Page 1

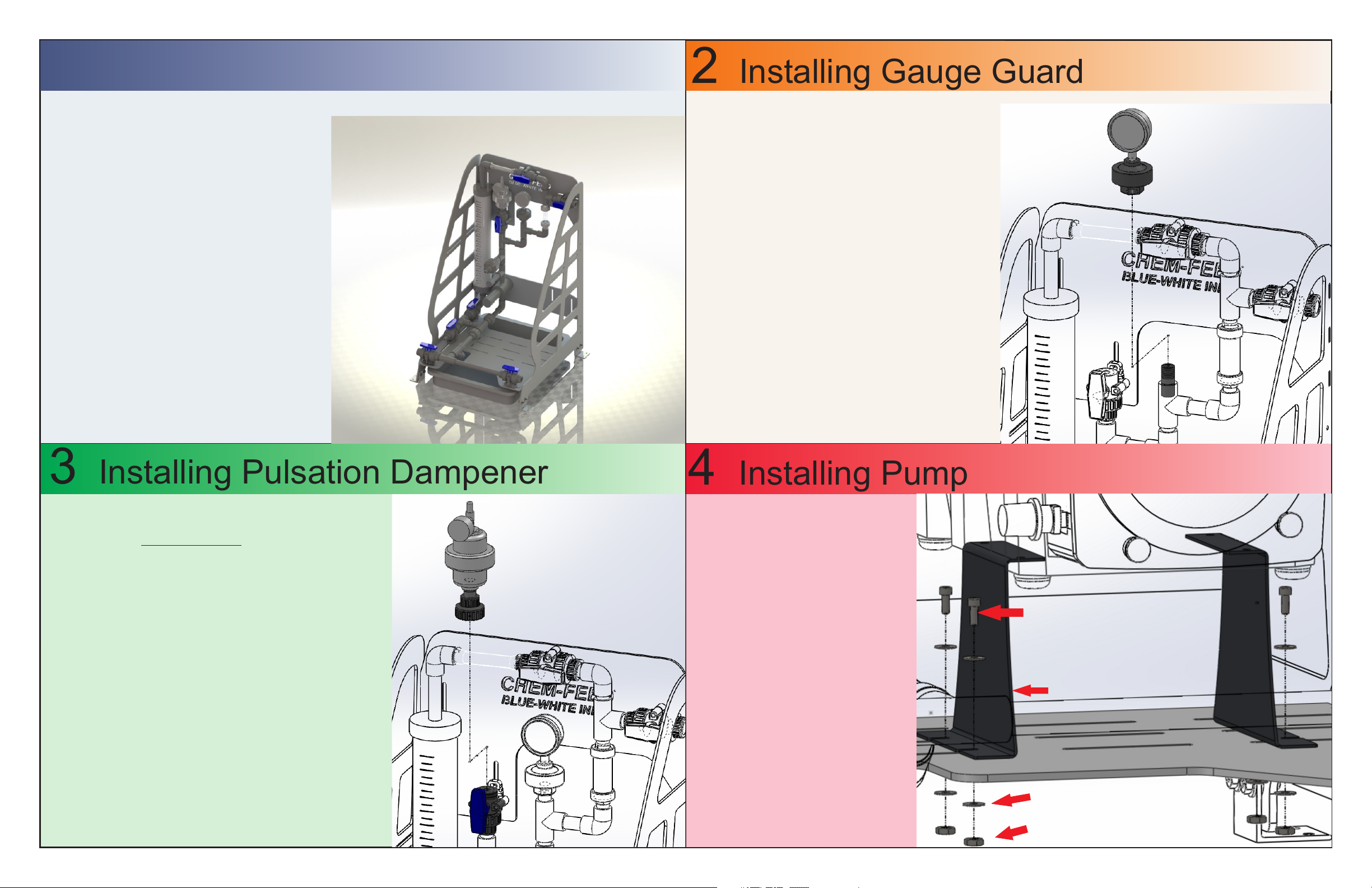

1 Location

Ÿ Choose an area located near chemical

supply tank, chemical injection point,

and electrical supply

Ÿ Mount Pump to the skid using enclosed

mounting hardware

2 Installing Gauge Guard

Ÿ Before installing gauge guard, PTFE (or

similar) thread tape should be used on the

male NPT to assure a seal.

Ÿ DO NOT over tighten or use pipe wrenches

on plastic pipe components

3 Installing Pulsation Dampener

Optional Item

Ÿ Remove all pressure from skid system

prior to dampener installation.

Ÿ Install dampener before charging or

pressurizing.

Ÿ DO NOT start system without first

charging or pressuring dampener.

Ÿ Always wear safety glasses and other

appropriate safety equipment when

installing, charging or repairing

dampener.

4 Installing Pump

Ÿ Mount pump to skid using

enclosed hardware.

