Page 1

It is not possible within the scope of these

instructions to fully acquaint the installer

with all the knowledge of electrical systems

that may be necessary to correctly install

this product. If the installer is not

knowledgeable in electrical systems we

recommend that an electrical professional

be retained to make the installation.

Installation

Warning

Before starting, disconnect the main

1. Disconnect all AC and DC power

ucts

positive cable from all batteries to eliminate

the possibility of a short circuit while

installing the meter. Also disconnect the AC

shore power cord from the boat to eliminate

the possibility of electrocution from AC

wiring near the DC ammeter.

Select a mounting location which is

protected from water on the meter front and

back and is not in an area where fl ammable

vapors from propane, gasoline or lead acid

batteries accumulate. The meter is not

ignition protected and may ignite such

vapors. There are two mounting methods

for the 8038 and 8005 ammeters, surface

mount or panel mount.

2. Select mounting location

Document 9289 Rev.D

PN 8005

0-15 Amperes PN 8038

0-25 Amperes PN 8005

Marine Electrical Prod

Analog DC Ammeter

Meter Specifi cations

Input Voltage: 8 Volts DC to 16 Volts DC

Amperage Draw: 1 Milliamp at full scale

Display: Analog scale

Accuracy: 3% of scale range

PN Inches Millimeters

It is not possible within the scope of these

instructions to fully acquaint the installer

with all the knowledge of electrical systems

that may be necessary to correctly install

this product. If the installer is not

knowledgeable in electrical systems we

recommend that an electrical professional

be retained to make the installation.

Installation

Warning

Before starting, disconnect the main

1. Disconnect all AC and DC power

Blue Sea Systems Inc.

Any Blue Sea Systems product with which

a customer is not satisfi ed may be returned

for a refund or replacement at any time.

Face Width: 8038 2 50.80

8005 2-1/2 63.50

Mounting Hole: 8038 1-1/2 38.10

8005 1-7/8 47.60

Guarantee

positive cable from all batteries to eliminate

the possibility of a short circuit while

installing the meter. Also disconnect the AC

shore power cord from the boat to eliminate

the possibility of electrocution from AC

wiring near the DC ammeter.

Select a mounting location which is

protected from water on the meter front and

back and is not in an area where fl ammable

vapors from propane, gasoline or lead acid

www.bluesea.com

E-mail conduct @ bluesea.com

Phone (360) 738-8230 Fax (360) 734-4195

425 Sequoia Drive Bellingham, WA 98226 USA

batteries accumulate. The meter is not

ignition protected and may ignite such

vapors. There are two mounting methods

for the 8038 and 8005 ammeters, surface

mount or panel mount.

