Page 1

F-2000

MODEL PC - MODEL PB - MODEL AO

OUTPUT BOARDS

INSTRUCTION MANUAL

R

Blue-White

Industries, Ltd.

5300 Business Drive

Huntington Beach, CA 92649

USA

Phone: 714-893-8529 FAX: 714-894-9492

E mail: sales@blue-white.com or techsupport@blue-white.com

Website: www.blue-white.com

Page 2

F-2000

1.0 F-2000 Electrical Wiring Connections

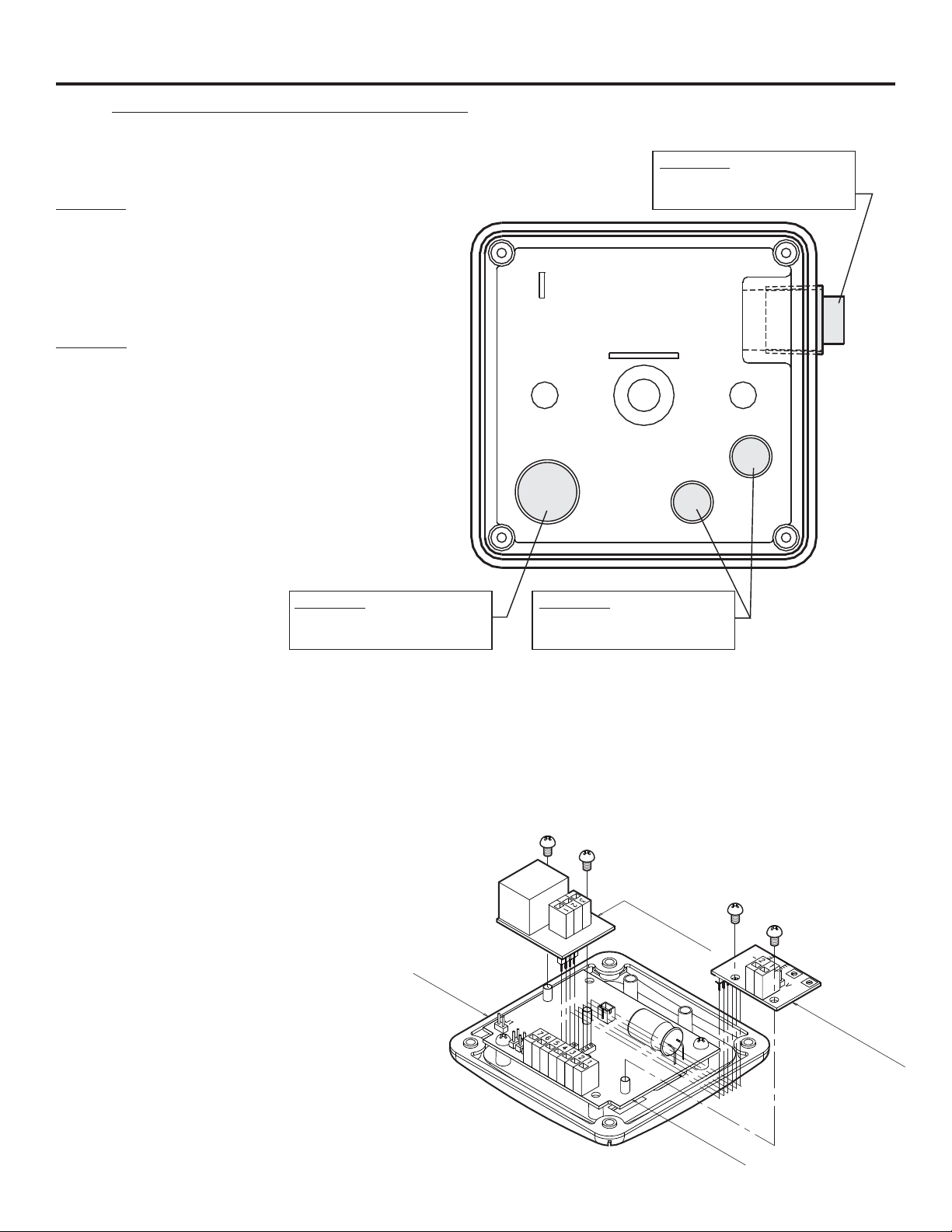

1.1Enclosure knock-out Instructions

Option A: Conduit Connection

1. Remove the red cap plug.

2. Install your pipe fitting (1/2 - 14 NPT male

end).

Page 2

Option A: 1 / 2-14 MPT

Red Cap Plug

(for pipe fitting)

Option B: Liquid-Tight Connections

Internal View

1. Remove knock-out(s) using a screwdriver.

2. Trim edge(s) with a knife and remove sharp

edges.

3. Install the provided liquid-tight connector(s).

Option B: 3/4 DIA.

Knock-out

(large liquid-tight connector)

Option B: 1/2 DIA.

Knock-out

(small liquid-tight connector)

Notes:

For the large liquid-tight connector (3/4” Knock-out), the acceptable cable diameter is between .200 - .394 in (5.1 -

10.0 mm).

For the small liquid-tight connector (½”Knock-out), the acceptable cable diameter is between .118 - .255 in (3.0 -

6.5 mm).

1.2Optional Circuit Board Installation

CAUTION: DISCONNECT POWER

SOURCE BEFORE SERVICING.

1. Carefully align optional board’s Pin

Header with the Pin Header socket

located on the main circuit board.

2. Press firmly into place.

3. Secure the board with the two screws

provided.

F-2000

Enclosure

Cover

(OPTIONAL BOARD)

N.C.

N.O.

