Page 1

HV-100EM

CONVECTION OVEN WITH MOISTURE

INSTALLATION - OPERATION - MAINTENANCE

NSN: 7310-01-600-5659

APL: 43A090038

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802)864-0183

PN 51702 Rev L (4/14)

© 2014 - G.S. Blodgett Corporation

Page 2

Your Service Agency’s Address:

Model

Serial number

Oven installed by

Installation checked by

Page 3

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alternation,

service or maintenance can

cause property damage, injury or death. Read the instllation, operation and maintenance instructions thoroughly

before installing or servicing

this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids in the vicinity of this or any

other appliance.

The information contained in this

manual is important for the proper installation, use, and maintenance of this oven. Adherence

to these procedures and instructions will result in satisfactory

baking results and long, trouble free service. Please read

this manual carefully and retain

it for future reference.

ERRORS: Descriptive, typographic or pictorial errors are

subject to correction. Specications are subject to change

without notice.

INSTALLATION

Oven Description and Specications ....................................... 2

Utility Connections - Standards and Codes ................................. 3

Oven Location and Shipping .............................................. 4

Ventilation ............................................................... 5

Oven Assembly

Possible Leg Bolting Patterns ......................................... 6

Leg Attachment ...................................................... 7

Oven Stacking ....................................................... 8

Utility Connections ................................................... 8

Supply Water and Plumbing .............................................. 10

Electrical Supply ....................................................... 11

OPERATION

MenuSelect Control

Control Description .................................................. 12

Oven Startup ....................................................... 13

Manual Cooking ..................................................... 13

Programmed Cooking ............................................... 13

Probe Cooking ...................................................... 13

During Any Cook Cycle .............................................. 14

At the End of Any Cook Cycle ........................................ 14

Oven Shutdown ..................................................... 14

Product Programming ............................................... 15

Using the USB Port .................................................. 16

Manager Programming .............................................. 17

MAINTENANCE

Spray Bottle Operating Procedure ........................................ 18

Cleaning and Preventive Maintenance .................................... 19

Replacement Parts ..................................................... 21

Second Level Programming .............................................. 29

Troubleshooting ......................................................... 30

Sequence of Operation .................................................. 32

Component Resistance Readings ........................................ 34

Probe Ohms Chart ...................................................... 34

Wiring Diagrams ........................................................ 35

Page 4

Installation

Oven Description and Specications

Blodgett ovens are quality produced using high grade

stainless steel with rst class workmanship.

The multiple speed fan, which is guarded against acci-

dental nger contact, is driven by a quiet and powerful

motor. The condenser draws out excess moisture from

the appliance. Condensation and waste water, which result during hydro cooking and cleaning, are continuously

drained.

The use of high quality insulation impedes excessive heat

radiation and saves energy.

The HV-100EM has legs which adapt easily to slightly uneven surfaces.

The practical oven doors, with viewing windows, have a

wide swing radius and handle which can be operated easily, even with wet or greasy hands.

ELECTRICAL RATINGS

VOLTAGE

440 60 15 3 20 18 18 3/4 HP 208-240VAC, 50/60 Hz

HZ

KW

PHASE

MAX LOAD (AMPS)

L1 L2 L2

Ease of operation is guaranteed through the simple arrangement of the controls. Graphic symbols make the appliance easy for even inexperienced kitchen staff to operate. The Cool Down mode, allows the oven cavity to cool

down rapidly with the door opened.

Cleaning is kept to a minimum. The interior is sprayed

with a self-acting cleaning solution which interacts with

humidity to easily remove crusts and stains. The oven is

designed for easy care and is welded water tight so that

the internal cooking cavity may be rinsed with a hose after

the cleaning process.

MOTOR

PLUMBING SPECIFICATIONS

WATER

Water pressure 30 PSI (207 kPa) minimum

50 PSI (345 kPa) maximum

Water connection 3/4” garden hose - Cold water only

Water pressure regulator setting Preset to 20 PSI (138 kPa)

Flow rate of 4 GPH

Minimum requirements TDS - less than 100 parts per million

Total Hardness - 80-120 parts per million

Chlorides - less than 30 parts per million

Chlorine - 0 parts per million

pH Factor - 7.0-8.0

DRAINAGE

Drain type Atmospheric Vented Drain

Drain connection 1” NPT Male

2

Page 5

Installation

Utility Connections - Standards and Codes

THE INSTALLATION INSTRUCTIONS CONTAINED

HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR SERVICE BY OTHER THAN QUALIFIED

PERSONNEL MAY RESULT IN DAMAGE TO THE OVEN

AND/OR INJURY TO THE OPERATOR.

Qualied installation personnel are individuals, a rm,

a corporation, or a company which either in person or

through a representative are engaged in, and responsible

for:

• the installation or replacement of gas piping and the

connection, installation, repair or servicing of equipment.

• the installation of electrical wiring from the electric

meter, main control box or service outlet to the electric appliance.

Qualied installation personnel must be experienced in

such work, familiar with all precautions required, and have

complied with all requirements of state or local authorities

having jurisdiction.

U.S. and Canadian installations

The installation must conform with local codes, or in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1, as applicable.

Installation must conform with local codes, or in the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70-Latest Edition and/or Canadian National

Electric Code C22.1 as applicable.

Appliance is to be installed with backow prevention in

accordance with applicable federal, province and local

codes.

Australia and general export installations

Instllation must conform with Local and National installation standards. Local installation codes and/or requirements may vary. If you have any questions regarding the

proper installation and/or operation of your Blodgett oven,

please contact your local distributor. If you do not have a

local distributor, please call the Blodgett Oven Company

at 0011-802-658-6600.

3

Page 6

Installation

Oven Location and Shipping

OWNER’S RESPONSIBILITIES

Installation responsibilities prior to service startup inspection

You are entitled to a free start-up inspection service by

our factory ASAP. Before a factory representative arrives

to perform a startup procedure, the owner must already

have satised the following requirements.

