Page 1

INCLUDES BASE FOR FILTER AND PUMP

NE6150 / NE6170

TOOLS REQUIRED

• Phillips head screwdriver

• Flat head screwdriver

• O-ring lube

6420

Page 2

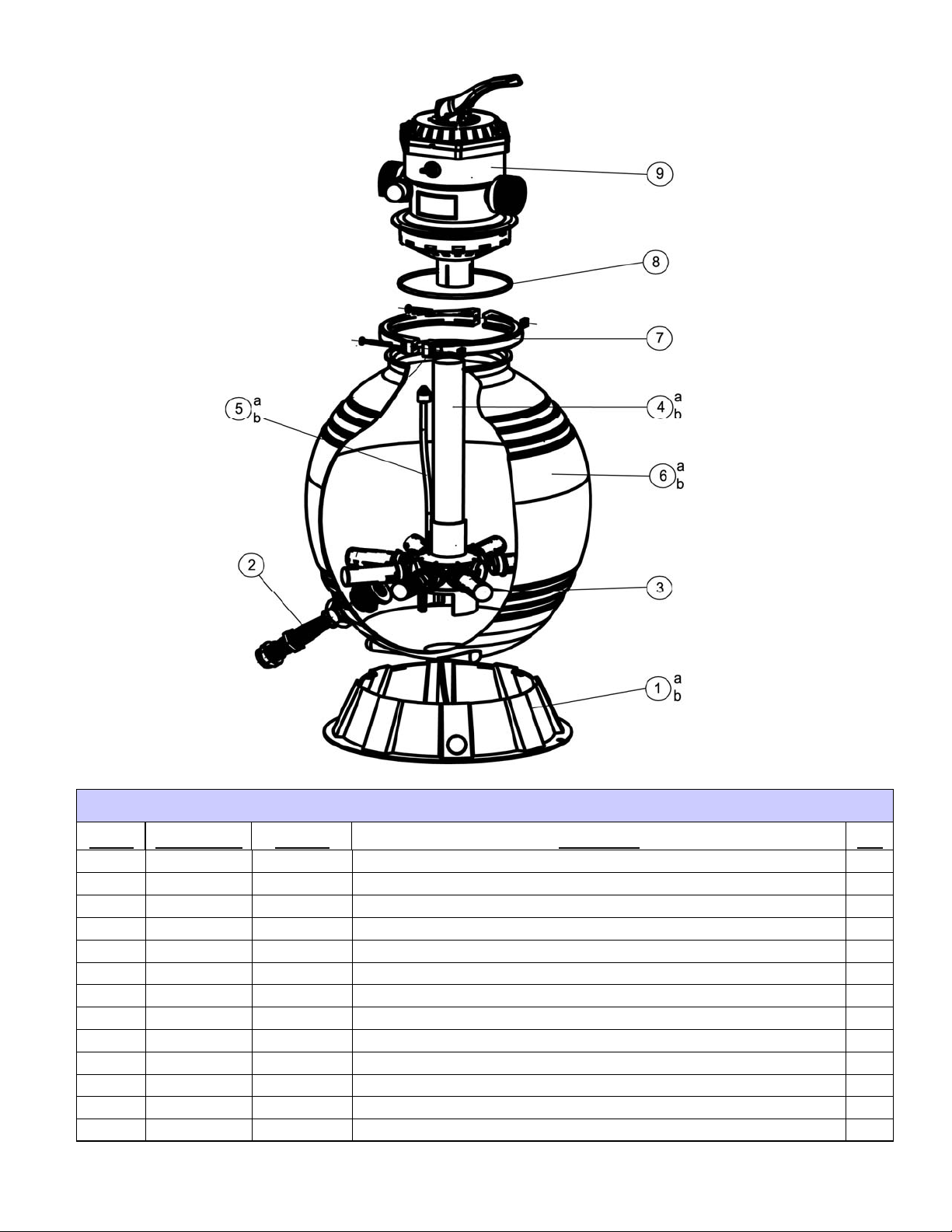

PARTS FOR SAND FILTER

NOTE

A. FILTER TANK

The quantity of parts and part numbers will vary for each filter.