C

F-2000-PC

F-2000-PB

(MAIN BOARD)

F-2000-RT

F-2000-AO

(OPTIONAL

BOARD)

Page 3

Page 3

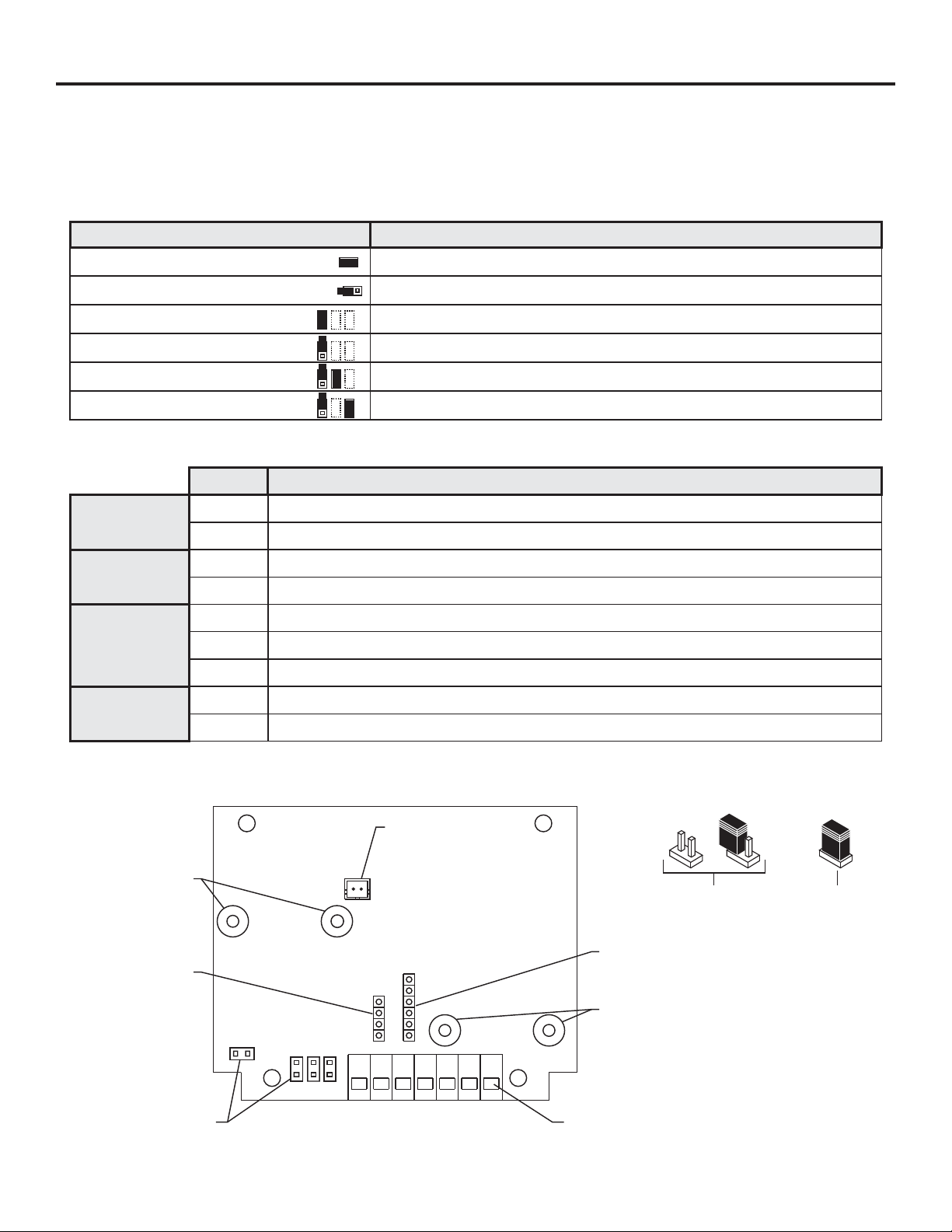

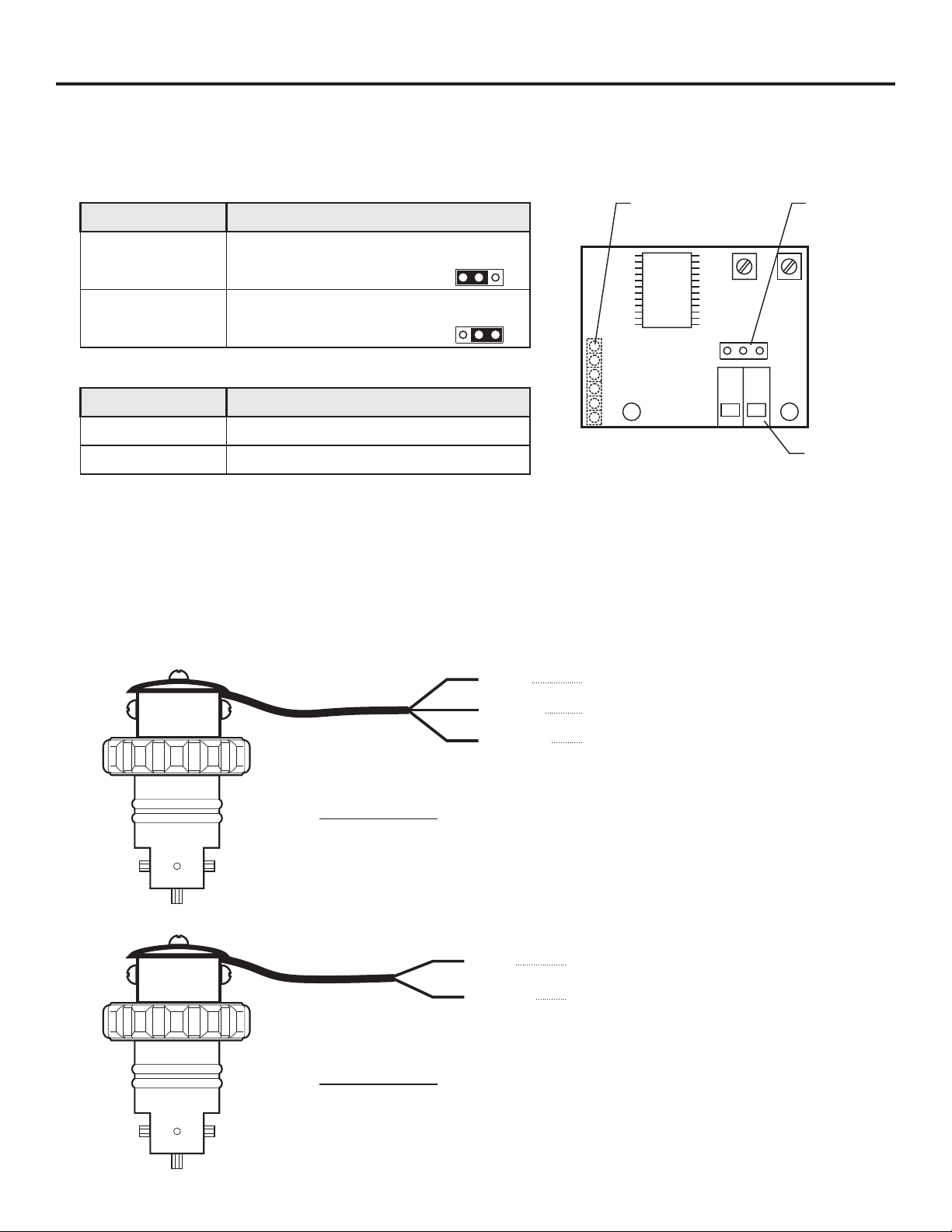

1.3Model RT Circuit Board Wiring

CAUTION: DISCONNECT POWER SOURCE BEFORE SERVICING.

Jumper Configuration

F-2000

Jumpers

J1 Installed

J1 Left Open

J2 Installed

J2 Left Open

J3 Installed and J4 Left Open

J3 Left Open and J4 Installed

Terminal Configuration

Terminal Function

Supply power

input

AC coil sensor

input

6

5

2

3

1

Hall Effect

sensor input

2

3

Open connector

pulse output

(from sensor)

7

4

Function

Battery Input (4 - 1.5 VDC, AA Cells)

Plug-In Transformer (115 VAC / 15 VDC, 220 VAC / 15 VDC, 230 VAC / 15 VDC)

Front Panel Programming is Disabled

Front Panel Programming is Enabled (factory default)

Hall Effect Sensor Input

AC Coil Sensor Input

Positive (+) power input (red wire from battery pack, or black with stripe wire from 15 VDC plug-in transformer)

