Page 1

SG3240

BLODGETT OVEN COMPANY

www.blodgett.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN M9741 Rev C (8/01)

E 2001 --- G.S. Blodgett Corporation

Page 2

SG3240 Series Conveyor Oven Owner -- Operator Manual

Introduction 2.........................................................................

Installation 5..........................................................................

Operation 24...........................................................................

Maintenance 31........................................................................

SG3240 Serie Transportørovn Ejer-- og o peratørmanual

Introduktion 37.........................................................................

Installation 40..........................................................................

Drift 59................................................................................

Vedligeholdelse 66......................................................................

SG3240 Serie Transportoven Gebruikershandleiding

Inleiding 72............................................................................

Installatie 75...........................................................................

Bediening 94...........................................................................

Onderhoud 102..........................................................................

Série SG3240 Four à convoyeur Manuel de l’utilisateur

Introduction 109.........................................................................

Installation 112..........................................................................

Fonctionnement 131.....................................................................

Maintenance 139........................................................................

Serie SG3240 Förderbandöfen Bedienerhandbuch

Einführung 146..........................................................................

Installation 149..........................................................................

Bedienung 168..........................................................................

Wartung 176............................................................................

Forno a convogliatore Serie SG3240 Manuale d’uso

Introduzione 183.........................................................................

Installazione 186.........................................................................

Funzionamento 205......................................................................

Manutenzione 213.......................................................................

SG3240 Series Forno de Correia de Transporte Manual do Operador -- Proprietário

Introdução 220..........................................................................

Instalação 223...........................................................................

Utilização 242...........................................................................

Manutenção 250.........................................................................

Horno de transportador Serie SG3240 Manual del operario

Introducción 257.........................................................................

Instalación 260..........................................................................

Funcionamiento 279......................................................................

Mantenimiento 287.......................................................................

SG3240 Serien Tunnelugn Användarhandbok

Introduktion 294.........................................................................

Installation 297..........................................................................

Drift 316................................................................................

Underhåll 323...........................................................................

Piec przeno śnikowy Seria SG3240 Instrukcja dla posiadacza i użytkownika

Wstęp 329..............................................................................

Instalowanie 332.........................................................................

Użytkowanie 351........................................................................

Konserwacja 359........................................................................

Page 3

SG3240 Series

Conveyor Oven

Owner --- Operator Manual

1

Page 4

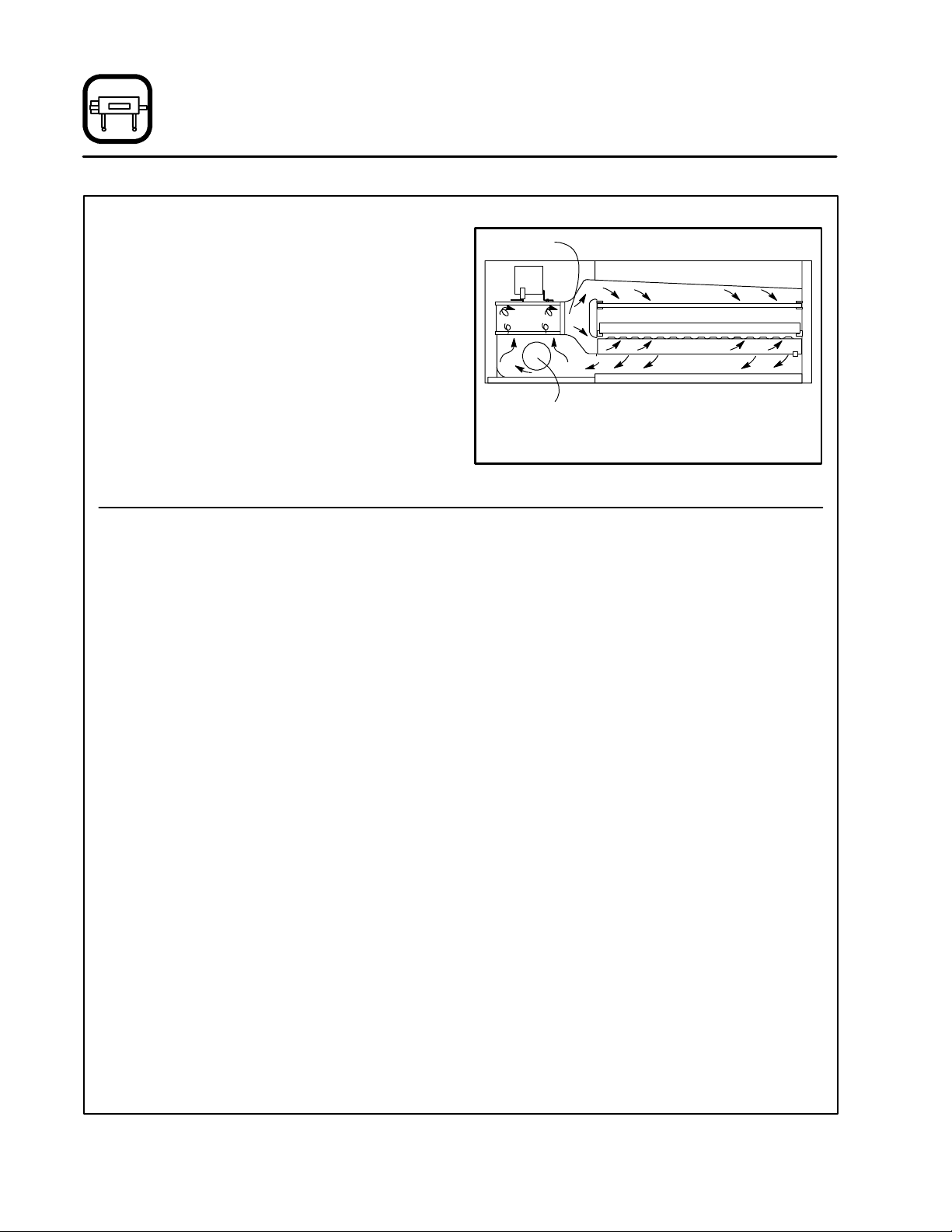

Introduction

Oven Description and Components

Cooking in a conveyor oven differs from cooking

in a conventionaldeck or range oven since heated

air is constantly recirculated over the product by

a fan in an enclosed chamber. The jets of moving

air continually strip away the layer of cool air surrounding the product, quickly allowing the heat to

penetrate. The result is a high quality product,

cooked at a lower temperature in a shorter amount

of time.

This Blodgett conveyor oven represents the latest

advancement in energy efficiency, reliability, and

ease of operation. Heat normally lost, is recirculated

within the cooking chamber resulting in substantial

reductions in energy consumption, a cooler kitchen

environment and enhanced oven performance.

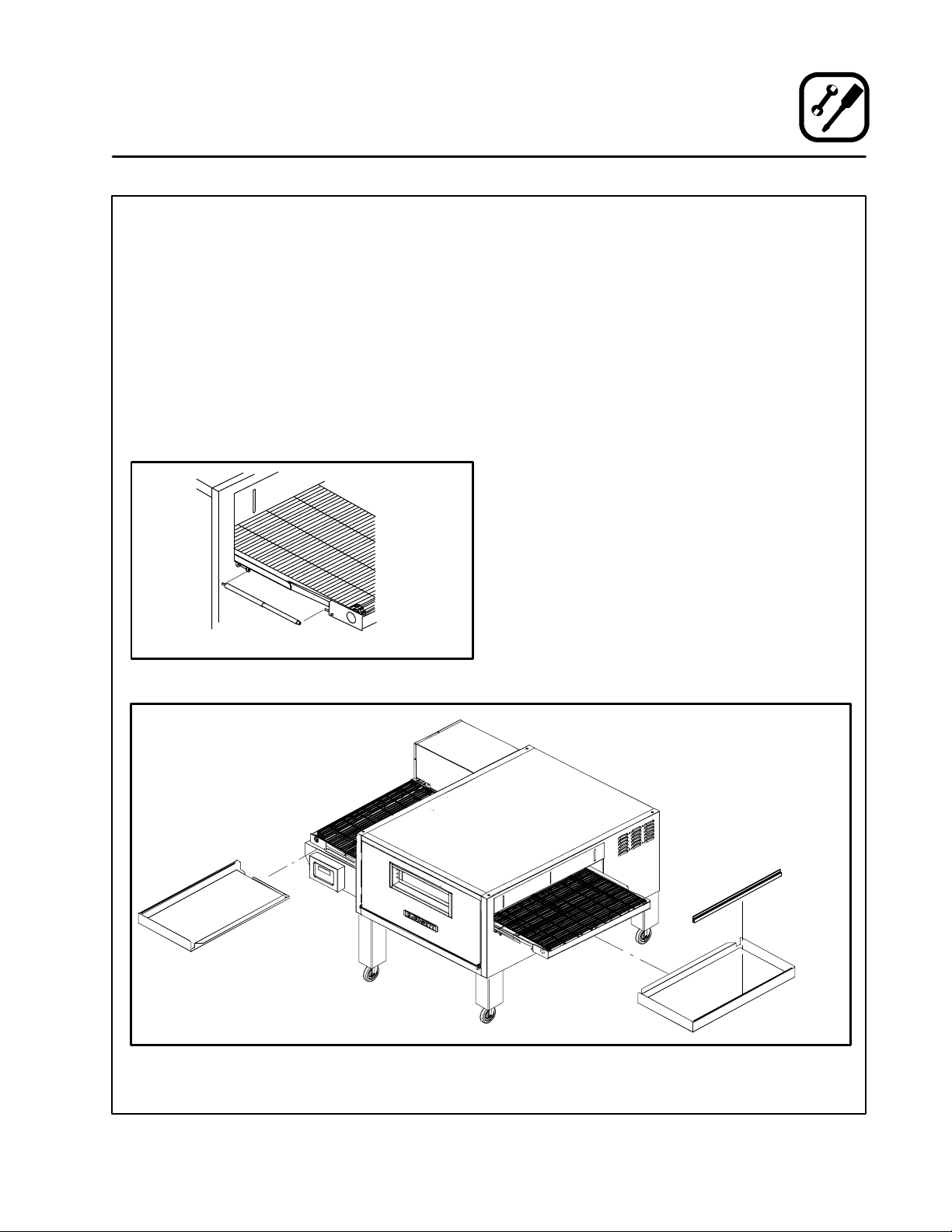

OVEN COMPONENTS

Conveyor Belt --- stainless steel chain link (con -

veyor) belt that carries product through the oven.

Conveyor Belt Master Links --- al l o w e a s y r e -

moval of the conveyor belt for more thorough

maintenance and cleaning. Identified by locating

double spaces between regular links on the belt.

Conveyor Rack Assembly (drive & idle sides) --located on both ends of the oven deck. The drive

side has a drive shaft and sprocket which slide into

the electrical box. The conveyor can be removed

as one piece without removing the belt.

Optional Folding Conveyor Rack Assembly --conveyor belt and rack assembly that carries

product through the oven. This rack folds for ease

of removal in small spaces. The conveyor can be

removed as one piece w ithout removing the belt.

Conveyor Belt Tensioners --- maintain tension on

theconveyorbelt.

Electrical Box --- contains electrical components,

wiring, cooling fans, drive motor , drive chain, and

combustion blower/burner assembly (gas ovens

only) or electric elements (electric ovens only).

Drive Motor --- provides power to move the conveyor belt. The operator and control system determine the speed. Belt travel direction (left to right or

right t o left) is factory set and is easily changed.

Drive Chain --- connects the drive motor sprocket

to the conveyor drive shaft sprocket.

Heated Air

Air Plate

Blower

Combustion

Chamber

AirFlowPatternforBlodgettConveyorOvens

Conveyor

Nozzles

Return Air

Figure 1

Baking Chamber --- products pass through the

baking chamber on the belt.

Nozzles --- distribute heated air from the bottom

of the baking chamber. Located inside the oven,

undertheconveyorbelt.

Nozzle Support Bracket --- removable bar that locates the front end of the nozzles. Located just inside the oven’s front door beneath the nozzles.

Air Flow Plate --- distributes heated air from the

top of the baking chamber.

Conveyor Support Angle Bars --- p r o v i d e s u p portforconveyorrackassembly.

Crumb Pans --- catch crumbs from products on

the conveyor. Located under conveyorbelt at both

ends of the baking chamber.

Operator Controls --- used to control oven temperature, belt speed and other functions.

Ignition Control Reset Button ( g as ov ens on ly ) --resets ignition control/gas burner after a lockout. Located on the lower panel of the control box.

Emergency Stop Button --- FOR EMERGENCY

USE ONL Y(damage may occur)! Press the red palm

switch located next to the operator control to shut

down the oven and stop the conveyor.

Front Access Door --- opens for access to cooking chamber allowing for easier cleaning.

2

Page 5

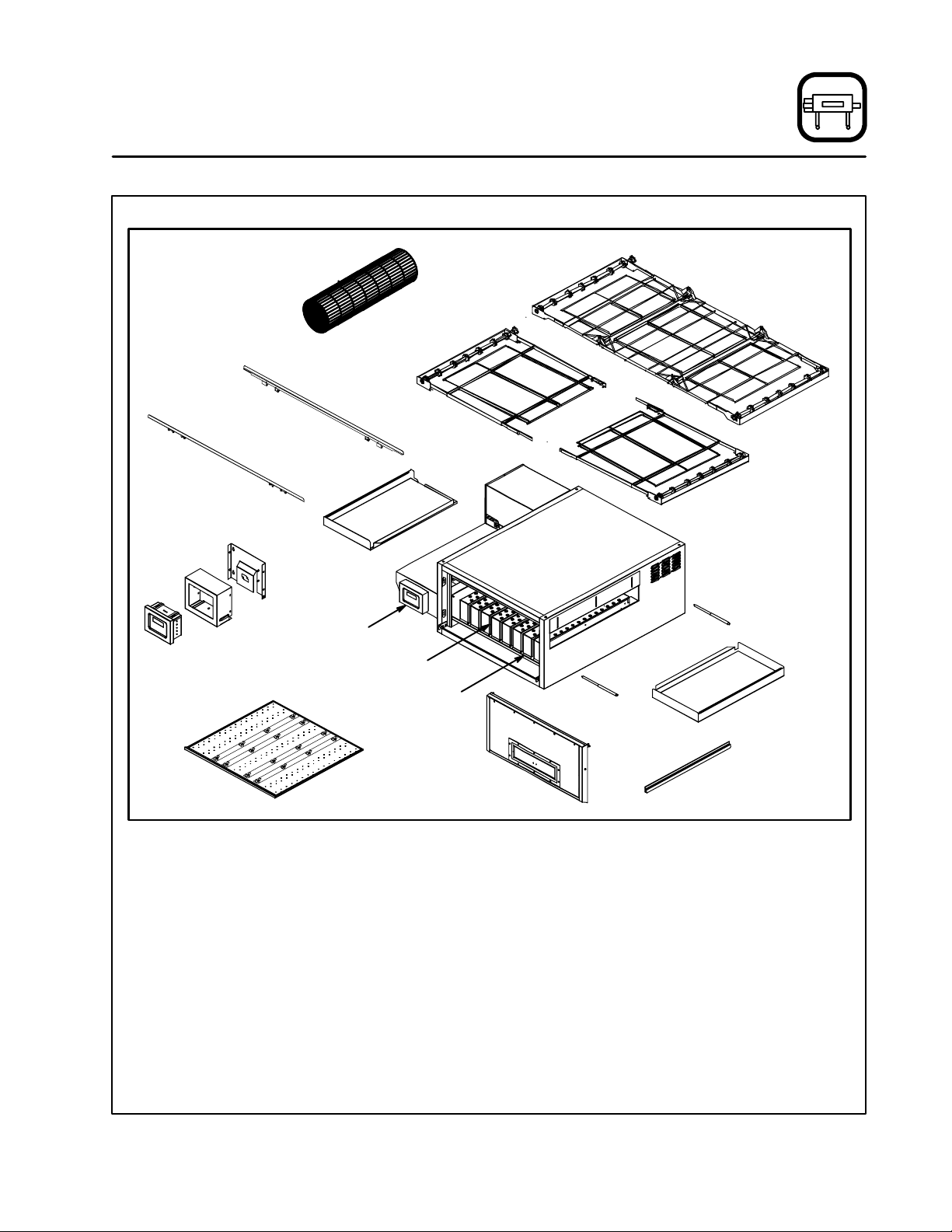

Introduction

Oven Description and Components

Remote

Housing

Operator

Control

Wire Conveyor Belt

Conveyor

Support

Angles

Remote Mounting

Bracket

Operator Control

Drive Side

Crumb Pan

Integral

Drive Side

Conveyor Rack

Nozzles

Nozzle Support

Bracket

Belt

Tensioner

Optional Folding Conveyor

(Shown without belt for clarity)