Socket Head

Screw, SS

#10-32 - .5”

(Qty: 4 per pump)

Brackets

SS (Qty: 4)

Washer, SS (Qty: 8)

Hex Nut, SS (Qty: 4)

80000-470 Rev. 12/20/2011

Page 2

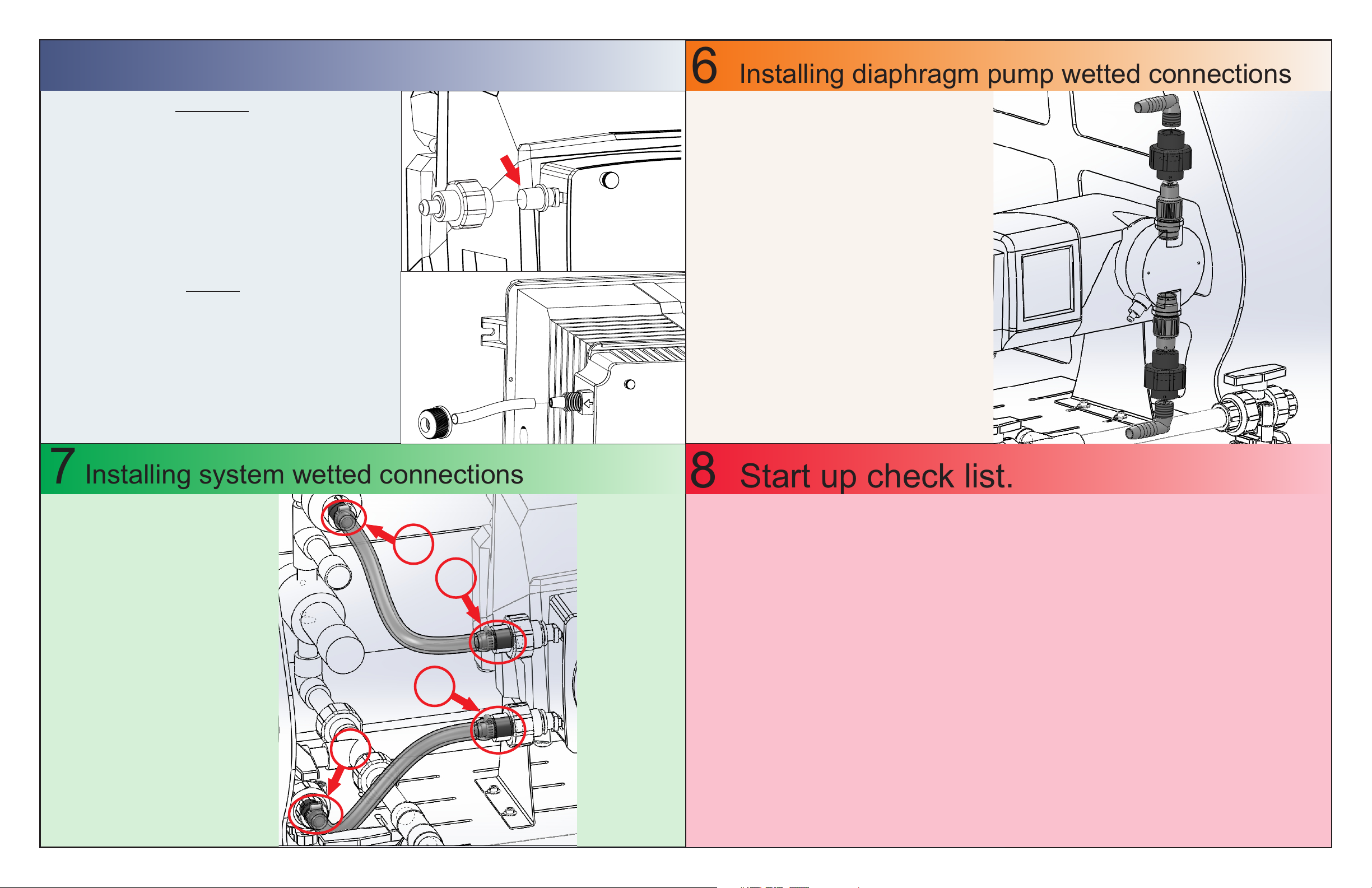

5 Installing pump wetted end connections

ProSeries

PTFE thread tape should be used on the

Ÿ

male NPT to assure a seal before the union is

installed.

Ÿ Screw Spears unions to the inlet and outlet of

the pump.

A-100N

Ÿ Remove the tube nut. Push the opaque outlet

(discharge) tubing onto the compression barb

of the fitting. Use the tube nut to secure the

tube. Hand tighten only.

½” Male

NPT

½” Male NPT

Fitting

1/4” Male

1/4” ID Tube

NPT

Compression

Fitting

6 Installing diaphragm pump wetted connections

Ÿ Attach in spears ½” NPT unions onto

the inlet and outlet fittings of the pump.

Ÿ Attach the hose barb adapters as

shown

7 Installing system wetted connections

1

2

Ÿ Connect tubing and clamps to

the pump system as shown.

Ÿ Tighten each clamp at each

location shown with a flat head

screwdriver to assure a seal

4

3

8 Start up check list.

Ÿ

Set PRV (Pressure Relief Valve) to desired cracking pressure for your system. Refer to the

included PRV instruction manual.

Ÿ Make sure all connections are tight to ensure that the pump will prime.

Ÿ Check all ball valve positions to ensure chemical will flow through properly.

Ÿ Proper eye and skin protection must be worn when installing and servicing pump.

Loading...

Loading...