Page 1

SAFETY

DO NOT INSTALL, OPERATE OR USE THIS EQUIPMENT UNTIL THE FOLLOWING

OPERATING AND SAFETY INSTRUCTIONS HAVE BEEN READ AND UNDERSTOOD.

This symbol is used to bring attention to safety precautions and instructions. When you

see this symbol, be alert and pay attention to all instructions. YOUR PERSONAL

SAFETY IS INVOLVED.

1. Blue Ox tow bars are designed for the coupler to be

parallel to the ground when it is attached to the

towed and towing vehicles. If the tow bar coupler

is at an angle, damage or accident could occur.

2. Blue Ox tow bars are designed to tow manual

transmission cars or automatics equipped with a

transmission pump, drive shaft disconnect or half

shaft disconnect.

3. The transmission is in neutral when towing.

4. Unlock the steering wheel to allow the front wheels

of the towed vehicle to track.

5. Be sure the front end of the car being towed is

properly aligned.

6. The use of safety cables or chains is REQUIRED BY

LAW. Model BX8805 (5ft) or BX8806 (6ft) Safety

Cables are recommended. The shorter BX8805 is

normally best.

7. Adjust the coupler for proper fit to the ball (see

coupler fit adjustment). For added security, place a

lock, pin or bolt through the hole provided in the

coupler locking lever. A BX8860 padlock is recommended.

8. Check clearance between vehicles in a turning

situation.

9. Most states require rear lighting on the towed car. A

BX8811 or BX8869 Wiring Kit is recommended.

10. Prior to a towing trip, be sure all towing accessories

and attachment points are secure. Check for cracked

welds and loose bolts. This is important on all

occasions but particularly on a new installation, when

they should be checked just prior to initial towing and

again after 100-200 miles of towing.

COUPLER FIT ADJUSTMENT

(Unlocked Position)

Locking Lever

(Locked Position)

Housing

Pin & Chain

(Optional)

11. Do Not Back Up when towing. This may damage

the tow bar assembly or the towed cars chassis.

12. Avoid sharp turns and rough terrain. Check assembly after unusual events and periodically on long

trips.

13. Do not use towed vehicle for storing luggage, etc.;

you may exceed the towing capacity of the tow bar.

