Page 1

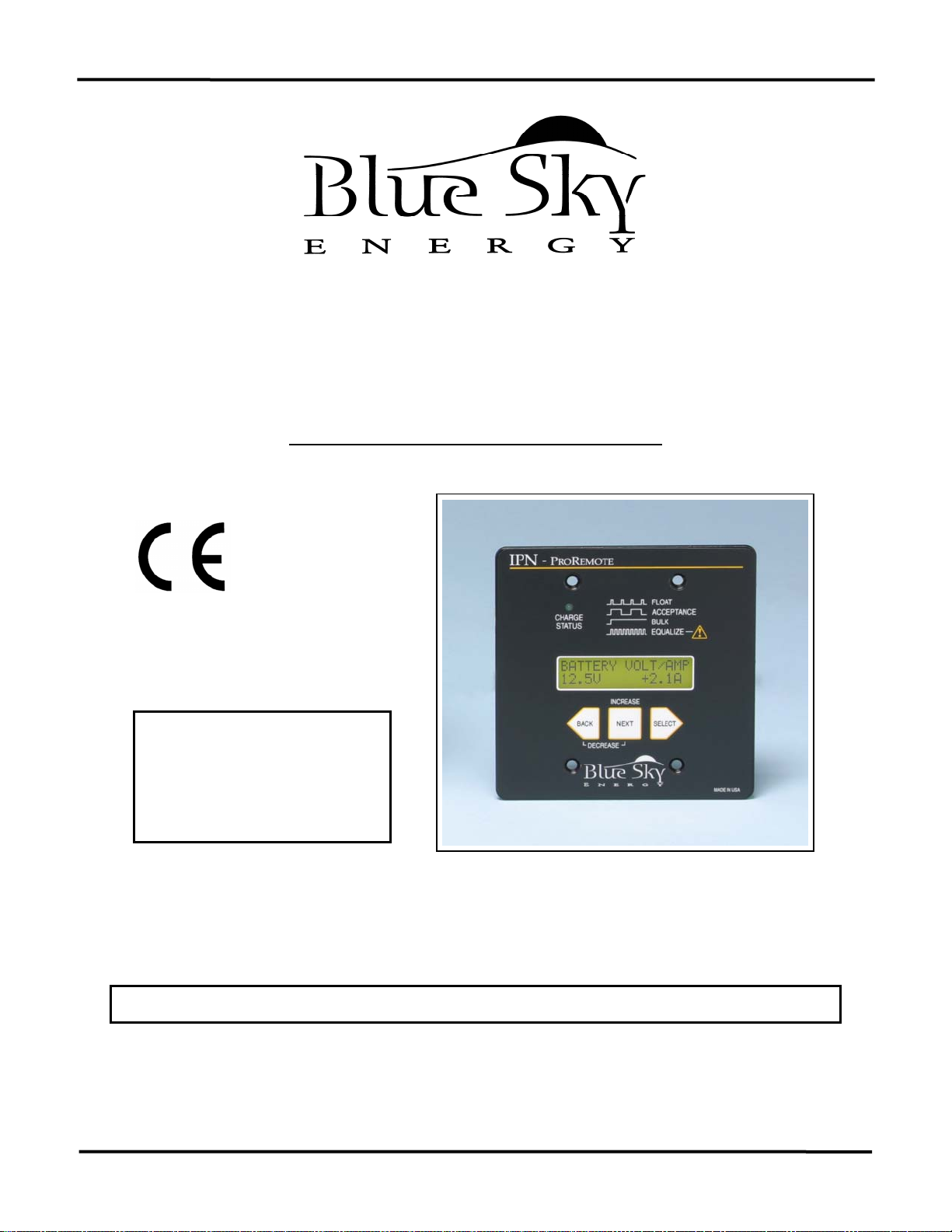

IPN-ProRemote

IPN™ network compatible charge controller and battery system monitor

INSTALLATION AND OPERATION MANUAL

CONFORMS TO

EN 61326-1:2006

EN 60335-1:2002 + A11:2004 + A1:2004

EN 60335-2-29:2004

This device complies with part 15 of the FCC

rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful

interference, and 2) This device must accept any

interference received, including interference that

may cause undesired operations.

THIS MANUAL INCLUDES IMPORTANT SAFETY INSTRUCTIONS FOR MODELS - IPNPRO, IPNPRO-S

SAVE THESE INSTRUCTIONS

ESTE MANUAL INCLUYE INSTRUCCIONES DE SEGURIDAD IMPORTANTES PARA LOS MODELOS - IPNPRO, IPNPRO-S

CONSERVE ESTAS INSTRUCCIONES

CE MANUEL CONTIENT D’INSTRUCTIONS IMPORTANTES POUR LES MODELES - IPNPRO, IPNPRO-S

PRIERE DE SAUVEGARDER CES INSTRUCTIONS

DIESES HANDBUCH ENTHÄLT WICHTIGE HINWEISE FÜR DIE MODELLE - IPNPRO, IPNPRO-S

BITTE BEHALTEN SIE DIESE HINWEISE

© Blue Sky Energy, Inc. 2008 430-0019 E

Page 2

Blue Sky Energy – IPN-ProRemote

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS................................................................................................................................ 2

PRODUCT DESCRIPTION...................................................................................................................................................... 2

Part Numbers and Options..................................................................................................................................... 2

OPERATION............................................................................................................................................................................ 3

Using The Function Keys ....................................................................................................................................... 3

NEXT.............................................................................................................................................. 3

BACK ............................................................................................................................................. 3

Using BACK & NEXT To Increase Or Decrease Settings.............................................................. 3

SELECT ......................................................................................................................................... 3

LCD Display and Backlight..................................................................................................................................... 4

Charge Status Indicator.......................................................................................................................................... 4

Remaining Battery Capacity................................................................................................................................... 4

How Remaining Battery Capacity Works ....................................................................................... 4

Charge Efficiency........................................................................................................................... 4

Accuracy ........................................................................................................................................ 5

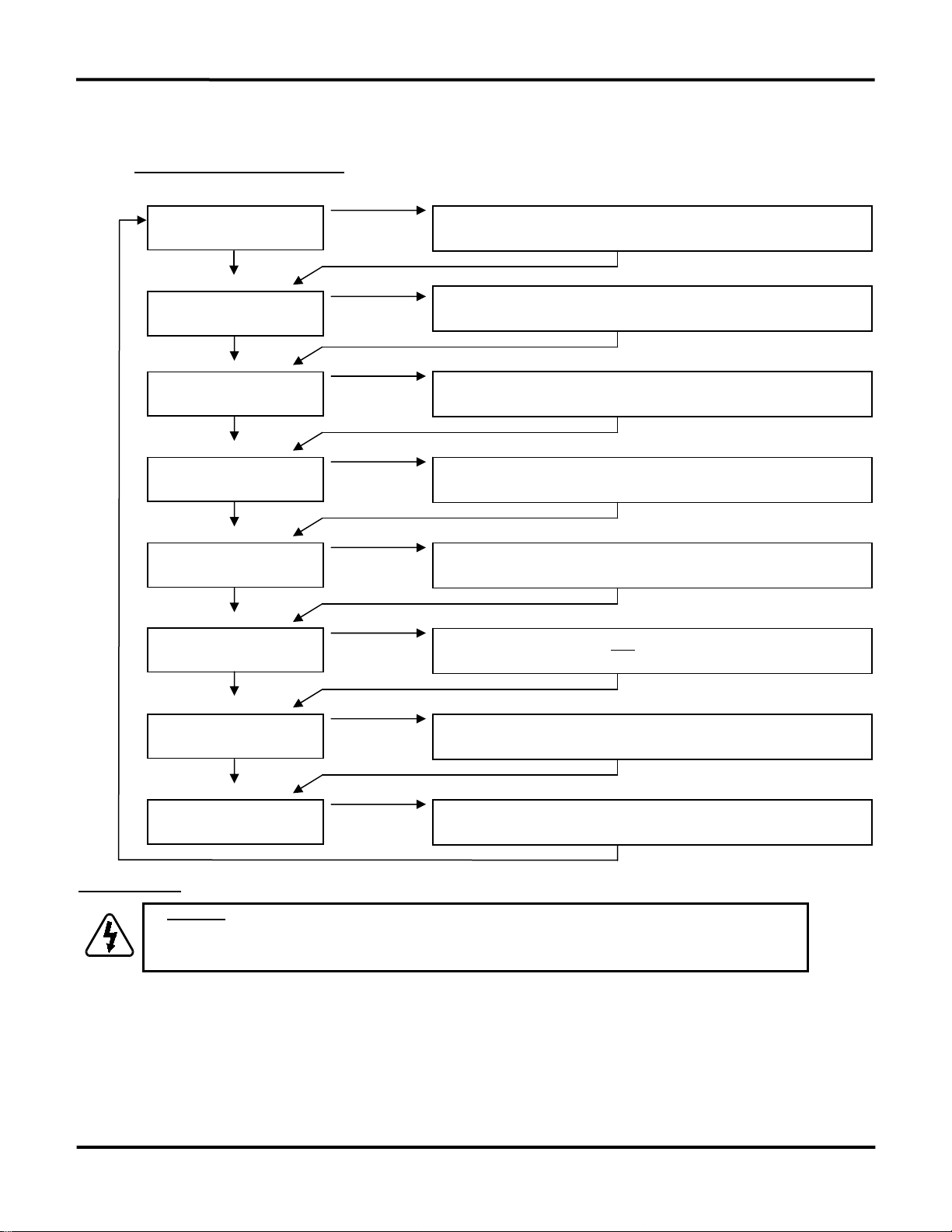

Menus..................................................................................................................................................................... 5

Using The Menus and Keys ................................................................................................................................... 9

Example – Setting Battery Amp-Hours ........................................................................................ 9

INSTALLATION....................................................................................................................................................................... 9

Electrostatic Handling Precautions......................................................................................................................... 9

IPN-ProRemote Setup............................................................................................................................................ 10

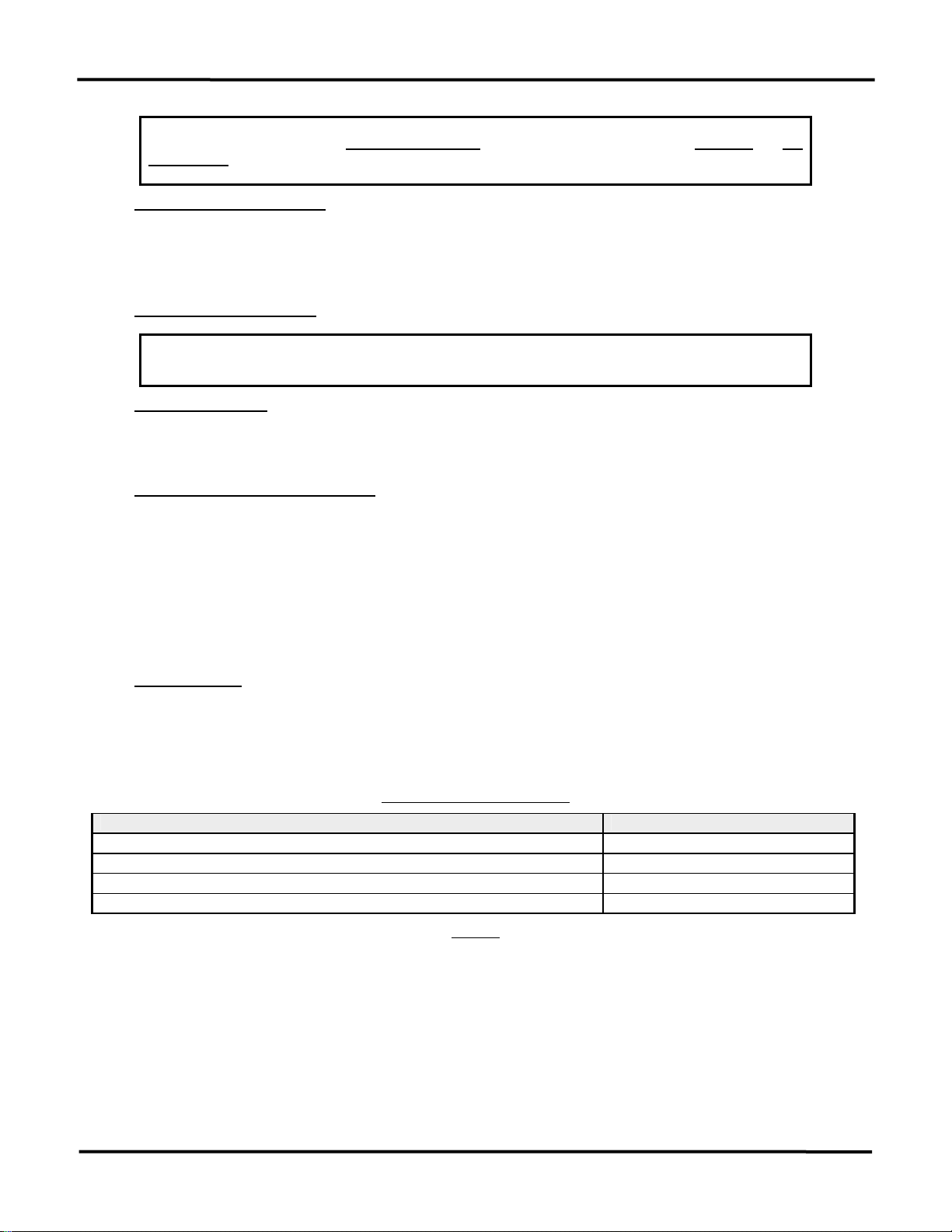

As Shipped Factory Default Settings .............................................................................................10

Restoring Factory Default Settings ................................................................................................10

Battery Amp-hour Rating................................................................................................................10

Charge Efficiency and Charge Efficiency Mode............................................................................. 10

Self Discharge Rate ....................................................................................................................... 10

Float Transition Current .................................................................................................................11

