rod is used as a sacrificial element within the volume of the storage tank. The

purpose of the magnesium anode rod is to protect the inside of the tank against corrosion.

Anode rods should be inspected twice in the first year and at least yearly once a time interval

for inspection has been developed. Water conditions can influence the consumption rate of

the anode rods. Please see the Maintenance section of this manual for instructions on how to

change the anode rods in your Bock water heater.

CAUTION: Hydrogen gas is produced in a hot water system served by this heater that has not been used for

a long period of time (2 weeks or more). Hydrogen gas is extremely flammable. To reduce the risk of injury

under these conditions, it is recommended that the hot water faucet be opened for several minutes at the

kitchen sink before using any electrical appliance connected to the hot water system. When hydrogen is

present, there will probably be an unusual sound such as air escaping through the pipe as the water begins to

flow. There should be no smoking or open flame near the faucet at the time it is open (UL 174).

TEMPERATURE AND PRESSURE RELIEF VALVE (T&P)

The T&P valve is factory installed. A discharge drain tube must be installed (responsibility of

the installer) and shall terminate plain, not threaded, 6 inches above the floor drain. The

drain tube material must be approved for temperatures of 120°F or greater, and a pressure of

150 PSI or greater.

BACK-FLOW PREVENTER (CLOSED LOOP SYSTEM)

Some local municipal codes and ordinances require the use of these devices on potable

(domestic) water lines. Where back-flow preventers are required, it will be necessary to

install a thermal expansion tank (designed for used with potable water) in order to prevent

pressure build up in the indirect heater and associated piping, which could cause the T&P

valve to discharge. Follow the expansion tank manufacturer’s recommendations when

selecting a tank for your hot water system.

Note: Working pressure of the water heater is 150 PSI. Do not exceed 150 PSI.