Idle Side

Conveyor Rack

Belt Tension-

er

Idle Side

Crumb Pan

Air Flow Plate

Front Access

Door

Figure 2

3

Product Stop

Page 6

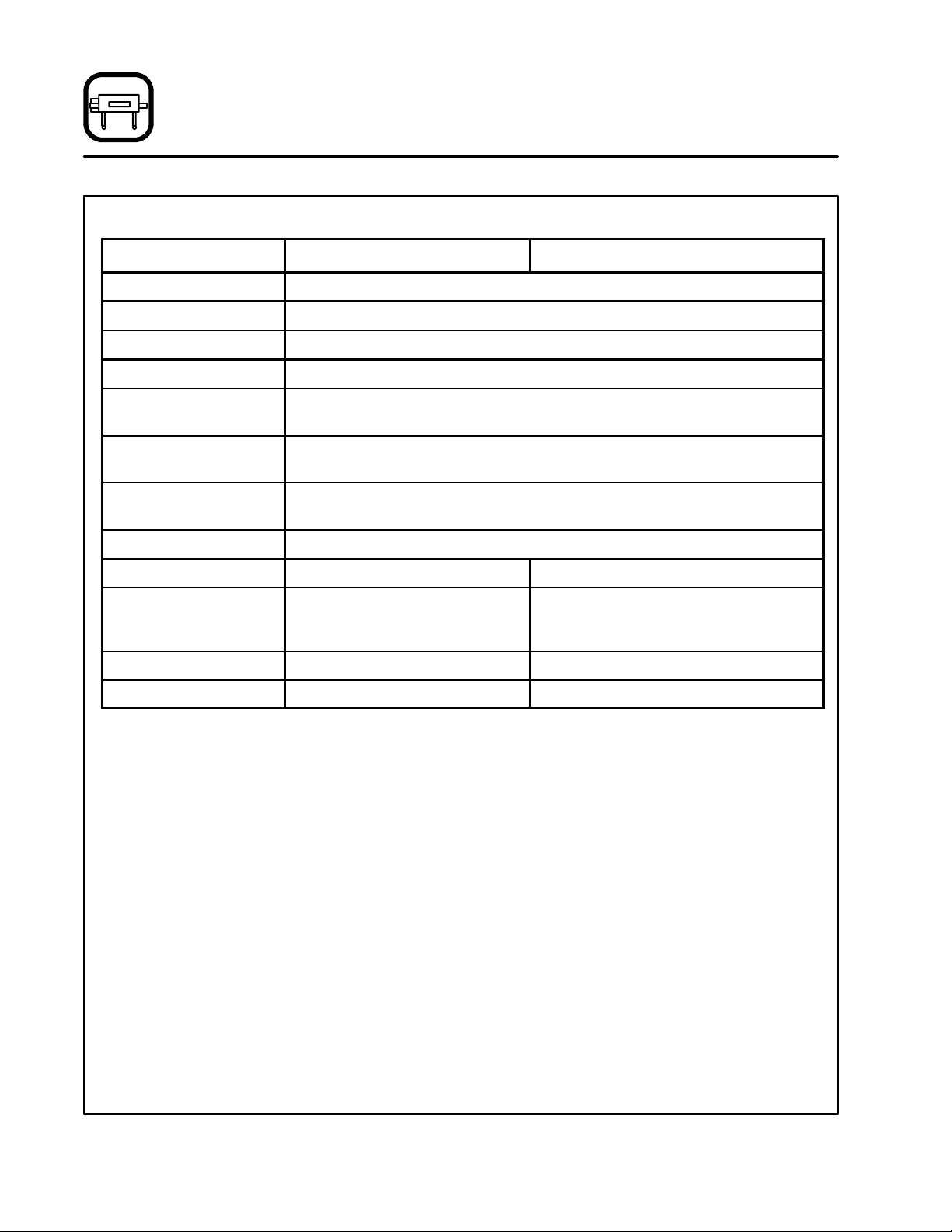

Introduction

Oven Specifications

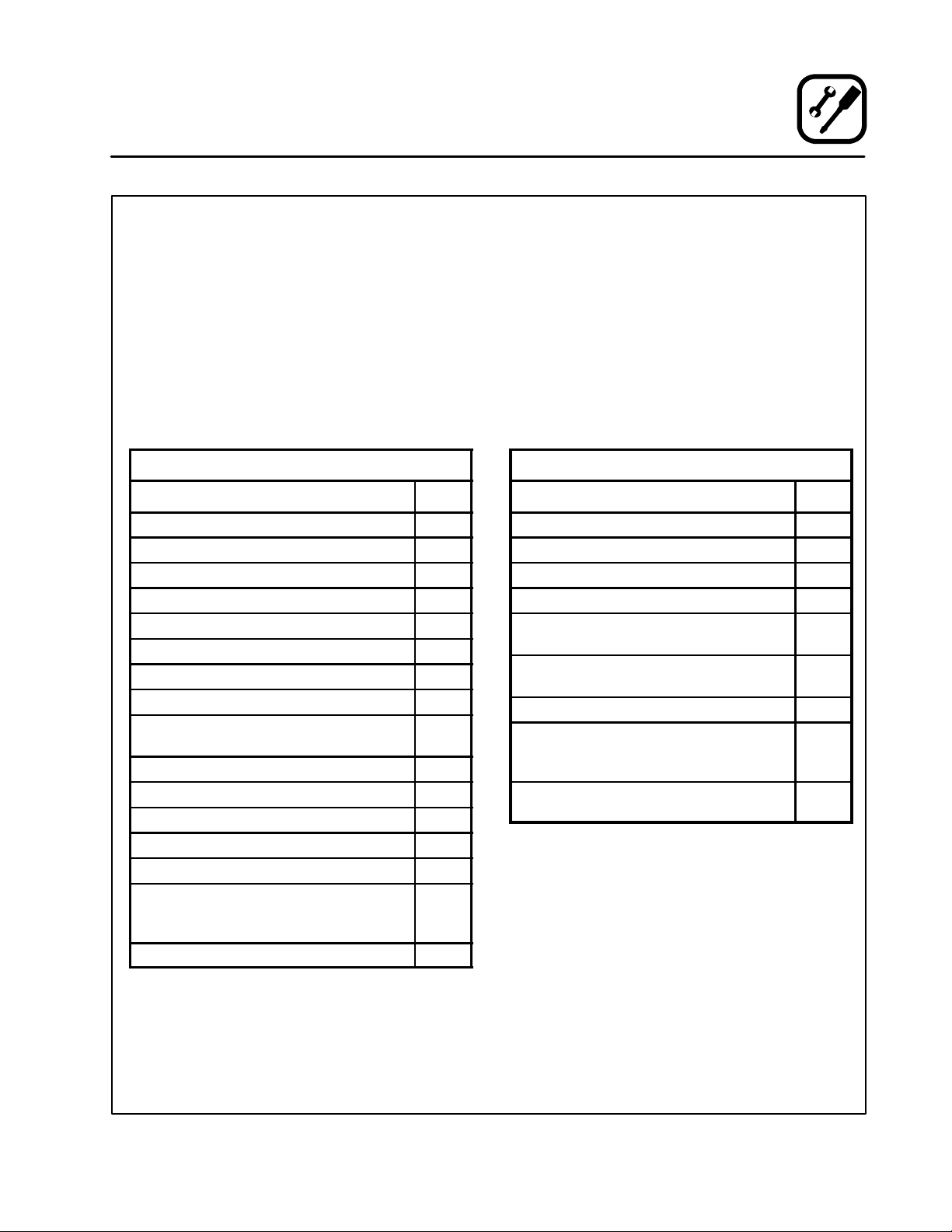

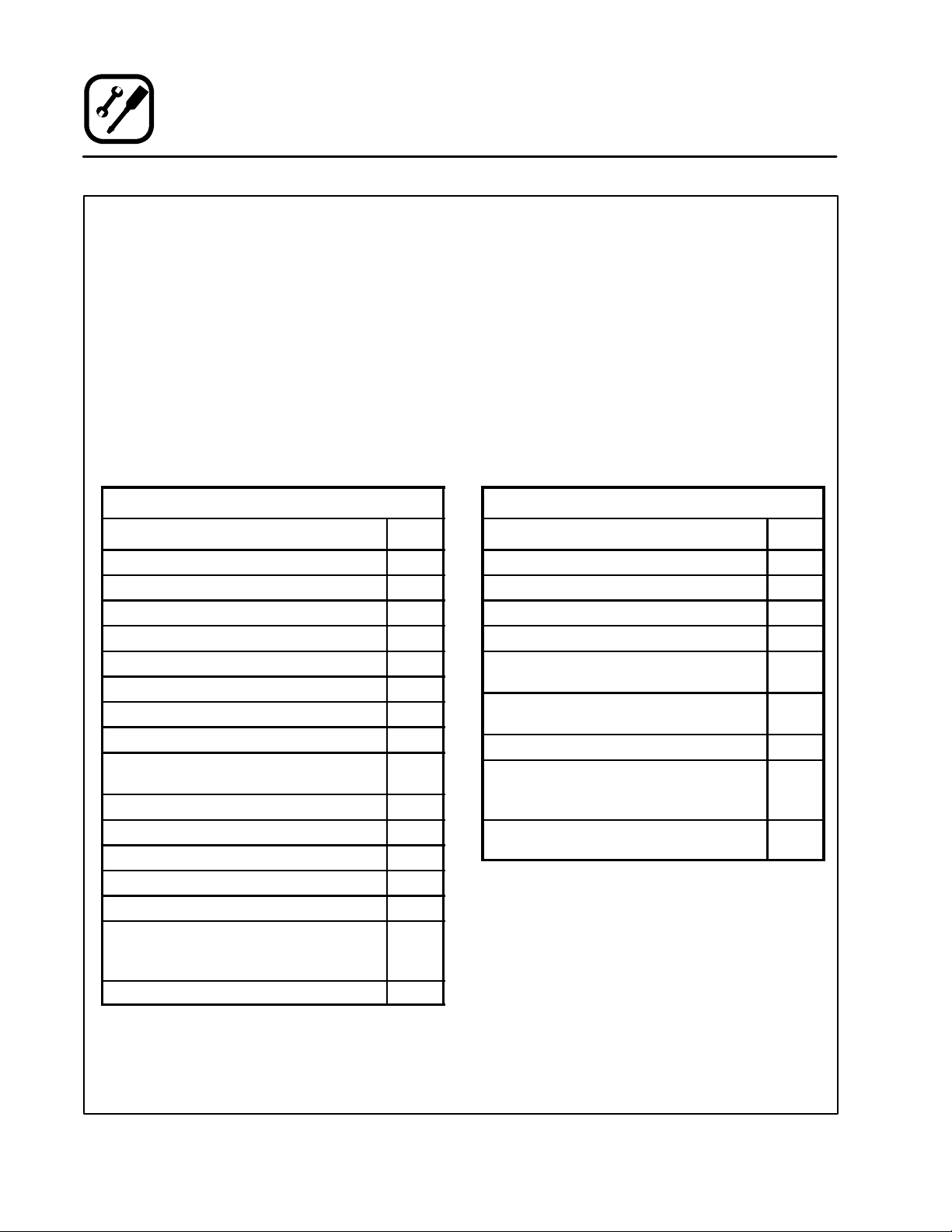

SPECIFICATIONS SG3240G/AA SG3240E/AA

Belt Width 81 cm (32”)

Cooking Zone Length 102 cm (40”)

Baking Area 0.83 m2(8.89 Sq. Ft.)

Product Clearance 10.2 cm (4”) maximum

Dimensions

(single unit)

Minimum

Wall Clearance

Maximum Operating

Tem per a tu r e

Bake Time 1 minute (minimum) 30 minutes (maximum)

Maximum Heat Input 32,2 kW/Hr. (110,000 BTU/Hr.) 27.0 kW/Hr.

Power Supply 230VAC, 1Φ,50Hz,

5 amp, 2 wire plus ground

(L1, N, GND)

Gas Supply Refertothetableonpage22. None

Gas Supply Connection 3/4” NPT None

*Add 35 cm (13.65”) to depth for triple stack caster cradles

196 cm x 135 cm* x 61 cm (77” x 53”* x 24”)

0cm(0”)fromrearandside

315_C (600_F)

230/400VAC, 3Φ WYE, 50Hz, 41.5 amp,

4 wire plus ground (L1, L2, L3, N, GND)

4

Page 7

Installation

Delivery and Inspection

All Blodgett ovens are shipped in containers to

prevent damage. Upon delivery of your new oven:

D

Inspect the shipping container for external dam age. Any evidence of damage should be noted

on the delivery receipt which must be signed by

the driver.

D

Uncrate the oven and check for internal damage. Ca rriers will accept claims for concealed

damage if notified within fifteen days of delivery

and the shipping container is retained for inspection.

Standard Components

Part Description Qty.

Main oven body 1

Nozzle (shipped installed) 8

Air plate (shipped installed) 1

Conveyor support angle 2

Drivesideconveyorrack 1*

Idle side conveyor rack 1*

Rolledwireconveyorbelt 1*

Extra piece of wire conveyor belt 1

Packet containing: conveyor belt

innerandoutermasterlinks

Belt tensioners 2*

Crumb pans 2

Product stop 1

Oven Supports (legs, casters) 4

Air Plate Hook 1**

Packet containing: 12 3/8-16 hex

head bolts, lockwashers and

washers for legs

Owner’s manual 1

1*

1

The Blodgett Oven Company cannot assume

responsibility for loss o r damage suffered in

transit. The carrier assumed full responsibility

for delivery in good order when the shipment

was accepted. We are, however, prepared to

assist you if filing a cl aim is necessary.

The oven can now be moved to the installation

site. Check the followinglist with Figure 2 on page

3 to be sure all items were received.

Options

Part Description Qty.

Optional folding conveyor assembly 1

Stacking Kit 1***

Packet containing: 4 alignment pins 1***

Triple stack casters 1****

Optional remote operator control with

attached 50’ cable

Optional remote operator control for

10’ cable

Optional remote 10’ cable 1

Packet containing: optional remote

operator control cable clamps and

hardware

Optional vent cover assembly or

chimney kit

NOTE: *** One required for double stacked units

Two required for triple stacked units

NOTE: **** Triple stacked units only

1

1

1

1

NOTE: * shipped assembled for the optional

folding conv e y o r

NOTE: ** shipped with bottom or single section

ovens only.

5

Page 8

Installation

Oven Location and Ventilation

OVEN LOCATION

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

The following clearances must be maintained between the oven and any combustible or non-combustible construction.

All units

D

Oven body sides --- 0 cm (0”)

D

Oven body back --- 0 cm (0”)

The following clearances must be available for

servicing.

All units

D

Oven body sides --- 96.5 cm (38”)

D

Oven body back --- 71 cm (28”)

NOTE: On gas models, routine servicing can

usuallybe accomplished within thelimited

movement provided by the gas hose restraint. If the oven needs to be moved

further from the wall, the gas must first be

turned off and disconnected from the oven

before removing the restraint. Reconnect

the restraint after the oven has been returned to its regular position.

It is essential that a sufficient air supply to the oven

be maintained to provide adequate combustion

and ventilation air.

D

Place the oven in an area that is free of drafts.

D

Keep the oven area free and clear of all combustibles such as paper, cardboard, and flammable liquids and solvents.

VENTILATION

A mechanically driven ventilation system is required for the removal of excess heat and cooking

vapors. For gas models, a ventilation system is

also required for t he removal of the products of

gas combustion. The necessity for a properly designed and installed ventilation system cannot be

over emphasized.

The following are general recommendations and

guidelines for good ventilation. Your specific application may require the services of a ventilation

engineer or consultant

The ventilation hood must work wellwith the building heating, ventilation and air conditioning

(HVAC) system. The hood exhaust and the supply

air flows should be sized appropriately. Supply air

must be provided by either the hood system or the

building HVAC system in order to prevent an excessive negative pressure in the oven area. Supply air should replace approximately 80% of the air

flow exhausted by the hood. The table below can

be used as a guideline, but the correct air flow values depend on the efficiency of the hood design,

the amount of air flow around the oven, and the

current air flow in and out of the kitchen or oven

area (for existing facilities).

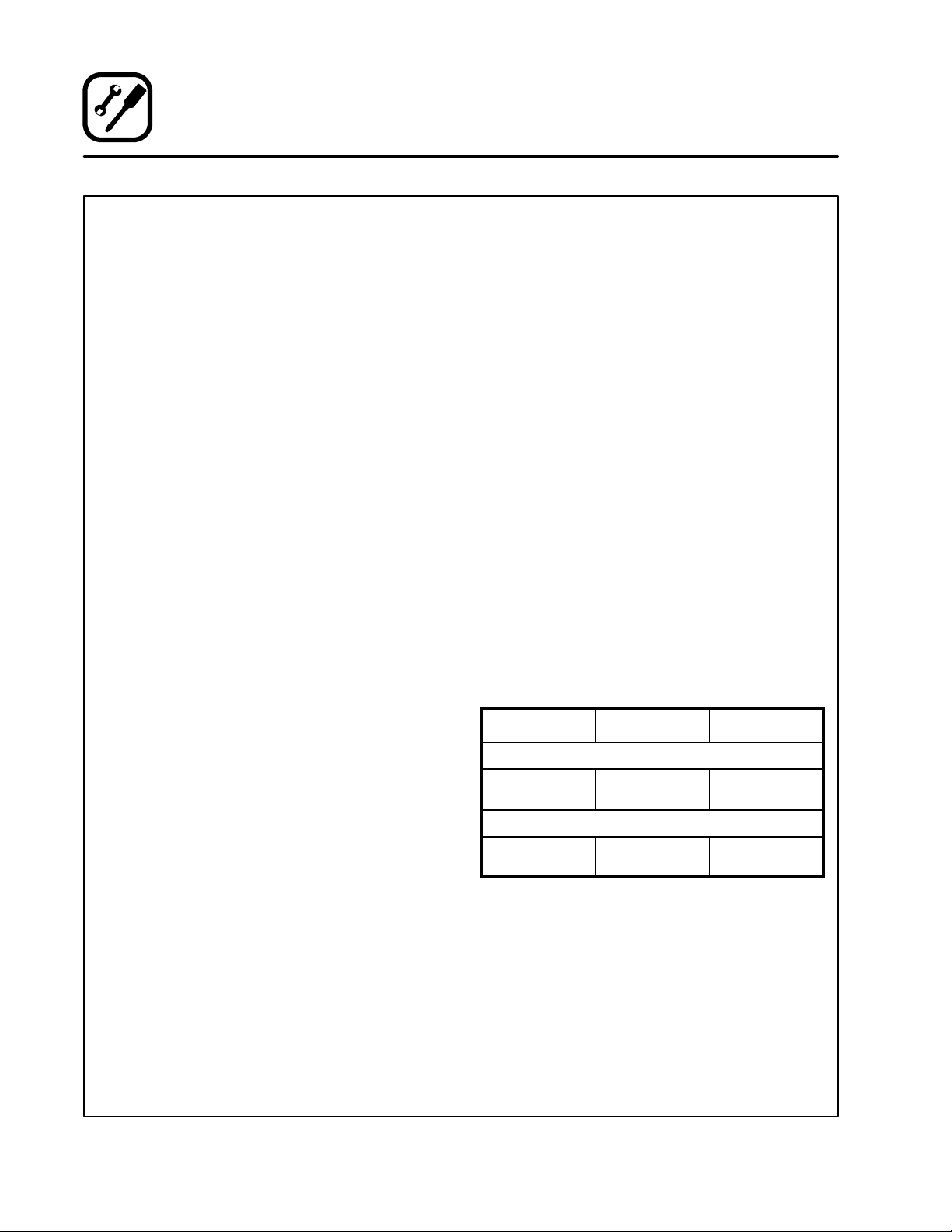

SINGLE

Exhaust Volume -- CFM (M3/min)

800-1000

(23-28)

Supply Requirements -- CFM (M3/min)

640-800

(18-23)

DOUBLE TRIPLE

1200-1800

(34-52)

960-1440

(27-41)

1800-2500

(52-71)

1440-2000

(41-56)

Ideally supply air would be provided through the

building HVAC system or, secondly, through the

hoodwith an in-line tempering unit. Air supplieddirectly from outside the building to the kitchen or

oven area, non-tempered, could be used as supplyair but the design would have to accommodate

potential operational and environmental drawbacks.

6

Page 9

Installation

Oven Location and Ventilation

NOTE: In NO case should supply air blow at or

near the cooking chamber openings. This

will adversely affect the cooking consistency and the reliability of the oven.

