Page 1

SONIC-PRO

Series S4

d

ProSeries

2

TWO-YEAR

WARRANTY

Ultrasonic Flow Meter

Installation and Operating Manual

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 2

Page 1

Safety Precautions

Thank you for purchasing the Sonic-Pro series S4 ultrasonic flowmeter.

This instruction manual provides important information regarding the safe installation,

operation and maintenance of the flowmeter. Please read it carefully before attempting to

install or operate the meter. A copy of this manual should be kept by the operator. Extra

copies of this manual are available from your supplier or directly from the manufacturer.

The following important symbols are used throughout this manual and on labeling affixed to

the flowmeter:

CAUTION

risk of electric shock

Sonic-Pro

This symbol identifies a risk of electric shock where the possibility of injury or

death is present.

!

!

CAUTION

risk of danger

CAUTION

risk of danger

QUESTIONS REGARDING THE SAFE USE OF THIS PRODUCT AND OTHER TECHNICAL

ASSISTANCE MAY BE DIRECTED TO:

!

This symbol identifies a risk of injury or death is present.

In all cases, when this symbol is used on labeling affixed to the flowmeter, the

documentation needs to be consulted to find out the nature of the potential

HAZARD and any actions which have to be taken.

If the equipment is used in a manner not specified by this instruction manual,

the protection provided by the equipment may be impaired.

Blue-White Industries

714-893-8529

techsupport @blue-white.com

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 3

Sonic-Pro

Page 2

1.0 Product Overview

The Sonic-Pro series S4 Ultrasonic Flow Meter can measure fluid flow in water and many

other clean fluids with sound speeds that are similar to water. The meter measures fluid flow

using the Transit Time method. The S4 ultrasonic sound transducers do not touch the

process fluid and there are no moving parts. This method of flow measurement is safe, nonintrusive and requires little to no maintenance.

The fluid being measured must be relatively “clean” to enable the sound waves to complete

their circuit. The maximum amount of particles should not exceed . The 5% (50,000 ppm)

meter cannot measure through air. Air bubbles and excessive turbulence will disrupt the

sound beam.

The angle of the sound beam, as it travels through a material, is effected by the speed that

sound travels through that material. As the sound speed changes, the angle changes. Sound

travels through 68 F clean water at a speed of 1,481 meters per sec. The S4 ultrasonic

sound transducers are factory positioned for a fluid sound speed of 1,500 m/sec +/- 100.

They cannot be adjusted in the field.

Water that contains concentrations of other chemicals, or other chemicals entirely, may be

acceptable provided the chemical does not change the sound speed (SOS) more than

approximately +/- 100 meters per second and provided the fluid allows the sound beam to

pass through unimpeded. Note that the speed that sound travels through the fluid is effected

by changes in the fluid’s density.

O

The S4 includes a 6-button user interface that can be used to configure the meter. The

optimum sound speed setpoint can be adjusted by the user within the range of 1,500 m/sec

+/- 100 m/sec.

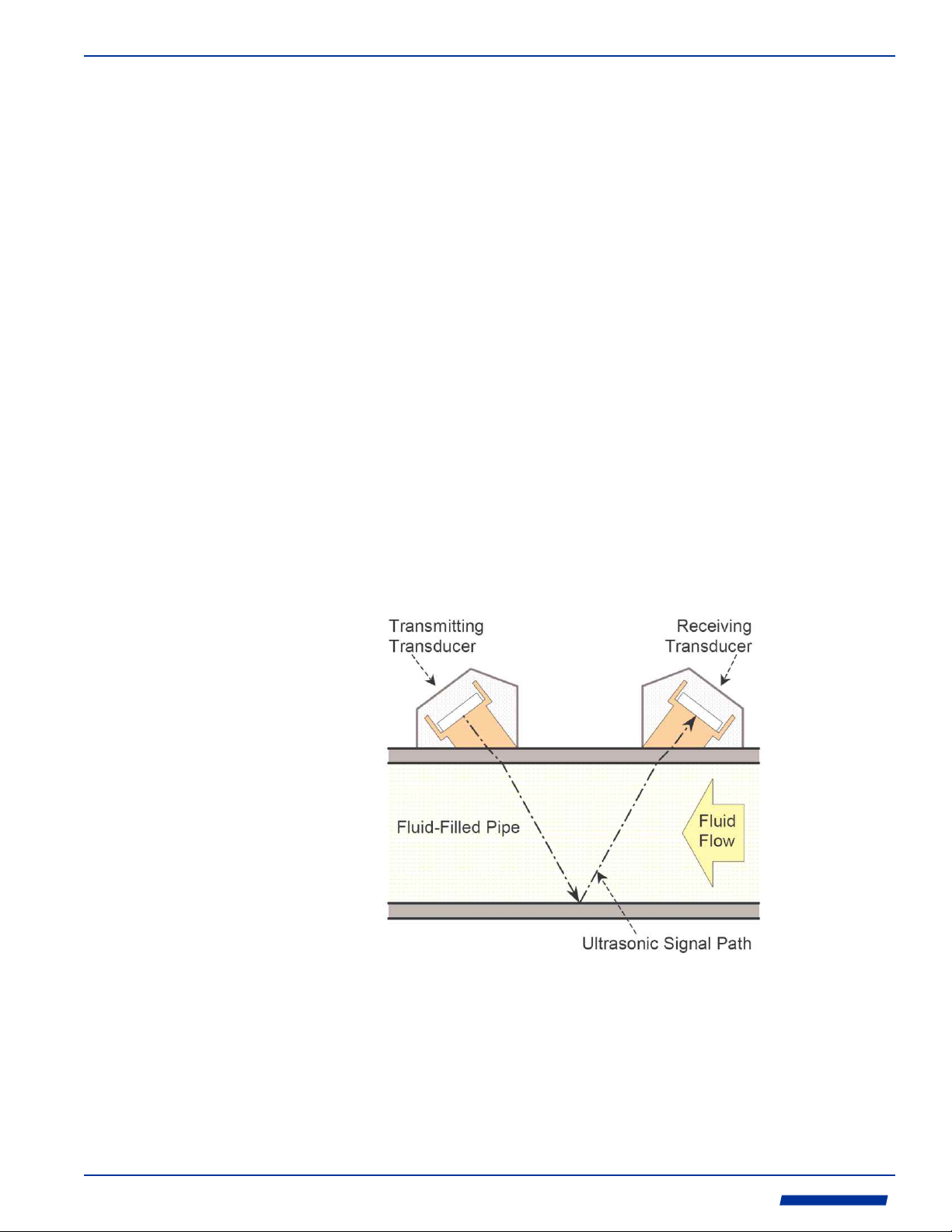

TRANSIT TIME MEASUREMENT PRINCIPLE

During operation in the Transit Time measurement method, a short ultrasonic signal burst

passes first in one direction and then in the other between two transducers separated along

the length of the pipe. When traveling in the same direction as fluid flow, the burst is carried

along by the fluid and arrives earlier as a result. When traveling against fluid flow, the burst is

held back by the fluid and arrives later. The SPU ( measures this Signal Processing Unit)

difference in time-of-flight in the two directions. From this, the actual time-of-flights, the

distance traveled in the fluid and the angle of the ultrasonic signal path, it calculates the fluid

velocity.

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 4

Page 3

Sonic-Pro

2.0 Flowmeter SPU Installation

2.1

Unpacking

2.2

Mounting

Location

!

risk of danger

The Sonic-Pro Flowmeter is shipped with the following items:

! Sonic-Pro Flowmeter SPU (Signal Processing Unit)

! Sonic-Pro Inline Pipe Fitting

! Enclosure Mounting Hardware (not included in sensor mounted units)

2 mounting plates

4 mounting plate screws (10-32 x .50”)

2 wall mounting screws (#10 x 1.00”)

1 pipe mounting clamp (maximum pipe diameter 10”)

! Instruction Manual

The Sonic-Pro was designed to be installed and operated by qualified personnel only. Do not

attempt to install or operate the meter if you are unsure. Seek qualified assistance. Please

note that warranty coverage does not include damage due to misuse or improper

installation.

If remote mounting the SPU, select a mounting location that is within reach of the transducer

cables and power supply. The transducer cable must not be cut or modified. Note that the

Sonic-Pro can accurately measure flow from either direction.

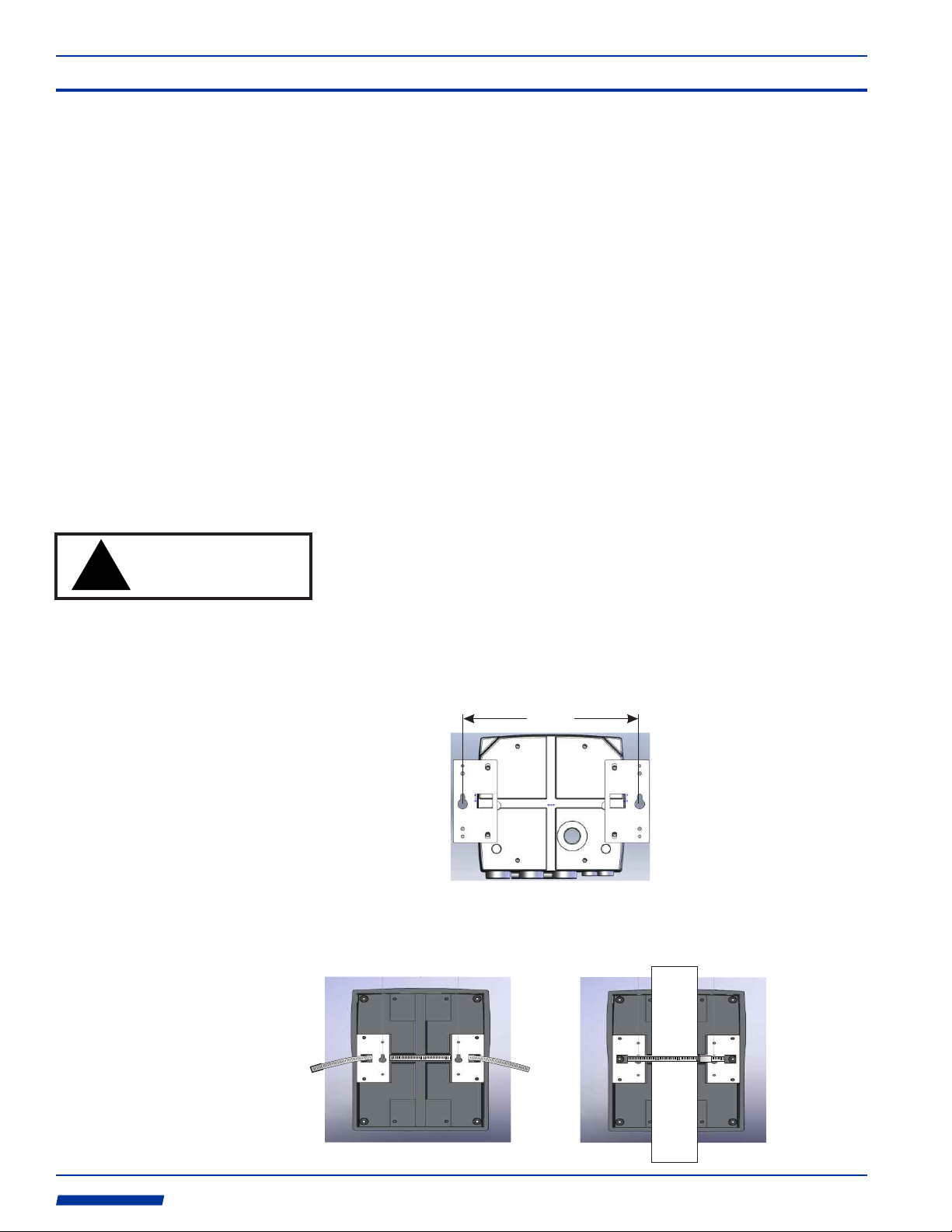

The SPU can be mounted on a wall or on a horizontal or vertical run of pipe. Although the

Sonic-Pro is designed to withstand outdoor conditions. A cool, dry location, where the unit

can be easily monitored is recommended. Special ventilation is not required.