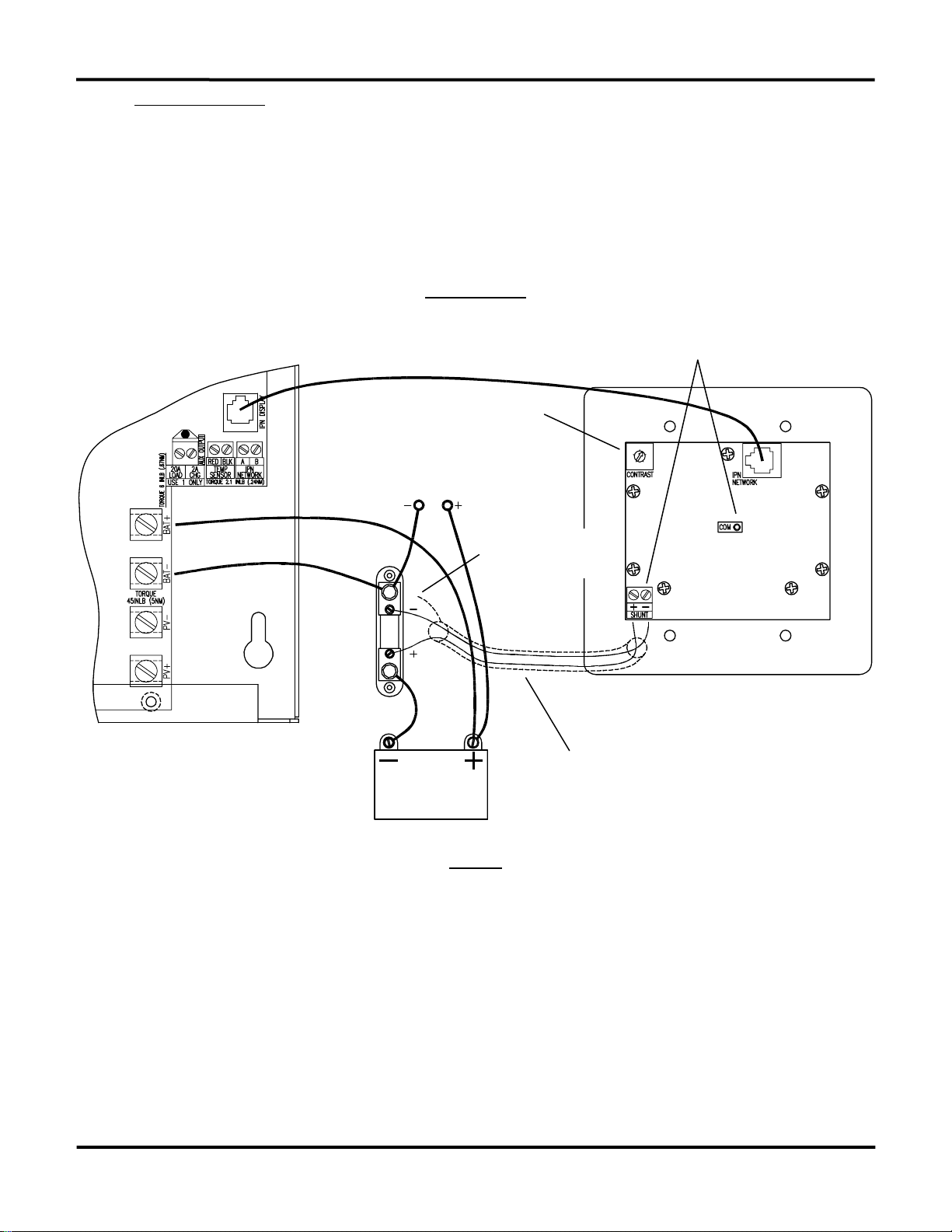

Current Shunt......................................................................................................................................................... 12

Current Shunt Signal Wiring...........................................................................................................12

Resetting Current Shunt Zero ........................................................................................................12

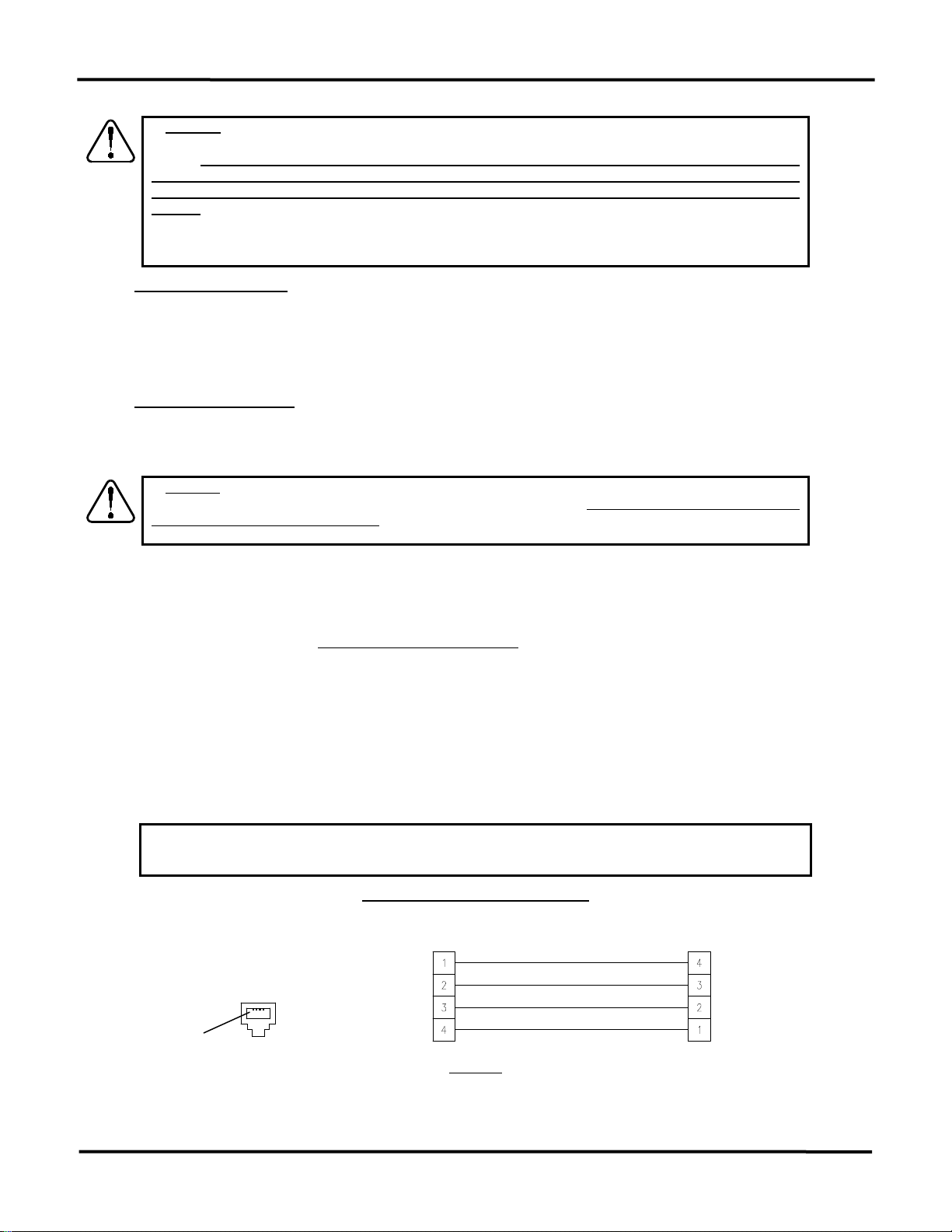

Charge Controller Connection................................................................................................................................12

Mounting................................................................................................................................................................. 13

TROUBLESHOOTING GUIDE................................................................................................................................................13

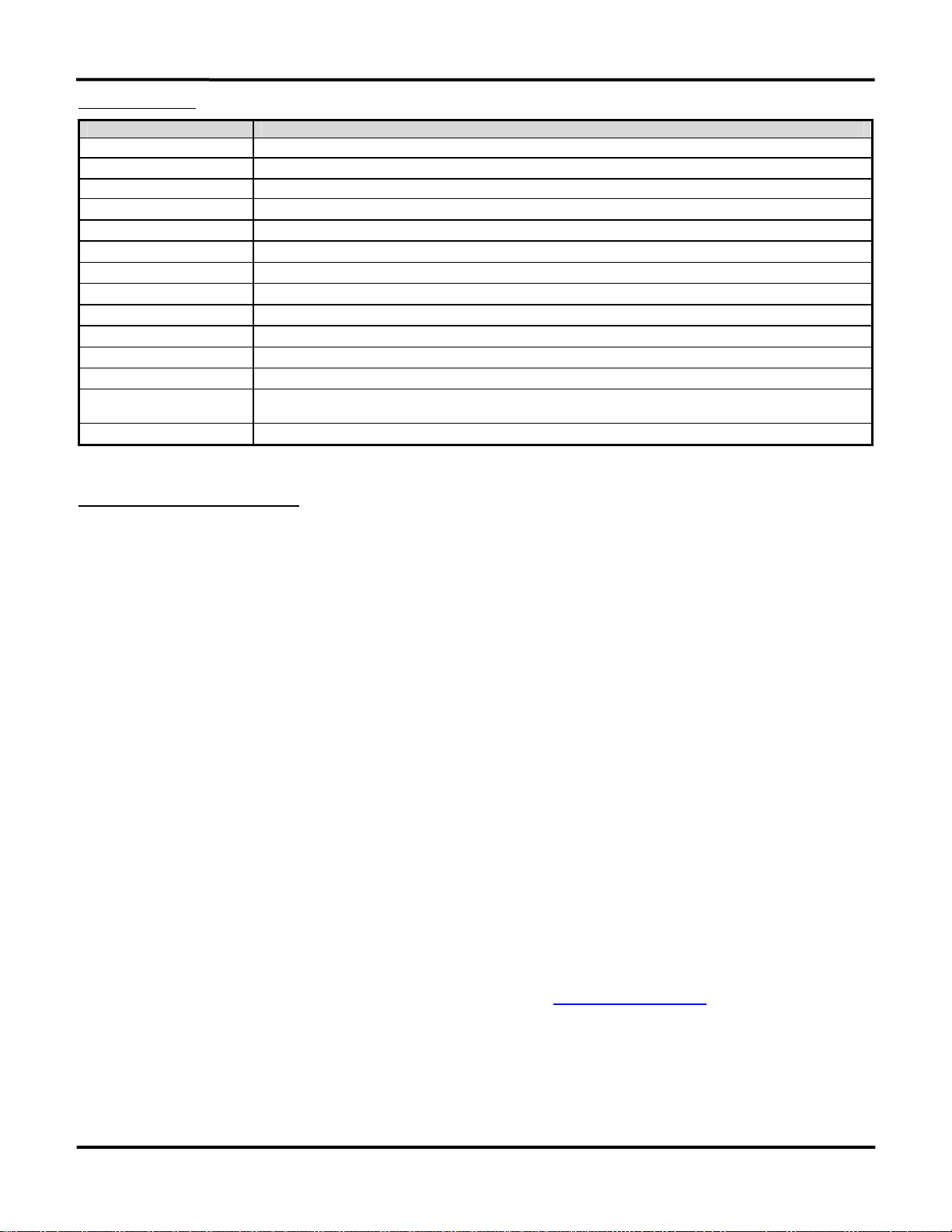

SPECIFICATIONS................................................................................................................................................................... 15

TWO YEAR LIMITED WARRANTY........................................................................................................................................ 15

TABLES AND FIGURES

Table 1 Charge Status Indicator ................................................................................................................. 4

Table 2 Self Discharge Rate .......................................................................................................................10

Table 3 Maximum Network/Power Cable Length........................................................................................ 13

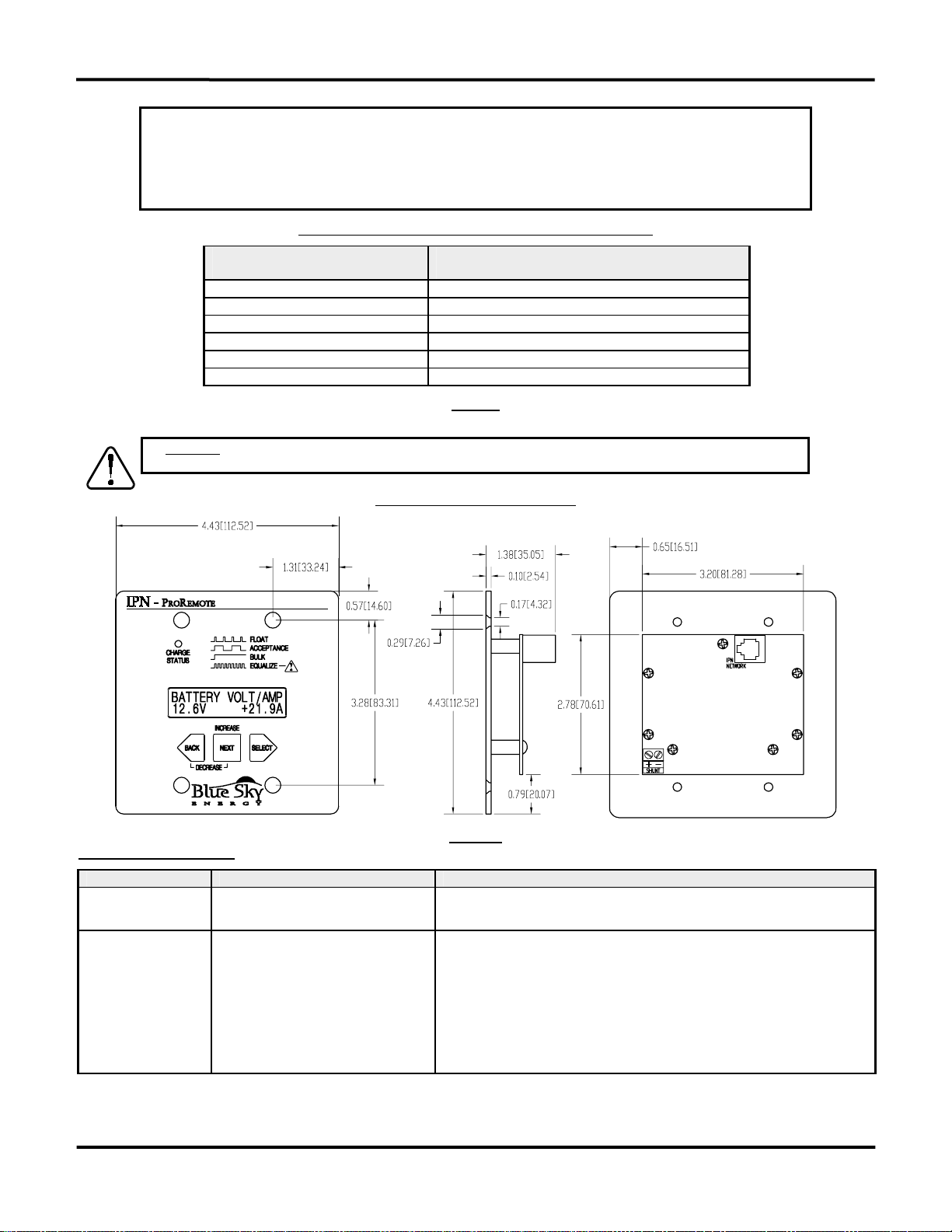

Figure 1 Display Panel ................................................................................................................................. 3