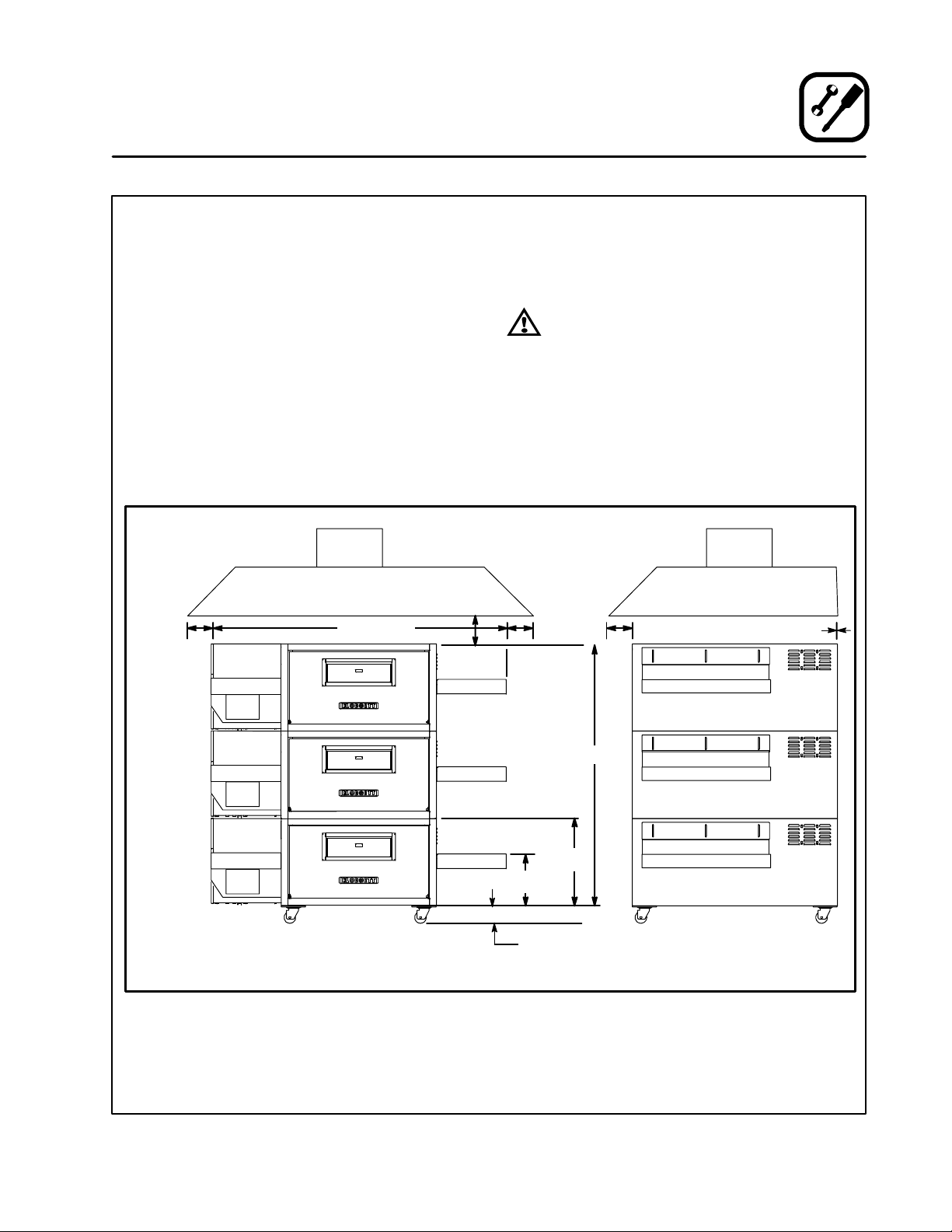

The hood should be sized to completely cover the

equipment plus an overhang of at least 15 cm (6”)

on all sides not adjacent to a wall. It may be allowable in some jurisdictions to cover just the baking

chamber plus a 15 cm (6”) overhang. The distance

from the floor to the lower edge of the hood should

not exceed 2.1m (7’). See Figure 3.

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installationand/or

7.6 cm (3”)

Minimum

15.2 cm (6”)

Minimum

196 cm (77”)

operation of your Blodgett oven, please contact

your local distributor. I f you do not have a local distributor, please call the Blodgett Oven Company at

0011-802-860-3700.

WARNING:

Failure to properly vent the oven can be

hazardous to the health of the operator

and may result in operational problems,

unsatisfactory baking and possible damage to the equipment.

Damage sustained as a direct result of improper ventilation will not be covered by

the Manufacturer’s warranty.

15.2 cm (6”)

Minimum

0cm (0”)ifwallor

15.2 cm (6”)

Figure 3

7

182 cm (72”)

61 cm

36.1 cm

(14.2”)

(24”)

Triple Stack --- 5.1 cm (2”)

Double Stack --- 43.8 cm (17.25”)

Single Stack --- 59 cm (23.25”)

Page 10

Installation

Oven Assembly

OVEN SUPPORTS

Single and Double Stacked Units

1. Boltthe leg/caster assemblies to the oven with

3/8-16 hex head bolts, lockwashers and

washers.

On gas models attach the restraint bracket to

the left rear leg as shown in Figure 4.

NOTE: Install the locking casters on the front

of the oven. The front of the oven contains the front access door.

2. Have several persons carefully lift the oven off

thepalletandsetitontothecasters.

3. Engage the brakes on the front casters.

Front of

Oven

Strain Relief

Bracket

Left rear leg and strain relief bracket shown

Figure 4

8

Page 11

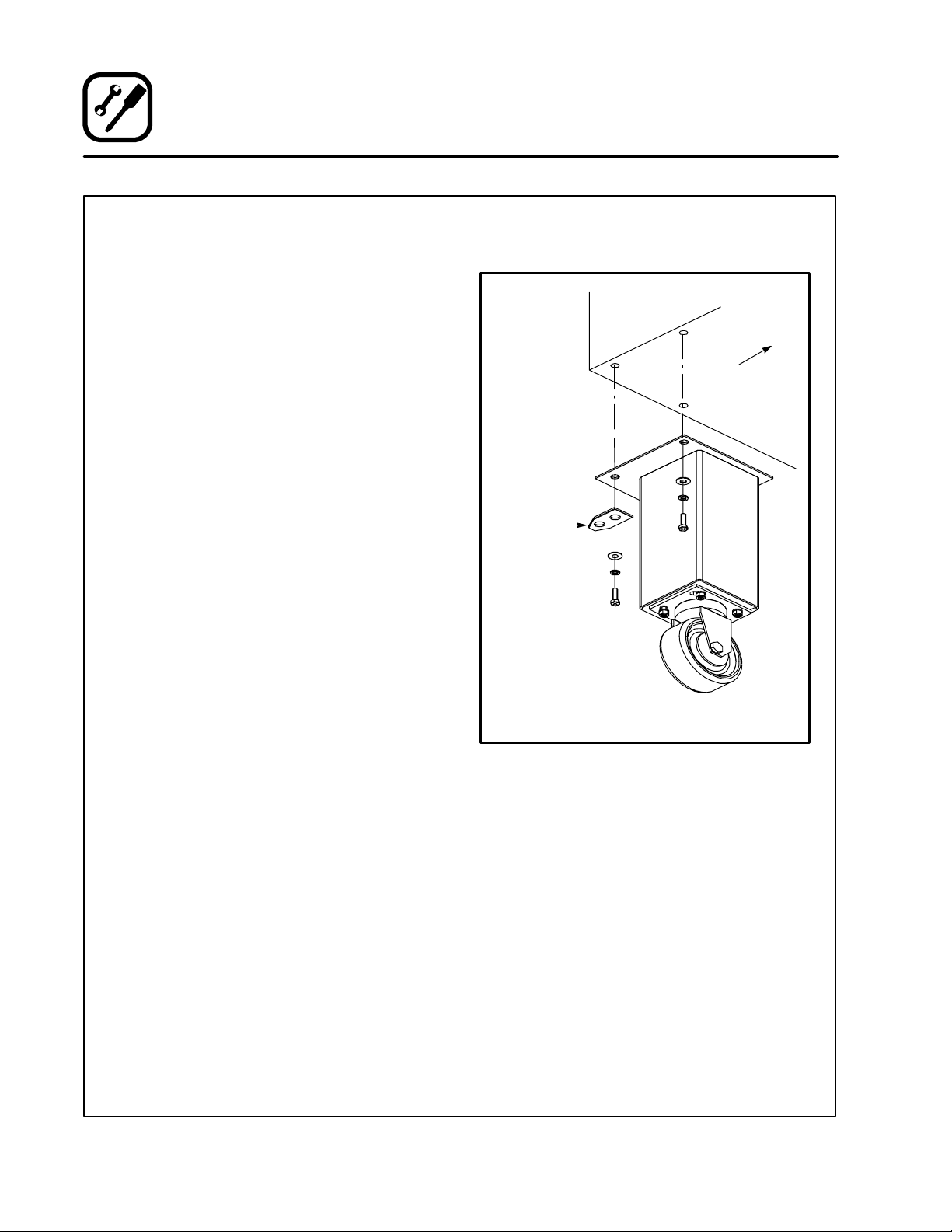

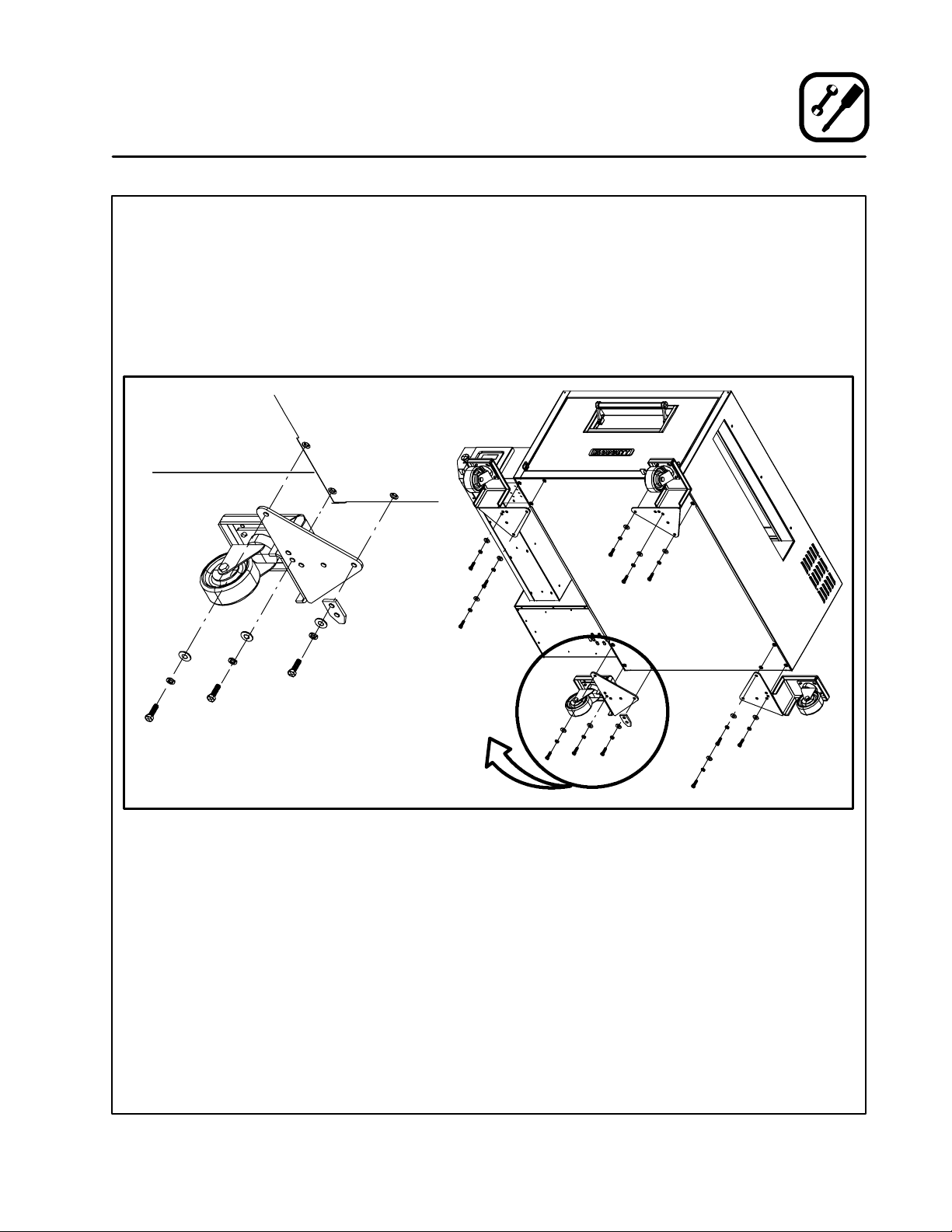

Triple Sta cke d Units

1. Mount the caster assemblies to the oven with

3/8-16 x .125 cap screws, lockwashers and

washers. See Figure 5 for correct caster

orientation.

On gas models attach the restraint bracket to

theleftrearcasterasshowninFigure5.

Installation

Oven Assembly

NOTE: Install the locking casters on the front

of the oven. The front of the oven contains the front access door.

2. Have several persons carefully lift the oven off

thepalletandsetitontothecasters.

3. Engage the brakes on the front casters.

View A

Strain Relief

Bracket

See View A

Figure 5

9

Page 12

Installation

Oven Assembly

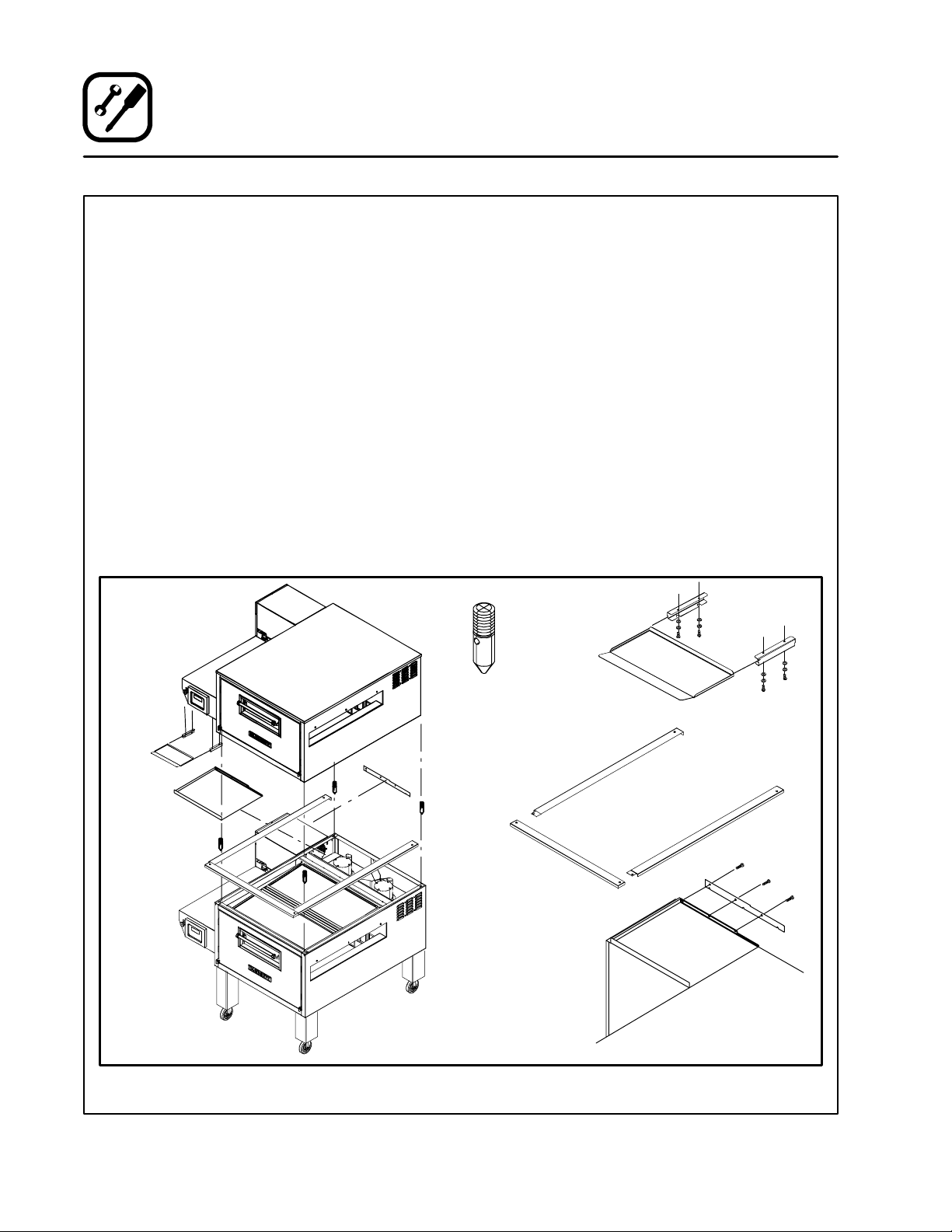

STACKING THE OVENS (if applicable)

1. Install the supports on the bottom unit as described.

2. Have several persons carefully lift the oven off

thepalletandsetitontothecasters.

3. Engage the brakes on the front casters.

4. Rest the top oven on its back. Install the four

oven alignment pins into the outside corner

mounting holes provided on the bottom of the

oven.

5. Assemble the three long stacking trim pieces

on the top of the bottom (or middle) oven.

Align the holes over the holes for the alignment pins.

6. Have several persons carefully place the

upper oven on top of the lower oven. Align the

alignment pins with the knock-out holes in the

top the lower oven.

7. Placethe stacking plate on top of the electrical

box on the bottom unit.

NOTE: The back of the plate should line up

with the back of the electrical box.

8. Loosen the three screws on the top of the electrical box side panel on the lower oven.

9. Slide the slots in the bottom of the stacking

trim over the loosened screws. Tighten the

screws.

10. Attach the stacking trim to the side of the

stacking plate with the screws provided.

11. Attach the heat shield brackets to the bottom

of the control tunnel using screws, lockwashers and washers.

NOTE: The stops on the brackets should be

located away from the control.

12. Slide the heat shield into the brackets.

Heat Shield

Oven

Alignment

Pin

Brackets

Heat

Shield

and

Brackets

Stacking

Plate

Stacking

Trim

Alignment

Pin

Figure 6

Electrical

Box

Heat

Shield

Stacking

Trim

Stacking

Trim

Stacking

Plate

Oven

10

Page 13

Installation

Oven Assembly

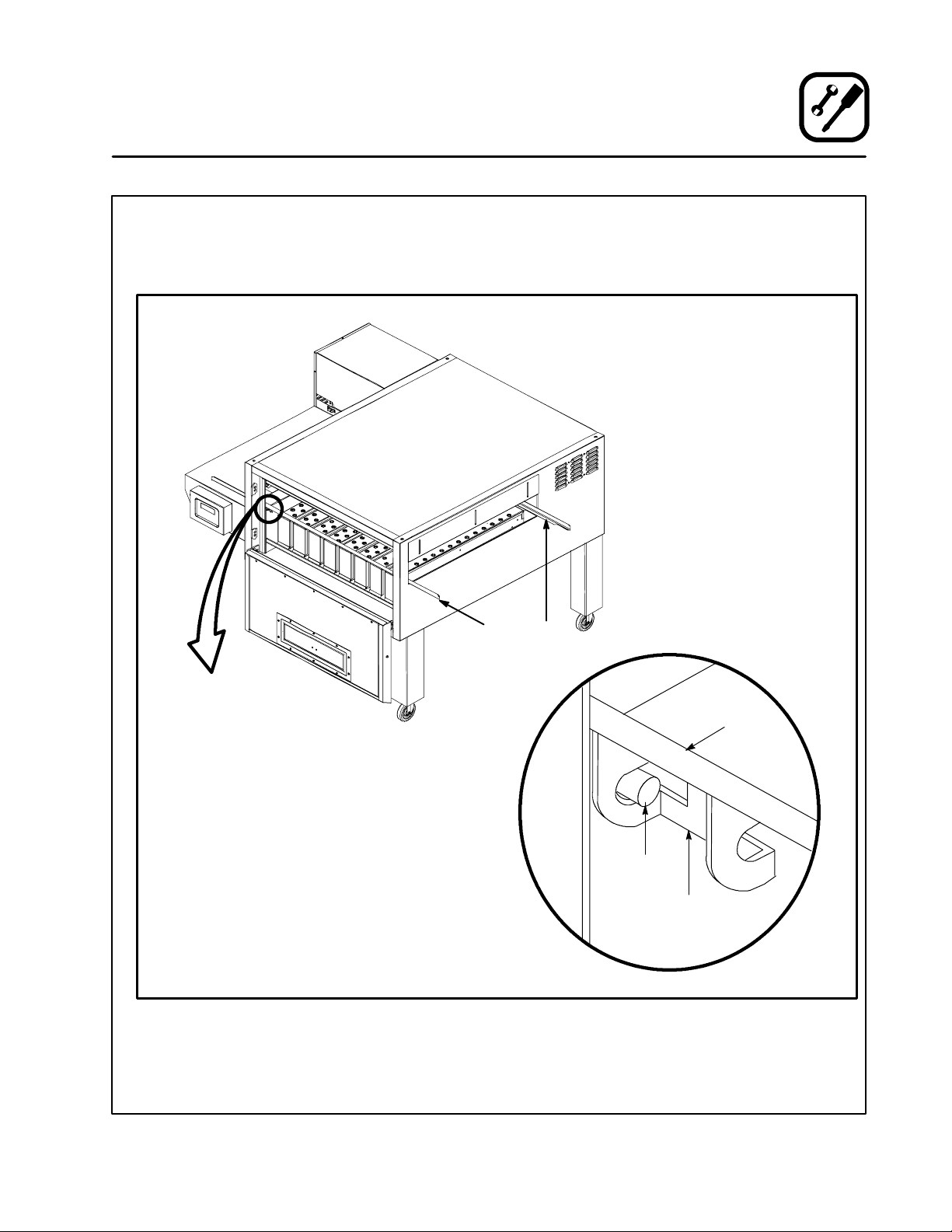

CONVEYOR SUPPORT ANGLES

1. Slide the conveyor support angles into the

oven.