CAUTION

Do not position the equipment so that it is difficult to disconnect the power

supply cord.

2.3

Wall or Pipe

Mounting

When the SPU is not mounted directly to the Inline Fitting, the SPU must be installed on a

solid, secure surface such as a solid wall, panel, wall studs, etc. DO NOT install the meter

on drywall with anchor bolts.

8.00 in

[20.3 cm]

The SPU can be mounted on horizontal or vertical pipe. The pipe must be secure and of

sufficient strength to support the weight of the SPU.

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 5

Sonic-Pro

Page 4

3.0 Ultrasonic Transducer Installation

3.1

Pipe Fitting/

Transducer

Installation

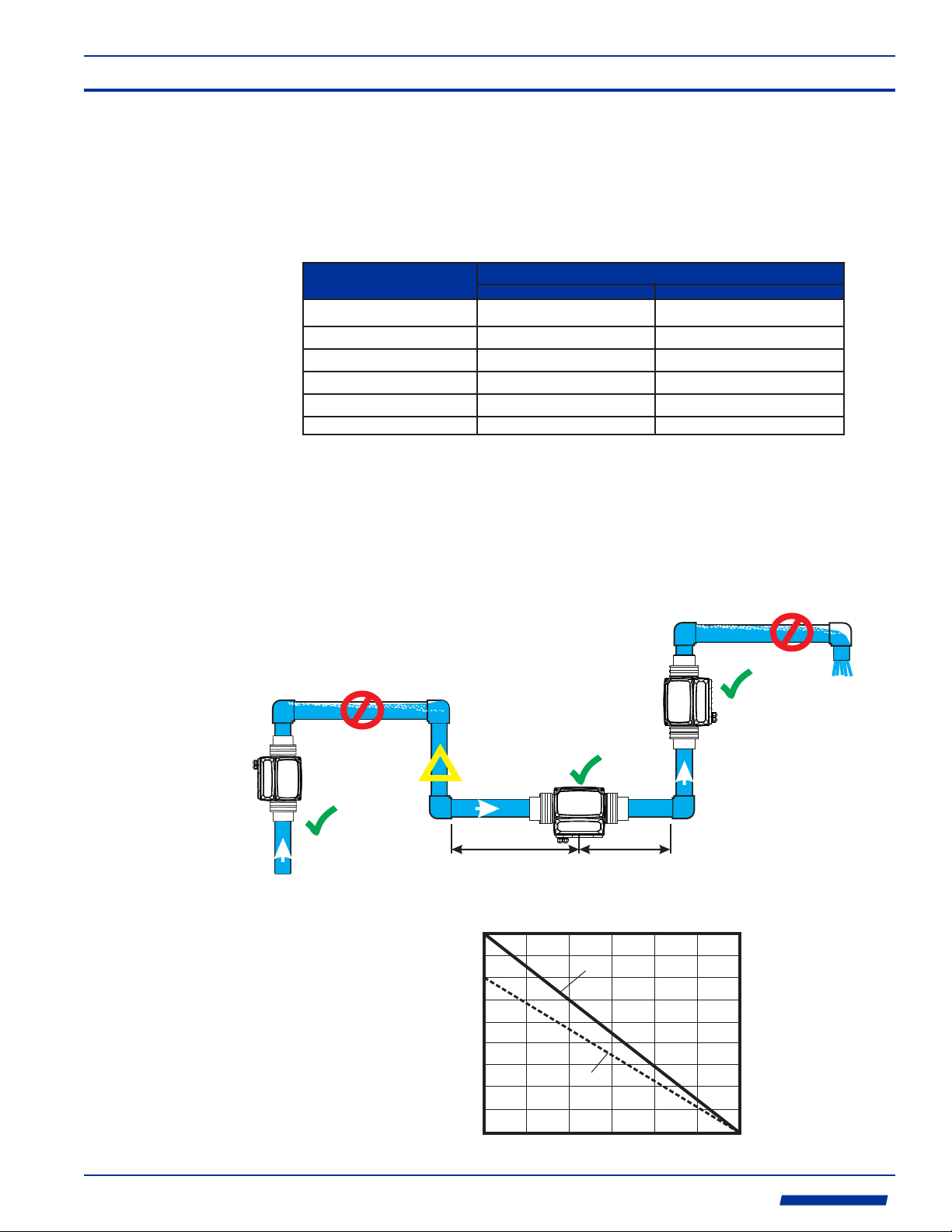

Minimum Straight Pipe Length Requirements

The Sonic-Pro’s sound wave beam is only affected by fluid that actually passes through the

beam and therefore, the meter will not measure with high accuracy if the fluid velocity is not

consistent across the entire pipe diameter. Flow disturbances such as pumps, elbows, tees,

and valves in the flow stream can cause swirl patterns and vortices that will affect the

measurement accuracy or disrupt flow measurement capability. Install the transducers on a

straight run of pipe as far as possible from any disturbances. The distance required for high

accuracy will depend on the type of disturbance.

Type of Disturbance

Flange

Reducer

o

90 Elbow

o

Two 90 Elbows - 1 Direction

o

Two 90 Elbows - 2 Directions

Gate valve or Pump

Upstream from Transducers

5 x Nominal Pipe Size

7 x Nominal Pipe Size 5 x Nominal Pipe Size

10 x Nominal Pipe Size 5 x Nominal Pipe Size

15 x Nominal Pipe Size 5 x Nominal Pipe Size

20 x Nominal Pipe Size 5 x Nominal Pipe Size

25 x Nominal Pipe Size 5 x Nominal Pipe Size

Straight Lengths of Pipe Required

Downstream from Transducers

5 x Nominal Pipe Size

Transducer Mounting Requirements

!

The meter can be mounted on horizontal or vertical runs of pipe.

!

Mounting anywhere around the diameter of vertical pipe is acceptable, however, the pipe

must be completely full of fluid at all times.

!

Back pressure is required on downward flows to ensure a full pipe.

!

See the minimum straight length of pipe requirement chart above.

!

Related piping must be independently supported. The meter should not be allowed to

support the weight of related piping.

NO

Pipe must be full

NO

Air could be trapped

Down flows

must have

back pressure

OK

!

160° F (71° C)

150° F (65° C)

140° F (60° C)

130° F (54° C)

120° F (49° C)

110° F (43° C)

100° F (38° C)

TEMPERATURE F (C)

90° F (32° C)

80° F (27° C)

70° F (21° C)

OK

L >= 5DL >= 10D

See minimum straight length requirements above

INLINE PIPE FITTING

TEMPERATURE VS PRESSURE

HDPE and 316SS Adapters

PVC Adapters

0

50 100

WORKING PRESSURE (PSI/g)

150

200 250

300

OK

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 6

Page 5

Sonic-Pro

4.0 Wiring Installation

4.1

Electrical

Connections

4.2

Cable Gland

Liquid-Tight

Connections

The meter must be powered by 15 to 28 volts DC. Depending on the model ordered, an

AC/DC plug-in transformer may have been be supplied for this purpose. See the diagram

below for wiring of output signals, communications signals and process control relays.

The transducer cable length is factory fixed. Do not attempt to modify the length of these

cables. Various cable lengths are available from the factory. Contact the factory if you need

assistance.

Shielded cable is recommended for signal output connections.

The Sonic-Pro SPU wiring compartment is equipped with:

Ÿ Three liquid-tight cable gland connectors for cable diameter from .200 to .394 inches (5.1

to 10.0 mm).

Ÿ Two liquid-tight cable gland connectors cable for diameters from .118 to .255 inches (3.0 to

6.5 mm).

Ÿ One communications cable liquid-tight cable gland grommet for cable diameters from .190

to .205 inches. It is provided for any one of the following cable types:

Ethernet Cable

RS-232 serial cable

Note that the blank grommet plug should be used when the communications cable grommet

is not required.

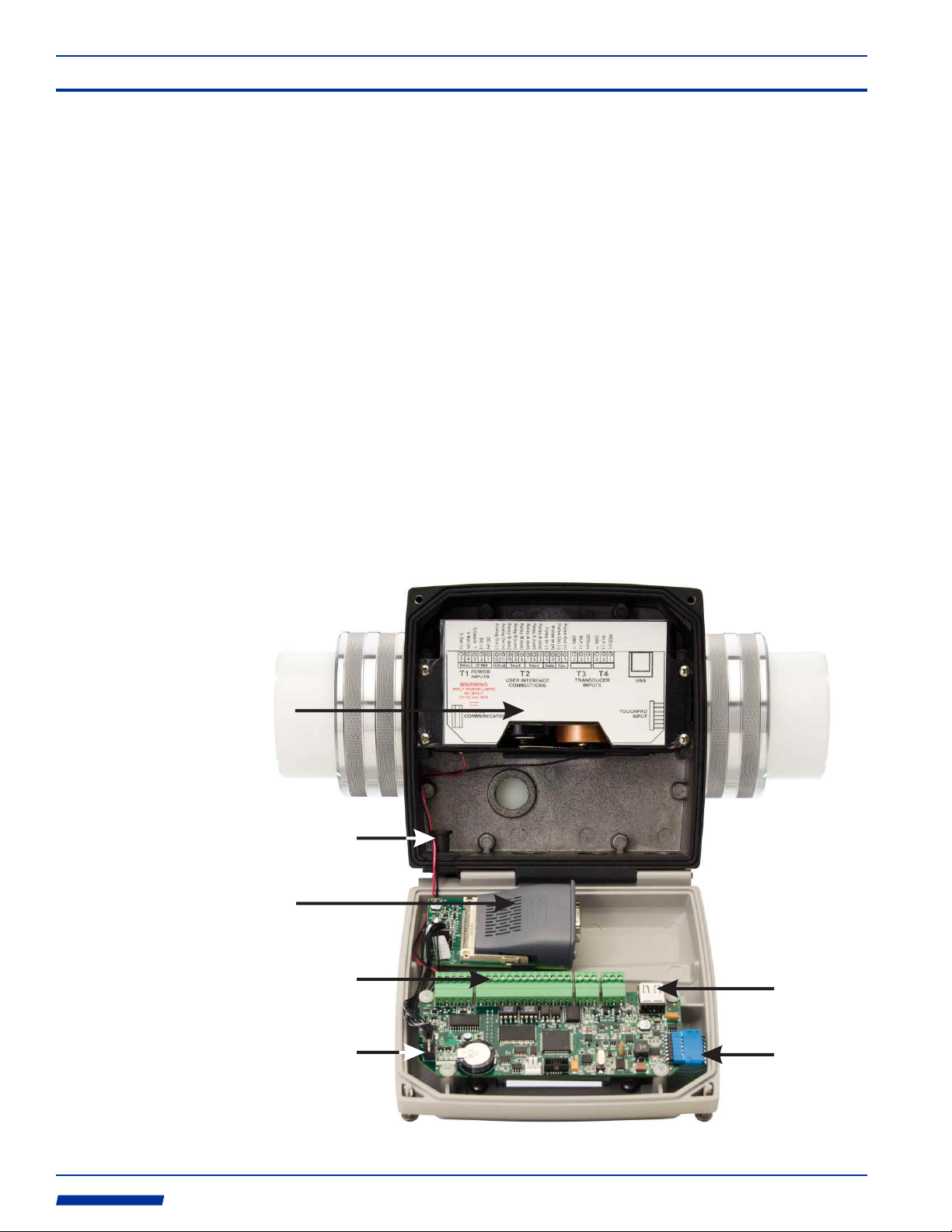

4.3

Wiring

Compartment

Back-up

Battery

Compartment

(4 D cells -

not included)