Ground (-) power input (black wire from battery pack or 15 VDC plug-in transformer)

Ground (-) input (black wire from coil sensor body)

Pulse input (yellow or red wire from coil sensor body)

Positive (+) input (red wire from hall effect sensor)

Ground (-) input (black wire from hall effect sensor)

Pulse input (bare wire from hall effect sensor)

NPN positive (+) signal output

NPN negative (-) signal output

(Max voltage: 24VDC, Max load: 15mA, 2k ohm pull-up recommended.)

F-2000 RT Board

F-2000 PC Board

Mounting Screw

Bushings

SIP Socket for

F-2000 PC Board

Jumpers

BAT = ON

J1

J3

J2

PHM

Backup Battery

Connector

J4

7654321

SIP Socket for

F-2000 AO Board

F-2000 AO Board

Mounting Screw

Bushings

Terminal Blocks

Jumper Positions

Jumper Not

Installed (open)

Jumper

Installed

Page 4

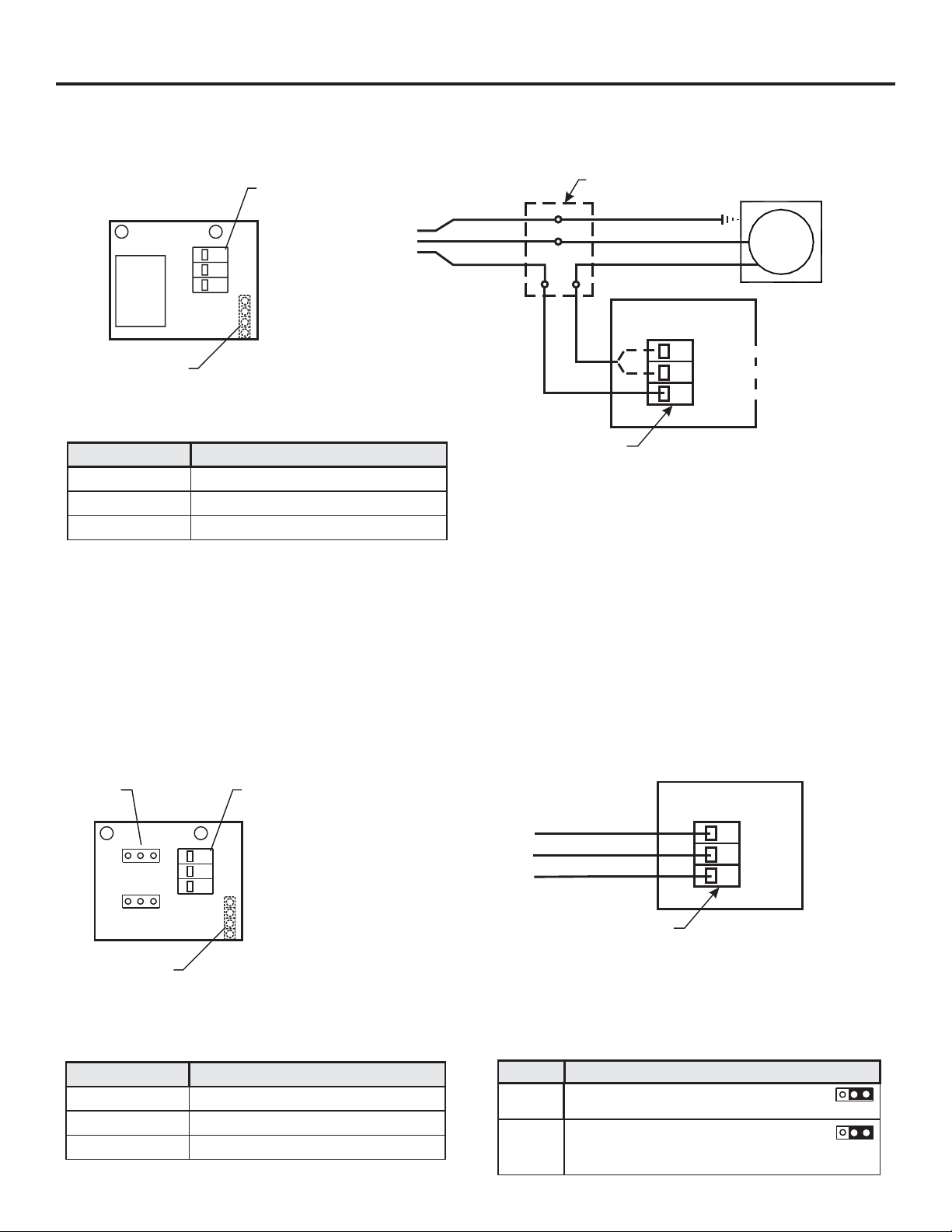

F-2000

1.4Model PC Circuit Board Wiring

CAUTION: DISCONNECT POWER SOURCE BEFORE SERVICING.