2. Rotate the angle such that the slots in the

brackets engage the pins on the oven.

Conveyor Angle

Supports

See View A

Angle

Support

Pin

Bracket

View A (Installed)

Figure 7

11

Page 14

Installation

Oven Assembly

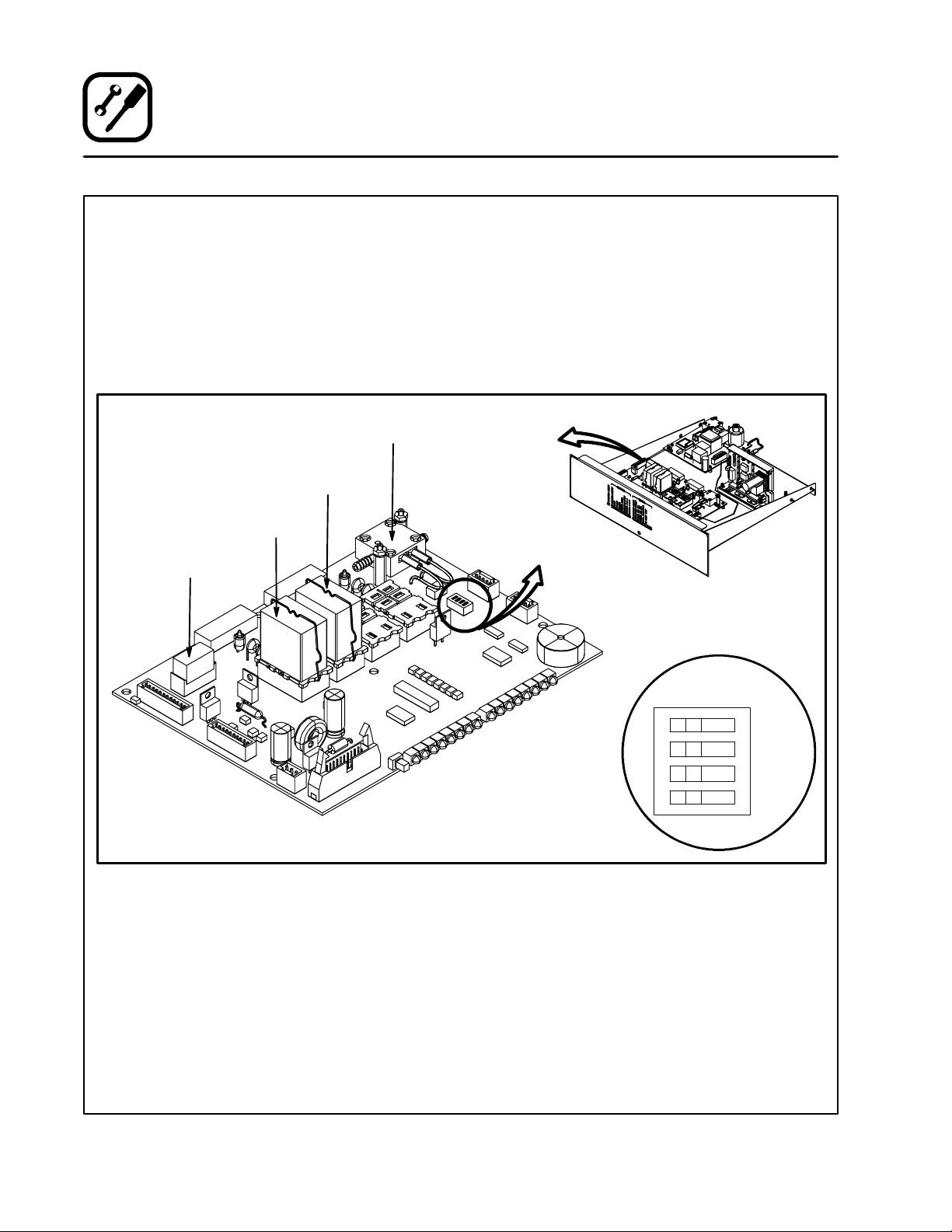

CONVEYOR BELT DIRECTION

Conveyor travel is factory set for either left to right or

right to left belt operation. If the opposite direction is

required, the polarity of the drive motor must be reversed as follows and the conveyor belt must be removed, reversed and reinstalled or the belt will be

damaged. Refer to page 14 for belt installation instructions.

Circulation Blowers’

Pressure Switch

Blower 2

Relay

Blower 1

Relay

Heat

Relay

To reverse polarity:

1. DISCONNECT THE POWER CORD TO THE

OVEN.

2. Flip the dipswitch marked DIR1 on SW4 (switch

4) on the interface board. See Figure 8.

NOTE: The interfac e board is locate d on the

pull out tray at the bottom of the electrical box.

Interface Board

(See View A)

Switch 4

(See View B)

Interface Slide Tray

View B

Interface Board --- View A

SW4

ENB 2

DIR 2

ENB 1

DIR 1

Figure 8

12

Page 15

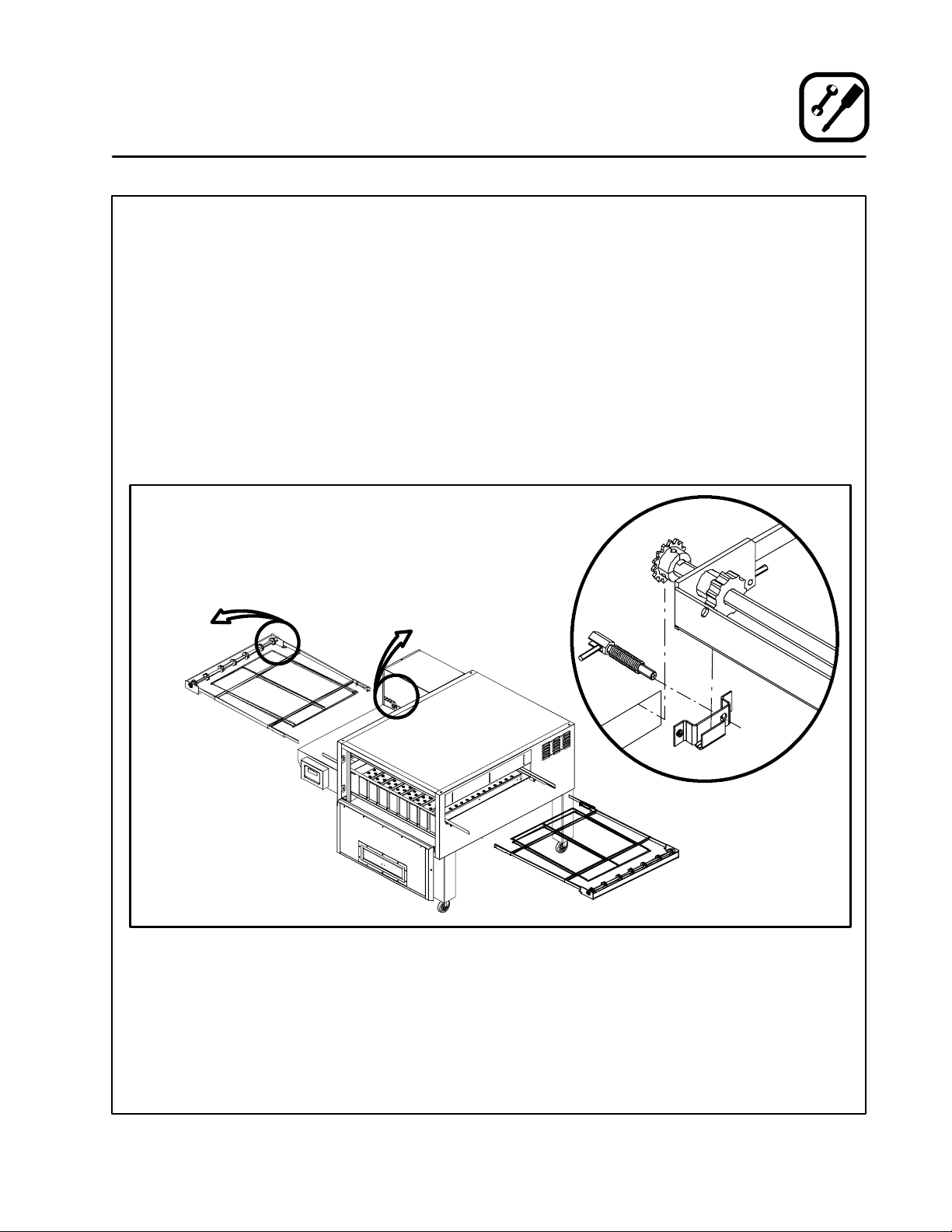

STANDARD CONVEYOR ASSEMBLY

Conveyor Racks

1. Slide the drive side conveyor support rack

onto the conveyor support angles.

NOTE: The sprocket on the conveyor rack must

be inside the electric al box after being

pushed into the oven. See View A.

2. Install the drive chain around the drive motor

sprocket and the sprocket on the conveyor

rack. Pull the conveyor rack forward to tighten

the chain.

3. Securetheconveyorusingtheconveyorlocating pin. Install the pin from the inside of the elec-

Installation

Oven Assembly

trical box, through the conveyor bracket and

intotheconveyorrack.SeeViewA.

4. Slide the idle side conveyor rack onto the conveyor support angles until it touches the drive

side conveyor rack.

NOTE: If the mounting hole cannot be lined up or

the chain is too loose, the drive motor will

need to be repositioned.

View A

See View A

Drive Side

Conveyor Rack

Sprocket

See View A

Locating

Pin

Conveyor

Bracket

Idle Side

Conveyor Rack

Figure 9

13

Page 16

Installation

Oven Assembly

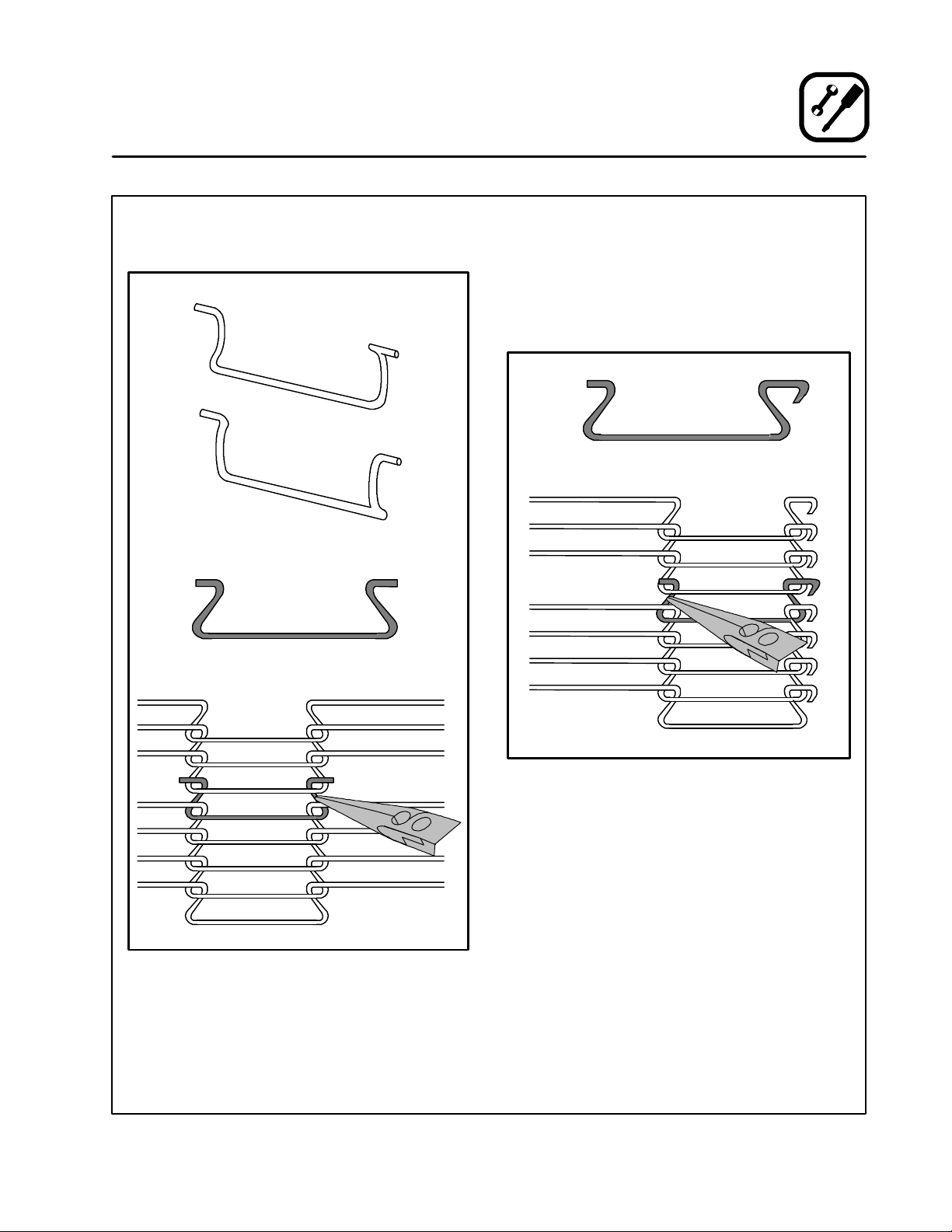

Conveyor Belt

NOTE: The following directions are written for left to

right travel. For right to left travel, thread the

belt from the left side of the oven. The two

ends will meet on the right side of the oven.

Belt Top

Direction of

Travel

Figure 10

1. Thread the conveyor belt from the right side of

the oven. The conveyor belt has loops on both

ends. The loops must travel backwards on the

conveyor rack to prevent belt damage. See

Figure 11 for proper belt orientation.

Push the belt through the conveyor rack

threading in between the top and bottom

guide rods. Stop when there is approximately

31 cm (12”) of belt hanging out on the left side.

2. Thread the belt around the sprockets on the

left conveyor rack.

3. T akethe remainder of the belt, loop it around the

sprockets on the right conveyor rack.

4. Push the remainder of the belt through the

oven cavity on top of the conveyor racks.

5. Each end of the belt should meet approximately

15 cm (6”) past the end of the left conveyor rack.

Figure 11

14

Page 17

Installation

Oven Assembly

6. Install the inner master links to connect the

two ends of the conveyor belt. See Figure 12.

Proper

Position

Upside-down

InnerMasterLink

7. Install the outer master links to finish connecting the two ends of the conveyor belt. See

Figure 13.

NOTE: The extra piece of wire belt can be used to

make additional master links if the original

links are lost or damaged.

Outer Master Link

Figure 12

Figure 13

15

Page 18

Installation

Oven Assembly

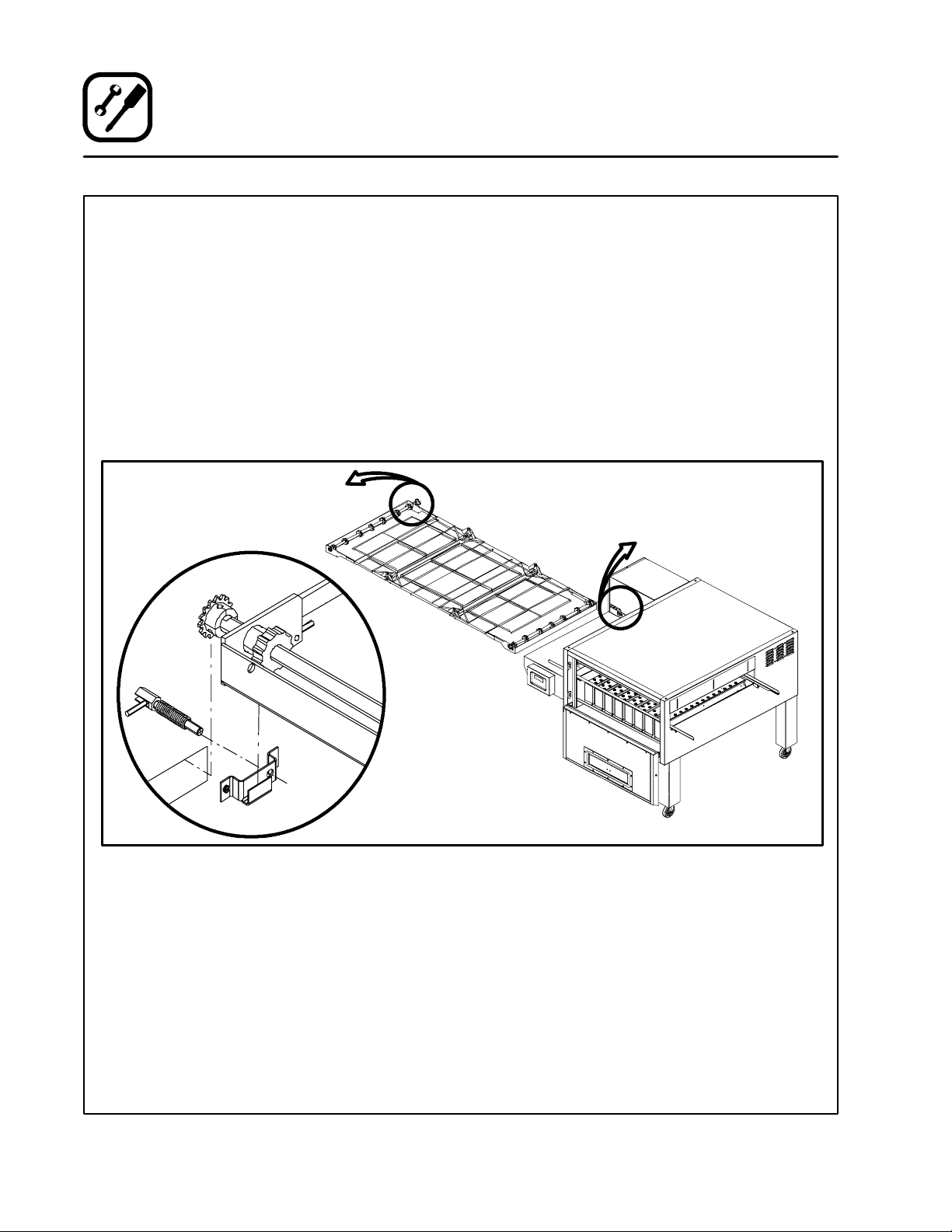

OPTIONAL FOLDING CONVEYOR

The folding conveyor assembly must be installed

from the electrical box side of the oven.

1. Unfold the right side of the conveyor.

2. Push the conveyor onto the conveyor support

angles.