1. Oven(s) are uncrated, stacked (if applies) and put in

place.

NOTE: Please refer to Leg Attachment and Stacking.

Maximum shelf loading - 60 lbs (27.3 Kg)

OVEN LOCATION

The well planned and proper placement of your oven will

result in long term operator convenience and satisfactory

performance.

Certain minimum clearances must be maintained between the oven and any combustible or non-combustible

construction.

• Oven body sides - 0” (0cm)

• Oven body back - 6” (152.4cm)

SHIPPING

NOTE: The following parts are shipped with the oven.

PART # DESCRIPTION QTY.

R10955 Cleaning spray bottle 1

33136 Power cord 2

52723 Drain elbow connection 2

52724 5’ drain hose 1

R2207 Hose clamp 4

R10889 10’ water hose 1

52728 3’ water hose 1

52596 Water manifold 1

52713 Utility box 1

52734 Utility line retainer bracket 1

52715 Vent extension bracket 1

52349 Cavity vent extension 1

52648 4” vent extension hose 1

33196 Seismic legs, set 1

315 1/2-13 x 3/4” stacking bolts 4

34907 Kit, set of ship deck legs 1

In addition, the following clearances are recommended

for servicing.

• Oven body sides - 12” (30cm)

• Oven body back - 12” (30cm)

4

Page 7

VENTILATION

The necessity for a properly designed and installed ventilation system cannot be over emphasized. The ventilation system will allow the unit to function properly while

removing unwanted vapors and products of combustion

from the operating area.

The appliance must be vented with a properly designed

mechanically driven exhaust hood. The hood should be

sized to completely cover the equipment plus an overhang of at least 6” (15 cm) on all sides not adjacent to a

wall. The capacity of the hood should be sized appropriately and provisions made for adequate makeup air.

WARNING!!

Failure to properly vent the oven can be hazardous to the health of the operator; and will

result in operational problems, unsatisfactory

baking, and possible damage to the equipment. Damage sustained as a direct result of

improper ventilation will not be covered by the

Manufacturer’s warranty.

Installation

Ventilation

When installed in the Commonwealth of Massachusetts,

this appliance must be interlocked with the hood exhaust

system so that the appliance may be operated only when

the hood exhaust system is running.

U.S. and Canadian Installations

Refer to your local ventilation codes. In the absence of

local codes, refer to the National ventilation code titled,

“Standard for the Installation of Equipment for the Removal of Smoke and Grease Laden Vapors from Commercial

Cooking Equipment”, NFPA-96- Latest Edition.

General Export Installations

Installation must conform with Local and National installation standards. Local installation codes and/or requirements may vary. If you have any questions regarding the

proper installation and/or operation of your unit, please

contact your local distributor. If you do not have a local

distributor, please call Blodgett at 0011-802-658-6600.

5

Page 8

Installation

Oven Assembly

POSSIBLE LEG BOLTING PATTERNS

There are two leg mounting options. See Figure 1.

36.19 (2 PLACES)

27.94 (2 PLACES)

.875 (8 PLACES)

35.00 (2 PLACES)

26.75 (2 PLACES)

.313 (8 PLACES)

35.00 (2 PLACES)

2.50

(4 PLACES)

36.19 (2 PLACES)

3.50 (4 PLACES)

.56 HOLE (4 PLACES)

See page 4 for

part numbers

Figure 1

6

Page 9

LEG ATTACHMENT

1. Align the threaded stud on the right front leg to the

bolt hole located in the bottom corner of the oven.

Turn the leg clockwise and tighten to the nearest full

turn.

2. Align the leg plate holes with the bolt holes.

Figure 2

3. Install the utility box before securing the right front

leg. Align the holes in the utility box bracket to the

holes in the leg plate. See Figure 3.

Installation

Oven Assembly

Figure 4

6. Tip the oven up on the newly installed front legs.

7. Repeat the above steps for the right rear leg.

Install the retainer bracket before securing the right

rear leg. Align the holes in the retainer bracket to the

holes in the right leg plate. See Figure 5.

8. Secure the leg and retainer bracket with the two 3/4”

bolts provided.

4. Secure the leg and utility box with the two 3/4” bolts

provided.

Utility Box

Figure 3

5. Repeat steps 1, 2 and 4 with the left front leg.

Retainer

Bracket

Figure 5

9. Install the left rear leg.

10. Tip the oven onto the feet and place in position. Level

the oven by screwing the adjustable feet in or out as

necessary.

7

Page 10

Installation

Oven Assembly

OVEN STACKING

1. Place the upper oven on top of the lower oven.

2. Bolt the two ovens together from behind using the

stacking brackets.

