Page 1

Aftersales Training Product Information.

E92 M3 Complete vehicle.

BMW Service

www.Bimmerfest.com

Page 2

The information contained in the Product Information and the Workbook form an integral part of

the training literature of BMW Aftersales Training.

Refer to the latest relevant BMW Service information for any changes/supplements to the

Technical Data.

Information status: 07/2007

conceptinfo@bmw.de

© 2007 BMW Group

München, Germany. Reprints of this publication or its parts require the written

approval of

BMW Group, München.

VS-12 Aftersales Training

www.Bimmerfest.com

Page 3

Product Information.

E92 M3 Complete vehicle.

The 4th Generation M3

The integrated overall M concept

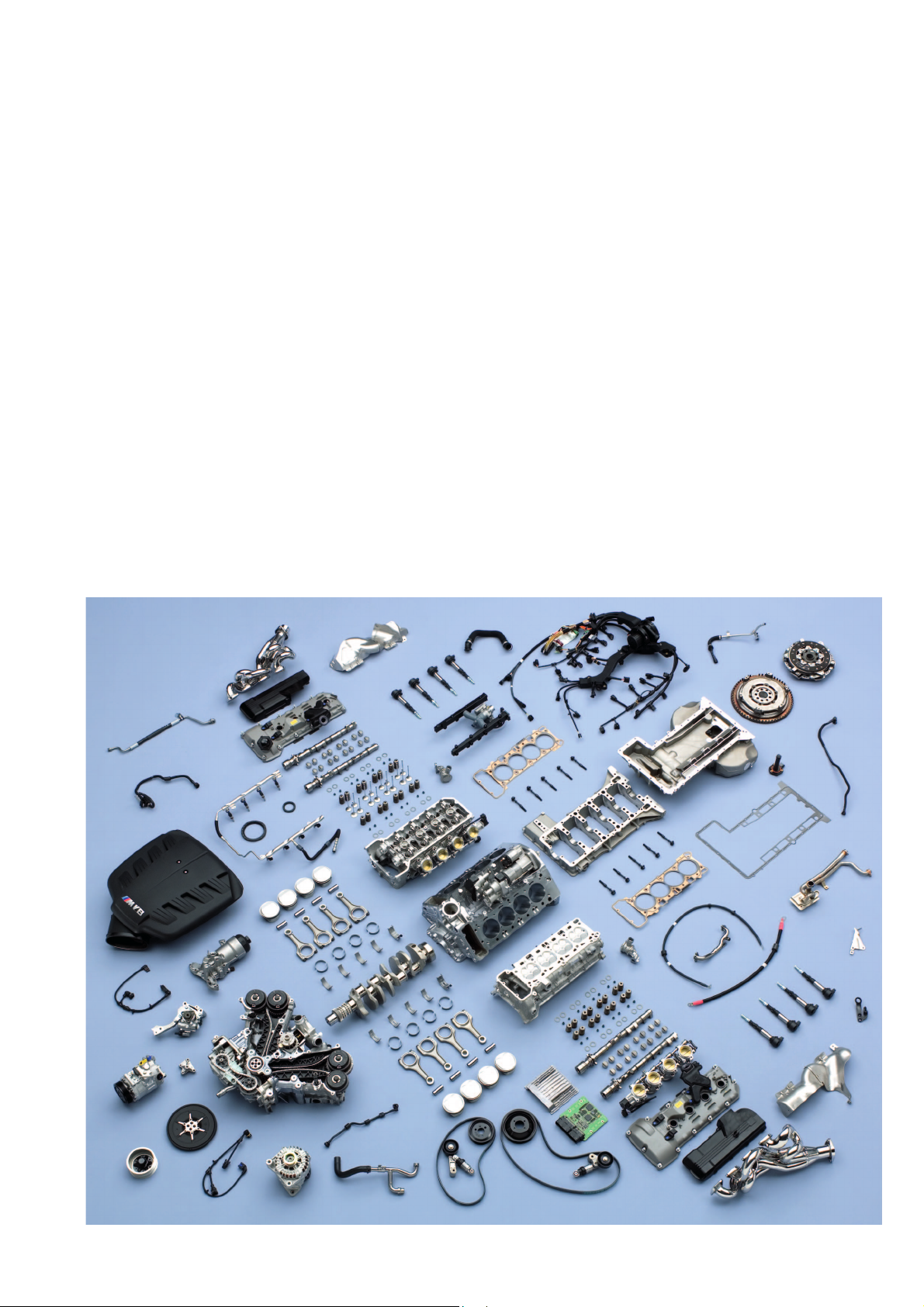

The S65B40 engine with 8 cylinders and

exceptional high engine-speed concept

www.Bimmerfest.com

Page 4

Notes on this product information

Symbols used

The following symbols are used in this product information to facilitate

better comprehension and to draw attention to important information.

3 Contains information to facilitate better understanding of the

described systems and their function.

1 Identifies the end of a note.

Information status and national variants

BMW vehicles conform to the highest safety and quality standards.

Changes in terms of environmental protection, customer benefits and

design render necessary continuous development of systems and

components.Consequently, this may result in deviations between this

product information and the vehicles available in the training course.

This document describes only EURO variants of left-hand drive vehicles.

Some controls or components may be arranged differently in right-hand

drive vehicles from the way shown on the graphics in the product

information. Further differences may arise as the result of the equipment

variants used in specific markets or countries.

Additional sources of information

Further information on the individual subjects can be found in the

following:

- Owner's Handbook

- BMW diagnostic system

- Workshop systems documentation

- SBT BMW Service Technology.

www.Bimmerfest.com

Page 5

Contents.

E92 M3 Complete vehicle.

Models

M3 Models 1

Introduction 3

Foreword 3

History 4

M3 concept 6

Competitor comparison 15

System overview 17

Vehicle electrical system/terminal status 17

MDrive 20

System components 25

Body/Interior trim and equipment: 25

S65B40O0 Engine 41

MSS60 Engine Control System 63

Drive train 73

Chassis and suspension 82

1

Service information 99

M3 concept 99

S65B40O0 Engine 100

MSS60 Engine control system 101

Drive train 102

Chassis and suspension 103

www.Bimmerfest.com

Page 6

www.Bimmerfest.com

Page 7

5

Models.

E92 M3 Complete vehicle.

M3 Models

Four Generations of the M3

EU Models E30 E36 E46 E92

M3 Coupé

2.3

(Evo. I)

Year 86-91 1990 92-95 1995 95-00 01-06 2003 07-

4 cyl.

Engine model

S14B23

Coupé

2.5

Evo. III

4 cyl.

S14B25

Coupé

3.0

6 cyl.

S50B30

Coupé

3.0

GT

6 cyl.

S50B30

Coupé

3.2

6 cyl.

S50B32

Coupé

3.2

6 cyl.

S54B32O0

Coupé

3.2

CSL

6 cyl.

S54B32T0V8S65B40O0

Coupé

4.0

Cylinder capacity

3

]

[cm

Power

[hp/kW] 200/147 238/175 286/210 295/217 321/236 343/252 360/265 420/309

At engine speed

[rpm]

max.

Power [hp/kW]

per litre 87/64 96/70 96/70 99/73 100/74 105/77,3 111/ 82 105/77.3

Torque [Nm]

At engine speed

[rpm] 4750 4750 3600 3900 3250 4900 4900 3900

EU weight*

[kg]

DIN power to

weight ratio

[kg per hp/kW] 6.0/8.2 5.0/6.9 5.1/7.0 4.9/6.7 4.5/6.2 4.4/5.9 3.9/5.2 3.8/5.1

Accel.

0-100 km/h [s]

1000 m** [s] 27.2 26.7 25.6 25.5 24.7 24.2 23.5 23.3

V

[km/h] 235 248 250*** 250*** 250*** 250*** 250***

max

2302 2467 2990 2990 3201 3246 3246 3999

6750

>7000

240 240 320 323 350 365 370 400

1275 1275 1535 1535 1535 1570 1460 1655

6.7 6.5 6.0 5.9 5.5 5.2 4.9 4.8

7000

> 7000

7000

7280

7000

7280

7400

7600

7900

8000

7900

8000

(280)

8300

8400

250*** (280)

* unladen weighton-the-road, with 75kg load,

fuel tank 90 % full, no optional equipment

** standing start

www.Bimmerfest.com

*** electronically controlled down/limited

(in brackets: increase in option V

max

)

1

Page 8

5

Comparison with E46 M3 and E92 335i

EU Models E92 M3 E46 M3 E92 335i

Coupé Coupé Coupé

Year 07- 01-06 07Engine model V8

S65B40O0

Cylinder capacity [cm3] 3999 3246 2979

Power [hp/kW] 420/309 343/252 306/225

At maximum

speed [rpm]

8300

8400

6 cyl.

S54B32O0

7900

8000

6 cyl. series

N54B30U0

5800

7000

Power [bhp/kW] per litre 105/77.3 105/77.3 102.7/75.5

Torque [Nm] 400 365 400

At engine speed [rpm] 3900 4900 1300-5000

EU weight*[kg] 1655 1570 1600

DIN power to weight ratio

[kg per hp/kW] 3.8/5.1 4.4/5.9 5.0/6.8

Acceleration

0-100 km/h [s]

1000 m** 23.3 24.2 24.5

V

[km/h] *** 250 (280) 250 250

max

* unladen weighton-the-road, with 75kg load,

fuel tank 90 % full, no optional equipment

** standing start

*** electronically controlled down/limited

(in brackets: increase in option V

4.8 5.2 5.5

).

max

2

www.Bimmerfest.com

Page 9

6

Introduction.

E92 M3 Complete vehicle.

Foreword

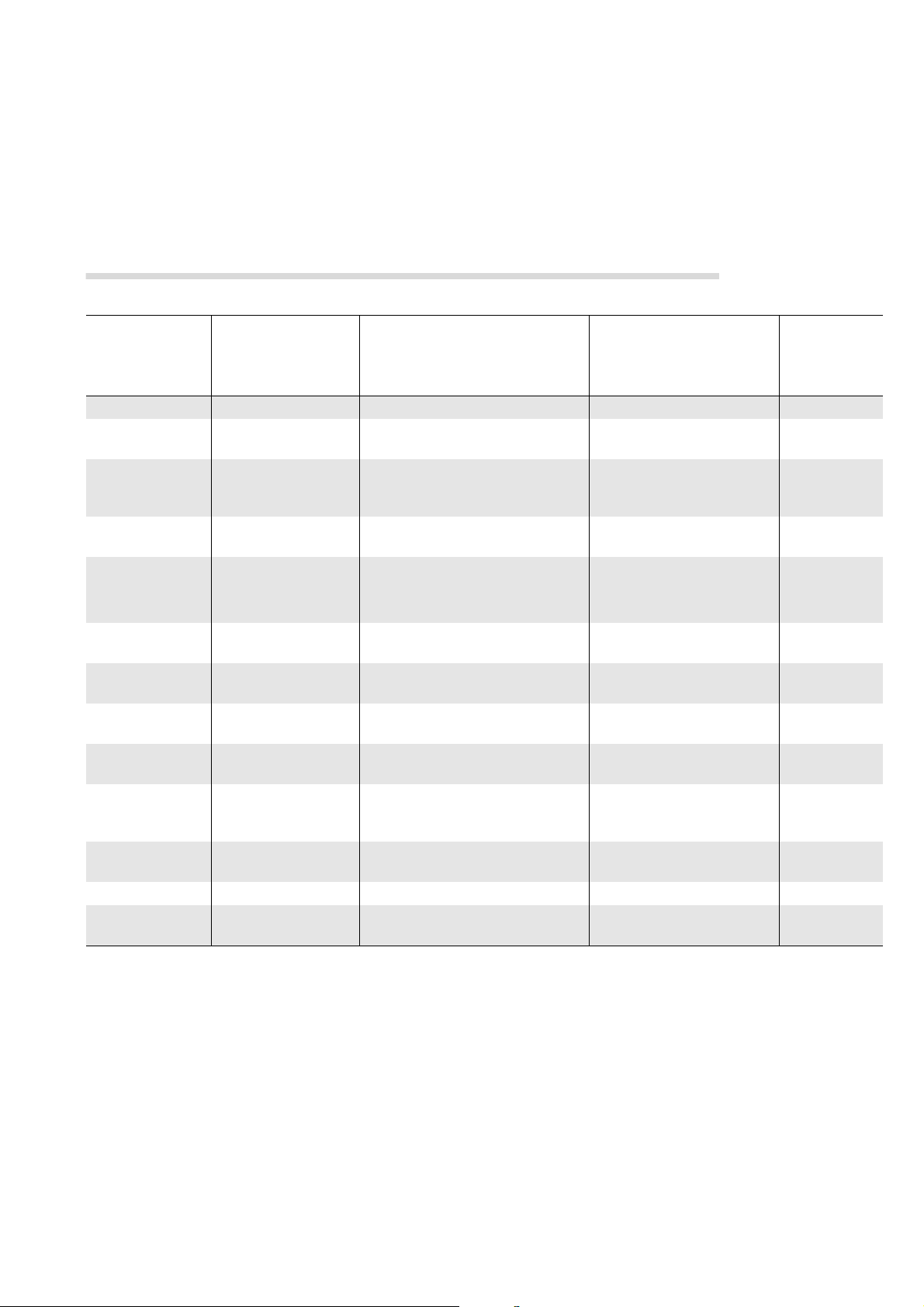

A new addition to the ’M’ family has just

arrived. The new BMW M3.