3. Unfoldtheleftsideoftheconveyorandcontinue to push onto the support angles.

NOTE: Push until the sprocket on the folding

convey o r is inside the electric al box.

See View A.

See View A

View A

Sprocket

4. Install the drive chain around the drive motor

sprocket and the sprocket on the folding conveyor. Pull the folding conveyor to tighten the

chain.

5. Secure the folding conveyor using t he conveyor locating pin. Install the pin from the inside of the electrical box, through the conveyor bracket and into the folding conveyor.

See View A.

NOTE: If the mounting hole cannot be lined up or

the chain is too loose, the drive motor will

need to be repositioned.

Folding Conveyor

(shown without belt for clarity)

See View A

Locating

Pin

Conveyor

Bracket

Figure 14

16

Page 19

Installation

Oven Assembly

CONVEYOR BELT TENSIONER

Each tensioner installs between the idle end of the

conveyor (the side opposite the drive) and the

bracket under each conveyor support angle.

1. The belt tensioner contains a spring to adjust

the length. Compress the spring to shorten

the length of the belt tensioner.

2. Insert the pin on the end of the tensioner into

the hole in the bracket under each conveyor

support angle.

3. Expand the tensioner to engage the pin located on the conveyor rack.

Belt

Tensioner

Figure 15

CRUMB PANS

1. Slidethedrivesidecrumbpanundertheconveyor rack from the front. The notch in the

crumb pan must line up with the drive shaft.

2. When the notch is lined up with the drive shaft,

push the crumb pan into the cooking chamber.

Hook the end of the crumb pan over the end of

theconveyorrack.

3. Slide the idle side crumb pan under the end of

theconveyorrack.

4. Slide the product stop over the end of the idle

side crumb pan.

Drive Side

Crumb Pan

Notch

Product Stop

Idle Side

Crumb Pan

Figure 16

17

Page 20

Installation

Oven Assembly

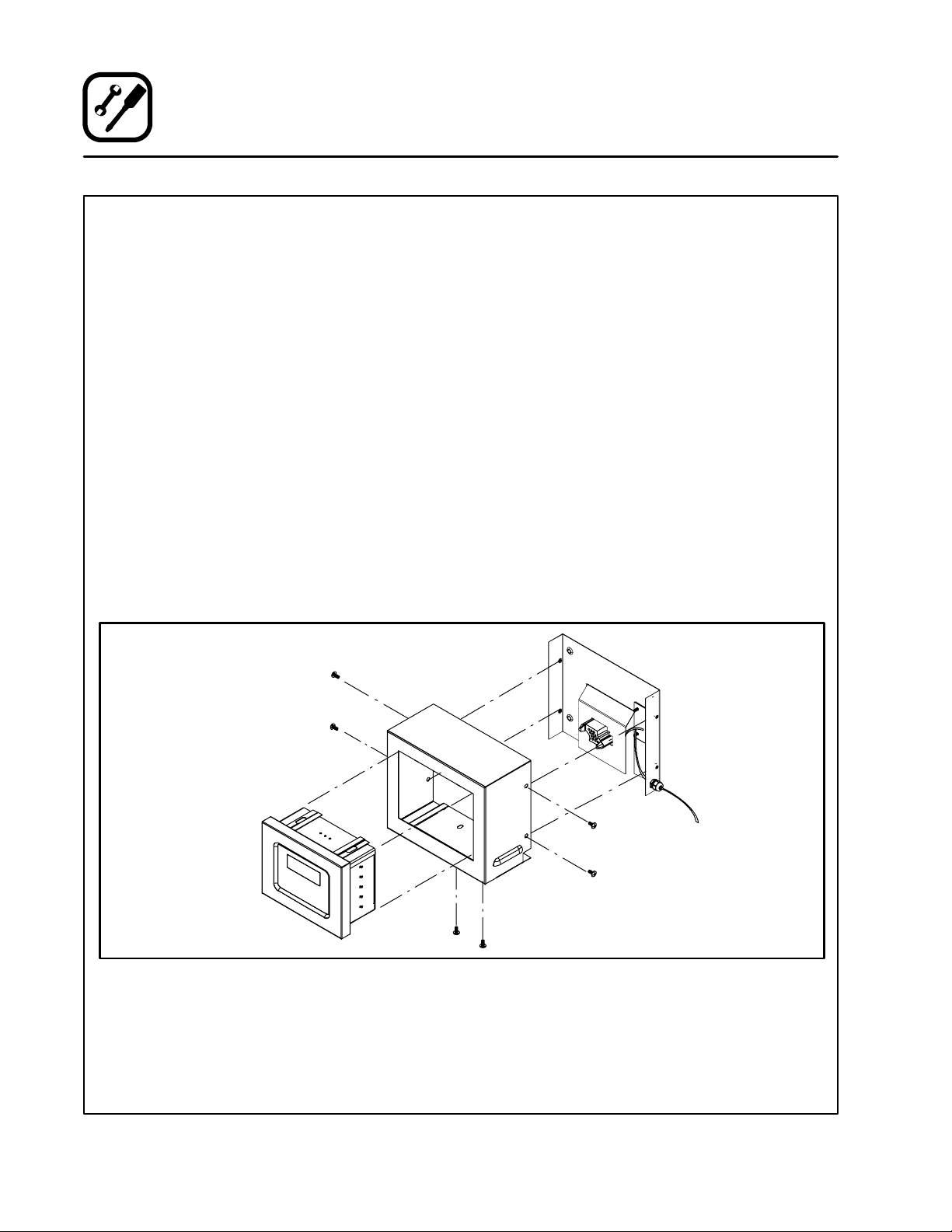

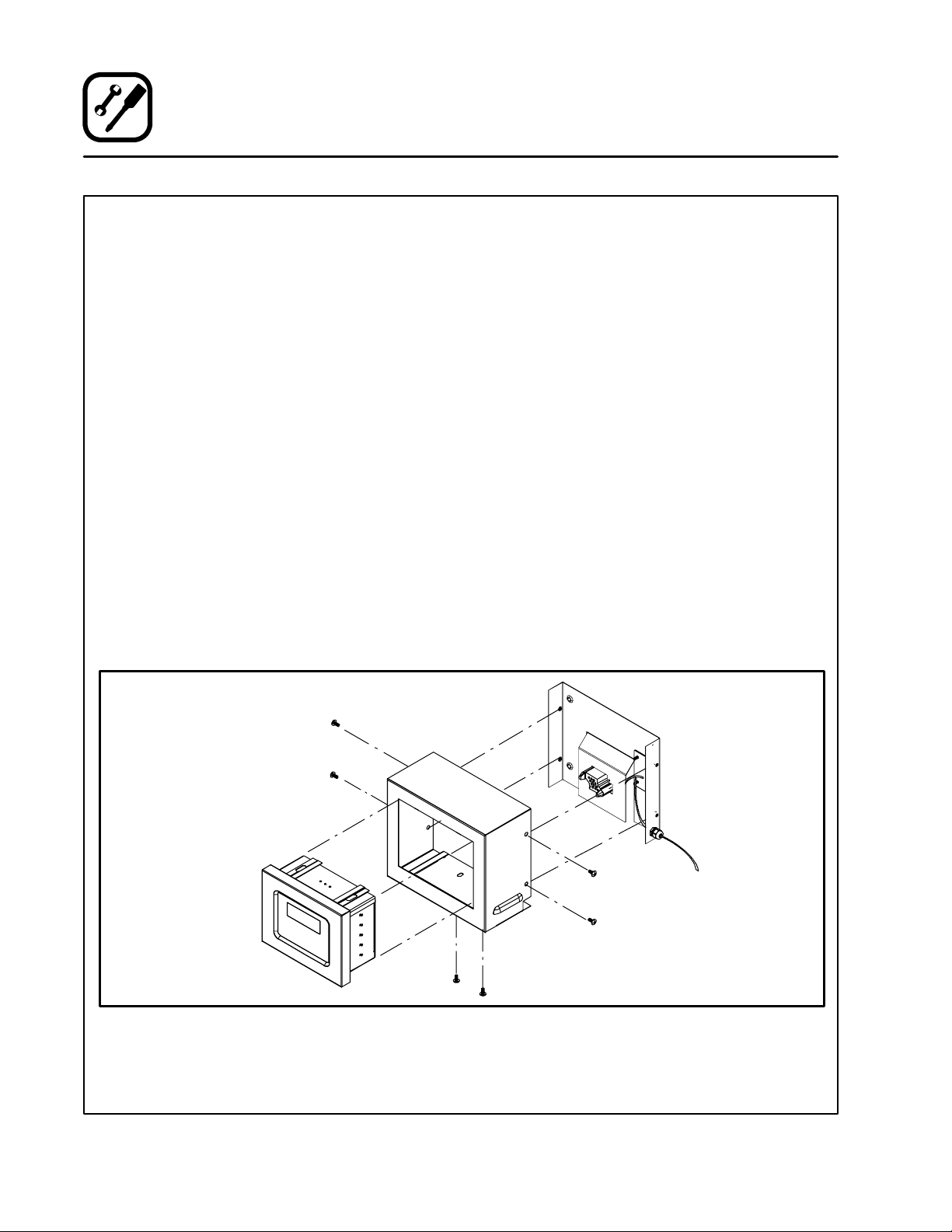

OPTIONAL REMOTE COMPUTER CONTROL

1. Remove all screws and disassemble operator

control and mounting bracket assembly from

the housing.

2. Oneendoftheremotecableisshippedattached to the oven. Push the other end of the

cablethroughtheaccessholeinthelower

right side of the mounting bracket assembly

until the strain relief rests against the side of

the bracket.

3. Thread the end of the cable through a locknut.

Tighten the locknut to the strain relief.

4. Attach the cable connector to the circuit

board.

5. Use the mounting bracket as a t emplate to

mark the location for installing mounting bolts

into the wall.

NOTE: Up to 1/4” diameter bolts can be used.

Thebolttypeshouldbedeterminedby

the wall construction.

6. Attach the mounting bracket to the wall using

the mounting bolts.

7. Slide the remote housing over the mounting

bracket. The holes on the sides of the housing

must line up with the holes on the sides of the

bracket. The control cable will line up with the

large slot in the mounting bracket.

8. Secure the housing to the mounting bracket

with the screws removed in step 1.

9. Insert the operator control into the housing.

Secure the control with the screws removed in

step 1.

Operator

Control

Remote Mounting

Bracket Assembly

Remote

Housing

Figure 17

18

Page 21

Installation

Oven Assembly

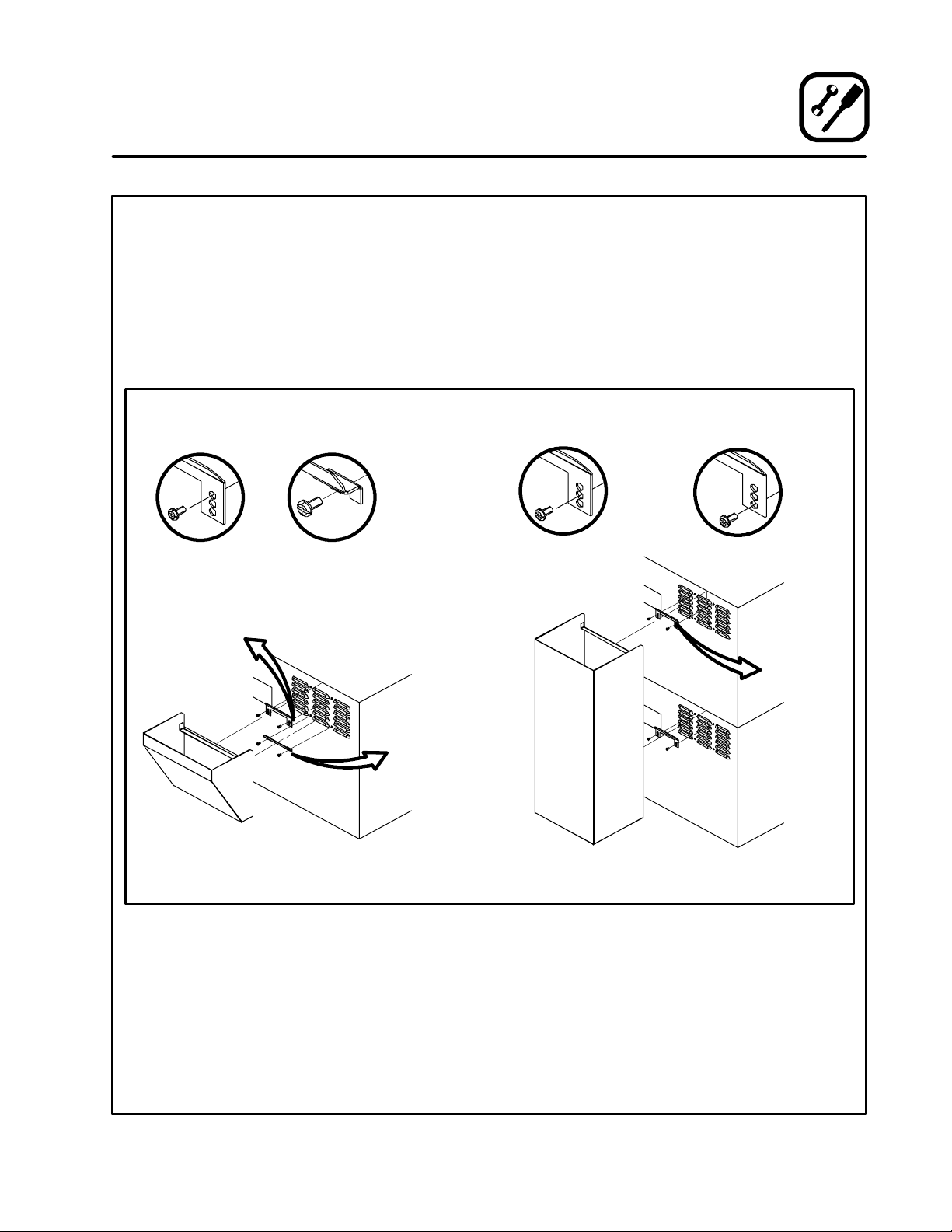

OPTIONAL VENT COVER/CHIMNEY

1. Fasten a chimney hanger to the holes at the

top of the louverson the idle end of each oven.

NOTE: Chimney hangers have three sets of

holes. For single ovens use the top

holes. For double stack use the middle

holes. For triple stack use the bottom

holes.

View A

(Chimney Hanger)

See

View A

Vent Cover

View B

(Vent Cover Hanger)

2. Single ovens only --- Fasten the vent cover

hanger to the holes at the bottom of the

louvers on the idle end of the oven.

NOTE: Not required for stacked units.

3. Slide the vent cover (chimney) down onto the

hangers. The closed end must be down.

View C

(Chimney Hanger

Double Stack)

Chimney

View D

(Chimney Hanger

Triple Stack)

See

Views

C&D

Single Ovens

See

View B

Stacked Ovens

Figure 18

19

Page 22

Installation

Utility Connections --- Standards and Codes

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATIONAND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and responsible for:

D

the installation or replacement of gas piping

and the connection, installation, repair or

servicing of equipment.

D

the installation of electrical wiring from the electric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be exper ienced in such work, familiar with all precautions

required, and have complied with all requirements

of state, national and/or localauthorities havingjurisdiction.

Installation must conform with Local and National

codes and installation standards. Local installation codes a nd/or requirements may vary. I f you

have any questions regarding the proper installation and/or operation of your Blodgett oven,

please contact your local distributor. If you do not

have a local distributor, please call the Blodgett

Oven Company at 0011-802-860-3700.

20

Page 23

Installation

Gas Connection

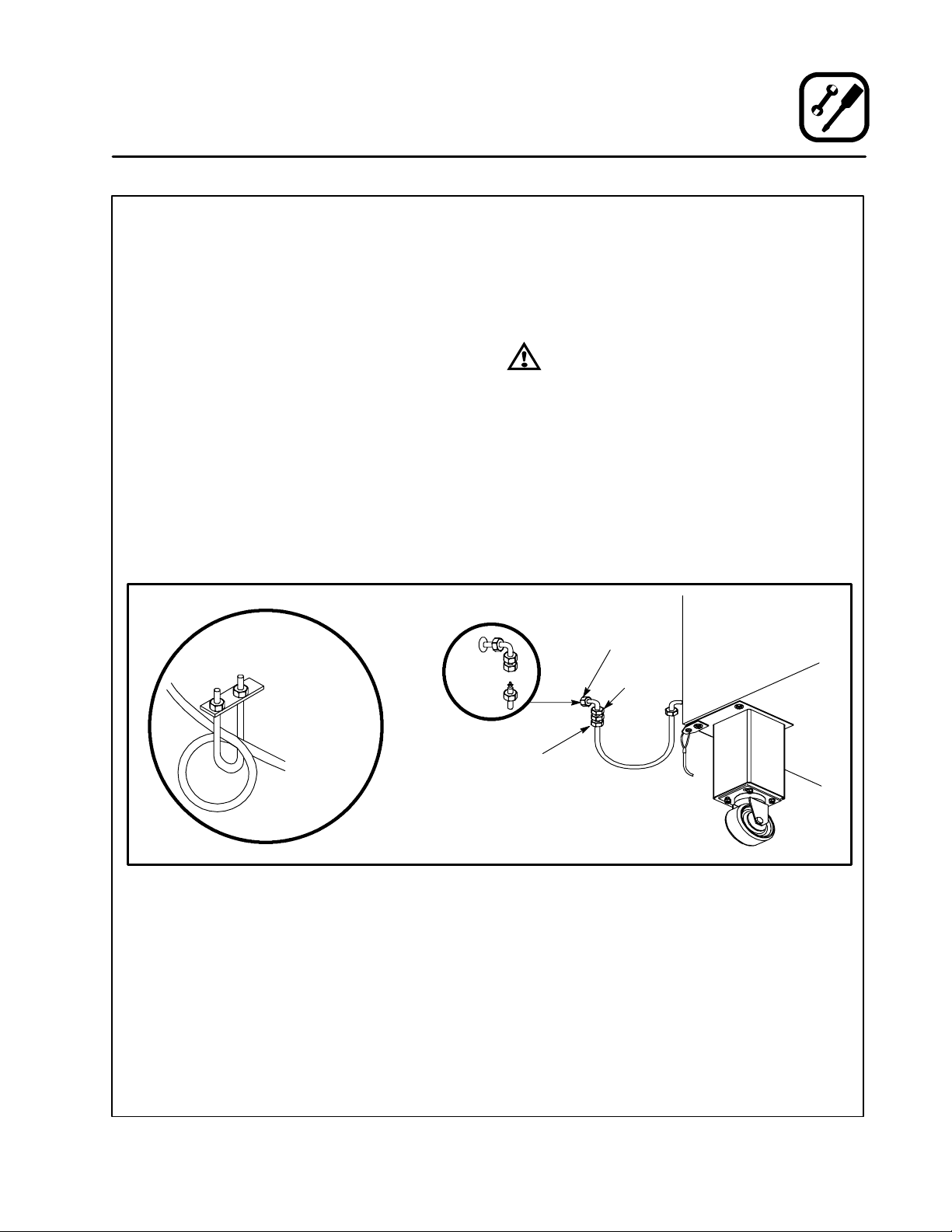

GAS HOSE RESTRAINT

If the oven is mounted on casters, the installer a

commercial flexible connector with a minimum of

1.9 cm (3/4”) inside diameter must be used along

with a quick connect device.