UTILITY CONNECTIONS

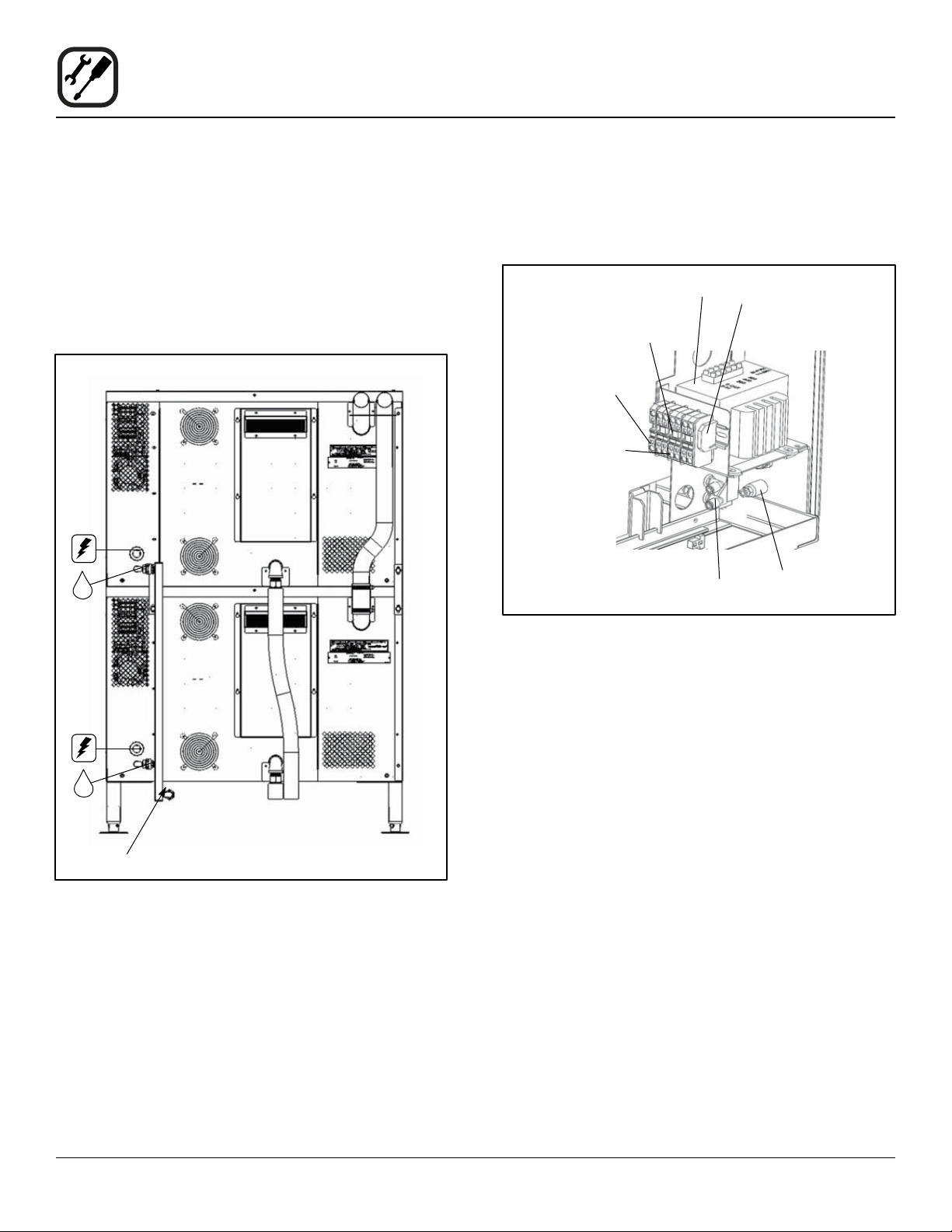

NOTE: Refer to Figure 6 for location of utility connection

on the back of the ovens.

Cavity Vents

Electrical

1. Remove the two screws from above and below the

control panel. Slide the panel out to access the terminal blocks. Refer to page 7.

Transformer

Shorting

Jumper

Ground Lug

Terminal

Terminal

Block

1/4 Swivel

Elbow

End Stop

1/4 Straight

Fitting

Water Manifold

Drains

Figure 6

Figure 7

2. Connect the power cord to the top unit. Run the cord

down the back of the oven, using the provided strain

relief.

3. Then route the cord under the oven, supporting it on

the retainer bracket on the rear right leg. Connect to

the top right receptacle on the utility box at the front

of the oven. See Figure 8.

4. Connect the power cord to the bottom unit.

5. Run the cord down the back of the oven, using the

provided strain relief.

6. Then route the cord under the oven, supporting it on

the retainer bracket on the rear right leg. Connect to

the bottom right receptacle on the utility box at the

front of the oven. See Figure 8.

8

Page 11

Top Oven

Electric Cord

Installation

Oven Assembly

Cavity Vent Extension

1. Attach the cavity vent extension using the silicon tubing and two clamps provided.

2. Remove the existing screw and use it to secure the

top section in the bracket. The tabs on the bracket will

deect for a secure t.

Bottom Oven

Electric Cord

Utility

Box

Retainer

Bracket

Figure 8

7. Reattach the right side panels once the electrical connections are complete.

Water and Drain

1. Attach the water manifold to the back of the ovens.

2. Attach the short water hose from the water manifold

to the utility box underneath the oven.

Utility

Box

Utility Supply Connection

1. Connect incoming power from the ship to the electrical connection on the utility box underneath the oven.

See Figure 10.

2. Connect the cold water supply from the ship to the

incoming water connection on the utility box underneath the oven. A 10’ water hose is supplied for your

convenience. See Figure 10.

Incoming

Electrical

Supply

Incoming

Water

Supply

Short

Hose

Water Manifold

Figure 9

3. Attach the supplied elbow assembly to the oven drain

outlet on both units.

4. Attach the supplied drain hose to the top unit.

5. Cut for proper length into the funnel drain. Use the

remaining piece of hose for the bottom oven if necessary. See Figure 6 for location of drain connection on

back of ovens.

Figure 10

9

Page 12

Installation

Supply Water and Plumbing

WATER CONNECTION

NOTE: Must use COLD WATER ONLY.

A shut off valve is to be provided adjacent to the oven.

WARNING!!

Operating the appliance without a water

regulator installed will invalidate your warranty.

This product must be installed by a licensed Plumber or

Gas Fitter when installed within the Commonwealth of

Massachusetts.

DRAIN CONNECTION

The drain should be run to an open oor drain avoiding

exible hose that could sag and allow trapped water to

accumulate.

Specic water/drain connection for City of Los Angeles

1. Each drain line from the appliance shall be routed

without dips or sags to terminate above the ood level

rim of an approved indirect waste receptor.

2. The appliance shall be installed in accordance with

the manufacturer’s printed instructions and the LAPC

and LAMC, 1999 editions.

