Blue-White F-2000 User Manual

F-2000

MODEL PC - MODEL PB - MODEL AO

OUTPUT BOARDS

INSTRUCTION MANUAL

R

Blue-White

Industries, Ltd.

5300 Business Drive

Huntington Beach, CA 92649

USA

Phone: 714-893-8529 FAX: 714-894-9492

E mail: sales@blue-white.com or techsupport@blue-white.com

Website: www.blue-white.com

F-2000

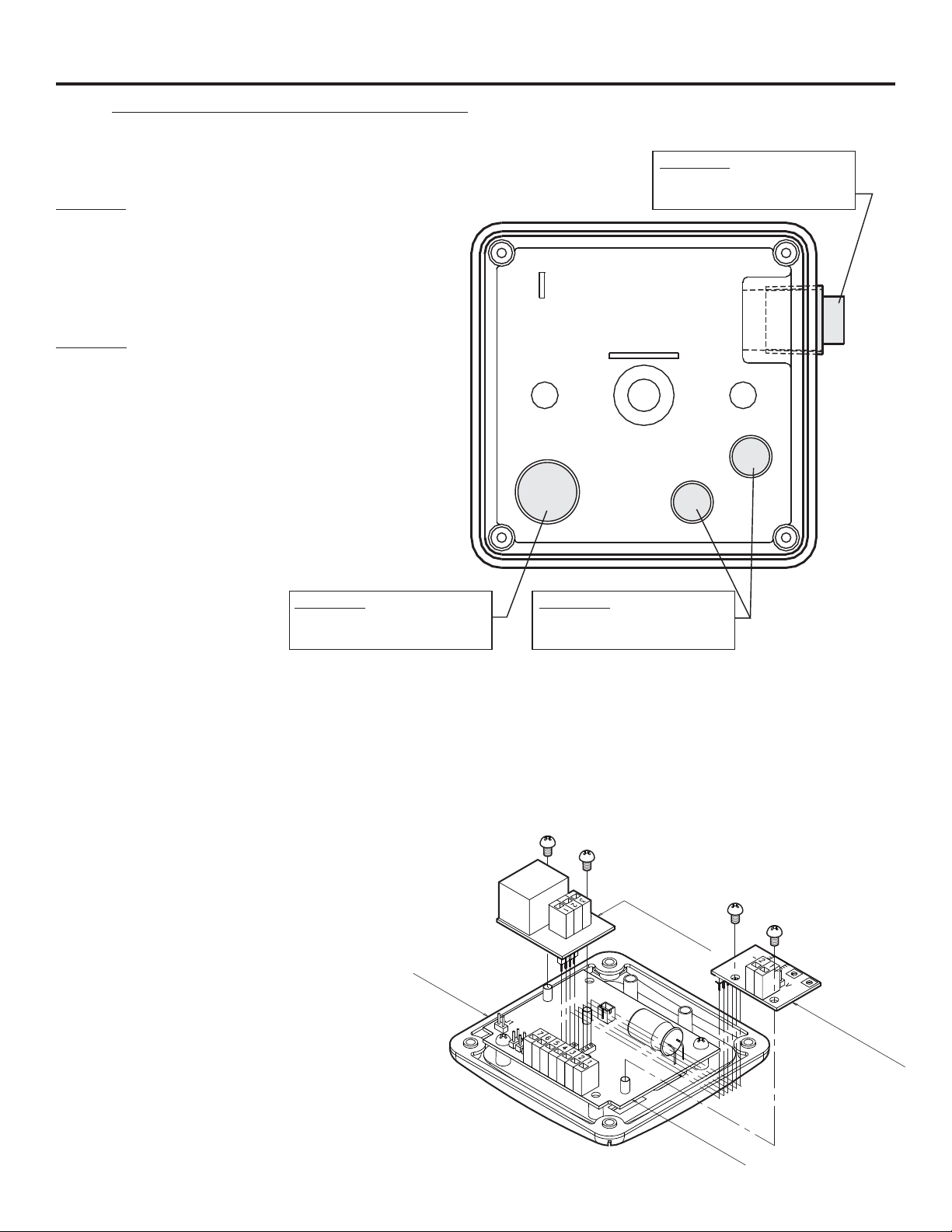

1.0 F-2000 Electrical Wiring Connections

1.1Enclosure knock-out Instructions

Option A: Conduit Connection

1. Remove the red cap plug.

2. Install your pipe fitting (1/2 - 14 NPT male

end).

