Page 1

BATTERY CHARGER

User Manual

7521 (25A) and 7522 (40A)

P12

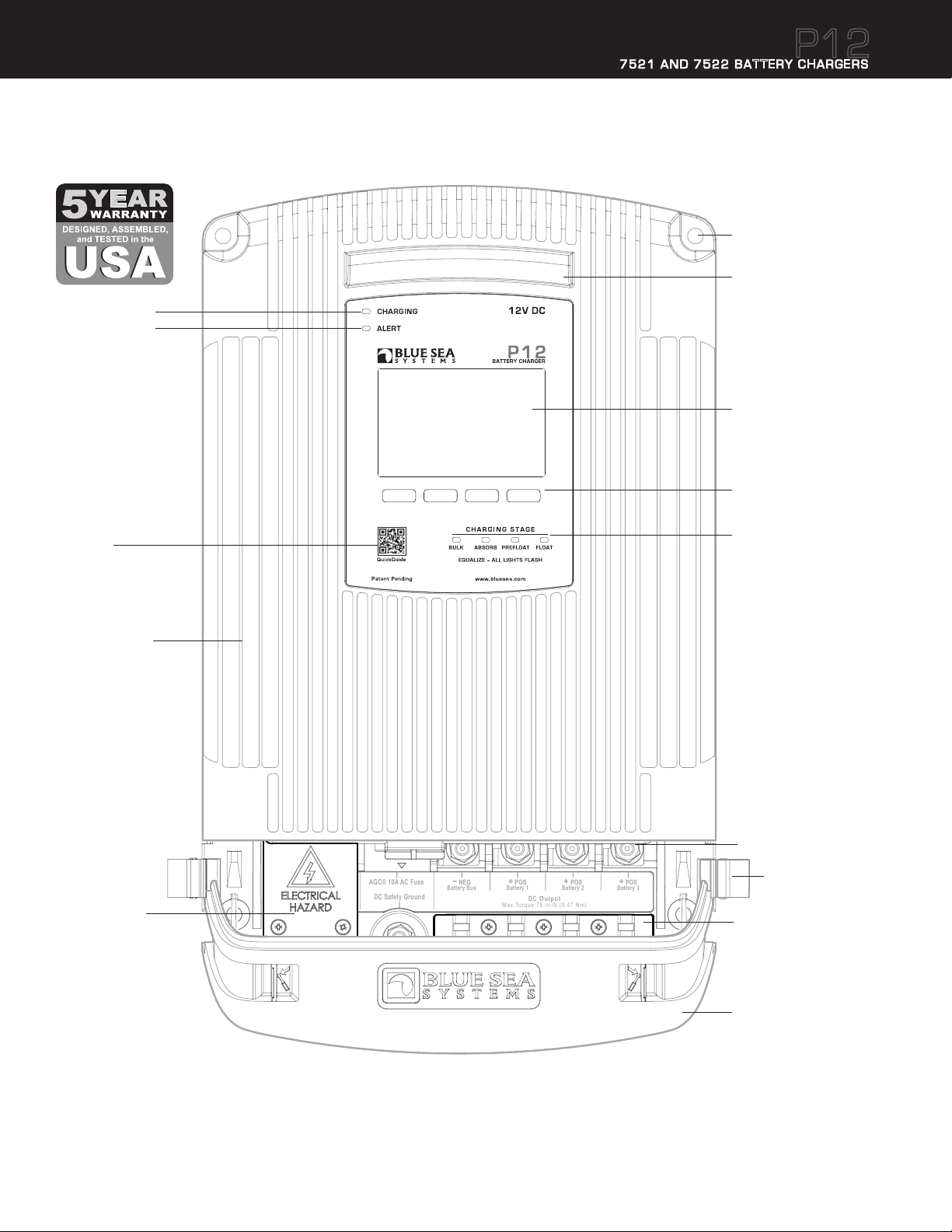

CHA RGING

ALE RT

Quick Guide

Pate nt Pe nding

12V DC

P12

BAT TERY CHARG ER

CH A RG IN G S TA G E

EQUA LIZE – A LL LI GHTS FLASH

www. blues ea.co m

Part Number 7521 7522

Total Output Current (Limited) 25A 40A

Nominal Output Voltage 12V DC

Output Connections 3 positive

1 negative

Universal AC Input Voltage 90–265V AC

Nominal AC Input Frequency 45–65 Hz

Maximum Output Voltage 16.0V DC

Output Voltage Accuracy 0.05V DC

Minimum Operating Temperature -20°C (-4°F)

Maximum Operating Temperature 70°C (158°F)

Minimum Storage Temperature -30°C (-22°F)

Maximum Storage Temperature 80°C (176°F)

Maximum Parasitic Current 2mA

N° article 7521 7522

Courant maximum de sortie totale 25A 40A

Tension de sortie nominale 12V CC

FLOA TABSO RBBULK PREF LOAT

Raccordements de sortie 3 positifs

1 négatif

Tension d'entrée CA universelle 90–265V CA

Fréquence d'entrée CA nominale 45–65 Hz

Tension de sortie maxi. 16,0V CC

Précision de tension de sortie 0.05V CC

Température de fonctionnement mini. -20°C (-4°F)

Température de fonctionnement maxi. 70°C (158°F)

Température de stockage mini. -30°C (-22°F)

Température de stockage maxi. 80°C (176°F)

Courant parasite maxi. 2mA

Regulatory

Design and construction compliance to UL-1236

marine (including ignition protection) and CSA 22.2

No. 107.2-0 standards. Meets all elements of the

ABYC A-31 and certain NMEA requirements. To view

the most current regulatory certifications,

visit www.bluesea.com/P12.

DES IG NED

ASSEMBLED

and TESTED

in the

U SA

Scan for

additional

product

information

Read and understand the contents of this User Manual. It contains important safety, handling, and operational instructions for the P12 Battery Chargers.

This User Manual describes the product mentioned herein at the time of its publication. Specifications and performance are subject to change at the discretion

of Blue Sea Systems. To view the most current revision of this publication visit bluesea.com/P12.

Page 2

Page 3

Table of Contents

Important Safety Instructions 2

P12 Battery Charger Overview 3–4

Specifications 5

Installation Tables 5

• Table A: Minimum Recommended Wire Size

• Table B: Recommended DC Circuit Protection

• Table C: Typical AC Regional Wire Colors

• Table D: AC Wire - Circuit Protection Selection Chart

• Table E: Default Voltages by Battery Type

Product Dimensions and Installation Clearances 6

Included Components 7

Supplies Needed 8

Installation Instructions 9–10

Initial Charger Setup 11

Advanced Charger Setup 12–13

Reset to Manufacturer Defaults 13

Absorption Parameters and Timers 14

Temperature Parameters 15

Equalization 16–17

Screen Summary 18–19

Alert Screens and Diagnostics 20–21

Optional Installation 22–23

• Automatic Charging Relays (ACRs)

Optional P12 Battery Charger Remote 24–27

Warranty and Contact Information 28

P12 Charge Management System 29

Specifications are subject to change. See bluesea.com/P12 for current information.

1

Page 4

IMPORTANT SAFETY INSTRUCTIONS

7521 AND 7522 BATTERY CHARGERS

P12

READ AND SAVE THESE INSTRUCTIONS

WARNING

Refers to a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Refers to a potentially hazardous situation which, if not avoided, may result in injury.

WARNING

The P12 Battery Charger should be installed by a qualified marine electrician. Improper installation can result in electrical shock which may

cause serious injury or death. To reduce the risk of electrical shock, mount vertically in a dry, well ventilated location. Charge these battery

types: Flooded, AGM, Gel, or TPPL Lead Acid batteries. Must consult battery manufacturer specifications for other battery types to

avoid damage.

CAUTION

Before beginning electrical installation, read the instruction manual. Disconnect all AC and DC power sources. Do not make final connections

to the batteries until DC connections on the charger are made and verified. Do not make or break electrical connections to batteries while

charging or for up to 30 minutes after charging. Other than parts accessed under the termination cover, there are no user serviceable parts

within the battery charger enclosure. Contact Blue Sea Systems for servicing.

GROUNDING PRECAUTIONS

Marine battery chargers and inverters have two grounding connections, one from the AC system and one from the DC system. ABYC requires

the AC grounding system to be connected to the DC grounding system through the distribution systems. Additionally, the chargers make

connections to both systems. It is very important the systems be connected properly before the charger is installed. Otherwise the charger

grounding system may become the sole connection between AC and DC ground and it may not be sized large enough to provide system wide

safety function. The AC grounding conductor is the conductor with green, or green with yellow stripe included in the AC power cable and should

be sized the same as the power and neutral conductors (see Table C page 5 for AC wire color). This will connect to the right most terminal in

the AC connection block. There is also chassis connection terminal for a DC safety grounding wire. The DC safety ground should be green or

marked green and sized equal to, or one wire size smaller, than the DC charge wires.