3. A backow protection device may be required by local codes. If so, install on the potable water system

directly ahead of the appliance. The backow protection device shall be any of the following: an approved

pressure type vacuum breaker installed at least 12”

above the highest point of use, a double check valve

backow preventer or a reduced pressure principal

backow preventer.

10

Page 13

NOTE: Electrical connections must be performed by a

qualied installer only.

Before making any electrical connections to these appliances, check that the power supply is adequate for the

voltage, amperage, and phase requirements stated on

the rating name plate mounted on the appliance.

The circuit breaker that is used to provide power to this

appliance must have a minimum of .076” (3mm) contact

spacing. The circuit breaker must meet all Local and National installation standards.

All appliances must be installed in accordance with Local

or National Electrical codes.

A wiring schematic is located in the slide out panel.

NOTE: Disconnect the power supply to the appliance be-

fore servicing.

Installation

Electrical Supply

WARNING!!

Improper installation may invalidate your warranty.

A strain relief for the power supply cord is provided.

WARNING!!

If the supply cord is damaged, it must be

replaced by a special cord or assembly available from the manufacturer or its service

agent.

Figure 11

11

Page 14

Operation

MenuSelect Control

1

4

CONTROL DESCRIPTION

1. START/STOP KEY - press to start, cancel or pause

the bake

2

3

5

9

2. COOL DOWN KEY - initiates oven cool down cycle

3. BAKE MORE KEY - press at the end of a bake cycle

to add additional bake time in one minute increments

4. DISPLAY - displays time or temperature and other

information related to oven function and/ or programming

5. NAVIGATION PAD - used to enter set points, time,

and programmable settings. Also used to select the

programmed product

6. TEMP KEY - used to set or change the bake temperature

11

14

15

17

18

21

22

23

6

8

7

10

12

13

16

19

20

24

7. TIME KEY - used to set or change the bake time

8. COMBI KEY - press to enter combi mode

9. STEAM KEY - press to enter steam mode

10. HOT AIR KEY - press to enter hot air mode

11. RETHERM KEY - press to enter retherm mode, this

mode uses steam to reheat frozen or precooked product. Retherm has a temperature limit of 250-300°F

12. STEAM ON DEMAND KEY - used to initiate steam

injection cycle

13. PROBE KEY - press to use core probe cooking

14. FAN KEY - press to select the fan speed

15. LIGHT KEY - press to turn the lights on and off

16. VENT KEY - press to manually open and close the

oven vent

17. PROGRAM KEY - press to enter product programming and save programmed settings

18. ESCAPE KEY - press to back up one step during programming

Figure 12

19. MAINTENANCE KEY - press to enter manager programming and save programmed settings

20. ALPHA/NUMERIC KEYPAD - used to program recipes

21. POWER KEY - used to place control in and out of

standby mode

22. CORE PROBE CONNECTION - plug core temperature probe in here when using probe cooking

12

Page 15

Operation

MenuSelect Control

23. CIRCUIT BREAKER - Used to turn power to the unit

on or off

24. USB PORT - Used to download programming information from a USB drive

OVEN STARTUP

1. Be sure the circuit breaker is pushed in. The display

ashes OFF PRESS POWER KEY TO START.

NOTE: If the real time clock and auto wake up func-

tions are enabled the display reads PRESS

POWER KEY TO START AUTO START.

2. Press the POWER KEY (21). The display reads

PREHEAT and the oven heats to the last manual set

temperature in the hot air mode. The display ashes

READY / IDLE and the alarm beeps 5 times when the

oven is at temperature and ready to bake.

MANUAL COOKING

1. Press the arrows on the NAVIGATION PAD (5) until

the display reads MANUAL.

2. Press the TIME KEY (7). Use the either the arrows or

the alpha/numeric keypad to enter the desired bake

time. Press OK on the NAVIGATION PAD (5) to set

the bake time.

NOTE: Time is set in one minute increments using

the arrows. To set time in less than one minute increments use the alpha/numeric keypad.

3. Press the TEMP KEY (6). Use the arrows or the alpha/numeric keypad to enter the desired bake temperature. Press OK to set the bake temperature. The

oven preheats to the new temperature.

NOTE: Temperature is set in 5 degree increments us-

ing the dial. To set time in less than 5 degree

increments use the alpha/numeric keypad.

4. Press the desired mode key, combi, steam, hot air or

retherm.

If Combi or Retherm are selected, use the arrows or

the alpha/numeric keypad to enter the desired percentage of steam.

NOTE: Retherm has a temperature limit of 250-300F.

When the display ashes READY / IDLE, open the

doors. Load the product.

5. Press the START/STOP KEY (1) to begin the bake

cycle. The timer counts down and the display alternates between the cooking mode and the name of

the product.

PROGRAMMED COOKING

1. Press the down arrow key until the name of the product is highlighted, or use the alpha/ numeric keypad

to enter a recipe number. Press OK to select. The

oven preheats to the programmed temperature in the

correct cooking mode. The display ashes READY /

IDLE and the alarm beeps 5 times when the oven is

at temperature and ready to bake.

2. Open the doors. Load the product.

3. Press the START/STOP KEY (1) to begin the bake

cycle. The timer counts down and the display alternates between the cooking mode and the name of

the product.

PROBE COOKING

1. Press the PROBE key (13) to select the probe mode.

The display reads CORE PROBE COOK & HOLD.

Use the arrowsl to select either YES or NO. Press OK

to select.

If YES is selected, Cook & Hold has been enabled. In

the Cook & Hold mode, the oven cavity lowers to the

product pull temperature as the product cooks.

If NO is selected, Cook & Hold has not been enabled

the cavity maintains the cook temperature.

2. Use the arrows to enter the desired product pull temperature in the display. Press OK to save the pull temperature.

3. Press the TEMP KEY (6). Use the arrows or the alpha/numeric keypad to enter the desired bake temperature. Press OK to set the bake temperature. The

oven preheats to the new temperature.