Page 2

Option A: 1 / 2-14 MPT

Red Cap Plug

(for pipe fitting)

Option B: Liquid-Tight Connections

Internal View

1. Remove knock-out(s) using a screwdriver.

2. Trim edge(s) with a knife and remove sharp

edges.

3. Install the provided liquid-tight connector(s).

Option B: 3/4 DIA.

Knock-out

(large liquid-tight connector)

Option B: 1/2 DIA.

Knock-out

(small liquid-tight connector)

Notes:

For the large liquid-tight connector (3/4” Knock-out), the acceptable cable diameter is between .200 - .394 in (5.1 -

10.0 mm).

For the small liquid-tight connector (½”Knock-out), the acceptable cable diameter is between .118 - .255 in (3.0 -

6.5 mm).

1.2Optional Circuit Board Installation

CAUTION: DISCONNECT POWER

SOURCE BEFORE SERVICING.

1. Carefully align optional board’s Pin

Header with the Pin Header socket

located on the main circuit board.

2. Press firmly into place.

3. Secure the board with the two screws

provided.

F-2000

Enclosure

Cover

(OPTIONAL BOARD)

N.C.

N.O.

C

F-2000-PC

F-2000-PB

(MAIN BOARD)

F-2000-RT

F-2000-AO

(OPTIONAL

BOARD)