A simple letter andnumbercombinationwhich

has become synonymous with an extremely

powerful and dynamic performance car.

The M3 is now in its fourth generation with a

history of success in the world of motor sport,

winning races across the globe since its

beginning back in 1985. Not only has the race

version of the M3 gained a successful motor

sports heritage, its on road credentials live up

to the expectations and demands of today’s

M3 drivers. The E92 M3 will be launched in

the middle of 2007.

This preciselybalanced sportscar will set new

benchmarks in driving dynamics for sport

coupes. As with its predecessor the focus has

been on optimizing the power to weight ratio

whilst maintaining the high engine speed

concept. This combination ensures that both

power and driving agility are exceptional,

placing the M3 in an even higher level of sport

car competition.

1 - E92 M3 side panel

3

www.Bimmerfest.com

Page 10

6

History

E30 M3

Approx. 18,000 vehicles delivered,

Coupé and Convertible. Two engines

worldwide.

3 - The E30 M3 Cecotto takes part in the German Touring Car

Championships.

2 - E30 M3

1986

The E30 M3 celebrates its launch with a 4cylinder engine (S14B23) and 194/200 hp,

with/without catalytic converter.

1987

The M3 dominates touring car racing on the

world’s race tracks. Roberto Ravaglia brings

the World Championship title back to Munich.

The limited edition Evo I with 200 hp

(S14B23) arrives.

1988

The sought-after Evo II now features 220 hp

(S14B23).

Those who prefer ’open-top’ driving can

choose the M3 Convertible.

1989

The M3 wins 16 national and European titles,

including the European mountain

championship for touring cars.

The special edition Cecotto with 215 hp

(S14B23) makes its debut.

1990

The M3 is awarded 15 international and

national titles.

The limited number of Evo IIIs with catalytic

converter and 238 hp (S14B25) are quickly

snapped up.

E36 M3

Over 70,000 vehicles; Coupé,

Convertible and Saloons are produced,

not including the Z3 M Roadster and Z3

M Coupé. The M3 is available with two

different engines and vehicle

configurations; one for the EU, and

another for US release.

4 - E36 M3

1992

The second M3 generation, the E36 M3 with

6-cylinder engine and 286 hp (S50B30/US

S52B30 with 240 hp) causes a stir, the

individual version makes its worldwide debut

at the Geneva Motor Show. The highpressure VANOS variable camshaft control

(single VANOS) is used for the first time in an

M engine.

1993

The E36 M3 is now also available as a

Convertible.

1994

Steve Soper, Joachim Winkelhock and

Johnny Cecotto win the touring car world

championship.

A 4-door saloon model of the E36 M3 is

offered for the first time.

The homologation series of the M3 GT

(Coupé only) develops 295 hp (S50B30).

4

www.Bimmerfest.com

Page 11

6

1995

The E36 M3 European model is completely

upgraded. For example, it now features, a

compound brake with brake discs made from

compound materials, and high-pressure

double VANOS, enabling the engine

(S50B32) to reach 321 hp (US release

S52B32 still has 240 hp). The model remains

available only as a Coupé and a Convertible.

1996

The E36 M3 is made available with sequential

M transmission (SMG I).

E46 M3 Over

80,000 vehicles delivered, Coupé and

Convertible. One worldwide engine.

5 - E46 M3

2000

The third generation, the E46 M3 has a 6cylinder engine with a high engine speed

concept and 343 hp (S54B32). This first M

"high engine speed concept" engine

impresses the automotive experts and earns

the "Engine of the Year" award. The M3

becomes the first M vehicle to be delivered

with fully variableM limited slipdifferential with

up to 100 percent lock effect as a standard

feature.

2001

The M3 Convertible combines the fascination

of M power with the fun of open-top driving.

The 2nd generation sequential M

transmission (SMG II) is available.

2002

With the M3 CSL which produces 360 hp

(S54B32HP), the BMW M shows how a highperformance vehicle can be optimized still

further through the use of lightweight

construction materials in an intelligent

lightweight design. The M track mode (now

known as M dynamic mode), SMG Launch

Control (automatic upshift in S mode shortly

before maximum speed), and an electronic

ATF level are all used for the first time.

6 - E46 M3 CSL

E92 M3

The Coupé era begins. One worldwide

engine.

7 - E92 M3

2007

The fourth generation of the M3 arrives

featuring the S65B40 high-speed 8-cylinder

engine.

www.Bimmerfest.com

5

Page 12

6

M3 concept

8 - E92 M3 (Diagonal view from front)

• Body

In addition to the sporty and dynamic

appearance in both the external design and

the interior, the main features were weight

optimization and a reinforced bodyshell for

improved dynamic handling.

A further outstandingfeature of the E92M3

is also once again the sophisticated

aerodynamics typical of the M series.

9 - E92 M3 (Diagonal view from rear)

6

www.Bimmerfest.com

Page 13

6

• M-specific equipment

Exterior:

Front zone with generous air inlets,

"Powerdome" engine hood with air inlet,

carbon roof, side gills, outside mirrors, sill,

wheel rim design, extended wheel arches,

and the boot with spoiler and four exhaust

tailpipes all combine to provide the initial

impression.

Interior:

Sill trim strips, seats, steering wheel,

instrument cluster, switches in the centre

console and the gear lever design all

increase the anticipation.

• Engine

Under the engine hood, the 8-cylinder

power pack is the high-speed S65B40.

With individual throttle butterflies, a

generous intake air and exhaust manifold,

and many more refined M-specific features

such as the MSS60 engine control, the

S65B40 is once again an outstanding

highlight of the M series.

• Drive

Double-disc clutch, 6-gear manual

transmission and the fully variable M

limited-slip differential ensure the forward

momentum.

• Chassis and suspension

Front and rear axles with new suspension

geometry and M-specific suspension

settings with 18" tyres.

Specific objectives of the development

were weight optimization, and in particular,

control of the longitudinal and lateral

acceleration/power that is generated when

enjoying the pleasure of driving the M3.

The M3 brake with compound brake discs,

new high-performance brake pads and

standard M series ABS/DSC guarantee

optimum braking efficiency and active

safety.

• Electrical system

The electrical equipment and bus structure

of the M3 are based on the E92.

The optional MDrive menu can be used to

preset/configure the standard Servotronic

and the M engine dynamics control

(enhanced with "Sport Plus"), the optional

electronic damper control EDC-K (in the

E9x series only available in the M3) and the

DSC M dynamic mode.

In the E9x series, the BMW Individual High

End audio system isofferedfor the first time

in the M3.

www.Bimmerfest.com

7

Page 14

6

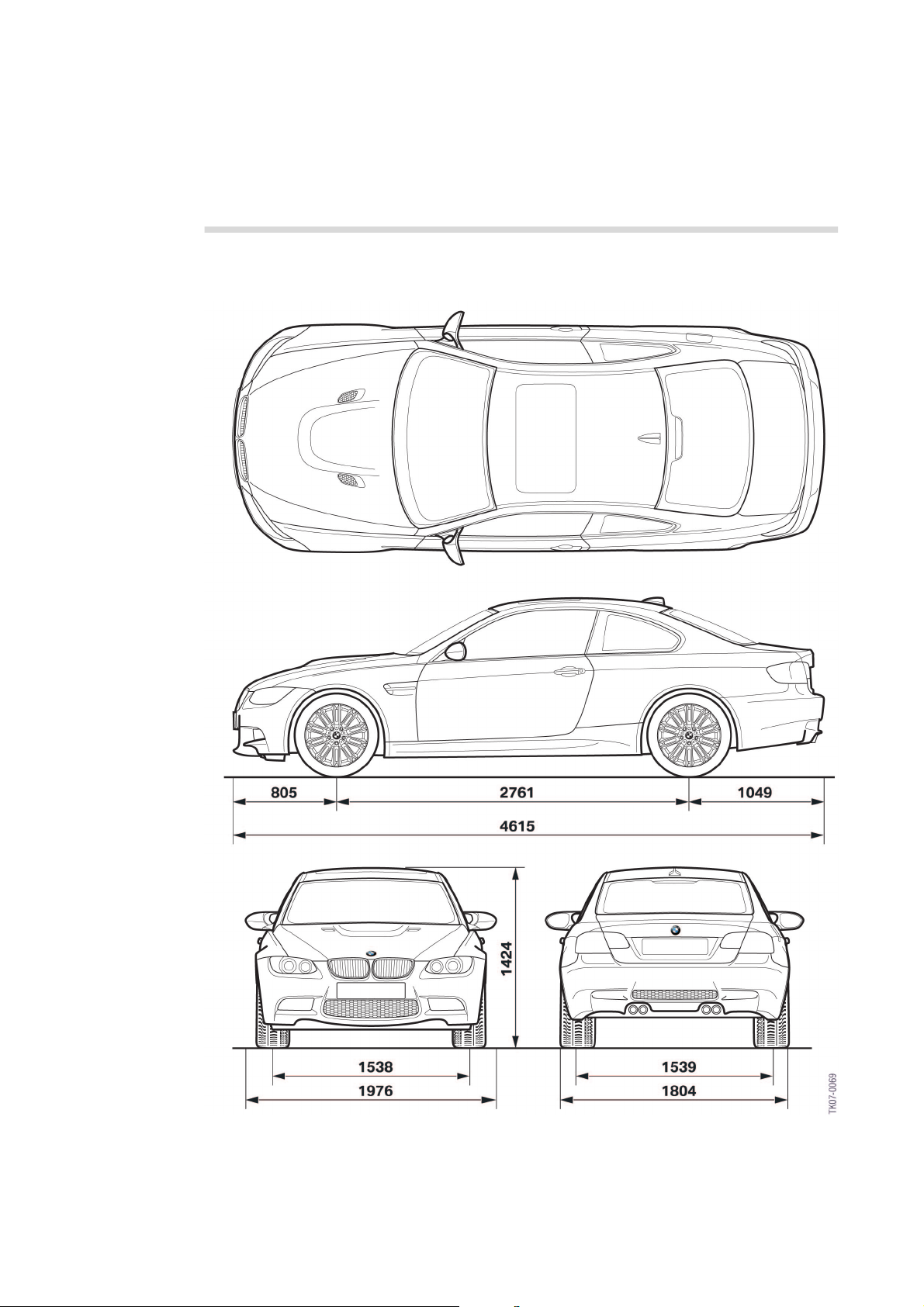

Dimensions and Vehicle Data

Garage dimensions

10 - Dimensions of the E92 M3

8

www.Bimmerfest.com

Page 15

Vehicle data comparison

6

Designation/Unit of

Measurement

Seats 4 5 4

Length [mm] 4615 4492 4580

Body width [mm] 1804 1780 1782

Width above mirror [mm] 1976 1924 1985

Height [mm] 1424 1383 1375

EU unladen weight [kg] 1655 1570 1600

Load volume [litres] 430 410 430

CwxA 0.68 0.66 0.62

Wheelbase [mm] 2761 2731 2760

Track width, front [mm] 1538 1508 1500

Track width, rear [mm] 1539 1525 1507

Steering

Average overall ratio

Manual transmission

gear ratio

Gear 1/2/3/4/5/6/R

Rear-axle finaldrive gearratio

[:1] fully

variable M limited slip

differential

E92 M3 E46 M3 Coupé E92 335i

Rack

12.5

GS6-53BZ (M)

4.055/2.396/1.582/1.192/

1/0.872/3.678

3.85

Yes

Rack

15.4

S6S420G

4.227/2.528/1.669/1.226/

1/0.828/3.746

3.62

Yes

Rack

16.0

GS6-53BZ

4.055/2.396/1.582/1.192/

1/0.872/3.678

3.08

No

Tyre type/Wheel rim type/

Front rim offset [mm]

Tyre type/Wheel rim type/

Rear rim offset [mm]

Brake disc front/rear

Diameter x thickness [mm]

Type of fuel [RON] 98 (min. 95) 98 (min. 95) 98 (min. 91)

Tank capacity/Reserve [litres] 63/8 63/8 63/8

EU consumption/distance

total [litres/km] 12.4/510 11.9/530 9.5/665

EU-CO2 emission [g/km] 295 287 228

Permitted emission limits Europe: EU4/E-OBD-EU4;

245-40 ZR 18/8.5Jx18/

IS29

265-40 ZR 18/9.5Jx18 /

IS23

(M Compound)

360x30/350x24

USA: US-LEV/US-OBDLEV 2, EVAP-LEV 2;

Japan: Japan LEV 200/

Japan OBD (same as EOBD)

225-45 ZR 18/8Jx18/

IS47

255-40 ZR 18/9Jx18 /

IS26

(M Compound)

325x28/328x20

EU3 EU4 (as for E92 M3)

225-45 WR 17 RSC/8Jx17/

IS34

255-40 WR 17 RSC/8.5Jx17/

IS37

(Compound)