See breakdown on following page for model specific part lists.

B. BASE

C. 6 WAY VALVE

D. CLOSURE CLAMP

H. HOSE CLAMPS (6)

E. STANDPIPE

I. PRESSURE GAUGE

J. STRAIGHT FITTING

F. LATERALS (8)

(3)

N. DRAIN PLUG

G. VALVE O-RING

K. TEFLON TAPE

L. 3’ 1-1/2” HOSE

2

M. 6’ 1-1/2” HOSE (2)

NOTE: Pre-installed on

tank

O. SIGHT GLASS

Page 3

SANDMANFILTERPARTSNE6150A(18")&NE6170A(22")

REF # Mrf Model # Order # Descripton Qty

1A

1B

2

3

4 A

4 B

5 A

5 B

6 A

6 B

7

8

9

AC 18601 NEP2121 18" sand filter base

AC 22601 NEP2122 22"sand filter base

AC 22602 NEP2123 Drain plug assembly

AC 18604 NEP2124 Lateral for 18" and 22" sand filter

AC 18605 NEP2125 Center pipe & folding umbrella lateral holder for 18" sand filter

AC 22605 NEP2126 Center pipe & folding umbrella lateral holder for 22" sand filter

AC 18606 NEP2127 Air release assembly 18" sand filter 380 mm

AC 22606 NEP2128 Air release assembly 22" sand filter 490mm

AC 18607 NEP2129 18" Filter tank

AC 22607 NEP2130 22" Filter tank

AC 18608 NEP2131 Flange clamp

AC 18609 NEP2132 O-ring for valve/tank

AC 08621RP NEP2133 6-way valve

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 4

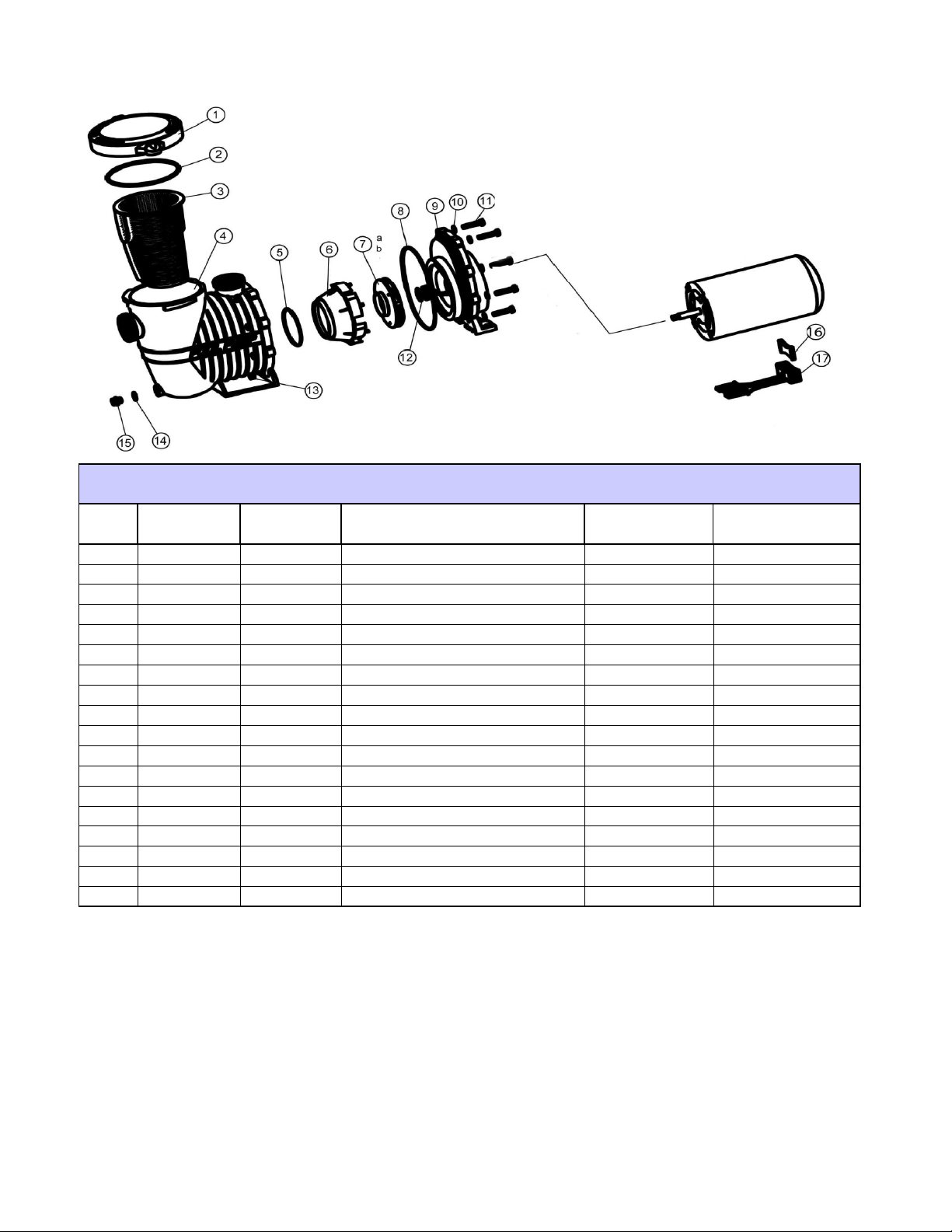

SANDMANPUMPNE6150B/6170BPARTSBREAKDOWN

1HP 1.5HP

KEY #

7A AC81493 NEP2140 IMPELLAR1.HP 1

7B AC81507 NEP2141 IMPELLAR1.5HP 1