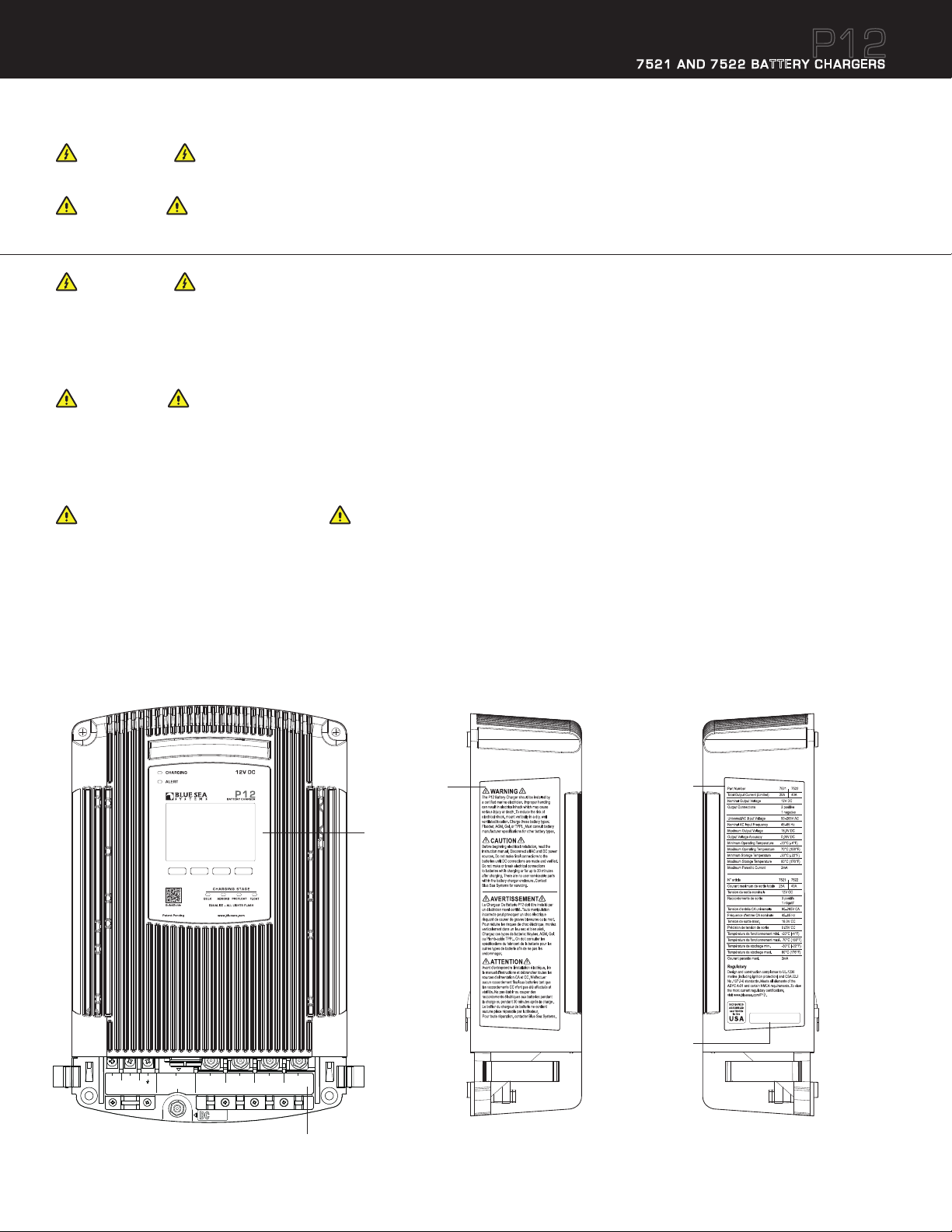

Warnings

Display

Specifications

Serial

Serial No. xxxxxxxxxxx

Number

M4 x 10

Line Neutral

Ground

AGC® 10A AC Fuse

− NEG

+ POS

+ POS

Battery Bus

DC Safety Ground

AC Input

Max.Torque 20 in-lb (2.25 Nm)

M3 x 25mm M3 x 30mm

SAFETY

GROUND

Battery 1

DC Output

Max.Torque 75 in-lb (8.47 Nm)

Battery 2

Battery 3

+ POS

Terminations

2

Specifications are subject to change. See bluesea.com/P12 for current information.

Page 5

P12 Battery Charger Overview

7521 AND 7522 BATTERY CHARGERS

P12

The Blue Sea Systems P12 Battery Charger is dry mount device designed for use in marine applications and other harsh environments where reliability, ease of

use, and high performance are of primary importance. To this end, the P12 is designed, assembled, and tested in Bellingham, Washington, USA. Critical

components, including all electronic circuitry, are of US manufacture.

The P12 is designed to charge three electrically independent batteries or battery banks. The P12 has the unique capability to individually move each battery

out of the Absorption charging stage. This ensures batteries near their full charge do not continue to receive high constant voltages necessary in the Absorption

stage. This is optimal treatment for long battery life. Charge Coordination integrates with the Blue Sea Systems family of Automatic Charging Relays (ACR) to

force separation of the battery banks while the P12 is operational, to allow the batteries to individually exit the absorption stage. After fourteen days of

continuous Float, the charger will repeat the normal charge cycle to assure good battery health.

For reliability, the P12 has a rugged cast aluminum housing with high heat dissipating capability for minimum cooling fan run times. The electronic design has

given special consideration to operation in areas of inconsistent AC power quality. The P12 has a Power Factor Corrected nominal AC input range of 90V to

265V AC within which it will produce its full rated DC charging output. It will continue to produce reduced DC output to as low as 75V AC. After a shut down

below 75V AC or when there is interrupted switching between AC sources, like switching between generator and shore power, the P12 will automatically perform

an orderly restart.

Central to the P12’s ease of use is the large plain-language full graphics control screen capable of displaying in French, English, Italian, German and Spanish.

The plain language display enables clear communication with the operator for setting precise charging parameters and providing a broad range of easily understood fault communications and operating history. An optional remote display brings much of this functionality to a secondary location away from the charger.

The P12 contains charge profiles for most batteries available today, including Flooded Lead Acid (FLA), Gel, Thin Plate Pure Lead (TPPL), and Absorbed Glass

Mat (AGM). In addition, a user configurable charge profile is available for other battery types.

The P12 has built-in safety features including: ignition protection, over and under temperature protection (sensed internally and at the batteries), DC reverse

polarity protection, DC over voltage protection, and surge and shor t circuit protection.

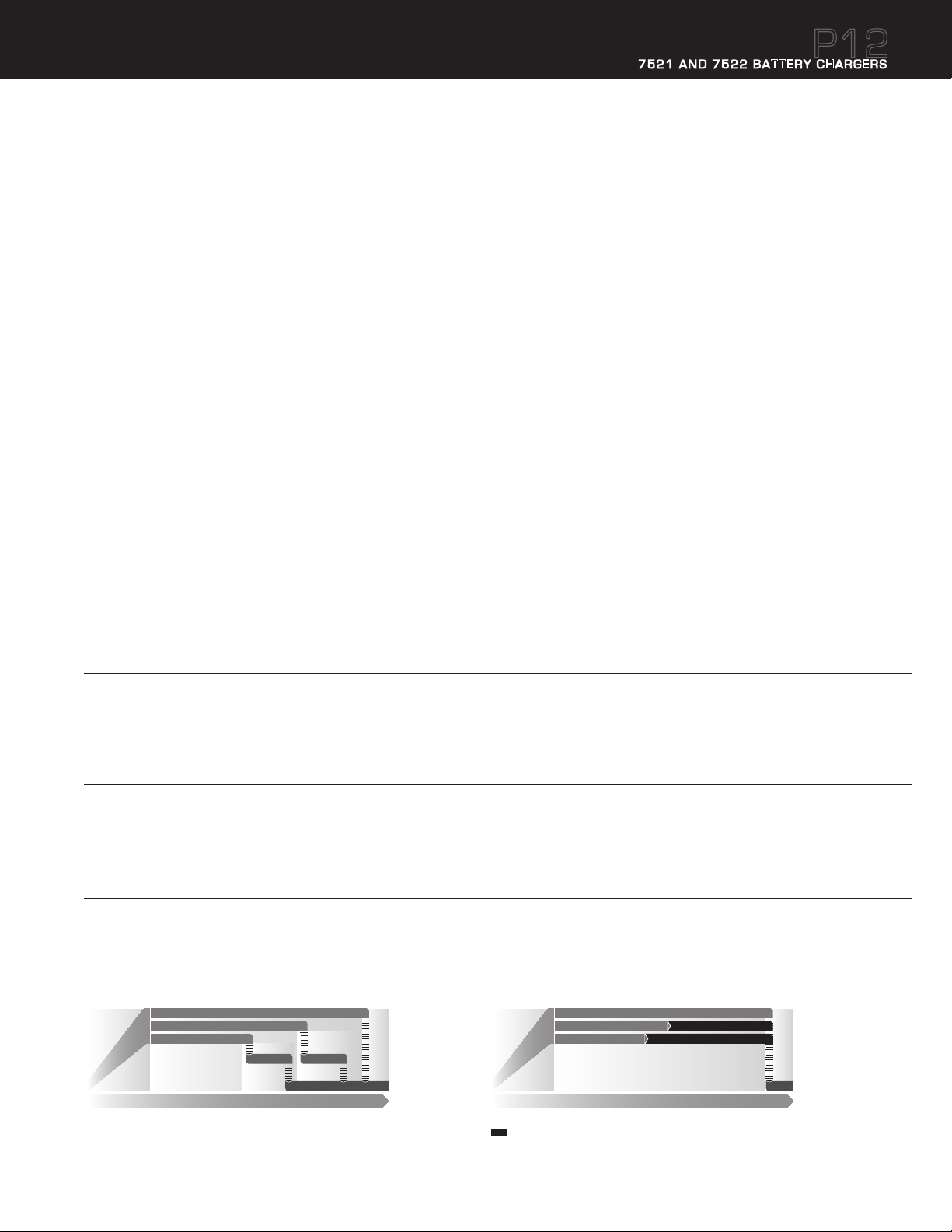

Four Stage Battery Charging

The definitions of the P12 charging stages are defined below. The charging stage LEDs on the front of the charger will indicate the current stage.

Bulk (Constant current)

The Bulk charging stage is the first stage in the battery charging process. It is where a majority of the charging actually takes place leaving batteries at approximately

75% to 80% of their final capacity. The goal of the Bulk stage is to drive current into the batteries quickly to increase their voltage. Once all the batteries have reached the

defined Absorption voltage then the charger will move them into the Absorption stage.

Absorption (Constant voltage)

In the Absorption charging stage the batteries complete their charging by being “topped off”. This is a less aggressive charging stage than bulk where the current going into a

particular battery bank will significantly reduce with time. The conditions for a battery bank to be considered “full” vary based on many different factors. In order for a battery

bank to leave the Absorption stage a number of different parameters must be met. The main parameters are the Absorption Timers which can be seen on

page 14. Outputs move individually from Absorption to Pre-Float. When all batteries have completed Absorption, the charger will move them into the Float stage.

Pre-Float (Constant voltage)

The Pre-Float charging stage is unique to the P12. Since the size of battery banks typically vary from one output to the next, there is a need to charge each bank independently.

Once all batteries are in Absorption battery banks may finish charging at different rates. Once a battery bank has met its unique Absorption parameters the P12 Charger will

independently move it into the Pre-Float stage. Pre-Float is the initial stage to maintain a fully charged battery. Batteries in Pre-Float can have up to a .5V difference

between batteries in Absorption. Up to two outputs can be in Pre-Float simultaneously.

Float (Constant voltage)

Float is the final charging stage for fully charged batteries. Batteries in this stage are being maintained at their defined float voltage. Typically his Float voltage

commonly has a 1.0V or greater difference from the Absorption voltage.

Conventional Three Stage Battery ChargingFour Stage Battery Charging

Battery 1

Battery 2

Battery 3

Bu lk

Absorption

T I M E

Example of Flooded Lead Acid Battery

Absorption

Absorption

PreFloat

PreFloat

Float

14.4V

13.9V

13.2V

Battery 1

Battery 2

Battery 3

Bu lk

Example of Flooded Lead Acid Battery

Forced Absorption: A period when batteries are potentially over charged.

Absorption

Absorption

Absorption

Forced Absorption

Forced Absorption

T I M E

Float

14.4V

13.2V

Specifications are subject to change. See bluesea.com/P12 for current information.

3

Page 6

−

NEG

Battery Bus

+

POS

Battery 1

+

POS

Battery 2

+

POS

Battery 3

DC Output

Max.Torque 75 in-lb (8.47 Nm)

AGC® 10A AC Fuse

DC Safety Ground

P12 Battery Charger Overview

Charging and

Alert indicators

7521 AND 7522 BATTERY CHARGERS

P12

Mounting holes

Clearance for:

M6, 1/4", or #12

mounting hardware

NOTE: Mounting holes are

not symmetrical please see

dimension drawing on page 6

Fan vent

Graphic LCD Display

Screen selection

buttons

Scan for

additional

information

Rugged, finned

cast aluminum case

AC strain

relief and

insulating cover.

AC input terminals

under cover.

Charging stage

indicators

DC output

Termination

cover latch

DC strain

relief clamp

4

Specifications are subject to change. See bluesea.com/P12 for current information.