Page 4

Terminal

Relay

Block

3

NC

2

NO

1

C

Earth Ground (green)

AC

Pin Header

(Other side)

Terminal Configuration

Terminal Terminal Block Connections

1

2

3

Output Type: Isolated relay SPDT (single poll double throw), NO / NC

Max. Load: 8 amps (AC) @ 115 VAC, 220 VAC, 230 VAC

Max. Voltage: 250 VAC, 125 VDC

Common

NO (Normally Open) contact

NC (Normally Closed) contact

7 amps (DC) @ 30 VDC (resistive load)

Common (-)

Hot (+)

Junction Box (not supplied)

Earth Ground (green)

Load Neutral (-)

Load Hot (+)

F-2000-PC Board

3-position

Terminal Block

External

Equipment

Load

(normally Closed Contact)

3

NC

(normally Open Contact)

NO

2

(common Contact)

1

C

1.5Model PB Circuit Board Wiring

CAUTION: DISCONNECT POWER SOURCE BEFORE SERVICING.

Jumpers

JP1

JP2

NC

IN

NO

EX

Pin Header

(Other side)

Terminal Configuration

Terminal Terminal Block Connections

1

2

3

Voltage input (+)

Switched output (NO/NC)

Ground (-)

3

2

1

Terminal

Block

G

OUT

V

Output Type: Non-Isolated contact closure switch, NO / NC

Max. Load: 100 milliamps (.10 amp)

Max. Voltage: 30 VDC if JP2 is set for external power.

15 VDC if JP2 is set for internal power and F-2000 is powered by plug-in transformer.

3 VDC if JP2 is set for internal power and F-2000 is powered by Batteries.

Max. Power: 3 Watts

Ground (-)

Switched Output (NO/NC)

Supply (+) (voltage input)

3-position

Terminal Block

Jumper Configuration

Jumper SettingsJumper

JP1

JP2

NC = Normally closed contacts

NO = Normally open contacts (default)

IN = Internal power

EX = External power (default)

Note: See above voltage limits

F-2000-PB Board

G

3

2

OUT

1

V

JP1

NC

NO

JP2

IN

EX

Page 5

Page 5

1.6Model AO Circuit Board Wiring

CAUTION: DISCONNECT POWER SOURCE BEFORE SERVICING.

Jumper Configuration

Output Jumper Settings

Connect P1 & P2 (leave P3 open) (factory

4-20 Milliamp

0-10 Volts DC

Terminal Configuration

Terminal Number Terminal Block Connections

default), Max Load = 250 Ohms

Connect P2 & P3 (leave P1 open), Max Load =

500 Ohms

P2

P3P1

P2

P3P1

Pin Header

(other side)

A

-

P2

21

F-2000

3 position

jumper Pin

P3P1

V

+

1

2

Output Type: Linear, Non-Isolated, powered loop.

Loop resistance: 250 ohm maximum for 4-20mA output

Positive (+) Analog Output Signal

Negative (-) Analog Output Signal

500 ohm maximum for 0-10 V DC

1.7Model FHXX and FCXX Sensor wiring

Model FHXX

Note: Output type - current sinking type hall effect sensor (13.5mA max).

Pull-up resistor is recommended. 5k ohm across red & bare wires.

RED

BARE

BLACK

Terminal

Block

Input Supply Voltage (+ 6 to 24 Vdc)

Signal Output (square wave)

Ground (-)

Model FCXX

RED

BLACK

Signal Output (Sine wave)

Ground (-)

Page 6

F-2000

2.0 HOW TO OPERATE THE MODEL PC and MODEL PB

2.1What Was The MODEL PC and PB Designed To Do?

In addition to the features of the MODEL RT, the model PC includes a single SPDT relay which can be used to

switch an external component such as a pump, valve, alarm buzzer, etc., on and off in order to assist in the

control of a process. The relay setpoints must be assigned to either the rate mode, the batch (total) mode, or

turned off. The MODEL PC cannot be battery operated.

The MODEL PB offers all of the features of the MODEL PC but includes a contact closure switch instead of a

relay and may be battery operated.

!

High level flow rate alarm.

!

Low level flow rate alarm.

!

High and low level flow “range” alarm.

!

Manual start or automatically timed start batch processing.

!

Proportional chemical feed injector pump control.

2.2What Features Are Available?

!

All controls are front panel programmable.

!

MODEL PC Max. switching load 8 Amp at - 115 VAC, 230 VAC, 220 VAC; 7 Amp at 30 VDC (resistive load).

!

MODEL PB Max. switching load 100 milliamp at 30 VDC.

!

NO / NC contact.

!

Rate alarms can be latched requiring a manual reset.

!

Programmable “alarm release value” provides hysteresis to prevent relay flickering (see page 28).

!

High and low range alarms can be independently programmed.

!

Alarm delay timer temporarily silences alarms for a programmed time from 0-999 seconds.

!

Independent display and resetting of batch count and batch amount.

!

Front panel clearing of batch counts and amounts can be disabled.

!

Turn on / off external devices, for a programmable time from 0-999 seconds per batch.

Page 6

2.3How Do I Program The MODEL PC & PB?

The Model PC & PB setpoints must be assigned to either the rate mode (option 1), the batch (total) mode

(option 2), or turned off (option 3).

Option 1 - Assign the setpoints to the RATE mode for applications involving the switching of external devices,

such as alarms or valves, when the rate of flow is greater than or less than the programmed flow

RATE value. The Model PC and PB is used to monitor flow RATE in this mode. Example: High or

low flow rate alarms.