Communications

Cable Grommet

Optional

Communications

Circuitry

Wiring Terminals

Main PCB

Transducer A Transducer B

USB

Connection

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

Communications

Circuitry

Input Socket

d

Touchpad

Connection

Page 7

Sonic-Pro

4.4

Wiring

Terminals

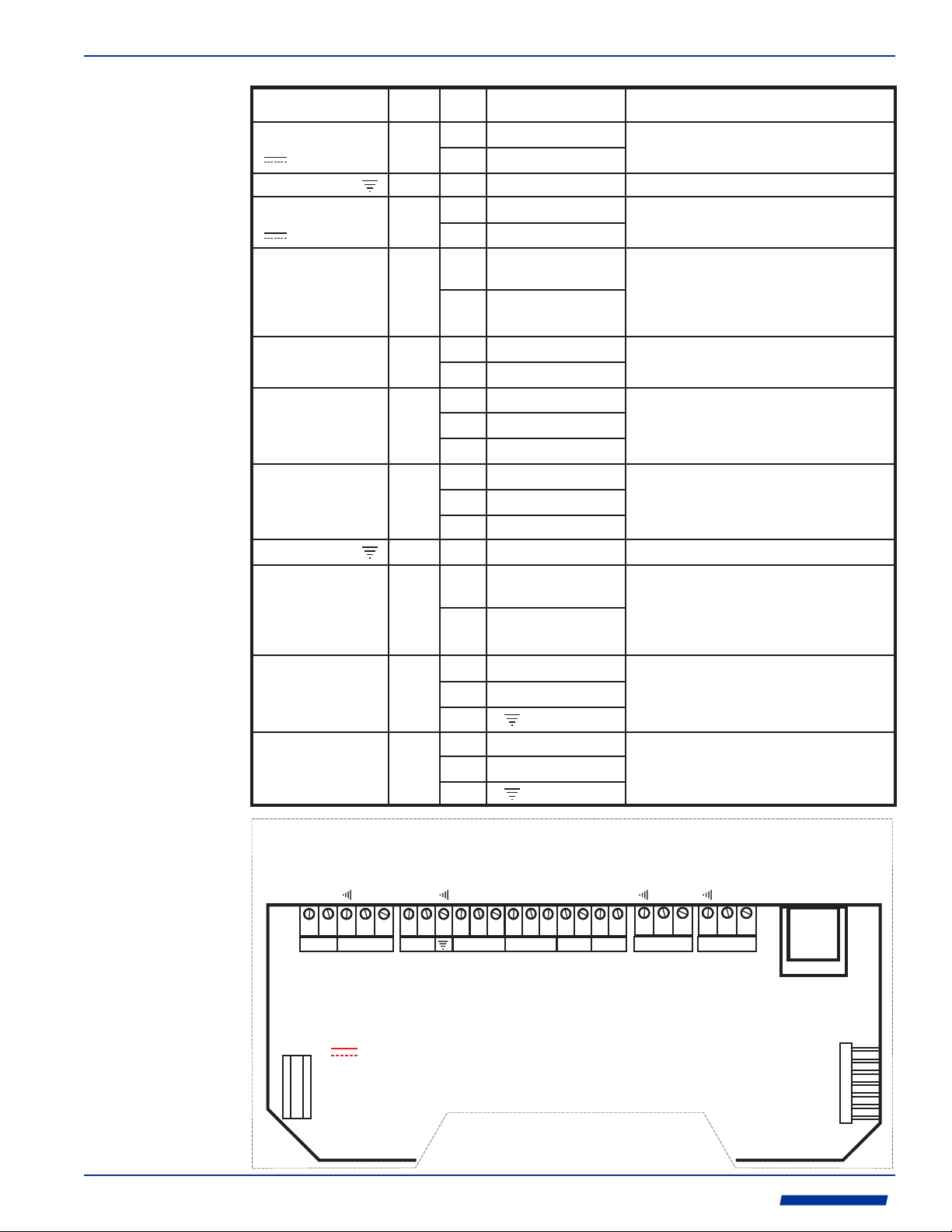

The terminal blocks are plug type capable of accepting 14 to 30 AWG wire.

FUNCTION TERM PIN # DESCRIPTION

POWER INPUT:

Primary power

Chassis Ground

POWER INPUT:

Battery Back-up power

PULSE FREQUENCY

OUTPUT:

Open Collector

PADDLEWHEEL

SENSOR INPUT:

AC Sine wave

RELAY ‘A’ OUTPUT

RELAY ‘B’ OUTPUT

Chassis Ground

ANALOG OUTPUT:

4-20 mA

TRANSDUCER

INPUT:

Transducer A

TRANSDUCER

INPUT:

Transducer B

T1

T1

T1

T2

T2

T2

T2

T2

T2

T3

T4

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

1

2

3

RATING

(+) 15-28 Vdc

(-) 15-28 Vdc

Ground

(+) Positive

(-) Negative

(+) Positive

(-) Negative

(+) Positive

(-) Negative

Normally Open

Common

Normally Closed

Normally Open

Common

Normally Closed

Ground

(+) Positive

(-) Negative

(+) Red

(-) Black

Green or Bare

(+) Red

(-) Black

Green or Bare

15-28Vdc, 400mA max

4 D cell size batteries

(Alkaline batteries only are acceptable)

Type: Open collector w/ internal 1 K pull-up to 5V.

Can be pulled up to 30V @ 10mA (3K pull-up)

Duty Cycle: 50%+/-5%

Frequency Range: 0-1000 Hz

Resolution: 1 Hz

Accuracy: 0.5% F.S.

Blue-White model FC sensor.

100mVp-p, 10 to 350Hz

Type: FORM C

Load capacity: 30V, 100mA max (ext. supplied)

Type: FORM C

Load capacity: 30V, 100mA max (ext. supplied)

Current output: 4-20 mADC, isolated.

Max Load Impedance: 1K ohm

Power: Internal

Resolution: 12 bits

Accuracy: Less than 0.1% F.S.

Update Rate: 1.0 s

Page 6

Analog Out (+)

Chassis

Analog Out (-)

V Bat (+)

V Bat (-)

5 4 3 2 1 10 9 8 7 6 5 4 3 2 1 3 2 13 2 1131211

Battery

T1 T2 T3 T4

WARNING

INPUT POWER LIMITS

DC INPUT

15~28 Vdc-15W

ANYBUS

COMMUNICATIONS

DC (-)

DC PWR

POWER

INPUTS

DC (+)

4-20 mA

Relay B (n/c)

Relay B (n/o)

Relay B (com)

Relay A (n/c)

Relay A (com)

Chassis

Relay B

USER INTERFACE

CONNECTIONS

Relay A

Relay A (n/o)

Pulse In (-)

Paddle

Pulse Out (-)

Pulse Out (+)

Pulse In (+)

Pulse

RED (+)

GRN

BLK (-)

Transducer A

TRANSDUCER

INPUTS

RED (+)

GRN

BLK (-)

Transducer B

USB

TOUCHPAD

INPUT

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 8

Page 7

Sonic-Pro

5.0 Operation

5.1

Power On

5.1.1

Battery Powered

operation

1. If power is present on Terminal T1 pins 1 & 2, the meter is always powered on.

2. If power is removed from Terminal T1 pins 1 & 2, and 4 D-Cell batteries are installed on

Terminal T1 pins 4 & 5, the meter will stay on (battery back-up). Under these conditions, the

meter can be turned on/off by pressing and holding the front panel ENTER button for three

seconds.

3. If power is only present on the battery Terminal T1 pins 4 & 5, then the meter can be

turned on/off by pressing and holding the front panel ENTER button for three seconds.

Operating time is limited when powered by batteries only.

While the batteries pack is provided primarily as back-up power, the S4 meter can be

operated solely with 4 D-cell batteries (not included). The meter can be configured to sleep

between measurements in order to conserve power. The approximate battery life is .....

Continuous Running

The following meter features are disabled during battery operation:

Ÿ Communications Module

Ÿ Analog output

Ÿ Pulse Frequency Output

10 / 10

128 Hr72 Hr 310 Hr 377 Hr 450 Hr

On / Sleep Time (seconds)

10 / 100 5 / 100 3 / 268

5.2

Run Screen

5.2.1

Fault Screen

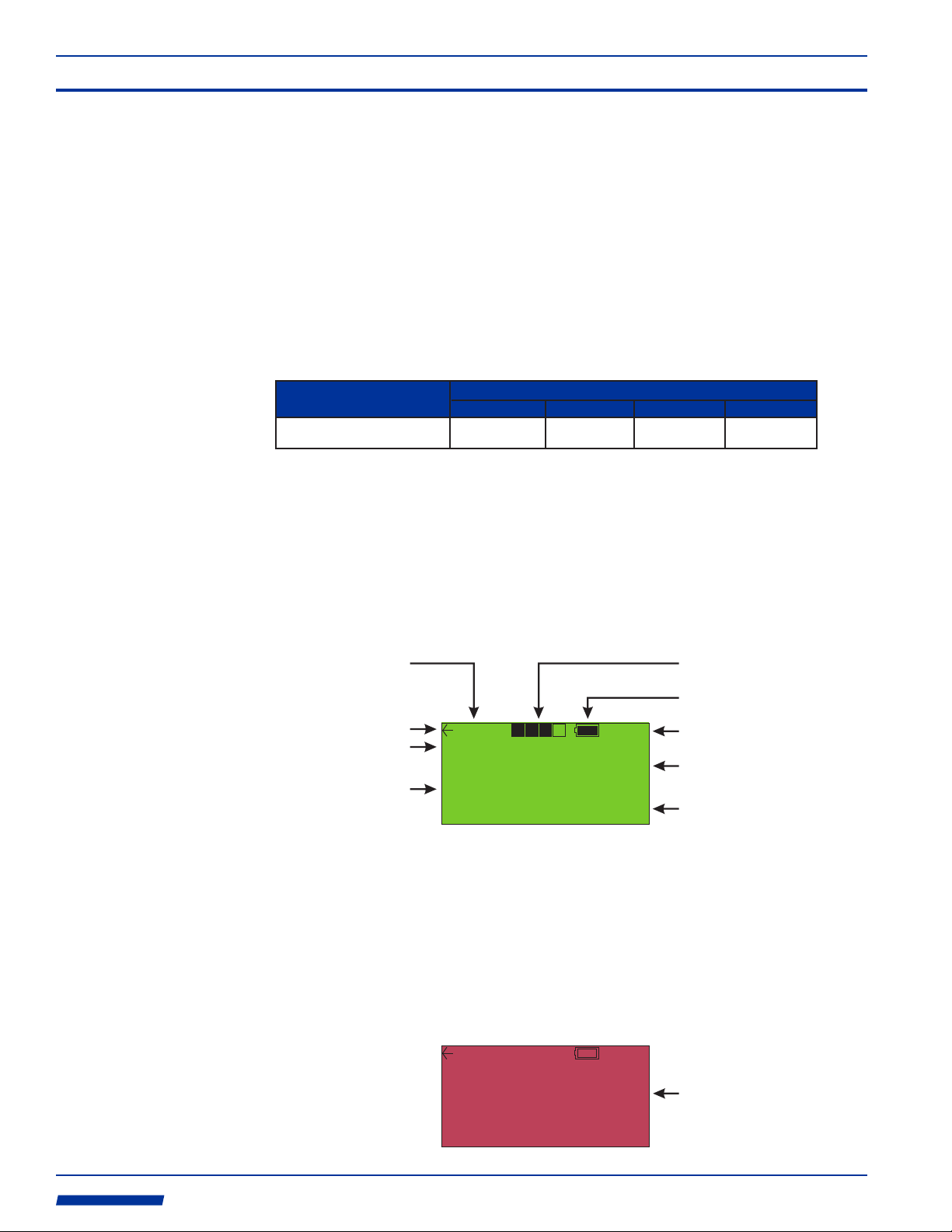

When the S4 is factory ordered with a pipe fitting/transducer, the pipe fitting data and the

default display feature parameters are pre-configured. When power is applied and there is

water in the pipe fitting, the following RUN display screen will be displayed.