348x30/336x22

www.Bimmerfest.com

9

Page 16

6

Engine and technical data

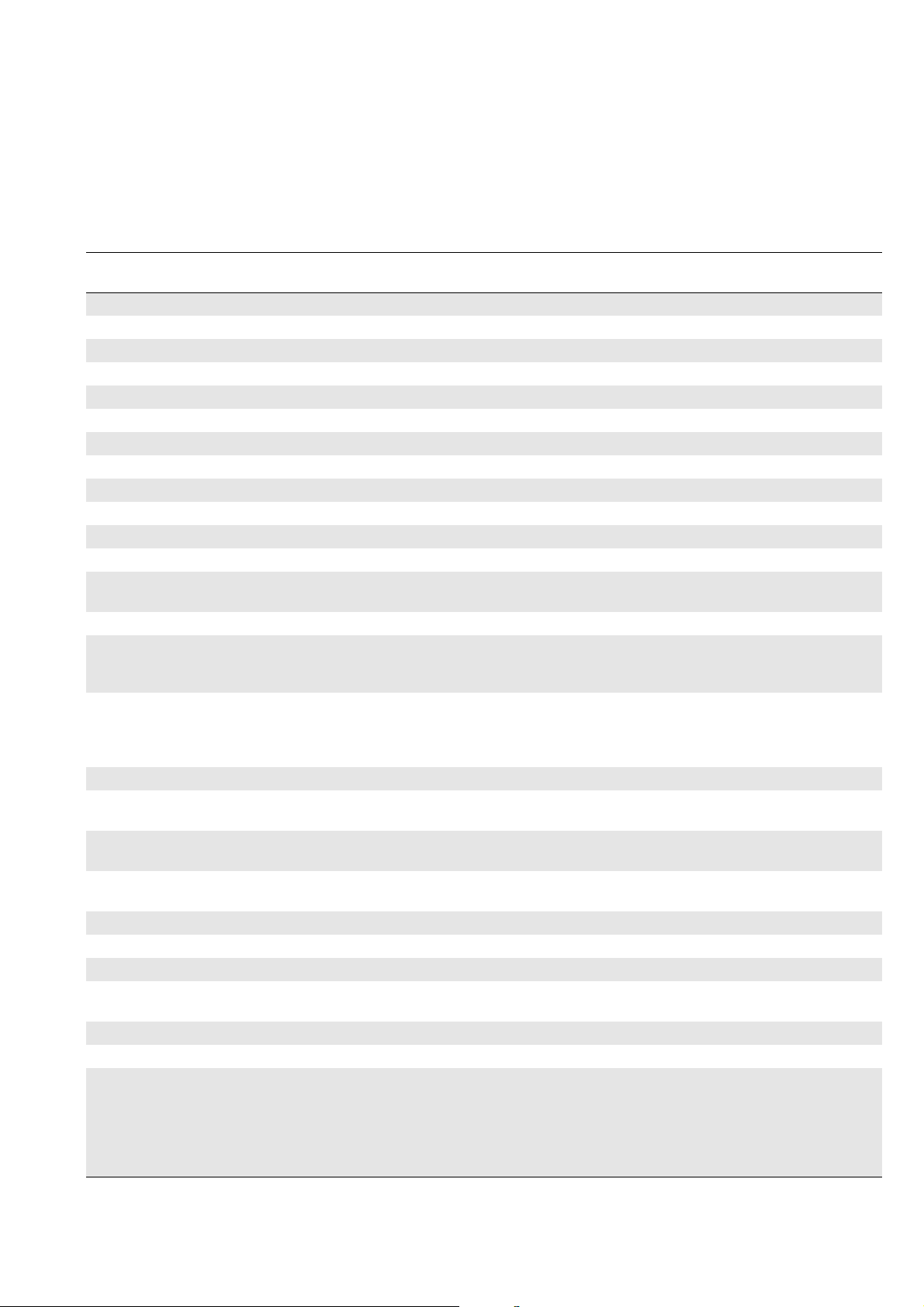

V8 with high engine speed concept

It will be the first time that a V8 engine has

been fitted in a series production M3. The

main concept behind this high-revving, high

performance enginewith a sportysound is the

extremely light, rigid and robust construction

which is capable of reaching extreme engine

speeds of up to 8,400 rpm. The engine

achieves an impressive 420 hp (over 100 hp

per litre).

The S65B40 is derived from its big brother,

the S85B50. The main changes can be seen

11 - S65B40 front view

in the engine oil system, VANOS valve gear

system and air intake system. Special

consideration has also been given to engine

weight optimization.

The engine with all its assemblies is built inthe

special engine production area of the Munich

BMW plant.

One standard engine is used throughout the

world and adapted to suit specific market

requirements.

10

www.Bimmerfest.com

Page 17

6

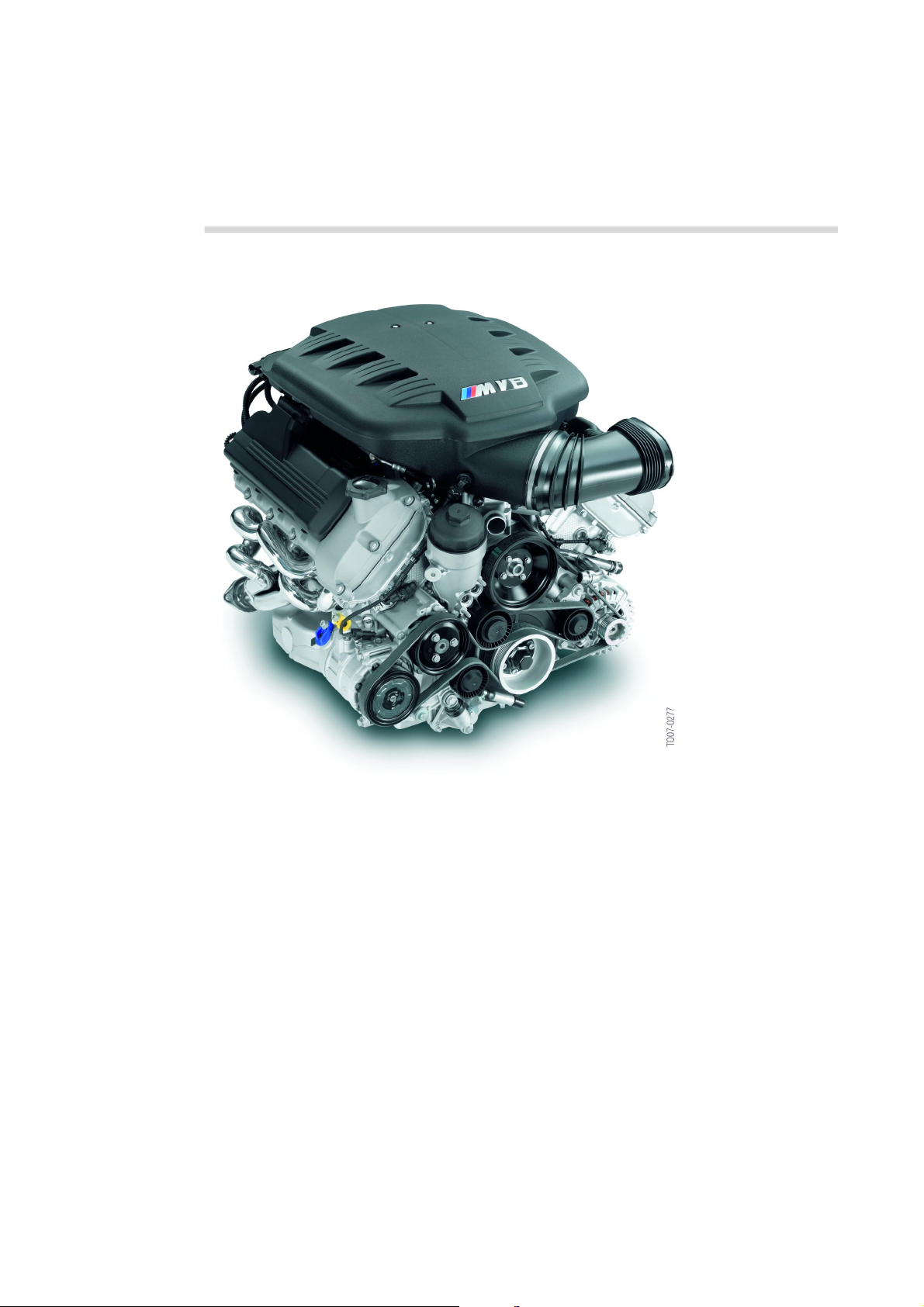

A new dimension to the high engine

speed concept

The M engineers consider the high engine

speed concept to be the most intelligent

strategy of obtainingthe maximum thrustfrom

a vehicle.

For example, in a modern formula 1 engine,

the crankshaft works at up to 19,000 rpm

(resulting in piston speeds of over 25 metres

per second).

The actual thrust at the driven wheels is the

decisive factor for car acceleration. This thrust

is achieved by the engine speed, the torque

and the short gear ratio.

12 - Formula 1 example

This concept has beenadopted forvehicles in

the 'M' range from motor sport. The fully

variable M limited-slip differential means that

the thrust is optimally distributed to the live

axle.

Furthermore, the S65B40 also includes the

established M-specific features such as

double VANOS, individual throttle butterflies

and high-performance engine electronics

(MSS60 control unit).

14 - S65B40 Notional view without the intake manifold

Technical workarounds by increasing the

cylinder capacity or boosting become

superfluous, thus avoiding the increased

engine weight and consumption often

associated with these methods.

The high engine speed concept helps to

achieve dynamically agile handling and the

maximum in sports driving performance

characteristics.

A maximum torque of 400 Newton meters at

3,900 rpm is reached. Approx. 85 percent

(340 Nm) can be utilized beyond the

enormous engine speed range of 6,500 rpm.

The S65B40 attains 8,400 rpm, and therefore

a value that was previously only reserved for

racing car engines or exotic custom vehicles.

3 For safety reasons, due to the engine

dynamics when the vehicle is stationary (i.e.

without a road-speed signal), it is already

down-controlled at 7,000 rpm to prevent the

engine speed from increasing into an

impermissible range. 1

13 - S65B40 View of the intake manifold

11

www.Bimmerfest.com

Page 18

6

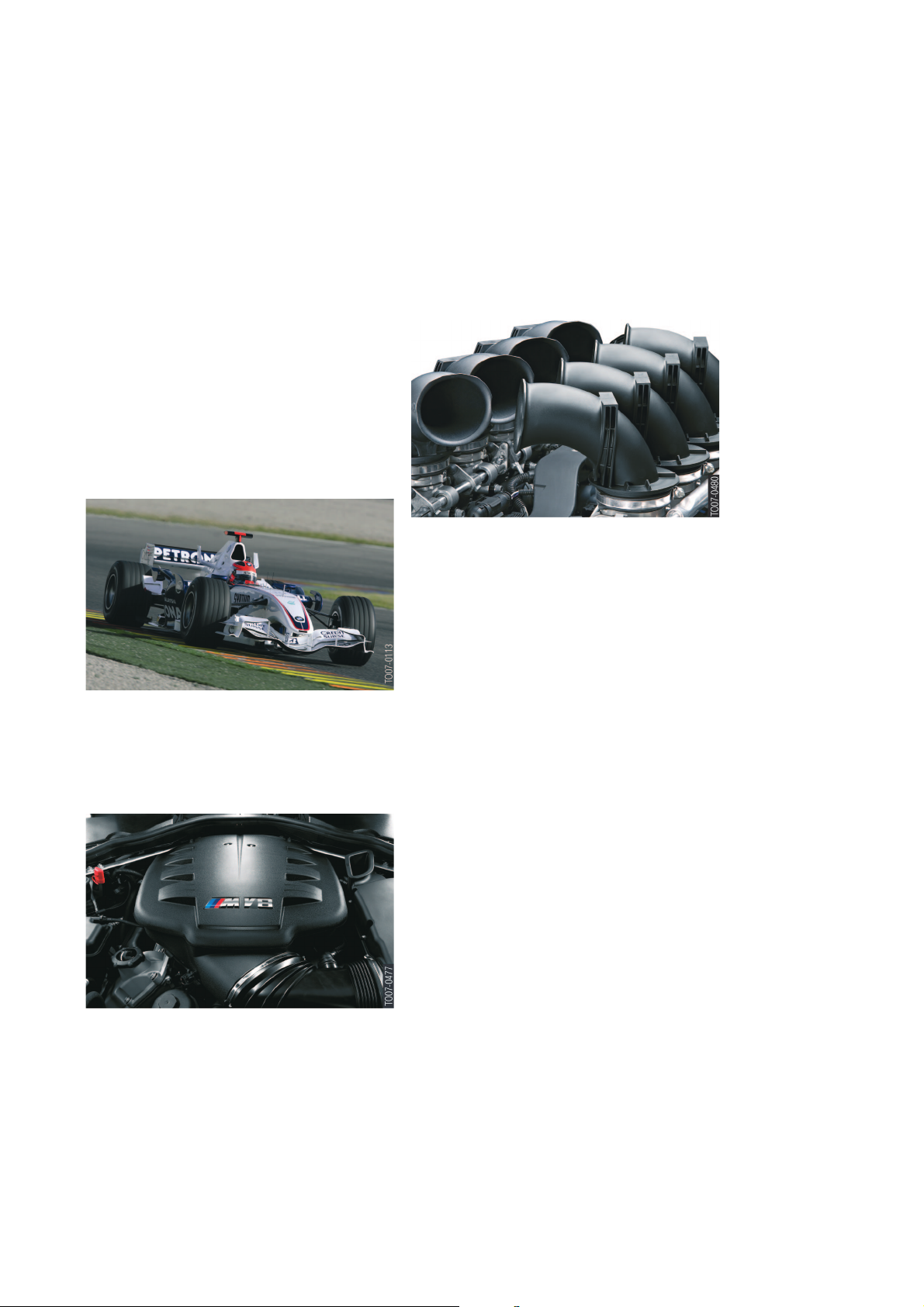

15 - E92 M3: S65B40O0 Power and Torque Curve 16 - E46 M3: S54B32O0 Power and Torque Curve