Option 2 - Assign the setpoints to the BATCH mode for applications involving the switching of external devices

such as chemical metering pumps, centrifical pumps, solenoid valves, etc., when the amount of flow

is greater than or less than the programmed batch amount value. In this mode, the Model PC is used

to monitor flow total. Example: Manual batch processing or proportional feed rate control.

Option 3 - The OFF mode opens the relay contacts regardless of the flow conditions. The setpoints are not

assigned.

SETPOINT MODE SELECTION PROGRAMMING SCREEN OPTIONS

OPTION

Option - 1 (page 27)

Option - 2 (page 32)

Option - 3

SELECTION FUNCTION

Setpoint - RATE Relay Setpoints are assigned to flow RATE mode.

Setpoint - BATCH Relay Setpoints are assigned to BATCH (accumulative or “total”) mode.

Setpoint - OFF Relay Setpoints are not assigned. Relay is not energized.

Page 7

Page 7

F-2000

OPTION 1. RELAY SETPOINTS ARE ASSIGNED TO THE RATE MODE.

When the setpoint mode selection screen is assigned to RATE, the following program screens are available:

PROGRAMMING SCREEN PROGRAMMING SCREEN FUNCTION

Setpoint - RATE - 1 High alarm flow RATE trigger value. (Factory default value = 000001)

Setpoint - RATE - 2 High alarm flow RATE release value. (Factory default value = 000001)

Setpoint - RATE - 3 Low alarm flow RATE trigger value. (Factory default value = 000001)

Setpoint - RATE - 4 Low alarm flow RATE release value. (Factory default value = 000001)

Setpoint - RATE - 5 Alarm reset delay time from 000 - 999 seconds. (Factory default value = 000)

The relay setpoints may be assigned in one of three ways:

Choice 1. High Alarm Only

The High Alarm Trigger Setpoint energizes the relay at a high flow rate value (high flow alarm). A single

trigger value is assigned to a flow rate value greater than the normal flow rate. The relay will energize

when the flow rate increases to the programmed value. In this option, the low trigger and release values

are not used and should be programmed to a value of zero.

Choice 2. Low Alarm Only

The Low Alarm Trigger Setpoint energizes the relay at a low flow rate value (low flow alarm). A single

trigger value is assigned to a flow rate value less than the normal flow rate. The relay will energize when

the flow rate decreases to the programmed value. In this option, the high trigger and release values are

not used and should be programmed to a value of zero.

Choice 3. High and Low Range Alarm Setpoints

The Range Alarm Setpoints energize the relay at both the high and low flow rate values (out-of-range

alarm). Both the high and low trigger values must be assigned creating an acceptable range of flow. The

relay will energize when the flow rate increases or decreases out of the acceptable range.

The relay action may be programmed in three ways:

Choice 1. Manual Unlatching requires the user to press the clear setpoints button to unlatch the relay (turn off the

alarm). The relay is energized and latched when the trigger value is reached and remains energized and

latched until the clear setpoints button is pressed.

To enable the feature, program the trigger and release values to the same value.

Choice 2. Automatic Unlatching requires the programming of a separate release point. When the setpoint is

triggered, the relay will automatically unlatch when this release value is crossed.

To enable the feature, program a different trigger and release value. The high release value must be less

than the high trigger value. The low release value must be greater than the low trigger value.

Choice 3. The Relay is Deactivated

To deactivate the relay, program all trigger and release values to zero.

NOTE: When latched, regardless of how the relay action is programmed, the relay may be unlatched manually by

pressing the front panel “clear setpoints” button. However if there is still an alarm condition (high or low trigger

value is exceeded), the relay will immediately re-latch. An alarm reset delay time can be programmed which will

delay the re-latching of the relay even though the alarm condition still exists. If the relay is being used to switch an

audible alarm, this feature allows for temporarily silencing the alarm, allowing time to affect repairs, without

actually disabling the alarm feature. The programmable time range is from 0-999 seconds.

Page 8

F-2000

FLOW RANGE ALARM EXAMPLE

Page 8

High Alarm

High setpoint trigger value 250.0 GPM

Hysteresis

High setpoint release value 240.0 GPM

Flow

Low setpoint release value 160.0 GPM

Hysteresis

Low setpoint trigger Value 150.0 GPM

Low Alarm

Note: If the relay flickers on and off due to unstable flow, readjust

the release value to increase the amount of hysteresis.

2.4Programming the MODEL PC & PB when the setpoints are assigned to rate.

Caution: An emergency shut off switch for externally controlled electrical equipment is recommended.

Note: The F-2000 must be powered by the AC Adapter.

Nominal

Range

Note: While in the programming mode, if no buttons are pressed within twenty seconds, the programming mode

is automatically exited without saving the input of the last screen.

Step 1 Enter the programming mode and assign the setpoints to the RATE mode.

!

Press for at least 1.25 seconds.

!

Press to by-pass the first six program screens until you reach the Rate Setpoint Screen (seventh screen).

!

Press to select Rate Setpoint On.

!

Press .

ENTER

ENTER

CLEAR

TOTAL

ENTER

Step 2 Enter the High Alarm Trigger Value or 0.

!

Press to select the digit or decimal point to be modified. The selected digit will blink.

!

Press to change the selected digit. Note: Setting the value to zero disables the High Alarm.

!

Press when you have entered your desired High Alarm Trigger Value.

CLEAR

SETPOINT

CLEAR

TOTAL

ENTER

RATE SETPOINT

00000

RATE SETPOINT

O

Page 9

Page 9

Step 3 Enter the High Alarm Release Value or 0.

!

Press to select the digit or decimal point to be changed. The selected digit will blink.

!

Press to change the selected digit. Note: This value must not be greater than the High Alarm Trigger Value.

CLEAR

SETPOINT

CLEAR

TOTAL

F-2000

000002

RATE SETPOINT

!

Press when you have entered your desired High Alarm Release Value.

ENTER

Step 4 Enter the Low Alarm Trigger Value or 0.

!

Press to select the digit or decimal point to be changed. The selected digit will blink.

!

Press to change the selected digit. Note: Setting the value to zero disables the Low Alarm.