Transducer Separation

Distance

Flow Direction

Flow Rate Units

0.28”

U.S Gallons/Min

25

Total Units

Ÿ Press the ENTER button to enter the menu system.

Ÿ Press the ESC button to clear the flow total to zero (if enabled in configuration).

Ÿ Press the up arrow p to toggle the flow rate to linear Feet/Sec., Meters/sec and back to

the configured user units of measure.

There are three possible FAULT indicator screens.

Ÿ FAULT 11 - Transducers are not connected or there is no fluid in the pipe.

Ÿ FAULT 12 - The allowable SOS (Speed Of Sound) error set-point has been exceeded.

Ÿ FAULT 21 - The configuration data is not valid.

U.S Gallons

0.28”

U.S Gallons/Min

XDCR Disc.

U.S Gallons

F-11

105

.

.

0”

1482

05469

Measurement Reliability

Battery Life

Measured Sound Speed

Flow rate

Flow Total

(press and hold ESC to clear)

Error Code

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

0

d

Page 9

Sonic-Pro

5.3

Menu

Navigation

Page 8

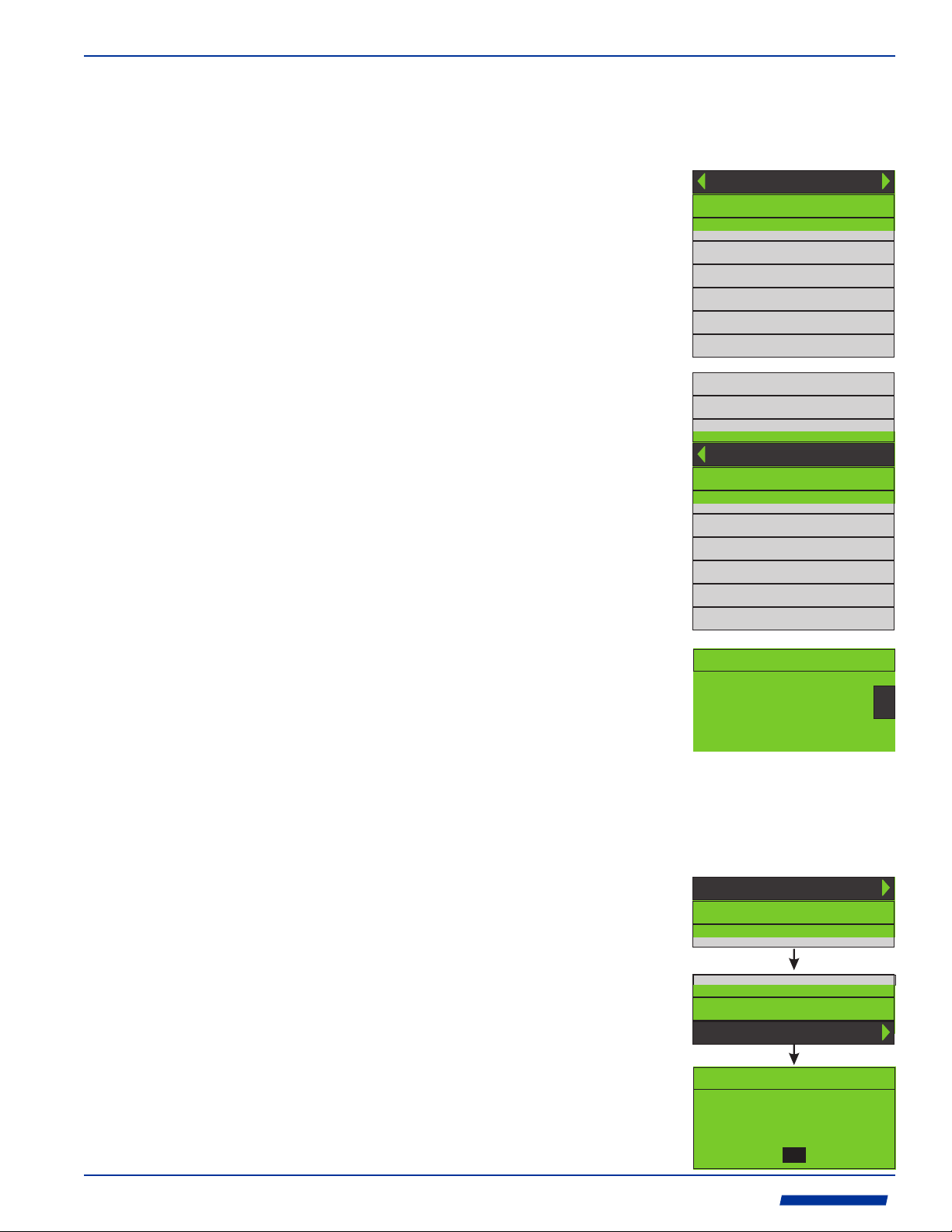

The Configuration Menu

From the RUN mode, press and release the ENTER button to enter the CONFIGURATION

menu. The following menu will be displayed:

5.3.1

Selecting and

Entering Menus

5.3.2

Selecting Optional

Items

Ÿ Press up arrow p or down arrow q to select menu items.

The selected item will be highlighted.

Ÿ Press right arrow u or ENTER to enter the selected menu.

Ÿ Press left arrow t to go back one menu.

Ÿ Notice the gray area. These menu items are hidden from

view. Press the up arrow p or down arrow q to display

hidden menu items.

Ÿ Press up arrow p or down arrow q to select optional

configuration items. The selected item will be highlighted.

Ÿ Press left arrow t or ENTER to choose the selected

optional item and return to the menu heading.

Paddle Wheel

XDCR Settings

Meter Settings

Output Settings

Clock

Calibration

Global Config.

About

U.S. Gallons

Ounces

U.S. Barrels Liq.

U.S. Barrels Oil

Cubic Feet

Acre Feet

Imperial Gallons

Cubic Meters

Liters

Milliliters

FR Custom V/Gal

5.3.3

Inputting Data

5.3.4

Save Configuration

Ÿ Press right arrow u or left arrow t to select a digit to

modify. Pressing the left arrow t will create additional

numbers to the left.

Ÿ Press up arrow p to increase or down arrow q to

decrease the value.

Ÿ Press ENTER to confirm the modifications and return to

the menu heading.

Ÿ Press ESC to cancel the modifications and return to the

menu heading.

Ÿ Press left arrow t to exit to the main menu.

Ÿ Press down arrow q to Highlight Save Config.

Ÿ Press right arrow u or ENTER to save the configuration

changes.

Ÿ Press ENTER to confirm the configuration changes have

been saved.

Ÿ Press up arrow p to RUN.

Ÿ Press right arrow u or ENTER to enter the RUN mode,

Enter Value

9.1000

0

Configuration

XDCR Settings

Save Config.

Configuration

XDCR Settings

Save Config.

Configuration

Configuration Saved!

OK

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 10

Page 9

Sonic-Pro

6.0 Configuration

The S4’s SPU can be used with a Paddle Wheel type sensor that outputs an AC Sine wave or

an Ultrasonic type sensor.

6.1

Configure the

SPU for a

Paddle Wheel

Sensor

6.2

Configure the

SPU for an

Ultrasonic

Inline Pipe

Fitting

Configuration

Paddle Wheel

When using an AC Sine wave Paddle Wheel type flow sensor and pipe fitting, the installer

must input the pipe fitting K-factor. The K-Factor is the total number of pulses output by the

sensor per gallon of fluid flow for a specific pipe fitting. The K-factor is different for each pipe

fitting. See the paddle wheel sensor’s instruction manual for a list of pipe fitting K-factors.

Configuration

Run

Save Config

Paddle Wheel

K-Factor

Enter Value

0.0000

When using Ultrasonic Transducers (XDCR), if the SPU and the Ultrasonic Inline Pipe

Fitting was shipped from the factory as a single model number, the SPU is pre-configured

with the proper model number and calibration constants shown on the calibration label

attached to the pipe fitting. If the pipe fitting was sold separately, the SPU will need to be

configured with the following data shown on the calibration label:

1. Measurement Units. The default value for all inline fittings is ENGLISH.

2. Model. The default value for all inline fittings is “C”.

3. Mount Method. The default value for all inline fittings is “V”.

4. Cable Length. Enter the length in feet. The available cable lengths are: 1 foot (SPU

mounted directly on the pipe fitting), 10, 25, 50 or 100 feet.

5. Flow Direction -> Direction. The default value for all inline fittings is “A -> B”.

6. Flow Direction -> Settings. Each flow direction has a unique SCALING and ZERO

VALUE number shown on the pipe fitting calibration label. Note that the ZERO number

may be POSITIVE or NEGATIVE.

7. Pipe Outside Diameter. Shown on the pipe fitting calibration label. Do not use your

inlet/outlet pipe size.

8. Pipe Wall Thickness. Shown on the pipe fitting calibration label. Do not use your

nominal pipe size.

9. Pipe Material. Shown on the pipe fitting calibration label. Do not use your inlet/outlet pipe

material.

10. Fluid Type. Select WATER or CUSTOM.

11. Fluid SOS. If WATER is selected, it is not necessary to input a fluid SOS. If “CUSTOM”

fluid type is selected, the Speed of Sound (SOS) for the custom fluid must be entered

manually. Note that the SOS must be within the pipe fitting’s SOS range.

Run

Save Config

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

XDCR Settings

d

Meas. Units

Transducer

Pipe

Fluid Fluid Type

ENGLISH

Mount Method

Cable Length(ft)

Flow Direction

Pipe Outside Dia.

Pipe Wall Thick.

Pipe Material

Pipe SOS

Fluid SOS

METRIC

Model

C

I

J

V

W

Enter Value

Direction

Settings

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

10

0000

A -> B

B -> A

A -> B

B -> A

Custom

HDPE

Custom

Water

Enter Value

0.0000 0.0000

Scaling(A->B)

Zero(A->B)

Scaling(B->A)

Zero(B->A)

Zero Value(B->A)

Sign(B->A)

Positive

Negative

Enter Value

Zero Value(A->B)

Sign(A->B)

Positive

Negative

Enter Value

0.0000

Enter Value

0.0000

Page 11

Sonic-Pro

6.2.1

Measurement

Units

Menu

Page 10

Select ENGLISH when entering the Pipe Outside Diameter and Pipe Wall Thickness

dimensional data in Inches. Select METRIC when entering pipe the Outside Diameter and

Pipe Wall Thickness dimensional data in millimeters.

Note that the factory default units is INCHES. These dimensions are shown on the

Calibration Detail label affixed to the pipe fitting:

6.2.2

Transducer

Menu

Meas. Units

Transducer

ENGLISH

METRIC

Model

Mount Method

Cable Length(ft)

Flow Direction

CALIBRATION DETAIL LABEL

C

I

J

V

W

Enter Value

10

Direction

Settings

A -> B

B -> A

A -> B

B -> A

Scaling(A->B)

Scaling(B->A)

Zero Value(B->A)

Enter Value

0.975 0.455

Zero(A->B)

Zero(B->A)

Sign(B->A)

Positive

Negative

Enter Value

Zero Value(A->B)

Sign(A->B)

Positive

Negative

Enter Value

0.975

Enter Value

0.455

6.2.2.1

Transducer

Model

6.2.2.2

Transducer

Mount Method

6.2.2.3

Transducer

Cable Length

There are three transducer MODELS available to select. When using the S4 Inline Pipe

Fitting/Transducer, select model C. See the model number ordering matrix for additional

transducer model options.