10 AC81558 NEP2145 HOUSINGWASHER 8 8

10 AC81566 NEP2146 HOUSINGBOLTS 88

12 AC81574 NEP2147 SEALSET 1 1

13 AC81582 NEP2148 HOUSINGNUTS 88

14 AC81590 NEP2149 DRAINPLUGO‐RING

15 AC81620 NEP2150 DRAINPLUG 11

16 AC81655 NEP2151 BASEBRACKET 11

17 AC84476 NEP2152 BRACEBRACKETSUPPORT 1 1

MFR Part # Order #

1AC81361 NEP2134 PUMPLID 1 1

2AC81396 NEP2135 PUMPLIDO‐RING 1 1

3AC81434 NEP2136 PUMPBASKET 11

4AC81469 NEP2137 STRAINERCASING 1 1

5AC81477 NEP2138 DIFUSSERO‐RING 1 1

6AC81485 NEP2139 DIFUSSER 11

8AC81523 NEP2143 CASINGO‐RIG 1 1

9AC81531 NEP2144 SEALPLATE 1 1

Description NE6150B NE6170B

1 1

Page 5

ASSEMBLY INSTRUCTIONS

FOR SAND FILTER

NOTE

Filter is partially assembled; however, nothing has been properly

tightened. DO NOT operate filter system without completing

assembly instructions.

STEP 1

• Using Phillips head screwdriver, remove the closure clamp (D) from the valve assembly.

need to unscrew one side completely as it can be removed and reinstalled without unscrewing

both screws

• Remove the valve (C) from the tank and place it to the side until instructed to reattach it.

.

You only

• Inside the tank you will find the standpipe (E) and

a plastic bag containing the laterals (F).

• Attach lateral to standpipe by pushing into opening

and turning to the right as shown above.

• Repeat for remaining seven laterals.

