Page 1

MICRO-FLO

MICRO-FLO

Digital Paddlewheel Flow meter

Operating Manual

R

Blue-White

Industries, Ltd.

5300 Business Drive

Huntington Beach, CA 92649

Phone: 714-893-8529 FAX: 714-894-9492

E mail: sales@blue-white.com or techsupport@blue-white.com

Website: www.blue-white.com

USA

Page 2

MICRO-FLOPage 2

TABLE OF CONTENTS

1.....Introduction....................................................................................2

2.....Features .............................................................. .............. ..............3

3.....Model number matrix ............ .............. .............. .............. ..............3

4.....Specifications ............ .............. .............. .............. .............. ..............4

4.1..Temperature and pressure limits...... .............. .............. ..............4

4.2..Dimensions ................................................... .............. ..............5

4.3..Replacement parts ........................... .............. .............. ..............5

5.....Installation.. .............. .............. .............. .............. .............. ..............6

5.1..Wiring connections ...................................................................6

5.2..Circuit board connections . ........................................................6

5.3..Flow verification output signal..................................................6

5.4..Panel or wall mountings............................................................7

6.....Operation.... .............. .............. .............. .............. .............. ..............7

6.1..Theory of operation...................................................................7

6.2..Control panel ...... .............. .............. ..........................................8

6.3..Flow stream requirements . .............. .............. .............. ..............8

6.4..Run mode display.......................................... .............. ..............8

6.5..Run mode operation ........................ .............. .............. ..............9

6.6..Viewing the K-factor......... .............. .............. .............. ..............9

7.....Programming............ .............. .............. .............. .............. ..............9

7.1..Field Calibration ............... .............. .............. .............. ..............9

7.2..Programming for body size/range S1 - S6 ..... .............. ..............10

7.3..Field calibration range setting S0 ..............................................11

Warranty information.......................... .............. .............. ..............12

1.0 Introduction

The Micro-Flo flowmeter is designed to display flow rate and flow total on

a six digit LCD display. The meter can measure bi-directional flows in

either vertical or horizontal mounting orientation. Six flow ranges and four

optional pipe and tubing connections are available. Pre-programmed

calibration K-factors can be selected for the corresponding flow range or a

custom field calibration can be performed for higher accuracy at a specific

flow rate. The meter is factory programmed for the correct K-factor of

the body size included with the meter.

Page 3

MICRO-FLO

2.0 Features

!

Four connection options available:

1/8” F/NPT, 1/4” F/NPT, 1/4” OD x .170 ID Tubing & 3/8” OD x 1/4”

ID Tubing sizes.

!

Six body size/flow range options available:

30 to 300 ml/min, 100 to 1000 ml/min, 200 to 2000 ml/min,

300 to 3000 ml/min, 500 to 5000 ml/min, 700 to 7000 ml/min.

!

3 model display variations:

FS = Sensor mounted display

FP = Panel mounted display (includes 6’ cable)

FV = No display. Sensor only. 5vdc current sinking output

!

6 digit LCD, up to 4 decimal positions.

!

Displays both rate of flow and total accumulated flow.

!

Open collector alarm setpoint.

! User selectable or custom programmable K-factor.

Flow units: Gallons, Liters, Ounces, milliliters

Time units: Minutes, Hours, Days

! Volumetric field calibration programming system.

! Non-volatile programming and accumulated flow memory.

! Total reset function can be disabled.

! Clear PVC viewing lens or PVDF chemical resistant lens.