Page 7

SECTION III: PRE-INSTALLATION

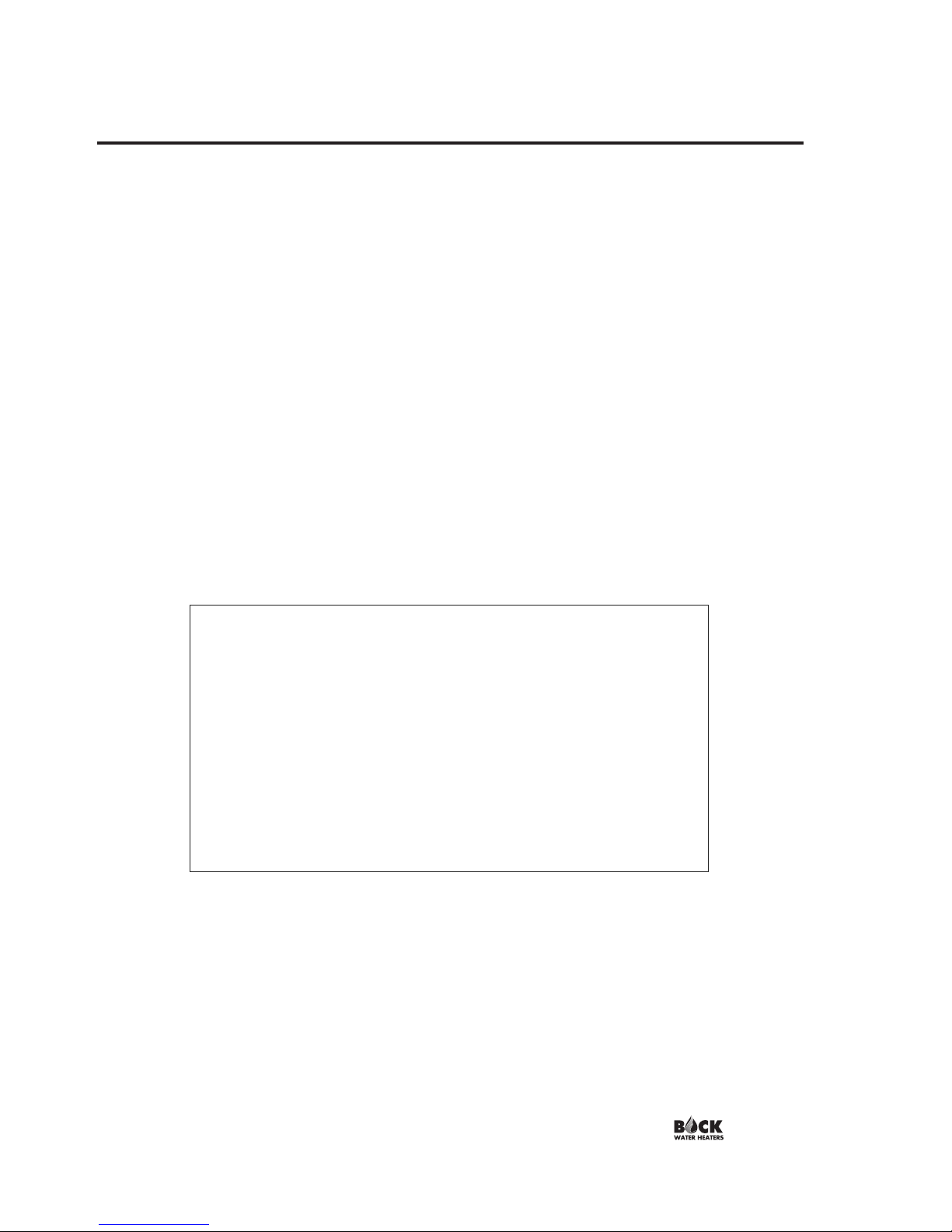

BOILER AND CIRCULATOR SIZING

The ratings published in this manual for your Bock indirect water heater can be obtained

through proper selection of boiler output and circulator capacity. As noted, the ratings in

Table 2 are based on a 77°F rise with 58°F potable water inlet temperature at a circulator

pump flow rate of 14 GPM. The boiler was set at 180°F. See Table 3 for additional first hour

ratings at pump flow rates of 8, 10, 12 and 14 GPM with 180°F and 200°F boiler water.

To determine the appropriate circulator for your system, follow these three steps:

1) Calculate the pressure drop of all straight pipe and fittings on the supply and return at the

desired flow rate.

2) Add the pressure drop from Step 1 to the pressure drop through the indirect coil tank

water heater coil (see Table 2 for friction loss) to obtain a total pressure drop.

3) Select a circulator pump that will provide adequate flow at the total pressure drop.