NOTE

4

You MUST install the laterals on the

standpipe INSIDE the tank as the

standpipe will not fit back through the

opening once laterals are attached.

Page 6

STEP 2

• The filter and pump should be attached to the base prior to filling the filter with sand as it

will be difficult to maneuver after the tank is full.

• In order to attach your pump to the base, determine which of the two pumps shown below

is most like your pump and follow the corresponding instructions for installation to the base.

A. CRADLE STYLE MOUNT

• Pumps with cradles located directly under the motor

should be aligned with the holes on the base in the

raised area where the six holes are close together.

This type of mount will require the use of two to four

mounting bolts from the hardware supplied with the

base.

• Line the pump up with the set of holes which are the

best fit for the pump and bolt in place.

• Proceed to STEP 3.

B. PLASTIC PUMP HOUSING MOUNT

• Pumps with plastic pump housing mounts should be

attached by aligning the openings with a set of the

OVAL shaped holes which are towards the center of

the base. This type of mount will require the use of

TWO mounting bolts from the hardware supplied with

the base.

If you are attaching a Speck SS E90 or SS E91

pump, use the larger oval holes towards the back

of the base.

• Bolt the housing of the pump through the base and

tighten.

• Proceed to STEP 3.

5

Page 7

STEP 3

• Before filling tank with sand, cover

standpipe with a plastic bag to prevent sand from

entering standpipe. Secure in place with rubber

band so it does not fall off.

• Once bag is secured, place standpipe in the bottom of

the sand tank. Make sure pipe is centered in tank

BEFORE pouring sand into tank because you will

NOT be able to move it once sand is in.

NOTE

NOTE

Sand should be filled no less than 1/2 way up the tank and no more

than 3/4. Over-filling will result in permanent damage to your

Filter System.

If the drain plug is not lined up with the third arrow OR it lifts

off the base, retry the aforementioned steps to properly

attach tank to base.

• Clear plastic tube attached to standpipe is an

air relief. As you are adding the sand into the

tank, try to hold the tube up against the stand

The white piece on the end of this tube

pipe.

should be ABOVE sand level when you are

done adding sand to the filter.

-

NOTE

DO NOT pull too hard when holding up air relief tube, if you

pull it off the bottom of the standpipe, sand will be able to

enter your pool through the hole.

6

Page 8

STEP 3 — CONTINUED

• Add filter grade sand (sold separately) to

filter tank around standpipe. The approximate

amount of sand necessary will vary based on

the size filter you purchased.

18” Tank .... 110 Lbs.

22” Tank

26” Tank

NOTE

• Remove plastic bag and fill tank with water until the tank is filled right below opening

of standpipe.

.... 220 Lbs.

.... 360 Lbs.

NEVER FILL SAND TANK MORE THAN 1/2 TO 3/4 OF THE WAY.

Adding too much sand can cause weak return flow.

STEP 4

• Locate o-ring (G) on bottom of 6-way valve (C).

• Lubricate with o-ring lube to ensure proper seal

on tank.

• Push o-ring against the lip of the valve. It MUST sit

flat against the lip to protect from leaking at the valve.

• Clean off any sand or debris on top lip of filter and

position valve over the opening of the standpipe.

• Valve will slide ONTO standpipe when positioned

properly in tank (as shown). Push down firmly to

make sure valve slides on all the way.

NOTE

You CANNOT pull standpipe up to secure

the valve. Pulling up can damage the

laterals and cause sand to get sent back

with water flow to pool.

7

Page 9

STEP 5

• Once valve is in place, hold clamp (D) as shown and

position clamp around lip of filter and over edge of

valve.

• The clamp should sit flat around the lip of the tank

and valve. If it is not sitting flat the clamp will leak.

• Cover threads of pressure gauge (I) with

tape

(K) and thread into the open hole on the

valve and hand tighten only.

eflon

T

• Make sure that the screws of the clamp are lined

up with the seams of the tank

on clamp a little at a time.

side so that both sides are tighten equally.