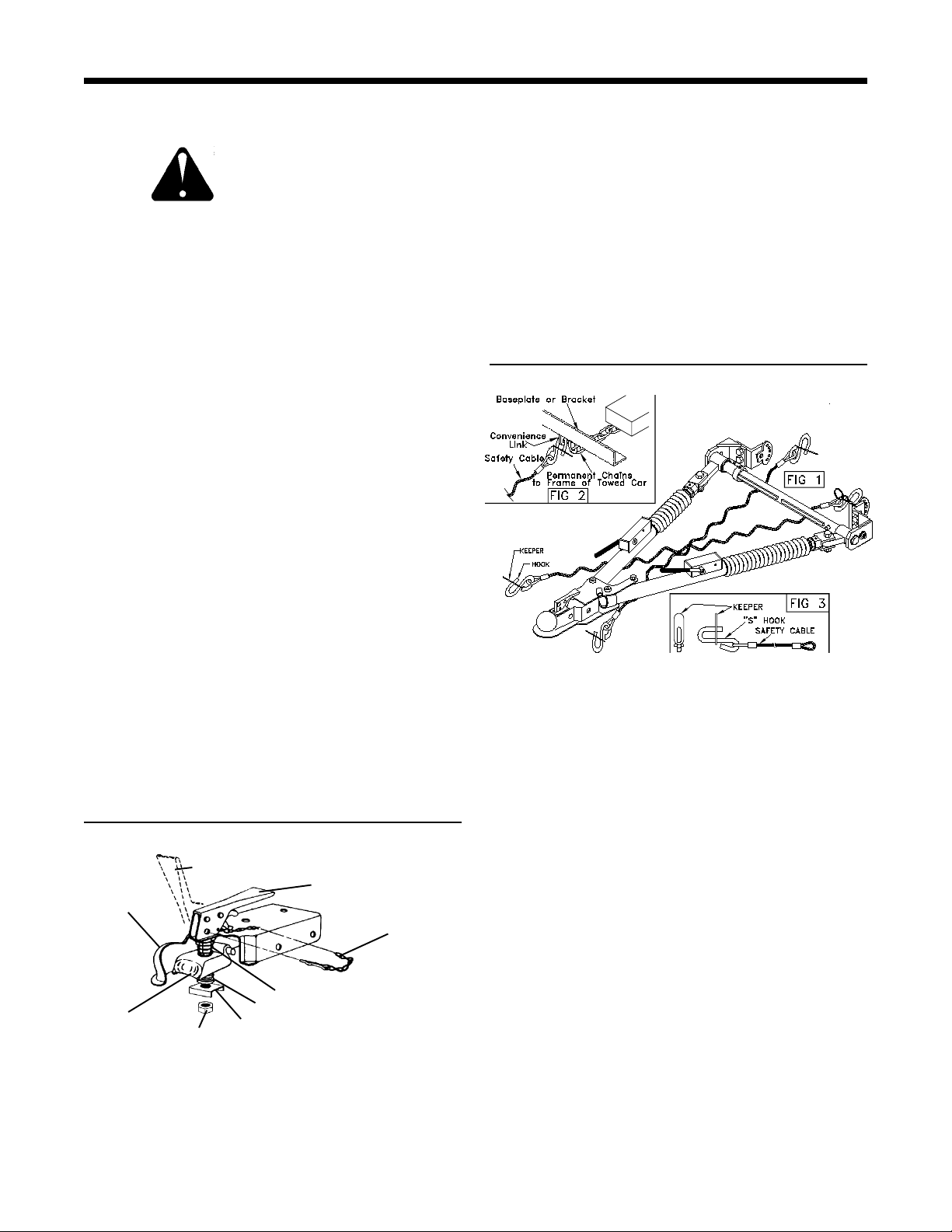

SAFETY CABLE INSTALLATION

1. Using the cable hooks, attach the cables to a solid

part of the chassis of the towed vehicle or to the

bracket convenience links on unibody cars. Slip the

end of the hook through the neoprene keeper to

prevent the hook from unhooking. (See Fig. 3)

NOTE: It is best to have permanent chains that

connect the convenience links to the frame of the

car. (See Fig. 2)

2. Cross the two safety cables under the tow bar. (See

Fig. 1) NOTE: Do not wrap around legs or damage

could occur to rubber boot.

3. Using the cable hooks, attach the opposite ends of

the cables to a solid part of the chassis of the towing

vehicle if at all possible. Slip the end of the hook

through the neoprene keeper to prevent the hook

from unhooking. (See Fig. 3)

Ball

Clamp

Lock Nut

Light Spring

Heavy Spring

Channel Lock

1.Using a 3/4" socket, tighten or loosen the nut until

firm contact between coupler and ball is established.

2.Check ball to housing tension periodically and

tighten if needed.

3.Lightly lubricate the ball.

292-2098 4/98 1 of 6

4. Adjust slack so that the cables cannot touch the

ground or become caught beneath the ball. If either

of these things happen, the cables may become

damaged and ineffective. DO NOT USE DAMAGED

CABLES!

5. If BX8805 or BX8806 cables are not used, be sure

each cable or chain used has at least the load rating

of the coupler (5000 lbs.).

Page 2

INSTALLATION / ADJUSTMENT

CAUTION: As with any mechanical product, care

should be taken during installation and operation, to

prevent your fingers from being pinched.