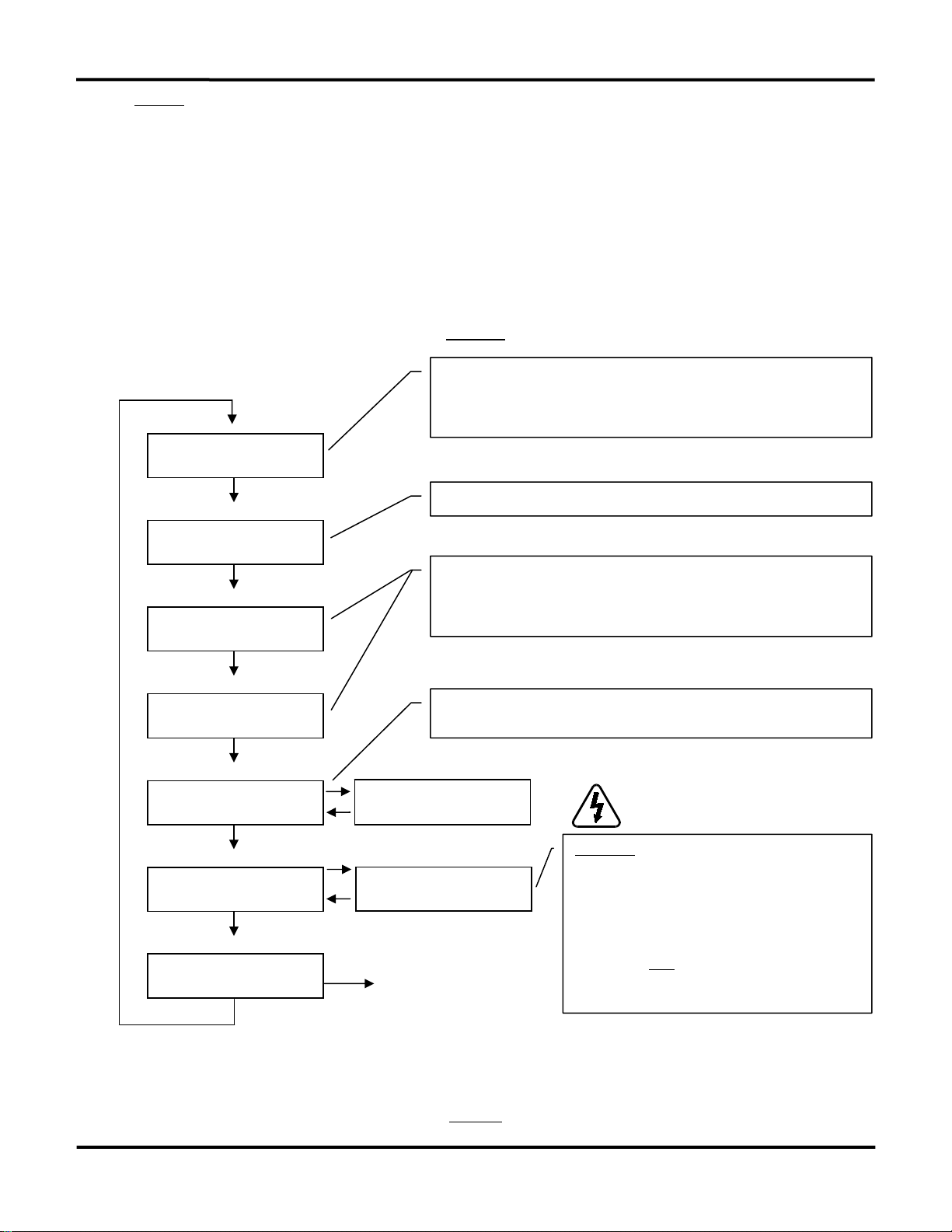

Figure 2 Top Menu....................................................................................................................................... 5

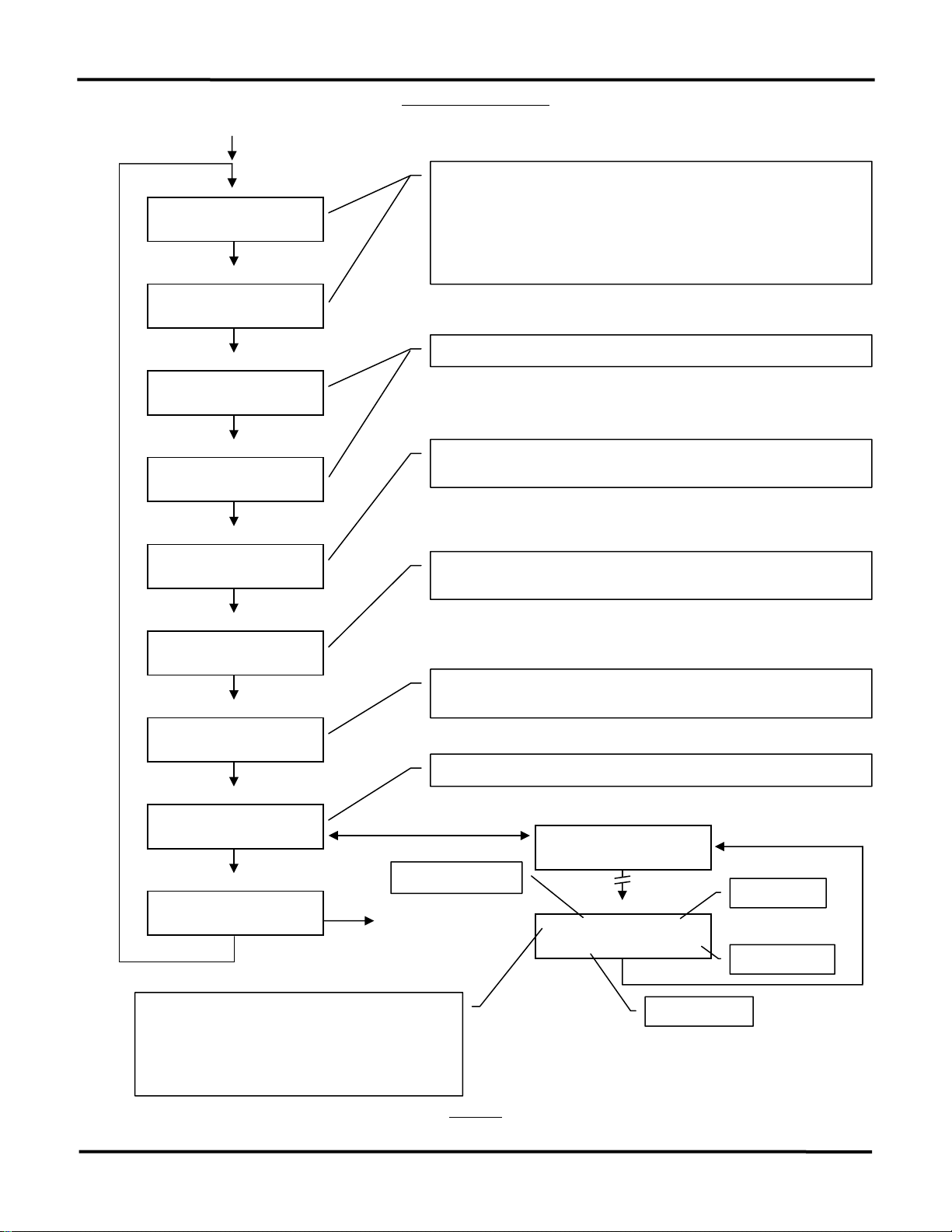

Figure 3 Advanced Display Menu ................................................................................................................ 6

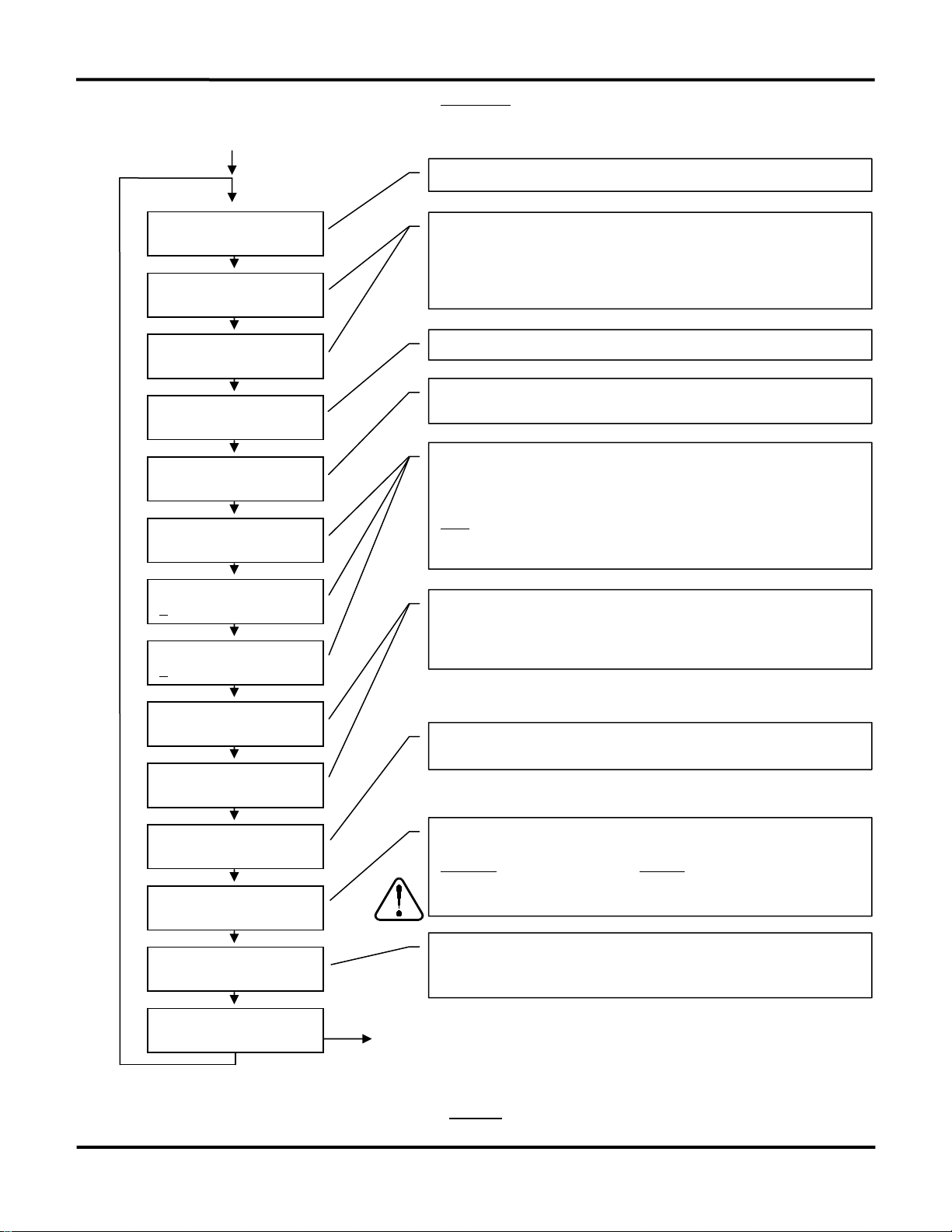

Figure 4 Setup Menu.................................................................................................................................... 7

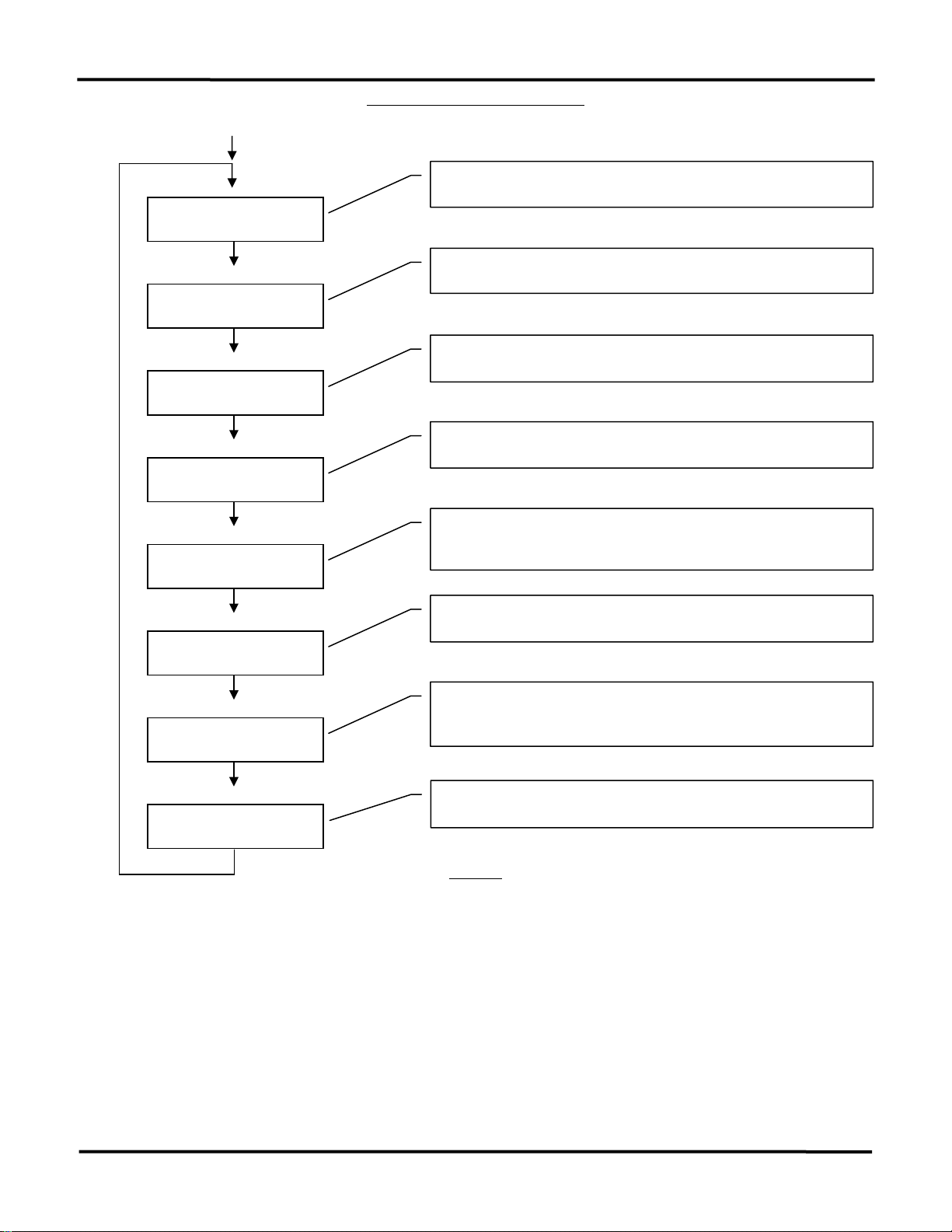

Figure 5 Battery Charge Parameters Menu ................................................................................................. 8