! Weather resistant Valox PBT enclosure. NEMA 4X

Page 3

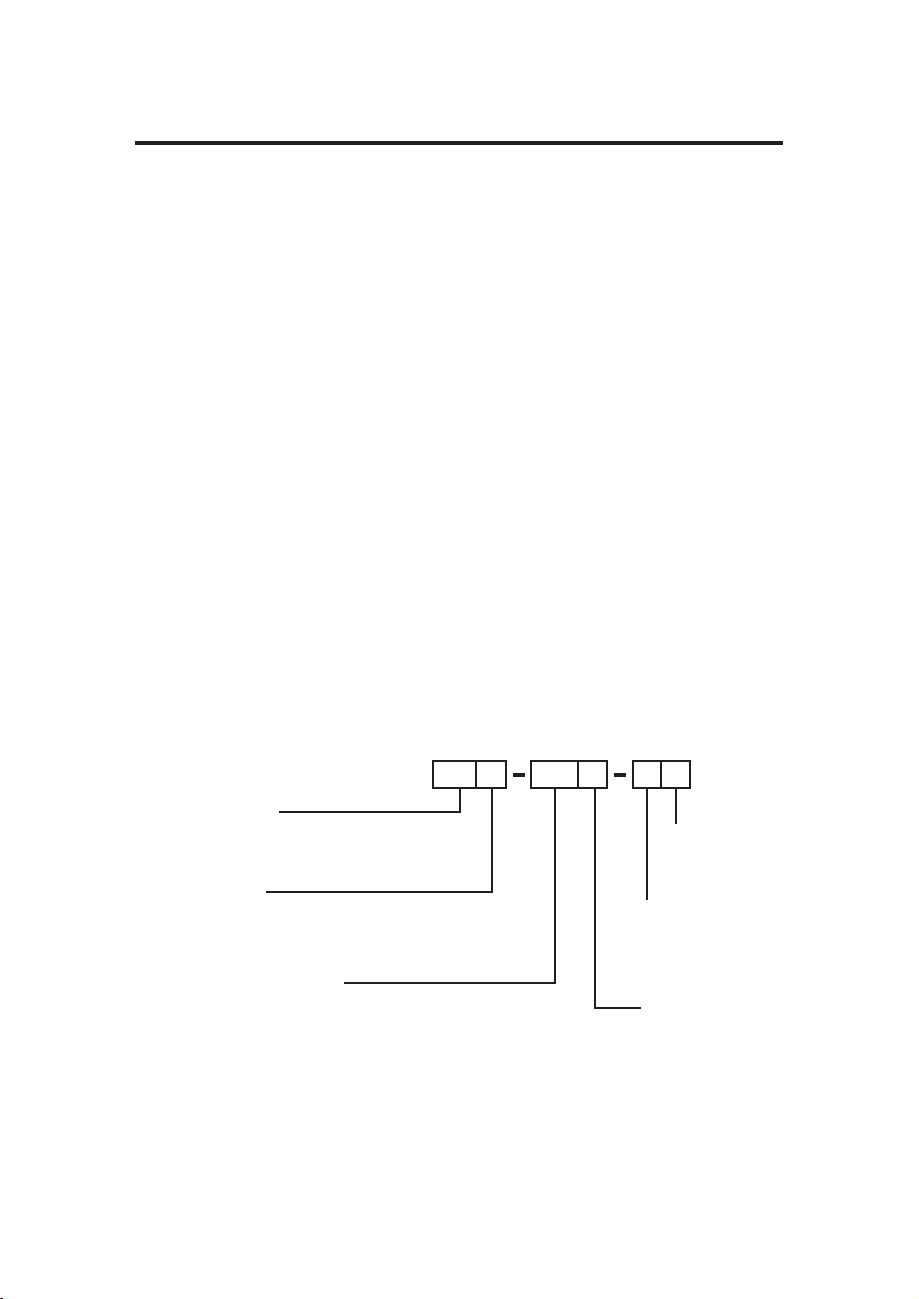

3.0 Model number matrix

METER FUNCTION

FS = Flow rate and Totalizing. On-sensor mounting

FP = Flow rate and Totalizing. Remote panel mounting

FV = Flow sensor only (no display)

POWER SUPPLY

1 = Transformer U.S. 115VAC/15VDC

2 = Transformer E.U. 220VAC/15VDC

3 = Transformer U.S. 230VAC/15VDC

None = No selection (customer supplied)

FLOW RANGE SELECTION

10 = 30-300 ml/min

20 = 100-1000 ml/min

30 = 200-2000 ml/min

40 = 300-3000 ml/min

50 = 500-5000 ml/min

60 = 700-7000 ml/min

O-RING SEAL

V = Viton

E = EPDM

CONNECTOR

4 = .250” OD tubing PVDF

5 = .125” Female NPT PVC

6 = .375” OD tubing PVDF

7 = .250” Female NPT PVC

LENS MATERIAL

0 = Clear PVC

1 = Opaque PVDF

Page 4

MICRO-FLOPage 4

4.0 Specifications

Max. Working Pressure:

PVC lens, 130 psig (9 bar) @ 70 F (21 C)

PVDF lens, 150 psig (10 bar) @ 70 F (21 C)

Max. Fluid Temperature:

PVC lens, F/NPT connectors 130 F (54 C) @ 0 PSI

PVDF lens, tubing connectors 200 F (93 C) @ 0 PSI

oo

oo

Full scale accuracy +/- 6%

Input Power requirement: 9 - 28 VDC (31mA @ 15Vdc)

Sensor only output cable: 3-wire shielded cable, 6ft

Pulse output signal: Digital square wave (2-wire) 25ft max.