NOTE: Temperature is set in 5 degree increments us-

ing the dial. To set time in less than 5 degree

increments use the alpha/numeric keypad.

13

Page 16

Operation

MenuSelect Control

4. Press the desired mode key, combi, steam, hot air or

retherm.

If Combi or Retherm are selected, use the arrows or

the alpha/numeric keypad to enter the desired percentage of steam.

NOTE: 0 has a temperature limit of 250-300 F.

5. Insert the core probe into the product. Load product

into the oven and close the door. Be sure that the

terminal end of the core probe is outside of the oven

and clear of the door.

6. Connect the core probe to the PROBE CONNECTION (22) at the bottom of the control.

NOTE: Do not connect the probe before the cook

mode has been selected.

7. The display gives the actual core probe temperature

as well as the oven set temperature.

8. When the product reaches the pull temperature the

buzzer sounds.

9. Press the START/STOP KEY (1) to silence the buzzer.

If using Cook & Hold - The cavity temperature continues to drop to the product pull temperature and the

display counts up, telling the operator how long the

product has been held. Disconnect the core probe

and remove the product when ready.

If not using Cook & Hold - The cavity remains at

the cook temperature. The display does not count up.

Disconnect the core probe and remove the product

when the buzzer sounds.

less than one minute increments use the alpha/numeric keypad.

3. The Steam on Demand LED ashes until the steam

time has expired.

Venting Moisture from the Oven Cavity

1. Press the VENT KEY (16). This manually opens the

vent until the key is pressed again to close it.

Pause a Bake Cycle

1. To pause a cook cycle, press the START/ STOP

KEY (1). The LED on the start/stop key ashes. The

bake cycle will pause until the key is pressed again.

Cancel a Cook Cycle

1. To cancel the cook cycle, press and hold the START/

STOP KEY (1).

AT THE END OF ANY COOK CYCLE

1. An alarm sounds, the display reads DONE.

2. If more bake time is desired, press the BAKE MORE

KEY (3). This will add an additional one minute of

time for each press of the key.

3. When you are satised with the bake, press the

START/STOP KEY (1) to silence the alarm. Open the

door to remove the product.

OVEN SHUTDOWN

1. Press the COOL DOWN KEY (2). The display reads

AUTO COOL DOWN ACTUAL TEMP. To speed up

the cool down process, open the doors and press the

VENT KEY (16) to open the vent.

DURING ANY COOK CYCLE

Steam On Demand

While in the Hot Air, Combi or retherm modes, the unit can

be set to steam for a timed period of up to 20 minutes.

At the end of the timed cycle the unit reverts back to the

original setting. Steam On Demand can be used at any

time during the cook cycle.

1. Press the STEAM ON DEMAND KEY (12).

2. Use the arrows or the alpha/numeric keypad to enter

the desired steam on demand time. Press OK to initiate Steam on Demand cycle.

NOTE: Steam on Demand time is set in one minute

increments using the arrows. To set time in

2. When the oven has cooled down, the display reads

OFF PRESS POWER KEY TO START.

NOTE: The lights shut off and the vent closes auto-

matically at the end of the cool down cycle.

14

Page 17

Operation

MenuSelect Control

PRODUCT PROGRAMMING

Entering the Program Mode

1. Press the PROGRAM KEY (17). If the control is password protected, the display reads ENTER CODE. Use the

alpha/numeric keypad to enter the manager passcode.

Press the OK to enter the program mode.

Naming a Product Recipe

NOTE: Use the following procedure to name a new prod-

uct or edit the name of an existing product.

1. For a new recipe, press the down arrow key to the

rst open product. Press OK to select.

To edit an existing name, press the down arrow key

to display the name to be changed. Press OK to select.

2. Use the arrows to scroll down to Edit Name.

Press OK to enter the edit name menu.

3. Use the arrows or the alpha/numeric keypad to select

the rst character. Press OK to advance to the next

character. Repeat for all remaining characters.

NOTE: Product names may be up to 10 characters

long and can contain spaces. Use the #1 key

to insert spaces in a recipe name.

NOTE: To select letters using the keypad, press the

appropriate key once if you need the rst letter on the key, twice for the second and three

times for the third. For example to enter the

letter L press the #5 key three times.

4. Press the PROG KEY (17). With SAVE highlighted,

press OK to save the product name.

4. Use the arrows to select the desired cooking mode.

Choose from combi, steam, hot air or retherm. Press

OK to set the cook mode.

If Combi or Retherm are selected, use the arrows or

the alpha/numeric keypad to enter the desired percentage of steam.

5. Use the arrows or the alpha/numeric keypad to enter

the desired cook temperature. Press OK to set the

bake temperature.

NOTE: Temperature is set in 5 degree increments

using the arrows. To set time in less than 5

degree increments use the alpha/numeric

keypad.

NOTE: Retherm has a temperature limit of 250-300F.

6. Use the arrows to select the desired fan speed.

Choose from gentle, low, high or turbo. Press OK to

set the fan speed.

Programming a Product Recipe

NOTE: The control can hold 99 recipes. Each recipe may

have up to 6 cooking stages.

1. Use the arrows to highlight the name of the product

to be programmed. Press OK to select the product.

2. The display reads PRODUCT NAME: STAGE 1.

Press OK to select the stage.

3. Use the arrows or the alpha/numeric keypad to enter

the desired bake time. Press OK to set the bake time.

NOTE: Time is set in one minute increments using

the arrows. To set time in less than one minute increments use the alpha/numeric keypad.

15

Page 18

Operation

MenuSelect Control

7. Use the arrows to select the fan rotation cycle.

Choose between manual or auto.

NOTE: This is the length of time the fan will rotate in

one direction before reversing.

If manual is selected, use the arrows or the alpha/

numeric keypad to enter the desired fan cycle. Press

OK to set the fan cycle.