Failure to follow these instructions will result in

a leak at the clamp.

. Tighten two screws

Alternating from side to

8

Page 10

STEP 6

• The valve ports are labeled “RETURN”, “PUMP” and “WASTE” with raised

letters next to the openings.

• Cover the threads of each straight fitting (J) with Teflon tape (K) and thread

one fitting into each of the 1-1/2” threaded openings on the valve.

• Attach one 6’ hose (M) to the bottom of the thru-wall skimmer and to the front

of the pump with (2) hose clamps

• Clamp one end of 3’ hose (L) to the top of the pump and the other end to the

threaded fitting on the

• Attach second 6’ hose (M) to the fitting on the “RETURN” port and secure the

opposite end to the fitting on the pool’s return with clamp.

• “WASTE” port will accept a standard fitting and a backwash hose

(sold separately) which will be used during maintenance.

• Check drain plug (N) at bottom of filter to ensure that it is screwed on tight.

“PUMP” port of the valve.

(H).

9

Page 11

OPERATING YOUR FILTER

NOTE

• Prime filter prior to starting up filter system. DO NOT turn motor on until system has been primed,

you can damage your pump.

• Make sure water in pool is up to middle of skimmer(s) and that there is nothing blocking water

flow from return(s) and skimmer(s) (i.e. plug, plate).

• Push down selector handle on valve and turn to notch labeled

and the valve is now in backwash position. Make sure backwash hose (sold separately) is

attached to the waste port so water will not spray all over you once pump is started.

• Remove lid of strainer basket on pump (if applicable) and fill with water. Skimmer and return lines

should be filled with water as well (when water level is in proper place in pool this will happen

naturally).

• Place cover back on basket and plug in/switch on pump. When pump starts up, water will come

out through the backwash hose. If the pump is properly primed, the water in the strainer basket

will fill completely and air pocket will be eliminated.

• Repeat above until all air is purged from the system then turn of

out of system, double check all connections to make sure they are properly tightened and try

again.

• To use filter, with pump OFF, push down selector handle on valve and turn to notch labeled

• Connect pump to power to start filter operation.

• Note pressure gauge reading at this time.

Your filter cannot be run if the water is not at the proper level in the

pool. Running the filter without water can cause serious damage to

your pump and filter.

BACKWASH

f the pump. If this does not get air

. Let go of handle

FILTER

.

• When pressure through return fades and pressure gauge reads 5 psi above starting pressure,

you will need to backwash the filter system to remove debris.

• Turn pump off before moving selector to

back on.

• Water will come out through the waste port, so position backwash hose where you would like

water to run out.

• NEVER backwash for longer than ONE MINUTE at a time! Backwashing longer than one minute

will cause sandblasting of internal components and can lead to damage of standpipe and/or

laterals and

urn pump of

• T

out the lines and prevent a puf

• Rinse for approximately 15 seconds and turn off pump again. Move selector back to filter and turn

pump back on. You are now filtering water.

• The

•

WASTE

• If there is a point where you would like to take water directly out of the pool, this is the option

available to do so.

• You may also vacuum on waste to take serious debris straight out of the pool if/when necessary.

• Remember, this is taking water out of the pool so watch the water level to protect your pump and

filter. If water drops below skimmer level you

RECIRCULA

used when adding chemicals to the pool, during pool opening or regular maintenance.

VOIDS WARRANTY.

f and move selector to

f of sand or debris back into the pool after backwashing.

position does not allow water to pass through the filter.

TE

allows you to move water in the pool WITHOUT filtering the water

BACKWASH

RINSE

position. Once in backwash, turn pump

position. Rinse will allow water to flow through to clear

MUST turn pump off.

This is usually

.

10

NOTE

NEVER move selector handle while pump is on. Pump MUST be

switched off to change the position of the valve. Failure to comply

ARRANTY

will cause damage to your valve and is not covered by

W

.