Figure 6 Wiring Diagram ..............................................................................................................................11

Figure 7 Network/Power Cable Schematic ..................................................................................................12

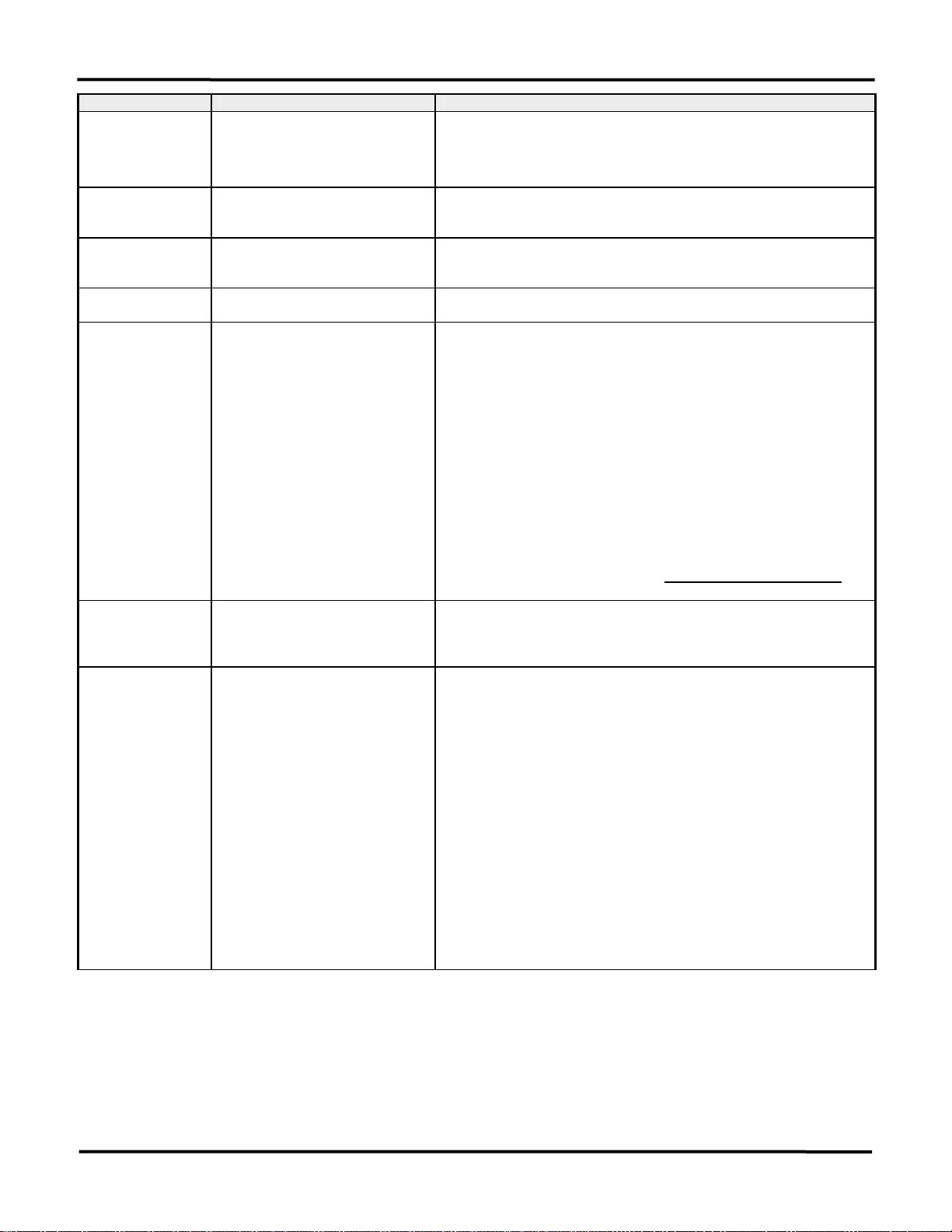

Figure 8 Detailed Dimensional Drawing....................................................................................................... 13

Versión en Español................................................................................................................................................................ 16

Version en Française.............................................................................................................................................................32

Deutsch Sprachversion.........................................................................................................................................................48

1

Page 3

Installation and Operation Manual

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important instructions for Models IPNPRO and IPNPRO-S

SAVE THESE INSTRUCTIONS

1. Refer installation and servicing to qualified service personnel. Incorrect installation or use may result in risk of electric shock or fire. No user serviceable parts

in this unit.

2. To reduce the risk of electric shock, fire or personal injury, the following symbols are placed throughout this manual to indicate dangerous conditions, or

important safety or operational instructions.

WARNING CAUTION IMPORTANT

Indicates dangerous conditions or electric

shock potential. Use extreme caution.

Indicates items critical to safe installation or

operation of the unit.

Follow these instructions closely for proper

operation of the unit

3. PERSONAL PRECAUTIONS

a) Working in the vicinity of lead-acid batteries is dangerous. Batteries produce explosive gasses during normal operation.

b) To reduce risk of battery explosion, follow these instructions and those published by battery manufacturer and manufacturer of any equipment you intend

to use in vicinity of battery.

c) Someone should be within range of your voice or close enough to come to your aid when you work near a lead-acid battery.

d) Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing or eyes.

e) Wear complete eye protection and clothing protection. Avoid touching eyes while working near battery.

f) If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters eye, immediately flood eye with running cold water for at

least 10 minutes and get medical attention immediately.

g) NEVER SMOKE or allow a spark or flame in vicinity of battery.

h) Be extra cautious to reduce risk of dropping metal tool onto battery. It might spark or short circuit battery or other electrical part that may cause explosion.

i) Remove personal metal items such as rings, bracelets and watches when working with a lead-acid battery. A lead-acid battery can produce a short circuit

current high enough to weld a ring or the like to metal, causing a severe burn.

j) Remove all sources of power, photovoltaic and battery before servicing or installing.

4. DISPLAY LOCATION & INSTALLATION

a) This unit employs components that tend to produce arcs or sparks. NEVER install in battery compartment or in the presence of explosive gases.

b) This unit must be installed and wired in accordance with National Electrical Code, ANSI/NFPA 70.

c) Unit is not water tight. Do not expose to rain, snow or excessive moisture.

d) Insure all terminating connections are clean and tight.

e) This unit is designed to be used with Integrated Power Net™ (IPN™) compatible charge controllers. Do not plug into anything other than an IPN

PRODUCT DESCRIPTION

compatible communications port.

The full featured IPN-ProRemote incorporates a multi-line backlit LCD display and three function keys to provide enhanced setup and monitoring of Blue

Sky Energy’s Integrated Power Net™ (IPN™) compatible charge controllers. The IPN-ProRemote provides the ability to access additional charge controller setup

parameters and adjust setup parameters to wider ranges than with the accompanying charge controller alone. Both the individual status and combined total of up

to 8 charge controllers can be monitored. The IPN-ProRemote also provides complete battery system monitoring. It displays net battery current and battery amphours from full by measuring the charge and discharge current from all charging sources and loads. Some of the many displays include; battery voltage and

current, PV voltage and current, PV charge amp-hours, and a highly accurate “fuel gage” type battery capacity indicator.

PART NUMBERS AND OPTIONS

• IPNPRO.........................................IPN-ProRemote, full featured IPN charge control and battery system monitor w/25 foot’ cable

• IPNPRO-S .....................................IPN-ProRemote with required 500A/50mV current shunt

• CS-500...........................................500V/50m millivolt current shunt

2

Page 4

Blue Sky Energy – IPN-ProRemote

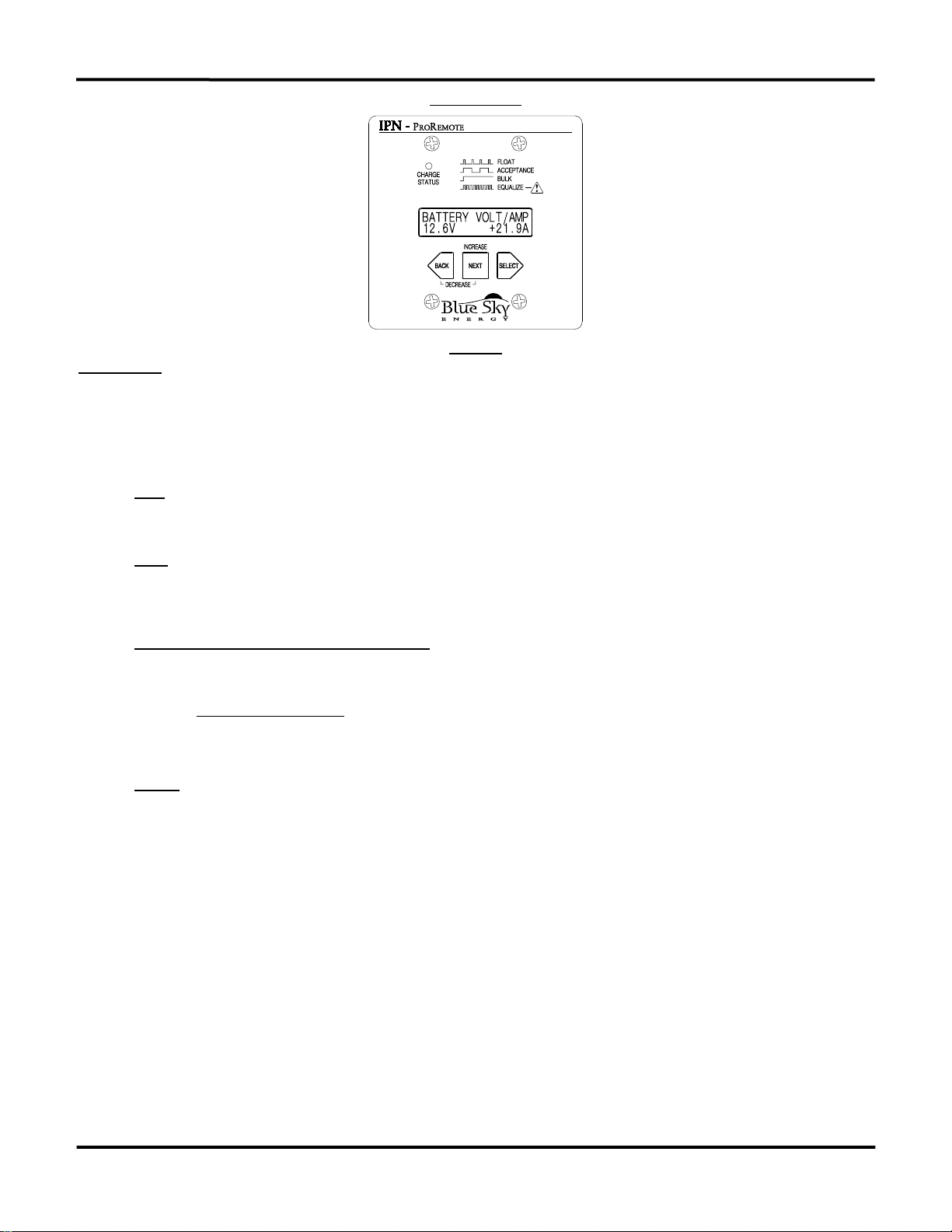

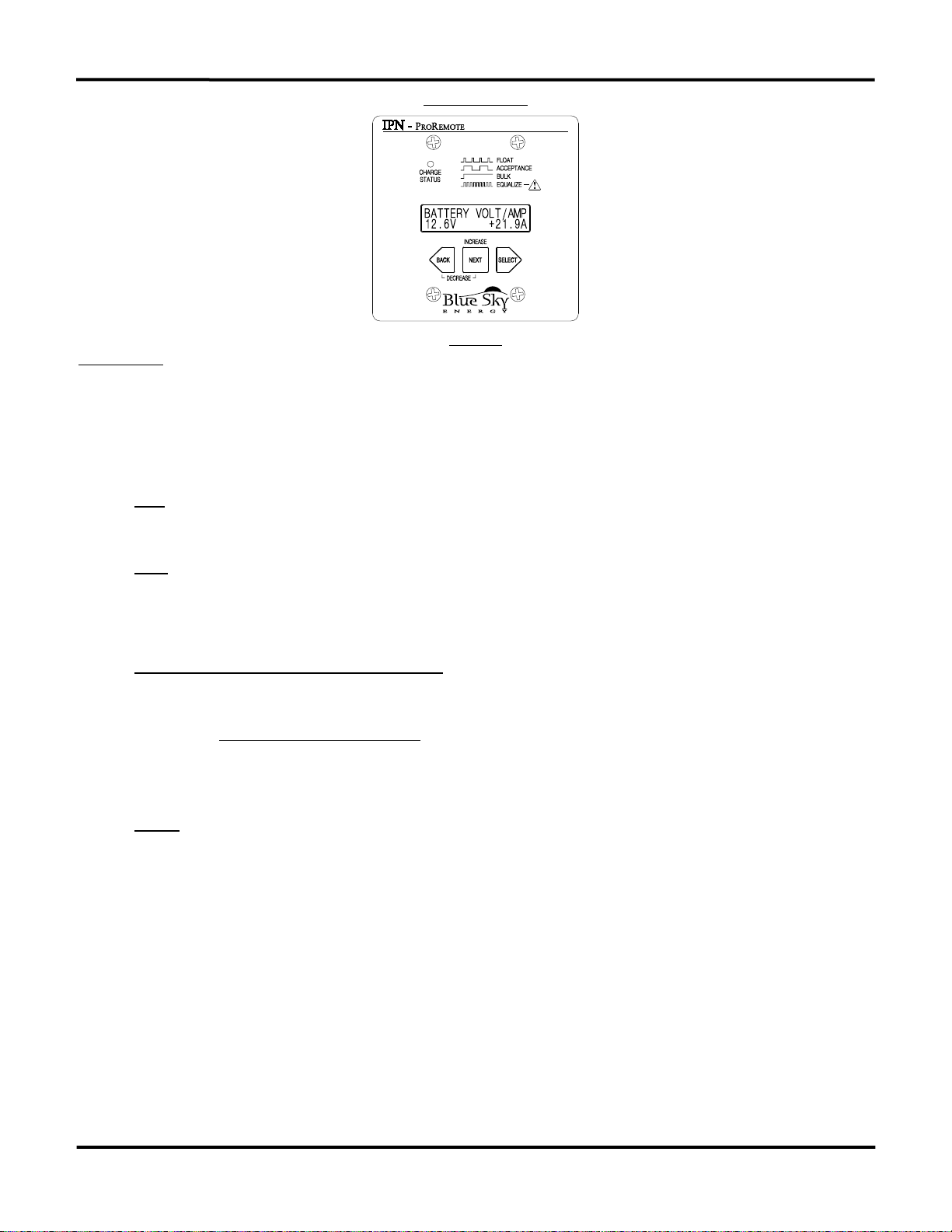

DISPLAY PANEL

FIGURE 1

OPERATION

All IPN-ProRemote operations and displays are controlled with the three function keys, BACK, NEXT and SELECT. Information typically of interest to the

casual user such as battery voltage, net battery current and remaining battery capacity are available in the Top menu. More technically inclined users may

want to see additional information in the Advanced Display menu, whereas installers may need to access the Setup or Battery Charge Parameters menus.