C

I

Transducer

Model

J

The transducers are factory set inside the pipe fitting and cannot be moved. Select the mount

method that is shown on the Calibration Detail label affixed to the pipe fitting.

Transducer

Model

Mount Method

V

W

Enter the transducer cable length. The available length options are:

1 = Sensor Mounted Display (no cable)

10 = 10 ft cable, transducer cable model number option “A”

25 = 25 ft cable, transducer cable model number option “B”

50 = 50 ft cable, transducer cable model number option “C”

100 = 100 ft cable, transducer cable model number option “D”

Transducer

Model

Mount Method

Cable Length(ft)

Enter Value

10

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 12

Page 11

6.2.2.4

Fluid Flow

Direction

Sonic-Pro

The relative flow direction is shown on the Calibration Detail label affixed to the pipe fitting.

Transducer

Model

Mount Method

Cable Length(ft)

Flow Direction

Direction

A -> B

B -> A

6.2.2.5

Fluid Flow

Direction

(CAL Settings)

Each of the flow directions (A to B and B to A) have a Scaling Factor and either a positive or

negative Zero Factor associated with it. The correct factors are shown on the Calibration

Detail label affixed to the ultrasonic flow sensor pipe fitting.

These are factory calibration factors that should not be changed without first

contacting the factory for technical assistance.

Transducer

Model

Mount Method

Cable Length(ft)

Flow Direction

Direction

Settings

A -> B

B -> A

Enter Value

0.975 0.455

Scaling(A->B)

Zero(A->B)

Scaling(B->A)

Zero(B->A)

Zero Value(B->A)

Sign(B->A)

Positive

Negative

Enter Value

Zero Value(A->B)

Sign(A->B)

Positive

Negative

Enter Value

0.975

Enter Value

0.455

6.2.3

Pipe

Menu

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

CALIBRATION DETAIL LABEL

Each pipe fitting has a specific Pipe Outside Dia., Pipe Wall Thick., Pipe Material and Pipe

SOS (Speed Of Sound) associated with it. The correct factors are shown on the Calibration

Detail label affixed to the ultrasonic flow sensor pipe fitting.

These are factory calibration factors that should not be changed without first

contacting the factory for technical assistance.

Pipe

d

Pipe Outside Dia.

Pipe Wall Thick.

Pipe Material

Pipe SOS

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Custom

HDPE

Page 13

Sonic-Pro

6.2.4

Fluid

Menu

Page 12

The sound transducers are located in the S4 pipe fitting. They are carefully positioned at the

factory for use with water at 68 degrees F which has a SOS (Speed Of Sound) of 1481

meters per second. (see page 28 for water SOS chart). The transducer placement cannot be

adjusted in the field. As the fluid’s sound speed moves away from the target Fluid SOS,

measurements become more difficult. If the speed that sound travels through the fluid is very

different than that of water, the meter will not function. The acceptable SOS range is from

1,400 to 1,600 m/sec.

The meter will display the SOS of the fluid being measured in the upper right hand corner of

the display.

Successful measurements are possible with fluids other than water provided the fluid’s SOS

is within the acceptable range and there are not too many particles or other sound blocking or

reflecting contaminants in the fluid which can inhibit the sound beam.

The target Fluid SOS value can be adjusted to maximize the meter’s ability to measure the

fluid. The chart below provides the sound speeds of a number of chemicals of specific

concentrations at specific temperatures. Diluted chemicals will have a different sound speed.

Select Custom from the Fluid Type menu, then input the SOS fluid in the Fluid SOS menu.

Fluid Fluid Type

Fluid SOS

Enter Value

0000

Custom

Water

Fluid Sound Speeds

Fluid

Water

Water

Water

Sea Water

Aluminum Sulfate 10% (Alum)

Ethylene Glycol (50% in water)

Gasoline

Hydrochloric Acid 32%

Hydrogen Peroxide 31%

Milk

Oil, Diesel

Oil, Motor (SAE 30)

Oil, Mineral

Potassium Hydroxide 50%

Sodium Hypochlorite 12%

Sulfuric Acid 96%

Sound Speed (meters/sec)

1403

1481

1543

1520

1900

1578

1250

1581

1530

1548

1250

1487

1431

2800

1835

1260

o o

Temp. F ( C)

32 (0)

68 (20)

212 (100)

68 (20)

68 (20)

77 (25)

77 (25)

68 (20)

68 (20)

77 (25)

77 (25)

68 (20)

77 (25)

68 (20)

68 (20)

68 (20)

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 14

Page 13

6.3

Configure the

SPU Meter

Settings

Sonic-Pro

In the Meter Settings menu, the data logging functions and the display features can be

configured.

Meter Settings

Logging

Display

Log Interval(s)

Rate Set Point 1

Rate Set Point 2

Tot. Set Point 1

Tot. Set Point 2

Tot. Set Point 3

Tot. Set Point 4

Tot. Set Point 5

Copy Logs

Delete Logs

Flow Rate Volume Units

Enter Value

Enter Value

Enter Value

Enter Value

Time Units

Fl. Rate Decimal

0.0000

0.0000

0.0000

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Seconds

Minutes

Hours

Days

Enter Value

U.S. Gallons

Ounces

U.S. Barrels Liq.

U.S. Barrels Oil

Cubic Feet

Acre Feet

Imperial Gallons

0

Cubic Meters

Liters

Milliliters

FR Custom V/Gal

Enter Value

0

Totalizer Volume Units

Fl. Total Decimal

Flow Average(s)

Enable Tot. Clear?

Low Fl. Cut-Off

High Fl. Cut-Off

Scaling Off-set

Zero Off-set

SOS Fault Window

Sleep Time(s)

Enter Value

Yes

Enter Value

Enter Value

Enter Value

FR Offset

Sign

Enter Value

Enter Value

No

999

1.0000

0

0

10

0

Enter Value

Enter Value

0.0000

Positive

Negative

U.S. Gallons

Ounces

U.S. Barrels Liq.

0

U.S. Barrels Oil

Cubic Feet

Acre Feet

Imperial Gallons

Cubic Meters

Liters

Milliliters

FR Custom V/Gal

Enter Value

0

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 15

Sonic-Pro

6.3.1

Logging

Menu

Page 14

Data logs are stored in the meter’s internal memory in a space delimited .TXT file that can

easily be copied to a removable USB flash drive located on the main circuit board. Each log

file includes the date and time, the flow rate (FR) and the flow total (TL). A total of 191,800

logs can be stored.

2013/12/29 09:15:00 FR 0.0000 TL 0.00

The Log Interval determines the number of seconds from 1 - 999,999 that the meter will wait

between logs.

If a value is entered into Rate Set Point 1, a new log will be generated every 60 seconds

while the measured rate of flow is greater than the configured value.

If a value is entered into Rate Set Point 2, a new log will be generated every 60 seconds

while the measured rate of flow is less than the configured value.

If a value is entered into any Tot. Set Point (1, 2, 3, 4 or 5), a new log will be generated

when the total accumulated flow value is equal to the configured value.

To access the log entries, you must copy the logs onto a USB flash drive and transfer the file

to a computer for reading. To copy all of the log entries, open the enclosure and insert a USB

flash drive. Highlight Copy Logs press either right arrow u or ENTER. When copying logs,

all of the logs must be copied. You may not copy only selected logs.

To delete ALL of the log entries, highlight Delete Logs then press either right arrow u or

ENTER. You may not delete only selected logs. All logs must be deleted.

Logging

Log Interval(s)

Rate Set Point 1

Rate Set Point 2

Tot. Set Point 1

Tot. Set Point 2

Tot. Set Point 3

Tot. Set Point 4

Tot. Set Point 5

Copy Logs

Delete Logs

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 16

Page 15

6.3.2

Display

Menu

Sonic-Pro

In the DISPLAY menu, the following features may be configured:

! Flow Rate - Volume Units

! Flow Rate - Time Units

! Flow Rate - Decimal Point Location

! Totalizer - Volume Units

! Totalizer - Decimal Point Location

! Flow Rate Averaging

! Enable/Disable clearing the totalizer from the front panel

! Low Flow Rate Cut-Off

! High Flow Rate Cut-Off

! Scaling Offset

! Zero Offset

! SOS Fault Window

! Sleep Time

Display

Flow Rate Volume Units

Time Units

Fl. Rate Decimal

Totalizer Volume Units

Fl. Total Decimal

Flow Average(s)

Enable Tot. Clear?

Low Fl. Cut-Off

High Fl. Cut-Off

Scaling Off-set

Zero Off-set

SOS Fault Window

Sleep Time(s)

Enter Value

Yes

Enter Value

Enter Value

Enter Value

FR Offset

Sign

Enter Value

Enter Value

No

999

1.0000

10

0

0

0

Seconds

Minutes

Hours

Days

Enter Value

Enter Value

Enter Value

0.0000

Positive

Negative

U.S. Gallons

Ounces

U.S. Barrels Liq.

U.S. Barrels Oil

Cubic Feet

Acre Feet

Imperial Gallons

0

Cubic Meters

Liters

Milliliters

FR Custom V/Gal

U.S. Gallons

Ounces

U.S. Barrels Liq.

0

U.S. Barrels Oil

Cubic Feet

Acre Feet

Imperial Gallons

Cubic Meters

Liters

Milliliters

TOT Custom V/Gal

Enter Value

0

Enter Value

0

6.3.2.1

Flow Rate Menu

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

In the Flow Rate menu, the Volume Units and Time Units may be selected from a list.

A custom volume unit may be created by selecting FR Custom V/Gal and entering the

number of gallons in the custom volume.

The Fl. Rate Decimal decimal point location may be set to a maximum of 5 digits.

Flow Rate Volume Units

Time Units

Fl. Rate Decimal

Seconds

Minutes

Hours

Days

Enter Value

U.S. Gallons

Ounces

U.S. Barrels Liq.

U.S. Barrels Oil

Cubic Feet

Acre Feet

Imperial Gallons

0

Cubic Meters

Liters

Milliliters

FR Custom V/Gal

Enter Value

0

Page 17

Sonic-Pro

6.3.2.2

Totalizer Menu

Page 16

In the Totalizer menu, the Volume Units may be selected from a list.

A custom volume unit may be created by selecting FR Custom V/Gal and entering the

number of gallons in the custom volume.

The Fl. Total Decimal decimal point location may be set to a maximum of 5 digits.

6.3.2.3

Flow Average

Setting

6.3.2.4

Clear Total

Setting

6.3.2.5

Low Flow Rate

Cut-off Setting

6.3.2.6

High Flow Rate

Cut-off Setting

Totalizer Volume Units

Fl. Total Decimal

Enter Value

U.S. Gallons

Ounces

U.S. Barrels Liq.

0

U.S. Barrels Oil

Cubic Feet

Acre Feet

Imperial Gallons

Cubic Meters

Liters

Milliliters

TOT Custom V/Gal

Enter Value

0

Flow Average(s) sets the running average period in seconds. Any number of seconds from 2

to 10 seconds is possible.

Flow Average(s)

Enter Value

0

Enable Tot. Clear? enables or disables the ability of the user to clear the accumulated total

flow by pressing the ESC button.

Enable Tot. Clear?

No

Yes

Low Fl. Cut-Off sets the minimum displayed flow rate. Calculated flow rate values less than

this value will be displayed as Zero and flow totalizing will not occur.

Low Fl. Cut-Off

Enter Value

0

High Fl. Cut-Off sets the maximum displayed flow rate. Calculated flow rate values greater

than this value will be displayed as the High Fl. Cut-Off value, totalizing will still occur.

High Fl. Cut-Off

Enter Value

999

6.3.2.7

Scaling Off-Set

Setting

6.3.2.8

Zero Off-Set

Setting

6.3.2.8

SOS

(Speed Of Sound)

Fault Window

Scaling Off-Set is a multiplier used to correct for flow inaccuracies. All flow rate values will

be multiplied by the Scaling Off-Set value and the result displayed and totaled.