INSTALLATION

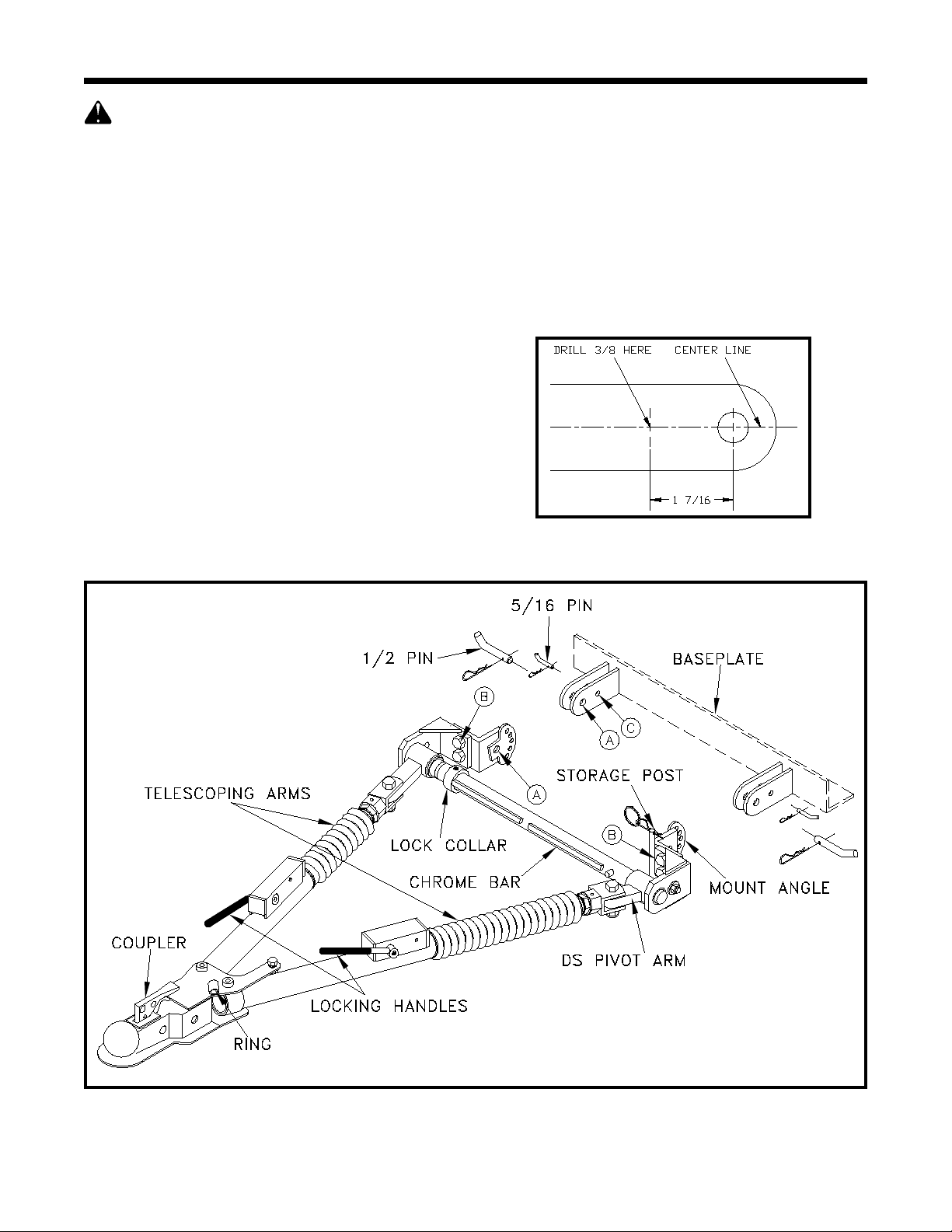

1. Refer to figure 1 while installing the tow bar. Hold

the Tow Bar in position with its tabs aligned inside

the baseplate tabs. Insert the 1/2 in. diameter pins,

provided with the baseplate, through the holes

labeled "A". Be sure to secure the pins with the

hairpin clips provided.

NOTE: If the tabs do not line up, the mount angles

on the tow bar can be adjusted by loosening the

bolts labeled "B". Be sure to tighten the bolts when

finished.

2. Fully extend the tow bar. (See Extending Tow Bar)

Hold the coupler parallel to the ground and rotate the

tow bar up or down until the top surfaces of the

mount angles are parallel with the coupler. Insert the

5/16 in. diameter pins through holes labeled "C" in

the baseplate and the nearest hole in the tow bar

tab.