Page 3

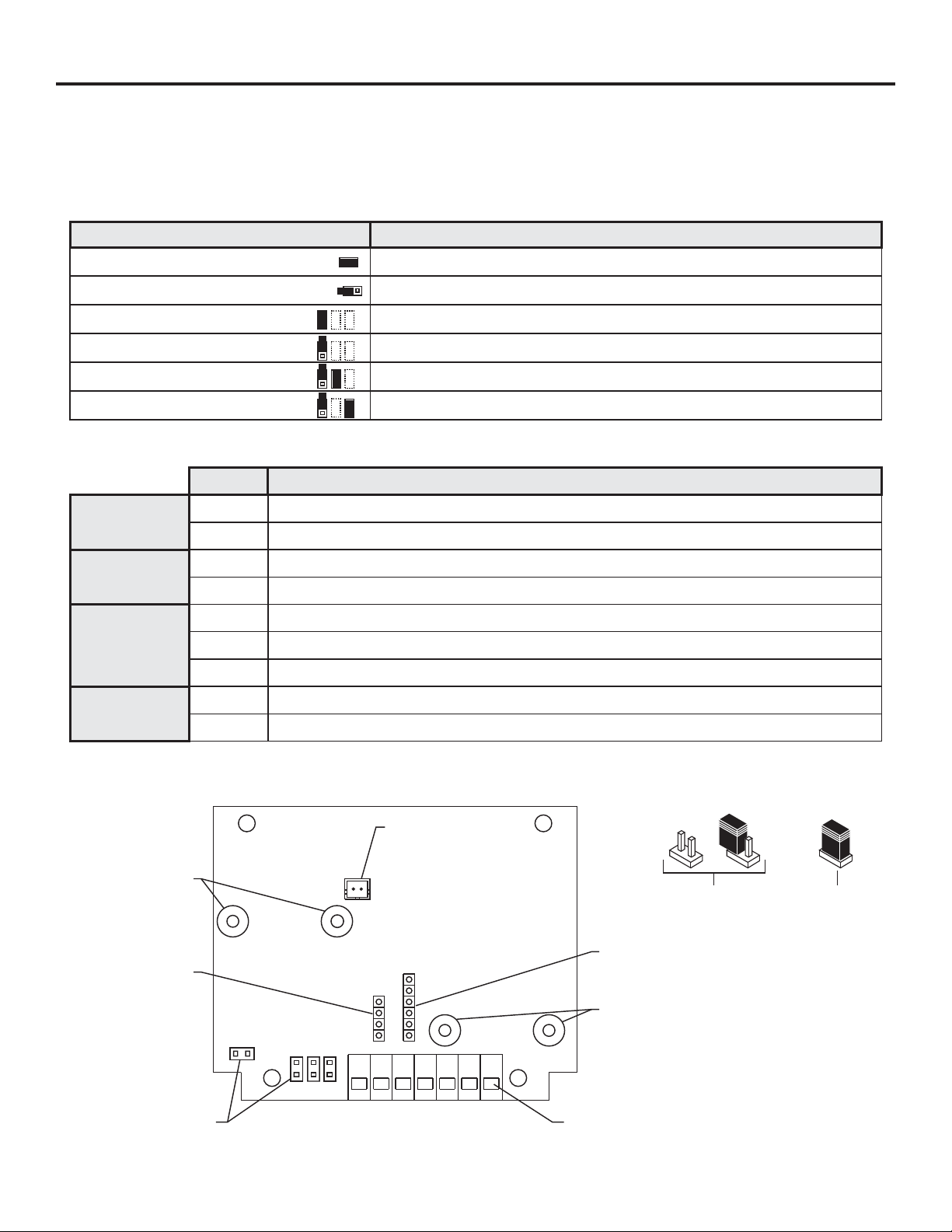

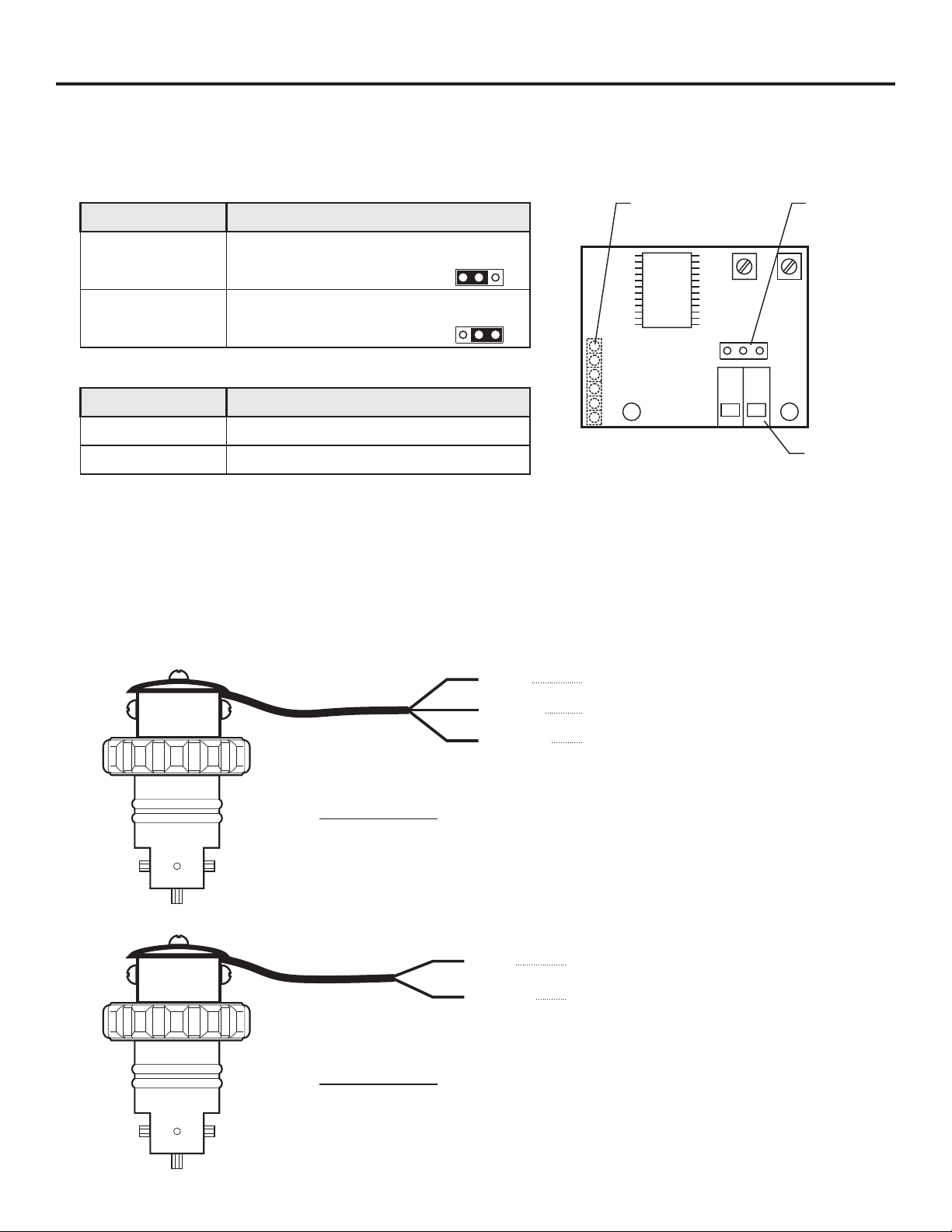

1.3Model RT Circuit Board Wiring

CAUTION: DISCONNECT POWER SOURCE BEFORE SERVICING.

Jumper Configuration

F-2000

Jumpers

J1 Installed

J1 Left Open

J2 Installed

J2 Left Open

J3 Installed and J4 Left Open

J3 Left Open and J4 Installed

Terminal Configuration

Terminal Function

Supply power

input

AC coil sensor

input

6

5

2

3

1

Hall Effect

sensor input

2

3

Open connector

pulse output

(from sensor)

7

4

Function

Battery Input (4 - 1.5 VDC, AA Cells)

Plug-In Transformer (115 VAC / 15 VDC, 220 VAC / 15 VDC, 230 VAC / 15 VDC)

Front Panel Programming is Disabled

Front Panel Programming is Enabled (factory default)

Hall Effect Sensor Input

AC Coil Sensor Input

Positive (+) power input (red wire from battery pack, or black with stripe wire from 15 VDC plug-in transformer)

Ground (-) power input (black wire from battery pack or 15 VDC plug-in transformer)

Ground (-) input (black wire from coil sensor body)

Pulse input (yellow or red wire from coil sensor body)

Positive (+) input (red wire from hall effect sensor)

Ground (-) input (black wire from hall effect sensor)

Pulse input (bare wire from hall effect sensor)

NPN positive (+) signal output

NPN negative (-) signal output

(Max voltage: 24VDC, Max load: 15mA, 2k ohm pull-up recommended.)

F-2000 RT Board

F-2000 PC Board

Mounting Screw

Bushings

SIP Socket for

F-2000 PC Board

Jumpers

BAT = ON

J1

J3

J2

PHM

Backup Battery

Connector

J4

7654321

SIP Socket for

F-2000 AO Board

F-2000 AO Board

Mounting Screw

Bushings

Terminal Blocks

Jumper Positions

Jumper Not

Installed (open)