!

Press when you have entered your desired Low Alarm Trigger Value.

CLEAR

SETPOINT

CLEAR

TOTAL

ENTER

Step 5 Enter the Low Alarm Release Value or 0.

!

Press to select the digit or decimal point to be changed. The selected digit will blink.

!

Press to change the selected digit. Note: This value must not be less than the Low Alarm Trigger Value.

!

Press when you have entered your desired Low Alarm Release Value.

CLEAR

SETPOINT

CLEAR

TOTAL

ENTER

000003

RATE SETPOINT

000004

RATE SETPOINT

Step 6 Enter the Alarm Reset Delay Timer in seconds or press

ENTER

to bypass this screen.

The alarm will be silenced (relay de-energized) for the programmed amount of time when is pressed.

After the delay time, if the alarm condition still exists, the relay will re-energize. This feature allows the user to

temporarily silence the alarm without disabling the alarm feature. The programmed time range is from 0 to 999

seconds.

!

Press to select the digit to be changed.

!

Press to change the selected digit. Note: Setting the value to zero disables the Alarm Reset Delay Timer.

!

Press to save your Alarm Reset Delay Time.

Step 7 Press and hold down for at least 1.25 seconds to exit.

CLEAR

SETPOINT

CLEAR

TOTAL

ENTER

ENTER

RATE SETPOINT

CLEAR

SETPOINT

0005

Page 10

F-2000

2.5Examples of Setpoint Assigned to Rate.

Example 1: An audible alarm must sound when the flow rate goes out of the range of 25 to 35 gallons

per minute.

Alarm

Page 10

Trigger

Trigger

35.0 GPM

25.0 GPM

Release 34.0 GPM

Flow

Release

Alarm

Step 1 Set the SETPOINT MODE SELECTION screen to SETPOINT - RATE.

Step 2 Set SETPOINT - RATE - 1, screen for a high range trigger value of 35.0.

Step 3 Set SETPOINT - RATE - 2, screen for a high range release value of less than 35 and greater than 25.

(If latching alarm is required, set the release value to 35).

Step 4 Set SETPOINT - RATE - 3, screen for a low range trigger value.

Step 5 Set SETPOINT - RATE - 4, screen for a low range release value of greater than 25 and less than 35.

(If latching alarm is required, set the release value to 25).

Step 6 Set SETPOINT - RATE - 5, to the desired alarm silencing delay time of 0 - 999 seconds(optional).

Step 7 Wire the alarm to the normally open terminals of the relay terminal block. See page 16.

Example 2: An audible alarm must sound if the flow rate goes below 82.5 cubic meters per hour.

26.0 GPM

Flow

Trigger 82.5 MH

3

Alarm

Release 84.0 MH

Step 1 Set the SETPOINT MODE SELECTION SCREEN to SETPOINT - RATE.

Step 2 Set SETPOINT - RATE - 1, screen for a high trigger value of 0. (High alarm not used, bypass).

Step 3 Set SETPOINT - RATE - 2, screen for a high release value of 0. (High alarm not used, bypass).

Step 4 Set SETPOINT - RATE - 3, screen for a low trigger value of 82.5.

Step 5 Set SETPOINT - RATE - 4, screen for a low release value of greater than 82.5 (example: 84.0).

Step 6 Set SETPOINT - RATE - 5, to the desired alarm silencing delay time of 0 - 999 seconds (optional).

Step 7 Wire the alarm to the normally open terminals block. See page 16.

3

Page 11

Page 11

Example 3: A solenoid valve must open if the flow rate goes above 225 gallons per minute.

F-2000

Open Valve

Trigger

225 GPM

Release 220 GPM

Flow

Step 1 Set the SETPOINT MODE SELECTION SCREEN] to SETPOINT - RATE.

Step 2 Set SETPOINT - RATE - 1, screen for a high trigger value of 225.

Step 3 Set SETPOINT - RATE - 2, screen for a high release value of less than 225. Example: 220

Step 4 Set SETPOINT - RATE - 3, screen for a low trigger value of 0. (Low alarm not used).

Step 5 Set SETPOINT - RATE - 4, screen for a low release value of 0. (Low alarm not used).

Step 6 Set SETPOINT - RATE - 5, to the desired alarm delay silencer time from 0 - 999 seconds (optional).

Step 7 Wire the value to the normally open terminals of the relay terminal block. See page 16.

Page 12

F-2000

Page 12

OPTION 2. RELAY SETPOINTS ARE ASSIGNED TO THE BATCH MODE.

BATCH AMOUNT - Two types of batch applications are available, manually started batches and automatically started

batches. Both types require the programming of a batch amount value.

In a manually started batch, the relay is energized manually by the user when the front panel clear setpoint

button is pressed and de-energized when the batch amount is reached. In this mode, the relay is switching a

valve or other device that is controlling the flow being measured.

In an automatically started batch, the relay is energized and the external equipment timer is started when the

batch amount is reached. The relay is de-energized at the end of the timer cycle.

AUTO RESET ON/OFF - The auto reset must be turned off for manual start batches and turned on for auto start batches.

EXTERNAL EQUIPMENT TIMER - The external equipment timer is only used with auto start batches.

When the setpoint mode selection screen is assigned to BATCH, the following program screens are available:

PROGRAMMING SCREEN PROGRAMMING SCREEN FUNCTION

Setpoint - BATCH - 1 Batch amount value.

Setpoint - BATCH - 2

Setpoint - BATCH - 3 External equipment timer amount in seconds (0 - 999).

Auto reset on or off (on for auto timed batches and proportional feed control, off for manually reset batches)

MANUAL BATCH START APPLICATION

Manual batch start requires pressing the clear setpoints button to energize the relay. The relay de-energizes when

the Batch Amount is reached. The clear setpoints button must be pressed again to begin the next batch.

CAUTION: A SEPARATE EMERGENCY SHUT-OFF SWITCH FOR EXTERNAL EQUIPMENT IS RECOMMENDED.

Application 1. Manual Batch Operation

In this operation, the relay is used to switch a device such as a valve or pump, that is controlling the flow being

measured.