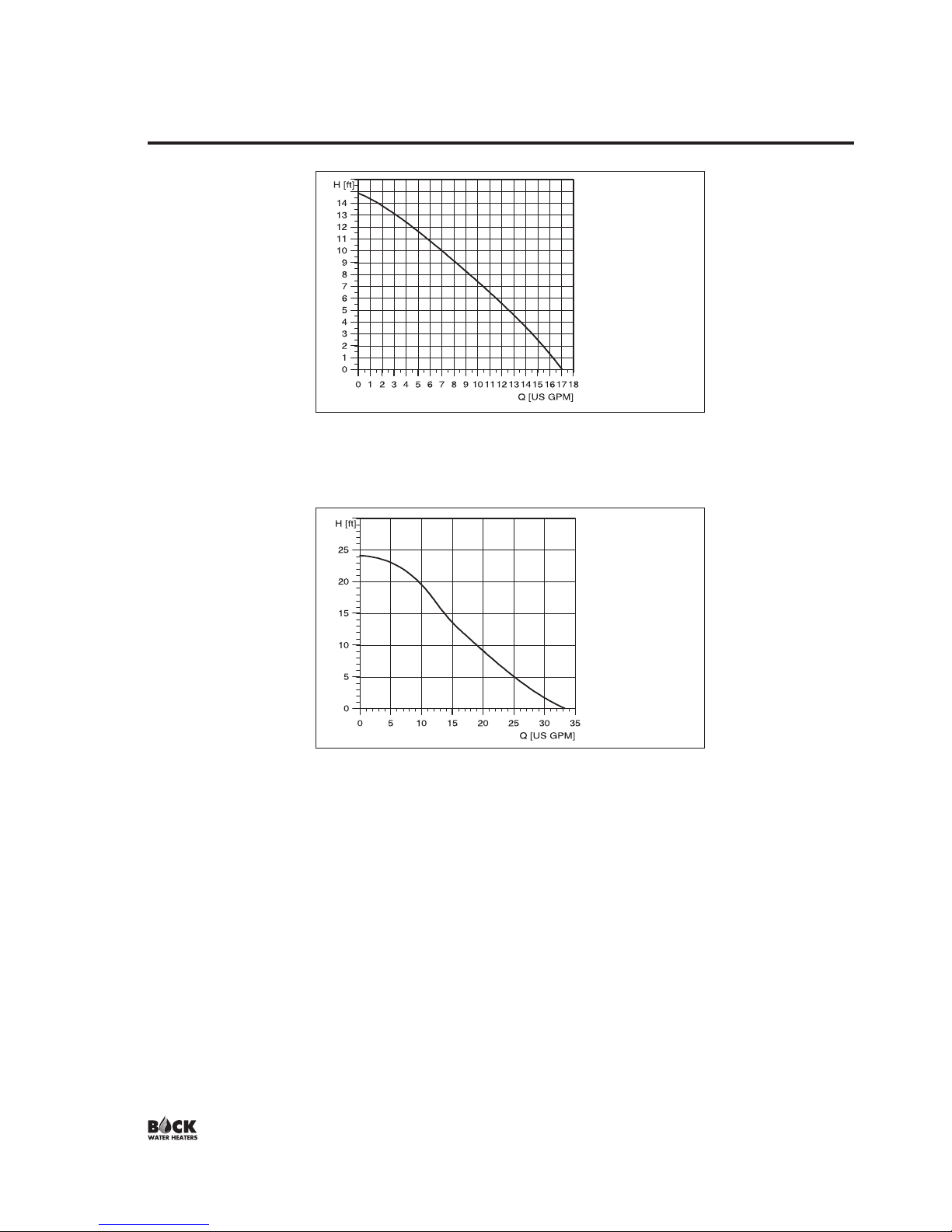

A pump performance curve should accompany every circulator pump. Figures 3-5 contain

performance curves for Taco and Grundfos circulator pumps, recommended by Bock.

Figure 3: Taco 00 Series performance curves

Page 8

UP 15-42F/FR

Closed Systems, 60 Hz

UP 26-64F

Closed Systems, 60 Hz

SECTION III: PRE-INSTALLATION (cont.)

Figure 4: GRUNDFOS UP 15-42F performance curve

Figure 5: GRUNDFOS UP 26-64F performance curve

Note: Zone valves on the heat source supply to the indirect heater are not recommended

and will drastically reduce performance.

System performance can also vary based on the heating capacity of the boiler. If the

minimum coil output (assume coil output = boiler output) listed in Tables 2 and 3 is not met,

the output (first hour rating) of the water heater will not be met at the selected flow rate.

To approximate the reduction in first hour rating as a result of low boiler capacity, use the

following formula:

New first hour rating = (First hour rating) * (Actual boiler output)/(Minimum coil output)

For example, the first hour rating of a 50SK at a 77°F rise with an 14 GPM heat source flow

rate using a boiler having a DOE heating capacity (output) of 60,000 BTU/Hr would be:

New first hour rating = (205 gal) * (60,000 BTU/Hr)/(94,000 BTU/Hr) = 131 gal

Page 9

BOILER

SUPPLY

SYSTEM

DOMESTIC

3/4"

HOT OUT

INDIRECT

WATER HEATER

BOILER

TO

BOILER

FROM

COLD

INLET

3/4"

VALVE

CHECK

PUMP

CIRCULATOR

RETURN

SYSTEM

BOILER

BOILER

1" NPT

1" NPT

BOILER

SYSTEM

SUPPLY

CIRCULATOR

PUMP

BOILER

SYSTEM

RETURN

BOILER

COLD

1 1/2"

INLET

WATER HEATER

INDIRECT

HOT OUT

DOMESTIC

1 1/2"

BOILER

FROM

TO

BOILER

CHECK

VALVE

1" NPT

1

1" NPT

1" NPT

Figure 7: 80SK, 119SK water connections

SECTION IV: INSTALLATION

WATER CONNECTIONS

All piping between the boiler and the indirect heater should be new copper with a

minimum size of 3/4” ID for models 30SK, 40SK, and 50SK. Use 1” minimum copper for

models 80SK and 119SK. Elbows should be minimized. A flow check valve must be

installed on the return line.

All piping to the inlet (cold) and outlet (hot) domestic water connections should be new

copper with a minimum size of 1/2” ID for models 30SK, 40SK, and 50SK. Use 3/4” ID

minimum for models 80SK and 119SK.

All piping should conform to local codes and ordinances. At a minimum, refer to IHLR 84

code if local codes are not in place. It is recommended that all piping be adequately

insulated with approved material to ensure minimum heat loss. If a re-circulation line is

used for domestic water, be certain that all lines are well insulated and the circulator is

temperature controlled. Install isolation valves to permit proper servicing. It is also

recommended to install a union on the domestic outlet to facilitate replacement of the hot

outlet / anode nipple on models 30SK, 40SK, and 50SK.

See Figures 6 and 7 for proper water connection installation.

Note: Indirect may be connected to a steam

boiler provided that all piping to and from

the boiler are below the water line of the boiler.

Boiler must also be protected by a low water

cut off safety device.