Voltage high = 5Vdc,

Voltage low < .25Vdc

50% duty cycle

Output frequency range: 4 to 500Hz

Alarm output signal: NPN Open collector. Active low above

programmable rate set point.

30Vdc maximum, 50mA max load.

Active low < .25Vdc

2K ohm pull up resistor required.

Enclosure: NEMA type 4X, (IP56)

Approximate shipping wt: 1 lb. (.45 kg)

oo

oo

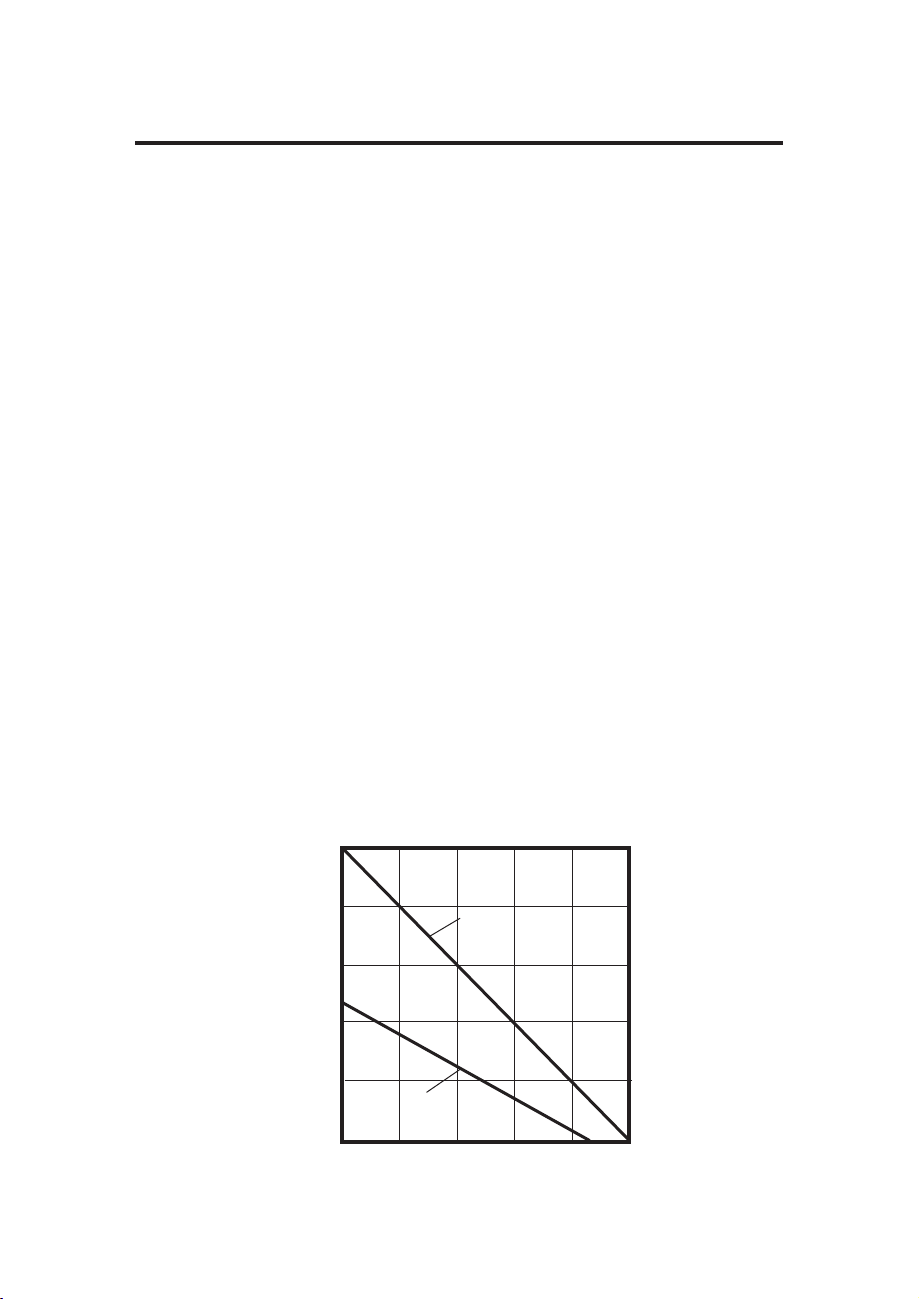

4.1 Temperature and Pressure limits

Maximum Temperature vs. Pressure

oo

200 F (93 C)

oo

174 F (79 C)

oo

148 F (64 C)

oo

122 F (50 C)

TEMPERATURE

oo

96 F (36 C)

oo

70 F (21 C)

Models with

PVC Lens or connectors

0 30(2) 60(4) 90(6) 120(8) 150(10)

STATIC PRESSURE PSI (BAR)