Termination

insulating

cover

Page 7

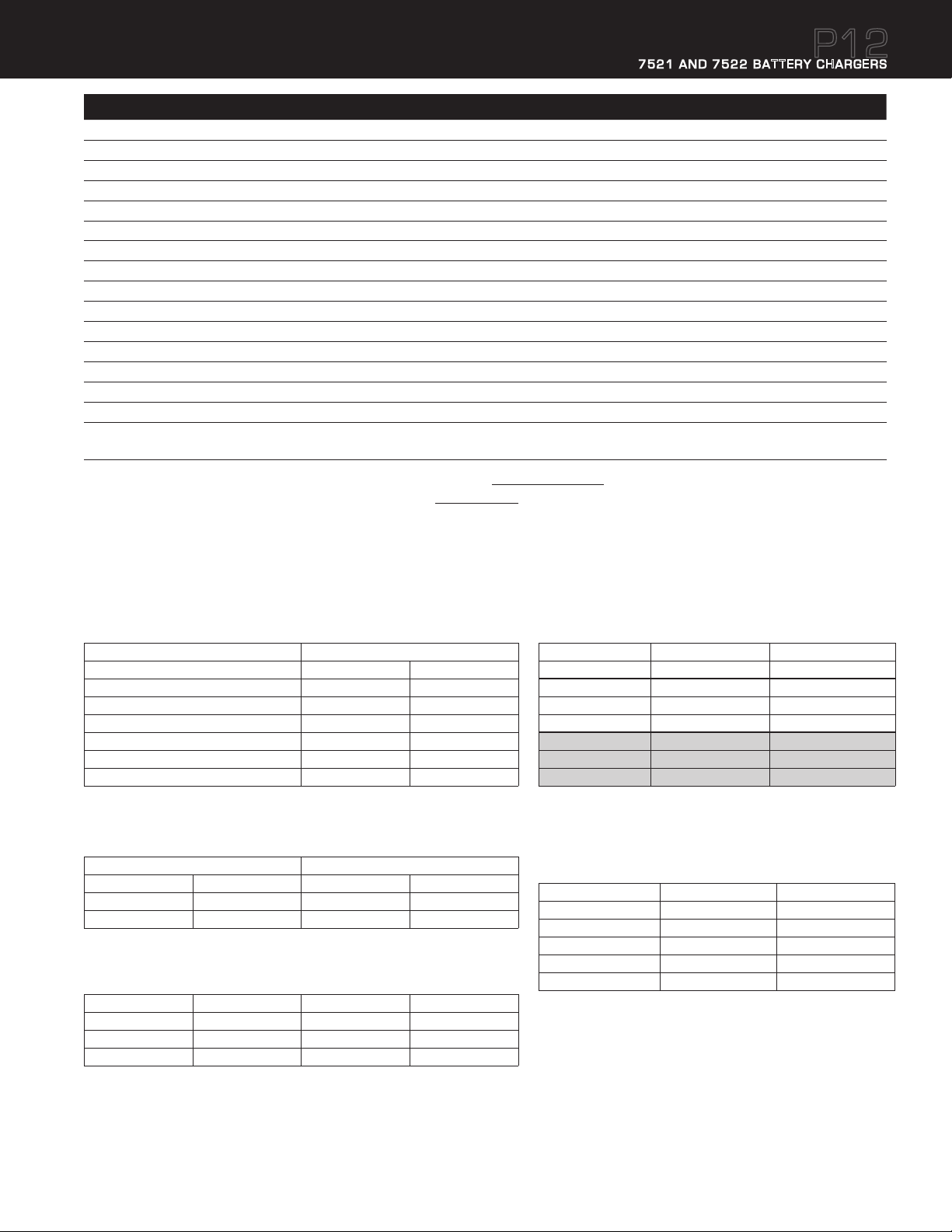

Specifications

7521 AND 7522 BATTERY CHARGERS

P12

7521 7522

Total Output Current 25A 40A

Input AC Current 4.5A @ 100V AC / 2.25A @ 200V AC 7.5A @ 100V AC / 3.75A @ 200V AC

Nominal Output Voltage 12V DC 12V DC

Output Connections 3 positive, 1 negative 3 positive, 1 negative

Universal AC Input Voltage 90V–265V AC 90V–265V AC

Input Frequency Range 45–65 Hz 45–65 Hz

Typical Float Voltage 13.5V DC 13.5V DC

Maximum Available Voltage 16.0V DC 16.0V DC

Output Voltage Accuracy 0.05V DC 0.05V DC

Minimum Operating Temperature −20°C (−4°F) −20°C (−4°F)

Maximum Operating Temperature 70°C (158°F) 70°C (158°F)

Minimum Storage Temperature −30°C (−22°F) −30°C (−22°F)

Maximum Storage Temperature 80°C (176°F) 80°C (176°F)

Warranty 5 Year 5 Year

Battery Types* Flooded, Gel, AGM, TPPL (Thin Plate Pure Lead) Flooded, Gel, AGM, TPPL (Thin Plate Pure Lead)

Recommended for Battery Bank Sizes**

* Consult batter y manufacturer specifications for other battery types to avoid damage. Do not mix battery types.

** Battery bank sizes are recommended for optimal charging efficiency-see bluesea.com/P12 for details. Larger and smaller size banks could charge well, but consume slightly

more power over the charging cycle.

160Ah Minimum, Example: 2 x Group 27

330Ah Maximum, Example: 3 x Group 31

Regulatory

Designed and constructed for compliance to UL-1236 Marine, CSA 22.2 No. 107.2, and ABYC A-31 standards. Ignition Protection per ISO 8846, and SAE J1171.

Meets FCC Part 15, Class B requirements. To view current regulatory specifications visit www.bluesea.com/P12.

220Ah Minimum, Example: 2 x Group 31

440Ah Maximum, Example: 4 x Group 31

Table A: Minimum Recommended Wire Size*

Conductor Length in feet (meters) Charger Rating

25A 40A

6 ft (1.83 meters) 14 AWG (2.5mm²) 8 AWG (10mm²)

10 ft (3.05 meters) 12 AWG (4mm²) 8 AWG (10mm²)

15 ft (4.57 meters) 10 AWG (6mm²) 6 AWG (16mm²)

20 ft (6.09 meters) 8 AWG (10mm²) 6 AWG (16mm²)

25 ft (7.62 meters) 6 AWG (16mm²) 4 AWG (25mm²)

Recommended Battery Fuse

* Based on 3% voltage drop. If fast charge recovery is important, use larger wire. Double the conductor

length entry to get a 1.5% drop, triple the conductor length to get a 1% voltage drop.

30A 60A

Table B: Recommended DC Circuit Protection

Appropriate Fuses and Fuse Holders Charger Rating

Fuse Type Fuse Holder 25A 40A

MRBF Terminal Fuses

AMI®/MIDI® Fuses 7720 Safety Fuse Block 5250 (30A Fuse) 5253 (60A Fuse)

5191 Terminal Fuse Block

5175 (30A Fuse) 5178 (60A Fuse)

Table C: Typical AC Regional Wire Colors

Region Line Neutral Ground (Earth)

North America Black White Green

Europe Brown Blue Green-Yellow

Australia/ New Zealand Brown or Red Blue or Black Green-Yellow

Table D: AC Wire - Circuit Protection Selection Chart

7521 (25A) 7522 (40A)

Input Watts 450 750

120V AC Application 4.5A @ 100V AC 7.5A @ 100V AC

Minimum AC Wire Size 18 AWG (0.75mm²) 16 AWG (1.5mm²)

Circuit Breaker 10A 15A

230V AC Application* 2.25A @ 200V AC 3.75A @ 200V AC

Minimum Wire Size 18 AWG (0.75mm²) 18 AWG (0.75mm²)

Circuit Breaker 5A – 10A 5A – 10A

* Typical of Europe

Table E: Default Voltages by Battery Type

Batteries should match in chemistry, although many AGM’s and flooded batteries are

compatible. Based on 25°C (77°F)

Type Absorb Volts Float Volts

FLA – Flooded Lead Acid 14.5V 13.5V

AGM – Absorbed Glass Mat 14.35V 13.3V

Gel – Gelled Electrolyte 14.1V 13.5V

TPPL – Thin Plate Pure Lead 14.7V

User Adjustable 12.5V Default 12.5V Default

¹ Taken from Odyssey Tech Notes, Northstar operation Manual

13.6V¹

Specifications are subject to change. See bluesea.com/P12 for current information.

5

Page 8

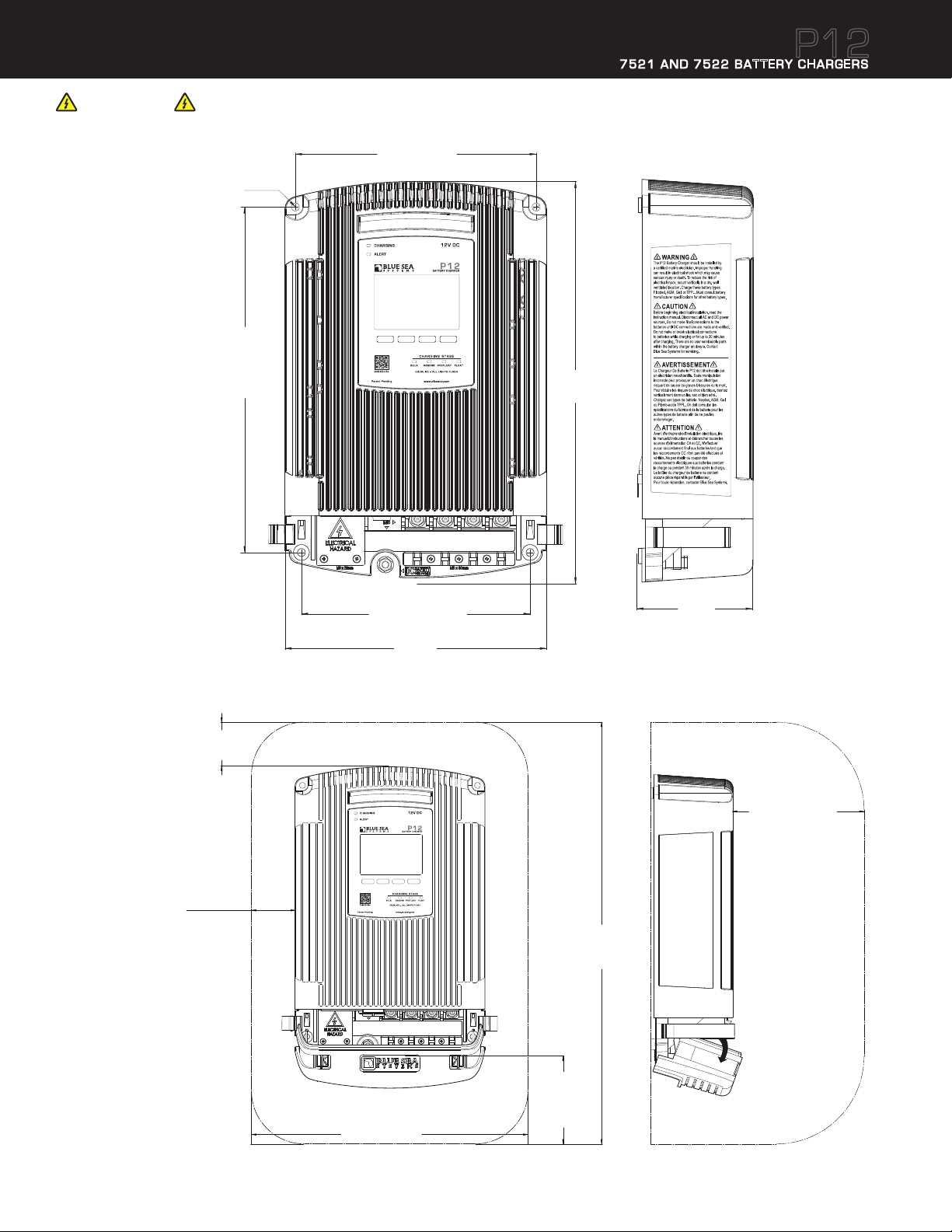

Product Dimensions

7521 AND 7522 BATTERY CHARGERS

WARNING

For drip proof performance, and to meet ABYC requirements, the P12 Battery Charger must be mounted vertically as shown below.