The gas hose restraint (heavy gauge cable), supplied with the oven, must be used to limit the

movement of the unit so that no strain is placed

upon the flexible connector. Locate the restraint as

follows:

D

The restraint bracket should be fastened to the

left rear oven support. See page 8 for installation of the restraint bracket.

D

The restraint should be short enough to prevent

any strain on the connector. See Figure 19 View

A for length adjustment detail.

D

With the restraint fully stretched the connector

should be easy to install and quick connect.

View A

Socket

Tighten after

adjusting length of

cable

Quick Connect

The permanent end of the restraint should be attached without damaging the building. DO NOT

attach the restraint to the gas piping or electrical

conduit! Use anchor bolts in concrete or cement

block. On wooden walls, drive hi test wood lag

screws into the studs of the wall.

WARNING!!

If the restraint is disconnected for any

reason it must be reconnected when the

oven is returned to its original position.

The restraint and quick connect must conform

with Local and National installation standards.

Local installation codes and/or requirements may

vary. If you have any questions regarding the

proper installation and/or operation of your Blodgett oven, please contact your local distributor. If

you do not have a local distributor, please call the

Blodgett Oven Company at 0011-802-860-3700.

Gas Supply Line

Socket

Plug

Gas

Hose

Figure 19

21

(See View A)

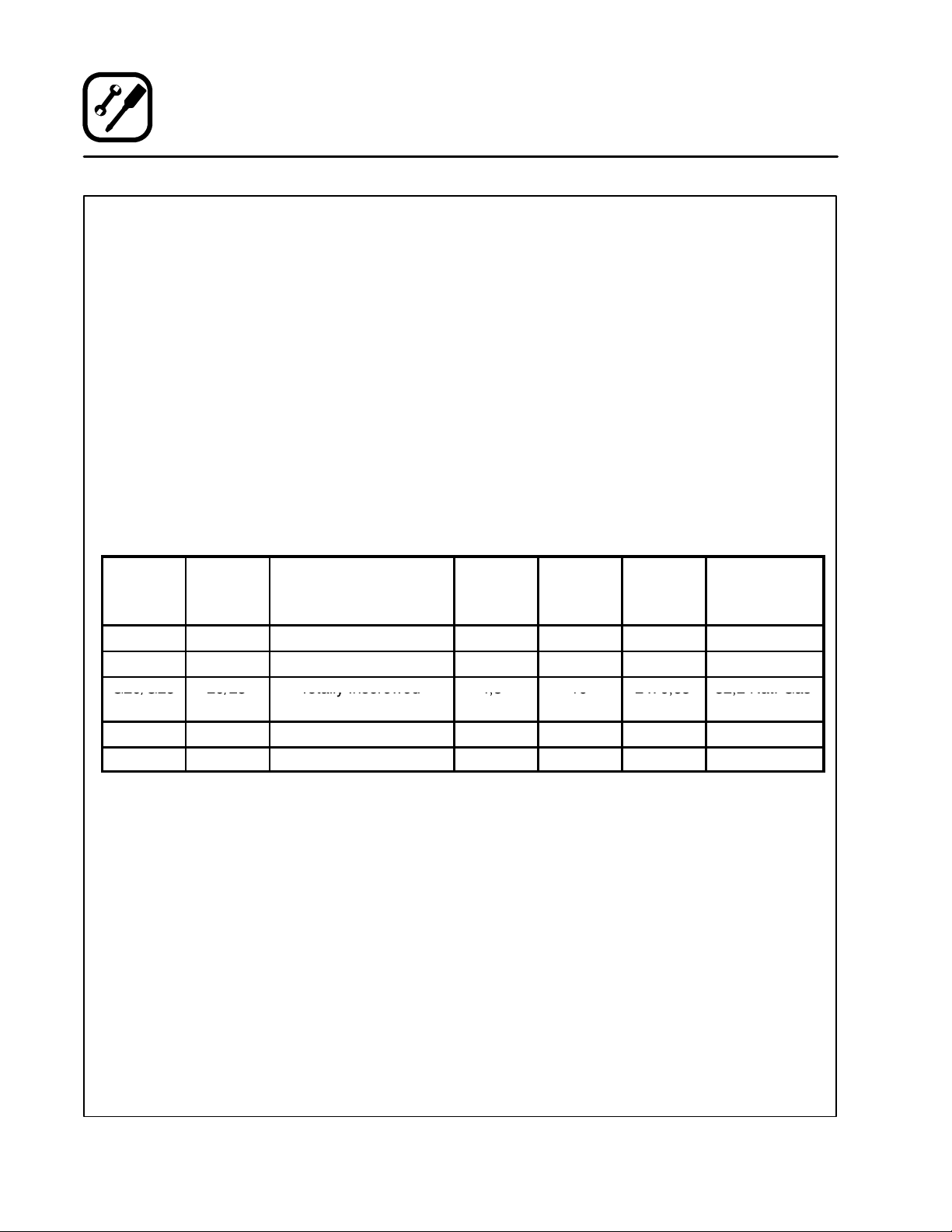

Page 24

Installation

G20/G2520/25TotallyInscrewe

d

4,8102x0,6332,2Nat.Ga

s

Gas Connection

Connect the oven to the gas line with the proper

type of gas according to Local and National Installation Standards.

SG3240G ovens are rated at 32,2 kW/Hr. (110,000

BTU/Hr.) Each oven has been adj usted at the factoryto operate with the type of gas specified onthe

rating plate attached to the left side of the operator

control.

Each oven is supplied with a regulating gas valve

to maintain the proper gas pressure. This valve

assembly is essential to the proper operation

of the oven and should not be removed or replaced with another model unless approved by

Blodgett.

DO NOT INSTALL AN ADDITIONAL REGULATOR

WHERE THE OVEN CONNECTS TO THE GAS

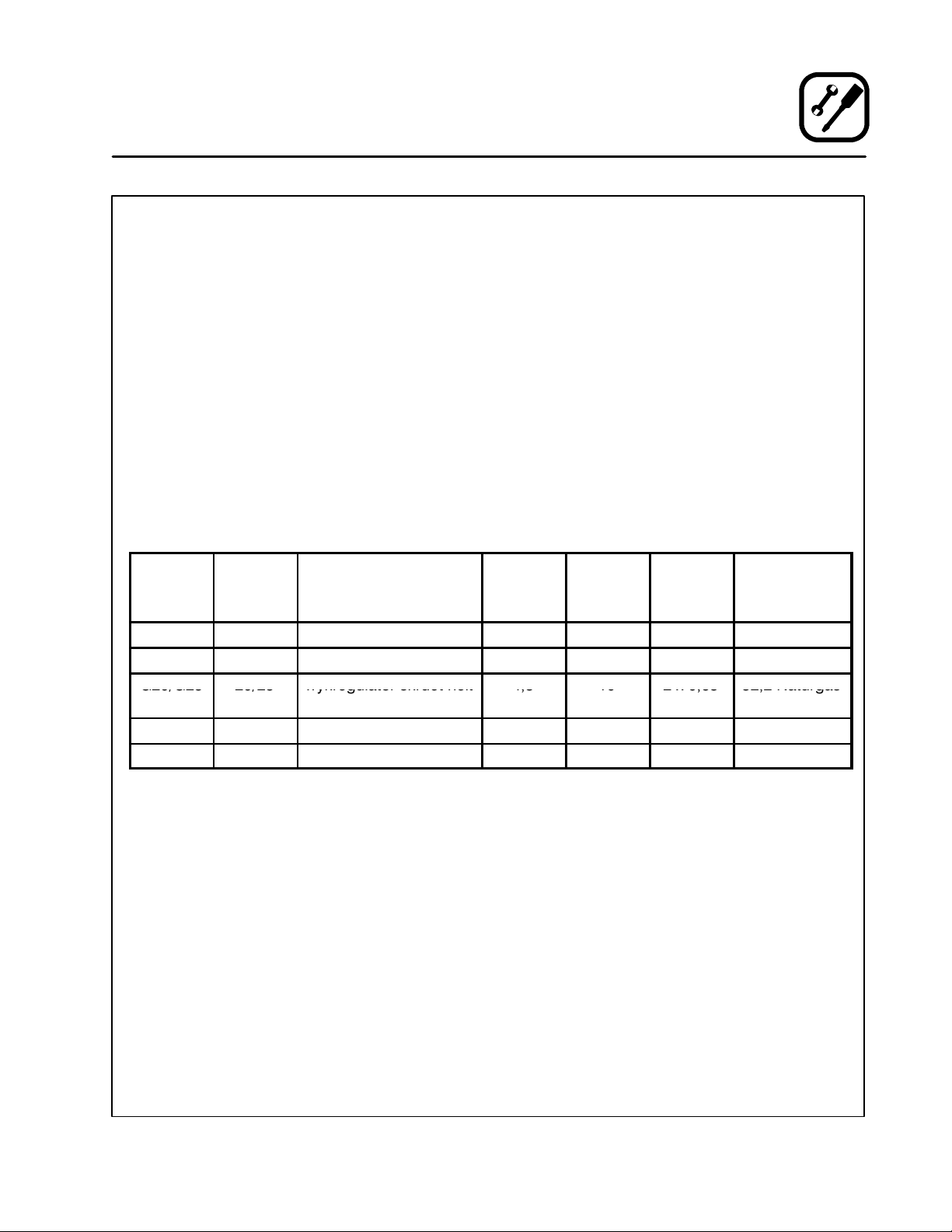

Type o f

Gas

G25 25 13,5 4,8 10 2 x 0,63 32,2 Nat. Gas

G20 20 8,7 4,8 10 2 x 0,63 32,2 Nat. Gas

G20/G25 20/25 Totally Inscrewed 4,8* 10 2 x 0,63 32,2 Nat. Gas

Inlet

Pressure

mbars

Burner

Pressure

mbars

Pressure Regulator

SUPPLY UNLESS THE SUPPLY EXCEEDS THE

MAXIMUM.

The oven and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of t hat system at test

pressuresinexcessof1/2psig(3.45kPa).

The oven must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas piping system at test pressures equal or less

than 1/2 psig (3.45kPa).

Setting Equipment for Other Types of Gas

Contact a qualified service agency to convert to

anothertypeofgas.

Injector

Diameter

mm

Air

Opening

mm

Pilot

Injector

mm

Standard

Delivery

Value kW (H

)

S

G30 30/50 20 2,8 10 2 x 0,30 32,2 Butane

G31 30/37/50 25 2,8 10 2 x 0,30 32,2 Propane

NOTE: * Use with pre-injector of 4.6 mm.

22

Page 25

Installation

Electrical Connection

Before making any electrical connections to this

unit, check that the power supply is adequate for

the voltage, amperage, and phase requirements

stated on the rating plate.

NOTE: Electrical connection must be performed

by a qualified installer only.

NOTE: The electrical installation must comply

with the national local codes and installation requirements.

A strain relief for the supply cord is required. The

installer must provide a supply cord bushing that

meets all Local and National Installation standards.

Wiring diagrams accompany this manual and are

attached inside the electrical box and on the rear

of the oven.

SG3240G

The SG3240G requires a 5 Amp, 50HZ, 1Φ,

230VAC, 3 wire service consisting of L1, N and

ground.

Connect the oven to a separate 230V, 50 hz power

supply with a supply cord and plug or rigid connection and circuit breaker. If a supply cord with

plug is used the appliance must be positioned so

thattheplugisaccessible.Thecircuitbreakeror

plug must disconnect all poles, including neutral,

with a contact separation of at least 3 mm.

SG3240E

The SG3240E requires a 41.5 amp, 50 HZ, 3Φ

WYE, 230/400 VAC, 5 wire service consisting of

L1, L2, L3, Neutral and ground.

Connect the oven to a separate 230V, 50 hz power

supply with a supply cord and plug or rigid connection and circuit breaker. If a supply cord with

plug is used the appliance must be positioned so

thattheplugisaccessible.Thecircuitbreakeror

plug must disconnect all poles, including neutral,

with a contact separation of at least 3 mm.

ConnectL1+L2+L3+neutral+ground.

THE BLODGETT OVEN COMPANY CANNOT AS-

SUME RESPONSIBILITY FOR LOSS OR DAMAGE

SUFFERED AS A RESULT OF IMPROPER INSTALLATION.

WARNING!!

Incorrect single phase wiring with other

than 208-240 VAC may result in extensive

damage to electrical components a nd fire

in the electrical box.

23

Page 26

Operation

Safety Information

THE INFORMATION CONTAINED IN THIS SECTION IS PROVIDED FOR THE USE OF QUALIFIED

OPERATING PERSONNEL. QUALIFIED OPERATING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONTAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE OVEN AND/OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPERATION OF THE EQUIPMENT DESCRIBED. A DHERENCE TO THE PROCEDURES RECOMMENDED HEREIN WILL HELP ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLE-FREE SERVICE.

Please take the time to read the following safety

and operating instructions. They are the k ey to the

successful operation of your Blodgett conveyor

oven.

SAFETY TIPS

For your safety read before operating

What to do if you smell gas:

D

DO NOT try to light any appliance.

D

DO NOT touch any electrical switches.

D

Use an exterior phone to call your gas supplier

immediately.

D

If you cannot reach your gas supplier, call the

fire department.

What to do in the event of a power failure:

D

The control system will automatically go into

standby mode. When the power is restored

press the ON/OFF k ey to restart the oven.

D

DO NOT attempt to operate the oven until the

power is restored.

D

Product in the cooking chamber should be removed. If there is product in the cooking

chamber it will continue to cook at a slower rate

for a few minutes.

NOTE: In the event of a shut-down of any kind,

allow a five (5) minute shut off period before attempting to restart the oven.

What to do for emergency shut down:

D

The unit is equipped with an emergency shut

down switch located on the front of the oven.

Should you need to stop the belt, fans, or heat

push the emergency switch. DO NOT use the

emergency switch as a general on/off switch or

damage to the blowers may occur.

General safety tips:

D

DO NOT use tools to turn off the gas control. If

the gas cannot be turned off manually do not try

to repair it. Call a qualified service technician.

D

If the oven needs to be moved for any reason,

the gas must be turned off and disconnected

from the unit before removing the restraint

cable. Reconnect the restraint after the oven

has been returned to its original location.

D

DO NOT remove t he electrical box cover or

open the lower control tray unless the oven is

unplugged.

D

This oven is not a hot food storage or holding

device. I t is not intended to be operated normally at less than 200_F(93_C).

Automatic Momentary Shut Down (SG3240G

ovens only)

Per agency requirement, the ignition control must

verify proper safety functions every 24 hours of

continous operation. If the oven is operated for 24

hours continuously, it will shut off for 10 seconds

including all blowers, then restart again. If any button is pressed during the off period, the oven will

not automatically restart.

24

Page 27

Operation

Standard Manual Control

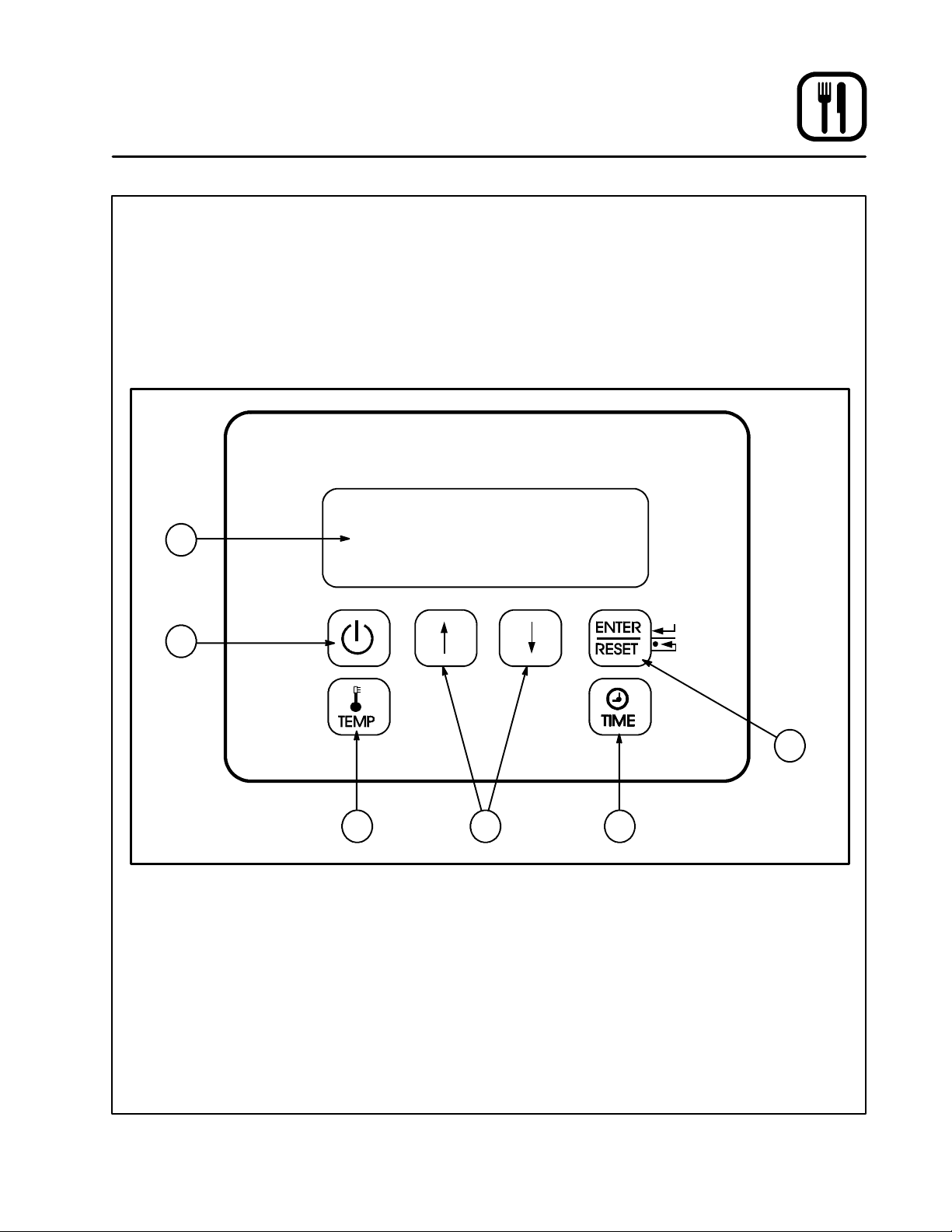

MANUAL CONTROL DESCRIPTION

1. DIGITAL DISPLAY --- two line display gives the

time, temperature and other control related information.

2. OV E N O N / O FF (ON/ STA N D BY) --- controls

power to the oven.

3. TEMPERATURE KEY --- press to change the

cook temperature.

1

2

4. ARROW KEYS --- press to change the set t ime

and temperature in the display.

5. TIME KEY --- press to change the cook time.

6. ENTER/RESET KEY --- press to save new

cook time or temperature. Also press to silencethe alarm in case of a fault. The alarm will

sound every ten seconds until the fault clears.

3 4 5

Figure 20

25

6

Page 28

Operation

Standard Manual Control

OPERATION

_

NOTE: Thefollowing example is in

_

will read

To turn the oven on:

1. Press the OVEN ON/OFF key (2). The control

defaults to the last time and temperature settings used.

The display reads:

NOTE: HEA T appears in the top line of the dis-

2. The fans begin to run. The conveyor belt begins to travel at the set cook time. The heat

rises to the setpoint temperature.

3. When the oven reaches the set temperature,

READY and SET TEMP flash alternately in the

top line of the display and an audible alarm

sounds.