Technical Data E92 M3 E46 M3 E6x M5/M6

Engine identifier S65B40O0 S54B32O0 S85B50O0

Engine type

firing order

firing interval [° KW]

Cylinder capacity [cm3] 3999 3246 4999

Bore [mm] 92 87 92

Stroke [mm] 75.2 91 75.2

Space between cylinders [mm] 98 91 98

Power [hp/kW]

at speed [rpm]

Torque [Nm]

at speed [rpm]

Breakaway speed [rpm] 8400 8000 8250

Compression ratio 12:1 11.5:1 12:1

Engine control

Combustion monitoring

Fuel delivery

Fuel delivery pressure [bar]

Camshaft drive 2x double-roller chain Double-roller chain 2x single-roller chain

Variable camshaft control

(VANOS)

Adjustment range E/A [°KW] 72-130/81-129 70-130/83-128 79-145/91-128

Kingpin inclination E/A [°KW] 58/48 60/45 66/37

Response time E/A [°KW] 256/256 260/260 268/260

Engine weight [kg] 202 217 240

V8 engine with 90° engine block and 17

mm cylinder bank offset

4 valves per cylinder.

1-5-4-8-7-2-6-3

90

420/309

8300

400

3900

MSS60

Ion current monitoring

DME => Electric fuel pump control (LolCAN) => three-phase flow pump

3-6

2x double (engine oil pressure)

oscillating rotor VANOS

6 in-line engine/

4 valves per cylinder

1-5-3-6-2-4

120

343/252

7900

365

4900

MSS54

Standard misfiring and

knock identification

DME

=> DC pump

5

Double

high-pressure VANOS

V10 engine (design as S65)

1-6-5-10-2-7-3-8-4-9

90/54

507/373

7750

520

6100

MSS65

Ion current monitoring

DME => Electric fuel pump

control (PWM) => Double

pump system

3-6

2x double

high-pressure VANOS

12

www.Bimmerfest.com

Page 19

6

Overview of Special Features

Body:

• M3 Front and rear apron

• Carbon fibre roof in matching colour, if no

optional sliding/tilt sunroof

• Gills in front side panels

• M3 outside mirrors

• Aluminium hood with "Power Dome" and

air inlet

• M dome braces, thrust panel and

underbody V-brace

• Weight-optimized bumper brackets, front

and rear

• Optimized heat isolation package

• Optimized noise isolation package

• Optimized underbody panelling, front and

rear.

Interior:

• M3 steering wheel

• M gear lever

• M driver foot supports

• M3 seats

• Lighter floor trim (carpet)

• Lightweight design through-loading in rear

Electrics:

• M3 Instrument cluster

• M-specific switches for gear lever in the

centre console

• Buttons for the tyre pressure system

between centre air conditioning outlets

• Intelligent generator control (IGR)

• AGM battery.

www.Bimmerfest.com

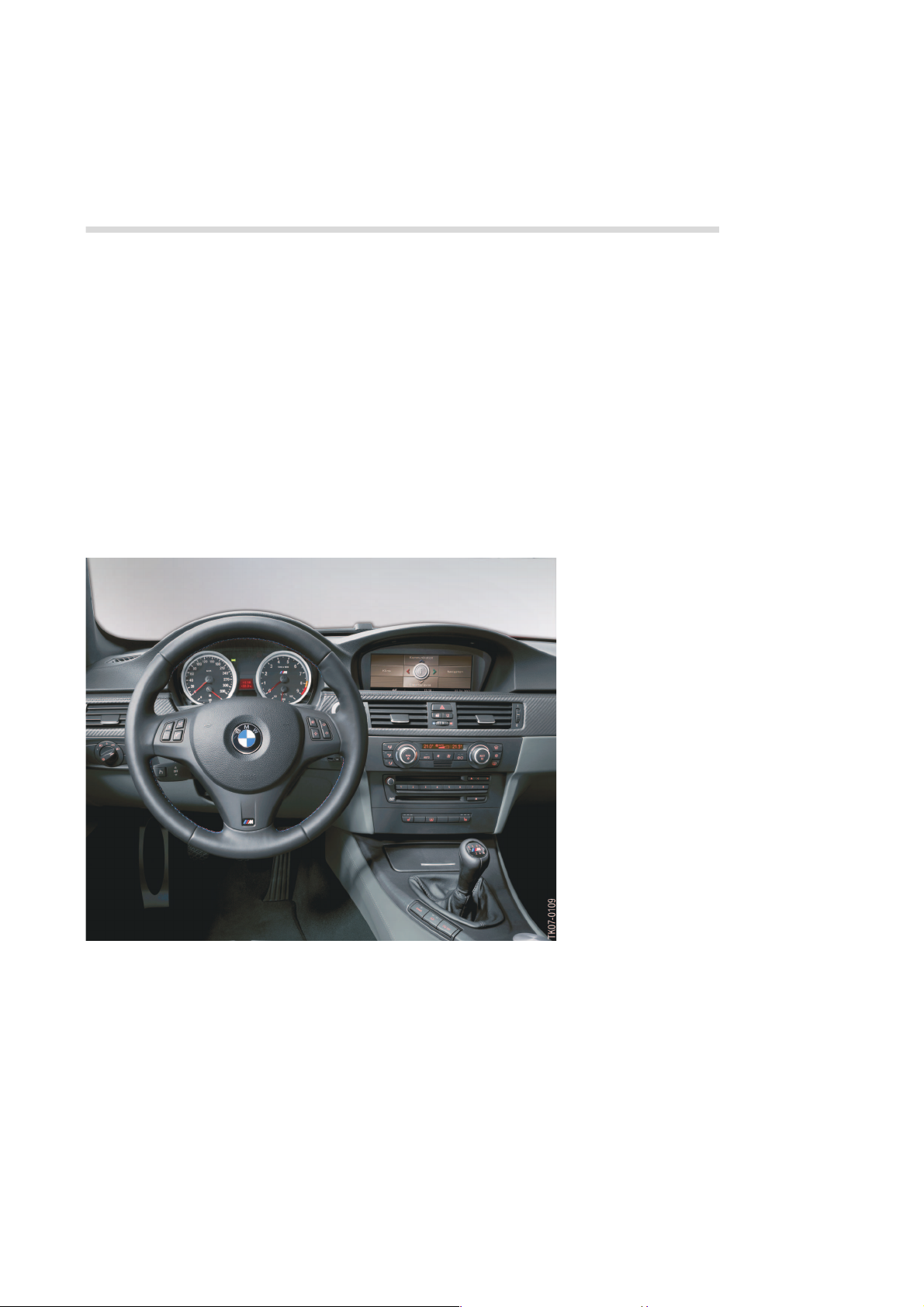

17 - E92 M3 cockpit

Engine:

• New high-engine-speed concept V8

engine S65B40 with MSS60 engine

control system

• M3 Air intake guide

• M Individual throttle butterflies

• M Ion-flow combustion monitoring

• M VANOS

• M3 Exhaust system

13

Page 20

6

Drive:

• Dual-disc clutch used in an M3 for the first

time

• M 6-gear manual transmission

• Fully variable M differential with locking

action

Chassis:

• M3 Rims, tyres

• M3 Compound brake system

• Adapted front axle carrier, M front axle

components

• Servotronic hydraulic steering, M steeringgear ratio

• Adapted rear axle carrier,

M rear axle components

M-specific options:

• MDrive menu

• EDC-K

• 19" M3 rims, tyres

• Seat back width adjustment (passive)

• Enhanced leather interior

• High speed down-control option 7ME "M

Driver’s Package" (280 km/h).

Individualization options:

• BMW Individual High End audio system

• Individual highly-polished shadow line

• Individual interior trim

• Individual paint finishes.

14

www.Bimmerfest.com

Page 21

Competitor comparison

6

Designation/Unit of

Measurement

Engine configuration/no.

of cylinders/Valves per

cylinder

Cylinder capacity [cm3] 3999 3596 4163 6208

Bore/Stroke [mm] 92/75.2 96.0/82.8 84.5/92.8 102.2/94.6

Power [hp/kW]

at speed [rpm]

Torque [Nm]

at speed [rpm]

Compression ratio, Type

of fuel [RON]

Power [hp] per litre 105.0 90.4 100.9 77.5

EU unladen weight [kg] 1655 1470 1725 1755

EU power to weight ratio

[kg per PS] 3.94 4.52 4.11 3.65

Acceleration

0-100 km/h [s]

V

[km/h] *

max

electronically limited

Drive type Rear axle Rear axle All-wheel Rear axle

Transmission 6-gear 6-gear 6-gear 7-gear automatic

Type of tyres, front/rear 245/265-40 ZR 18 235/265-40 ZR 18 4x255-40 ZR 18 255-40/35 R18

EU consumption, total

[litres/km] 12.4 11.0 13.4 14.2

Tank capacity [litres] 63 64 63 62

EU-CO

emission [g/km] 295 266 322 338

Permitted emissions

limits

Length/width/height

[mm]

CwxA 0.68 0.56 0.67 NA

Wheelbase/turning circle

[mm/m] 2761/11.7 2350/10.9 2648/11.3 2715/10.76

Track width front/rear

[mm]

EU payload [kg] 500 340 482 420

Load volume [litres]

2

E92 M3 Porsche 911

Carrera

V8 / 4 Boxter 6/4 V8 / 4 V8 / 4

420/309

8300

400

3900

12.0:1

98

4.8 5.0 4.8 4.7

250*

(280)