7.80" (198mm)

Top mounting

screw centers

Ø0.3" (6.6mm)

Mounting holes

Clearance for:

M6, 1/4", or #12

mounting hardware

NOTE: Mounting

holes are

not symmetrical

11.18"

(284mm)

Mounting

screw

centers

13.00"

(330.6mm)

P12

Installation Clearances

Recommended

top clearance

"

(50mm)

1.97

Recommended

side clearance

"

(50mm)

1.97

7.40" (188mm)

Bottom mounting

screw centers

8.46"

(215mm)

TOP

Recommended

overall

envelope height

"

(480.6mm)

19.00

3.66"

(93mm)

Recommended

clearance

for cooling fan exhaust.

do not block!

"

(150mm)

5.91

Recommended

clearance

for wire access

Recommended

overall envelope width

12.40

"

(315mm)

6

Specifications are subject to change. See bluesea.com/P12 for current information.

and inlet airflow.

"

(100.2mm)

3.94

Page 9

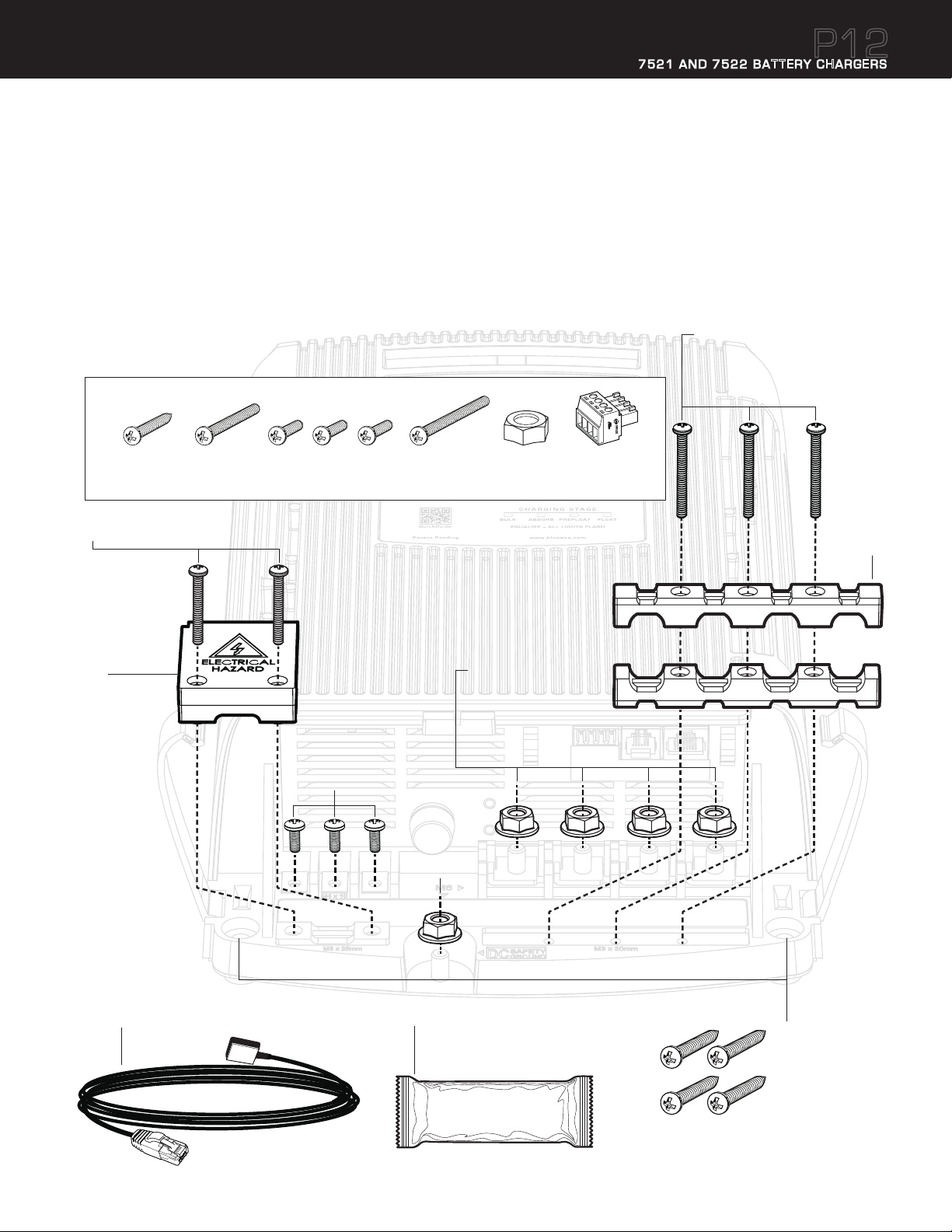

Included Components

1. Four Mounting Screws

2. Two AC Strain Relief and Insulating Cover Screws

3. One AC Strain Relief and Insulating Cover

4. Three AC Termination Screws: AC Line: Gold, AC Neutral: Silver, AC Ground: Green

5. Three DC Strain Relief C-Clamp Screws

6. One DC Strain Relief C-Clamp

7. Four DC Termination Nuts

8. One DC Safety Ground Nut

9. One Battery Temperature Sensor

10. One Packet of Dielectric Grease

11. Accessory Pack Includes:

Accessory Pack

AC Line

Gold

AC Neutral

Silver

AC Ground

Green

7521 AND 7522 BATTERY CHARGERS

P12

5

M3 x 30mm pan-head machine screws

(Use #1 Phillips screwdriver)

Recommended torque:

5–10 in-lb (0.6–1.1 Nm)

#12 x 1-1/4"

sheet metal screw

M3 x 25mm pan-head machine screws (Use #1 Phillips screwdriver)

2

Recommended torque: 5–10 in-lb (0.6–1.1 Nm)

M3 x 25mm

pan-head

machine screw

3

M4 x 10mm

pan-head

machine screws

M4 x 10mm pan-head

machine screws,

(Use #2 Phillips

screwdriver)

Recommended torque:

10–15 in-lb

(1.0–1.8 Nm)

4

M3 x 30mm

pan-head

machine screw

8

M6 serrated

flange hex-nut

7

M6 serrated flange hex-nuts

(Use 10mm socket wrench

with extension)

Recommended torque:

70–80 in-lb (8–9 Nm)

M6 serrated

flange hex-nut

(see #7 above)

Screw terminal

plug for ACR

connection

6

RJ11 connector with peel and stick

9

adhesive, 15 ft (4.6m) long tether

Used for Temperature Sensor and the

10

Optional Accessory P12 Remote Display

Connections (see pages 24–27). View

the MSDS for the Dielectric Grease at

bluesea.com/P12

Dielectric Grease

Specifications are subject to change. See bluesea.com/P12 for current information.

1

#12 x 1-1/4" sheet

metal screws (Use #3

Phillips screwdriver)

77

Page 10

Supplies Needed

7521 AND 7522 BATTERY CHARGERS

1. AC Wire (see Table D page 5)

NOTE: Wire length must reach from the panel to the battery charger AC Connections with proper routing, support, drip loops, service loops, and termination.

2. DC Wire: Black or Yellow for negative and red for each positive. (see Table A page 5)

NOTE: Yellow is preferred for negative however diagrams are drawn in black for visibility.

3. Fuse holders for connection to each battery. (see Table B page 5)

4. Fuses for fuse holders. (see Table B page 5)

5. Screwdrivers

• Flat blade screwdriver

• Phillips #1 – for AC Termination cover and DC Termination Strain Relief clamp

• Phillips #2 – for AC termination screws

• Phillips #3 – for mounting screws

6. Socket wrench

• 10mm socket with extension and ratchet handle or nut driver – for DC wire terminations

7. Ring terminals

• #8 ring terminals sized for AC/Supply wire gauge (quantity 3)

• ¼” or M6 ring terminals sized for DC wire sizes (quantity 4)

P12

8. Crimping tool or obtain wires that are pre-terminated

9. Appropriate heat shrink if pre-terminated wires were not acquired

8

Specifications are subject to change. See bluesea.com/P12 for current information.

Page 11

Installation Instructions

DC

AC

7521 AND 7522 BATTERY CHARGERS

The P12 Battery Charger default startup mode is “User”. The battery charger will maintain a voltage but will not

charge batteries in this mode. After proper installation see page 11 to set up your battery type.

Installation Steps

1. Before beginning electrical installation, disconnect all positive and negative AC and DC power sources.

2. To reduce the risk of electrical shock, mount the battery charger vertically, in a dry and well ventilated location.

For drip proof installation, mount the battery charger in a vertical orientation.

NOTE: The charger should be located near the batteries to minimize wire length and its associated voltage drop to maximize charging efficiency.

If the batteries are not close together, place the charger near the largest bank of batteries.

3. Remove the AC/DC termination cover by unlatching the yellow tabs. The cover hinges downward as shown.

P12

4. Then remove the AC and DC wire termination strain relief by unfastening the screws.

AC Strain Relief DC Strain Relief

5. Route DC wires from each charger output to batter y fuse holder, see Wiring Connections Diagram page 10.

NOTE: DC wiring should safely reach each battery positive and the battery negative common bus bar. Fuses should be installed at the battery positive

connections to prevent battery power from feeding back into a fault in the wiring, or in the battery charger. See Table A and B on page 5 for recommended values.

Best practices and ABYC standards recommend that every positive wire on the boat outside the engine starting circuit most have circuit protection.

Please reference ABYC E-11 electrical standard for the most up to date recommendations.

Specifications are subject to change. See bluesea.com/P12 for current information.

9

Page 12

Installation Instructions (continued)

6. Route the AC wires from the charger to the AC panel and terminate wires at the charger.

7. Make the AC source connections to the appropriate panel circuit breaker and leave in the “off” position. (see Table D page 5).

NOTE: Connect AC wiring, but do not energize the circuit until AC covers are installed, DC is connected, and DC fuses are installed.