2. Select mounting location

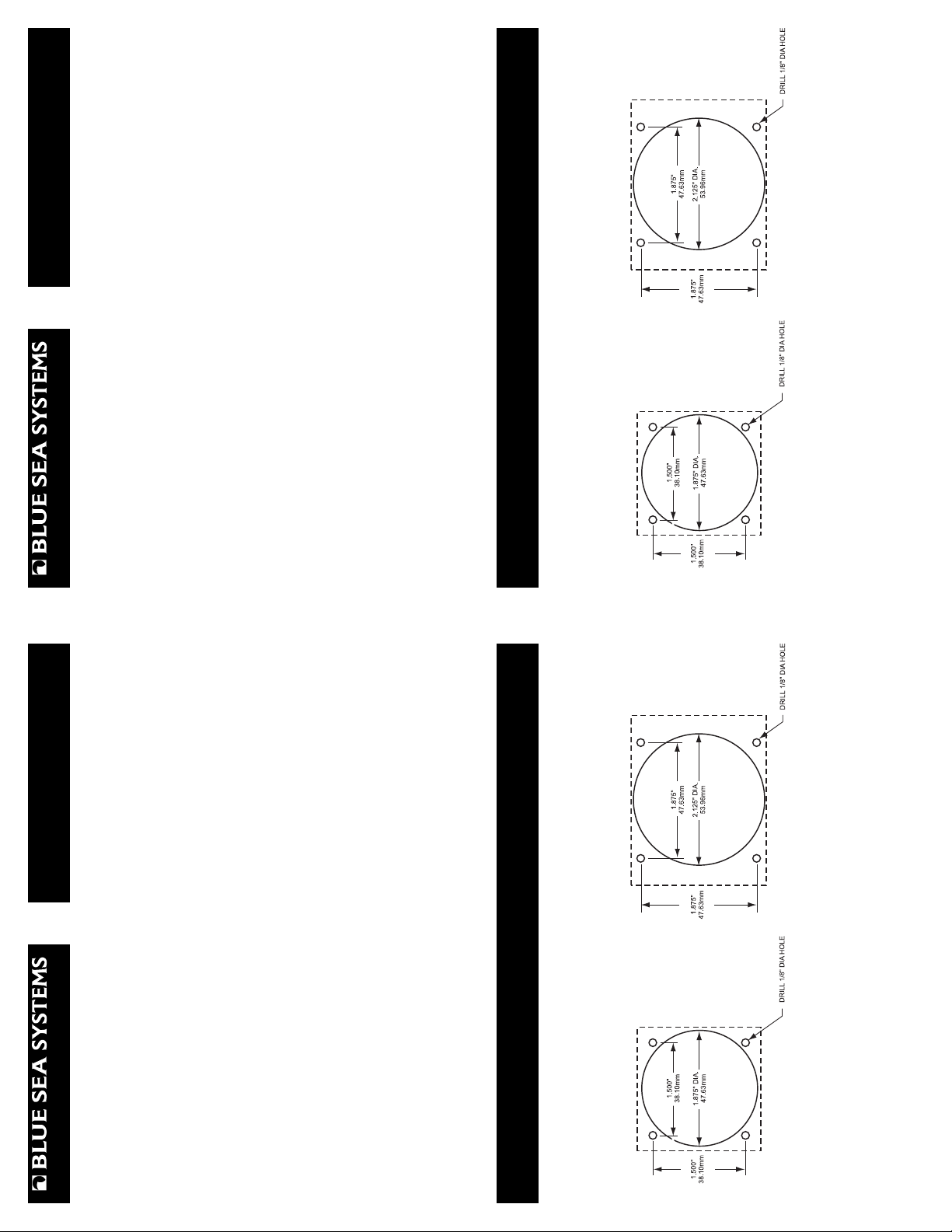

Surface Mount: Drill fi ve clearance holes a shown below. The part number of the meter will

determine the size and location of the clearance holes. Use the nuts and washers supplied in the

accessory package to secure the four mounting studs to the mounting surface. This method will

Installation (continued)

work on mounting surfaces up to 5/8” thick.

(

PN 8038

Panel Mount: For thicker mounting surfaces, the meter can be mounted into a 0.125” thick

panel. Blue Sea Systems offers meter mounting panels for our standard size meters only. For

part number 8005 use part number 8013 to mount a single meter or part number 8014 to mount

two meters.

PN 8005

ucts

0-15 Amperes PN 8038

Marine Electrical Prod

Analog DC Ammeter

0-25 Amperes PN 8005

Meter Specifi cations

Input Voltage: 8 Volts DC to 16 Volts DC

Amperage Draw: 1 Milliamp at full scale

Display: Analog scale

Accuracy: 3% of scale range

PN Inches Millimeters

Face Width: 8038 2 50.80

8005 2-1/2 63.50

Mounting Hole: 8038 1-1/2 38.10

Document 9289 Rev.D

Blue Sea Systems Inc.

Any Blue Sea Systems product with which

a customer is not satisfi ed may be returned

for a refund or replacement at any time.

8005 1-7/8 47.60

Guarantee

www.bluesea.com

E-mail conduct @ bluesea.com

Phone (360) 738-8230 Fax (360) 734-4195

425 Sequoia Drive Bellingham, WA 98226 USA

Surface Mount: Drill fi ve clearance holes a shown below. The part number of the meter will

determine the size and location of the clearance holes. Use the nuts and washers supplied in the

accessory package to secure the four mounting studs to the mounting surface. This method will

Installation (continued)

work on mounting surfaces up to 5/8” thick.

(

PN 8038

Panel Mount: For thicker mounting surfaces, the meter can be mounted into a 0.125” thick

panel. Blue Sea Systems offers meter mounting panels for our standard size meters only. For

part number 8005 use part number 8013 to mount a single meter or part number 8014 to mount

two meters.