Models with

PVDF Lens and connectors

Page 5

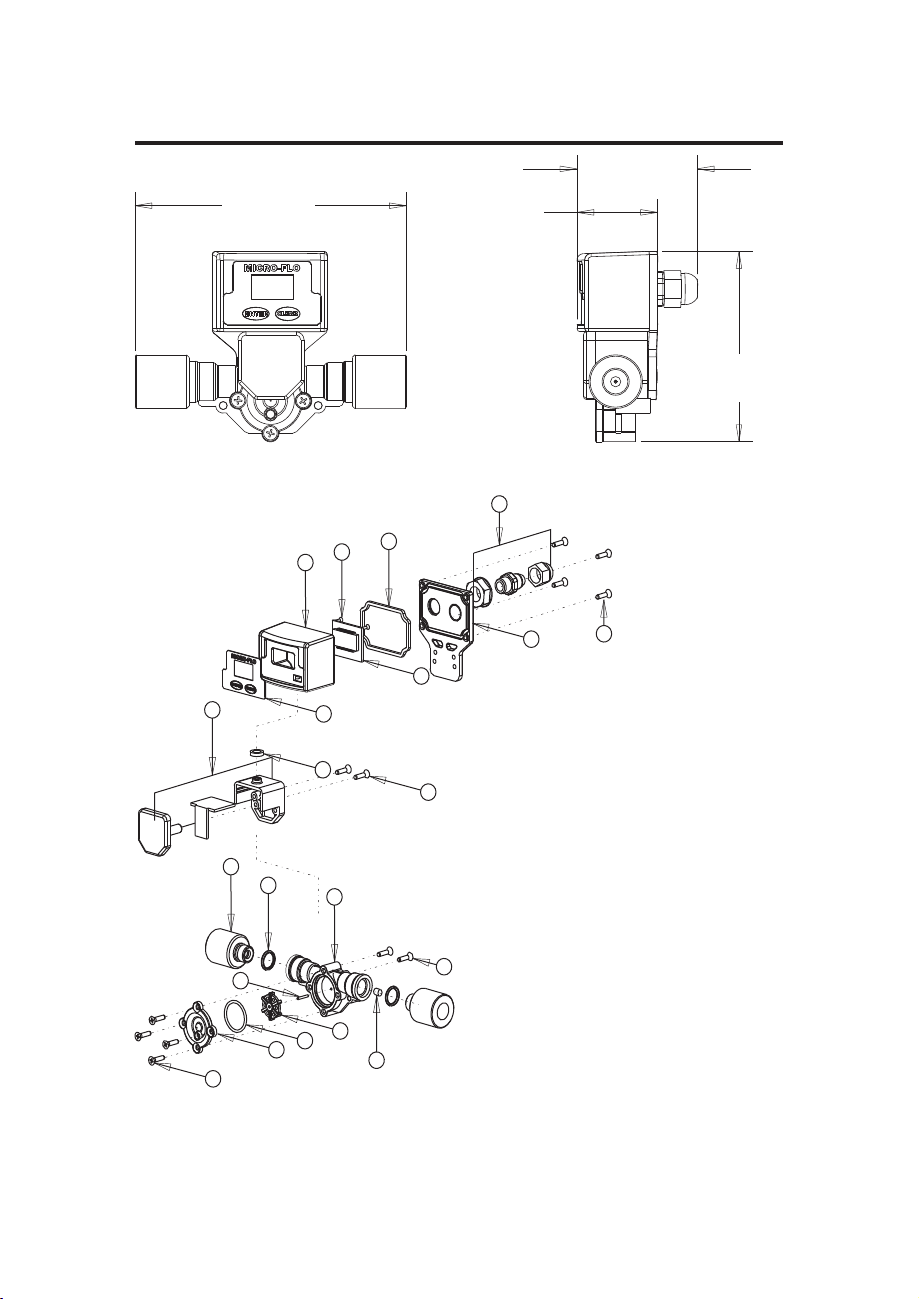

4.2 Dimensions

5.00 in

[127 mm]

Page 5MICRO-FLO

2.22 in

[56.26 mm]

1.48 in

[37.71 mm]

3.51 in

[89.03 mm]

4.3 Replacement Parts

20

13

10

9

5

1

14

22

6

7

4

3

2

18

16

17

15

Key Part No. Description Qty.

1 90011-190 Screw 6-32x.50 Phil Flt SS 4

2 90002-227 Lens Cap Clear PVC 1

90002-228 Lens Cap Opaque PVDF 3

90003-143 O-Ring Viton 1

3 90003-146 O-Ring EP

4 90002-229 Paddle PVDF 1

8

5 90007-592 Axle PVDF 1

6 90003-012 O-Ring Viton 2

90003-011 O-Ring EP

7 76001-300 Body S1 PVDF (30-300ml/min) 1

76001-301 Body S2 PVDF(100-1000ml/min)

76001-302 Body S3 PVDF (200-2000ml/min)

76001-303 Body S4 PVDF (300-3000ml/min)

76001-304 Body S5 PVDF (500-5000ml/min)

76001-305 Body S6 PVDF (700-7000ml/min)

8 90011-178 Screw #4x.50 Phil Blk 4

9 76000-137 Adapter .250 F/NPT PVC 2

8

21

76000-456 Adapter .125 F/NPT PVC

90002-038 Adapter .37OD x .25ID Tube PVDF

90002-042 Adapter .25OD x .17ID Tube PVDF

10 90010-252 Sensor 1

13 90002-242 Enclosure, Valox 1

14 90012-254 LCD display 1

15 90010-260 Circuit board 1

16 90006-604 Gasket, rear enclosure 1

17 90002-243 Cover, enclosure rear 1

18 90008-199 Liquid Tight Connector Set 1

19 90011-178 Screw #4x.62 Phil SS Blk 4

20 90011-177 Screw #2x.25 L Phil St 2

21 76001-299 Tubing connector seal 1

22 90006-605 Gasket, sensor mount seal 1

19

PARTS LIST

Page 6

5.0 Installation

5.1 Wiring Connections