Page 12

TROUBLESHOOTING

LOW

WATER FLOW

1. Check skimmer and pump

strainer baskets for debris.

2. Check for restrictions in intake

and discharge lines.

3. Check for air leak in intake

line (indicated by bubbles

returning to pool).

4. Backwash filter.

5. Bring sand level in filter down

to 1/2 full.

SHORT

FILTER CYCLES

1. Check for algae in pool and

superchlorinate as required.

2. Be sure chlorine and pH levels

are in proper range.

Adjust as required.

3. Check surface of filter sand for

crusting or caking. Remove

1” of sand if necessary.

4. Check hair and lint basket on

pump for possible air leak,

lubricate basket lid O-Ring as

necessary.

POOL WATER

WON’T CLEAR UP

1. Check chlorine, pH and total

alkalinity levels and adjust as

required.

2. Be sure flow rate through filter

is sufficient.

3. Operate filter for longer

periods.

4. Be sure valve is set on

“Filter” position.

5. Be sure sand is between

1/2 and 3/4 full in tank.

WINTERIZING

NOTE

• At the end of the season once you disconnect filter system, remove the valve from the tank. Valve

selector handle should be positioned BETWEEN any of the notches to allow for air ventilation

through the valve to protect from cracking.

• Remove drain plug from bottom of sand tank to drain water out of the filter tank. Keep this plug off

for the winter to allow any potential water build-up to escape from the tank.

• Empty ALL sand from the filter system and dispose of as it is recommended to replace sand

EACH season.

• Rinse out inside of tank and air dry

tank.

• Store tank in an area where it will be protected from the elements and keep valve and tank stored

APART to protect from condensation forming and causing cracks in the tank or valve.

• Run hose water through pump to rinse out and store in a warm, dry place for the winter.

Failure to winterize your filter properly may result in damage to the

tank which is NOT covered under any warranty

You

.

MAYremove laterals from standpipe and standpipe from

.

1

1

Page 13

NE6150 & NE6170

One Year Sandman Filter System

Warranty Registration Card

1745 Wallace Ave, Ste. B

St. Charles, IL 60174

1. Sandman Filter System has a one year warranty against defects in materials and workmanship.

To receive the warranty, the card must be filled

2. Filter System must be returned with a recei

idge was purchased. No warranty claim will be honored without a receipt.

cartr

3. Please notify Blue Wave Products in advance of any Sandman warranty claim prior to shipping the item back. Contact

our warranty claim department at warranty@splashnetxpress.com

4. The freight on the Sandman Filter System when returned must be prepaid.

5. Warranty claims will only be resolved with the shipment of a replacement product, no refunds will be given.

6. Improper installation, misuse or damages resulting from acts of nature will render this warranty null and void.

7. This warranty is in lieu of all other warranties expressed or implied and no responsibility is assumed for future damage

due to misuse. This warranty does not cover any damage from the elements such as wind, snow, heavy rains, etc. We are

not responsible for damage to the filter due to improper installation or excessive wear.

To send in this warranty card: Fill out below, detach and mail to the following address:

SANDMAN ABOVE-GROUND FILTER SYSTEM WARRANTY REGISTRATION FORM

Date Purchased: _____/_____/_____

Purchaser: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Address: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

City/State/Zip: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Phone: ( ) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Email: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Purchased from: _ _ _ _ _ _ _ _ __ _ _ _ _ _ _ _ _ _ _ _ _ _ _ __ _ _ _ _ _ _ _ _ _ _ _ _ _ _ __ _ _ _ _ _ _

Item Number: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ Purchase Price: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ __

out completely and returned.

pt showing date of purchase, purchase price, and the dealer from which the

.

BLUE WAVE PRODUCTS

1745 Wallace Ave. Suite B

St. Charles, IL 60174

Loading...

Loading...