If auto is selected, the program will use the default

fan cycle setting. The default is set through the Manager Programming. See page 17.

8. Use the arrows to set the vent position.

Choose between OPEN or CLOSE. Press OK to set

the vent position.

9. Use the arrows to scroll down to PRODUCT NAME:

STAGE 2. Press OK to select stage 2.

10. Repeat steps 2-9 for all remaining stages.

11. When al stages have been programmed, press the

PROGRAM KEY (17). To save the programming, use

the arrows to scroll to YES. Press OK. The control

exits the program mode.

USING THE USB PORT

1. With the power on, remove the cover of the USB port

(24) and insert the USB drive.

2. Press the MAINTENANCE KEY (19).

3. Turn the dial to highlight MANAGER PROGRAM.

Press the center of the dial to select.

4. Turn the dial to highlight either COPY RECIPE FROM

USB or COPY RECIPE TO USB, then press the center of the dial to select.

5. When the transfer is complete, press any key to return to the menu.

6. Turn the dial to highlight EXIT. Press the center of

the dial to select. The display returns to the previous

menu.

7. Turn the dial to highlight EXIT. Press the center of the

dial to select.

16

Page 19

Operation

MenuSelect Control

MANAGER PROGRAMMING

Entering the Manager Program Mode

1. Press the MAINTENANCE KEY (19). If the control

is password protected, the display reads ENTER

CODE. Use the alpha/numeric keypad to enter the

manager passcode. Press OK to enter the program

mode.

2. Use the arrows to highlight OVEN SETUP.

Press OK to select the product.

Programming Auto Start

NOTE: The Auto Start function enables the oven to turn

on at a programmed time of day and preheat to a

programmed temperature.

1. Use the arrows to highlight AUTO START. Press OK

to select.

2. Use the arrows to select either ON or OFF. Press OK

to select.

If ON is selected, the display reads AUTO START 24

HOUR TIME 00:00. Use the arrows to enter the time

you would like the oven to begin preheating. Press

OK to select.

The display reads AUTO START TEMP XXX. Use

the arrows to enter the desired preheat temperature.

Press OK to select.

Programming Oven Setup

These menus allow the manager to set up basic oven

functions

1. Use the arrows to highlight OVEN SETUP. Press

OK to select.

2. Use the arrows to highlight MANAGER PROGRAM.

Press OK to select.

Recipe Password - Select YES or NO to enable

password protection on recipe programming. If YES

is selected the passcode 3124 must be entered to

change recipe programming.

Temp Unit - Select either degrees F or C.

Cool Down Temp - Select the set temperature for

the oven to achieve in Cool Down mode

Temp Disp Rate - Set the rate, in seconds, at which

the display switches between actual and setpoint

temperature

Input Rsp Time - Set the length of time allowed to

input each variable when programming recipes before control automatically exits out

Setback Time - When not used for a period of time,

the oven temperature will automatically reduce to

conserve energy. This variable sets the length of time

the oven remains at the idle temperature before being lowered.

Ready Beep - Select either ON or OFF. This is the audible alarm that sounds when the oven has reached

the set temperature.

Cook Cool Fan - Select either YES or NO. This function allows the control to display OPEN OVEN DOOR

when you are attempting to lower the set temperature

of the oven.

Restore Manual - Select either YES or NO. This

variable enables the oven to remember the last settings used for manual cooking.

4. After editing a function, press OK to save.

5. When all desired functions have been edited, use the

arrows to highlight EXIT. Press OK to exit the manager programming mode.

3. Use the arrows to highlight the oven function you with

to change. Press OK to select. Choose from the following functions:

17

Page 20

Maintenance

Spray Bottle Operating Procedure

NOTE: Only use a commercial oven cleaner/degreaser

with the spray bottle. DO NOT use chemicals that

are not intended as oven cleaners. See chemical

manufacturer’s information for intended use.

1. Unscrew the sprayer head and ll the container to

the MAX mark. Screw the head assembly on rmly to

ensure an airtight seal. The liquid must be clean and

free from foreign matter. Do not overll - space must

be left for compressing air.

2. To build up pressure, pump approximately 20 full

strokes when the container is lled with liquid. The

higher the pressure, the ner the spray. If the container is only partially lled, then more pumping is re-

quired to compress the additional air space.

3. To spray, depress the trigger with your thumb.

4. Adjust spray nozzle for a wide spray pattern.

5. After a period of spraying, the pressure will drop. Restore the pressure by operating the air pump.

6. Release pressure after use by inverting the spray

head and depressing the trigger or by slowly unscrewing the spray head assembly which will allow

air to escape from around the lling aperture.

7. After use, rinse the spray bottle with clean water and

check that the hole in the nozzle is perfectly clean and

clear. Warm water (not hot) used with a household

detergent is a useful cleaning agent for this purpose.

NOTE: Further information can be found in the instruction

leaet supplied with your spray bottle.

WARNING!!

Protective clothing and eyewear should be

worn while using cleaning agents.

Pressure Pump

Spray Head

Pump

Pressure

Vessel

Clean the pump 2 or 3 times per week with warm water

Figure 13

Complete Spray Bottle - P/N R0006

Spray Head Repair Kit - P/N R6332

Spray Trigger

18

Page 21

CLEANING THE INTERIOR

Daily Cleaning

Daily cleaning of the appliance is essential for sanitation,

and to ensure against operational difculties. The stainless steel cavity may corrode with improper cleaning of

the oven. Use an oven cleaning detergent in conjunction

with the supplied spray bottle.

For difcult cleaning, allow the spray-on oven cleaner to

work longer before rinsing.

1. Cool the appliance down to 140°F (60°C) or, if the

oven has been idle, turn to the Steam mode for 3 to 4

minutes in order to warm the cavity surfaces.