8. Recommended Connection: Attach the batter y temperature sensor wire to the largest battery bank. If all battery banks are the same size attach to bank with the most loads.

Blue Sea Systems recommends using a high quality dielectric grease for remote control and temperature sensor connections.

a. Attach the sensor in the center of the long side of the batter y.

b. If multiple batteries are in a batter y bank attach sensor in the center between multiple batteries.

c. When external circumstances could create a significant difference in temperature on one side of a battery versus another, always attach temperature sensor

on warmest side.

9. Install appropriate DC Fuses. (see Table B page 5)

10. Confirm all connections are accurately installed per

Wiring Connections Diagram.

11. Secure AC and DC strain relief covers and fasten down.

12. Secure the termination cover back over the connected wires

and latch the yellow tabs.

13. Restore AC power and turn on the AC supply circuit

breaker to the battery charger.

14. Perform the chargers setup procedure as outlined in

Initial Charger Setup page 11.

7521 AND 7522 BATTERY CHARGERS

Temperature

Sense

RJ11 Port

Remote

Display

RJ45 Port

P12

Wiring Connections

Fuse Fuse Fuse

Line

Neutral Ground

AC Connections

#8 (M4) Ring Terminals

DC Safety

Battery 2 Battery 3Battery 1

DC Connections

1/4" (M6) Ring Terminals

Ground

Optional Installations see pages 22–23

1. Attach the batter y charger remote connection to the back of the P12 Battery Charger Remote using dielectric grease. Connect to the Remote Display/Com

port of the charger.

2. Connect the Automatic Charging Relay(s) (ACR) wire to the ACR Connection port(s)

NOTE: If you have a Blue Sea Systems ACR with Start Isolation it is possible to take advantage of the P12 Battery Chargers ability to integrate with it. The P12

is designed to charge three electrically independent batteries or battery banks. The P12 has the unique capability to individually move each battery out of

Absorption charging stage. This ensures batteries near their full charge do not continue to receive high constant voltages necessary in the Absorption stage. This

is optimal treatment for long battery life. Charge Coordination integrates with the Blue Sea Systems family of Automatic Charging Relays (ACR) to force separation

of the battery bank while the P12 is operational, to allow the batteries to individually exit the absorption stage. (see pages 22–23)

10

Specifications are subject to change. See bluesea.com/P12 for current information.

Page 13

Initial Charger Setup

7521 AND 7522 BATTERY CHARGERS

P12

During Initial Charger Setup, or after resetting to factory defaults, the following screens require user input to provide

functional battery charging.

1. Using the left or right arrow button, scroll to the desired language.

Press the Select button.

2. Once the desired language is highlighted, press OK button.

Press the Cancel button to go back.

3. Using the left or right arrow button, scroll to the desired battery type.

Press the Select button.

Note: If User mode is selected batteries will not charge until Absorb and Float voltages are altered.

See page 12-13 for Advanced Charger Setup.

4. Once the desired batter y type is highlighted, press the OK button.

Press the Cancel button to go back.

5. Press the Back button twice to go to the Charger Summar y screen.

Note: If battery type is unknown, see the label on the battery or contact a qualified marine electrician.

CAUTION

Selecting a battery type different from the connected batteries could limit the life of the

batteries and damage them.

Your charger is now operational.

For advanced setup options and information on Absorb and Float voltage, as well as absorb timers,

See page 12.

Specifications are subject to change. See bluesea.com/P12 for current information.

11

Page 14

Advanced Charger Setup

7521 AND 7522 BATTERY CHARGERS

Complete this setup to change language, limit fan noise, adjust backlight display and limit AC current draw.

1. Press the Menu button.

2. Press the left or right arrow buttons to scroll to the Fan Speed window

3. Press the Select button.

4. Press the up or down arrow buttons to select the desired speed.

a. High: The fan will spin up to its maximum speed. This is the recommended setting for optimal performance.

b. Low: The fan will spin up to a designated speed (below max). If there is a significant load on the charger, it may limit its maximum output current in

order to maintain a safe internal temperature.

c. Off: Forces the Fan to stay off. If there is significant load on the charger, it may limit its maximum output current to maintain a safe internal temperature.

NOTE: Selecting High or Low will not necessarily turn the fan immediately on or increase the fan speed. In either of these settings the charger will only alter the fan

speed if the internal temperature rises enough to warrant fan circulation. The fan Low setting is for quiet mode.

P12

5. Press the OK button once desired speed is reached.

6. Press the left or right arrow buttons to scroll to the Max Output window.

7. Press the Select button.

8. Press the up or down arrow buttons to select the desired maximum output amperage. Low output may be selected to reduce load on the AC source.

AC current is approximately one tenth of the DC current at 120V line voltage and one twentieth of the DC current at 240V line voltage.

NOTE: The designated maximum amperage is the total available amperage to be supplied among all 3 outputs. Selecting an amperage less than the maximum

could result in under charging of batteries.

9. Press the OK button once desired max amperage output is reached.

10. Press the left or right arrow buttons to scroll to the Display window.

11. Press the Select button.

12. Press the up or down arrow buttons to scroll to the desired display setting.

13. Press the Select button on the desired display setting to enable editing that setting.

a. Once selected, the amount of contrast and backlight can be adjusted using the left and right arrow buttons.

b. Press the OK button to enable desired setting.

14. Scroll to Backlight Timer and press the Select button.

a. Using the left and right arrow buttons you may adjust the length of seconds the backlight will remain on.

b. The backlight timer can be adjusted between 5 and 59 seconds. It may also be set permanently on or permanently off.

15. Press the OK button once desired backlight setting is reached.

16. Scroll to Language and press the Select button to adjust the display language.

17. Using the left or right arrow buttons scroll to the desired language.

18. Press the OK button.

12

Specifications are subject to change. See bluesea.com/P12 for current information.

Page 15

Advanced Charger Setup (continued)

19. Once desired display settings are enabled press Back.

20. Press the left or right arrow button to scroll to the Battery window.

21. Press the Select button.

7521 AND 7522 BATTERY CHARGERS

P12

Table E: Default Voltages by Battery Type

Batteries should match in chemistry, although many AGM’s and flooded batteries are

compatible. Based on 25°C (77°F)

Type Absorb Volts Float Volts

FLA – Flooded Lead Acid 14.5V 13.5V

AGM – Absorbed Glass Mat 14.35V 13.3V

Gel – Gelled Electrolyte 14.1V 13.5V

TPPL – Thin Plate Pure Lead 14.7V

User Adjustable 12.5V Default 12.5V Default

¹ Taken from Odyssey Tech Notes, Northstar operation Manual

22. While the cursor blinks on battery type press the Select button.

23. Use the left or right arrow buttons to scroll to desired battery type.

24. Press the OK button.

25. For optimal charging it is recommended to set absorption timers and End Absorb Amps. If Amp Hour Capacity is known, continue to page 14 for more information.

13.6V¹

NOTE: to adjust Absorb and Float voltage “User” must be the selected battery type. The default Absorb voltages for each battery type can be seen in Table E above.

Warning: Incorrect Absorb and Float voltages could reduce the life of your batteries. Contact your battery manufacturer for recommended Absorb and Float voltages.

CAUTION

Selecting a battery type different from the connected batteries could limit the life of the batteries and damage them.

26. Press the Back button twice to return to the Charger Summary screen.

27. Your P12 Battery Charger is now setup and fully operational.

Reset to Manufacturer Defaults

To reset the P12 Battery Charger to factory defaults, press and hold the two right buttons for ten seconds.

Press the OK button for five seconds to proceed with resetting to factory defaults or press the Cancel button to return to the previous screen.

Note: Resetting the P12 Battery Charger to factory defaults will erase previously saved data and settings.

Specifications are subject to change. See bluesea.com/P12 for current information.

13

Page 16

Absorption Parameters and Timers

7521 AND 7522 BATTERY CHARGERS

P12

CAUTION

The default Absorption Timer values are set to satisfy a majority of the battery configurations that exist. Unwarranted changes to Absorption timers could

result in damage to the batteries and reduced battery life. To optimize Absorption Timer based on specific configurations please contact your

battery manufacturer for setting guidelines for your specific battery.

The Absorption stage is the charging stage in which a battery “fills” to max capacity. Absorption timers help define the amount of time a battery bank will

remain in the Absorption stage. Having a correct Absorption time is vital for optimum charging of a battery bank. Under Absorption can lead to a battery

being consistently under-charged causing sulfate buildup. Over Absorption can dry out the electrolytes in a batter y. Both of these conditions can lead to

reduced battery life.

There are three user selectable parameters that help define when a connected battery bank will be moved from Absorption to either Pre-Float, or Float.

End Absorption Amps

The maximum amount of current that a battery bank can receive while in Absorption and still change to Float. If a

load is active and drawing more than the designated End Absorption Amps, the battery bank will not leave Absorption

until the maximum Absorption time is met. For a battery bank to move from Absorption to Float before the maximum

Absorption time is met, the minimum Absorption time must be met, and the amperage output must be less than or

equal to the designated End Absorb Amps.

Recommended End Absorption Amps

End Absorb Amps will vary based on your specific system. To set the correct End Absorb Amps it is recommended

that you monitor the amperage entering your battery banks near the end of the absorption cycle. Constant loads

will affect this number, and should be incorporated into End Absorb Amps if present. However, in a typical system

(without constant loads) it is recommended that the End Absorb Amps be 1% of your battery banks amp-hour

capacity (see Table F).

Table F: Approximate End Absorb Amps

(1% of Ah Capacity)

Flooded AGM Gel TPPL

Group

Size

24 75 0.8 79 0.8 73 0.7 76 0.8

27 90 0.9 92 0.9 86 0.9 91 0.9

31 105 1.1 105 1.1 97 1.0 102 1.0

4D 150 1.5 198 2.0 183 1.8 185 1.9

8D 200 2.0 245 2.5 225 2.3 228 2.3

1% End

Ah

Amps

1% End

Ah

Amps

1% End

Ah

Amps

1% End

Ah

Amps

Minimum Absorption Time: 1 hour default

The minimum amount of time a battery bank will be in Absorption. The batter y charger will not move a battery from Absorb to Float unless the Minimum Absorption Time is met.

Maximum Absorption Time: 4 hour default

The maximum amount of time a battery bank can remain in Absorption. While still maintaining its Absorption voltage, if a battery has been in Absorption for the maximum

designated time it will move into Float even if End Absorb Amps is elevated. This is commonly caused when active loads are present.

Recommended Absorption Time

Minimum and Maximum Absorb Times can vary from installation to installation. It is recommended that Minimum and Maximum Absorption Times be based on the time it takes

a battery bank to reach End Absorb Amps. Read and understand the End Absorb Amps section above and set according to your system. After an accurate End Absorb Amperage

is set, monitor the minimum and maximum time it takes for each battery bank to reach their End Absorb Amps. The Minimum Absorb Time should be based on the minimum time

it takes a particular battery bank to reach End Absorb Amps. The Maximum Absorb Time should be an hour more than it takes a deeply discharged battery bank to reach End

Absorb Amps. It is recommended to monitor charging while the battery banks are in different states of discharge to get the most accurate Minimum and Maximum Absorb Times.