Scaling Off-set

Enter Value

1.0000

Zero Off-Set is a factory calibration value used to offset the zero flow setpoint during the

initial calibration of the Ultrasonic Inline Pipe Fitting. The calibration value and sign should

match the ZERO: nnnn value and ZERO: +/-: xxx value shown on the Calibration Detail

label affixed to the pipe fitting.

These are factory calibration factors that should not be changed without first

contacting the factory for technical assistance.

Enter Value

Zero Off-set

FR Offset

Sign

0.0000

Positive

Negative

CALIBRATION DETAIL LABEL

The S4 will monitor the sound speed (SOS) of the measured fluid and report FAULT 12 if the

measured SOS exceeds the SOS Fault Window percentage value. The speed that sound

travels through the fluid will change if the density of the fluid changes (temperature change)

or if the fluid composition changes (chemical concentration, different chemicals, etc.). The

default value is 10%. The maximum allowable value is 50%.

SOS Fault Window

Enter Value

10

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 18

Page 17

6.3.2.9

Sleep Timer

Sonic-Pro

To conserve power, the S4 can be configured to “sleep” from 3 to 268 seconds per cycle. At

the end of each sleep cycle, the meter will “wake” for the number of seconds (from 2 to 10

seconds) as configured in the Flow Average feature, record data, and then return to sleep.

During the “wake” period, the display will remain blank.

The Flow Totalizer will estimate the amount of total fluid flow that would have been measured

while the meter was sleeping, using the following formula:

Total flow display value = T1 + (F1 + F2 / 2) x (N +1)

Where:

T1 = Last total before sleep

F1 = Last flow rate (units per second) before sleep

F2 = Flow rate average of the 1st second of wake-up (units per second)

N = Seconds of sleep (Sleep Timer Value)

note: the one second is added to the Sleep Time for accusation time at wake.

The sleep cycle can be interrupted by pressing the ENTER button.

Data logging cannot occur while sleeping. Logging will occur if the meter is “awake” and if it is

time to log data.

Sleep Time(s)

Enter Value

0

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 19

Sonic-Pro

6.4

Configure the

SPU Output

Settings

Page 18

In the Output Settings menu, the Analog 4-20mA, Pulse 0-1000 Hz, Contact Closures

and the Anybus Communications module functions can be configured.

Output Settings

Analog 4-20mA

Pulse 0-1000

Contact Closure

Anybus

Rate at Min Curr.

Min Analog O/P

Rate at Max Curr.

Max Analog O/P

Rate at Min Freq.

Min Frequency

Rate at Max Freq.

Max Frequency

Relay A

Relay B

Enter Value

0.0000

Enter Value

4

Enter Value

0.0000

Enter Value

20

Enter Value

0.0000

Enter Value

0

Enter Value

0.0000

Enter Value

1000

None A

Monitor Flow Rate

Monitor Totalizer

Faults A

None B

Monitor Flow Rate

Monitor Totalizer

Faults B

Type

Address

High Trigger A

High Release A

Low Trigger A

Low Release A

Time(s) A

Batch Amt. A

Contact Timer(s) A

High Trigger B

High Release B

Low Trigger B

Low Release B

Time(s) B

Batch Amt. B

Contact Timer(s) B

Profibus DPV1

Modbus RTU

Modbus TCP

Ethernet

Profinet

None

Profibus DPV1

Modbus RTU

Modbus TCP

Ethernet

Profinet

None

Enter Value

Enter Value

Enter Value

Enter Value

Enter Value

Enter Value

0

Enter Value

Enter Value

0

Enter Value

Enter Value

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

Enter Value

0

Enter Value

0

IP SET

192.168.234.123

OK CANCEL

IP SET

192.168.234.123

OK CANCEL

IP SET

192.168.234.123

OK CANCEL

ProSeries

0

0

0

0

0

0

0

0

0

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 20

Page 19

6.4.1

Analog

4-20mA

Output Menu

Sonic-Pro

An analog current output signal can be programmed within the range of 4-20mA.

Specify the flow rate at a minimum current (Rate at Min Curr.) and the corresponding

minimum analog current (Min Analog O/P).

Specify the flow rate at a maximum current (Rate at Max Curr.) and the corresponding

maximum analog current (Max Analog O/P).

The flow rates must not be the same. The current for the high flow rate may be smaller than

the current for the low flow rate in which case, the current will decrease with increasing flow

rate.

Flow rates are mapped to currents using a straight line through the two points specified.

Analog 4-20mA

Rate at Min Curr.

Min Analog O/P

Rate at Max Curr.

Max Analog O/P

Enter Value

0.0000

Enter Value

4

Enter Value

0.0000

Enter Value

20

6.4.2

Pulse

0-1000 Hz

Output Menu

A digital pulse output signal can be programmed within the range of 0-1000 Hz (pulses per

second).

Specify the flow rate at a minimum frequency (Rate at Min Freq.) and the corresponding

minimum frequency (Min Frequency).

Specify the flow rate at a maximum frequency (Rate at Max Freq.) and the corresponding

maximum frequency (Max Frequency).

The flow rates must not be the same. The frequency for the high flow rate may be smaller

than the frequency for the low flow rate in which case, the frequency will decrease with

increasing flow rate.

Flow rates are mapped to frequencies using a straight line through the two points specified.

Pulse 0-1000

Rate at Min Freq.

Min Frequency

Rate at Max Freq.

Max Frequency

Enter Value

0.0000

Enter Value

0

Enter Value

0.0000

Enter Value

1000

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 21

Sonic-Pro

6.4.3

Contact

Closure

Relay

Output Menu

Page 20

The S4 has two Form C relays. Each can be independently configured to energize when one

of the following conditions are met:

! A specific Flow Rate value is displayed, used for high, low or high/low range alarms.

! An Accumulated Total value has been measured. Used for triggering external equipment

when a configured batch amount is reached.

! A FAULT has occurred.

Contact Closure

Relay A

Relay B

None A

Monitor Flow Rate

Monitor Totalizer

Faults A

None B

Monitor Flow Rate

Monitor Totalizer

Faults B

High Trigger A

High Release A

Low Trigger A

Low Release A

Time(s) A

Batch Amt. A

Contact Timer(s) A

High Trigger B

High Release B

Low Trigger B

Low Release B

Time(s) B

Batch Amt. B

Contact Timer(s) B

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

6.4.3.1

CC Assigned to

Monitor Flow Rate

When in the Relay A or Relay B menu, selecting and then exiting the Monitor Flow Rate

menu will assigned that relay to monitor the rate of flow. The following functions are possible:

! Set a High Trigger flow rate value which when measured, will energize the relay.

! Set a High Release flow rate value which when measured, will de-energize the relay.

! Set a Low Trigger flow rate value which when measured, will energize the relay.

! Set a Low Release flow rate value which when measured, will de-energize the relay.

! Set a Time (s) in seconds (0-999) to delay energizing the relay when it is triggered.

When either of the relays are energized, the display back-light will turn blue.

When both the trigger and release values are configured for the same value, the relay will

latch. The user must press the ESC button to clear a latched relay.

Relay B

None B

Monitor Flow Rate

High Trigger B

High Release B

Low Trigger B

Low Release B

Time(s) B

Enter Value

Enter Value

Enter Value

Enter Value

Enter Value

0

0

0

0

0

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 22

Page 21

6.4.3.1

CC Assigned to

Monitor Totalizer

Sonic-Pro

When in the Relay A or Relay B menu, selecting and then exiting the Monitor Totalizer

menu will assigned that relay to monitor the accumulated to flow value. The following

functions are possible:

! Set a Batch Amount total flow value which when reached, will energize the relay.

! Set the Contact Timer(s) for the number of seconds (0-999) that the relay will remain

energized.

When either of the relays are energized, the display back-light will turn blue.

Monitor Totalizer

Batch Amt. B

Contact Timer(s) B

Enter Value

0

Enter Value

0

6.4.3.2

CC Assigned to

Monitor FAULTS

6.4.4

Anybus

Comm.

Menu

When in the Relay A or Relay B menu, selecting and then exiting the FAULTS menu will

assign that relay to energize when any of the following fault conditions exist.

Ÿ FAULT 11 - Transducers are not connected or there is no fluid in the pipe.

Ÿ FAULT 12 - The allowable SOS (Speed Of Sound) error set-point has been exceeded.

Ÿ FAULT 21 - The configuration data is not valid.

The display back-light will turn red when there is a FAULT condition.

Faults B

There are five different Anybus communications modules that can be installed in the S4

meter. Each optional module uses a different communications protocol.

Anybus Communications Options

Protocol

Profibus DPV

Modbus RTU

Modbus TCP

Industrial Ethernet/IP

Profinet IO

Network Connector Baud Rate

DB9F

DB9F

RJ45

RJ45

RJ45

Up to 12 Mbit/s

Up to 12 Mbit/s

10/100 Mbit/s full/half duplex

10/100 Mbit/s full/half duplex

100 Mbit/s full duplex

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

Communications

Cable Grommet

Optional Anybus

Communications

Module

d

Page 23

Sonic-Pro

Page 22

Select the module being used and enter the Port Address (for Profibus DPV or Modbus RTU

modules) or the IP ADDRESS ( for Modbus TCP, Industrial Ethernet/IP or Profinet IO

modules.

Anybus

Type

Address

Profibus DPV1

Modbus RTU

Modbus TCP

Ethernet

Profinet

None

Profibus DPV1

Modbus RTU

Modbus TCP

Ethernet

Profinet

None

Enter Value

0

Enter Value

0

IP SET

192.168.234.123

OK CANCEL

IP SET

192.168.234.123

OK CANCEL

IP SET

192.168.234.123

OK CANCEL

Use the following Anybus mapping structure to communicate with the module and monitor the

flowmeter. There are no send commands available.

Byte Bit Type No. of Bytes

1 0 Contact Closure 1 0: CC OFF, 1:CC ON

1 Contact Closure 2 0: CC OFF, 1:CC ON

2 Reserved

3 Reserved 1

4 Reserved

5 Reserved

6 Reserved

7 Reserved

2 0 Reserved

1 Reserved

2 Reserved

3 Reserved 1

4 Reserved

5 Reserved

6 Reserved

7 Reserved

3 Flow Rate double 8 Current flow rate value.

11 Totalizer double 8 Current totalizer value.

19 Fault Number Table char 6 Fault number table upto six faults.

25 Speed of Sound unsigned long 8 Current SOS value.

33 Goodness Of Meas. unsigned char 1 Current GOM - 1 to 4.

34 Reserved unsigned char 1

35 4 - 20mA Flow unsigned char 1 4 to 20mA current output

36 Reserved unsigned char 1

37 Flow Frequency unsigned char 8 Frequency output

45 Firmware Version unsigned char 8 8 ASCII characters. A11.22.33

53 Log Entry unsigned char 86 Log Entry String

Eg: 2013/12/29 09:15:00 FR 0.0000 TL 0.00

Description

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 24

Page 23

6.5

Configure the

Clock

Sonic-Pro

In the Clock menu, use the right arrow u or left arrow t to highlight the Year, Month, Day,

hour, or minute. Change the highlighted value using the up arrow p or down arrow q button.

To sve the entries, highlight OK and press ENTER.

The clock is powered by a supercapacitor, which is continuously charging while the meter is

powered, rather than a battery. It never has to be replaced.

Clock CLOCK SET

2013/07/24

14:31

OK CANCEL

6.6

Zero Flow

Calibration

6.7

Global

Configuration

The zero calibration data can be stored for one flow direction only. If the Pipe Fitting and

SPU was shipped from the factory as a single model number, the zero flow Calibration

required to link the SPU and the Pipe Fitting was performed at the factory for the A --> B flow

direction. No further calibration is necessary. If the flow direction is from A <--- B or if a new

Ultrasonic Inline Pipe Fitting is used, re-calibration may be necessary to achieve high

accuracy.