Maintenance

Cleaning and Preventive Maintenance

On stainless interiors, deposits of baked on splatter, oil,

grease or light discoloration may be removed with a good

non toxic industrial stainless steel cleaner. Apply cleaners

when the oven is cold and always rub with the grain of

the metal. The racks, rack supports and the blower wheel

may be cleaned in the oven or by removing them from the

oven and soaking them.

NOTE: DO NOT use corrosive cleaners not intended for

oven cleaning on your oven.

Recommended cleaners:

• ECOLAB Greasecutter Plus

2. Fill the spray bottle and pump air into the container

with the pressure pump.

3. Spray the interior of the oven with a cleaning solution.

Be certain to spray cleaner through the fan guard to

cover all surfaces.

NOTE: Never spray water into the appliance when

the temperature is above 212°F (100°C).

4. Let the cleaner work the time recommended by the

cleaning solution manufacturer. For difcult, baked on

grease, etc. allow to work over night.

5. Set the timer for 15 to 20 minutes.

6. Run the oven at 225°F (107°C) in the Steam mode.

This will soften all burned on residue.

7. Rinse the appliance interior with water (a hose is

supplied, but take care that only the interior cavity is

sprayed with water). Wipe the interior dry after rinsing.

8. The doors should be kept slightly open after cleaning.

This will allow the oven to vent and increase the life

of the door gasket.

• CELLO EZ Clean

• Diversey-Lever Advance Oven Cleaner

WARNING!!

Be sure to read and follow the MSDS or

safety instructions on the bottle for your oven

cleaner.

19

Page 22

Maintenance

Cleaning and Preventive Maintenance

Oven Weekly Cleaning

In addition to the daily cleaning, it is necessasry to clean

behind the fan guard of this oven on a weekly basis. This

is necessary for proper functioning of the oven. Scale will

build up on the fan and heat source leading to a less ef-

cient oven.

1. Turn off the oven. Make sure that the oven is cooled

down to under 140°F (60°C).

2. Remove the rack guides.

3. Rotate the two screws on the left side of the fan guard.

Figure 14

4. Remove the fan guard.

5. Thoroughly spray cleaner onto the fan and heat

source. Close the doors to allow the cleaner to work.

6. After ten minutes, rinse the cleaner off. Return the fan

guard to the closed position. Rotate the two screws to

secure the fan guard.

Remove and clean the blower wheel every 6 months.

CLEANING THE EXTERIOR

The exterior of the appliance may be cleaned and kept in

good condition with a light oil. Saturate a cloth and wipe

the appliance when it is cold; wipe dry with a clean cloth.

WARNING!!

DO NOT spray the outside of the appliance

with water or clean with a water jet. Cleaning

with a water jet can impregnate chlorides into

the stainless steel, causing the onset of corrosion.

PREVENTIVE MAINTENANCE

The best preventive maintenance measures are the proper initial installation of the equipment and a program for

cleaning the appliance routinely. The oven requires no lubrication. Contact the factory, the factory representative

or a local Blodgett service company to perform maintenance and repairs should they be required.

Figure 15

20

Page 23

MENUSELECT CONTROL

6

Maintenance

Replacement Parts

2

1

5

10

4

5

12

13

11

3

9

Ref. Part

No. No. Description

1 55178 CONTROL PANEL AND DECAL

2 39122 BOARD, 3 BUTTON PCB

3 53487 CONTROL, NAVIGATIONAL PAD (NAVY)

4 39781 MEAT PROBE JACK

5 M3367 NUT, 6-32 KEPS (QTY 4)

6 5805 SCREW, M, 6-32 X 3/8 PNHD PH (QTY 2)

8 51594 HARNESS, HV100E FRONT CONTROL

9 52185 CIRCUIT BREAKER, PANEL MOUNT

10 52647 USB CABLE

11 52600 SPACER, USB

12 52161 COVER, USB

13 38840 SCREW, MACH, 4-40 X 3/8, SS PAN HD

21

Page 24

Maintenance

Replacement Parts

DOORS

15

13

RH DOOR

12

7

4

11

9

8

2

9

1

10

6

9

7

8

5

9

3

LH DOOR

Ref. Part

No. No. Description

1 51552 ASSEMBLY, LH OUTER DOOR

2 51534 ASSEMBLY, INNER DOOR GLASS

3 50227 ASSY, LATCH RH

4 50228 ASSY, LATCH LH

5 50213 END CAP, HANDLE (QTY 2)

6 51542 ASSEMBLY, DOOR HANDLE

7 51539 PLATE, LATCH COVER (QTY 2)

8 51668 GASKET, DOOR LATCH (QTY 2)

9 16384 10-24 X .500 TRUSS HEAD MACH SCREW (QTY 4)

10 M6315 10-24 X 1/2 HEX WASHER HEAD SCREW, S/S (QTY 4)

11 50836 SCREW, #10-24 X 2.00 FLATHEAD (QTY 4)

12 51559 ASSEMBLY, RH OUTER DOOR

13 51556 ASSEMBLY, RH INNER DOOR GLASS

14 57953 DOOR TURNBUCKLE ASSEMBLY

15 52514 DOOR SWITICH ASSEMBLY

14

22

Page 25

Maintenance

LH OUTERDOOR SUBASSEMBLY (P/N 51552) BREAKDOWN

Replacement Parts

9

5

3

10

8

1

4

2

B

7

6

SECTION B-B

11

A

12

B

SECTION A-A

Ref. Part

No. No. Description

1 51523 DOORFRONT, LH

2 51161 GLASS, OUTER DOOR

3 51424 BUSHING, DOOR PIN

4 51664 TRIM, TOP DOOR

5 51528 TRIM, BOTTOM DOOR

6 51529 TRIM, VERTICAL DOOR (QTY 2)

7 51519 CLIP, DOOR GLASS

8 16470 NAMEPLATE, BLODGETT, 10 INCH

9 51450 DOOR CHANNEL, RH DOOR

10 60185 BUMPER, HIGH TEMPERATURE (QTY 6)