Absorption Timer Counter

The P12 battery charger uses a counter to determine the amount of time a batter y bank should remain in Absorb relative to the Maximum Absorb Time. The Absorb timers counter

can be seen in the System Status Screen and also referenced on page 19.

Available Timer Modes

When in Float or Standby, the timer will pause.

When in Pre-Float mode the timer for that channel will pause.

When in Bulk mode the remaining time will increase.

When in Absorption mode, the remaining time will decrease.

Once a battery bank’s Absorb timer is reduced to zero, then its output will be changed to Pre-Float. There are

other factors in a battery bank leaving the Absorption stage prior to the Absorb timer running out. Once all battery

banks leave Absorption, all outputs will enter the Float stage.

14

Specifications are subject to change. See bluesea.com/P12 for current information.

Page 17

Temperature Parameters

7521 AND 7522 BATTERY CHARGERS

P12

WARNING

Altering the default temperature parameters could cause serious property or personal damage. Contact your battery manufacturer to clarify the correct

temperature parameters for your specific batteries.

NOTE: Temperature parameters refer to the temperature measured at the temperature sensor, not the temperature of the charger. In this manual all temperatures

will be referenced in degrees in Celsius (°C). The user selectable range for battery temperature parameters is -20°C to 60°C. Ensure proper placement of battery

temperature sensor by referencing Step 8 on page 10

Minimum Charge Temperature: The default is 0ºC

The lowest temperature of the sensor in which the charger will continue charging. If the temperature sensor falls below the minimum charge temperature, the charger will enter

standby mode, and cease to charge.

CAUTION

Charging batteries below 0°C can be potentially dangerous. Internal battery liquid can freeze and charging a frozen batter y could cause serious property or

personal damage. Contact your battery manufacturer for minimum safe charging temperature for your batteries before altering.

Maximum Charge Temperature: The default is 50ºC

The highest temperature of the sensor in which the charger will continue charging. If the temperature sensor increases above the maximum charge temperature, the charger will

enter standby mode, and cease to charge.

CAUTION

Charging batteries above 50°C can be potentially dangerous. Contact your battery manufacturer for the maximum safe charging temperature for your

batteries before altering.

Battery Temperature Compensation (Tempco)

Battery temperature compensation is output voltage regulation based on battery temperature variances. Since batteries can see extreme temperature differences it is important

to regulate output voltage with temperature. A battery in a freezing environment should not be charged the same as a battery in a hot environment. The P12 Battery Charger

is set at a baseline of 25°C. Every degree variance from this baseline will result in a voltage variance on all outputs. For every degree above 25°C the charger will reduce all

output voltages by the value defined in Battery Tempco. For every degree below 25°C the charger will increase all output voltages by the value defined in Battery Tempco. For

example, with the default Battery Tempco set to -30mv/°C if the temperature sensor reads 26°C, then all output voltages will be reduced by .03V (30mv). If given the same

Battery Tempco and the temperature sensor reads 24°C, then all output voltages will be increased by .03V (30mv).

CAUTION

Altering the battery temperature compensation value incorrectly can cause adverse effects on your battery, by potentially reducing its life. Contact your

battery manufacturer to find out the specific temperature compensation parameters for your batteries.

Specifications are subject to change. See bluesea.com/P12 for current information.

15

Page 18

Equalization

7521 AND 7522 BATTERY CHARGERS

P12

WARNING

Equalization is a user selectable and potentially dangerous charging stage that should not be performed without sufficient knowledge. Personal or property

damage may occur if equalization is performed incorrectly. It is highly recommended that you seek professional guidance before performing equalization.

Equalization causes off gassing of harmful chemicals inside of the battery. Only perform equalization while the batteries are in a well-ventilated area away

from persons and animals.

CAUTION

Equalization may only be performed on flooded (wet) lead acid batteries. Serious personal or property damage may occur if equalization is

performed on any battery type other than flooded lead acid batteries.

Definition of Equalization

Equalization is an increased voltage overcharge performed only on flooded lead acid batteries. Once a battery is fully charged equalization increases the voltage and forces

additional charge into the battery to combat negative chemical side effects that can occur in flooded batteries. It is done to compensate for stratification, a

condition where the acid concentration is uneven throughout the battery, and typically higher at the bottom. It is also done to remove sulfate crystals that build up

on the lead plates in flooded batteries.

Prior to Equalization

Contact the manufacturer of your flooded lead acid batteries to confirm the parameters of equalizing your specific batteries. Every batter y manufacturer defines different

equalization parameters which are important to understand prior to equalization. All batteries must be fully charged and not under load from any device. The P12 Battery

Charger will not allow equalization to occur if batteries are discharged or powering any device.

Equalization Process

1. Confirm batteries are fully charged by verifying the charger is in Float mode with no active loads.

2. Turn off or disconnect all DC devices that are connected to the batteries. Disconnect the battery banks not being Equalized by removing the fuses at

the battery connection.

NOTE: Equalization will not occur if steps 1 and 2 are not met.

3. Confirm use of flooded lead acid batteries.

NOTE: Equalization will only occur if the battery type is set to “Flooded Lead Acid” (FLA) or “User”. Do not proceed if you are using any other battery type.

See bluesea.com/P12 for details.

4. From any screen simultaneously press and hold the left and right most buttons for 5 seconds.

5. Read and understand the caution screen before proceeding.

6. Press “I Accept” to continue.

7. Using the batter y manufacturer’s parameters, input the correct equalization voltage, amperage, and time on the battery bank you would like to equalize.

You may only equalize one battery bank at a time.

NOTE: Equalization parameters vary based on batter y size. Confirm parameters for every battery connected to the charger before continuing.

16

Specifications are subject to change. See bluesea.com/P12 for current information.

Page 19

Equalization (continued)

8. To change battery, use the up down arrow buttons to scroll the cursor to the Bat1 window.

9. Press the Select button.

10. Using the left and right arrow buttons, scroll between the three different battery banks connected to the charger.

11. Confirm Equalization parameters for the battery you wish to equalize.

12. Using the up down arrow buttons, scroll the cursor to the StartEQ window.

13. Press the Select button.

14. The charger will now begin to equalize and will display.

15. Monitor batteries and batter y temperature throughout the Equalization process.

16. You may pause Equalization at any time by pressing the pause button.

7521 AND 7522 BATTERY CHARGERS

P12

17. If at any point during Equalization a DC load is applied to the batter y being equalized, Equalization will stop.

NOTE: If you receive the below warning screen confirm batteries are fully charged and all DC loads connected to the batteries are turned off. Once complete proceed

back to step 1 of the Equalization process.

18. You may stop Equalization at any time by pressing the stop button.

NOTE: Pressing stop will return you to the Charger Summary screen.

19. Once the max Equalization voltage is reached the batter y bank will begin to equalize for the designated Equalization time.

20. After the designated Equalization time is met Equalization will stop and the charger will return to the Charger Summary Screen.

Specifications are subject to change. See bluesea.com/P12 for current information.

17

Page 20

Screen Summary

Charger Summary

The Charger Summary screen provides data of the battery’s status while the battery charger is operational.

Options:

- Press the History button to view previous charger performance

- Press the Menu button to view the Configuration Menu

How to Get Here:

From other screens in the charger, select the Back button.

Configuration Menu

The Configuration Menu has six user selections that allow modifications to Fan Speed, Charger Output,

Display, Battery Parameters, Temperature Limits, and Diagnostics.

Options:

- Scroll through the menu and select the desired option.

How to Get Here:

From the Charger Summary Screen, select the Menu button. From other screens, select the Back button.

Display Setup

The Display Setup allows the user to customize the display settings.

Options:

- Adjust Contrast

- Adjust Backlighting

- Set a Backlight Timer (length of time backlight will remain on)

- Select a language

7521 AND 7522 BATTERY CHARGERS

P12

How to Get Here:

From the Configuration Menu, select the Display button.

Charger Setup

The Charger Setup Menu is where the Battery Type and Absorb Timers are selected. Caution read

Absorption Parameters and Timers on page 14 before adjusting absorb timers.

Options:

- Select Battery Type or set Absorb Timers.

- If “User” is the selected battery type you may also adjust Absorb and Float voltage.

See page 14 for more information

How to Get Here:

From the Configuration Menu, select the Battery button.

18

Specifications are subject to change. See bluesea.com/P12 for current information.

Page 21

Screen Summary (continued)

Temperature Parameters

The Temperature Parameters screen indicates the minimum and maximum operating temperature based on the

temperature sensor. Read the Temperature Parameters section on page 15 before making any adjustments.

Options:

- Select Units and temperature parameters to adjust.

How to Get Here:

From the Configuration Menu, select Temp Limits.

System Status

The System Status screen indicates which systems are functioning and the current firmware installed on the device.

Options:

- Select the Back button to go to the Configuration Menu.

- Select the Next button to view the status of the Absorb timers.

How to Get Here:

From the Configuration Menu, select Diagnostics

System Status Absorb Timers

The System Status Absorb Timers screen indicates the current Absorb time of each battery bank, as well as the

AC input voltage. The up down arrows indicate if time is being added or subtracted from the timer. If paused

the charger is in Float or Standby and the Absorb Timer will remain at its current time.

Read about Absorb Timers on page 14.

Options:

- Select the Back button to go to the System Status Screen.

- Select the Next button to view the charger Hour Meter Screen.

7521 AND 7522 BATTERY CHARGERS

P12

How to Get Here:

From the System Status Screen, select the Next button.

System Status Hour Meter

The System Status Hour Meter screen displays the overall time the charger has spent running at different

amperage levels.

Options:

- Select the Back button to go to the System Status Absorb Timers Screen.

How to Get Here:

From the System Status Absorb Timers Screen, select the Next button.

History

The History screen graphically displays the charging voltage and amperages per battery.

Options:

- Select the Back button to go to the Charger Summary Screen.

- Select individual batteries to view charging summary.

- Press and hold any Bat button for 3 seconds to switch from First 8 Hour view to Continuous.

How to Get Here:

From the Charger Summary Screen, select the History button.

Specifications are subject to change. See bluesea.com/P12 for current information.

19

Page 22

Alert Screens and Diagnostics

7521 AND 7522 BATTERY CHARGERS

P12

If at any time during the chargers life the red Alert light goes on, then the charger is not providing optimal performance.

The below Alerts encompass all of the possibilities for the charger to under perform. Alerts will be indicated by the red

Alert light as well as a pop-up screen explaining the reason.

Reverse Polarity or Short Circuit

The P12 Battery Charger has the ability to determine if batteries are incorrectly connected to the charger. Upon

supplying AC power to the charger if a reverse polarity or short circuit situation exists the Reverse Polarity or Short

Circuit Screen will be displayed. Shut off AC power and correct the connection issue. Once corrected, turn on AC

power and attempt to use the battery charger as normal. If no aler t screen displays then the charger is

fully operational.

Reverse Polarity or Short

Turn Off AC Power

Check DC Connections

WARNING

If AC power is being supplied to the battery charger and batteries are connected incorrectly (reverse polarity or

short circuit), damage will occur to the internals of the battery charger. This will render the battery charger

non-operational. Never make connections while AC power is supplied to the battery charger. Personal and property damage may occur and the chargers warranty will be void.

