Page 1

AMBASSADOR

TM

Serial No.

®

OPERATOR, PARTS, AND

INSTALLATION MANUAL

BX7302

AMBASSADOR® Tow Bar

Class III (5000 lb) 2 Inch Ball Coupler

©2003, 05, 07, 08, 09 Automatic Equipment Mfg. Co.

One Mill Road, Industrial Park

Pender, Nebraska 68047

Page 2

Installation Instructions

BX7302 Ambassador Tow Bar

Tow Bar Installation

1. Hold the Tow Bar in position, with its tabs aligned inside the

baseplate tabs and insert the pins. Insert quick pins into the

baseplate pins to hold them in position.

2. Install safety cables or chains and adjust coupler.

3. Do not substitute other devices if the pins are lost.

4. DEALER OR INSTALLER: BE CERTAIN USER RECEIVES

INSTRUCTION SHEETS.

Notice

1. Blue Ox Tow Bars are designed for the coupler to be parallel

to the ground when it is attached to the towed and towing

vehicles. If the Tow Bar coupler is at an angle, damage or

accident may occur.

2. Blue Ox Tow Bars are designed to tow manual transmission

cars or automatics equipped with a transmission pump, drive

shaft disconnect or half shaft disconnect.

3. The transmission should be placed in neutral to tow. (Refer

to your vehicle's owners manual for details)

4. Unlock the steering wheel to allow the front wheels of the

towed vehicle to “track”.

5. Be sure front end of the car being towed is properly aligned.

6. The use of safety cables or chains is REQUIRED BY LAW.

Blue Ox Model BX8805 (5ft) or BX8806 (6ft) Safety Cables

are recommended. The shorter BX8805 is normally best.

7. Adjust the coupler for proper fi t to the ball (see coupler fi t

adjustment). For added security, place a lock, pin or bolt

through the hole provided in the coupler locking lever.

8. Check clearance between vehicles in while turning.

9. Most states require rear lighting on the towed car. A BX8869,

BX8811 or BX8847 Wiring Kit is recommended.

10. Prior to a towing trip, check to be sure all towing accessories

and attachment points are secure. Check for cracked

welds and loose bolts. This is important on all occasions

but particularly on a new installation, when they should be

checked just prior to initial towing and again after 100-200

miles of towing.

11. Do Not Back Up when towing. Backing up may damage the

Tow Bar assembly or the towed car’s chassis.

12. Avoid sharp turns and rough terrain. Check installation after

an unusual event and periodically on long trips.

13. Do not use towed vehicle for storing luggage, etc.; you may

exceed the towing capacity of the Tow Bar.

WARNING: Ensure that your towing vehicle is of adequate

size to properly control your towed vehicle. The weight and

braking capacity should be large enough to handle both

vehicles in an emergency situation. Check your towing

vehicle manufacturers recommendations for towing, hitch

load, and braking capacities. The hitch, ball, motorhome

chassis, and safety cables (each individual cable) need to be

rated at a minimum for the weight of the vehicle being towed.