See Figures 2, 3, 4 and 5 for a complete description of each display screen.

USING THE FUNCTION KEYS

NEXT

The NEXT key is used primarily to scroll through menus. Each press of NEXT advances the display to the next screen in that menu. One more press

once you reach the bottom of a menu returns you to the top of that menu.

BACK

The BACK key is used primarily to back out of functions, setting screens, or advanced menus, similar to the “escape” key on a computer. Each press

of BACK backs you out of an advanced menu, function or setting screen without performing the function or changing the setting. Pressing in the BACK Top

menu toggles between the two most commonly used screens, Battery Volt/Amp and Remaining Battery Capacity.

Using BACK & NEXT to Increase Or Decrease Settings

All settings are changed in a parameter setting screen where the word “SETTING” flashes in the display. Pressing NEXT while in a parameter setting

screen causes the parameter to go to the next value or increases a numeric setting.

Pressing BACK while holding NEXT pressed in a parameter setting screen decreases numeric settings. If BACK is pressed without holding NEXT

pressed, BACK will perform it’s normal function and exit the parameter setting screen. To decrease a setting, press and hold NEXT, then additionally press

and hold BACK. The number or setting will decrease while BACK and NEXT are pressed. When the you have passed the desired setting going down,

release BACK first and then release NEXT. Then use NEXT to increase the setting to the desired value.

SELECT

The SELECT key takes action based on the indicator in the lower right of the display, which may show SEL►, SET►, or CLR► (i.e., Select, Set or

Clear). To minimize the possibility of taking unintended action, SELECT does not act immediately. You must press and hold the SELECT for 4 seconds

before the action is taken.

• SEL► is used to select a next level menu, or enter a parameter setting screen.

• SET► is shown in parameter setting screens where the word “SETTING” flashes in the display. Once the parameter is raised or lowered to the

desired value in a parameter setting screen, pressing SET► stores the new value into memory and returns to the previous screen. SET► is also

shown in the Restore Default Settings and Reset Current Shunt Zero screens where SET► directly executes these functions following the normal

4 second delay.

• CLR► is used to clear values in stored data screens such as Min or Max Battery Voltage, Total Charge Amp-hours, etc. It will also appear in the

Equalize Enabled screen and will manually cancel the present equalize cycle.

3

Page 5

Installation and Operation Manual

LCD DISPLAY AND BACKLIGHT

The Liquid Crystal Display (LCD) may be backlit for improved readability. Switching backlight ON increases IPN-ProRemote power consumption from

roughly 0.25W to 1.0W. Backlight can be set for ON, OFF or AUTO from the Advanced Setup menu. The default setting of AUTO will cause backlight to

remain ON for one minute following the last key press. When backlight has turned OFF in AUTO, the first press of any key turns backlight ON only without

performing that key’s normal function. The keys perform their normal function once backlight is ON.

CHARGE STATUS INDICATOR

An LED charge status indicator is provided on the face of the unit. The charge status indicator will be OFF when the charge controller is not charging, and

will be ON solid or blinking when the battery is being charged.

CHARGE STATUS INDICATOR CHARGE MODE

OFF CHARGE OFF

CONTINUOUSLY ON BULK

BLINKING • 1 SEC ON / 1 SEC OFF

BLINKING • 0.2 SEC ON / 1 SEC OFF

RAPID BLINKING • 0.2 SEC ON / 0.2 SEC OFF

REMAINING BATTERY CAPACITY

The IPN-ProRemote provides a high accuracy indication of remaining battery capacity based on amp-hour counting. The resulting remaining battery

capacity computation is displayed as both Percent Remaining and as a Bar Graph. Note that the amp-hours from full counter and the associated remaining

battery capacity indication will show dashes (

hour counting.

How Remaining Battery Capacity Works

– – – ) until the accompanying charge controller fully charges the battery which is required to initialize amp-

A battery stores electrical charge in units referred to as “amp-hours” (AH). An amp-hour is the product of current (in amps) times time (in hours). 10

amp-hours could be consumed by a 10 amp load operating for 1 hour, a 0.2 amp load for 50 hours, or 100A load for

battery current as displayed in the Top Menu Battery Volt/Amp screen to compute amp-hours which is displayed in the Top Menu Battery Amp-Hrs From Full

screen. As the battery is charged (positive current) or discharged (negative current) the IPN-ProRemote keeps a running total of how many battery amphours have been removed or restored. Discharge amp-hours are applied directly to the amp-hours from full counter causing amp-hours from full to increase.

Charge amp-hours cause the amp-hours from full counter to decrease, but are reduced by the Charge Efficiency Factor to account for the fact that batteries are not

100% efficient at receiving charge. Additionally, batteries loose charge on their own due to self discharge which is periodically computed and added to the amphours from full counter. Self discharge changes with battery temperature and will be corrected for temperature if the accompanying charge controller includes a

battery temperature sensor.

Counting amp-hours into and out of the battery and using charge efficiency and self discharge rate arrives at the amp-hours from full value displayed in the

Top Menu Battery Amp-Hrs From Full screen. This value is used with the battery’s published “20hr rate” amp-hour rating to compute remaining battery

capacity. If the battery was 220 amp-hours and the amp-hours from full counter value was at –110 amp-hours, remaining battery capacity would show 50%.

The battery amp-hour rating is specified at 25°C, but actual battery capacity changes with temperature. If the accompanying charge controller includes a battery

temperature sensor, the IPN-ProRemote will correct available battery amp-hours based on battery temperature. Cooler batteries have reduced capacity, and if the

battery was at 0°C, then actual battery capacity is reduced to 79% of 220 amp-hours and remaining capacity would show 37%.

Charge Efficiency

Charge efficiency refers to how many amp-hours are absorbed by the battery compared to how many charge amp-hours are delivered. A charge efficiency

factor of 94% means that for each 100 amp-hours of charge delivered, the battery increases charge by 94 amp-hours. Charge efficiency is typically very high when

the battery is highly discharged, and becomes lower when the battery is near full charge.

The Charge Efficiency factor can be set to a Fixed number or can be set to automatically update based on past battery behavior. Most systems will

benefit from the Auto Adjust setting which is the factory default. In Auto Adjust, the IPN-ProRemote will compute actual charge efficiency if the battery was

discharged at least 10%, and the accompanying charge controller is what brought the battery back to full charge. The Charge Efficiency factor update rate is

filtered so that it takes approximately 5 charge/discharge cycles to completely update the Charge Efficiency factor.

CHARGE STATUS INDICATOR

TABLE 1

ACCEPTANCE

FLOAT

EQUALIZE

1

/10 hour. The IPN-ProRemote uses net

4

Page 6

Blue Sky Energy – IPN-ProRemote

███████

►

►

►

MENUS

net battery current and remaining battery capacity are present in the Top menu. More technical users may access additional menus where advanced displays and

setup capability reside. Refer to menu Figures 2, 3, 4 and 5.

Accuracy

Remaining Battery Capacity will tend to be better if;

• The charge controller delivers at least 3 amps per 100 amp-hours of battery capacity.

• The charge controller is what normally brings the battery back to full charge.

• The battery is fully charged by the charge controller often to minimize error build up resulting from the non-ideal characteristics of batteries. The

more the battery is cycled without becoming fully charged, the greater the error buildup.

• Charge Efficiency Mode is set to AUTO ADJUST.

There are four menus; Top, Advanced Display, Setup, and Battery Charge Parameters. Displays typically accessed by most users such as battery voltage,

TOP MENU

Shows battery voltage and “net” battery current. Net battery current is the

algebraic sum of all chargers and loads connected to the battery. A positive value

is charging, whereas a negative value is discharging. +30 amps of charge current

and –5 amps of load current will display a net current of +25.0amps.

BATTERY VOLT/AMP

12.6V +25.0A

INPUT CHG OUT

+19.8A +25.8A

BATTERY CAPACITY

BATTERY AMP-HRS

FROM FULL -150

AUX BAT AUX CHG

12.0V -ON-

EQUALIZE NOW AT

AT 15.4V? SEL

ENTER ADVANCED

DSPLY/SETUP SEL

70%

LOAD CONTROL

OUTPUT -ON-

EQLZ 120min LEFT

AT 15.4V CLR

Sum of input and output current for all charge controllers on the IPN network.

Total battery amp-hours from full. Amp-hours from full are used to compute

remaining battery capacity which is shown as Percent Remaining and as a Bar

Graph. Dashes (

– – – ) are shown until the battery is fully charged by the

accompanying charge controller and the 100% full charge point is established.

Shows either IPN Master auxiliary battery voltage and charge ON/OFF status, or

load control status depending on function selected in the charge controller.

WARNING: Not all batteries can be safely equalized.

Always follow battery manufacturers recommendations

pertaining to equalization. Selecting “Equalize Now”

starts the equalization cycle unless equalize is disabled

in the charge controller. Equalize continues until

equalize “time at voltage” time accumulator counts down

to zero minutes left, or equalize is manually canceled

with “CLR►”. Note

the voltage shown is the basic

equalize setpoint and does not include the effects of

temperature compensation.

To Advanced Display/Setup

menus if selected.

FIGURE 2

5

Page 7

Installation and Operation Manual

►

►

►

ADVANCED DISPLAY Menu

From Top menu

LAST FULL CHARGE

10 DAYS AGO

LAST EQUALIZE

22 DAYS AGO

MAX BAT VOLTS

15.4V CLR►

MIN BAT VOLTS

11.9V CLR►

TOTAL CHG AMP-HR

+1980AH CLR

LIFETIME BAT AH

-9876543AH CLR

BAT TEMPERATURE

25C 77F

VIEW CHARGE UNIT

STATUS SEL

ENTER SETUP

MENUS SEL►

To Setup menus

if selected.

Controller address #0 – 7. NEXT scrolls through each

controller status screen. BACK returns to Advanced Display

menu.

* Screen will be blank except for address if controller not

communicating on network.

Days since last full charge or equalize. The equalize day counter resets upon

commencing equalize.

Day counter accuracy is +1 / -0 days as day counter transitions occur following

each 24 hour period from when battery power was applied. Consider applying

battery power late in the evening to improve counter accuracy. Maximum range is

255 days which is also shown if days are unknown.

Captures minimum and maximum battery voltage since last cleared.

Captures total output amp-hours of all charge controllers on the IPN network since

last cleared.

Serves as battery “odometer” capturing total discharge amp-hours since last

cleared. Value saved to non-volatile memory once per day.

Shows present battery temperature if optional sensor installed on charge

controller.

Selects status display of controllers on IPN network.

0 +25C OUT 12.3A

IN 17.5V 12.0A

Internal temperature *

Output current *

7 +29C OUT 14.5A

IN 18.5V 15.0A

PV Input current *

PV Input voltage *

FIGURE 3

6

Page 8

Blue Sky Energy – IPN-ProRemote

►

►

►

►

►

►

►

SETUP Menu

From Advanced Display menu

SET BAT AMP-HRS

220AH SEL

SET CHG EFICENCY

94% SEL

SET CHGEFCY MODE

AUTO ADJUST SEL

SET SELF-DISCHG

12%/MONTH SEL►

SET MAXIMUM BAT

VOLTS 15.5V SEL►

SET AUX OUT MODE

BAT VOLTS SEL►

SET AUX OUT OFF

<

11.5V SEL►

SET AUX OUT ON

>

12.6V SEL

POST-DUSK LIGHTS

ON 2.5 HRS SEL►

PRE-DAWN LIGHTS

DISABLED SEL

SET BACK-LIGHT

AUTO SEL►

RESET CURRENT

SHUNT ZERO SET

RESTORE DEFAULT

SETINGS SET►

SET BAT CHARGE

PARAMETERS SEL

To Battery Charge Parameters menu

if selected.

Total battery amp-hours at 25°C, 20hr rate.

With charge efficiency set to 94%, battery is expected to retain 94 amp-hours for

each 100 amp-hours of charge. With charge efficiency mode set to FIXED, charge

efficiency value remains as set. If set to AUTO ADJUST it automatically adjusts

based on actual charge efficiency to continuously improve remaining battery

capacity accuracy.

Self discharge rate in percent per month at 25°C.

Maximum charge voltage setpoint limit regardless of other settings or temperature

compensation.

Sets IPN Master charge controller “load control” mode to be based on battery

VOLTS or battery AMP-HOURS. Setting units (V or AH) in setting screens change

based on present mode setting.

--------------

Be certain to set voltage settings even if using amp-hour control as the

Note:

charge controller will default to voltage control if battery amp-hours are

unavailable.

Enables, disables and sets ON time for lighting control mode. Lighting control

mode is disabled if BOTH Post-Dusk and Pre-Dawn timers are set to DISABLED

(<0.5 hrs). Lighting control mode is enabled if EITHER Post-Dusk or Pre-Dawn

timers are set to a time value. See charge controller operators manual.

Sets display backlight to ON, OFF or AUTO. In AUTO, backlight remains ON for

one minute following last key press.

Corrects for “zero offset” in net battery current display.

--------------

CAUTION:

inaccurate battery current & amp-hour readings will result. See Resetting Current

Shunt Zero section of manual before proceeding!

Be certain shunt signal is a true zero before performing this function or

Restores all factory default settings in the IPN-ProRemote and charge controllers,

except for auxiliary output settings in slave controllers. Only the Master’s auxiliary

output settings are available over the IPN network and are restored.

FIGURE 4

7

Page 9

Installation and Operation Manual

►

BATTERY CHARGE PARAMETERS Menu

From Setup menu

SET ACCEPT CHG

14.4V SEL►

SET FLOAT CHG

13.4V SEL

SET EQUALIZ CHG

15.2V SEL►

SET EQUALIZ TIME

2.0HRS SEL►

SET AUTO EQUALIZ

30DAYS SEL►

SET T-COMP SLOPE

-5.00mV/C/C SEL►

SET FLOAT CURENT

1.5A/100AH SEL►

SET ACCEPT TIME

2.0HRS SEL►

Sets Acceptance charge voltage setpoint.

Range 10.0 to 80.0V.

Sets Float charge voltage setpoint.