Figure 6: 30SK, 40SK, 50SK water connections

Page 10

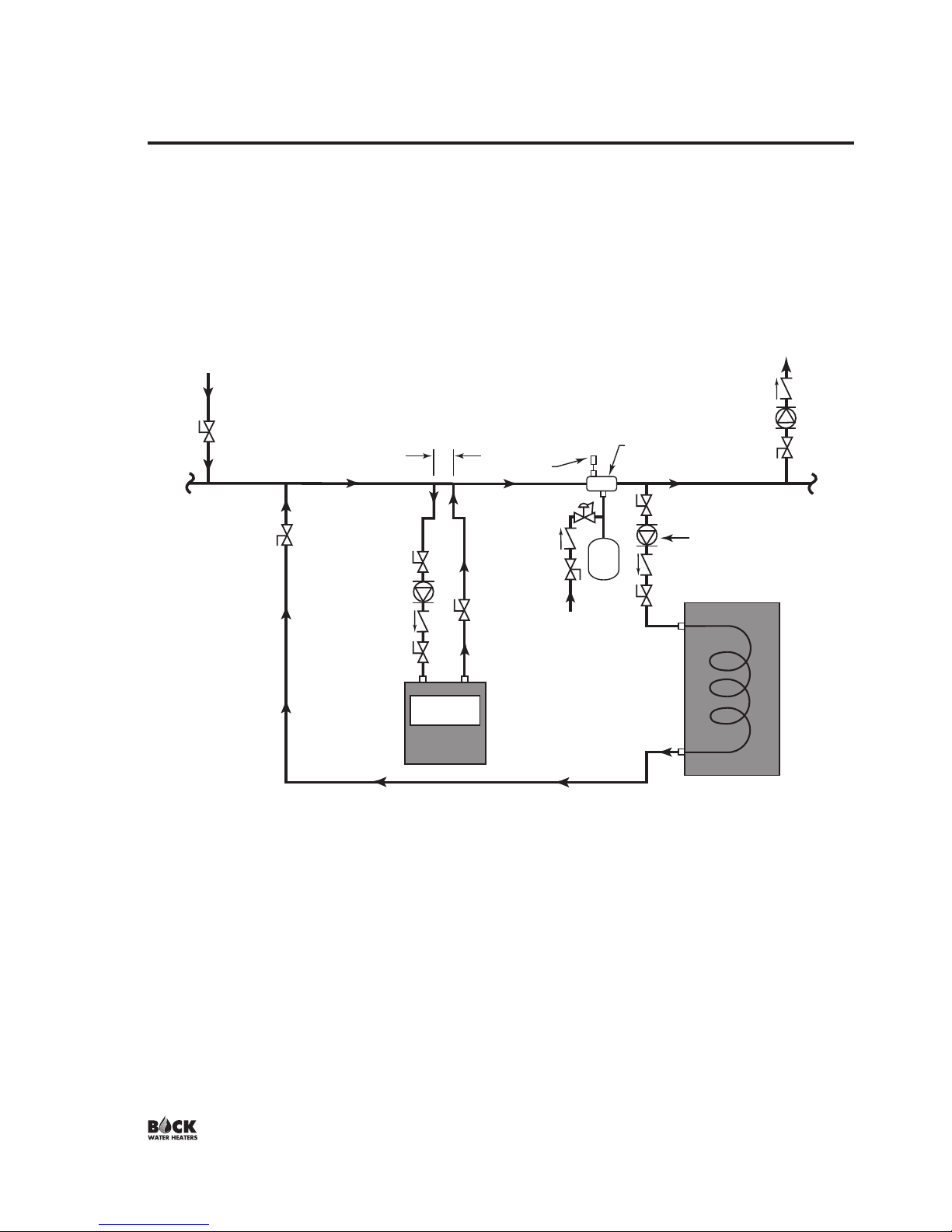

See Figure 8 for piping your Bock indirect water heater to a low-mass boiler (diagram

recommended by boiler manufacturer).

SECTION IV: INSTALLATION (cont.)

CHECK

VALVES

ZONE

CIRCULATORS

ISOLATION

VALVES

ADDITIONAL

ZONES

INDIRECT

CIRCULATOR

INDIRECT WATER

HEATER

TO

HEATING

ZONE

AIR

SEPARATOR

AIR VENT

EXPANSION

TANK

COLD

WATER

INLET

BOILER

CIRCULATOR

LESS THAN (4)

PIPE DIAMETERS

BOILER

FROM

HEATING

ZONE

ISOLATION

VALVES

ADDITIONAL

ZONES

Figure 8: Bock Indirect with Low-Mass Boiler

Loading...

Loading...