Page 1

®

Your Blue-White F- 462 Series

®

!

Your Blue-White flowmeter was designed to be easy to

install.

!

Please read the Instruction Guideline on the next page

before installing your flowmeter.

!

This flowmeter is an instrument, special care should be

taken when handling and installing.

Inspection of the Flowmeter and Compatibility

Installation Instructions

09/18/2012

80000-395

F- 462

Blue-White

Industries, Ltd.

R

Materials of Construction

Meter Body: Polysulfone

Float: PTFE (Based on model)

Adapters: Polysulfone

Float Stop: Polyethylene

Union Nuts: Nylon

O-Rings: Viton

Scale: Permanent, dual scale silkscreen (black ink)

Accuracy: ± 2% of full scale reading

!

Check for damage while unpacking the flowmeter.

!

Remove any instruction sheets and shipping materials that may have been

inserted into the meter body for shipping reasons.

!

Remove the box containing the float. Note the floats position before

removing the float from the meter body (tube). The float must be installed in

the same direction when assembling the flowmeter.

!

Remove the pipe fitting adapters with o-rings and the union nuts. Note the

proper location of the o-ring in the groove. Be sure the o-ring is properly

seated during installation.

!

Be sure the meter and the materials of construction are suitable for your

application.

!

The maximum temperature and pressure is shown on the following pages.

®

!

Although the meter may be suitable for use with other fluids, Blue-White

meters are tested with water and air only. If you are not sure that the meter

is compatible with your fluid, consult the factory.

!

The meter can be damaged by UV light. Do not install the meter in direct

sunlight.

®

!

Blue-White guarantees the meter is suitable with air and water only.

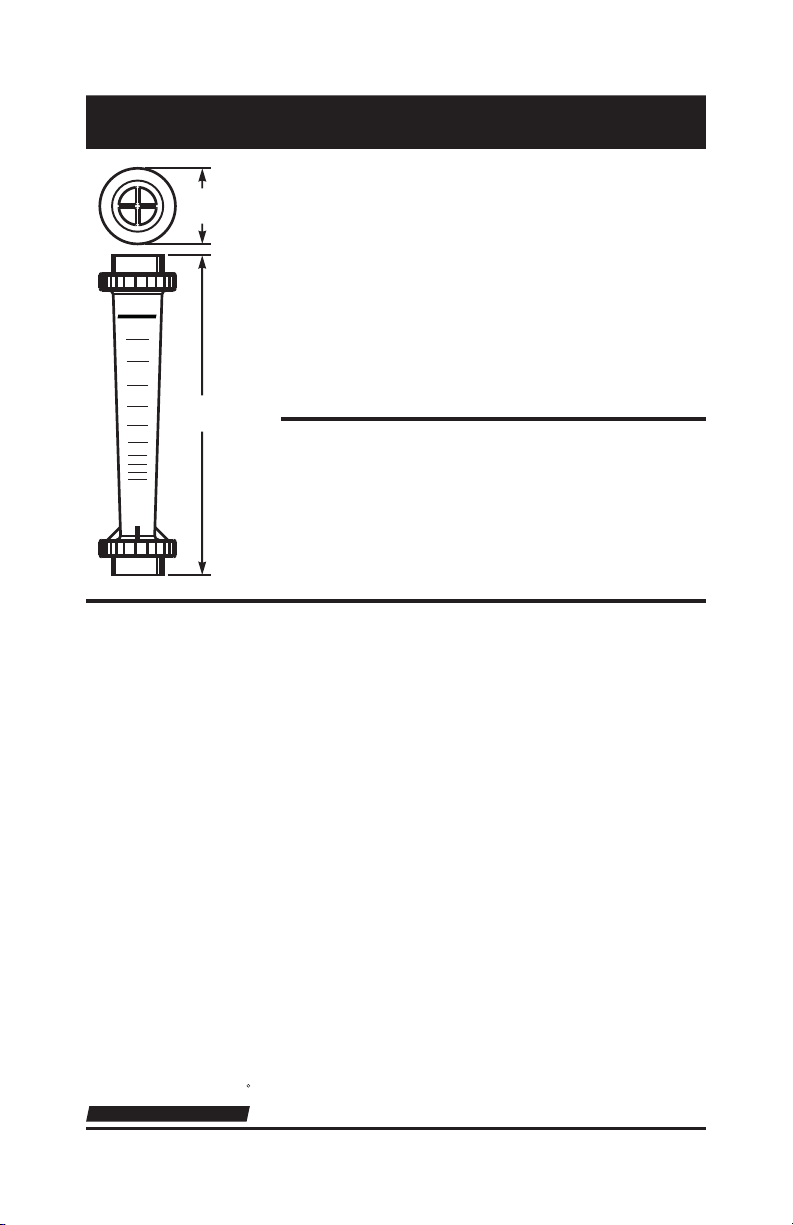

18-7/8 in.