EU 4 EU 4 EU 4 EU 4

4615/1804/1418 4427/1808/1310 4586/1816/1415 4652/1740/1413

1538/1539 1486/1534 1559/1569 1493/1474

430 135 460 435

325/239

6800

370

4250

11.3:1

98

285 250* 250*

Audi RS4 MB CLK 63

AMG

420/309

7800

430

5500

12.5:1

98

481/354

6800

630

5000

11.3:1

98

www.Bimmerfest.com

15

Page 22

6

16

www.Bimmerfest.com

Page 23

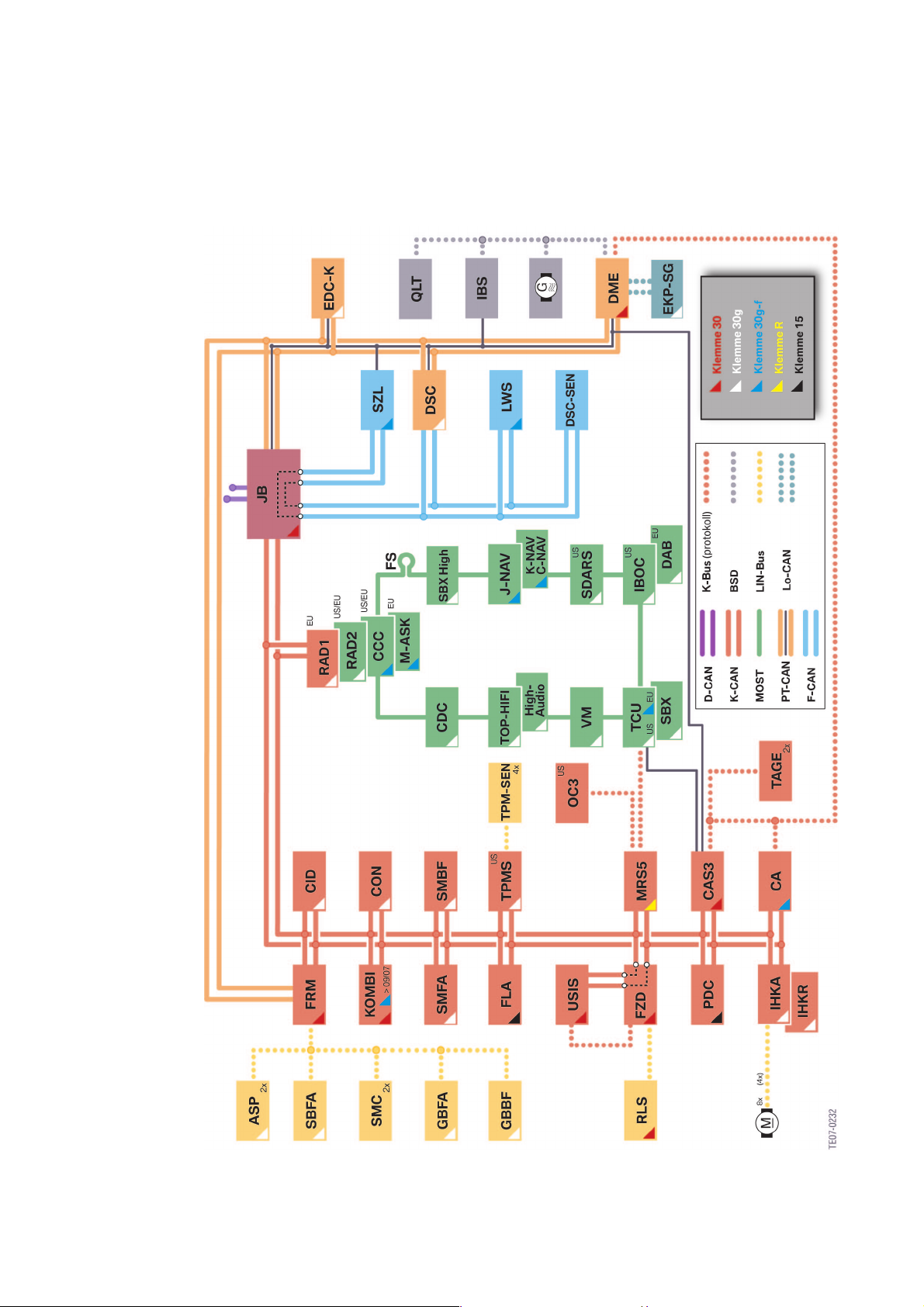

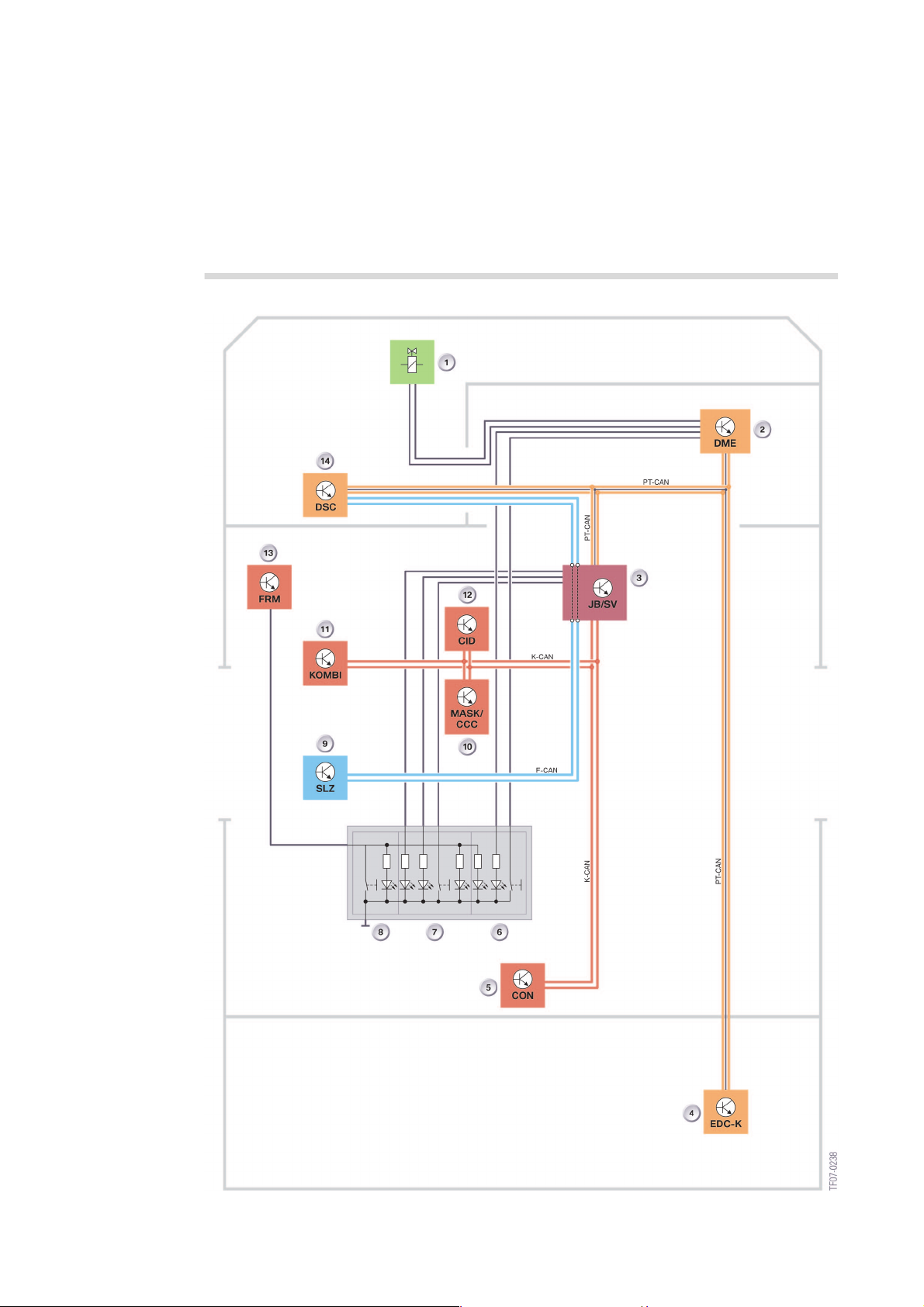

7

System overview.

E92 M3 Complete vehicle.

Vehicle electrical system/terminal status

The vehicle electrical system is based on the

E92 series production vehicle system and has

been adapted for the M3.

www.Bimmerfest.com

17

Page 24

7

18

1 - E92 M3 vehicle electrical system overview and terminal status

www.Bimmerfest.com

Page 25

7

Index Explanation Index Explanation

ASP Outside mirrors IHKR Integrated heating/air conditioning

system

CA Comfort Access JB Junction box

CAS Car Access System KOMBI Instrument cluster

CCC Car Communication Computer LWS Steering angle sensor

CDC (Compact) CD changer M-ASK Multi-audio system controller

CID Central information display MRS5 Multiple restraint system, 5th

generation

CON Controller OC3 Seat occupancy detector mat (US)

DAB Digital Audio Broadcast PDC Park distance control

DME Digital motor electronics QLT Quality, level, temperature oil

sensor

DSC Dynamic Stability Control RAD Radio1 or Radio2

DSC-SEN DSC sensor RLS Rain light sensor

DWA Anti-theft alarm system SBFA Switch block, driver's door

EDC-K Continuous Electronic Damping

Control

EKP Electric fuel pump control unit SBX High Interface box High

FLA High beam assistant SDARS Satellite tuner (US only)

FRM Footwell module SMBF Passenger's seat module

FS MOST direct access SMC Stepper motor controller

FZD Roof function centre SMFA Driver's seat module

GBBF Seat beltextendercontroller,front

passenger

GBFA Seat belt extender controller,

driver

HighAudio

IBOC In Band On Channel (Digital

IBS Intelligent battery sensor USIS Ultrasonic passenger-

IHKA Integrated automatic heating/air

BMW Individual High End

Audiosystem

Radio)

conditioning system

SBX Interface box (ULF functionality)

(Bluetooth telephony, voice input

and USB/audio interface)

SZL Steering column switch cluster

TAGE Outside door handle electronics

TCU Telematics Control Unit

TOP-HiFi Top-HiFi amplifier

compartment sensor

VM Videomodule (only for US)

www.Bimmerfest.com

19

Page 26

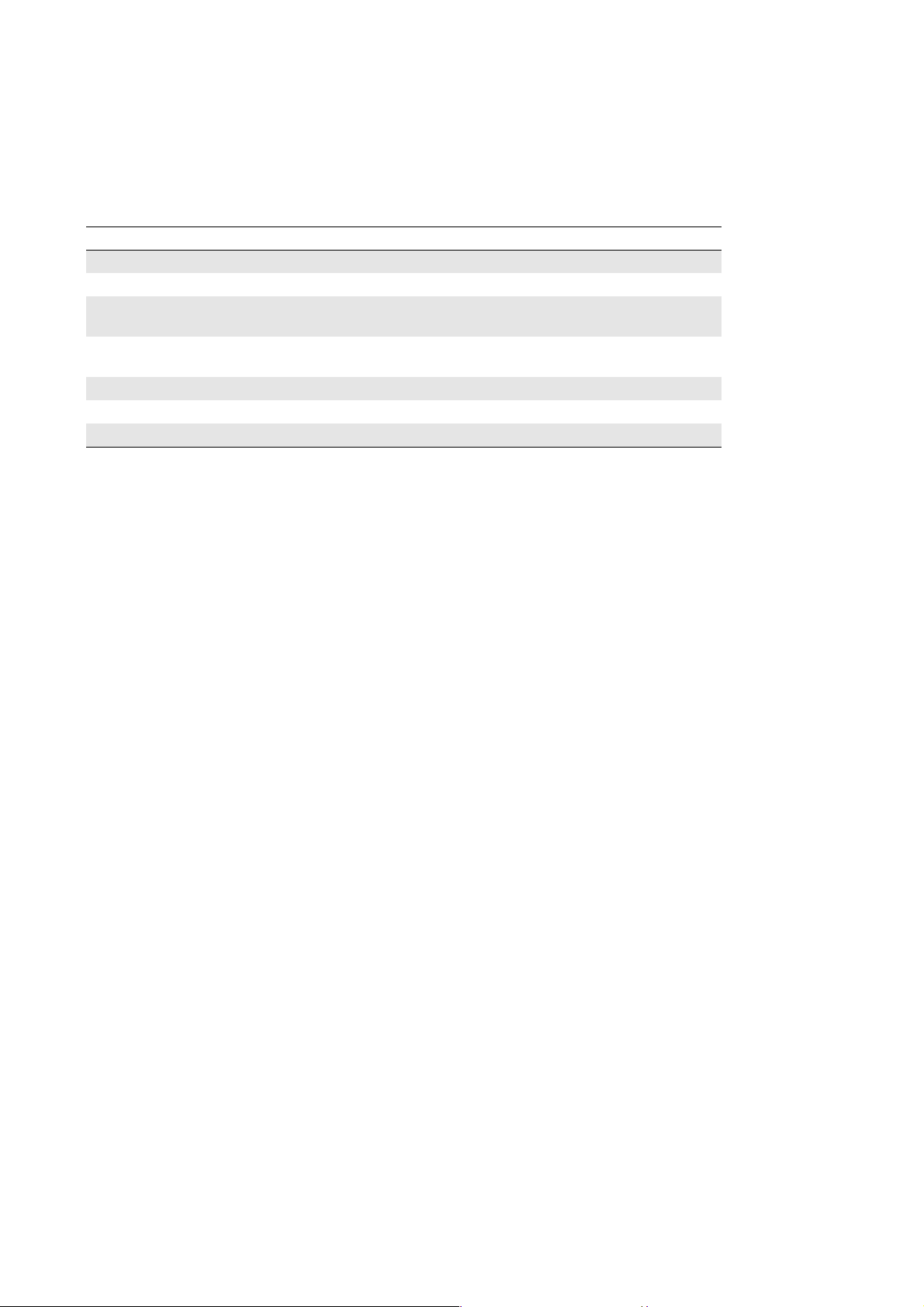

7

MDrive

MDrive system circuit diagram

20

2 - E92 M3 MDrive system circuit diagram

www.Bimmerfest.com

Page 27

7

Index Explanation Index

1 Servotronic valve 8 DSC button

2 DME MSS60 9 Steering column switch cluster

3 Junction box distribution box 10 Multi audiosystemcontroller/Car

Communication Computer

4 Electronic Damping Control

controller

5 iDrive controller 12 Instrument cluster

6 POWER button 13 Footwell module

7 EDC button 14 Dynamic Stability Control

11 Central information display

The MDrive option

The MDrive menu known from the M5/M6 is

now also available as an option (SA 2MD) in

the M3.

Starting from the iDrive main menu, the

MDrive menu can be called up by pressing on

the iDrive controller and selecting M settings.

The iDrive controller can be used to configure

the different MDrive settings ready to be

called up.

The overall setting is called up/activated by

pressing on the M button on the steering

wheel. Pressing the M button again or

restarting the vehicle deactivates the settings.

The settingscan, of course, be retrievedagain

using the M button.

The following is a list of menu items with

selection options that are currently

available in the MDrive menu:

• M Engine Dynamics Control (Power)

– "Unchanged"

– "Normal"

– "Sport"

– "Sport Plus"

• DSC

– "Unchanged"

– "OFF"

– "ON"

– "M Dynamic mode"

• Servotronic

– "Normal"

– "Sport"

• EDC-K (only if fitted)

– "Unchanged"

– "Comfort"

– "Normal"

– "Sport".

By selecting "Unchanged", whentheMbutton

is pressed (i.e. the settings in the MDrive

menu are called up), the current settings of

this system are retained.

Example:

The driver has deactivated the Dynamic

Stability Control function using the DSC

button.