NOTE: On baseplates manufactured prior to 1991,

these holes "C" must be drilled. Using a 3/8 drill bit,

drill holes on the center line of the baseplate tabs, 1

7/16 inches from the center of the existing hole.

(Figure 2) Be sure to secure the pins with the hairpin

clips provided.

3. Fold the tow bar for storage. (See Unhooking /

Folding section)

4. DEALER OR INSTALLER: BE CERTAIN USER

RECEIVES INSTRUCTION SHEETS.

Figure 2

Figure 1

292-2098 4/98 2 of 6

Page 3

HOOKING UP / EXTENDING

HOOKING-UP TO THE TOWING VEHICLE

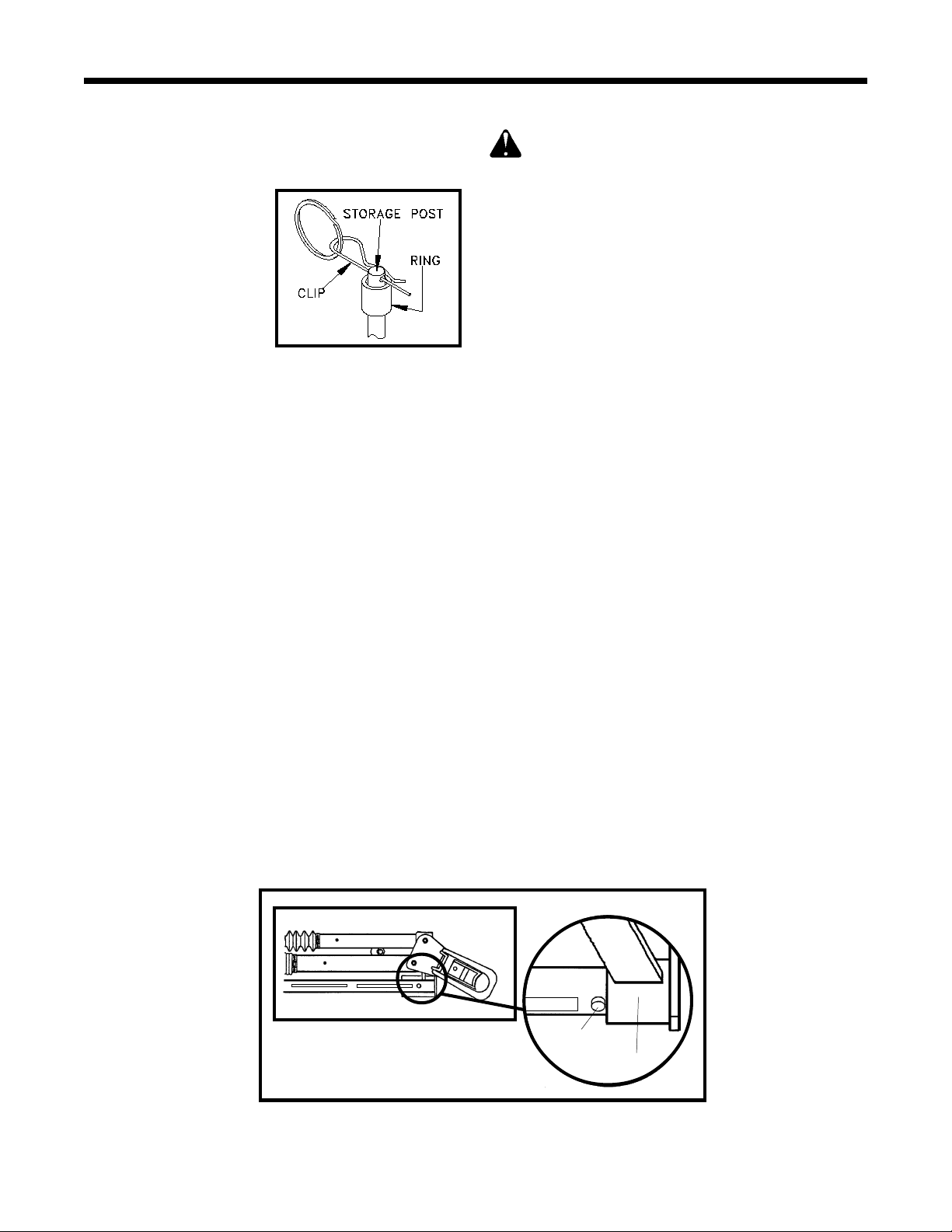

Make sure you are able to identify the tow bar parts,

(Figure 1), before proceeding.

1. Release the clip.

(Figure 3) Using your

right hand, raise the

front end of the tow

bar and begin to slide

the DS pivot arm

across the chrome

bar. Important:

Keep the front end of

the tow bar up to keep

pressure off of the

slide rail.

2. Slide the DS pivot arm all the way to the right side

(drivers side), over the safety stop on the forward

side of the chrome bar, and against the edge (Figure

4). Once against the edge, roll the front of the tow

bar forward and down. The tow bar leg is now

locked into position and ready to use.

HITCHING UP COUPLER

1. Position the towing vehicle on a level surface with

approximately 100 ft. to 200 ft. of straight driveway

ahead and engage the parking brake. (Later, You

will be driving straight ahead to latch the legs when

extending the tow bar.) Position the towed vehicle

behind the towing vehicle in the approximate towing

position and engage the parking brake of the towed

vehicle.

Figure 3

EXTENDING TOW BAR

Caution: It is possible to extend the tow bar by

driving away with the towing vehicle. As you drive

away, the towed vehicle will wander around until,

eventually, both sides may lock. Even though they

may lock this way, we DO NOT recommend towing

any vehicle until the operator has confirmed that

the leg latches have been properly locked as

outlined below.

1. On the towed vehicle; disengage parking brake, set

up the transmission for towing, (See SAFETY

section - Page 1, Item 2) and unlock the steering

wheel. Drive the towing vehicle straight forward