Thermal Regulation

The P12 Battery Charger is equipped with an intelligent thermal regulation device for safe charging. If at any point

during charging a thermometer image begins to blink in the upper right hand corner of the screen, then the charger

has entered Thermal Regulation. This is not a failure, but a reduced current output state. While in this state the

internal temperature is being regulated by controlling the maximum output current. The maximum output current will

appear at the bottom of the Charger Summary Screen indicating the total amount of current available to supply all

outputs. While in Thermal Regulation, the charger will reduce output current to keep the charger at a safe operating

temperature. The output can be regulated all the way down to zero but is not likely. The most common correction for

this state is to increase the fan speed to High. If the fan speed is already set to High check for blockage around the

fan vent that can be removed. If the condition persists, it is advisable to reposition the battery charger in a cooler,

more ventilated location.

Fan

The P12 Battery Charger is equipped with a variable speed fan. The fan is used to dissipate warm air produced from

high output currents during charging. The aluminum case of the P12 Battery Charger provides a large amount of heat

dissipation but for optimal performance the fan must be performing properly. If at any point the fan fails to perform

at its designated setting the Fan Alert Screen will appear. If this alert screen appears shut off AC power to the

battery charger as well as all battery connections. Determine if there is a blockage in or around the fan vent and

correct. Turn on AC power and check to see if the Fan Alert Screen appears. If the Fan Alert Screen does not appear

and the fan seems to be operating correctly, then continue to use the battery charger normally. If the Fan Alert

Screen appears contact Blue Sea Systems for fan replacement instructions.

Fan Fault

Check Fan for Blockage

Battery Temperature Sensor

As discussed in the Temperature Parameters section (page 15), there is an external battery temperature sensor

supplied with the unit. If at any point the temperature sensor records a temperature beyond the defined temperature

limits, the battery charger will display the Battery Temperature Alert Screen. In this situation all battery charging will

stop until the proper battery temperature is restored. Normal operation will not commence unless two degrees within

the temperature parameters. For example, if the maximum temperature parameter is set to 50°C and the

temperature sensor reads 51°C then the Battery Temperature Alert Screen will display. In this situation the battery

charger will not charge until the battery temperature sensor reads a maximum of 48°C. If no temperature sensor is

in use then battery temperature is not monitored and this alert will not be displayed.

Battery Temperature

Out of Limits

CAUTION

Alteration of battery temperature parameters without sufficient knowledge is dangerous and can cause personal or proper ty harm. If the battery temperature sensor goes

outside a designated parameter, contact your battery manufacturer for further information on specific battery temperatures.

Internal Temperature Sensor

The P12 Battery Charger is equipped with two internal temperature sensors. These sensors are unrelated to the

supplied external battery temperature sensor. If the Internal Temperature Sensor Alert Screen appears, then one

or more of the internal temperature sensors is not recording correct temperature data. Once in this state all battery

charging will stop. This form of temperature alert can not be corrected by the user. Contact Blue Sea Systems for

further information regarding internal temperature sensor aler ts.

Internal Temp Below -20° C

Charger Will Restart When

Internal Temp Above -18° C

20

Specifications are subject to change. See bluesea.com/P12 for current information.

Page 23

Alert Screens and Diagnostics (continued)

AC Input Voltage Too Low

The minimum input voltage for the P12 Battery Charger is 90V AC. However, due to common voltage sags caused

by spikes in power, the internal hardware of the P12 Battery Charger can continue to charge for brief periods

below 90V AC. If the AC input voltage drops below 75V AC, the alert screen on the right will appear. While in this

state the charger will cease to charge any batteries. Shut off power at the AC source for two minutes, and then

restart. If the alert screen persists, attempt to use a different AC power source, or contact an electrician to

diagnose the problem.

AC Input Voltage Too High

The maximum input voltage for the P12 Battery Charger is 265V AC. If the input voltage is above 265V AC the

alert screen on the right will appear. In this state the charger will cease to charge any batteries. Shut off power at

the AC source for two minutes and then restart. If the alert screen persists, attempt to use a different AC power

source, or contact an electrician to diagnose the problem.

DC Output Voltage Too High

If at any point the charger detects a DC output voltage greater than 17.8V DC for five seconds, then the alert

screen on the right will appear. In this state the charger will cease to charge any batteries in order to prevent

damage. Shut off AC power for two minutes, and then restart. If the alert screen persists, shut off AC power and

contact Blue Sea Systems for further assistance.

7521 AND 7522 BATTERY CHARGERS

AC Input Voltage too Low

Check for Proper AC Source

AC Input Voltage Too High

Check for Proper AC Source

DC Output Voltage Too High

Charger is off to prevent damage

Disconnect AC for 2 mins. then restart

P12

DC Fuse

The P12 Battery Charger has two internal DC fuses that are not accessible by the user. If the DC Fuse Alert Screen

appears, disconnect AC power and all battery connections. The battery charger will require servicing by Blue Sea

Systems. No attempts should be made to replace the fuses by the user. Contact Blue Sea Systems for further

instructions regarding DC fuse replacement.

CAUTION

Any attempt to replace the DC fuses will void warranty.

Hardware Failure

There are many complex internal electrical components on the P12 Battery Charger. If any of the vital hardware

components fail the Hardware Failure Alert Screen will appear. Shut off AC power for two minutes, and then

attempt to restart. If there is no longer a Hardware Failure Alert Screen, proceed to use the charger normally. If the

Hardware Failure Alert Screen persists, disconnect AC power and all battery connections, and contact Blue Sea

Systems for further assistance.

Equalization Overload

If at any point during equalization the total output current of the battery charger is greater than the defined

Maximum Equalization Current the Equalization Overload Alert Screen will appear. To correct, confirm batteries

are fully charged, and all loads are turned off prior to equalization. If mandatory 24-hour loads are present you may

adjust the Maximum Equalization Current accordingly. Once corrected, the equalization process must be restarted.

Internal Fuse Failure.

Contact Blue Sea Systems

360.738.8230

Hardware Fault

Turn Off AC For 2 Minutes

Then Turn Power On

EQ stopped-Max Current Limit

Make sure battery is charged

and all loads removed!

WARNING

Increasing the Maximum Equalization Current beyond your battery manufacturers recommendations is potentially

dangerous. Consult your battery manufacturer for proper equalization currents.

Specifications are subject to change. See bluesea.com/P12 for current information.

21

Page 24

Optional Installation

7521 AND 7522 BATTERY CHARGERS

P12

Integrate the P12 Battery Charger with Blue Sea Systems Automatic Charging Relays to take

advantage of Charge Coordination.

NOTE: If you have a Blue Sea Systems ACR with Start Isolation, it is possible to take advantage of your P12 charger’s ability to integrate in order to optimize

charging of your batteries.

Automatic Charging Relays (ACRs) combine battery banks when a charging voltage is present in order to share charge between battery banks. However, due to the P12 Battery

Charger’s ability to independently optimize charging for each battery bank it is favorable to isolate all battery banks by disengaging the ACR(s) ability to combine.

NOTE: The P12 Battery Charger can integrate with up to two Automatic Charging Relays (ACRs)

SI-ACR and m-ACR Installation Instructions (PN 7610 and PN 7601) to Enable Start Isolation

1. Disconnect the DC Negative (Ground) wire going to the ACR.

2. If present, disconnect the Start Isolation wire connected to ACR.

3. Connect a wire from the ACR 1 port marked “SI” (Start Isolation) on the P12 Battery Charger to the Start Isolation terminal (SI) on the ACR.

4. Connect a wire from the ACR 1 terminal marked “ES” (Engine Start Switch) on the P12 Battery Charger to the terminal or wire running from the start key switch to

the starter solenoid. Make this connection through an in-line fuse of 1 to 10 Amps.

NOTE: This connection can be made at the start key switch or at the starter solenoid, but must be to the line that is +12V DC positive only when cranking. Connection

to a line that is positive while the engine is normally running will prevent the charging relay from working properly.

5. Re-connect DC Negative (Ground) wire on the ACR

6. If connecting two ACRs, repeat steps 1 through 5 using the second ACR, engine, and the P12 Battery Charger ports associated with ACR 2

ENGINE

START

SWITCH

OPTIONAL CONNECTION OPTIONAL CONNECTION

FUSE

ON

START

OFF

Automatic

Charging

Relay

GROUND

START

ISOLATION

REMOTE LED

ESSI ES SI

ACR 1 ACR 2

SI: Start Isolation (ACR)

ES: Engine Start Switch

ESSI ES SI

ACR 1 ACR 2

Temperature

SI: Start Isolation (ACR)

ES: Engine Start Switch

Temperature

Sensor

FUSEFUSE

Remote

Display

Remote

Sensor

Display

BATTERY CHARGER LED REMOTE

7520

Automatic

Charging

Relay

GROUND

START

ISOLATION

REMOTE LED

22

START

FUSE FUSE

DC GROUND

HOUSE

Specifications are subject to change. See bluesea.com/P12 for current information.

START

ENGINE

START

SWITCH

FUSE

ON

START

OFF

Page 25

Optional Installation (continued)

7521 AND 7522 BATTERY CHARGERS

P12

ML-ACR Installation Instructions (PN 7620 and PN 7622) to Enable Start Isolation*

1. Disconnect the black ground wire connected to the ML-ACR wire harness.

2. If present, disconnect all Start Isolation wires connected to the Brown, Green, and Orange wires in ML-ACR wire harness.

3. Connect a wire from the ACR 1 port marked “SI” (Start Isolation) on the P12 Battery Charger to both the Brown and Green wires in the ML-ACR wire harness.

NOTE: Connecting the “SI” (Start Isolation) wire to only one of the ML-ACR isolation wires will not properly integrate the P12 battery charger with your ML-ACR.

4. Connect a wire from the ACR 1 terminal marked “ES” (Engine Start Switch) to the terminal or wire running from the start key switch to the star ter solenoid.

NOTE: This connection can be made at the start key switch or at the starter solenoid, but must be to the line that is +12V DC positive only when cranking. Connection to

a line that is positive while the engine is normally running will prevent the charging relay from working properly.

5. Re-connect the black DC Negative (Ground) wire in the ML-ACR wire harness

6. If connecting two ML-ACRs repeat steps 1 through 5 using the second ML-ACR, engine, and the P12 Battery Charger ports associated with ACR 2

* The ML-ACRs also support “Engine Isolation” which

keeps an ACR open if two engines are running

simultaneously. Operating in this mode while using

Charger Coordination requires a special installation.

See bluesea.com/P12 for details.