On sensor mounted units, the output signal

wires must be installed through the back panel

using a second liquid-tite connector (included).

To install the connector, remove the circular

knock-out. Trim the edge if required. Install the

extra liquid-tite connector.

MICRO-FLOPage 6

KNOCK-OUT ½” diameter

Power Input

On panel or wall mounted units, wiring may be

Rear view

installed through the enclosure bottom or

through the back panel. See below.

5.2 Circuit Board Connections

Alarm output

Open Collector

30 VDC max

50mA max

(-)

NPN

loop

(+5 to 30 Vdc)

(+)

2K ohm

CIRCUIT

BOARD

5K ohm

(+12 to 25 Vdc)

Pulse output

Digital sq. Wave

5 VDC high

<.25 VDC low

50% duty cycle

NOTE: To reset the circuit board: 1) Disconnect power 2) Apply power while pressing the

two front panel buttons.

(-)

Programming disable jumper (un-installed).

Install on both pins to disable programming.

Power input (+ 9 to 28 Vdc)

Power input ( ground )

Sensor input (+) RED

Sensor input (signal) BARE

Sensor input ( - ) BLACK

Front panel touch pad

ribbon cable connection

5.3 Flow Verification Output Signal

When connected to external equipment such as a PLC, data logger, or BlueWhite metering pump, the pulse output signal can be used as a flow verification

signal. When used with Blue-White metering pumps, connect the positive (+)

terminal on the Micro-Flow circuit board to the pump’s yellow signal input wire

and the negative (-) terminal to the black input wire.