(479.4 mm)

4-5/8 in.

(117.5 mm)

Industries, Ltd.

Blue-White

Industries, Ltd.

®

Page 2

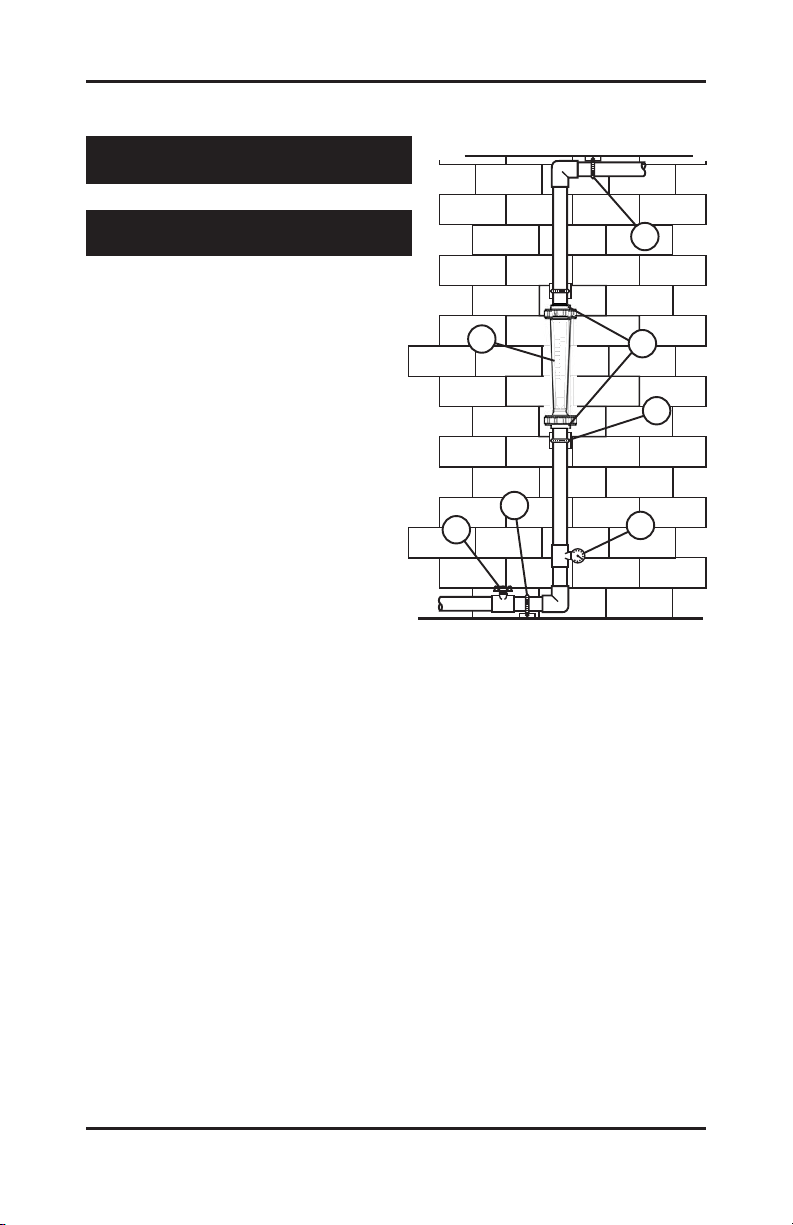

5

1

3

3

3

2

4

Floor

Ceiling

Caution: Follow these instructions to

avoid failure.

Danger: Wear eye protection when

installing or removing flowmeter.

1. Flowmeter must be installed in an exact

vertical plane to ensure accuracy.

Be certain of proper plumbing alignments.

The meterbody material can be damaged

by UV rays. Do not install in direct

sunlight.

2. Pipe dope and glue will damage

the meter!

Use only PTFE tape on the threaded

adapters. Polysulfone meter body and

fittings cannot tolerate PVC Glue

and/or pipe dope. Even fumes can

cause severe damage. If you are

installing your flowmeter to a glued

pipe configuration, install the flowmeter

after all glued fittings are dried and

lines are purged of all fumes. Never

hold the meter body with pliers or like

tools. Union nuts should be hand

tightened only. DO NOT OVER-TIGHTEN!