Range 10.0 to 80.0V.

Sets Equalize voltage setpoint.

Range 10.0 to 80.0V.

Sets Equalize time.

Range 0.5 to 10 hours.

Sets days between automatic Equalize. Range is 10 to 400 days. Fully MANUAL

equalization is selected by a setting of less than 10 days.

Sets charge voltage temperature compensation factor. Range is -0.00 to -

8.00mV/°C/cell.

Sets Float Transition Current. Range 0.1 to 10.0A per 100 AH. A setting of 0 (zero)

disables function such that full charge is based on acceptance charge time only.

See charge controller operators manual.

Sets Acceptance charge time.

Range 0.0 to 10.0 hours.

FIGURE 5

8

Page 10

Blue Sky Energy – IPN-ProRemote

►

►

►

►

►

USING THE MENUS AND KEYS

Moving through the menus, functions and changing settings is consistent throughout all functions and screens. The following example illustrates typical

operation.

Screen shown Action taken to move to next screen or step

INSTALLATION

ELECTROSTATIC HANDLING PRECAUTIONS

All electronic circuits may be damaged by static electricity. To minimize the likelihood of electrostatic damage, discharge yourself by touching a water faucet

or other electrical ground prior to handling the unit and avoid touching components on the circuit boards. The risk of electrostatic damage is highest when relative

humidity is below 40%.

Example – Setting Battery Amp-Hours (to 440 amp-hours in this example)

BATTERY VOLT/AMP

12.6V +25.0A

ENTER ADVANCED

DSPLY/SETUP SEL

LAST FULL CHARGE

10 DAYS AGO

ENTER SETUP

MENUS SEL

SET BAT AMP-HRS

220AH SEL

SETTING AMP-HRS

220AH SET►

SETTING AMP-HRS

440AH SET

SET BAT AMP-HRS

440AH SEL

¾ WARNING: Read, understand and follow the Important Safety Instructions. Install in accordance with National Electrical Code,

Press NEXT 6 times to move down to Advanced Display/Setup select screen.

Press SELECT for 4 seconds to move to the top of the Advanced Display menu.

Press NEXT 8 times to move down to Enter Setup Menus select screen.

Press SELECT for 4 seconds to move to the top of the Setup Menu.

Press SELECT for 4 seconds to move to Battery Amp-Hours parameter setting

screen.

Select desired value with NEXT. Note the word “SETTING” flashes in all

parameter setting screens.

Press SELECT for 4 seconds to save new setting and move back to Battery AmpHours screen.

Press BACK 2 times to return to Top menu.

ANSI/NFPA 70. To reduce risk of electric shock, remove all sources of power before installing. Connections other than those shown

in Figures 6 & 7 void the limited warranty. Note that Figures 6 & 7 are not meant to show all wiring, circuit protection and safety

requirements for a photovoltaic electrical system.

9

Page 11

Installation and Operation Manual

IPN-ProRemote SETUP

¾ The IPN-ProRemote has various setup parameters all of which are preconfigured at the factory. Most installations require no

Discharge Rate. Factory default settings shown below reside in the IPN-ProRemote. All other settings shown in the Setup and

Battery Charge Parameters menus reside in the charge controller.

setup changes other than increasing Acceptance Charge Time

Factory defaults are configured for two or four (12V or 24V respectively) deep cycle lead-antimony 6V GC2 golf cart batteries in series.

As Shipped Factory Default Settings

• Amp-hours .................................................. 220 amp-hours • Self Discharge Rate ................................................ 12%/month

• Charge Efficiency ....................................... 94% • LCD Backlight .......................................................... Auto

• Charge Efficiency Mode ............................ Auto Adjust

Restoring Factory Default Settings

¾ Factory defaults can be easily restored into the IPN-ProRemote and accompanying charge controllers using the Restore

Default Settings function in the Setup menu. All defaults are restored except for auxiliary output settings in slave charge

controllers.

Battery Amp-Hour Rating

The amp-hour setting is used by both the Remaining Battery Capacity function and Advanced Charge Control. The setting should be the total published

25°C 20hr rate amp-hour rating of the total battery bank. For systems with more than one battery, battery amp-hours add when batteries are placed in parallel.

When batteries are placed in series battery voltage adds and amp-hours do not.

Charge Efficiency & Charge Efficiency Mode

Charge Efficiency relates to how much charge is absorbed by the battery compared to charge delivered. With charge efficiency set to 94%, the battery is

expected to retain 94 amp-hours for each 100 amp-hours of charge delivered. Charge Efficiency Mode determines whether Charge Efficiency remains at a

fixed number or automatically updates based on actual battery behavior. The factory settings of 94% (Charge Efficiency) and AUTO ADJUST (Charge

Efficiency Mode) are typically suitable for most systems and do not require adjustment.

Systems which may benefit from a FIXED Charge Efficiency Mode are those with less than 2 amps of charge current per 100 amp-hours of battery

capacity, or where another charging source is what typically brings the battery back to full charge. For these systems a suitable Charge Efficiency value

needs to be determined experimentally. Try AUTO ADJUST first and see what charge efficiency the IPN-ProRemote computes over 5 –10 “normal”

charge/discharge cycles. You may then want to lock this value in place by setting Charge Efficiency Mode to FIXED. A perfect Charge Efficiency setting will

cause the Amp-hours From Full counter to just reach 0 (zero) when the charge controller switches to Float indicating full charge.

Self Discharge Rate

All batteries self discharge at some rate which varies greatly based on battery type and temperature. The Self Discharge Rate entered should be the

battery manufacturers 25°C value. In systems that cycle regularly, self discharge is typically a small contributor to total discharge compared to load current

and an accurate Self Discharge Rate value is not as important. In systems where load current is low, self discharge may be a large contributor to total

discharge and an accurate Self Discharge Rate is much more important. The Self Discharge Rate will be automatically corrected for temperature if the

accompanying charge controller includes a battery temperature sensor.

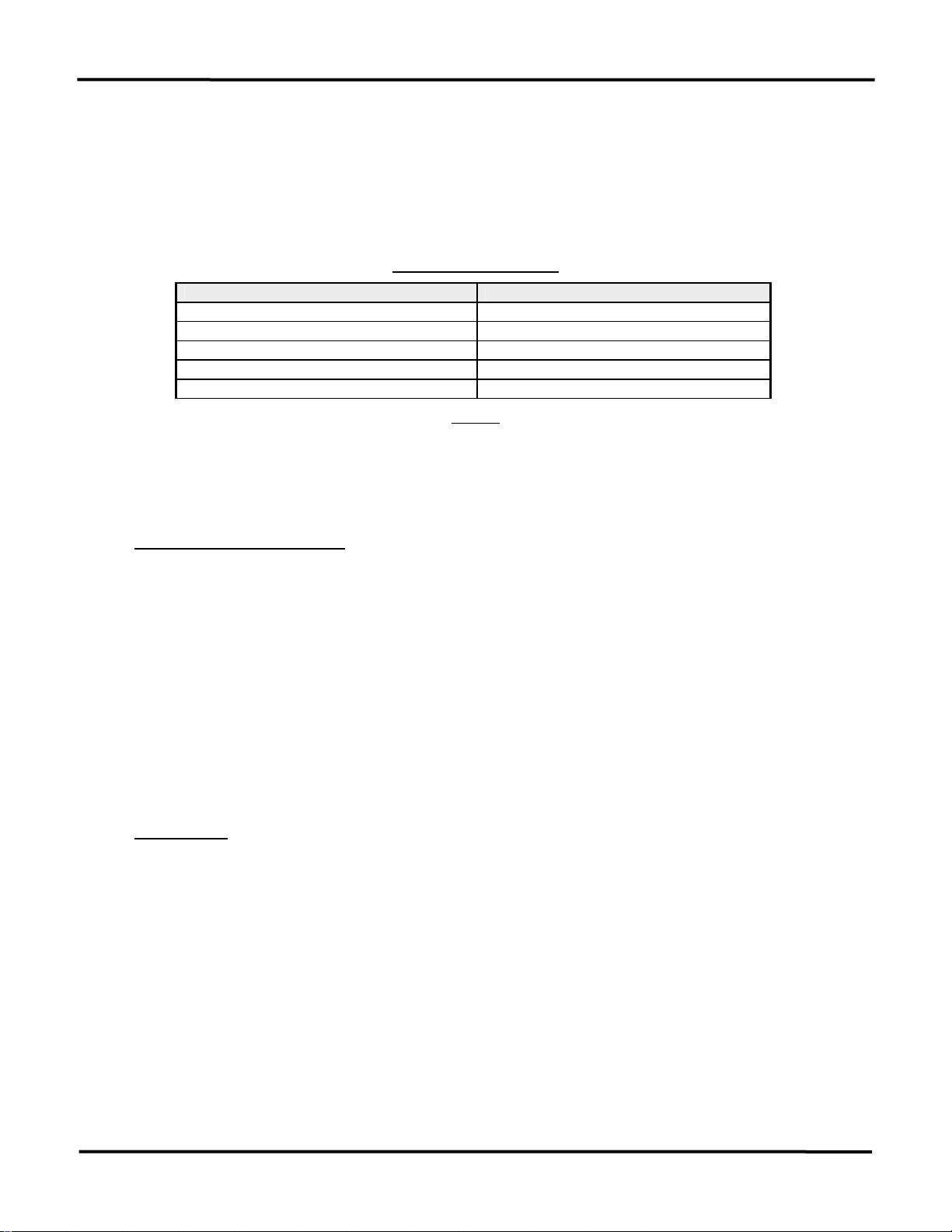

TYPICAL SELF DISCHARGE RATE

BATTERY CONSTRUCTION SELF DISCHARGE RATE

Vented Liquid Electrolyte • Lead-Antimony

Vented Liquid Electrolyte • Lead-Calcium

Gel • Lead-Calcium

AGM • Lead-Calcium

to 4 hours, and entering actual battery Amp-Hours and Self

12%/Month

5%/Month

3%/month

2%/month

TABLE 2

10

Page 12

Blue Sky Energy – IPN-ProRemote

by the IPN-ProRemote is to use net battery charge current matched to battery size in amp-hours. With the IPN-ProRemote the charge controller will consider the

battery fully charged and to switch to Float if net battery current drops below the Float Transition Current setting while the battery is at the Acceptance voltage

setpoint. The factory default Float Transition Current setting (Float Current in the Battery Charge Parameters menu) of 1.5 amps per 100 amp-hours of battery

capacity is suitable for most batteries. With the factory default Battery Amp-Hour setting of 220 amp-hours, the battery would be considered fully charged when net

battery charge current decreases to less than 3.3 amps while at the Acceptance voltage setpoint.

battery current is unable to decrease to the Float Transition Current due to battery age or damage, charge will terminate after a reasonable time period.

Float Transition Current

“Time in Acceptance” is an accepted method to determine when the battery is fully charged if net charge current is unknown. A preferred method provided

To assure that net charge current is what determines when the battery is full, Charge Time should be increased to approximately 4 hours. This is so that if

WIRING DIAGRAM

Voltage difference must be < ±1.0V with highest

charge/discharge current expected and backlight on.

Network and power cable

Display contrast

To all loads and

charging sources

Shield drain wire,

connect to earth ground

500A/50mV

Shunt

IPN-ProRemote

rear view

IPN network compatible

charge controller

Current Shunt Signal Wiring

(SB3024iL shown)

Battery

FIGURE 6

11

Page 13

Installation and Operation Manual

CURRENT SHUNT

¾ CAUTION: A 500A/50mV current shunt must be used with the IPN-ProRemote. The shunt is used to measure net battery current

and must be installed in series with battery negative. Damage caused by installation in series with battery positive will void the limited

warranty. All negative current carrying conductors from all charging sources and loads must connect to the charge controller side of

the shunt as shown in Figure 6 such that all current flowing to or from battery negative flows through the shunt. Current carrying

conductors (other than the shunt) attached to battery negative will produce inaccurate battery current readings and amp-hour

counting. Shunt signal cable length should be limited to roughly 300 feet (91.5m) maximum. Tighten shunt power connection

bolts to 11 ft-lb (14.9 nm) and #10 sensing screws to 20 in-lb (2.3 nm). IPN-ProRemote shunt signal wire compression terminals

are to be tightened to 2.1 in-lb (0.24 nm). Note that the battery temperature sensor lug is not a current carrying conductor and

battery is being charged. The +/– shunt signal connections must connect to the corresponding +/– IPN-ProRemote shunt terminal block locations for proper

current polarity reading on the Battery Volt/Amp screen. The shunt produces very sensitive microvolt level signals and signal wires must be twisted pairs.

Lengths less than 35 feet (10.7m) can be unshielded twisted pairs if routed away from power or noise generating conductors. Shielded twisted pair cable is

preferred for lengths greater than 35 feet (10.7m) or where electrical noise is expected. Terminate shield drain wire to earth ground at one end only.

including normal electronic component aging. A Reset Current Shunt Zero function is provided to compensate for zero offset and provide an accurate zero

reading.

the accuracy of the current shunt measurement system zero, a true zero must be applied as described above. Failure to provide a true zero signal in this

manner will not reflect the true accuracy of the current shunt measurement system zero.

To reset current shunt zero and remove zero offset error:

CHARGE CONTROLLER CONNECTION

any charge controller on the network using the standard 4 conductor RJ-11 voice telephone cable supplied.

must remain on battery negative.

Current Shunt Signal Wiring

The shunt itself is not a polarized device. Once installed in series with battery negative it produces the +/– signal polarity shown in Figure 6 when the

Resetting Current Shunt Zero

The sensitive nature of the shunt signal measurement circuits can produce a slight drift or offset in the zero reading (0.0A) due to several factors

¾ CAUTION: It is critically important that a Reset Current Shunt Zero function not be performed without first providing a true zero

current signal to the IPN-ProRemote. This is accomplished by temporarily placing both shunt sensing wires at the current

shunt under the same #10-32 signal screw. Failure to provide a true zero signal in this manner before executing the Reset

Current Shunt Zero function will result in inaccurate battery current readings and amp-hour counting.

Do not confuse small charge or discharge currents flowing in the shunt due to normal system operation as zero offset error. For the purpose of testing

1. Place both shunt signal wires under the same #10 shunt sense signal screw on the current shunt to provide a true zero signal.

2. Perform the Reset Current Shunt Zero function from the Setup Menu.

3. Press BACK twice to return to the Battery Volt/Amp screen to examine the new zero reading. If zero is not within ±0.1A or better repeat the Reset

Current Shunt Zero function and check again.