approximately 50 ft. to100 ft. or until the locking

handles are engaged and locked. (When locked they

will "pop" up)

NOTE: If only one locking handle is locked, simply

turn the top of the towed vehicle's steering wheel

towards the unlocked side, approximately 1/2 to 3/4

turn, before continuing forward. Check to insure both

legs are latched properly before towing.

IMPORTANT: The steering wheel on the towed

vehicle must be unlocked at all times while being

towed. Failure to do so will create hazardous driving

conditions.

2. Install safety cables or chains and lighting. (See

safety cable installation - page1).

2. Adjust the coupler. (See Cplr Fit Adjstmnt - Pg. 1)

3. Pulling from the coupler, the arms will now telescope

out for self alignment. Place the coupler on a 2" ball

and lock the coupler by pushing down on the locking

lever. (See coupler fit adjustment) Important: For

safety, you should put the pin provided, a padlock, or

a bolt with nut through holes on the coupler lever. A

BX8860 padlock is recommended.

Figure 4

Safety Stop

DS Pivot Arm

292-2098 4/98 3 of 6

Page 4

FOLDING / MAINTENANCE

UNHOOKING / FOLDING

1. Park the towing vehicle with vehicle in tow, in a

straight line, on a flat, level surface to insure

minimum pressure is exerted on the tow bar legs.

This will aid in releasing the locking handles.

Engage the towing vehicle parking brake.

Place the towed vehicle either in park for automatic

transmissions or securely in first gear for manual

transmissions. Unhook the lighting and safety

cables.

2. Push straight down on the end of the locking handles

to release each leg.

3. Remove the coupler from the ball.

4. With the driver's side locking handle now pressed

down, slide arm in toward car. Swing the tow bar up

and back until the coupler is pointing up, and the DS

pivot arm is free to slide the arm left (past the safety

stop and slide rail) for storage. Now lower the "ring"

(welded on top the coupler) down over the storage

post and insert the clip. (Figures 1 & 3)

MAINTENANCE

1. This tow bar requires periodic maintenance. It will be

subjected to road dirt and weather during use. The

following tips will help maintain the condition of your

new tow bar.