Page 7

5.4 Panel or wall mounting

Wiring through enclosure

bottom for dry applications

Panel or wall

mounting screw

locations

Through panel wiring

for water resistant

applications

1.75 in

[45 mm]

Page 7MICRO-FLO

Recommended panel or

wall mounting cut-out

for wire connection opening

6.0 Operation

6.1 Theory of operation

The Micro-Flo flowmeter is designed to measure the flow rate and accumulate the total volume of a fluid. The unit contains a paddle wheel that has six

(6) through holes to allow infrared light to pass through, a light-detecting

circuit and a LCD-display electronic circuit.

As fluid passes through the meter body, the paddle wheel spins. Each time

the wheel rotates a DC square wave is output from the sensor. There are six

(6) compete DC cycles induced for every revolution of the paddle wheel.

The frequency of this signal is proportional to the velocity of the fluid in the

conduit. The generated signal is then sent into the electronic circuit to be

processed.

The meter is factory programmed for the correct K-factor of the body

size included with the meter.

The Micro-flo flowmeter includes the following features:

! Displays either the flow rate or the accumulated total flow.

! Provides a pulse output signal that is proportional to the flow rate.

! Provides an open collector alarm output signal. Active low at flow rates

above the user programmed value.

! Provides user selectable, factory preset calibration k-factors.

! Provides a field calibration procedure for more precise measurement.

! Front panel programming can be disabled by a circuit board jumper pin.

1.00 in

[25 mm]

Page 8

MICRO-FLOPage 8

6.2 Control Panel

Enter Button (right arrow) -

! Press and release - Toggle between

Rate, Total, and Calibrate screens in

the run mode. Select program

screens in the program mode.

! Press and hold 2 seconds - Enter

and exit program mode. (Automatic

exit program mode after 30 seconds

of no inputs).

Clear/Cal (up arrow) -

! Press and release - Clear total in the run mode. Scroll through and Select

options in the program mode.

NOTE: To reset the circuit board: 1) Disconnect power 2) Apply power while pressing the two

front panel buttons.

6.3 Flow stream requirements

! The Micro-flo flowmeter can measure fluid flow in either direction.

! The meter must be mounted so that the paddle axle is in a horizontal

position - up to 10 off the horizontal is acceptable.

! The fluid must be capable of passing infra-red light.

! The fluid must be free of debris. A 150 micron filter is recommended -

especially when using the smallest body size (S1), which has a 0.031”

through hole.

o

6.4 Run mode display

Body size/range

0 = Field calibrate

1 = 30-300 ml/min

2 = 100-1000 ml/min

3 = 200-2000 ml/min

4 = 300-3000 ml/min

5 = 500-5000 ml/min

6 = 700-7000 ml/min

Function indicator

R = Flow rate indicated

T = Flow total indicated

Alarm indicator

SetP (steady) = active

SetP (flashing) = alarm

none = not programmed

6.5 Run mode operation

S

1

ENTER

RMin

S

1

ENTER

T

ML

ML

FLOW RATE DISPLAY - Indicates rate of flow, S1 = body size/range

#1, ML = units displayed in milliliters, MIN = time units in minutes, R

0

= flow rate displayed.

FLOW TOTAL DISPLAY - Indicates accumulated total flow, S1 =

body size/range #1, ML = units displayed in milliliters, T = total

0

accumulated flow displayed.

Field Calibration indicator

Cal (steady) = active

Cal (flashing) = calibrating

none = factory cal. active

Cal

ML

S

1

SetP

RMin

0

Flow units indicator

ML = Milliliters

OZ = Ounces

GAL = Gallons

LIT = Liters

Display Value

Rate time base indicator

Min = Rate per minute

Hr = Rate per hour

Day = Rate per day

Page 9

6.6 Viewing the K-factor (pulses per unit)

ML

s1

R Min

0

ENTER

CLEAR

While in the run mode, Press and hold ENTER then

CAL /

press and hold CLEAR to display the K-factor.