To change the cook temperature:

1. Press the TEMPERATURE key (3).

The display reads:

2. Press the ARROW keys (4) to scroll to the desired cook temperature.

C if programmed in celsius.

SET TEMP XXXF HEAT

COOK TIME XX:XX

play whenever the control calls for heat.

SET POINT TEMP

F. T he di s p l a y

XXXF

3. Press the ENTER key (6) to set the new cook

temperature.

To ch a ng e t he c o ok time :

1. Press the TIME key (5).

The display reads:

2. Press the ARROW keys (4) to scroll to the desired cook time.

3. Press the ENTER key (6) to set the new cook

time.

To display the actual oven temperature:

1. Press both ARROW keys (4) .

The display reads:

2. Press the down arrow key to return the display

to the setpoint time and temperature.

To turn the oven off:

1. Press the OVEN ON/OFF key (2). The oven is

equipped with a cool-down feature for motor

shaft and bearing protection. This enables the

blower motor(s) to run regardless of the controller status. The blower(s) continue to run

until the oven cools to a safe temperature.

SET COOK TIME

XX:XX

TEMP XXXF

D OWN --- E X I T

26

Page 29

Operation

Programmable Menu Control

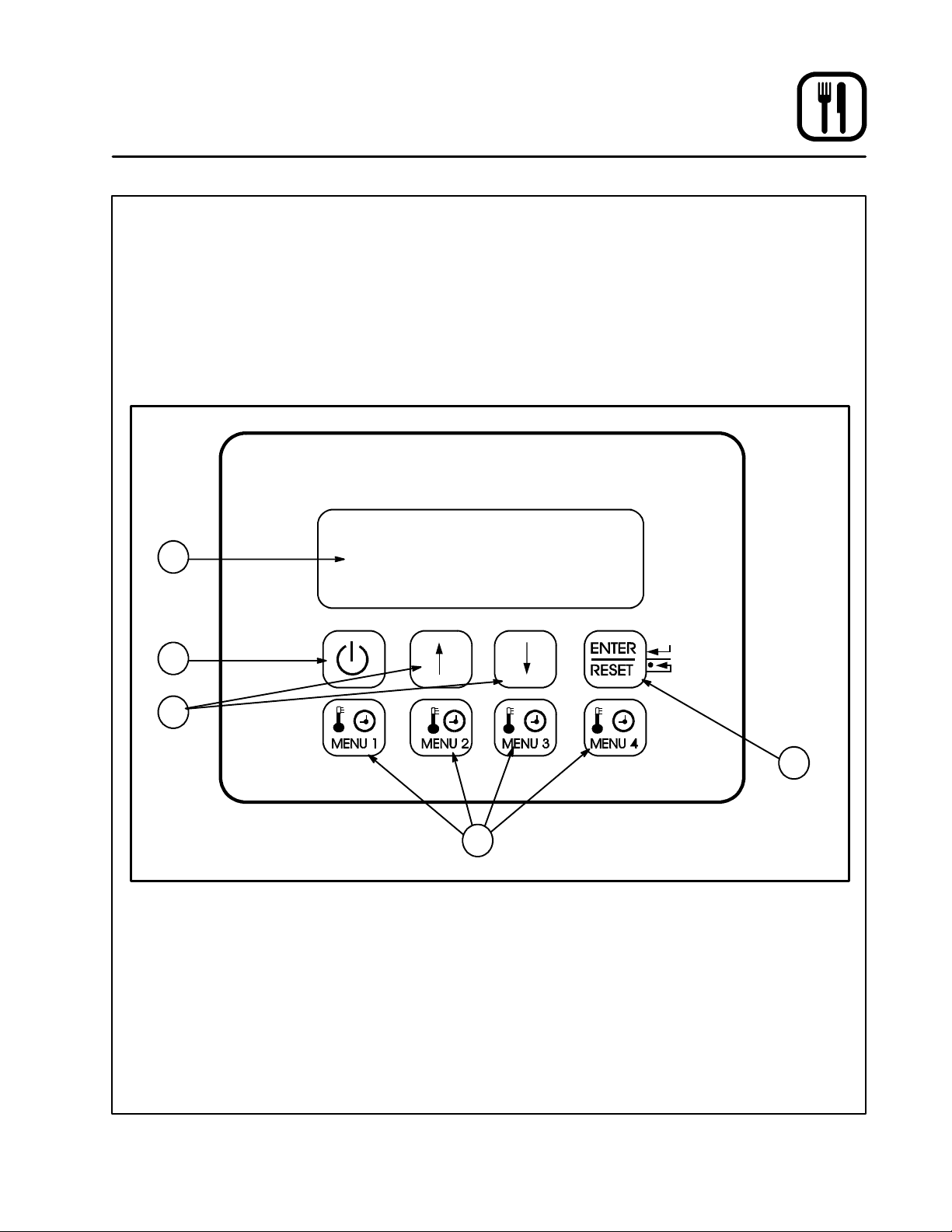

MENU CONTROL DESCRIPTION

1. DIGITAL DISPLAY --- two line display gives the

time, temperature and other control related information.

2. OV E N O N / O FF (ON/ STA N D BY) --- controls

power to the oven.

3. ARROW KEYS --- press to change the timeand

temperature in the display. Also press to scroll

through menus during programming.

1

2

4. MENU KEYS --- programmable product keys.

Up to four different time and temperature settings can be saved.

5. ENTER/RESET KEY --- press to save settings

while programming. A lso press to silence the

alarm in case of a fault. The alarm will sound

every ten seconds until the fault clears.

3

5

4

Figure 21

27

Page 30

Operation

Programmable Menu Control

MENU PROGRAMMING

_

NOTE: Thefollowing example is in

_

will read

To enter programming mo de:

1. With the oven off, press and hold the UP

ARROW key (3) and the ENTER/RESET key

(5) simultaneously for approximately three

seconds.

The display reads:

2. Press and hold the U P ARROW key (3) until

the bottom line of the display reads 111 (the

store access code).

3. Press the ENTER/RESET key (5) to enter the

programming mode.

To pro g ra m t he m enu k eys :

1. The display reads:

2. Press the MENU key (4) t o be programmed.

NOTE: For this example we will program

3. The display reads:

Use the ARROW keys (3) to scroll to the desired cook temperature.

Press the ENTER key (5) to store the new cook

temperature.

4. The display reads:

Use the ARROW keys (3) to scroll to the desired cook time.

Press the ENTER key (5) to store the new cook

time.

5. The display flashes:

C if programmed in celsius.

ACCESS CODE

SELECT MENU KEY

MENU1,2,3,OR4

menu key 1.

MENU-1 SELECT TEMP

XXXF PRESS ENTER

MENU-1 COOK TIME

XX:XX PRESS ENTER

PROGRAM DONE

F. T he di s p l a y

000

MENU-1

To exit the programming mode:

1. Press and hold the UP A RROW key (3) and the

ENTER/RESET key (5) simultaneously for approximately three seconds.

NOTE: If no key is pressed for 60 seconds, the con-

trol automatically exits the program mode.

OPERATION

1. Press the OVEN ON/OFF key (2). The control

defaults to the last time and temperature settings used.

The display reads:

NOTE: HEA T appears in the top line of the dis-

play whenever the control calls for heat.

2. Press the desired MENU key (4).

3. The fans begin to run. The conveyor belt begins to travel at the set cook time. The heat

rises to the setpoint temperature.

4. When the oven reaches the set temperature,

READY and SET TEMP flash alternately in the

top line of the display and an audible alarm

sounds. The conveyor belt begins to travel at

the set cook time. The heat rises to the set point temperature.

NOTE: To change the cook time and temperature

press any of the other menu keys.

To display the actual oven temperature:

1. Press both ARROW keys (4) .

The display reads:

2. Press the down arrow key to return the display

to the setpoint time and temperature.

To turn the oven off:

1. Press the OVEN ON/OFF key (2). The oven is

equipped with a cool-down feature for motor

shaft and bearing protection. This enables the

blower motor(s) to run regardless of the controller status. The blower(s) continue to run

until the oven cools to a safe temperature.

M-X TEMP XXXF HEAT

COOK TIME XX:XX

XXXF

D OWN --- E X I T

28

Page 31

Operation

Oven Adjustments for Cooking

The combination of belt time, oven temperature,

and air flow are important for achieving quality results from your Blodgett conveyor oven. Use the

following guidelines to adjust the belt time a nd

oven temperature of your unit. For questions regarding further oven adjustments, please contact

your local Blodgett Sales Representative for a ssistance.

CONVEYOR SPEED AND OVEN TEMPERATURE

Conveyor belt speed (cook time) and oven temperature are the two variables used w h en fine tuning your oven for a specific product. To determine

the optimum bake time and temperature, make

small changes for each trial and keep one variable

constant. For example, if the oven temperature is

238_C (460_ F) and the belt speed is 7 minutes,

but the pizza is not browned enough, increase t he

temperature to 246_C (475_F) and keep the belt

speed the same. However, if the center of the pizza

is not completelycooked, keep the oven temperature the same, and increase the bake time to 7

minutes and 30 seconds. In general, raise the

bake temperature to increase browning, and

lengthen the belt time to increase doneness.

FINISHED PRODUCT TEMPERATURES

Internal temperatures of the cooked products

should be measured immediately after the product exits the cooking chamber to ensure a safe

food temperature. Internal pizza temperatures

should be over 74_C (165_F). Minimum temperature guidelines vary depending on the food items.

AIR FLOW ADJUSTMENTS

Slide the product clearance adjustment plates to

the lowest possible setting for your menu items.

Lowering the clearance plates will reduce the

amount of hot air escaping from the chamber

openings.

Air flow adjustments may be necessary to fine

tune the oven for your particular product. The air

plate, located at the top of the baking chamber,

containsholesthat can be covered using Block-off

Plates. The plates can easily be adjusted to regulate the air flow for your particular needs. Use the

following guidelines to adjust the Block-off Plates.

SeeFigure22.

1. Ensure the oven is Off and completelycooled.

2. Open the front access door.

3. Using the supplied air plate hook, pull the air

plateoutoftheoven.

4. Remove the wing nuts, screws, and washers

holding the Block-off Plates.

5. Adjust the plates.

6. Replace the wing nuts, screws, and washers

to tightly secure the Block-off plates in their

new locations. Make a sketch of the final airplate setup for future reference.

NOTE: One or two block-off plates may be left

off entirely if appropriate to obtain the

desired results.

7. Replace the air plate, and close the front ac-

cess door.

The following examples illustrate air flow regulation.

NOTE: The first half of the oven chamber greatly

affects the initial baking of the product,

while the last half largely affects the browning.

D

A good bake time and t emperature have been

established, but more top browning is desired.

Slide one of the Block-off Plates to uncover a

row of holes toward the exit end of the oven.

D

The bottom of the pizza is golden brown, but the

top is too dark. Close rows at the exit end of the

oven to reduce final browning.

D

The center of the pizza is still doughy and the

toppings are not fully cooked. Open up rows at

the chamber entrance and close rows at the

chamber exit.

29

Page 32

Operation

Oven Adjustments for Cooking

Air Flow Plate

Block-Off

Plate

Product Clearance

Adjustment P late

Figure 22

30

Page 33

WARNING!!

Always disconnect the power supply be-

fore cleaning or servicing the oven.

WARNING!!

If gas ovens need to be moved, the gas

must be turned off and disconnected from

the unit before removing the restraint. Reconnect the restraint after the oven has

been returned to its original location.

Follow this recommended cleaning schedule for

proper oven performance.

DAILY:

1. Clean the conveyor belt using a wire brush.

Allow any foreign material to drop into the

crumb pans.

2. Empty and clean the crumb pans.

3. Make sure cooling fans are operating. Exhaust air should be blowing out from both:

D

the louvers on the right side toward the rear

D

the perforated holes on the bottom of the

unit, under the emergency stop button.

EVERY THREE MONTHS:

1. Brush then clean the louvers on both ends of

theovenwithacleandampcloth.

EVERY SIX MONTHS:

1. Unplug the oven. Disconnect the gas connections.

2. Remove the crumb pans and product stop

from the ends of the conveyor. See page 17.

3. Open and lower or remove the front access

door.

4. Pull the air plate out of the oven cavity using

the air plate hook provided with the oven.

5. Pull each nozzle out of the oven cavity.

6. Remove the nozzle support bar.

Maintenance

Cleaning

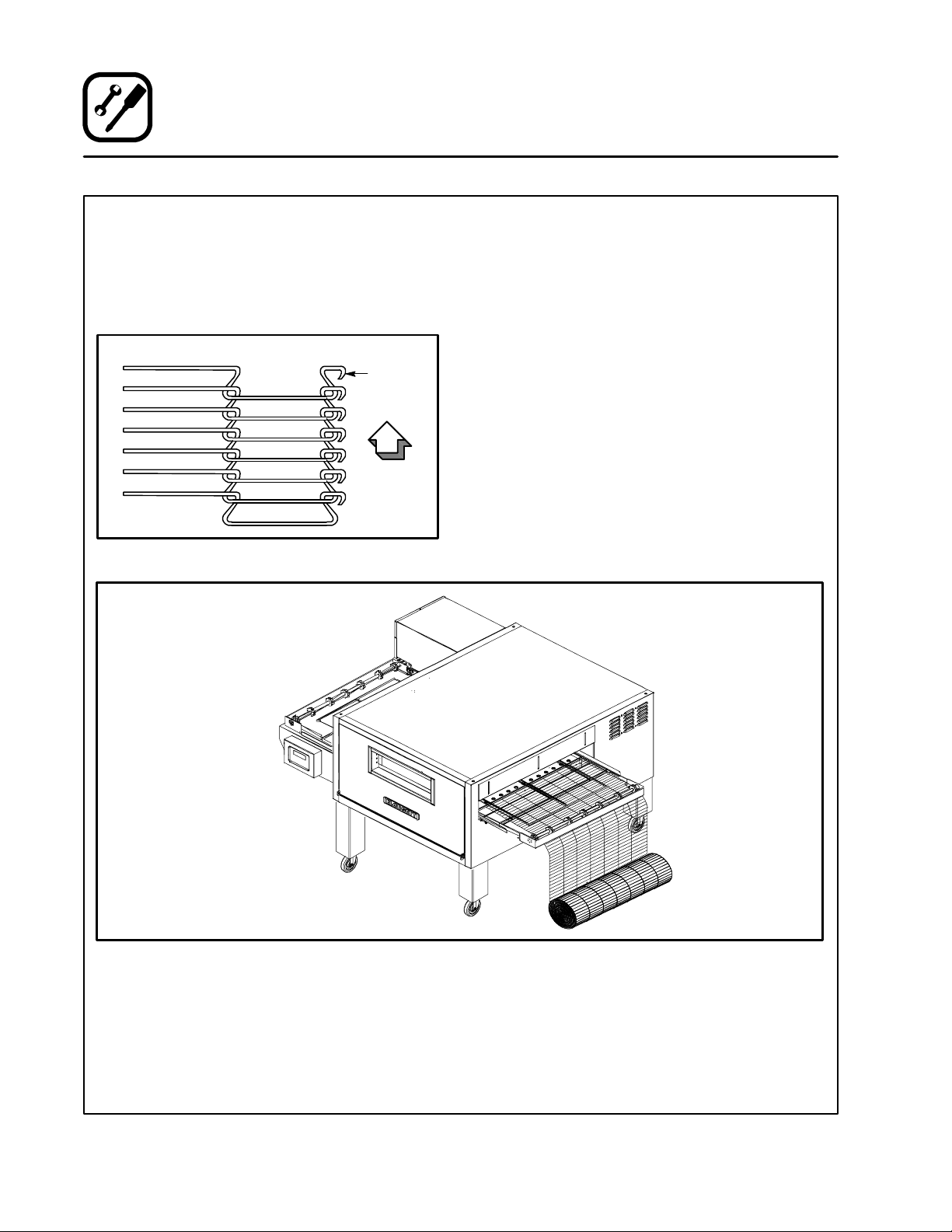

7. Clean the conveyor assembly as follows:

NOTE: The conveyor and cooking chamber

may be cleaned while the conveyor is

installed. However, we recommend removing the conveyor for thorough

cleaning.

8. Remove the conveyor locating pin that secures the conveyor assembly to the conveyor

bracket. The pin has a pull ring located under

the drive chain, behind the electrical box access door.

9. Push the conveyor assembly in to loosen the

drive chain. Remove the drive chain from the

conveyor sprocket. If unable to push the assembly, loosen motor mounts.

10. Standard conveyor assemblies:

The standard conveyor can be removed and

cleaned in one piece with the belt on.

--- Slide the conveyor assembly out from the

drive side of the oven.

If space is limited, the conveyor can be

disassembled and removed as follows:

--- Use needle-nose pliers to remove the

conveyor belt master links. See page 15.

--- Slide the belt out from one end. Be sure to

roll the belt as shown in Figure 23.

Otherwise the belt will be upside down

when rethreading.

--- Slide the right conveyor rack out of the

oven.

--- Slide the left conveyor rack out from the

drive side of the oven.

Folding conveyor assemblies:

--- Slide the folding conveyor assembly out

from the drive side of the oven. Fold the

sections over as they come out of the

cooking chamber .

11. Remove the conveyor support angles. Twist to

slide them off of the mounting pins. See page

11.

31

Page 34

Cleaning

Maintenance

12.Cleanovencomponentsasfollows:

--- Clean the conveyor, crumb pans, nozzles,

nozzle support bar, conveyor support

angles and the air plate with a hot

water/detergent mix. Rinse with clean

water. For difficult cleaninguse a heavy duty

degreaserorovencleanerthatissafefor

aluminum.

--- Clean the oven interior with an all purpose

cleaneroranovencleanerthatissafefor

aluminum.

13. Reassemble the oven. Be sure the nozzles are

installed in the correct order. See Figure 23.

NOTE: The closed front end of the nozzles are

marked with the nozzle part number.

Standard Conveyor Assembly

( may be removed as one piece --- disassembled here for clarity)

EVERY 12MONTHS:

A factory authorized service person should:

1. Open and clean the inside of the control box.

2. Check and tighten all electrical connections.

3. Check conveyor drive chain for cleanliness,

proper lubrication and alignment.

If maintenance is required contact your local service company, a factory representative or the

Blodgett Oven company.

1hole

M8862 M8863

2holes

M8862

M8862

M8862

Nozzle Identification

from front of nozzles

View A

M8863

M8863

M8863

M8863

See View A

M8862

Figure 23

32

Page 35

Maintenance

Troubleshooting Guide

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Operator control display is blank and there is no power to the oven.

S

Power outlet is not live (new installations).

S

Oven not plugged in.

S

Emergency stop button is pushed in.

S

Fuse(s) are blown.

S

24 VDC power supply’s internal breaker tripped.

S

24 VDC power supply defective.

SYMPTOM: Conveyor belt will not run or stops. Display reads M O T O R F A U LT --- C ALL S E R V I C E .

S

Belt hooked on something in oven.

S

Belt overloaded.

S

Defectiveconveyordrivemotor.

S

Defectiveconveyordrivemotorcontroller.

S

Have a qualified person ensure that the power

outlet is live.

S

Check that the power cord is connected.

S

Pull the button out to disengage the emergency

stop.

S

Unpug the oven power cord. Check the 5A fuses

behind the electrical box access door. Call service if blown.

S

Unplug the oven power cord for 15 minutes.

Check the fuses then reconnect.

S

*

S

Turn oven OFF. Unhook and resolve problem.

S

Remove product until the belt starts to move and

call service.

S

*

S

*

SYMPTOM: Operator control display is blank and the oven is on.