Jumper

Installed

F-2000

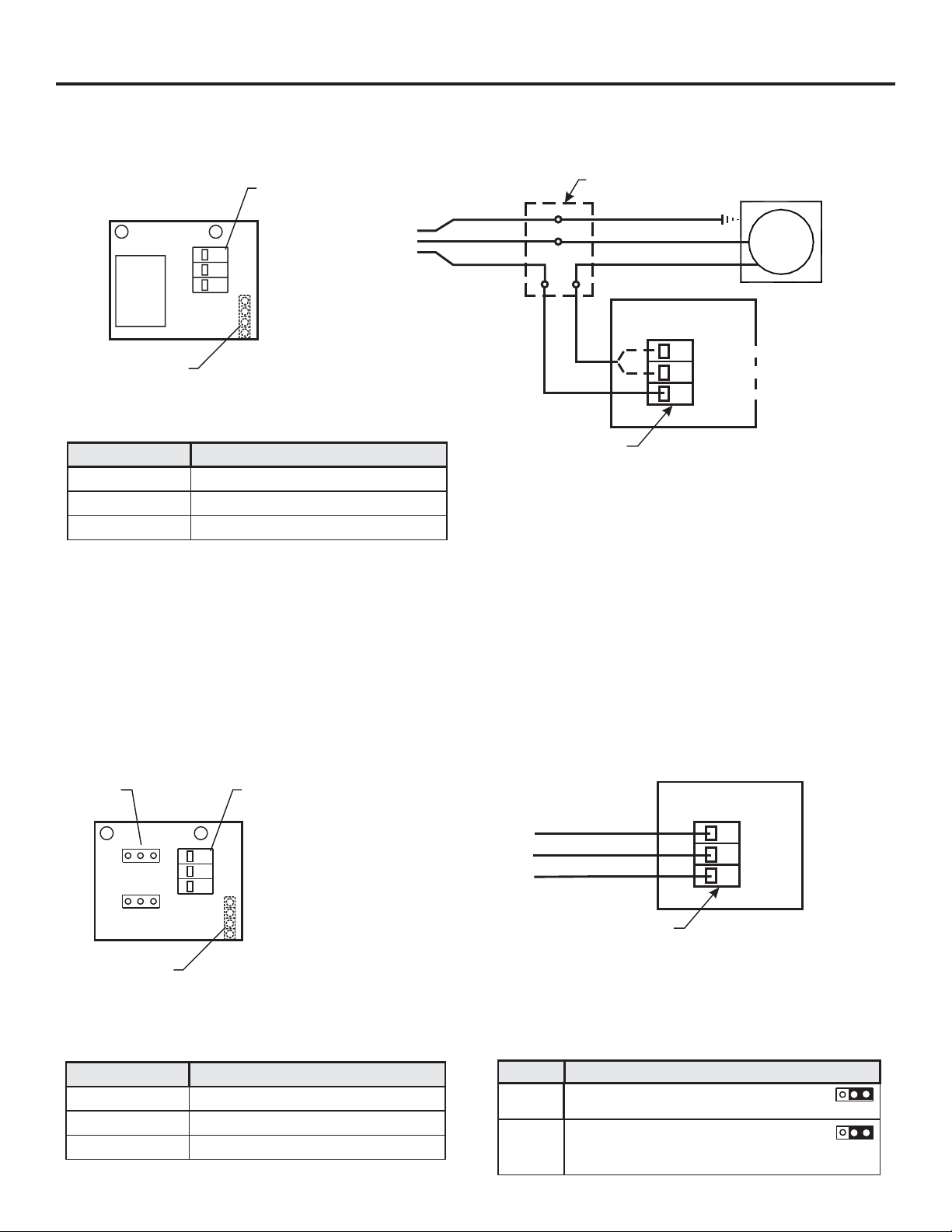

1.4Model PC Circuit Board Wiring

CAUTION: DISCONNECT POWER SOURCE BEFORE SERVICING.

Page 4

Terminal

Relay

Block

3

NC

2

NO

1

C

Earth Ground (green)

AC

Pin Header

(Other side)

Terminal Configuration

Terminal Terminal Block Connections

1

2

3

Output Type: Isolated relay SPDT (single poll double throw), NO / NC

Max. Load: 8 amps (AC) @ 115 VAC, 220 VAC, 230 VAC

Max. Voltage: 250 VAC, 125 VDC

Common

NO (Normally Open) contact

NC (Normally Closed) contact

7 amps (DC) @ 30 VDC (resistive load)

Common (-)

Hot (+)

Junction Box (not supplied)

Earth Ground (green)

Load Neutral (-)

Load Hot (+)

F-2000-PC Board

3-position

Terminal Block

External

Equipment

Load

(normally Closed Contact)

3

NC

(normally Open Contact)

NO

2

(common Contact)

1

C

1.5Model PB Circuit Board Wiring

CAUTION: DISCONNECT POWER SOURCE BEFORE SERVICING.

Jumpers

JP1

JP2

NC

IN

NO

EX

Pin Header

(Other side)

Terminal Configuration

Terminal Terminal Block Connections

1

2

3

Voltage input (+)

Switched output (NO/NC)

Ground (-)

3

2

1

Terminal

Block

G

OUT

V

Output Type: Non-Isolated contact closure switch, NO / NC

Max. Load: 100 milliamps (.10 amp)

Max. Voltage: 30 VDC if JP2 is set for external power.