Page 9MICRO-FLO

Body

Size

s1

181336

Flow Range

(ml/min)

30-3001

100-10002

200-20003

300-30004

500-50005

700-70006

Pulses per

181,336

81,509

42,051

25,153

15,737

9,375

ENTER

Gallon

CLEAR

Release ENTER and CLEAR to return to run mode.

CAL /

Pulses per

Liter

47,909

21,535

13,752

6,646

4,157

2,477

60 / K = rate scale factor

rate scale factor x Hz = flow rate in

volume per minute

1 / K = total scale factor

total scale factor x n pulses = total volume

Useful formulas

7.0 Programming

The Micro-Flo flowmeter uses a K-factor to calculate the flow rate and

total. The K-factor is defined as the number of pulses generated by the

paddle per volume of fluid flow. Each of the six different body sizes have

different operating flow ranges and different K-factors. The meter is

factory programmed for the correct K-factor of the body size included

with the meter.

The meter’s rate and total displays can be independently programmed to

display units in milliliters (ML), ounces (OZ), gallons (GAL), or liters

(LIT). Rate and total can be displayed in different units of measure. The

factory programming is in milliliters (ML).

The meter’s rate display can be independently programmed to display time

base units in minutes (Min), Hours (Hr), or Days (Day). The factory

programming is in minutes (Min).

For greater accuracy at a specific flow rate, the meter can be field calibrated. This procedure will automatically over-ride the factory K-factor with

the number of pulses accumulated during the calibration procedure. The

factory default settings can be re-selected at any time.

7.1 Field Calibration

Any body size/range can be field calibrated. Calibration will take into

account your specific application’s fluid properties, such as viscosity and

flow rate, and increase the accuracy of the meter in your application.

The Body Size/Range must be set for “S0” to enable the calibration mode.

Follow the programming instructions on pages 10 & 11 to reset the Body

Size/Range and perform the calibration procedure.

Page 10

MICRO-FLOPage 10

7.2 Programming for body size/ranges S1through S6 -

Press and Hold ENTER to initiate the programming mode.

S

1

ENTER

1

ENTER

R Min

2

ENTER

R Min

3

ENTER

RMin

1

ENTER

T

2

ENTER

T

3

RST Y

ENTER

T

1

ENTER

R SetP

ML

ML

ML

ML

ML

off

BODY SIZE/RANGE - Select your body size. Selected body size flashes.

CLEAR

Press and release to select. S1 > S2 > S3 > S4 > S5 > 6 > S0

CAL /

Note: Select S0 for field calibrating any body size range.

RATE UNIT OF MEASURE - current unit of measure setting flashes

CLEAR

0

0

0

0

0

Press and release to select. ML > OZ > GAL > LIT

CAL /

RATE DECIMAL LOCATION - current decimal display setting flashes.

CLEAR

Press and release to select. 0 > 0.0 > 0.00 > 0.000 > 0.0000

CAL /

RATE TIME BASE - current time base unit of measure setting flashes.

CLEAR

Press and release to select. Min > Hr > Day

CAL /

TOTAL UNIT OF MEASURE - current unit of measure setting flashes

CLEAR

Press and release to select. ML > OZ > GAL > LIT

CAL /

TOTAL DECIMAL LOCATION - current decimal display setting flashes.

CLEAR

Press and release to select. 0 > 0.0 > 0.00 > 0.000 > 0.0000

CAL /

TOTAL RESET ENABLE - current Y (yes) or N (no) setting flashes.

CLEAR

Press and release to select. Y > N

CAL /

ALARM SETPOINT ENABLE - current ON or OFF setting flashes.

CLEAR

Press and release to select. ON > OFF

CAL /

S

ENTER

If “off”

If “on”

2

000000

RSetP

ENTER

p

000.000

RSetP

ENTER

ALARM SETPOINT VALUE - current value setting flashes.

CLEAR

Press and release to select the digit to change.

CAL /

CLEAR

ENTER

ALARM VALUE DECIMAL LOCATION - current decimal

display setting flashes.

CLEAR

CAL /

Press and hold ENTER then press CLEAR

CAL /

to change the selected digit.

Press and release to select. 0 > 0.0 > 0.00 > 0.000

> 0.0000

If range “S0” is selected, continue to field calibration procedure, next page.