2. Keep the tow bar covered when not in use, on or off

of the towing vehicle. This will cut down on the dust

and dirt build up on the inside legs and latches of the

tow bar.

3. Periodically clean the entire surface of the tow bar

with a mild soap and water solution. Wipe dry with a

clean cloth.

LUBRICATION

1. Approximately once per year you should remove the

small cable ties holding the rubber boots on the legs,

slide the boots back, and apply a light coat of

multipurpose grease to each of the inside legs to

insure smooth operation. Secure each boot back in

place with an 8 inch nylon cable tie (available at

most automotive and hardware stores. (Figure 5)

Figure 5

292-2098 4/98 4 of 6

Page 5

292-2098 4/98 5 of 6

REPLACEMENT PARTS

IMPORTANT: Use only genuine factory replacement parts on your Tow Bar. Do not substitute homemade or nontypical parts. If a bolt is lost or in need of replacement, for your safety and the preservation of your Tow Bar, be sure to use a replacement bolt of the same grade (Usually Grade 5).

Repair parts may be ordered through your nearest Automatic dealer or distributor.

Page 6

Ref. Qty. Part Description

No. No.

1 2 207-0735 .............................. Locking Handle, SS

2 1 61-4142 ...... Passenger Side Round Outside Leg

3 1 61-4144 .............. Driver Side Round Outside Leg

4 2 61-4149 ................................. Pivot Arm Receiver

5 1 61-4150 ...................... Passenger Side Pivot Arm

6 1 61-4151 ............................. Driver Side Pivot Arm

7 1 61-4990 ................... Coupler Assembly, DM7007

293-0273 .................. Class III Coupler Repair Kit

8 2 62-3311 ................................. Latch Handle Assy.

9 1 62-3235 ............. Driver Side Inner Leg Assembly

10 1 62-3236 ..... Passenger Side Inner Leg Assembly

11 - 84-0024 ...... Driver Side Complete Leg Assembly

12 - 84-0025 ..... Passenger Side Complete Leg Assy.

13 1 101-5158 .... Washer, 1 1/4 X 7/16 X 3/16, Plated

14 2 229-0469 ................. Spacer, Locking Handle, AL

15 4 201-0051 1/2-13 x 1 1/2 Hex Head Bolt, Grade 5

16 2 201-0283 ...... 1/2-13 x 2 Hex Head Bolt, Grade 5

17 1 201-0368 3/8-16 x 1 1/4 Hex Head Bolt, Grade 5

18 8 201-0504 ......................... 1/4-20 x 1/4 Set Screw

19 1 201-0517 ... 3/8-16 X 3/8 Socket Head Set Screw

20 1 201-0548 ........7/16-20 x 1 1/4 Hex Bolt, Grade 5

21 2 201-0557 ....... 1/2 X 2 1/4 X 3/8-16 Shoulder Bolt

22 4 202-0094 ...................................... 1/2-13 Hex Nut

23 2 202-0071 .....................3/8 Flange Whiz Lock Nut

24 2 202-0143 .......................... 1/2-13 Essna Jam Nut

25 2 202-0144 ....... 3/8-16 Hex Nut w/ Nylon, Jamlock

26 1 299-0124 .... Passenger Side Attachment Bracket

27 1 203-0010 ................................... 3/8 Lock Washer

REPLACEMENT PARTS

Parts List

Ref. Qty. Part Description

No. No.