Page 2

Panel Mount

Surface Mount

PN 8005

PN 8038

Installation (continued)

The 8005 and 8038 ammeters utilize an internal shunt as their current sensing device. The

3. Wire Selection

Panel Mount

Surface Mount

PN 8005

nature of current measurement is that the full current to be measured must fl ow through the

sensing device. Therefore it is necessary to run wire to the meter of suffi cient size to carry the

current to be measured. The wire size will vary depending on the total distance of the wire run,

the TOTAL length of the positive and negative wires. There must be a fuse or circuit breaker in

the positive wire lead to the meter. Choose a wire and fuse based on the table below.

Wire Run (Feet) 10 15 20 25 30 35 40 50 60 70 80

* These maximum allowable fuse sizes (Maximum allowable wire amperages) are for wires

outside of engine spaces. Wires inside engine spaces have a maximum allowable wire

amperage of 15% less, therefore maximum allowable fuse sizes must be reduced by 15%.

Notice the difference between a serial connection and a parallel connection in the diagram

below. Internal shunt ammeters are mounted in a serial confi guration.

Wire Size (AWG) 10 10 8 6 6 6 4 4 2 2 2

Maximum Fuse (A)* 60 60 80 120 120 120 160 160 210 210 210

4. Connection

The 8005 and 8038 ammeters are calibrated at the factory and recalibration should never be

necessary. However, if adjustment does become necessary the needle may be reset to the zero

mark. In the center of the black area on the meter front is an adjustment screw. This screw

activates a small cam that defl ects the meter needle slightly to adjust the needle position. Using

a small screw driver, turn the screw no more than 90 degrees right or left, as necessary. DO

Choose the site in the circuit to be measured where the meter is to be installed. It may be either

in the positive or negative side of the circuit.

Break the circuit at this point and install the meter. Be certain to attach the wire end nearest the

positive side of the circuit to the meter terminal marked + (positive). Attach the wire nearest the

negative side of the circuit to the meter terminal marked - (negative)

NOT ROTATE THE ADJUSTMENT SCREW THROUGH 360 DEGREES.

5. Calibration

Installation (continued)

PN 8038

The 8005 and 8038 ammeters utilize an internal shunt as their current sensing device. The

nature of current measurement is that the full current to be measured must fl ow through the

sensing device. Therefore it is necessary to run wire to the meter of suffi cient size to carry the

current to be measured. The wire size will vary depending on the total distance of the wire run,

3. Wire Selection

the TOTAL length of the positive and negative wires. There must be a fuse or circuit breaker in

the positive wire lead to the meter. Choose a wire and fuse based on the table below.

Wire Run (Feet) 10 15 20 25 30 35 40 50 60 70 80

* These maximum allowable fuse sizes (Maximum allowable wire amperages) are for wires

outside of engine spaces. Wires inside engine spaces have a maximum allowable wire

amperage of 15% less, therefore maximum allowable fuse sizes must be reduced by 15%.

Notice the difference between a serial connection and a parallel connection in the diagram

below. Internal shunt ammeters are mounted in a serial confi guration.

Wire Size (AWG) 10 10 8 6 6 6 4 4 2 2 2

Maximum Fuse (A)* 60 60 80 120 120 120 160 160 210 210 210

4. Connection

The 8005 and 8038 ammeters are calibrated at the factory and recalibration should never be

necessary. However, if adjustment does become necessary the needle may be reset to the zero

mark. In the center of the black area on the meter front is an adjustment screw. This screw

activates a small cam that defl ects the meter needle slightly to adjust the needle position. Using

a small screw driver, turn the screw no more than 90 degrees right or left, as necessary. DO

Choose the site in the circuit to be measured where the meter is to be installed. It may be either

in the positive or negative side of the circuit.

Break the circuit at this point and install the meter. Be certain to attach the wire end nearest the

positive side of the circuit to the meter terminal marked + (positive). Attach the wire nearest the

negative side of the circuit to the meter terminal marked - (negative)

NOT ROTATE THE ADJUSTMENT SCREW THROUGH 360 DEGREES.

5. Calibration

Loading...

Loading...