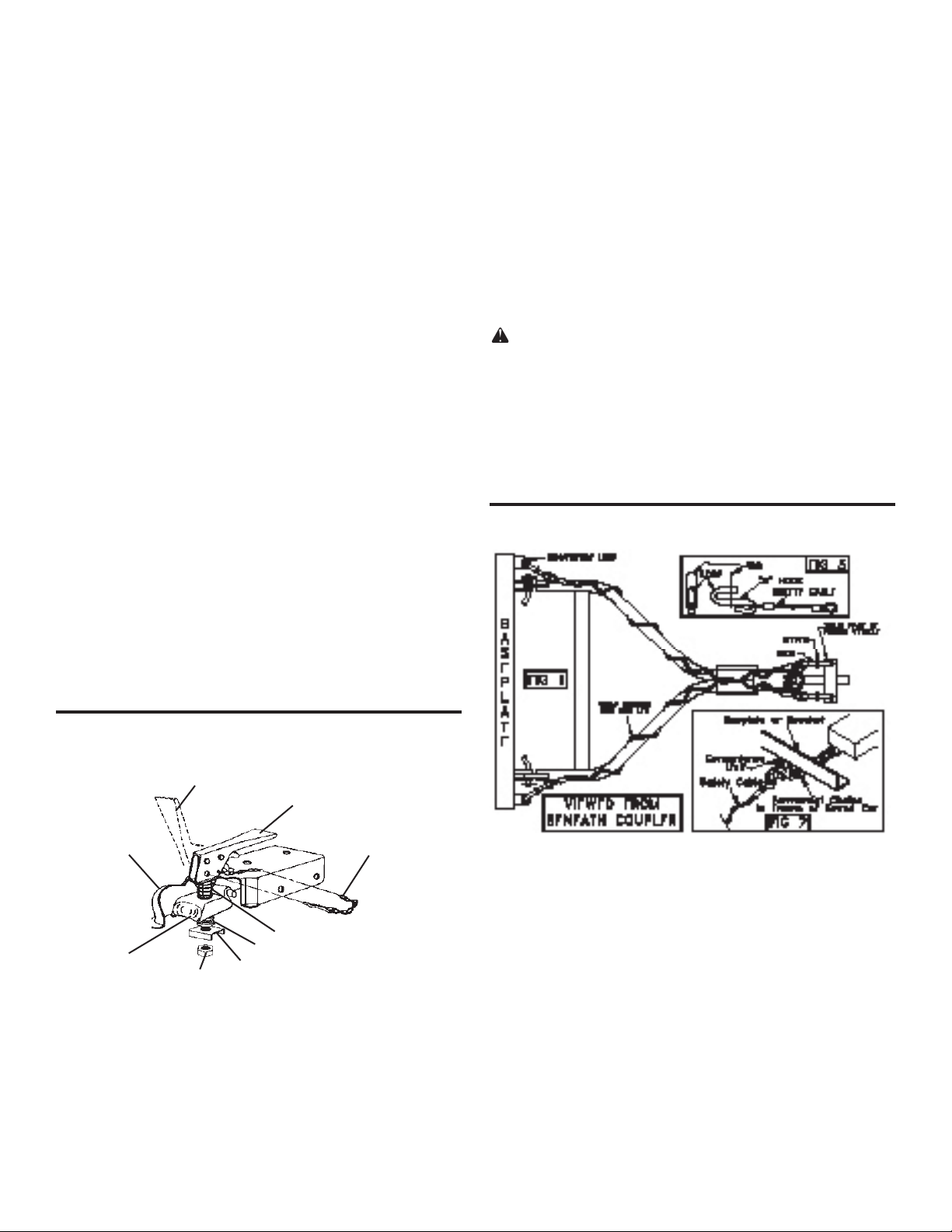

SAFETY CABLE INSTALLATION

COUPLER FIT ADJUSTMENT

(Unlocked Position)

Housing

Ball

Clamp

Lock Nut

1. Using a 3/4" socket, tighten or loosen the nut until fi rm con-

tact between coupler and ball is established.

2. Check ball to housing tension periodically and tighten if

needed.

3. Lightly lubricate the ball.

A coupler repair kit is available from Automatic

Equip. by ordering P/N 293-0272.

Locking Lever

(Locked Position)

Pin & Chain

(Optional)

Light Spring

Heavy Spring

Channel Lock

©2003, 05, 07, 08, 09 Automatic Equipment Mfg. Co.

One Mill Road, Industrial Park

1. Using the cable hooks, attach the cables to a solid part of the

chassis of the towed vehicle or to the baseplate convenience

loops. Slip the end of the hook through the neoprene keeper

to prevent the hook from unhooking. (See Fig. 3) NOTE: It is

recommended to have permanent chains that connect the

convenience loops to the frame of the car. (See Fig. 2)

2. Wrap each cable once or twice around their respective tow bar

leg and cross them under the coupler area. (See Fig. 1)

3. Using the cable hooks, attach the opposite ends of the cables to

a solid part of the chassis of the towing vehicle if at all possible.

Slip the end of the hook through the neoprene keeper to prevent

the hook from unhooking. (See Fig. 3)

4. Adjust slack so that the cables cannot touch the ground or become caught beneath the ball. If either of these things happen,

the cables may become damaged and ineffective. DO NOT USE

DAMAGED CABLES!

Pender, Nebraska 68047

Page 2 of 2 292-0779 4/23/09

Loading...

Loading...