S

Connection at the rear of the operator control

has come loose. The oven should continue to

run and respond to any faults, but the operator

control will not function.

*

Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that

Allrepairs and/or adjustments be done by your localBlodgett service agency and not by the owner/operator. Blodgett cannot assume

responsibility for damage as a result of servicing done by unqualified personnel.

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

PLEASE!!

Write down exactly any error message displayed on the operator control display. Report all

error messages.

S

Shut off manual gas valve. Once the oven has

cooled down unplug the oven and call service.

(SG3240G).

S

Press the emergency stop button and call service (SG3240E).

33

Page 36

Maintenance

Troubleshooting Guide

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Burner will not fire (SG3240G) or elements will not heat (SG3240E).

S

Control turned off.

S

Temperature set point not above the ambient

temperature.

S

Convection blower motor(s) not running.

Display: BLOWE R FA U LT --- C ALL S E R VI C E

S

Fuse(s) are blown.

S

Emergency stop button is pushed in.

For SG3240G ovens only

S

Manual gas valve closed.

S

Combustion blower motor not running.

Display: COMBUSTION BLWR FAIL --- CALL

SERVICE

S

Combustion blower pressure switch defective or

not set properly.

Display: COMB PS FA ULT --- CALL SERVICE

S

Burner did not ignite properly or flame ceased.

Display: IGNITION ALARM --- PRESS RESET

or NO FLAME SENSE - -- RESET OR CALL SERVICE

S

Press ON/OFF key.

S

Set to the desired temperature. See page 26 of

the Operation section for instructions.

S

*

S

Unplug the oven power cord and check the fuses

(SG3240E). Call service if necessary.

S

Pull the button out to disengage the emergency

stop.

S

Open valve.

S

*

S

*

S

Press the reset button on the electrical box

control tray, located to the left of the LED

indicator lights. Call service if necessary.

SYMPTOM: Oven will not reach desired temperature.

S

Manifold gas pressure to too low (SG3240G).

S

Gas pressure to oven is too low (SG3240G).

S

Convection blower motor(s) not running.

S

Fuse(s) are blown.

S

Emergency stop button is pushed in.

S

Defective heating element relay (SG3240E).

S

Heating element(s) burned out (SG3240E).

S

Temperature hi-limit switch tripped (open) or out

of adjustment or defective.

Display: HI LIMIT TRIP --- RESET EGO

S

Internal problem with control.

*

Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that

Allrepairs and/or adjustments be done by your localBlodgett service agency and not by the owner/operator. Blodgett cannot assume

responsibility for damage as a result of servicing done by unqualified personnel.

S

*

S

Contact local gas representative.

S

*

S

Unplug the oven power cord and check the fuses

(SG3240E). Call service if necessary.

S

Pull the button out to disengage the emergency

stop.

S

*

S

*

S

Press red EGO reset button on rear of electrical

box. Call service if necessary.

S

*

34

Page 37

Maintenance

Troubleshooting Guide

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: Burner operates sporadically (SG3240G).

S

Air pressure switch out of adjustment.

S

Manifold gas pressure is too low.

S

Gas supply pressure to oven not correct.

SYMPTOM: Control displays: BLOWER ZONE HOT --- CHECK HOOD/LOUVERS.

S

Ventilation hood air flow has slowed or stopped.

S

Louvers are dirty or clogged, restricting cooling

air flow.

SYMPTOM: Control displays: BLOWER ZONE OVERTEMP --- CALL SERVICE.

S

Ventilation hood air flow has slowed or stopped.

S

Blower compartment cooling fan has stopped or

louvers are dirty or clogged, restricting cooling

air flow.

S

Note display readout during problem. Call service.

S

*

S

Contact local gas representative.

S

Check hood function.

S

Check for airflow out of the louvers on the right

side of the oven toward the rear. If none, call service. If minimal clean louvers, see page 31.

S

Check hood function.

S

Check for airflow out of the louvers on the right

side of the oven toward the rear. If none, call service. If minimal clean louvers, see page 31.

SYMPTOM: Control displays: FA U LT --- C HE C K P R O B E .

S

Loose probe leads at control.

S

Indicated probe is open or shorted.

*

Denotes remedy is a difficult operation and should be performed by qualified personnel only. It is recommended, however, that

Allrepairs and/or adjustments be done by your localBlodgett service agency and not by the owner/operator. Blodgett cannot assume

responsibility for damage as a result of servicing done by unqualified personnel.

WARNING!!

Always disconnect the power supply before cleaning or servicing the oven.

S

*

S

Note display readout during problem. Call service.

35

Page 38

SG3240 Serie

Transportørovn

Ejer--- og operatørmanual

36

Page 39

Introduktion

Ovnbeskrivelse og –komponenter

Bagning i transportørovn adskiller sig fra bagning

i en almindelig plade- eller komfurovn, eftersom

opvarmet luft konstant cirkuleres over produktet

ved hjælp af en vifte i det aflukkede kammer.

Luftstrålerne fjerner konstant det lag af kølig luft,

der omgiver produktet, hvilket bevirker at varmen

trænger hurtigt igennem. Resultatet er et produkt

af høj kvalitet, der er tilberedt ved lavere

temperatur og på kortere tid.

Blodgett transportørovn repræsenterer det nyeste

og ypperste indenfor energieffektivitet,

pålidelighed og brugervenlig betjening. Varme,

der normalt går tabt, bliver atter cirkuleret i

tilberedningskammeret, hvilket bevirker en

væsentlig reduktion i energiforbruget, køligere

køkkenmiljø og større ovnydelse.

OVNKOMPONENTER

Transportørbælte – bælte (transportør) med

kædeled af rustfrit stål, som fører produktet ind

gennem ovnen.

Samleled på transportørbælte –gørdetletat

fjerne transportørbæltet ved mere grundig

vedligeholdelse og rengøring. De kan kendes på,

at man finder dobbelte afstande mellem de

almindelige led på bæltet.

Transportørholdersamling (aktive & passive

sider) – sidder på begge ender af ovnfladen.

Aktivsiden har en drivaksel og tand på kædehjul,

som glider ind i den elektriske boks.

Transportøren kan fjernes i ét stykke uden at

fjerne bæltet.

Ekstra foldestativ til transportør –

transportørbælte og stativsamling, der fører

produktet gennem ovnen. Dette stativ kan foldes,

så det er lettere at fjerne fra små områder.

Transportøren kan tages ud i ét stykke uden at

fjerne bæltet.

Opspændere til transportørbæltet –fastholder

opspændingen på transportørbæltet.

Elektrisk boks – rummer elektriske komponenter,

ledninger, kølevifter, drivmotor, drivkæde og

samling af forbrændingsblæser/-brænder (kun til

gasovne) eller elektriske elementer (kun til

elektriske ovne).

Opvarmet luft

Luftplade

Blæser

Forbrændingskammer

Luftstrømningsmønster i Blodgett transportørovne

Transportør

Dyser

Returluft

Figur 1

Drivmotor – sørger for kraft til at bevæge

transportørbæltet. Operatøren og styresystemet

bestemmer hastigheden. Bæltets

bevægelsesretning (venstre-til-højre eller

højre-til-venstre) er indstillet på fabrikken og kan

let ændres.

Drivkæde – forbinder drivmotorens tandhjul til

transportørdrivakslens tandhjul.

Bagekammer – produkterne passerer gennem

bagekammeret på bæltet.

Dyser – fordeler opvarmet luft fra bagekammerets

bund. De sidder inde i ovnen under

transportørbæltet.

Dysestøtteholder – stang, der kan fj ernes, som

styrer dysernes forende. Den er placeret lige

indenfor ovnens fordør under dyserne.

Luftstrømningsplade – fordeler opvarmet luft fra

øverst i bagekammeret.

Vinkeljern til transportørstøtte – sørger for at

understøtte transportørstativsamlingen.

Krummepander – fanger krummer fra produktet

på transportørbæltet. De sidder under

transportøren ved begge ender af

bagekammeret.

Operatørs styrepanel –brugestilatstyre

ovntemperatur, bæltehastighed og andre

funktioner.

37

Page 40

Introduktion

Oven Description and Components

Nulstillingsknap til tændingsstyring (kun

gasovne) – nulstiller

tændingsstyring/-gasbrænder efter aflukning.

Sidder på kontrolboksens nederste panel.

Nødstop –KUNTILBRUGIN∅DSITUATION

(skader kan forekomme)! Tryk på den røde

Transportørbælte af

wire

Aktive side på

transportørstativ

Vinkler til

transportørstøtte

Fjernmonteringsh

older

Fjernbetjen

ingshus

Aktive sides

krummepande

håndfladekontakt, der sidder ved siden af

operatørstyringen for at slukke ovnen og standse

transportøren.

Adgangsdør foran – åbnes for at få adgang til

bagekammeret, så det lettere kan gøres rent.

Ekstra foldetransportør

(vist uden bælte for

klarheds skyld)

Passiv side på

transportørstativ

Operatørstyringl

Luftstrømningsplade

Indbygget

operatørstyring

Dyser

Dysestøtteholder

Adgangsdør

Bælteopspænder

Bælteopspænder Passiv sides

krummepande

Produktstop

foran

Figur 2

38

Page 41

Introduktion

Ovnspecifikationer

SPECIFIKATIONER SG3240G/AA SG3240E/AA

Bæltevidde 81 cm (32”)

Længde på bagezone 102 cm (40”)

Bageområde 0,83 m2(8,89 Sq. Ft.)

Afstand for produkt 10,2 cm (4”) maksimum

Dimensioner

(enkelt enhed)

Min. afstand til væg 0 cm (0”) fra bagende og side

Maksimal

driftstemperatur

Bagetid 1 minut (min.) 30 minutter (max.)

Max. varmetilførsel 32,2 kW/t. (110,000 BTU/t.) 27.0 kW/t.

Strømtilførsel 230 VAC, 1F, 50 Hz, 5 amp. 2

Gastilførsel Se tabellen på side 57. Ingen

Tilslutning af

gastilførsel

*Tilføj 35 cm (13,65”) til dybden for støbejernsholdere i tredelt stakning

wirerplusjord(L1,N,GND)

3/4” NPT Ingen

196 cm x 135 cm* x 61 cm (77” x 53”* x 24”)

315_C (600_F)

230/400 VAC, 3 Ö WYE, 50 Hz, 41,5

amp.,4wirerplusjord(L1,L2,L3,N,

GND)

39

Page 42

Installation

Levering og inspicering

Alle ovne fra Blodgett forsendes i containere for at

forhindre beskadigelse. Når Deres nye ovn

afleveres:

D

Inspicér forsendelsescontaineren for alle ydre

skader. Ethvert tegn på beskadigelse skal

noteres på leveringskvitteringen, som

chaufføren skal underskrive.

D

Tag ovnen ud af kassen og kontrollér, om der er

skader indvendigt. Transportfirmaera ccepterer

krav for skjulte skader, hvis de får besked

indenfor 15 dage efter leveringen og

forsendelsescontaineren tilbageholdes for

inspektion.

Standard komponenter

Delbeskrivelse Kvan.

Hovedovnens hus 1

Dyse (forsendes umonteret) 8

Luftplade (forsendes umonteret) 1

Støttevinkel til t ransportør 2

Transportørstativ på aktiv side 1*

Transportørstativ på passiv side 1*

Transportørbælte af rullet wire 1*

Ekstra stykke transportørbælte w ire 1

Pakke med transportørbæltes ind-og

udvendige samleled

Bælteopspændere 2*

Krummepander 2

Produktstop 1

Ovnstøtter (ben, støbejern) 4

Krog til luftplade 1**

Pakke med 12 3/8-16

sekskantbolte, låseskiver og

spændeskiver til ben

Ejers manual 1

1*

1

Blodgett Oven Company tager intet ansvar for

tab eller skader, der pådrages i transit.

Transportfirmaet påtog sig fuldt ansvar for

levering i go d stand, da forsendelsen blev

accepteret. Vi er dog indstillet på at være

behjælpelige, hvis det er nø dvendigt at gøre

krav på erstatning.

Ovnen kan nu flyttes til det sted, hvor den skal

installeres. Check nedenstående liste sammen

med Figur 2 på side 38 for at være sikker på, at alle

dele er modtaget.

Ekstradele

Delbeskrivelse Kvan.

Ekstra foldetransportørsamling 1

Stakningsudstyr 1***

Pakke med 4 opstillingsstifter 1***

Tredelt stakning med støbejernsben 1****

Ekstra fjernbetjent operatørstyring

med vedhæftet 50’ kabel

Ekstra fj ernbetj ent operatørstyring til

10’ kabel

Ekstra fjernbetjent 10’ ka bel 1

Pakke med ekstra fjernbetjent

operatørstyrings-kabelklemmer og

beslag

Ekstra samling til ventilationsdække

eller aftræksudstyr

BEMÆRK: *** Derkræves1tilenhedermed

dobbelt stakning

Derkræves2tilenhedermed

tredelt stakning

BEMÆRK: **** Kun til enheder med tredelt

stakning

1

1

1

1

BEMÆRK: * forsendes samlet med den ekstra

foldetransportør

BEMÆRK: ** forsendes kun med bund- eller

enkeltsektionsovne.

40

Page 43

Installation

Ovnens placering og ventilation

OVNENS PLACERING

Deres ovns gennemtænkte og k orrekte placering

vil på lang sigt forenkle operatørens opgaver og

sikre tilfredsstillende ydelse.

Nedenstående mellemrum skal holdes mellem

ovnen og enhver form for antændelig eller

ikke-antændelig konstruktion.

Alle enheder

D

Ovnhusets sider --- 0 cm (0”)

D

Ovnhusets bagside --- 0 cm (0”)

Følgende mellemrum skal findes for

servicering.

Alle enheder

D

Ovnhusets sider --- 96.5 cm (38”)

D

Ovnhusets bagside --- 71 cm (28”)

BEMÆRK: På gasmodeller kan rutinemæssig

serviceeftersyn som regel udføres

indenfor den begrænsede

bevægelighed, som gasslangens

holder giver. Såfremt det er nødvendigt

at flytte ovnen længere væk fra

væggen, så skal gassen først slukkes

og adskilles fra ovnen, før holderen

flyttes. Sæt holderen på igen, efter

ovnen er sat tilbage på sin rette plads.

Det er tvingende nødvendigt, at der sørges for

tilstrækkelig lufttilførsel til ovnen hele tiden,

således at forbrænding og luftventilation er

tilfredsstillende.

D

Placér ovnen på et sted, hvor der ikke er træk.

D

Hold området omkring ovnen ryddet og fri for

antændelige materialer --- såsom papir, pap

ellerbrandfarligevæskerogopløsningsmidler.

VENTILATION

Et mekanisk drevet ventilationssystem er

påkrævet til at fjerne overskydende varme og

bagedampe. Ved gasmodeller skal der desuden

bruges et ventilationssystem til at fjerne produkter

fra gassens forbrænding. Vigtigheden af er

ordentligt designet og monteret

ventilationssystem kan ikke understreges kraftigt

nok.

Nedenstående er generelle anbefalinger og

retningslinier for god ventilation. Netop Deres

produkt skal muligvis tilses af en

ventilationsingeniør eller –konsulent.

Ventilationsemhætten skal fungere godt i samspil

med bygningens system t il opvarmning,

ventilation og klimaanlæg. Emhættens

udstødning og tilførsel af luftstrømning skal have

en passende størrelse. Luft skal tilføres enten via

emhættesystemet eller bygningens varme--- og

ventilationssystem for at forhindre opbygning af

for stort undertryk i ovnområdet. Tilført luft bør

erstatte ca. 80 % af den luftstrømning, som

emhætten udstøder. Nedenstående tabel kan

bruges som retningslinie, men de korrekte

værdier for luftstrømning afhænger af, hvor

effektivt emhættens design er, luftmængden

omkring ovnen, samt den aktuelle luftstrømning,

dergårindogudafkøkkenetellerovnområdet(for

eksisterende faciliteter).

ENKELT

Udstødningsmængde – CFM (M3/min)

800-1000

(23-28)

Sikkerhedskrav – CFM (M3/min)

640-800

(18-23)

DOBBELT TREDEL T

1200-1800

(34-52)

960-1440

(27-41)

1800-2500

(52-71)

1440-2000

(41-56)

Ideelt tilføres luften gennem bygningens varmeog ventilationssystem eller, som næste trin,

gennem emhætten ved hjælp af en indsat

tempereringsenhed. Luft tilført direkte udefra

bygningen til køkkenet eller ovnområdet uden

temperering kan anvendes som lufttilførsel, men

udformningen skal kunne rumme eventuelle

drifts- og miljømæssige minusser.

41

Page 44

Installation

Ovnsplaceringogventilation

BEMÆRK: Under INGEN omstændigheder bør den

tilførte luft blæse på eller nær ved

bagekammerets åbninger. Det vil have

dårlig indvirkning på ba gekonsist ense n

og ovnens pålidelighed.

Emhætten bør være i en størrelse, der fuldstændig

dækker udstyret samt med et udhæng på mindst

15 cm på alle sider der ikke er op mod en væg. I

visse områder, kan det være nok at kun dække

bagekammeret, plus et udhæng på 15 cm.

Afstanden fra gulvet til emhættens nederste kant

børikkeoverstige2,1m.SeFigur3.

Installationen skal være i overensstemmelse med

lokale og internationale installationsstandarder.

Lokale installationsregler og/eller –krav kan

variere. Har De nogen spørgsmål vedrørende

7,6 cm (3”)

Minimum

15,2 cm (6”)

Minimum

196 cm (77”)

korrekt installation og/eller drift af Deres Blodgett

ovn, så vær venlig at kontakte den lokale

forhandler. Hvis der ikke er en lokal forhandler, så

ring til Blodgett oven Company på tlf.

0011-802-860-3700.

ADVARSEL:

Undladelse af at ventilere ovnen ordentligt

kan være farligt for operatørens heldbred,

og det kan resultere i driftsmæssige

problemer, utilfredsstillende bagning og

muligvis skader på udstyret.

Skader, der direkte skyldes forkert

ventilering dækkes ikke af producentens

garanti.

15,2 cm (6”)

Minimum

0 cm (0”) hvis væg, ellersr

15.2 cm (6”)

Figur 3

42

182 cm (72”)

61 cm

36,1 cm

(14.2”)

(24”)

Tredelt stakning --- 5,1 cm (2”)

Dobbelt stakning --- 43,8 cm (17,25”)

Enkelt stakning --- 59 cm (23,25”)

Page 45

OVNST∅∅∅∅TTER

Enheder med enkelt og dobbelt stakning

1. Fastbolt ben/støbejernssamlinger til ovnen

med 3/8 -16 bolte med sekskantet hoved,

låseskiver og spændeskiver.

På gasmodeller montér holderbeslaget på

venstre bagben, som det ses på Figur 4.

BEMÆRK: Montér fastlåsningsjernene foran

på ovnen. F orreste adgangsdør

sidder på ovnens forside.

2. Få flere personer til omhyggeligt at løfte ovnen

fra pallen og placere den støbejernsbenene.

3. Slå bremserne til på de forreste jernben.

Installation

Ovnens samling

Ovnens

forside

Fastspændings

beslag

Her ses venstre bagben og

fastspændingsholder

Figur 4

43

Page 46

Installation

Ovnens samling

Enheder med tredelt stakning

1. Sæt støbejernssamlingerne på ovnen med

3/8-16 x 0,125 hovedskruer, låseskiver og

spændeskiver.Se Figur 5 for korrekt retning af

støbejernsben.