28 1 203-0011 ................................. 7/16 Lock Washer

29 2 61-3824 ...................... Mushroom Mount Bracket

30 1 203-0072 ... Machine Bushing, 10 Ga. x 1 1/2 x 1

31 2 203-0129 ...... 1 Inch Internal Tooth Lock Washer

32 1 207-0688 .......................... Driver Side Inside Leg

33 1 207-0689 ................... Passenger Side Inside Leg

34 2 220-0033 ............................. Spring Pin, 1/4 x 3/8

35 2 222-0068 ......................... Spring, Locking Handle

36 1 229-0210 ......................................1 1/2 Split Ring

37 1 229-0244 .................................. # 10 Hair Pin Clip

38 1 299-0128 ........................................... Storage Pin

39 2 229-0386 ................................................ Leg Stop

40 2 299-0247 .................. Locking Handle Bolt, Plated

41 2 250-0156 .......................................... Rubber Boot

42 2 250-0157 ............. Foam Grip, 3/8 X 3 5/8 X 5/64

43 2 290-0275 ..........................8 Inch Nylon Cable Tie

44 2 290-0328 ................. Cap Plug, Red, 1 1/2 Round

45 4 290-0332 ............. Cap Plug, Black, 1 1/4 Square

46 2 290-0364 ..........................9 Inch Nylon Cable Tie

47 1 292-0797 ....... Decal, Safety Cables (Not Shown)

48 1 292-1206 ........... Decal, Instructions (Not Shown)

49 2 299-0121 ................................................ Boot Nut

50 1 292-2097 .......... ID Sticker, BX4335 (Not Shown)

51 2 292-1035 ................. Decal, Blue Ox (Not Shown)

52 1 299-0279 .................. Tube, Lock Collar, Chrome

53 1 299-0126 ............................... Cross Tube, Plated

54 2 299-0234 ......................... Swivel, Locking Handle

55 2 290-0377 ...................................... Plastic Washer

292-2098 4/98 6 of 6

Page 7

RANGEFINDER III

TM

OPERATOR, PARTS, AND

INSTALLATION MANUAL

BX4335

RANGEFINDER III

Class III (5000 lb) 2 Inch Coupler

TOWING PRODUCTS DIVISION

TM

Tow Bar

Page 8

QUICK REFERENCE GUIDE

HOOKING UP & EXTENDING FOR TOWING

1. Align vehicles in towing position with straight driveway

ahead and parking brakes locked.

2. Slide driver side pivot arm across over safety stop.

Place ball coupler on 2 inch ball.

3. Drive towing vehicle forward until both legs are locked.

(Locking Levers Up)

4. Install safety cables and towed vehicle lighting.

5. Detailed instructions appear on pages 3-4.

TO BE VALID, THE WARRANTY CARD MUST BE

COMPLETED IN ITS ENTIRETY BY AN AUTHORIZED

DISTRIBUTOR OR DEALER AND SENT TO AUTOMATIC

EQUIPMENT MFG. CO., PENDER, NEBRASKA. FAILURE

TO DO SO WILL VOID THE WARRANTY.

UNHOOKING & FOLDING FOR STORAGE

1. Park vehicles in a straight line on level surface. Apply

towing vehicle parking brake. Place towed vehicle in

park or 1st gear for manual transmissions.

2. Remove safety cables and towed vehicle lighting.

3. Disengage leg latches. Slide driver side pivot arm

towards passenger side. Place coupler ring on

storage post and pin in place.

4. Detailed instructions appear on page 4.

Repair parts may be ordered through your nearest

Automatic dealer or distributor.

Product Safety Policy Statement

It is, and shall continue to be, a primary objective of Automatic Equipment Manufacturing

Company to provide customers with safe and reliable products. Automatic will, and has, established safety procedures in product design, manufacture, promotion and sales; and will coordinate

efforts to promote customer safety to the greatest extent possible. Each department has primary

responsibility for the promotion of safety under the guidelines of the Product Safety Committee.

WARNING: Insure that your towing vehicle is of adequate size to properly control

your towed vehicle. The weight and braking capacity should be large enough to handle

both vehicles in an emergency situation. Check your towing vehicle manufacturers

recommendations for towing, hitch load, and braking capacities.

292-2098 4/98

Automatic Equipment Mfg. Co. l One Mill Road, Industrial Park

Pender, Nebraska 68047

© 1997 Automatic Equipment

Mfg. Co. Pender, NE 68047

Loading...

Loading...