Example: a pump is turned on and off to fill containers to a preset amount of fluid. The fluid being pumped is also

the fluid being measured by the F-2000.

1. The pump is wired to the normally open relay contacts of the F-2000.

2. Manually pressing the front panel “clear setpoints” button starts the batch by energizing the relay, which

switches on power to the pump. The SETPOINT display icon illuminates.

3. The displayed Batch Number increments by one.

4. The displayed Batch Amount increases based on the pump flow rate.

5. When the programmed Batch Amount is reached, the relay de-energizes, turning off the pump. The SETPOINT

display icon disappears.

6. The batch is complete.

Note: The batch may be interrupted and re-started by pressing the “clear setpoints” button. The SETPOINT

display icon flashes.

AUTOMATIC BATCH START APPLICATION

Automatic Batch Start requires programming the EXTERNAL EQUIPMENT TIMER to a specific time from 000 999 seconds. When the batch amount is reached, the relay energizes and the timer starts. The relay de-energizes

when the number of seconds programmed is reached.

Page 13

Page 13

Application 2. Proportional Chemical Feed Operation

In this operation, the relay is used to switch a device such as a valve or pump, that is being controlled by the flow

being measured.

Example: A chemical injection pump is turned on for a preset amount of time when the Programmed Batch

Amount is reached, thus injecting an amount of chemical per an amount of measured flow.

1. The chemical injection pump is wired to the normally open relay contacts.

2. The flow measurement begins.

3. The displayed Batch amount increases based on the flow rate being measured.

4. When the programmed Batch Amount is reached, the following occurs:

a. The external equipment timer begins.

b. The relay energizes turning on the chemical injection pump.

c. The Batch Amount Resets to zero.

d. The next batch flow rate measurement begins and the displayed Batch Amount increases.

e. When the External Equipment Timer cycle ends, the relay de-energizes turning off the chemical injection

pump.

5. The displayed Batch Number increments by one.

6. The batch is complete.

F-2000

Note: The chemical pump may be stopped and re-started by pressing the clear setpoints button.

Application 3. Automatically Timed Batching Operation

In this operation, the relay is used to switch a device, such as a valve or pump, that is controlling the flow being

measured.

Example: A solenoid valve is wired to the normally closed contact of the F-2000 relay. In the de-energized relay

state, the valve is energized and open, which permits the flow being measured to flow. When the programmed

batch amount is reached, the relay is energized, opening the relay circuit which closes the valve, and a time delay

cycle begins. After the time delay cycle, the relay de-energizes which opens the solenoid valve and the next batch

begins.

CAUTION: WHEN WIRED TO THE NORMALLY CLOSED CONTACTS OF THE RELAY, EXTERNAL EQUIPMENT

WILL BE ENERGIZED IF THE CLEAR SETPOINTS BUTTON IS PRESSED. A SEPARATE

EMERGENCY SHUT-OFF SWITCH FOR EXTERNAL EQUIPMENT IS RECOMMENDED.

1. The solenoid valve is wired to the normally closed contacts.

2. The flow measurement begins.

3. The displayed Batch Amount increases based on the flow rate being measured.

4. When the programmed Batch Amount is reached, the following occurs:

a. The time delay cycle (External Equipment Timer) begins.

b. The relay energizes closing the valve which stops the flow.

c. The batch amount resets to zero.

5. When the External Equipment Timer cycle ends, the relay de-energizes, opening the solenoid valve.

6. The displayed Batch Number increments by one.

7. The batch is complete.

Page 14

F-2000

Page 14

2.6Programming The MODEL PC & PB When Setpoints Are Assigned To Batch

Note: The F-2000 must be powered by the AC adapter.

CAUTION: A SEPARATE EMERGENCY SHUT-OFF SWITCH FOR EXTERNAL EQUIPMENT IS RECOMMENDED.

Step 1 Enter the programming mode and assign the setpoint to the BATCH mode.

!

Press for at least 1.25 seconds.

ENTER

BATCH SETPOINT

O

!

Press to by-pass the first six program screens until you reach the Batch Setpoint Screen (seventh screen).

!

Press to select Batch Setpoint ON.

!

Press .

Step 2 The Setpoint Batch-1 screen, Batch Amount Value is selected.

This screen is used to enter the batch amount value. The relay will energize when the

accumulated total flow equals the programmed value.

!

Press to select the digit or the decimal to be modified. The selected digit will blink.

!

Press to change the selected digit.

!

Press when you have finished.

Step 3 The Setpoint Batch-2 screen, Auto Batch Start On or Off is enabled.

This screen is used to toggle the auto Batch Start function On and Off.

Note: Select On for auto-Start Batches and Off for manual Start Batches.

ENTER

CLEAR

TOTAL

ENTER

CLEAR

SETPOINT

CLEAR

TOTAL

ENTER

00000

BATCH SETPOINT

2

BATCH SETPOINT

O

!

Press to select On or Off.

!

Press when you have finished.

Step 4 The Setpoint Batch-3 screen, external equipment Timer amount

This screen is used to enter the number of seconds per batch that the relay will be energized.

Note: Set to zero for manual Start Batch operations.

!

Press to select the digit to be modified.

!

Press to change the selected digit.

!

Press when you’ve finished.

CLEAR

TOTAL

ENTER

(in seconds) is displayed.

CLEAR

SETPOINT

CLEAR

TOTAL

ENTER

3

BATCH SETPOINT

000

Page 15

Page 15

2.7Examples of Setpoint Assigned To Batch

Example 1: Proportional feed application. A chemical feed pump must run for 3 seconds for every 12.57

liters of flow measured.

Step 1 Set the SETPOINT MODE SELECTION screen to SETPOINT - BATCH.

Step 2 Set SETPOINT - BATCH - 1 screen for a batch amount value of 000012.57

Step 3 Set SETPOINT - BATCH - 2 screen for automatic batch start.

Step 4 Set SETPOINT - BATCH - 3 screen for external equipment timer on-time of 003 seconds.

Step 5 Wire the pump to the normally open terminals of the relay terminal block.

Step 6 The pump will start automatically when the batch amount is reached.