4. Zero offset correction data is now stored in memory and retained if power is lost.

5. Return current shunt signal wires to their normal shunt sense screw positions.

Each charge controller includes an IPN DISPLAY connector which provides power and IPN network connection. The IPN-ProRemote can plug into

¾ Standard 4-pin telephone cables swap pin numbers end-to-end. If cables are custom terminated or cable couplers are used,

be certain pin swap is maintained. Do not plug into anything other than a IPN-compatible communications port. Total maximum

cable length should be limited to approximately 500 feet (152.4m).

NETWORK / POWER CABLE SCHEMATIC

Standard 4-pin telephone cable pin swap

RJ-11 Modular plug

Viewed from open end

Where cable is inserted

Pin 1

FIGURE 7

12

Page 14

Blue Sky Energy – IPN-ProRemote

¾ When Backlight is on, the IPN-ProRemote can draw up to 100mA from the charge controller. For proper operation of the shunt

MOUNTING

current measurement circuits, total voltage difference between the IPN-ProRemote circuit common and the shunt must be kept to

less than ±1.0V when Backlight is on and maximum charge or discharge current is flowing in the system. If long network/power

cables are used, wire size may need to be increased to keep voltage difference between the “COM test point” and “SHUNT –” on

the back of the IPN-ProRemote to within ±1.0V or less at all times. Table 3 below shows wire size for a more conservative

recommended voltage drop limit of 0.50V maximum.

¾ CAUTION:. The unit is designed to mount into a standard US duplex wall mount box. It is not watertight and must be protected

from rain, snow and excessive moisture.

MAXIMUM NETWORK/POWER CABLE LENGTH FOR 0.50V DROP

WIRE GAUGE

AWG

MAXIMUM RECOMMENDED CABLE LENGTH

FEET / METERS

30 AWG 45 / 13.7

28 AWG 73 / 22.2

26 AWG 117 / 35.7

24 AWG 187 / 57.0

22 AWG 295 / 89.9

20 AWG 475 / 144.8

TABLE 3

DETAILED DIMENSIONAL DRAWING

FIGURE 8

TROUBLESHOOTING GUIDE

SYMPTOM PROBABLE CAUSE ITEMS TO EXAMINE OR CORRECT

Display blank No power

Display turns on, but

battery voltage shows

IPN-ProRemote not communicating with

charge controller

– –.–V rather than a

number

Charge controller not properly powered.

Network cable faulty, not plugged in or cable pins do not swap per Figure 7.

Network cable faulty.

Charge controller or IPN-ProRemote may have locked up, re-boot by momentarily

removing battery and PV power from charge controller.

One charge controller is not set to Master, or more than one charge controller is set

to Master.

Controller-to-controller network cable not wired A-to-A, B-to-B, or wires are open or

short.

13

Page 15

SYMPTOM PROBABLE CAUSE ITEMS TO EXAMINE OR CORRECT

No data shows in the

View Charge Unit

Status screen

Charge controller not communicating

with IPN-ProRemote

Controller-to-controller network cable not wired A-to-A, B-to-B, or wires are open or

short.

More than one charge controller is set to be Master or more one charge controller

set to same slave address.

Days since last

equalize or full charge

shows 1 day too many

Days since last

equalize reset without

The day counter increments once each 24

hours since battery power was applied.

Day counter updates when equalize

starts

Normal operation. This potential 1 day error may be eliminated by rebooting the charge

controller in the middle of the night so that the counter increments at this time rather

than during the day.

Normal operation. The equalize day counter is reset when equalize starts rather than

when it ends.

equalize completing

Net battery current

Signal wires on shunt reversed Swap signal wire positions on shunt.

polarity reversed

Battery current seems

inaccurate

Remaining Battery

Capacity & Amp-

Some charging sources or loads do not

go through shunt

Shunt wiring incorrect or faulty.

Shunt signal wires picking up electrical

noise

Excessive voltage drop in network cable

to IPN-ProRemote or in system power

wiring

Net battery current not reading 0.0A with

zero amps flowing

Charge controller has not finished

charging battery

Confirm that no other current carrying conductors other than the shunt cable is

connected to battery negative.

Shunt wired in series with battery positive, should be negative.

One or both shunt signal wires open or short.

Confirm signal wires are twisted pairs.

Consider using shielded twisted pair cable for signal wires.

Relocate signal wires away from power or noise generating wiring.

Confirm that with backlight ON and with highest possible charge or discharge current

flowing in system, voltage difference between “COM test point” and “SHUNT –” on

the back of the IPN-ProRemote is less than ±1.0V at all times, with less voltage

drop being better. Correct wiring as necessary. Consider not using backlight.

Perform Reset Current Shunt Zero function exactly as described in this manual to

remove zero offset.

Normal operation. Remaining Battery Capacity & Amp-Hours From Full displays

show dashes until the battery is fully charged which initializes amp-hour counting.

Hours From Full show

dashes (– – –)

Remaining Battery

Capacity or AmpHours From Full seem

inaccurate

Shunt not properly reading net battery

current

Incorrect battery amp-hours entered

Incorrect Charge Efficiency factor

Battery not fully charged for an extended

period

Charge controller is not what normally

fully charges the battery

Self Discharge Rate set incorrectly

Temperature sensor faulty

Net battery current must read correctly to properly count Amp-Hours From Full,

which is used to compute Remaining Battery Capacity. See Battery Current Seems

Inaccurate.

Confirm correct 25°C 20Hr rate battery amp-hour value.

Confirm Charge Efficiency factor and Charge Efficiency Mode are set correctly.

Incorrect net battery current readings can cause Charge Efficiency to become very

inaccurate. Reset to 94%.

Since battery charge / discharge behavior is not ideal, error in the Amp-Hours From

Full counter builds as the battery cycles without becoming full. Try to fully charge

the battery often.

To get the best accuracy, the charge controller should be what normally or at least

regularly brings the battery back to full charge.

Confirm proper 25°C value is entered.

Many factors are temperature compensated. Confirm proper temperature sensor

operation as described in the charge controller manual.

Installation and Operation Manual

14

Page 16

Blue Sky Energy – IPN-ProRemote

SPECIFICATIONS

SPECIFICATIONS IPN-ProRemote

Current Shunt 50 mV / 500 amp

Battery Ammeter

Battery Size 20 – 10,000 Amp-hours

Power Consumption

Remaining Battery Capacity

Based on amp-hour counting • Appropriate factors temperature compensated

Amp-hours From Full 0 – 16,383 Amp-hours

Total Charge Amp-hours 0 – 16,383 Amp-hours, user resetable

Lifetime Battery Amp-hours 0 – 9,999,999 Amp-hours

Days Since Full Charge 0 – 255 Days

Days Since Equalize 0 – 255 Days

Backlight Mode ON, OFF or AUTO

Panel Dimensions

Communication, Power

& Cabling

Powered by IPN compatible charge controller via 4-pin telephone cable. Charge controller cable length to 500’

4½”H x 4½”W x 1½”D (11.4cm x 11.4cm x 3.8cm) • Fits standard duplex wall mount box

(152.5m). Current shunt connection via twisted pair cable, Length to 300’ (91.5m)

Environmental

As a part of our continuous improvement process

specifications are subject to change without prior notice

TWO YEAR LIMITED WARRANTY

Blue Sky Energy, Inc. (hereinafter BSE), hereby warrants to the original consumer purchaser, that the product or any part thereof will be free from

defects due to defective workmanship or materials for a period of two (2) years subject to the conditions set fourth below. If within the coverage of this limited

warranty, BSE will repair or replace the product at BSE’s discretion. The original consumer purchaser is responsible for all transportation costs and insurance

related to returning the product to BSE. BSE will cover standard ground transportation costs and insurance to return the product to the original consumer within the

continental US.

1. This limited warranty is extended to the original consumer purchaser of the product, and is not extended to any other party.

2. The limited warranty period commences on the date the product is sold to original consumer purchaser.

3. This limited warranty does not apply to any product or part thereof damaged by; a) alteration or disassembly, b) repair or service not rendered by

a BSE authorized repair facility, c) accident or abuse, d) corrosion, e) lightning or other act of God, or f) operation or installation contrary to

instructions pertaining to the product.

4. BSE’s liability for any defective product or any part thereof shall be limited to the repair or replacement of the product, at BSE’s discretion. BSE

will not be liable for any loss or damage to person or property, or any other damages, whether incidental, consequential or otherwise, caused by

any defect in the product or any part thereof. Some states do not allow exclusions or limitations of incidental or consequential damages, so the

above limitation may not apply to you.

5. Any implied warranty for merchantability or fitness for a particular purpose is limited in duration to the length of this warranty. Some states do not

6. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

allow exclusions or limitations on how long an implied warranty lasts, so the above limitation may not apply to you.

7. To obtain warranty repairs, contact BSE at 800-493-7877 or 760-597-1642 to obtain a Returned Goods Authorization (RGA) number. Mark the

outside of the package with the RGA number and return the product, postage prepaid and insured to the address below. A copy of the purchase

receipt identifying original consumer purchaser and date purchased must accompany the product to obtain warranty repairs.

2598 Fortune Way, Suite K

800-493-7877 • 760-597-1642 • Fax 760-597-1731 • www.blueskyenergyinc.com

Range ±773.3A FS • Accuracy ±0.5% FS

0.25W Typical • 1.0W Typical with backlight on

-40 – +40°C, 10 – 90% RH non-condensing

Blue Sky Energy, Inc.

Vista, CA, 92081, USA

With optional battery temperature sensor

15

Page 17

Installation and Operation Manual

IPN-ProRemote

Controlador de carga compatible con red IPN

MANUAL DE INSTALACIÓN Y OPERACIÓN

CONFORME A

EN 61326-1:2006

EN 60335-1:2002 + A11:2004 + A1:2004

EN 60335-2-29:2004

Este dispositivo cumple con la parte 15 de las

reglas de FCC. La operación está sujeta a las

siguientes dos condiciones: 1) Este dispositivo

no puede causar interferencia dañina y 2) Este

dispositivo debe aceptar toda interferencia

recibida, incluyendo interferencia que pueda

causar operaciones indeseadas.

ESTE MANUAL INCLUYE INSTRUCCIONES DE SEGURIDAD IMPORTANTES PARA LOS MODELOS - IPNPRO, IPNPRO-S

CONSERVE ESTAS INSTRUCCIONES

™ y monitor de sistema de baterías

16

Page 18

Blue Sky Energy – IPN-ProRemote

TABLA DE CONTENIDOS

INSTRUCCIONES DE SEGURIDAD IMPORTANTES........................................................................................................... 18

DESCRIPCIÓN DEL PRODUCTO.......................................................................................................................................... 18

Números de parte y opciones ................................................................................................................................19

OPERACIÓN...........................................................................................................................................................................19

Uso de las teclas de función ..................................................................................................................................19

NEXT..............................................................................................................................................19

BACK ............................................................................................................................................. 19

Uso de BACK y NEXT para incrementar o reducir ajustes............................................................19

SELECT .........................................................................................................................................19

Visor de LCD y retroiluminación............................................................................................................................. 20

Indicador de estado de carga.................................................................................................................................20

Capacidad remanente de la batería....................................................................................................................... 20

Cómo funciona la capacidad remanente de la batería...................................................................20

Eficiencia de carga......................................................................................................................... 20

Precisión ........................................................................................................................................ 21

Menús..................................................................................................................................................................... 21

Uso de menús y teclas...........................................................................................................................................25

Ejemplo – Configuración de los Amp-horas de batería..................................................................25

INSTALACIÓN ........................................................................................................................................................................ 25

Precauciones electrostáticas de manipulación ......................................................................................................25

Configuración del IPN-ProRemote......................................................................................................................... 26

Valores predeterminados de fábrica ..............................................................................................26

Restablecimiento de los valores predeterminados de fábrica .......................................................26

Régimen de Amp-horas de batería................................................................................................ 26

Eficiencia de carga y modo de eficiencia de carga........................................................................ 26

Régimen de autodescarga............................................................................................................. 26

Corriente flotante de transición ......................................................................................................27

Derivación de corriente ..........................................................................................................................................28

Cableado de la señal del derivador de corriente............................................................................28

Reinicio del cero de la corriente del derivador............................................................................... 28

Conexión del controlador de carga ........................................................................................................................28

Montaje .................................................................................................................................................................. 29

GUÍA DE RASTREO DE FALLAS.......................................................................................................................................... 29

ESPECIFICACIONES..............................................................................................................................................................31

GARANTÍA LIMITADA DE DOS AÑOS ................................................................................................................................. 31

TABLAS Y FIGURAS

Tabla 1 Indicador de estado de carga......................................................................................................... 20

Tabla 2 Régimen de autodescarga............................................................................................................. 26

Tabla 3 Máxima longitud de cable de red/potencia..................................................................................... 29

Figura 1 Panel del visor................................................................................................................................ 19

Figura 2 Menú superior ................................................................................................................................21

Figura 3 Menú avanzado del visor ...............................................................................................................22

Figura 4 Menú de configuración...................................................................................................................23

Figura 5 Menú de parámetros de carga de batería......................................................................................24

Figura 6 Diagrama de cableado................................................................................................................... 27

Figura 7 Esquema de cableado de red/alimentación................................................................................... 28

Figura 8 Dibujo dimensional detallado .........................................................................................................29

17

Page 19

Installation and Operation Manual

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Este manual contiene instrucciones importantes para los modelos IPNPRO E IPNPRO- S

CONSERVE ESTAS INSTRUCCIONES

1. Deje la instalación y las reparaciones en manos de personal de servicio calificado. La instalación o uso incorrecto puede resultar en riesgo de descarga

eléctrica o fuego. No hay partes reparables por el usuario en esta unidad.

2. Para reducir el riesgo de recibir descargas eléctricas, fuego o daños personales, se han colocado los siguientes símbolos a lo largo de este manual para

indicar condiciones peligrosas o instrucciones importantes de seguridad u operación.

ADVERTENCIA PRECAUCIÓN IMPORTANTE

Indica condiciones peligrosas o potenciales

descargas eléctricas. Use extrema precaución.

Indica artículos críticos para instalar u operar

la unidad en forma segura.

Siga estas instrucciones al pie de la letra para

una un funcionamiento correcto de la unidad.