ESSI ES SI

ACR 1 ACR 2

Temperature

SI: Start Isolation (ACR)

ES: Engine Start Switch

Remote

Sensor

Display

ML-Series

Automatic

Charging

Relay

A B

ENGINE

START

SWITCH

OFF

START

OPTIONAL CONNECTION OPTIONAL CONNECTION

ON

START

HOUSE

START ISOLATION #1 (BROWN)

START ISOLATION #2 (GREEN)

ENGINE ISOLATION #3 (ORANGE)

GROUND (BLACK)

ESSI ES SI

ACR 1 ACR 2

SI: Start Isolation (ACR)

ES: Engine Start Switch

ML-Series

Automatic

Charging

Relay

A B

Temperature

Sensor

Remote

Display

7520

BATTERY CHARGER LED REMOTE

ISOLATION #1 (BROWN)

ISOLATION #2 (GREEN)

ISOLATION #3 (ORANGE)

GROUND (BLACK)

ENGINE

START

SWITCH

START

ON

START

OFF

DC GROUND

Specifications are subject to change. See bluesea.com/P12 for current information.

23

Page 26

Optional Accessory

P12 Battery Charger Remote

Indicates battery charger stage, alerts, and controls basic battery charger functions

7520 BATTERY CHARGER REMOTE

Scan for

additional

product

information

P12

LED Indicators

• Charging: Quick check for green light confirms charging

• Charge Stage: Displays charging stage including PreFloat for each battery

• Equalize: Indicates when the charger is in equalization mode

• Fan Mode: Indicates charger’s internal fan mode

• Charge Output: Displays the percentage of output current for each battery. Will also indicate maximum output setting when maximum output is adjusted

to accommodate for AC source limitations.

• Alert: Provides warning and alert status for quick diagnostics

Four Control Buttons

• Fan: User adjustable settings (OFF, LOW, or HIGH)

• Dim/ Alarm: Provides adjustment to brightness of LEDs on display as well as Silence function for alarms.

• Output: User adjustable charger output when AC source limitations exist that require lowering the AC current draw.

• Standby: Places P12 Battery Charger into standby mode

Specifications

Minimum Operating Temperature −20°C (−4°F)

Maximum Operating Temperature 60°C (140°F)

Minimum Storage Temperature −30°C (−22°F)

Maximum Storage Temperature 70°C (158°F)

Mounting Hole Cutout 1-1/4” (31.75 mm)

Dimensions Height: 3.01” (76.56 mm)

Width: 4.15” (105.46 mm)

Depth: .95” (24.01 mm)

Mounting Hardware Included #6 Screws

Electrical:

On State Operating Current <300mA sourced from charger

Communications:

Protocol Proprietary

Maximum Cable Length 150 ft (45.7 m)

Cable Cat5e (Standard US)

Regulatory

Surface Mount Gasket creates an IP67 waterproof seal on unit face--temporary immersion for 30 minutes.

Cable Connection

The P12 Battery Charger Remote uses one Cat5e cable for communication and power.

P12 Battery

24

Charger Remote

P12 Battery Charger

RJ45 Port

Specifications are subject to change. See bluesea.com/P12 for current information.

Page 27

Included Components

1. Four Mounting Screws

2. One Cover

3. One Remote Assembly

4. One Mounting Gasket

5. One 25 ft (7.6 m) Cat5e Cable

6. One Packet of Dielectric Grease

Dielectric Grease

Used for Temperature Sensor and

6

Remote Display Connections. View

the MSDS for the Dielectric Grease

at bluesea.com/P12

2

#6 x 1" pan-head sheet metal screws

1

(#2 Phillips screwdriver)

Recommended torque:

5–10 in-lb (0.6–1.1 Nm)

3

7520 BATTERY CHARGER REMOTE7520 BATTERY CHARGER REMOTE

P12

4

Dimensioned Drawing

4.15"

(105.46mm)

2.52"

(63.88mm)

(73.70mm)

2.90"

3.01"

(76.56mm)

1.50"

(38.10mm)

3.69"

(93.66mm)

5

Mounting Hole Cutout

Ø1-1/4"

(31.75mm)

Clearance holes

for #6 screws

0.57"

(14.36mm)

0.38"

(9.65mm)

Specifications are subject to change. See bluesea.com/P12 for current information.

25

Page 28

Display Indicators

4. Charge Output

7520 BATTERY CHARGER REMOTE

P12

1. Charging

2. Charge Stage

BULK

ABSORB

PREFLOAT

FLOAT

EQUALIZE

3. Fan Mode

CHARGING

Charge Stage

BULK

ABSORB

PREFLOAT

FLOAT

EQUALIZE

Fan Mode

1

HIGHLOWOFF

13. Fan Mode

2

QuickGuide

7520 BATTERY CHARGER REMOTE

Charge Output

100%

75%

50%

3

25%

10%

<5%

1

DIM /

OUTPUT

15. Output

14. DIM/Alarm

1. Charging:

SOLID ON (Green): Indicates Charging mode and will operate according to its charging stage.

BLINKING (Green): Transitioning from Standby to a Charging state.

OFF: Standby mode - will not charge a batter y or supply current to loads.

2. Charge Stage:

Bulk - BLINKING (Green): Indicates Bulk stage on all batteries

Absorb - BLINKING (Green): Indicates Absorb stage on all batteries

Prefloat*- SOLID ON (Green): Indicates PreFloat stage on any of three batteries

Float - SOLID ON (Green): Indicates Float stage on all batteries

Equalize - BLINKING (Yellow): Indicates Equalize stage on any of three battery branches.

P12

3

2

16. Standby

Alert

DC

AC

5. Thermal Regulation and

6. Internal Temperature Sensor

7. Battery Temperature Sensor

8. Fan

9. DC Fuse

10. AC Input Voltage

Too High or Low

11. Reverse Polarity

or Short Circuit

12. Hardware Failure,

DC Output Voltage Too High,

or Equalization Overload

3. Fan Mode:

SOLID ON (Green): Indicates fan LOW or HIGH mode.

SOLID ON (Yellow): Indicates fan OFF mode.

BLINKING (Yellow): Indicates that the fan is OFF and the charger is limiting its output current to protect from eventual overheating. If full output is desired, the

Fan Mode needs to be set to LOW or HIGH to keep the charger cool. If the fan is OFF the charger will limit its output based on its internal temperature sense.

4. Charge Output:

SOLID ON (Green): Charge Output LEDs are used to monitor the output on three batteries and limit the output using the output button. In normal operation, the Charge

Output LEDs show the percentage of the absolute maximum current on each batter y. The range of each individual percentage is as follows:

<5%: 0% ≥ output < 5%

10%: 5% ≥ output < 17.5 %

25%: 17.5% ≥ output < 37.5%

50%: 37.5% ≥ output < 62.5%

75%: 62.5% ≥ output < 87.5%

100%: 87.5% ≥ output < 100%

BLINKING (Green): Indicates that the charger is limiting its output. There are two situations where this could occur:

1) The output of the charger is being limited per the user’s output setting.

2) The charger is limiting output to protect itself from overheating. In this situation, the Charge Output will blink alongside the yellow Thermal Regulation Alert.

26

Specifications are subject to change. See bluesea.com/P12 for current information.

Page 29

Alerts and Diagnostics

7520 BATTERY CHARGER REMOTE

P12

5. Thermal Regulaton:

SOLID ON (Yellow): The charger temp output limit LED indicator will blink to notify the user that the charger is limiting its output to protect itself from eventual overheating.

The most common correction for this state is to increase the fan speed to High. If the fan speed is already set to High check for blockage around the fan vent that can

be removed. If the condition persists, it is advisable to reposition the battery charger in a cooler, more ventilated location. See page 20 for more details.

6. Internal Temperature Sensor:

BLINKING (Red): Indicates a problem with the thermistor temperature sense internal to the charger. If that is the case, the charger will immediately go into standby mode.

This form of temperature alert can not be corrected by the user. Contact Blue Sea Systems for further information regarding internal temperature sensor aler ts.

7. Battery Temperature Sensor:

BLINKING (Red): Indicates the battery temperature is out of range. The charger will not charge a battery exceeding temp limits and will therefore go into standby

mode immediately. The remote will signal its alarm. If at any point the temperature sensor records a temperature beyond the defined temperature limits, the battery

charger will display the Batter y Temperature Alert Screen. In this situation all battery charging will stop until the proper batter y temperature is restored. Normal operation

will not commence unless two degrees within the temperature parameters. See page 20 for more details.

8. Fan:

BLINKING (Red): Indicates the chargers’ internal fan is not working properly. See page 20 for more details.

9. DC Fuse:

BLINKING (Red): Indicates the chargers’ internal DC fuse is blown. The P12 Battery Charger has two internal DC fuses that are not accessible by the user. Disconnect AC

power and all battery connections. The batter y charger will require servicing by Blue Sea Systems. No attempts should be made to replace the fuses by the user. Contact

Blue Sea Systems for further instructions regarding DC fuse replacement.

10. AC Input Voltage Too High or Low:

BLINKING (Red): Indicates charger AC power is out of range. See page 21 for more details.

11. DC Reverse Polarity or Short Circuit:

BLINKING (Red): Indicates a reverse polarity or short circuit condition is present on the DC output. The remote will signal its alarm. See page 20 for more details.

12. Hardware Failure, DC Output Voltage Too High, Equalization Overload: ALL ALERT LEDs BLINKING (Red): Indicates fault state.

Go to the P12 Battery Charger to see the pop-up screen explaining the reason.

Buttons

13. Fan Mode:

Press to scroll through fan mode selections OFF, LOW or HIGH.

14. Dim /Alarm:

- Normal operation: Press to Dim LED brightness.

- Fault Condition: Press once to silence Alarm buzzer.

15. Output:

Limits the charger’s output to a certain percentage of its absolute maximum. Press the output button once to show the current output setting on Charge Output LEDs.

Press again to scroll through settings. The setting is shown via a row of solid LEDs correlating to the percentage. The user can set the output from 100% down to 25%.

16. Standby:

Puts the charger in Standby mode. If the charger is in charging mode, press once to go to Standby. If in Standby, press once to start charging again.

A blinking charging LED indicates the charger is transitioning from Standby to Charging.

Specifications are subject to change. See bluesea.com/P12 for current information.

27

Page 30

Warranty and Contact Information

Register your P12 Battery Charger at bluesea.com/warranty

Blue Sea Systems stands behind its products for as long as you own them. Blue Sea Systems will replace or issue a credit for any of its products found

to be defective in materials or manufacture. P12 Battery Chargers and P12 Remote Displays are warranted for a period of five years from the date of first

purchase. No compensation will be allowed for products not returned to Blue Sea Systems for analysis, nor will compensation be made for labor required

to replace any defective product. Please contact Customer Service for an RMA number prior to shipping any product back to Blue Sea Systems. Blue Sea

Systems cannot accept liability for damage due to the use of the P12 Battery Charger.

“Date of first purchase” means:

1. The date on which the product was purchased by the first retail customer

2. The date on which the first retail customer purchases a vessel on which the product was installed

Blue Sea Systems will (at its sole discretion) repair or replace any product which is:

1. Proven to be defective in materials or workmanship

2. Returned to Blue Sea Systems (or its agent) during the warranty period in accordance with this warranty

The replacement battery charger may be new or refurbished in as-new condition. Such repair or replacement will be the sole remedy by Blue Sea Systems

under this warranty. Any repaired or replacement product will be warranted in accordance with this warranty for the unexpired balance of the warranty period

on the original product.

Blue Sea Systems Technical Support

Monday through Friday