3. Wall, floor and ceiling mounts and supports are to be carefully aligned and

sturdy. Wall, floor and ceiling supports are recommended as needed. This is

to maintain pipe alignment and to prevent vibration.

4. Solenoid valves will damage the meter!

Avoid a system that will impose a sudden burst of flow to the meter. Such a

burst will cause the float to impact the float stop with destructive force. Solenoid

valves, or other quick opening valves cannot be used unless meter is protected

against sudden bursts of flow.

5. High pressures and temperatures will damage the meter!

The maximum acceptable temperature and pressure is interdependent. The

maximum acceptable working pressure is dependent on the actual fluid temperature. The maximum acceptable fluid temperature is dependent on the actual

working pressure. (see Temperature Vs. Pressure chart).

Installation Guideline

Page 3

Blue-White

Industries, Ltd.

R

Pressure Temperature and

Pressure and temperature limits are inversely proportional. At the maximum

suggested pressure the temperature should approach 70°F / 21°C; at the

maximum suggested temperature the pressure should approach zero psi. We

cannot guarantee our flowmeters will not be damaged either at or below the

suggested limits simply because of many factors which influence meter integrity;

stress resulting from meter misalignment, damage due to excessive vibration

and/or deterioration caused by contact with certain chemicals as well as direct

sunlight. These situations and others tend to reduce the strength of the materials

from which the meters are manufactured.

Flowmeters are tested and calibrated for water or air only.

Although meters may be suitable for other chemicals, Blue-White

cannot guarantee their suitability. It is the responsibility of the user

to determine the suitability of the flowmeter in their application.

Application Note

Maintenance

The “Exploded View” drawing illustrates assembly of the F- 462 series meter. If

your flowmeter needs to be cleaned refer to this drawing when reassembling the

unit. The tapered tube may be cleaned with a soft bottle brush. Use a MILD soap

and water solution for cleaning purposes. Hard water deposits can be removed

with a 5% acetic acid solution (vinegar). Note the floats “up” position.

Maximum Temperature vs. Pressure

PSIg / BAR

Temperature

130°F / 54.4°C

120°F / 48.9°C

110°F / 43.3°C

100°F / 37.8°C

90°F / 32.2°C

160°F / 71.1°C

80°F / 26.7°C

70°F / 21.1°C

0 / 0 25 / 1.7 50 / 3.4 75 / 5.2 100 / 6.9 125 / 8.6

150°F / 65.6°C

180°F / 82.2°C

200°F / 93.3°C

170°F / 76.7°C

140°F / 60.0°C

190°F / 87.8°C

150 / 10.3

Page 4

BLUE-WHITE INDUSTRIES LIMITED WARRANTY

FLOWMETERS are warranted to be free of defects in material and workmanship

for up to 12 months from the date of factory shipment. Warranty coverage is

limited to repair or replacement of the defective flowmeter only. Blue-White

Industries does not assume responsibility for any other damage that may occur.

This warranty does not cover damage to the flowmeter that results from misuse

or alterations, nor damage that occurs as a result of: meter misalignment,

improper installation, over tightening, use of non- recommended chemicals, use

of non-reccomended adhesives or pipe dopes, excessive heat or pressure, or

allowing the meter to support the weight of related piping. Flowmeters are tested

and calibrated with water and air only. Although meters may be suitable for other

chemicals, Blue-White cannot guarantee their suitability.

Flowmeters are repaired at the factory only. Call or write the factory to receive a

Return Authorization Number, carefully pack the flowmeter to be returned,

including a brief description of the problem. Note the RA number on the outside

of the carton.

BLUE-WHITE INDUSTRIES

5300 Business Drive - Huntington Beach, CA 92649

(714) 893-8529 l Fax: (714) 894-9492

URL: www.Blue-White.com

Email: sales@blue-white.com

Techsupport@blue-white.com

Blue-White

Industries, Ltd.

R

1

Polysulfone

6

Meterbody

1

5

Float

F- 462 Exploded View and Parts List

Catalog Number Description Amount Item

1

2

3

F-452004N Union Nut, Nylon 2

F-452330N Adapter, 2" FNPT, Polysulfone 2

F-452002 Float Stop, Polysulfone 2

4

F-452043N

O-ring, Viton

2

1

2

3

4

5

6

2-20 GPM, PTFE

5-50 GPM, PTFE

8-80 GPM, PTFE

Loading...

Loading...