Page 1

Project

Item No.

Quantity

HV-100G

HV-100G

Full-Size Gas Hydrovection Oven

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

Controls

MenuSelect control can hold multi-stage pro-

gramming for up to 99 products, includes Cook

& Hold, core probe cooking and USB port

Touchscreen control allows cooking with timer

and core probe simultaneously. Includes shelf

timing, cooking compensation and multi-shelf

recipes. Holds up to 255 recipes.

Legs/casters/stands:

11” (279mm) adjustable legs

11” (279mm) seismic feet

34” (864mm) stainless steel open stand with

rack guides

Extra stainless steel oven racks

Additional core probe

Chicken roasting rack

Multi-purpose fry rack

Water pressure regulator

Side heat shield

Backflow preventer

Standard depth baking compartment - accepts five 18” x 26” standard fullsize baking pans in left-to-right positions.

All data is shown per oven section, unless otherwise indicated.

Refer to operator manual specification chart for listed model names.

EXTERIOR CONSTRUCTION

Fully welded angle-iron frame

Stainless steel front, top, back and sides

Simultaneous split door operation with catch-latch system

Triple mounted door design with turnbuckle assembly

Black glass doors with one piece curved handle

Dual pane tempered viewing window with hinged inner glass for easy cleaning

Retractable hand shower for ease of cleaning

INTERIOR CONSTRUCTION

316 stainless steel coved corner liner for easy cleaning

Five stainless steel racks and ten rack positions

Two halogen interior lights for superior visibility

Drain in oven cavity

Up to 2.5” of Super Wool Plus insulation for greater heat retention

OPERATION

Standard control with function selection for hydro low, hydro high, hot air, and

cool down

Retherm and Fry bands on control

Three inshot burners

Direct spark ignition

Removeable core temperature probe

Hydrovection cook modes provide low or high humidity

Hot air cook mode for baking and pastries

One touch cooking

Four speed auto-reversing fan motor for even bake

Cavity vent control provides ability to release steam at the push of a switch

Thermostatically controlled quench system, Eco-Friendly

STANDARD FEATURES

25” (635mm) adjustable stainless steel legs (for single units)

8-1/2” (216mm) stainless steel legs with casters (for double sections)

1 year parts and 1 year labor warranty

* For all international markets, contact your local distributor.

BLODGETT OVEN COMPANY

www.blodgett.com • 44 Lakeside Avenue, Burlington, VT 05401 • Phone: (802) 658-6600 • Fax: (802) 864-0183