MDrive setting: M Engine dynamics control

"Sport Plus"; DSC "Unchanged"; Servotronic

"Sport".

The driver presses the M button on the

steering wheel to call up the M settings.

Only the "Sport Plus" and Servotronic "Sport"

settings for M engine dynamics control are

activated.

DSC remains deactivated.

www.Bimmerfest.com

21

Page 28

7

Information on the menu items

M Engine Dynamics Control (Power)

Apart from"Unchanged", three enginecontrol

programs are available;

"Normal", "Sport" and "Sport Plus".

The options determine how spontaneously

the engine responds to actuation of the

accelerator pedal.

The maximum engine power is not changed.

Using the power button in the centre console,

the driver can only choose between "Normal"

and "Sport".

"Sport Plus" is only available in the MDrive

menu.

3 - E92 M3 centre console

with iDrive controller

DSC

Apart from the "Unchanged" setting, in the

DSC submenu, the options "OFF" "ON" and

"M Dynamic mode" can be selected.

If "M DynamicMode" is selected, theDynamic

Stability Control (DSC) permits higher slip

values at the wheels.

The system does not activate the stabilizing

function until very close to the handling limit

range, when itinfluences engine outputand/or

actively engages the brakes.

In "OFF" mode, an experienced sports car

driver can also completelydeactivate the DCS

function.

Using the DSC button in the centre console,

the driver can switch between "OFF" and

"ON" or if "M Dynamic Mode" is active,

between "M Dynamic Mode" and "OFF".

"M Dynamic Mode" is only available in the

MDrive menu.

EDC-K

If option 223 continuous Electronic Damper

Control is fitted together with MDrive, in

addition to "Unchanged", three EDC

programs can be selected in the MDrive

menu: "Comfort", "Normal" and "Sport".

The driver can use the EDC button in the

centre console toswitchsequentially between

the three programs.

22

www.Bimmerfest.com

Page 29

7

Servotronic

The settings that can be selected for the

Servotronic steering function are "Normal"

and "Sport". Depending on the selection, the

appropriate characteristic curve for powerassisted steering is active.

This selection option is only available in the

MDrive menu. Without MDrive, the customer

has nooption, and a fixed programmedspeeddependent characteristic curve is used.

"Key-dependent settings" menu

Under "M settings", the "Key-dependent

settings" menu is also available as well as the

MDrive menu.

This allows key-specific settings for certain

MDrive menu items.

M engine dynamics control and EDC settings

are currently possible, which are assigned to

the specific key used during the configuration

(configuration => ZV closing action =>

memorizing).

Under the M engine dynamics control menu

item, "Normal" or "Sport" can be selected.

In the EDC menu item, the options "Comfort",

"Normal" or "Sport" can be selected.

www.Bimmerfest.com

23

Page 30

7

24

www.Bimmerfest.com

Page 31

8

System components.

E92 M3 Complete vehicle.

Body/Interior trim and equipment:

Bodyshell

Due to changes to the wheel arch and the

carbon roof, the bodyshell components shown

in blue

have a different part number to the seriesmodel E92.

1 - E92 M3 bodyshell components, view from above

2 - E92 M3 bodyshell components, view from below

www.Bimmerfest.com

25

Page 32

8

New body side panels which are 20mm wider

each sideover the flaredrear wheel archesare

typical of the ’M’ design.

To ensure the necessary M3 wheel clearance

at the rear wheel arch, the side frame wheel

arch has been extended by approximately 20

mm, and the 180° joining lip edge inside the

wheel arch has been rolled upwards to further

increase the wheel clearance in the wheel

housing.

3 - E92 M3 Rear weel arc

26

www.Bimmerfest.com

Page 33

Additional reinforcements

8

4 - E92 M3 Overview of additional bolted-on reinforcements

The E92 M3 is equipped with a v-shaped

reinforcement brace in the engine

compartment, known as thedomestrut, which

consists of five separate components. It is

secured to the suspension strut dome and

screwed centrally to the middle of the

bulkhead.

5 - E92 M3 Dome strut

www.Bimmerfest.com

27

Page 34

8

The E92M3, just likethe E46 M3,is equipped

with a reinforcement plate, known as the

thrust panel, made from aluminium alloy.

The thrust panel primarily increases the

torsional strength while also acting as a lower

The V-shaped braces used in the rear

underbody area of the series production E92

have been strengthened and adapted, and in

the M3are permanently welded to the tension

strut and screwed to the body with the

transmission tunnel bridge (in the series E92

motor cover and oil pan protection. The thrust

panel is fitted to the axle carrier with six bolts

from below, and has two openings for

changing the oil.

6 - E92 M3 thrust panel

they are screwed to the tension strut and

welded to the bridge).

The bridge has been strengthened and

adapted. In theM3, it isalso used to mountthe

exhaust line.

28

www.Bimmerfest.com

7 - E92 M3 Rear axle braces

and transmission tunnel

bridge

Page 35

Exterior Body

8

8 - E92 M3 View of M3-specific external body components

9 - E92 M3 View of M3-specific external body components

www.Bimmerfest.com

29

Page 36

8

The doors and the tailgate are taken from the

series-model E92. All other external body

components are new.

• New "Powerdome" aluminium hood lid with

air apertures. The aperture on the left when

viewed in the direction of travel is used for

incoming engine air, and the right-hand

aperture offers optical symmetry.

10 - E92 M3 Power Dome

aluminium hood lid

30

www.Bimmerfest.com

Page 37

8

• The roof on the E92 M3 is manufactured

from carbon fibre. This has reduced the

overall vehicle mass on the upper level of

the car by approximately 5 kg, therefore

considerably lowering the centre of gravity.

Unlike the E46 M3 CSL, a roof rack system

can be assembled on the E92 M3 with

carbon fibre roof. The carbon fibre roof of

the E92 M3 has specific inserts for roof

luggage rack brackets.

The repair procedures and

options are similarto or the sameas the M6

(see the service literature for more

information).

If the sunroof option is selected, a steel roof

similar to the series model E92 is fitted.

• An advanced plastic material is used for the

front side panels, which are wider than

those used on the series E92. The side

panels include the model-specific "M side

gills" withintegrated side indicatorsand M3

emblem.

• The side sills are more highly accentuated,

in accordance with the M design criteria.

11 - E92 M3 Carbon roof

12 - E92 M3 Front side panel

13 - E92 M3 Side sill trim

www.Bimmerfest.com

31

Page 38

8

• The ’M’ designedexterior door mirrors have

an optimized air flow design. The mirror

surface area is larger to comply with future

legislation. The mirror base mounting has

been adapted to suit the new mirror unit.

The functions of the outside mirrors are the

same as the series production E92. Driver

and passenger mirrors are electrically

heated and adjusted.

14 - E92 M3 Outside mirrors

on the vehicle

• The cover capof the exteriormirror housing

is painted in the body colour.

15 - E92 M3 Outside mirror (view from the mirror side)

Outside mirrors with memory and folding

functions and/or automatic anti-glare

control are optionally available.

16 - E92 M3 Outside mirror (view from the trim side)

32

www.Bimmerfest.com

Page 39

8

• The tailgate is taken from the series

production E92. Therear spoiler (Gurney)is

attached as a standard feature on the E92

M3. It can optionally be removed.

With the option 7ME "M Driver’s Package"

(high speed limiting), the spoiler is

permanently fixed.

The new M3isfitted with larger wheelhousing

covers that accommodate the larger wheels

and flared wheel arches. The front wheel

housing cover has been adapted specifically

to meet the M3 requirements.

Front wheel housing cover

18 - E92 M3 Front wheel housing cover

17 - E92 M3 Tailgate and

Rear wheel housing cover

19 - E92 M3 Rear wheel housing cover

spoiler (Gurney)

www.Bimmerfest.com

33

Page 40

8

Front End Module

The front end module has a new single piece

M-specific thermoplastic bumper trim and is

fitted to a reinforced lightweight plastic

bracket.

20 - E92 M3 Front end module

Index Explanation Index Explanation

1 Bumper trim 3 Bumper bracket

2 Shock absorber foam

21 - E92 M3 Bumper brackets

34

www.Bimmerfest.com

Page 41

8

22 - E92 M3 Front bumper

trim

The bumper trim is colour coded to the car.

The front M3 bumper has apertures for the

kidney grill, engine air inlet, PDC ultrasonic

sensors (optional), the headlight-cleaning

Headlight cleaning system (SWR)

system and the mounting for the towing eye.

Front bi-xenon headlamp units are identical to

the series E92. The M3 front bumper

overhang is longer than that of the series E92.

The container for the M3 headlight cleaning

system is new. The design has been changed

from the series E92 in order to provide the

necessary spacefor installing the M3 sidegills

with integrated indicators in the M style. The

filler neck and the line for the headlight

cleaning system are new, together with the

fixed washer nozzles on the bumper trim.

www.Bimmerfest.com

23 - E92 M3 Headlight

cleaning system

The wiring harness section for the headlight

cleaning system has been adapted

accordingly.

35

Page 42

8

Rear End Module

24 - E92 M3 Rear end module

Index Explanation Index Explanation

1 Bumper trim 3 Bumper bracket

2 Shock absorber foam

The rear end module also features a new,

single-piece bumper trim in the M style made

from a special thermoplast material. The

bracket is also made from reinforced

lightweight plastic.

The module has apertures for the bumper

grid, PDC ultrasonicsensors (optional) andthe

mounting for the towing eye.

25 - E92 M3 Rear bumper trim

36

www.Bimmerfest.com

Page 43

Sound insulating mat and thermal

insulation

8

New sound insulation and thermal insulation

covers have been installed.

The sound-insulatingmats areattached in the

vehicle interior to the bulkhead and

26 - E92 M3 Sound insulating

mat and thermal insulation

transmission tunnel, and the thermalinsulation

is mounted in the underbody area of the

exhaust system and the engine.

www.Bimmerfest.com

37

Page 44

8

Other underbody panelling

27 - E92 M3 Underbody panelling

The underbody panels have been optimized

to ensure the best possible vehicle

aerodynamics and the maximum possible

cooling capacity for the driveline components.

38

www.Bimmerfest.com

Page 45

Interior Body

8

The M3 floor insert in the luggage

compartment has been modified to

accommodate the M Mobility System.

28 - E92 M3 Implementation of the M Mobility System

29 - E92 M3 Seat structure

Index Explanation Index Explanation

1 Seat upholstery 3 Seat width adjustment

2 Backrest

Two M3 seat versions are available: The

’Speed’ version is a cloth/leather combination

that is included in the standard equipment,

and the ’Novillo’ is a full leather seat option.

The "Novillo" type is also available in an

extended version. In the extended version, the

bottom of the dashboard and the side walls of

the centre console are also covered with

leather in a matching colour.

The versions also differ in their covers and

stitching.

The frame and the foam structure are

identical.

The front head restraints feature the M logo,

as in the E6x M5.

In order to provide an enhanced sporting

character and more hold, the seat cushions

and backrests inEuropean vehicles havebeen

further developed. In US vehicles, only the

front seat backrests have been revised. The

seat upholstery installed in US vehicles is the

same as that used on the E92 series-model

sport seat.

www.Bimmerfest.com

39

Page 46

8

The optional backrest width adjustment is a

further development of the series E93 sport

seat andis available as an optiontogether with

a lumbar support. In the M3, this is manually

operated (passively).

The rear backrest cover is always black.

The ’Speed’seat is currentlyonly available ina

combination of black leather and anthracite

fabric covering.

The leather ’Novillo’is currently available inthe

following finishes:

• Black leather

• Palladium silver leather

• Fox red leather

• Bamboo beige leather

New door trim/side trim panels are used.

The frame with rear seat bench with through-

loading capability has enabled further weight

savings in the E92 M3 (similar to the E46 M3

CSL). This is achieved through the use of

lighter materials, which are processed using a

special method for seat construction in a

sandwich design (1).

30 - E92 M3 "Novillo" seat in palladium silver

31 - E92 M3 Sectional view of the frame of a rear seat back (1)

32 - E92 M3 Rear seat bench

40

www.Bimmerfest.com

Page 47

8

S65B40O0 Engine

Engine block with bedplate construction

33 - S65B40 Engineblock with

bedplate construction

Index Explanation Index Explanation

1 Engine block (upper section) 3 Bedplate construction (lower

section)

2 Grey cast iron inlays

The construction and materials are identical to

the S85; the upper low-pressure die-cast

crankcase is made from an aluminium-silicon

alloy.

The cylinder bores are formed using exposed

hard silicon crystals, rendering the use of

cylinder liners redundant.

The lower crankcase (bedplate) is also

constructed using die-cast aluminium. Due to

the extreme forces, grey cast iron inlays are

used to reinforce the bedplate construction.

These also limit crankshaft bearing clearances

over a greater temperature range and thus

have a positive effect on the oil flow rate.

www.Bimmerfest.com

41

Page 48

8

Crankshaft

The five-bearing crankshaft is forged from a

single piece, including the two double-chain

wheels for driving the valve gear. The gear

wheel for the oil pump drive is flangemounted. The cylinder spacingis 98 mm. The

crankshaft possesses a high level of bend

resistance and high torsional strength at a

relatively low weight. The crank pin offset is

90°. The diameter of the main bearing journal

is 60 mm. The crankshaft end float is

controlled by a thrust bearing located at the

fifth main bearing.