F-2000

Example 2: Manual batch application. In a truck depot, an attendant must open a solenoid valve

allowing 2,000 gallons of water to flow into each truck.

Step 1 Set the SETPOINT MODE SELECTION screens to SETPOINT - BATCH

Step 2 Set SETPOINT - BATCH - 1 screen for a batch amount value of 00002000

Step 3 Set SETPOINT - BATCH - 2 screen for automatic BATCH START OFF.

Step 4 Set SETPOINT - BATCH - 3 screen for external equipment timer on-time of 000 seconds.

Step 5 Wire the solenoid valve to the normally open terminals of the relay terminal block.

Step 6 Press to begin the first batch.

CLEAR

SETPOINT

Page 16

F-2000

3.0 HOW TO OPERATE THE MODEL AO

3.1What Was The MODEL AO Designed To Do?

!

Output a 4-20mA or 0-10VDC signal which is proportional to the flow.

3.2What Features Are Available?

!

Front panel programmable zero and span.

!

20-4mA and 10-0VDC inverted logic capabilities.

!

Front programming can be disabled for security.

!

4-20mA or 10VDC output signal (factory default) selected via jumper pin located on the circuit board.

3.3How Do I Program The MODEL AO?

Note: The F-2000 must be powered by AC Adapter

Note: The output signal can be inverted. Either the low or the high output signal may be assigned to the lower or

Programming Screen Programming Screen Function

Page 16

MA 1

MA 2

Input the desired flow rate which corresponds to an output signal of 4mA or 0VDC. This

value may be either the high or the low point in the range.

Input the desired flow rate which corresponds to an output signal of 20mA or 10VDC. This

is the opposite range point from the MA 1 setting (above).

Step 1 MA 1, Flow Rate at Low Output Signal (4mA or 0VDC).

!

Press for at least 1.25 seconds to activate programming mode.

!

Press to toggle through the different display screens until you reach the MA screen.

!

Press to select the digit to be changed. Note: The selected digit will blink.

!

Press to change the selected digit.

!

Press .

ENTER

ENTER

CLEAR

SETPOINT

CLEAR

TOTAL

ENTER

Step 2 MA 2, Flow Rate at High output Signal (20mA or 10VDC).

!

Press to select the digit to be changed.

CLEAR

SETPOINT

MA

00000

00000

2

MA

!

Press to change the selected digit.

!

Press .

CLEAR

TOTAL

ENTER

Page 17

Page 17

4.0 Programming Menu Flow Chart

F-2000

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

SCREEN

000000

RATE

00000

2

RATE

3

RATE

O00000

TOTAL

00000

2

TOTAL

3

TOTAL

MODEL PC UNITS ONLY

CLEAR

TOTAL

RATE sETPOINT

OFF

OFF

OFF

sETPOINT

DESCRIPTION

MODIFYING

RATE 1 - Rate Scale Factor

RATE 2 - Rate Decimal Factor

RATE 3 - Battery Save Mode On / Off

TOTAL 1 - Total Scale Factor

TOTAL 2 - Total Decimal Factor

TOTAL 3 - Clear Total Enable On / Off

SETPOINT MODE ASSIGN - on rate / on batch / off

Setpoint ON - Assigned to RATE

CLEAR

SETPOINT

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

SETPOINT

CLEAR

TOTAL

CLEAR

TOTAL

Or

Or

CLEAR

TOTAL

CLEAR

TOTAL

ENTER

ENTER

ENTER

ENTER

ENTER

CLEAR

TOTAL

BATCH SETPOINT

ENTER

ENTER

ENTER

MODEL AO UNITS ONLY

00000

RATE SETPOINT

00000

2

3

4

5

BATCH SETPOINT

2 OFF

BATCH SETPOINT

3

BATCH SETPOINT

RATE SETPOINT

00000

RATE SETPOINT

00000

RATE SETPOINT

000

RATE SETPOINT

00000

00000

Setpoint Rate 1 - High Alarm Trigger

Setpoint Rate 2 - High Alarm Release

Setpoint Rate 3 - Low Alarm Trigger

Setpoint Rate 4 - Low Alarm Release

Setpoint Rate 5 - Alarm Delay Timer

Setpoint ON - Assigned to BATCH

Setpoint Batch 1 - Batch Amount

Setpoint Batch 2 - Auto Reset On / Off

Setpoint Batch 3 - External Equip. Timer

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

Or

Or

Or

Or

Or

Or

Or

Or

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

ENTER

ENTER

00000

MA

00000

2

MA

MA-1 - Low Analog Out Value

MA-2 - High Analog Out Value

CLEAR

SETPOINT

CLEAR

SETPOINT

Or

Or

CLEAR

TOTAL

CLEAR

TOTAL

Page 18

Warranty

!

Blue-White flowmeters are warranted to be free from defects in material and workmanship for 12 months from date of

factory shipment. Warranty coverage is limited to repair or replacement of the defective flowmeter only.

!

This warranty does not cover damage to the flowmeter that results from misuse or alterations, nor damage that occurs

as a result of: meter misalignment, improper installation, over tightening, use of non-recommended chemicals, use of

non-recommended pipe dopes or adhesives, excessive heat or pressure or allowing the meter to support the weight of

related piping.

!

Flowmeters are repaired at the factory only. Call or write the factory to receive a RA (return authorization) number.

Carefully pack the flowmeter to be returned, including a brief description of the problem, chemical used, and a description of the application. Note: Write the RA number on the outside of the shipping carton.

!

Prepay all shipping costs. The factory does not accept C.O.D. Shipments. Damage that occurs during shipping is the

responsibility of the sender.

Users of electrical and electronic equipment (EEE) with the WEEE marking per Annex IV of

the WEEE Directive must not dispose of end of life EEE as unsorted municipal waste, but

use the collection framework available to them for the return, recycle, recovery of WEEE

and minimize any potential effects of EEE on the environment and human health due to the

presence of hazardous substances. The WEEE marking applies only to countries within the

European Union (EU) and Norway. Appliances are labeled in accordance with European

Directive 2002/96/EC.

P.N. 80000-390 Rev 4/09/2009

Contact your local waste recovery agency for a Designated Collection Facility in your area.

Loading...

Loading...