15 VDC if JP2 is set for internal power and F-2000 is powered by plug-in transformer.

3 VDC if JP2 is set for internal power and F-2000 is powered by Batteries.

Max. Power: 3 Watts

Ground (-)

Switched Output (NO/NC)

Supply (+) (voltage input)

3-position

Terminal Block

Jumper Configuration

Jumper SettingsJumper

JP1

JP2

NC = Normally closed contacts

NO = Normally open contacts (default)

IN = Internal power

EX = External power (default)

Note: See above voltage limits

F-2000-PB Board

G

3

2

OUT

1

V

JP1

NC

NO

JP2

IN

EX

Page 5

1.6Model AO Circuit Board Wiring

CAUTION: DISCONNECT POWER SOURCE BEFORE SERVICING.

Jumper Configuration

Output Jumper Settings

Connect P1 & P2 (leave P3 open) (factory

4-20 Milliamp

0-10 Volts DC

Terminal Configuration

Terminal Number Terminal Block Connections

default), Max Load = 250 Ohms

Connect P2 & P3 (leave P1 open), Max Load =

500 Ohms

P2

P3P1

P2

P3P1

Pin Header

(other side)

A

-

P2

21

F-2000

3 position

jumper Pin

P3P1

V

+

1

2

Output Type: Linear, Non-Isolated, powered loop.