Page 2

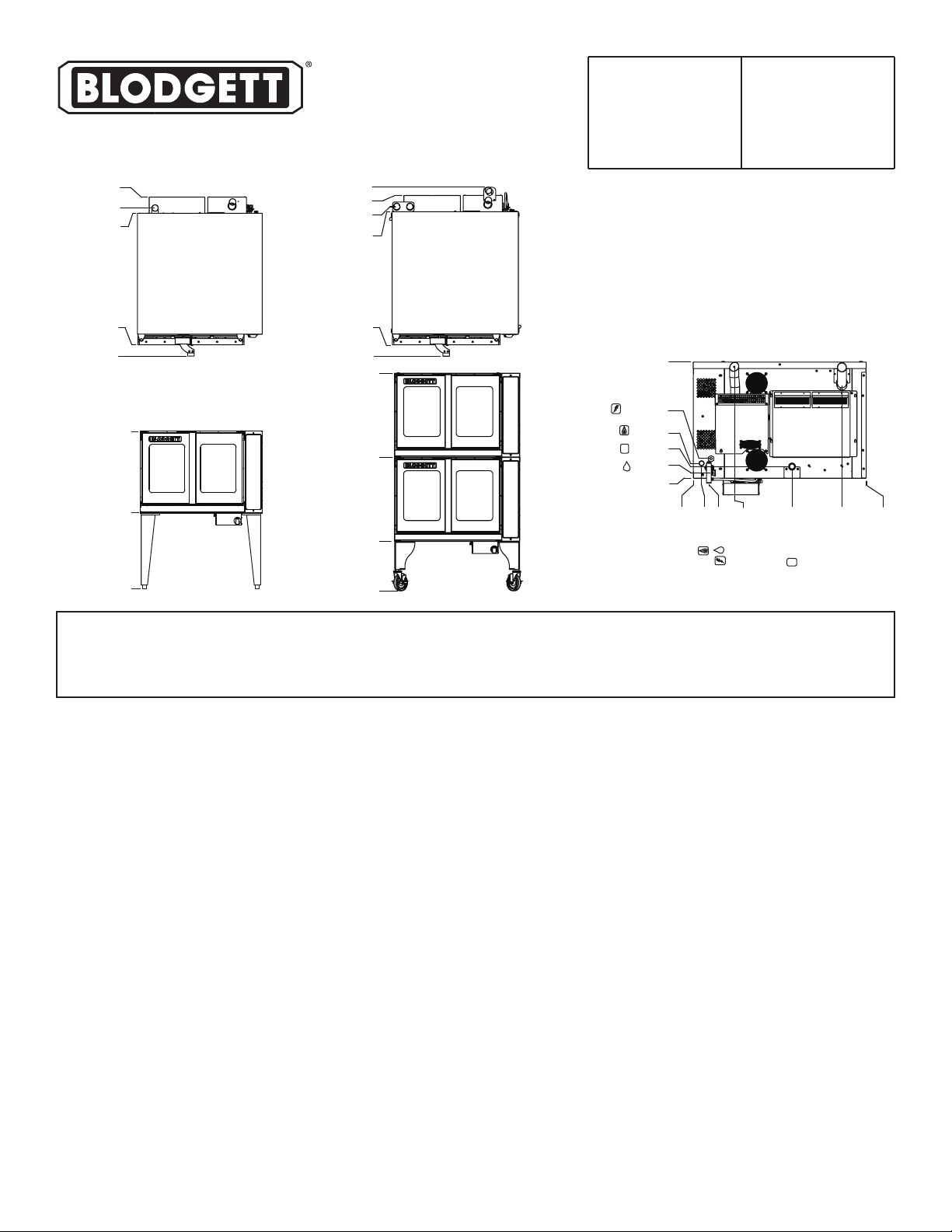

HV-100G

21.7 [551]

38.1 [968]

48.5 [1232]

45.2 [1148]

43.6 [1107]

TOP VIEW

Single Oven

3.4 [86]

0 [0]

50.6 [1284]

25 [635]

0 [0]

SHORT FORM SPECIFICATIONS Provide Blodgett full-size hydrovection oven model HV-100G, (single/double) compartment with fully welded angle iron frame. Each compartment

shall have fully welded 316 stainless steel liner. Liner to be coved top and bottom. Unit shall accept five 18” x 26” standard full-size bake pans. Doors shall be triple mounted, black

glass with dual pane thermal glass windows, curved handle and simultaneous operation. Unit shall be heated by 60,000 BTU gas burner. Air in baking chamber distributed by single

inlet blower wheel powered by a four speed, auto-reversing, 3/4 HP motor with thermal overload protection. Each chamber shall be fitted with bright halogen lamps, and five standard

stainless steel removable racks. Retractable hose reel mounted just below the control for easy cleanup. Unit shall have manual control with hydro low and hydro high moisture control,

hot air and cool down modes. Breaker shut off switch on front panel for easy service. 1 year parts and 1 year labor warranty Provide options and accessories as indicated.

51.0 [1295]

48.5 [1232]

45.2 [1148]

43.6 [1107]

3.4 [86]

0 [0]

66.1 [1679]

40.6 [1031]

15 [381]

0 [0]

TOP VIEW

Double Stack

DIMENSIONS ARE IN INCHES [MM]

25.6 [650]

4.28 [109]

3.3 [84]

D

2.6 [66]

1.2 [31]

APPROVAL/STAMP

0 [0]

0 [0]

1.8 [46]

REAR VIEW

3.4 [86]

9.0 [229]

FLUE

VENT

D

32.7 831]

DIMENSIONS:

Floor space

Single 38.1” (968mm) W x 48.5” (1232mm) D

Double Stack 38.1” (968mm) W x 51” (1295mm) D

Interior 29” (737mm) W x 20” (508mm) H x 23.43” (595mm) D

Single on casters Add 4-1/2” (114mm) to height

Product clearance from combustible and non-combustible construction

Oven sides 0” (0mm) Blodgett recommends 4” clearance from any

heat source on the control panel side of the oven, an

optional heat shield should be considered

Oven back 6” (152mm)

Minimum Entry Clearance

Uncrated 25.6” (650mm)

Crated 37-1/2” (953mm)

GAS SUPPLY (per section):

3/4” NPT

Inlet Pressure: Maximum Input:

Natural 7.0” W.C. static to unit Single 60,000 BTU/hr

Propane 14.0” W.C. static to unit Double 120,000 BTU/hr

POWER SUPPLY (per section):

Standard 115VAC, 10 amp, Nema 5-20R dedicated receptacle

Option 208/240VAC, 5 amp, Nema 6-15 dedicated receptacle

Export Export voltages available on request

Blodgett recommends a Pass & Seymour, model 2095, GFCI for this oven

model due to the use of a variable frequency drive.

WATER & DRAIN CONNECTION (per section):

Drain 1” NPT drain connection Maximum drain temperature 140°F (60°C)

Water 3/4” NPT garden hose - cold water only

Appliance is to be installed with backflow protection in accordance with Federal,

State or Local codes.

WATER SUPPLY (per section):

Good quality water feed is the responsibility of the owner. Water quality must be

within the following general guidelines.

TDS: 40-125 ppm Hardness: 35-100 ppm pH: 7.0 - 8.5

Silica: <13 ppm Chlorides: <25 ppm Chlorine: <0.2 ppm

Chloramine: <0.2 ppm

The best defense against poor water quality is a water treatment system designed

to meet your water quality conditions. Blodgett offers optional systems from

Optipure.

Water Pressure 30(min)-50(max) PSI

Water Consumption 2.5 - 4.0 GPH based on cooking mode

SHIPPING INFORMATION:

Approx. Weight

Per section 520 lbs. (236 kg)

Crate sizes

37-1/2” (952mm) x 43-1/2” (1105mm) x 51-3/4” (1315mm)

(2 crates required for double)

NOTE: The company reserves the right to make substitutions of components

without prior notice

Printed in U.S.A.

NOTE: FOR COMMERCIAL USE ONLY

P/N 54468 Rev Q (9/15)

Loading...

Loading...