For design reasons, the firing order

1-5-4-8-7-2-6-3 was chosen

for the S65, instead of the firing order

1-5-4-8-6-3-7-2 more commonly employed

in BMW V8 engines.

3 The identification marking of the bearing

shells is engravedonthe crankcase and onthe

first crank web. 1

42

Connecting rods

The weight-optimized, high tensile steel

connecting rods split by fracture separation

and the pistons are the same as those used in

the S85 engine. For weight reduction, the

upper section of the connecting rod has a

trapezium-shaped cross-section.

www.Bimmerfest.com

34 - S65B40 crankshaft with

magnification of theupper

section of the connecting

rod

3 The large connecting rod eye is

asymmetrically groundto reducethe length of

the engine. This means that the installation is

direction-specific.

For the workshop, bearing shells are available

in a repair stage (for more information, see the

service documentation). 1

Page 49

Pistons

8

Index Explanation

1 Pistons

2 Taper-faced ring

3 Gudgeon pin

4 Piston skirt

5 Oil scraper ring (VF system)

6 Compression ring (plain

compression ring with spherical

contact face)

35 - S65B40 Pistons

A piston is manufactured from a cast

aluminium alloy and weighs approximately

480 grams including gudgeon pin and piston

rings. The piston design is the same as the

S85 piston (piston shaft with galvanized iron

coating [Ferrostan] and a running-in layer

containing tin. The installation position is

direction-specific.

www.Bimmerfest.com

43

Page 50

8

Oil Supply

44

36 - S65B40 Hydraulic schematic of oil supply

www.Bimmerfest.com

Page 51

8

Index Explanation Index Explanation

1 Cylinder bank 1 VANOS exhaust

hydraulic motor

2 Cylinder bank 1 VANOS inlet

hydraulic motor

3 Cylinder bank 2 VANOS inlet

hydraulic motor

4 Cylinder bank 2 VANOS exhaust

hydraulic motor

5 Cylinder bank 1 VANOS exhaust

multiway adjustment valve

6 Cylinder bank 1 VANOS sieve filter

(max. 300 µm) before multiway

adjustment valve

7 Cylinder bank 1 VANOS inlet

multiway adjustment valve

8 Cylinder bank 2 VANOS inlet

multiway adjustment valve

9 Cylinder bank 2 VANOS sieve filter

(max. 300 µm) before multiway

adjustment valve

10 Cylinder bank 2 VANOS exhaust

multiway adjustment valve

11 Cylinder bank 1VANOS non-return

valve

12 Cylinder bank 2VANOS non-return

valve

13 Cylinder bank 1 chain tensioner 27 Sump

14 Cylinder bank 1 and 2 non-return

valve from chain lubrication

15 Cylinder bank 2 chain tensioner

16 Main oil channel (lubrication points

engine block and cylinder head)

17 Oil pressure switch

18 Oil filter bypass valve

19 Oil filter

20 Oil filter outlet aperture

21 Non-return valve

22 Pressure limiting valve

23 Piston cooling nozzles

24 Oil pressure regulation line

25 Volume flow-controlled hinged

valve main oil pump

26 Oil return pump

Two oil pumps areinstalled in the S65 engine;

the oil return pump, which is driven via a

gearwheel by a crankshaft, and the volume

flow-controlled mainoil pump, driven via chain

drive by the oil return pump.

www.Bimmerfest.com

In the S85, the VANOS high pressure pump is

installed instead of the S65 oil return pump,

and the S85 oil return pump is contained in a

housing together with the main oil pump

(tandem pump).

45

Page 52

8

37 - S65B40 Oil pumps

Index Explanation Index Explanation

1 Oil intake area ofthe oil return pump 3 Main oil pan

2 Front, smaller section of the oil pan 4 Oil intake area of the main oil pump

Since there is no space to install a tandem

pump in the S65, the oilreturn pump hasbeen

moved from the main oil pump housing and

installed instead of the VANOS high-pressure

pump. This allows the pump drive principle

(crankshaft => gearwheel => pump => chain

=> pump) to be maintained. As in the S85, the

volume flow-controlled main oil pump is a

hinged-valve oil pump with a feed capacity

adjusted to suit the VANOS low-pressure

system.

The duocentric design of the oil return pump

ensures that oil is always available at the inlet

pipe of themain oil pump inthe rear area ofthe

oil pan,

i.e. even when braking sharply from high

speeds.

The electrical oil return pumps installed in the

S85 for scavenging the cylinder heads are no

longer required, which results in a further

weight saving.

This is made possible by the lower number of

cylinders, modification of the oil return routes,

and the large capacity of the oil pan.

The oilpan has acapacity of 8.3 litres (S859.3

litres).

The oil supply is also guaranteed at extreme

longitudinal and lateral accelerations of up to

1.4 times the normalgravitationalacceleration.

The oil filter housing is installed on the engine.

46

www.Bimmerfest.com

Page 53

8

Cylinder Head

The cylinderhead is constructed from a single

piece of aluminium alloy.

To reduce the number of sealing faces, the

secondary air channel has been integrated

back into the cylinder head.

The design of the cylinder head is based on

the S85. Changeshavebeen made in thefront

engine compartment to the VANOS and the

timing chain.

The inlet and exhaust tracts have been further

airflow-optimized. The integrated idle air

channel has been discontinued and replaced

by an idle air bar for each cylinder bank.

As in the S85, the camshafts are

manufactured as a hollow-cast, one-piece

construction with integrated sensor gears.

The weight-optimized valves with a 5 mm

shaft diameter and the spherical bucket

tappets with hydraulic valve clearance

adjustment are also used.

38 - S65B40 Cylinder head

Index Explanation Index Explanation

1 Camshaft 5 Intake passage

2 Bucket tappet with hydraulic valve

clearance adjustment

3 Beehive-shaped valve springs 7 Connection flange of the

4 Cylinder head

6 Valve

integrated secondary air channel

www.Bimmerfest.com

47

Page 54

8

Index Explanation

1 Spherical contact surface

2 Box tappet

3 Guide lug

These bucket tappets with a cylindrical

camshaft contact surface and rotational lock

allow a high level of convexity. This results in

effective valve lift characteristics with the

smallest possible tappet diameter and hence

tappet mass (ideal for high engine speeds).

39 - E92 M3 Bucket tappet

Technical Data E92 M3 E46 M3 E6x M5/M6

Engine identifier S65B40 S54B32 S85B50

Valve operation Bucket tappet Drag arm Bucket tappet

Valve head ∅ E/A [mm]

Valve shaft ∅ [mm]

Valve lift [mm]

autom. compensation for play

35/30.5

5

11.35

Yes

35/30.5

6

12

No

35/30.5

5

11.7 E; 11.5 A

Yes

48

www.Bimmerfest.com

Page 55

8

Camshaft drive

As in theS85,the inlet camshafts are drivenby

chain drive and the exhaust camshafts are

driven by a gearwheel drive. This means that

the inlet and exhaust camshafts always have

an opposite direction of rotation. In contrast to

the S85, which works with two single-roller

chains between the crankshaft and the inlet

crankshafts, in the S65, two double-roller

chains are installed. This is because of the

higher chain drive load in the V8 S65.

40 - S65B40 Drive valve

control

Technical Data E92 M3 E46 M3 E6x M5/M6

Engine identifier S65B40 S54B32 S85B50

Camshaft drive 2x double-roller chain Double-roller chain 2x single-roller chain

The VANOS adjustment units are an integral

component of the valve control and are

mounted on therelevant camshaft bya central

bolt.

3 The central bolts of the inlet and exhaust

side have a CCW thread, please refer to the

repair instructions. 1

www.Bimmerfest.com

49

Page 56

8

VANOS

This has been made possible by the

considerably stronger switching moments at

the camshaft comparedtothe10-cylinder and

6-cylinder engine, particularly in the lower

engine speed range. The low-pressure

system uses these switching moments to

adjust the overall gear ratio.

The oil is directed to the sealed oil chambers

(3 and 4) of the VANOS adjustment unit.

When the chambers are pressurized with oil

pressure, onechamber allows the camshaft to

advance whilst the other chamber allows the

camshaft to retard.

50

41 - S65B40 VANOS hydraulic motor

Index Explanation

1 Optimized hydraulic rotor pressure

surfaces

2 Optimized inlet channel

oil chamber 1

3 Oil chamber 1

4 Oil chamber 2

5 Optimized inlet channel

oil chamber 2

The compact double VANOS system fitted to

the S65 engine operates at normal oil

pressure, unlike the S85 engine (which uses

high oil pressure). The low-pressure system

means that the high-pressure pump and

additional pressure lines and reservoir are

unnecessary. This results in a space saving as

well as a weight reduction of approx. 8.4 kg.

www.Bimmerfest.com

42 - S65B40 VANOS Hydraulic schematic of a cylinder bank

Index Explanation

1 Oil supply from the main oil

gallery

2 Non-return valves

3 Sieve filter upstream from

control valves

4 Hydraulic motor at the inlet and

exhaust camshaft

5 Multiway adjustment valves inlet

and exhaust side

6 Oil return flange to the oil sump

The VANOS oil pressure is supplied by the

engine’s mainoil pump. TheVANOS oil flowis

controlled by one multiway valve for each

camshaft. These VANOS multiway valves are

controlled by the MSS60 and are directly

installed in the cylinder head.

Page 57

43 - S65B40 VANOS hydraulic motor

Index Explanation

1 Locking pin spring

2 Locking pin

3 Spiral-wound spring

8

As with the S85, the VANOS adjustment unit

of the inlet camshaft drives the VANOS

adjustment unit of the exhaust camshaft by

means of a constantly meshed gear.

At zero pressure, a locking pin (2) also holds

the VANOS unit in the normal position or

engine start position.

The spiral-wound spring (3) is also used for

coordinating the adjustmenttimebetween the

advance and retard adjustment.

In contrast to AG petrol engines, the spiralwound spring for the inlet and exhaust sides is

mounted in the opposite working direction,

since the camshafts in the S65 rotate in the

opposite direction.

The principle of action of the hydraulic motor

in this M VANOS is based on the VANOS in

current BMW petrol engines and is optimized

for the S65 in terms of oil supply and drainage

diameters, and in the rotor surface area.

www.Bimmerfest.com

51

Page 58

8

44 - S65B40 Control diagram

Index Explanation

A [mm] Valve lift

B [°] Crankshaft angle

1 Exhaust camshaft

2 Inlet camshaft

The setting angle of the inlet camshaft is 58°

in relation to the crankshaft. The exhaust

camshaft has a setting angle of 48°.Asinthe

S85 engine, this VANOS also reaches an

adjustment rate of 360° camshaft per second.

Technical Data E92 M3 E46 M3 E6x M5/M6

Engine identifier S65B40 S54B32 S85B50

Variable camshaft

control (VANOS)

Adjustment range E/A

[°KW]

Kingpin inclination E/A

[°KW]

Response time E/A

[°KW]

2x double (engine oil

pressure) oscillating rotor

VANOS

72-130/81-129 70-130/83-128 79-145/91-128

58/48 60/45 66/37

256/256 260/260 268/260

3 The service instructions should be

followed exactly. TheVANOS adjustment unit

must not be disassembled. 1

Double

high-pressure

VANOS

2x double

high-pressure

VANOS

52

www.Bimmerfest.com

Page 59

8

Ancillary belt drive

The main belt drive drives the coolant pump

and the generator, while the auxiliary belt drive

drives the airconditioning compressor andthe

power-assisted steering pump.

The generator andthe coolant pump areinthe

same position as in the S85. The coolant

pump is identical to the S85, but has a larger

belt pulley.

45 - S65B40 Belt drive

www.Bimmerfest.com

53

Page 60

8

Air intake guide/Oil separator/Secondary air system

46 - S65B40 Air intake guide

Index Explanation Index Explanation

1 Engine hood air inlet 3 Air inlet in the bumper

2 Air inlet behind the ornamental

grilles of the BMW kidney

The combustion air enterstheenginevia three

flow-optimized air guides. Anairinletislocated

on the left side of the engine hood when

viewed in the direction of travel. To maintain

an optical balance in the appearance of the

engine hood, another intake grill is located on

the right-hand side, but this is blinded and

does not perform any function.

The second air inlet guide is located behind

the kidney grilles of the BMW kidney.

The third air inlet guide is on the left below the

front bumper.

The S65 has a large, single-piece air collector

for the intake air to both cylinder banks.

A cylindrical air filter element (4) with an

enlarged surface area is used.

The filtered air flows into the intake manifold,

from where it flows through eight integrated

4 Air filter element

individual inlet pipes and into the individual

throttle valve assemblies.

To optimize air resistance, no air-mass sensor

is installed in the intake area.

The air flow is determined using a modelbased calculation from the aperture of the

throttle valve assemblies and the idle speed

actuator, the VANOS adjustment position, the

engine speed, the air temperature and the

atmospheric pressure.

For safety reasons, an additional pressure

sensor is mounted in the idle speed system

(see idle speed control).