3. PRECAUCIONES PERSONALES

a) El trabajo en las proximidades de baterías de plomo-ácido es peligroso. Las baterías producen gases explosivos durante la operación normal.

b) Para reducir el riesgo de explosión de la batería, siga estas instrucciones y aquellas publicadas por el fabricante de la batería y del fabricante de cualquier

equipo que quiera usar en las proximidades de una batería.

c) Debe haber alguien en el rango de alcance de su voz o suficientemente cerca para darle ayuda cuando trabaja cerca de una batería de plomo-ácido.

d) Disponga de buena cantidad de agua potable y jabón en las cercanías en caso de que el ácido de la batería entre en contacto con la piel, ropa u ojos.

e) Utilice protección completa para sus ojos y su ropa. Evite tocar sus ojos mientras trabaje cerca de una batería.

f) Si el ácido de la batería entra en contacto con la piel o la ropa, lave inmediatamente con agua y jabón. Si entra ácido en el ojo, inmediatamente enjuague

el ojo con agua corriente fría por lo menos durante 10 minutos y obtenga atención médica inmediatamente.

g) NUNCA FUME o permita la presencia de una chispa o una llama en las proximidades de la batería.

h) Sea extremadamente precavido para reducir el riesgo de dejar caer una herramienta metálica en la batería. Esto puede generar una chispa o

cortocircuitar la batería u otras partes eléctricas que pueden causar una explosión.

i) Quítese todos los artículos metálicos personales tales como anillos, brazaletes y relojes cuando trabaje con una batería de plomo-ácido. Una batería de

plomo ácido puede producir una corriente de cortocircuito suficientemente alta como para soldar un anillo o similar a algún metal, causando una

quemadura severa.

j) Quite todas las fuentes de energía, el fotovoltaico y la batería antes de reparar o instalarlo.

4. UBICACIÓN E INSTALACIÓN DEL VISOR

a) Esta unidad emplea componentes que tienden a producir arcos o chispas. NUNCA lo instale en un compartimiento para baterías ni en presencia de

gases explosivos.

b) Esta unidad debe ser instalada y cableada de acuerdo con el Código Eléctrico Nacional (“National Electrical Code”) ANSI/NFPA 70.

c) La unidad no es a prueba de agua. No la exponga a lluvia, nieve ni a humedad excesiva.

d) Asegúrese de que todas las conexiones terminales estén limpias y ajustadas.

e) Esta unidad está diseñada para ser usada con los controladores de carga compatibles con la red Integrated Power Net™ (IPN™). No la conecte a nada

que no sea un puerto de comunicaciones compatible con IPN.

DESCRIPCIÓN DEL PRODUCTO

El IPN-ProRemote con prestaciones completas incorpora un visor LCD retroiluminado multilínea y tres teclas de función para proveer una configuración

mejorada y monitoreo de los controladores de carga compatibles con la red Blue Sky Energy’s Integrated Power Net™ (IPN™). El IPN-ProRemote provee la

capacidad de acceder a parámetros adicionales de configuración del controlador de carga y ajustar los parámetros de configuración para rangos más amplios que

con el controlador incluido solamente. Pueden monitorearse tanto los estados individuales como los combinados totales de hasta 8 controladores de carga. El

IPN-ProRemote también provee un monitoreo completo del sistema de batería. Muestra en el visor la corriente de batería y los Amp-horas por completo mediante

la medición de la corriente de carga y descarga de todas las fuentes y cargas. Algunas de las múltiples pantallas incluyen: voltaje de batería y corriente, voltaje y

corriente de PV, Amp-horas de carga del PV y un indicador de capacidad de batería tipo “medidor de combustible”.

NÚMEROS DE PARTE Y OPCIONES

• IPNPRO.........................................Monitor de control de carga y del sistema de batería IPN con prestaciones completas y cable de 25 pies

• IPNPRO-S .....................................IPN-ProRemote con la derivación necesaria de corriente de 500A/50mV

• CS-500...........................................Derivador de corriente de 500V/50m milivoltios

18

Page 20

Blue Sky Energy – IPN-ProRemote

PANEL DEL VISOR

FIGURA 1

OPERACIÓN

Todas las operaciones del IPN-ProRemote y las pantallas son controladas por medio de las tres teclas de funciones: BACK (anterior), NEXT (siguiente) y

SELECT (seleccionar). La información que típicamente resulta de interés para el usuario casual, tal como el voltaje de la batería, la corriente de la red de

baterías y la capacidad remanente de batería está disponible en el menú superior. Los usuarios con inclinaciones más técnicas pueden desear ver

información adicional en el menú de visor avanzado “Advanced Display” mientras que los instaladores podrían necesitar acceder a la configuración o a los

menús de parámetros de carga de batería. Vea las figuras 2, 3, 4 y 5 para obtener una descripción completa de cada pantalla del visor.

USO DE LAS TECLAS DE FUNCIÓN

NEXT

La tecla NEXT (Siguiente) es usada principalmente para recorrer los menús. Cada vez que se presiona NEXT el visor avanza a la siguiente pantalla

de ese menú. Si se presiona una vez más al llegar al final de un menú, regresa al inicio de ese menú.

BACK

La tecla BACK (Anterior) es usada principalmente para retirarse de las funciones, pantallas de ajustes o menús avanzados. Es similar a la tecla

“Escapar” Esc de las computadoras. Cada vez que se presiona BACK, se sale de un menú avanzado, de una función o de una pantalla de configuración sin

llevar a cabo la acción de esa función ni cambiar la configuración. Presionando en el menú superior la tecla BACK se conmuta entre las dos pantallas más

comúnmente usadas: Voltios/amperios de la batería y capacidad remanente de la batería.

Uso de BACK y NEXT para incrementar o reducir ajustes

Todos los ajustes son cambiados en una pantalla de configuración de parámetros donde la palabra “SETTING” destella en el visor. Presionando

NEXT mientras se está en una pantalla de ajuste de parámetros hace que el parámetro vaya al siguiente valor o incremente un valor numérico de ajuste.

Presionando BACK mientras se retiene presionada NEXT en una pantalla de configuración de parámetros hace que se reduzcan los valores

numéricos de ajuste. Si se presiona BACK sin mantener presionada NEXT, BACK realizará su función normal y se retirará de la pantalla de ajuste de

parámetros. Para reducir un ajuste, presione y mantenga presionada NEXT y luego, adicionalmente presione y mantenga presionada BACK. El número del

ajuste se reducirá mientras BACK y NEXT sean presionadas. Cuando haya pasado el valor de ajuste deseado al descender, libere primero BACK y luego

libere NEXT. Luego use NEXT para incrementar el ajuste al valor deseado.

SELECT

La tecla SELECT (Seleccionar) entra en acción basándose en el indicador de la parte inferior derecha del visor, el cual puede mostrar SEL►,

SET►, o CLR► (por ejemplo, Select, Set o Clear). Para minimizar la posibilidad de llevar a cabo una acción no deseada, SELECT no actúa en forma

inmediata. Se deberá presionar y mantener presionada la tecla SELECT por 4 segundos antes de que la acción sea tomada.

• SEL► es usada para seleccionar un menú del siguiente nivel o ingresar en una pantalla de configuración de parámetros.

• SET► aparece en las pantallas de ajuste de parámetros donde la palabra “SETTING” destella en el visor. Una vez que el parámetro es

aumentado o reducido al valor deseado en una pantalla de ajuste de parámetros, al presionar SET► almacena el nuevo valor en memoria y

regresa a la pantalla previa. SET► aparece también en el restablecimiento de valores predeterminados Restore Default Settings y en el reinicio

de cero del ajuste de la derivación de corriente Reset Current Shunt Zero, donde SET► ejecuta directamente esas funciones siguiendo el

retardo normal de 4 segundos.

• CLR► es usado para borrar valores en las pantallas de datos almacenados, tales como voltaje mínimo y máximo de batería, Amp-horas de

carga total, etc. También aparecerá en la pantalla de ecualización habilitada “Equalize Enabled” y cancelará manualmente el ciclo de

ecualización actual.

19

Page 21

Installation and Operation Manual

VISOR DE LCD Y RETROILUMINACIÓN

El visor de cristal líquido (LCD) puede ser retroiluminado para mejorar la legibilidad. Al encender la retroiluminación (ON) se incrementa el consumo

de energía del IPN-ProRemote en aproximadamente 0.25W a 1.0W. La retroiluminación puede ajustarse a encendida ON, apagada OFF o AUTO desde el

menú de configuración avanzada. La configuración predeterminada de AUTO hará que la retroiluminación permanezca encendida (ON) por un minuto,

después de la última presión de una tecla. Cuando la retroiluminación se ha apagado en AUTO, la primera presión de cualquiera de las teclas encenderá la

retroiluminación únicamente, pero sin llevar a cabo la función normal de dicha tecla. Las teclas cumplirán con su función normal una vez que la

retroiluminación esté encendida.

INDICADOR DE ESTADO DE CARGA

El frente de la unidad viene provisto con un LED indicador de estado de carga. El indicador de estado se apagará cuando el controlador de carga no esté

cargando y estará encendido (ON) en forma continua o destellando cuando la batería esté siendo cargada.

INDICADOR DE ESTADO DE CARGA MODO DE CARGA

APAGADO (OFF) CARGA APAGADA

CONTINUAMENTE ENCENDIDO (ON) MASIVA

DESTELLANDO • 1 SEGUNDO ENCENDIDO/ 1 SEGUNDO APAGADO

DESTELLANDO • 0.2 SEGUNDOS ENCENDIDO / 1 SEGUNDO APAGADO

DESTELLO RÁPIDO • 0.2 SEGUNDOS ENCENDIDO / 0.2 SEGUNDOS APAGADO

CAPACIDAD REMANENTE DE LA BATERÍA

El IPN-ProRemote provee una indicación de alta precisión de la capacidad remanente de la batería, basada en la cuenta de amperios por hora. El

cómputo de capacidad remanente de batería resultante es presentado en pantalla como porcentaje remanente y como gráfico de barra. Note que los

amperios por hora del contador completo y la indicación de capacidad remanente de la batería asociada mostrarán guiones (

de carga que la acompaña cargue completamente la batería, lo cual es necesario para iniciar el conteo de amperios por hora.

Cómo funciona la capacidad remanente de la batería

Una batería almacena carga eléctrica en unidades llamadas amperios por hora (Ah). Un amperio por hora es el producto de la corriente en (amperios)

por el tiempo (en horas). 10 amperios por hora pueden ser consumidos por una carga de 10 amperios en una hora de operación, una carga de 0.2 A en 50

horas o una carga de 100 A en 1/10 horas. El IPN-ProRemote usa la corriente de batería de la red según se muestra en la pantalla del menú superior de

V/A Top Menu Battery Volt/Amp para computar los Amp-horas, lo cual es mostrado en la pantalla Top Menu Battery Amp-Hrs From Full. A medida que la

batería es cargada (corriente positiva) o descargada (corriente negativa) el IPN-ProRemote mantiene informado el total de cuántos Amp-horas han sido

quitados o restablecidos. Los Amp-horas de descarga son aplicados directamente a los Amp-horas a partir de un contador completo, haciendo que se

incrementen los Amp-horas del total. Los Amp-horas de la carga hacen que los Amp-horas del total del contador decrezcan, pero son reducidos por el

Factor de Eficiencia de Carga para tomar en cuenta el hecho de que las baterías no son 100% eficientes al recibir carga. Adicionalmente, las baterías

pierden carga por sí mismas debido a la autodescarga, la cual es periódicamente computada y agregada al contador los Amp-horas del total. Los cambios

por la autodescarga por las variaciones de temperatura de la batería serán corregidos si el controlador de carga que lo acompaña incluye un sensor de

temperatura de batería.

El conteo de Amp-horas hacia y desde la batería y el uso del régimen de autodescarga y eficiencia de carga llegan al valor de Amp-horas (amp-horas) a

partir de carga completa mostrado en pantalla en la pantalla del menú superior de Amp-horas de batería a partir de carga completa. Este valor es usado con el

régimen de Amp-horas publicado para la especificación de batería “régimen de 20h” para computar la capacidad remanente de baterías. Si la batería era de 220

Amp-horas y el valor del contador de los Amp-horas a partir de carga completa eran de –110 amp-horas, la capacidad remanente de batería debería mostrar

50%. El régimen de Amp-horas de batería está especificado a 25°C, pero la capacidad real de la batería cambia con la temperatura. Si el controlador de carga

que la acompaña incluye un sensor de temperatura de batería, el IPN-ProRemote corregirá los Amp-horas de batería disponibles, en base a la temperatura de la

batería. Las baterías más frías tienen una capacidad reducida y si la batería estuviera a 0°C, entonces la capacidad real de la batería se reduce a 79% de los 220

Amp-horas y la capacidad remanente sería mostrada como de un 37%.

Eficiencia de carga

La eficiencia de carga se refiere a cuántos Amp-horas son absorbidos por la batería en comparación con cuántos Amp-horas de carga son provistos. Un

factor de eficiencia de carga del 94% significa que por cada 100 Amp-horas de carga entregada, la batería incrementa la carga por 94 Amp-horas. La eficiencia de

carga es típicamente muy alta cuando la batería está altamente descargada y se vuelve menor cuando la batería está cerca de la carga completa.

El factor de eficiencia de carga puede ser ajustado en un número fijo o puede ajustarse para actualizarse automáticamente, en base al

comportamiento previo de la batería. La mayoría de los sistemas se beneficiarán del ajuste automático, el cual está predeterminado de fábrica. En ajuste

automático, el IPN-ProRemote computará la eficiencia de carga real si la batería fue descargada por lo menos un 10% y los controladores de carga que la

acompañan son los que le llevaron nuevamente a la batería a la condición de plena carga. El régimen de actualización del factor de eficiencia de carga es

filtrado, de modo que le toma aproximadamente 5 ciclos de carga/descarga para actualizar completamente el factor de eficiencia de carga.

INDICADOR DE ESTADO DE CARGA

TABLA 1

DE ACEPTACIÓN

FLOTANTE

ECUALIZACIÓN

– – –) hasta que el controlador

20

Page 22

Blue Sky Energy – IPN-ProRemote

███████

►

►

MENÚS

Parameters). Las pantallas a las que típicamente accede la mayoría de los usuarios, tales como voltaje de batería, corriente de batería de la red y capacidad

remanente de batería están presentes en el menú Superior Top Menu. Los usuarios más técnicos pueden acceder a menús adicionales donde residen las

pantallas avanzadas y la capacidad de configurar. Vea las figuras 2, 3, 4 y 5 relacionadas con el menú.

Precisión

La capacidad remanente de batería tenderá a ser mejor si:

• El controlador de carga provee al menos 3A por cada 100 Amp-horas de capacidad de batería.

• El controlador de carga es el que normalmente hace retornar a la batería a la condición de carga completa.

• La batería es cargada completamente por el controlador de carga en forma frecuente para minimizar la acumulación de errores resultantes de las

características no ideales de las baterías. Cuantos más ciclos de batería no lleguen a la carga completa, mayor será la acumulación de errores.

• El modo de eficiencia de carga está configurado para ajuste automático AUTO ADJUST.

Hay cuatro menús: Superior (Top), Visor Avanzado (Advanced Display), Configuración (Setup), y Parámetros de carga de batería (Battery Charge

MENÚ SUPERIOR

Muestra el voltaje de la batería y la corriente de batería de la red. La corriente de