Loop resistance: 250 ohm maximum for 4-20mA output

Positive (+) Analog Output Signal

Negative (-) Analog Output Signal

500 ohm maximum for 0-10 V DC

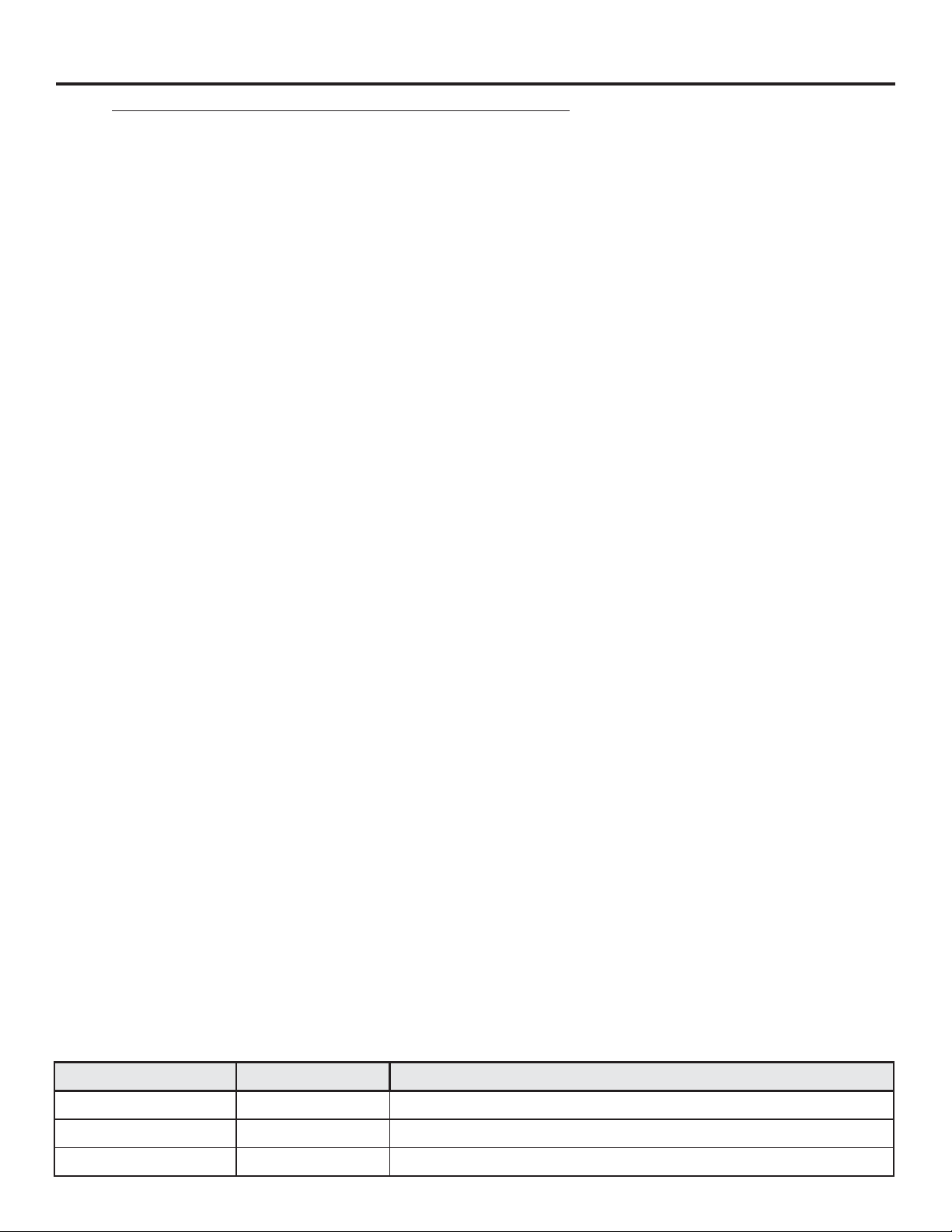

1.7Model FHXX and FCXX Sensor wiring

Model FHXX

Note: Output type - current sinking type hall effect sensor (13.5mA max).

Pull-up resistor is recommended. 5k ohm across red & bare wires.

RED

BARE

BLACK

Terminal

Block

Input Supply Voltage (+ 6 to 24 Vdc)

Signal Output (square wave)

Ground (-)

Model FCXX

RED

BLACK

Signal Output (Sine wave)

Ground (-)

F-2000

2.0 HOW TO OPERATE THE MODEL PC and MODEL PB

2.1What Was The MODEL PC and PB Designed To Do?

In addition to the features of the MODEL RT, the model PC includes a single SPDT relay which can be used to

switch an external component such as a pump, valve, alarm buzzer, etc., on and off in order to assist in the

control of a process. The relay setpoints must be assigned to either the rate mode, the batch (total) mode, or

turned off. The MODEL PC cannot be battery operated.

The MODEL PB offers all of the features of the MODEL PC but includes a contact closure switch instead of a

relay and may be battery operated.

!

High level flow rate alarm.

!

Low level flow rate alarm.

!

High and low level flow “range” alarm.

!

Manual start or automatically timed start batch processing.

!

Proportional chemical feed injector pump control.

2.2What Features Are Available?

!

All controls are front panel programmable.

!

MODEL PC Max. switching load 8 Amp at - 115 VAC, 230 VAC, 220 VAC; 7 Amp at 30 VDC (resistive load).

!

MODEL PB Max. switching load 100 milliamp at 30 VDC.

!

NO / NC contact.

!

Rate alarms can be latched requiring a manual reset.

!

Programmable “alarm release value” provides hysteresis to prevent relay flickering (see page 28).

!

High and low range alarms can be independently programmed.

!

Alarm delay timer temporarily silences alarms for a programmed time from 0-999 seconds.

!

Independent display and resetting of batch count and batch amount.

!

Front panel clearing of batch counts and amounts can be disabled.

!

Turn on / off external devices, for a programmable time from 0-999 seconds per batch.

Page 6

2.3How Do I Program The MODEL PC & PB?

The Model PC & PB setpoints must be assigned to either the rate mode (option 1), the batch (total) mode

(option 2), or turned off (option 3).

Option 1 - Assign the setpoints to the RATE mode for applications involving the switching of external devices,

such as alarms or valves, when the rate of flow is greater than or less than the programmed flow

RATE value. The Model PC and PB is used to monitor flow RATE in this mode. Example: High or

low flow rate alarms.

Option 2 - Assign the setpoints to the BATCH mode for applications involving the switching of external devices

such as chemical metering pumps, centrifical pumps, solenoid valves, etc., when the amount of flow

is greater than or less than the programmed batch amount value. In this mode, the Model PC is used

to monitor flow total. Example: Manual batch processing or proportional feed rate control.

Option 3 - The OFF mode opens the relay contacts regardless of the flow conditions. The setpoints are not

assigned.

SETPOINT MODE SELECTION PROGRAMMING SCREEN OPTIONS

OPTION

Option - 1 (page 27)

Option - 2 (page 32)

Option - 3

SELECTION FUNCTION

Setpoint - RATE Relay Setpoints are assigned to flow RATE mode.

Setpoint - BATCH Relay Setpoints are assigned to BATCH (accumulative or “total”) mode.

Setpoint - OFF Relay Setpoints are not assigned. Relay is not energized.

Loading...

Loading...