54

www.Bimmerfest.com

Page 61

8

Oil separators

47 - S65B40 Oil separator connection point to the intake manifold

The oil separators are bolted onto the cylinder

head covers. The connection between the oil

separator and the intake manifold is not

screwed but plugged. This reduces the risk of

incorrect assembly.

As is typical for the M series, no crankcase

pressure control is mounted/integrated.

Secondary air system

The secondary air pump is mounted on the

rear side oftheengine in the "V"ofthe cylinder

banks. The secondary air is guided into the

relevant exhaustchannel via a check valveand

an air channel integrated in the cylinder head.

An upstream secondary air pump hot-film airmass sensormeasures the secondary air flow.

The structure and function are the same as

the system inthe E60 M5andare described in

the PI E60 M5.

www.Bimmerfest.com

55

Page 62

8

Individual throttle butterfly system

56

Index Explanation Index Explanation

1 Double throttle valve sensor

cylinder bank 1 and 2

2 Individual throttle valve assemblies

The design principle of the S65 individual

throttle valve air intake system is the same as

the S85 and consists of eight individual

throttle valve assemblies and two electrical

throttle valve actuators. One electric throttle

valve positioner activates four individual

throttle butterflies of one cylinder bank, which

are mechanically coupled. The throttle valve

position for each cylinder bank is recorded

using a double throttle valve sensor on the

shared throttle body shaft. A signal is sent

directly to the throttle valve actuator

responsible for this cylinder bank. The throttle

3 Electrical throttle-valve actuator

valve actuator can therefore independently

adjust the throttle valve position specified by

the MSS60.

The second signal is sent to the MSS60 for

checking purposes.

For communication with the MSS60, the two

electrical throttle valve actuators use a shared

DK-CAN bus (DK-CAN).

www.Bimmerfest.com

48 - S65B40 Single throttle

valve system

Page 63

Idle control system

8

Index Explanation Index Explanation

1 Pressure sensor on idle air bar,

cylinders 1-4

3 Idle air bar, cylinders 5-8

One common idle speed actuator for both

cylinder banks controls the air supply at idle

speed andat low engine loads. Theidle speed

actuator is located in the V formed by the two

cylinder banks, and controls the idle air supply

using a throttlevalve.The air enters theshared

bar for each cylinder bank via the relevant air

ducts, and from there is guided into each

throttle body below the throttle valve.

The idle speed actuator receives control

instructions from the MSS60 via its own local

CAN bus (LoCAN).

2 Throttle valve

To ensure emergency operation in the event

of the failure of one or both throttle valve

sensors (even without the hot film air-mass

sensor), an additional pressure sensor is

integrated on the idle air bar (as in the

S54B32HP (M3 CSL)). This allows evaluation

of the pressure conditions behind the throttle

valves. This pressure is also used for the

plausibility check of filling and load in normal

operation.

49 - S65B40 Idle speed air

system

www.Bimmerfest.com

57

Page 64

8

Fuel supply system

58

50 - E92 M3 Fuel supply system

Index Explanation Index Explanation

1 Tank filling supports 5 Fuel tank

2 Tank leakage diagnosis unit 6 Left fuel supply unit

3 Activated carbon filter 7 Tank vent line

4 Right fuel supply unit 8 Engine fuel supply line

The fuel tank is based on the series E92 tank,

although the shape has been changed to

accommodate the exhaust system. Both intank units are new. The fuel pump is installed

in the right-hand unit, and the pressure

regulator is installed in the left-hand unit in

front of the fuel filter.

The ventilation lines havebeen adapted,while

all other lines have been taken from the E92

335i. The US release is fitted with a tank

leakage diagnosis unit.

The electrical controls are described in the

MSS60 engine control system.

www.Bimmerfest.com

Page 65

Cooling System

8

Index Explanation Index Explanation

1 Gearbox oil cooler 2 Engine oil cooler

51 - E92 M3 Oil cooler

52 - E92 M3 complete cooler

package

Index Explanation Index Explanation

1 Gearbox oil cooler 3 Engine coolant cooler

2 Engine oil cooler 4 Steering oil cooler

www.Bimmerfest.com

59

Page 66

8

The mechanical coolant pump was takenfrom

the S85.

The water pump belt pulley has been adapted

due to the reduced water flow rate in the S65

compared with the S85 and has a larger

diameter, which has allowed a reduction in

pump speed.

A one-piece crossflow radiator is used to cool

both banks,unlike the S85engine which has a

two-piece radiator, one part for each bank.

The following components have been

adjusted for the M3: The expansion tank for

the coolant, the crossflow radiator, the radiator

hoses, the thermostat and the electric fan.

The gear oil and steering oil coolers are also

installed in the series-model E92.

Index Explanation Index Explanation

1 Engine cooler package 3 Expansion tank

2 Cooler fan

The control of the electric fan is described in

the MSS60 engine control system.

53 - E92 M3 Engine radiator

60

www.Bimmerfest.com

Page 67

8

Exhaust system

The exhaust pipes of the M vehicles are

manufactured using the innovative internal

high pressure forming technology (IHU). The

"IHU" technology was used for the first time in

the worldin 1992 in the BMWM3, since when

it has undergone continual refinement.

Nowadays, it isalso used in AGvehicles. Using

the IHU technology, the seamless stainless

steel exhaust pipes are formed under a

pressure of up to 800 bar. This results in

extremely thin wall thicknesses of between

0.65 and 1.0 millimetres, which means both

the weight of the exhaust system and the

response characteristics of the catalytic

converters can be optimized. At the same

time, the IHU technology enables

unprecedented styling and even more

efficient geometric tolerances. The largest

possible pipe cross-sections are used, thus

minimizing flow resistance. The complete

exhaust system is manufactured in stainless

steel and has a dual flow.

The 4-in-1 exhaust manifold in each cylinder

bank, as used in motor sport, has a length and

cross-section designed to enable optimal use

of dynamics in the exhaust flow and to avoid

unnecessary exhaust backpressure.

54 - E92 M3 Exhaust system

Index Explanation Index Explanation

1 Manifold 4 Front exhaust silencer

2 Catalytic converter close to the

engine

3 Main catalytic converter

The exhaust system has one quickresponding metal catalytic converter close to

the engine per exhaust line, (approx. 20 cm

behind the exhaust manifold), followed by the

5 Final muffler

metal main catalytic converter. The front

silencer and the final muffler shared by both

exhaust lines with a volume of 35 litres are

constructed in an absorption design.

www.Bimmerfest.com

61

Page 68

8

The lambda oxygen sensors are located

before and after both engine-side catalytic

converters. The exhaust temperature sensor

installed in previous M models is no longer

required and is replaced by an internal

calculation model in the control device.

The S65 fulfils the requirements of the

European EU4 standard and the American

LEV 2 classification.

3 At maximum operating temperatures, the

entire exhaust system canexpand in length by

35 mm. 1

62

www.Bimmerfest.com

Page 69

8

MSS60 Engine Control System

The S65 features a revised engine control

system, the MSS60, which is based on the

MSS65 in the S85 engine.

This engine control system is designed for

engine speeds of up to 9,000 rpm.

These engine control unitsbelongto the latest

generation and are characterized by an

55 - E92 M3 Engine control

system MSS60

extremely high data processing capability,

processing millions of calculationsper second.

The main functions are described in the

product information for the E60 M5.

The following is a description of the areas of

the system that differ from the MSS65.

www.Bimmerfest.com

63

Page 70

8

On-board network connection

64

56 - MSS60 On-board network connection

www.Bimmerfest.com

Page 71

8

Index Explanation Index Explanation

1 Electrical cooling fan 13 Safety battery terminal (SBK)

2 Alternator 14 AGM battery.

3 Starter 15 Intelligent battery sensor (IBS)

4 Control valve in the air conditioning

compressor

5 Oil condition sensor 17 IHKR/IHKA control unit

6 Secondary air pump relay 18 Multiple restraint system (MRS5)

7 Injection nozzle supply relay 19 Clutch module (KS)

8 Engine control unit MSS60 20 Brake light switching module

9 OBD2 diagnosis connector (TD

output from MSS60 and D-CAN to

JB)

10 Junction box (JB) and distribution

box (SV)

11 Evacuating pump relay for brake

servo action

12 High-current circuit breaker (250 A)

16 Electric fuel pump control unit

21 Instrument cluster

22 Car Access System (CAS3)

23 Dynamic stability control (DSC)

www.Bimmerfest.com

65

Page 72

8

Ion current combustion monitoring

The ion current combustion monitoring isalso

used in the MSS60 for knock identification

and misfiring identification. In principle, the

method ofaction isidentical to the S85 and its

MSS65.

The S85 has two ion current monitoring

devices, each ofwhich covers awhole cylinder

bank. In the S65, the electronic ion current

system is integrated intoeach ignitioncoil and

the ion current monitoring devices are not

required.

During ignition, the measurement current is

stored in a capacitor integrated in the ignition

coil, and after ignition, is available at the spark

plug electrode. In the S65, the ion current

measurement and evaluation is also

performed exclusively by the MSS60.

The functional range of the ion current

electronics has been further refined. There is

no longer aneed for twomeasurement control

lines, and the ignition current and the ion

current measurement signal have been

combined into a single transmission route

(separate in the S85). For the purposes of

smoothing the voltage and electromagnetic

compatibility, an "ignition suppression

capacitor" is installed in the wiring harness of

each cylinder bank (in the S85 this is in the ion

current control device). This is electrically

connected using terminal 87 and the vehicle

earth.

3 If the ignition suppression capacitor is

defective, this can lead to faults in the

communications and/or audio electronics

when the engine is running. 1

66

57 - MSS60 Simplified basic

layout of ion current

monitoring

Index Explanation Index Explanation

1 Microcontroller ignition 8 Output amplifier of the ion current

measurement signal

2 Output amplifier of the ignition

signal

3 Ion current input amplifier 10 Ignition output stage

4 Digital signal processor for ion

current measurement signal

5 MSS60 Engine control system 12 Zener diode for limiting the

6 Ignition suppression capacitor (one

per cylinder bank for 4 cylinders)

7 Input amplifier for ignition signal 14 Spark plugs

9 Ignition coil with integrated ion

current electronics

11 Capacitor for storing measured flow

measured voltage

13 Primary and secondary coil

www.Bimmerfest.com

Page 73

8

The following diagrams show the ion current

curve (bottom) in relation to the development

of combustion pressure (top). This curve is

used for the evaluation of combustion quality

and the identification of misfiring.

Combustion knock is identified in the ionic

current measurement signal in the form of

oscillations within a defined measuring

window. The measuring window is after

position 3 of the previous diagram.

58 - Combustion curve (top) and ionic current (bottom)

Index Explanation

1 Ionic current maximum by

induction of ignition coil

2 Ionic current maximum due to

ignition (flame front directly in

area of spark plugs)

3 The ionic current progression is

a function of the pressure curve

Depending on the engine load, the level of the

ionic current generatedat the spark pluglies in

the range 50-500 µA and is only measured by

the electronic system in the mA range.

www.Bimmerfest.com

59 - MSS60 Representation of normal combustion and combustion knock

Index Explanation

A Ionic current (mA)

B Section of measuring window

1 Normal combustion (no knocking)

2 Combustion knock

The same spark plugs are used as in the S85

(basic value approx. 60,000 km).

3 For design reasons, the firing order 1-5-

4-8-7-2-6-3 is used in the S65, instead of the

firing order 1-5-4-8-6-3-7-2 more commonly

employed in BMW V8 engines until now. 1

67

Page 74

8

Fuel supply system

68

60 - MSS60 Fuel supply system circuit diagram

www.Bimmerfest.com

Page 75

8

Index Explanation Index

1 Engine control unit MSS60 7 Fuel tank

2 Junction box 8 Multiple restraint system

5th generation (MRS5)

3 Electric fuel pump control unit 9 Car Access System

3rd generation (CAS3)

4 Fuel pump with three-phase

motor

5 Tank fill level sensor, right 11 Fuel pressure sensor

6 Tank fill level sensor, left

10 Instrument cluster

A separate control unit is used for the electric

fuel pump (EKP-SG). The EKP control signals

from theMSS60 are produced via a dedicated

CAN bus (LoCAN) (M5: PWM signal). The

EKP control unit is made ready for operation

by the MSS60 via the input terminal 87. The

load current is controlled via a relay at the

terminal 30g by CAS3.

In the event of a crash that reaches the

relevant threshold value, the MRS5 requests

an interrupt to the fuel supply via the K-CAN

connection to CAS3.

There is now only one fuel pump (the M5 has

two). This has a three-phase motor, which

ensures sufficient torque across the whole

pump speed range. The pump speed is used

to provide the required fuel pressure of 3-6

bar, depending on the engine operating state.

A fuel pressure sensor (in the front wheel arch

on the left) sends its signal to the MSS60.

If the pressure sensor fails or there is a fault in

the CAN bus and in the engine emergency

program, the fuel pump is operated at full

speed. In this process, the pressure is limited

to 6 bar by the mechanical pressure sensor.

The signals fromboth tank fill levelsensorsare

sent to the junction box and are forwarded to