The meter can be re-calibrated in the field by selecting Calibration and pressing the right

arrow u or ENTER button. The pipe must be full of fluid and there must be no movement of

the fluid in the pipe during the calibration process.

Note that performing a Zero Flow Calibration does not affect the Flow Direction

configuration settings shown on the Calibration Detail Label: Zero and Zero +/- variables:

transducer/Flow Direction/Settings/A -> B/

Calibration

Calibration

Clear Cal. Value

CALIBRATION

CANCEL

No

Yes

In the Global Config. menu, the user can configure a password, restore the factory default

configuration data, save and restore configuration data to a USB thumb drive, and update or

view the current firmware version.

Global Config.

Password

Save Conf. To USB

Restore USB Conf.

Firmware Update

Change Password

Enter Value

Save Conf. To USB

USB Drive Found!

Config. Copied To USB

Restore USB Conf.

Config. File Found.

Erasing Config File..

Restored Config.

Firmware Upgrade

USB Drive Found.

Press ESC to upgrade

Change Password

Old Pass.:

NEW Pass.:

OK CANCEL

OK

OK

OK

0000

0000

0

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 25

Sonic-Pro

6.7.1

Password

Page 24

The S4 is shipped from the factory with the default password 0000. If a new password is not

configured, the meter will allow saving changes to the configuration at the main menu.

Configuration

Run

Save Config

A user defined four digit password can be entered to replace 0000.

Change Password

Change Password

New Pass.:

Confirm Pass.:

OK

1234

1234

CANCEL

Once a new password has been configured, it must be entered to allow saving any changes

made to the configuration data. Once entered, the Save Config function is possible at the

main menu.

Global Config.

Password

Enter Value

1234

Once entered, the user defined password can be changed to any four digit number.

Change Password

Change Password

Old Pass.:

NEW Pass.:

1234

5678

OK CANCEL

6.7.2

Save/Restore

Config

6.7.3

Firmware

Update

Enter master password 3408 to clear any stored password.

The S4 configuration settings can be save and restored using a USB flash drive.

Save Conf. To USB

Restore USB Conf.

Save Conf. To USB

USB Drive Found!

Config. Copied To USB

OK

Restore USB Conf.

Config. File Found.

Erasing Config File..

Restored Config.

OK

The S4 firmware can be upgraded to the latest version. Download from www.blue-white.com

to a USB flash drive.

Configuration data will not be erased.

Firmware Update

Firmware Upgrade

USB Drive Found.

Press ESC to upgrade

OK

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 26

Page 25

Sonic-Pro

_________General Operation__________

Measuring Principle

Ultrasonic - Transit Time.

Fluid Types

Water to 5% (0 to 50,000 ppm) particulate.

Fluid Velocity Range

0.5 to 30 feet per second (0.15 to 9 meters per second)

Nominal Pipe Sizes

0.50, 0.75, 1.00, 1.50 and 2 inch IPS pipe sizes

Accuracy

+/-2% of rate > 1 ft/sec, +/-0.10 ft/sec < 1 ft/sec

_____Inline Pipe Fitting/ Transducer____

Pipe Fitting/Transducer

NEMA 4X (IP66), High Density Polyethylene

Connection option A -

High Density Polyethylene, Female NPT threads

Maximum fluid temperature: 14 F to 160 F (-10 C to 71 C)

Maximum operating pressure: 300 PSI/g at

Connection option B -

316 Stainless Steel, Female NPT threads

Maximum fluid temperature: 14 F to 160 F (-10 C to 71 C)

Maximum operating pressure: O300 PSI/g at 70 F

Connection option C -

PVC, Female Slip

Maximum fluid temperature: 14 F to 140 F (-10 C to 60 C)

Maximum operating pressure: O300 PSI/g at 70 F

Connection option D -

316 Stainless Steel, 150# Flat Face Flange (without gaskets)

Maximum fluid temperature: 14 F to 160 F (-10 C to 71 C)

Maximum operating pressure:

Cable - field replaceable

Shielded coaxial RG/U Type: 59. FEP jacket, black. RoHS Compliant

Connector: thermoplastic locking. NEMA 4X (IP66)

Available lengths: 10ft (3m), 25 ft. (7m), 50 ft. (15m), 100 ft. (30m)

160° F (71° C)

150° F (65° C)

140° F (60° C)

130° F (54° C)

120° F (49° C)

110° F (43° C)

100° F (38° C)

TEMPERATURE F (C)

90° F (32° C)

80° F (27° C)

70° F (21° C)

Model

Number

05

07

10

15

20

0

Pipe

Size

1/2”

3/4”

1”

1-1/2”

2”

O O O O

O O O O

O O O O

O O O O

300 PSI/g at 70 F

70 F

O

O

INLINE PIPE FITTING

TEMPERATURE VS PRESSURE

HDPE and 316SS Adapters

PVC Adapters

50 100

WORKING PRESSURE (PSI/g)

FLOW RANGES

Min. Flow (0.5 fps)

GPM (LPM)

0.36 (1.36)

0.67 (2.54)

1.12 (4.24)

2.75 (10.4)

4.60 (17.4)

150

200 250

Max. Flow (30 fps)

GPM (LPM)

300

21.9 (82.9)

40.4 (153)

67.3 (255)

165 (625)

276 (1045)

_______SPU (Signal Processing Unit)_______

Enclosure

NEMA 4X (IP66), Powder coated aluminum, SS clamps and hardware.

Dimensions: 7.24H x 6.69W x 3.11D inches (184H x 170W x 79D mm)

Weight 3.7 lb. (1.7 Kg.)

Mounting

Pipe fitting, wall or pipe (vertical or horizontal) mounting. Hardware included.

Power Requirements

15-28 VDC; 15 watts maximum

Operating Temperature

O O O O O O O O

14 F to 140 F (-10 C to 60 C) Storage: -40 F to 158 F (-40 C to 70 C)

Display

VGA backlit LCD, UV resistant.

Simultaneous Rate and Total: 8 digit maximum

Decimal location configurable to 5 places.

Display Language

English

Keypad

Six-button positive action tactile switch keypad.

Security

Programmable 4-digit password.

Display Volume Units

Independently configurable Rate and Total display units in: U.S. Gallons,

ounces, barrels (US liquid), barrels (US oil), cubic ft, acre ft, Imperial (British)

gallons, liter, cubic meter, or user defined “custom” units.

Rate display in feet or meters per second.

Display Time Units

Seconds, minutes, hours, days.

Display/Output Response Time

1.0 second.

Flow Rate Display Averaging

Selectable: 0.50, 1.0, 2.5, 5.0 (default), 10.0 seconds.

Data Outputs

!

Isolated 4-20 mA output - fully configurable, invertible

!

0-1000 Hz Pulse output - fully configurable, invertible

Data Logging

Date/time stamped flow rate and flow total data in FAT32 file format, easily

imported into Excel. Configurable to trigger on time interval (1-999,999 sec),

rate and/or total set-point values. Store up to 191,800 log events in the

memory buffer, downloadable to flash memory via USB port.

Process Control

Two independently configurable relays.

Type: FORM C

Load capacity: 30V, 100mA max (ext. supplied)

!

Configure to flow rate for high/low/range rate alarm. Programmable

release values enable auto release or manual latching operation.

!

Configure to flow total for automatically triggered, timed batch operations

for proportional feed applications.

External Communications

Computer connection via optional Communications Modules:

! Industrial Ethernet/IP

! Modbus RTU

! Modbus TCP

! Profinet RT/IO

! Profibus DPV1

When equipped with a communications module, the following data

transfer is possible:

1. Flow rate

2. Flow total

3. Fault/warning codes

4. Log data

5. CC1 relay status

6. CC2 relay status

7. Current fluid sound speed

8. Number of Goodness of Measurement boxes filled in

9. Analog output value (4-20 mA)

10. Frequency output value (0-1000 Hz)

11. Firmware version

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 27

Sonic-Pro

7.1 Model Number System7.0 Specifications

Signal Processing Unit (SPU) - Display

Sonic-Pro Base model

S4

Communications Options

D

Industrial Ethernet/IP

E

Modbus RTU

F

Modbus TCP/IP

PROFINET RT/IO

G

PROFIBUS-DPV1

H

Standard 4-20mA and High Speed Pulse output only

X

Input Power (15 - 30 VDC required - all units include D cell battery pack, 4 D cell batteries are not included)

Without power supply (customer supplies 15-30 VDC)

0

1

U.S. 115VAC~50/60 / 15VDC plug-in transformer

2

Europe 220VAC~50/60 / 15VDC plug-in transformer

3

U.S. 230VAC~50/60 / 15VDC plug-in transformer

Inline Pipe Fitting/Transducer

Inline pipe fitting/transducer (see pipe size and material options below)

C

Without inline pipe fitting/transducer

X

Transducer Cable Length and Connection Type

10 ft cable length - with field replaceable liquid-tight cable plug and socket

A

25 ft cable length - with field replaceable liquid-tight cable plug and socket

B

50 ft cable length - with field replaceable liquid-tight cable plug and socket

C

100 ft cable length - with field replaceable liquid-tight cable plug and socket

D

Display mounted directly on the inline pipe fitting/transducer - no transducer cables

X

Inline pipe fitting transducer only (no display) - without cables

Z

Inline Pipe Fitting/Transducer

Fluid Sound Speed Working Range

0

Nominal IPS Pipe Connection Size

Water like fluids 1500 +/- 100 m/sec

05

Pipe Connection Type and Material

07

1/2”

A

F/NPT , HDPE

Inline Body Material

Polyethylene (HDPE)

G

Sonic-Pro S4 Part Number Matrix

3/4”

1”

10

B

15

1-1/2”

F/NPT, 316SS

Page 26

20

2”

C

Slip, PVC

Flange, 316SS

D

D

S4

C

1

07

A

0

A

G

Sample Part Number

Inline Pipe/Transducer Only

Sonic-Pro TransducerST

Transducer Model

Transducer Cable Length and Connection Type

Pipe Configuration Specifications

ST

- -

C

-

015AG

B

Sample Number

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 28

Page 27

7.2 Sound speed data

Water Sound Speeds

O

Temp COTemp F

0 32 1403

5 41 1427

10 50 1447

20 68 1481

30 86 1507

40 104 1526

50 122 1541

60 140 1552

70 158 1555

80 176 1555

90 194 1550

100 212 1543

Sound Speed (meters/sec)

Sonic-Pro

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 29

Sonic-Pro

7.3 Dimensional Drawings

6.69 in

170 mm

6.52 in

166 mm

7.24 in

184 mm

1.24 in

31 mm

.58 in

15 mm

.81 in

21 mm

.70 in

18 mm

6.52 in

166 mm

1.50 in

38 mm

TYP.