If range S1 through S6 is selected, return to program screen or

press and hold ENTER to exit the programming mode.

Page 11

Page 11MICRO-FLO

7.3 Field calibration size/range setting S0 - Continuation of programming

sequence when range “S0” is selected.

The meter should be installed as intended in the application.

The amount of fluid that flows through the meter during the calibration

procedure must be measured at the end of the calibration procedure.

Allow the meter to operate normally, in the intended application, for a period of

time. A test time of at least one minute is recommended. Note - the maximum

number of pulses possible is 52,000. Pulses will accumulate in the display. After

the test time period, Stop the flow through the meter. The pulse counter will

stop.

Determine the amount of fluid that passed through the meter using a graduated

cylinder, scale, or other method. The measured amount must be entered in

calibration screen #4 “MEASURED VALUE INPUT.”

ENTER

ENTER

If “no”

Cal

1

Run n

If “yes”

CALIBRATION “RUN” REQUEST - Current N (no) setting flashes.

CLEAR

Press and release to select. Y > N

CAL /

Cal

2

000000

Cal

3281

ENTER

ML

Cal

3

35083

ENTER

ML

Cal

4

000000

ENTER

p

ML

Cal

000.000

ENTER

CALIBRATION READY - Zeros flash.

CLEAR

Press and release to start calibration counter. Start

CAL /

flow through the meter. Begin measuring fluid.

Pulses will begin to accumulate. (CAL icon blinks).

CALIBRATION COMPLETE - Pulse count displayed.

CLEAR

CLEAR

Stop flow through the meter. Press and release

CAL /

CAL /

to stop calibration counter. (CAL icon stops

blinking).

VOLUME UNITS - current units setting flashes.

CLEAR

Press and release to select units of measure used

CAL /

in the calibration . ML > OZ > GAL > LIT

MEASURED VALUE INPUT - Input the amount of fluid

measured. The selected digit blinks.

CLEAR

Press and release to select the digit to change.

CAL /

CLEAR

ENTER

MEASURED VALUE DECIMAL LOCATION - current

decimal display setting flashes.

CLEAR

CAL /

Press and hold ENTER then press CLEAR

CAL /

to change the selected digit.

Press and release to select. 0 > 0.0 > 0.00 >

0.000 > 0.0000

Page 12

BLUE-WHITE INDUSTRIES LIMITED WARRANTY

FLOWMETERS are warranted to be free of defects in material and workmanship

for up to 12 months from the date of factory shipment. Warranty coverage is

limited to repair or replacement of the defective flowmeter only. Blue-White

Industries does not assume responsibility for any other damage that may occur.

This warranty does not cover damage to the flowmeter that results from misuse

or alterations, nor damage that occurs as a result of: meter misalignment,

improper installation, over tightening, use of non- recommended chemicals, use

of non-reccomended adhesives or pipe dopes, excessive heat or pressure, or

allowing the meter to support the weight of related piping. Flowmeters are tested

and calibrated with water and air only. Although meters may be suitable for other

chemicals, Blue-White cannot guarantee their suitability.

Flowmeters are repaired at the factory only. Call or write the factory to receive a

Return Material Authorization number, carefully pack the flowmeter to be

returned, including a brief description of the problem. Note the RMA number on

the outside of the carton.

Prepay all shipping costs. The factory does not accept COD Shipments. Damage

that occurs during shipping is the responsibility of the sender.

R

Blue-White

Industries, Ltd.

5300 Business Drive

Huntington Beach, CA 92649

Phone: 714-893-8529 FAX: 714-894-9492

E mail: sales@blue-white.com or techsupport@blue-white.com

Website: www.blue-white.com

USA

Users of electrical and electronic equipment (EEE) with the WEEE marking per Annex IV of

the WEEE Directive must not dispose of end of life EEE as unsorted municipal waste, but

use the collection framework available to them for the return, recycle, recovery of WEEE

and minimize any potential effects of EEE on the environment and human health due to the

presence of hazardous substances. The WEEE marking applies only to countries within the

European Union (EU) and Norway. Appliances are labeled in accordance with European

Directive 2002/96/EC.

Contact your local waste recovery agency for a Designated Collection Facility in your area.

# 80000-406 Rev. 4/23/2010

Page 13

Page 14

Loading...

Loading...