22 mm

.86 in

Sonic-Pro SPU

3.11 in

79 mm

6.23 in

158 mm

3.14 in

80 mm

.35 in

9 mm

8.00 in

203 mm

Page 28

3.2 in

81 mm

2.5 in

64 mm

Pipe

Size

2"

1.5"

1"

.75"

.5"

Sonic-Pro Inline Pipe Fittings

15.36in

39.0cm

OW

OL

B

Flanged Fittings

OL OW A B C

7.47in

[18.97cm]

7.24in

[18.39cm]

7.24in

[18.39cm]

7.24in

[18.39cm]

7.24in

[18.39cm]

8.02in

[20.38cm]

7.35in

[18.68cm]

6.76in

[17.18cm]

6.45in

[16.45cm]

6.20in

[15.75cm]

1.94in

[4.93cm]

1.50in

[3.81cm]

.96in

[2.45cm]

.74in

[1.88cm]

.55in

[1.39cm]

A

C

4.75in

[12.07cm]

3.88in

[9.86cm]

3.12in

[7.92cm]

2.75in

[6.99cm]

2.38in

[6.05cm]

6.00in

[15.24cm]

5.00in

[12.70cm]

4.25in

[10.80cm]

3.88in

[9.86cm]

3.50iin

[8.89cm]

Pipe

Size

2"

1.5"

1"

.75"

.5"

12.78in

32.45cm

E

OL

OW

NPT Fittings

OL OW D E

7.24in

[18.39cm]

7.24in

[18.39cm]

7.24in

[18.39cm]

7.24in

[18.39cm]

7.24in

[18.39cm]

6.97in

[17.71cm]

6.53in

[16.59cm]

5.98in

[15.18cm]

5.90in

[14.97cm]

5.83in

[14.80cm]

1.94in

[4.93cm]

1.50in

[3.81cm]

.96in

[2.45cm]

.74in

[1.88cm]

.55in

[1.39cm]

D

3.90in

[9.91cm]

3.33in

[8.45cm]

2.75in

[6.99cm]

2.75in

[6.99cm]

2.75in

[6.99cm]

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 30

Page 29

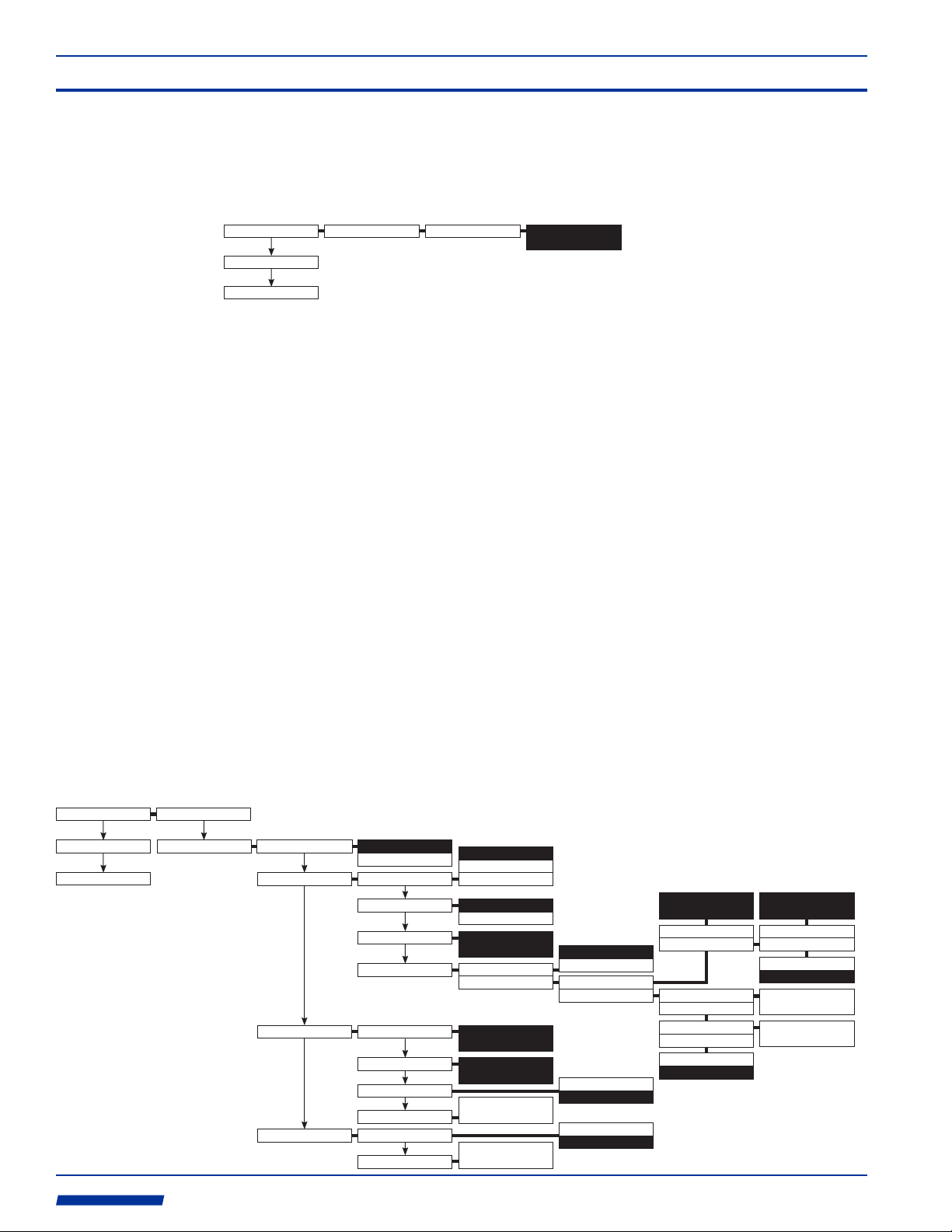

7.4 Menu Flow Chart

Configuration

Run

Save Config

Paddle Wheel

XDCR Settings

Meter Settings

K-Factor

Meas. Units

Enter Value

ENGLISH

METRIC

Transducer

Mount Method

Cable Length(ft)

Flow Direction

Pipe

Pipe Outside Dia.

Pipe Wall Thick.

Pipe Material

Pipe SOS

Fluid Fluid Type

Fluid SOS

Logging

Log Interval(s)

Rate Set Point 1

Rate Set Point 2

Tot. Set Point 1

Tot. Set Point 2

Tot. Set Point 3

Tot. Set Point 4

Tot. Set Point 5

Copy Logs

Delete Logs

Display

Flow Rate Volume Units

Model

0.0000

C

I

J

V

W

Enter Value

0.0000

Direction

Settings

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Time Units

Fl. Rate Decimal

A -> B

B -> A

A -> B

B -> A

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Enter Value

0.0000

Seconds

Minutes

Hours

Days

Enter Value

Enter Value

0.0000

Scaling(A->B)

Zero(A->B)

Scaling(A->B)

Zero(A->B)

Zero Value(A->B)

Sign(A->B)

Positive

Negative

Custom

Water

U.S. Gallons

Ounces

U.S. Barrels Liq.

U.S. Barrels Oil

Cubic Feet

Acre Feet

Imperial Gallons

Cubic Meters

Liters

Milliliters

FR Custom V/Gal

0

Sonic-Pro

Enter Value

0.0000

Zero Value(A->B)

Sign(A->B)

Positive

Negative

Enter Value

0.0000

Enter Value

0.0000

Custom

HDPE

Enter Value

0

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

Totalizer Volume Units

Fl. Total Decimal

Flow Average(s)

Enter Value

Enable Tot. Clear?

Yes

Low Fl. Cut-Off

High Fl. Cut-Off

Enter Value

Enter Value

Enter Value

0

No

0

U.S. Gallons

Ounces

U.S. Barrels Liq.

0

U.S. Barrels Oil

Cubic Feet

Acre Feet

Imperial Gallons

Cubic Meters

Liters

Milliliters

TOT Custom V/Gal

Enter Value

0

999

Scaling Off-set

Zero Off-set

SOS Fault Window

Enter Value

1.0000

FR Offset

Sign

Enter Value

Enter Value

0.0000

Positive

Negative

10

Sleep Time(s)

Enter Value

0

d

Page 31

Sonic-Pro

Page 30

Output Settings

Analog 4-20mA

Pulse 0-1000

Contact Closure

Clock CLOCK SET

Calibration

Clear Cal. Value

Global Config.

Save Conf. To USB

Restore USB Conf.

Firmware Update

Change Password

Anybus

2013/07/24

14:31

OK CANCEL

Calibration

Password

Rate at Min Curr.

Min Analog O/P

Rate at Max Curr.

Max Analog O/P

Rate at Min Freq.

Min Frequency

Rate at Max Freq.

Max Frequency

CALIBRATION

CANCEL

No

Yes

Enter Value

0

Save Conf. To USB

USB Drive Found!

Config. Copied To USB

OK

Restore USB Conf.

Config. File Found.

Erasing Config File..

Restored Config.

OK

Firmware Upgrade

USB Drive Found.

Press ESC to upgrade

OK

Change Password

Old Pass.:

NEW Pass.:

0000

0000

OK CANCEL

Relay A

Relay B

Enter Value

0.0000

Enter Value

4

Enter Value

0.0000

Enter Value

20

Enter Value

0.0000

Enter Value

0

Enter Value

0.0000

Enter Value

1000

None A

Monitor Flow Rate

Monitor Totalizer

Faults A

None B

Monitor Flow Rate

Monitor Totalizer

Faults B

Type

Address

High Trigger A

High Release A

Low Trigger A

Low Release A

Time(s) A

Batch Amt. A

Contact Timer(s) A

High Trigger B

High Release B

Low Trigger B

Low Release B

Time(s) B

Batch Amt. B

Contact Timer(s) B

Profibus DPV1

Modbus RTU

Modbus TCP

Ethernet

Profinet

None

Profibus DPV1

Modbus RTU

Modbus TCP

192.168.234.123

Ethernet

192.168.234.123

Profinet

None

192.168.234.123

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

Enter Value

0

IP SET

OK CANCEL

IP SET

OK CANCEL

IP SET

OK CANCEL

ProSeries

by Blue-White Ind.

Industries, Ltd.

Industries, Ltd.

d

Page 32

Limited Warranty

!

Blue-White Sonic-Pro flowmeters are warranted to be free from defects in material and workmanship for 24

months from date of factory shipment. WARRANTY COVERAGE IS LIMITED TO REPAIR OR REPLACEMENT

OF THE DEFECTIVE FLOWMETER ONLY. UNDER NO CIRCUMSTANCES SHALL BLUE-WHITE BE LIABLE

FOR ANY CONSEQUENTIAL OR INCIDENTAL LOSES OR DAMAGES THAT SHOULD ARISE FROM THE USE

OF THE FLOWMETER AND IN NO EVENT SHALL THE COMPANIES LIABILITY EXCEED THE PURCHASE

PRICE PAID BY THE PURCHASER FOR THE PRODUCT.

!

This warranty does not cover damage to the flowmeter that results from misuse or alterations, nor damage that

occurs as a result of improper installation.

!

Blue-White assumes no liability for the acceptability of the flowmeter in a specific application. THE USER MUST

DETERMINE THE ACCEPTABILITY OF THE PRODUCT AND ITS FITNESS FOR USE IN THE SPECIFIC

APPLICATION.

!

Flowmeters are repaired at the factory only. Call or write the factory to receive a RMA (return materials authorization) number. Carefully pack the flowmeter to be returned and write the RMA number on the outside of the shipping

carton. Include a brief description of the problem and the application.

!

Prepay all shipping costs. The factory does not accept C.O.D. Shipments. Damage that occurs during shipping is

the responsibility of the sender.

Users of electrical and electronic equipment (EEE) with the WEEE marking per Annex IV of the

WEEE Directive must not dispose of end of life EEE as unsorted municipal waste, but use the

collection framework available to them for the return, recycle, recovery of WEEE and minimize

any potential effects of EEE on the environment and human health due to the presence of

hazardous substances. The WEEE marking applies only to countries within the European Union

(EU) and Norway. Appliances are labeled in accordance with European Directive 2002/96/EC.

Contact your local waste recovery agency for a Designated Collection Facility in your area.

ProSeries

2

TWO-YEAR

WARRANTY

ProSeries

TM

by Blue-White Ind.

5300 Business Drive, Huntington Beach, CA 92649 USA

Phone: 714-893-8529 FAX: 714-894-9492

E mail: sales@blue-white.com or techsupport@blue-white.com URL: www.blue-white.com

P.N. 80000-493 DRAFT Rev. 06222014

Loading...

Loading...