11 R1278 RIVET, 1/8” POP S/S

12 16384 10-24 X .500 TRUSS HEAD MACH SCREW (QTY 14)

23

A

Page 26

Maintenance

Replacement Parts

RH OUTERDOOR SUBASSEMBLY (P/N 51559) BREAKDOWN

2

SECTION B-B

A

7

11

9

8

10

1

6

12

13

3

5

B

Ref. Part

No. No. Description

1 51558 DOORFRONT, RH

2 51529 TRIM, VERTICAL DOOR (QTY 2)

3 51664 TRIM, TOP DOOR

4 51528 TRIM, BOTTOM DOOR

5 51424 BUSHING, DOOR PIN

6 51161 GLASS, OUTER DOOR

7 51519 CLIP, DOOR GLASS

8 60185 BUMPER, HIGH TEMPERATURE (QTY 6)

9 R1278 RIVET, 1/8” POP S/S

10 16384 10-24 X .500 TRUSS HEAD MACH SCREW (QTY 14)

11 51541 CENTER GASKET CHANNEL, INNER

12 52475 GASKET RETAINER, OUTER

13 51610 GASKET, CENTER DOOR

B

4

A

SECTION A-A

24

Page 27

MOTOR

Maintenance

Replacement Parts

6

1

10

8

5

9

3

4

2

7

Ref. Part

No. No. Description

1 54294 MOTOR MOUNT ASSEMBLY

2 R8423 GORETEX GASKET, .25 X .18 (QTY 2)

3 54296 PLATE, FAN BRACKET COVER

4 R4244 SHAFT SEAL

5 R8955 SEAL RETAINER W/KEY

6 55301 MOTOR, 220V, 1/2 HP

8 R0726 WASHER, LOCK # 10 (QTY 4)

9 R1539 10-32 X .50 HXWHD MACHINE SCREW (QTY 4)

7 8628 NUT, 5/16 -18 SERRATED FLANGE (QTY 4)

10 M0959 FITTING, COMPRESSION

25

Page 28

Maintenance

Replacement Parts

ELECTRICAL PANEL

30

19

1

11

5

24

9

38

43

42 28

2

38

17

3

41 34 15

39

14

13

23

7

4

31

8

20

18

32

2

3316

27

10

2526

6

Ref. Part

No. No. Description

1 51110 BRACKET, ELECTRICAL MOUNTING

2 51588-2 DRAWER SLIDE, MOVING (QTY 2)

3 24356 TRANSFORMER, 120V TO 24V 80VA

4 M9616 AXIAL FAN, 4” (24V)

5 M9608 24VDC POWER SUPPLY

6 51436 DUCT, LOWER AIR

7 51437 BRACKET, INVERTER DRIVE

8 38605 TERMINAL BLOCK 3 POLE

9 51122 BRACKET, COOLING DIVIDER

10 52535 ASSY, WATER MANIFOLD (NAVY)

11 51435 BRACKET, POWER SUPPLY SLIDE

12 15847 GROMMET, RUBBER 11/16

13 51489 BRACKET, I/O BOARD

14 54380 INTERFACE BOARD

26

Page 29

ELECTRICAL PANEL (CONTINUED)

Ref. Part

No. No. Description

15 50952 TERMINAL BLOCK, 5 POSITION PUSH IN

16 51614 SCREW, #8-32 X .25 PAN PH (QTY 17)

17 4812 #10 X 3/8 PH SCREW (QTY 8)

18 34706 SCREW,MACH M3X.5X10MM SS PNHD (QTY 4)

19 16821 SCREW, #5-40 X 3/16 PH PHILLIPS MACHINE (QTY 3)

20 51516 PROBE, 3/16” DIA. 1K OHM RTD

21 51595 HARNESS, HV100E 208-240V

22 51593 HARNESS, HV100E REAR OVEN

23 51622 WIRE TIE BASE, BACK MOUNT (QTY 11)

24 52292 2” WIDE CABLE CARRIER

25 52351 BLUE POLYURETHANE TUBING (QTY 2)

26 52352 GREEN POLYURETHANE TUBING

27 52353 RED POLYURETHANE TUBING

28 52446 CIRCUIT BREAKER W/ TRIP COIL, 25A, 3 POLE

30 R5770 SCREW, 1/4-20 X .50 PANHEAD (QTY 2)

31 37951 SCREW, MACHINE, PAN HEAD #4-40 X 1.00 (QTY 2)

32 4068 GROMMET, BLACK RUBBER

33 R5056 CUSHION CLAMP

34 52680 INVERTER DRIVE, J1000, PROGRAMMED

38 R11090 ENDSTOP, DIN RAIL (QTY 2)

39 52706 RESISTOR, MOTOR BRAKING

41 R1278 RIVET, 1/8” POP S/S (QTY 2)

42 52717 CONTACTOR, 3PHASE 24VDC COIL

43 51454 FUSE HOLDER

44 51455 FUSE, 7A 600V (QTY 2)

45 51453 TRANSFORMER

46 52204 GROUND LUG TERMINAL

47 52201 TERMINAL BLOCK

48 R11100 SHORTING JUMPER

49 R11090 END STOP (BOTH ENDS)

50 51617 1/4” SWIVEL ELBOW

51 51616 1/4” STRAIGHT FITTING

52 52813 HARNESS, 480V

53 53902 NOISE FILTER

Maintenance

Replacement Parts

49

45

48

46

27

47

50

51

Page 30

Maintenance

Replacement Parts

INTERIOR COMPONENTS

1

18

3 4 6 7

1

2

5

13 12

Ref. Part

No. No. Description

1 54856 RACK SUPPORT

2 53101 LIGHT BULB

3 55303 BLOWER WHEEL W/KEY

4 51488 DOOR CATCH

5 53081 LIGHT GLASS

6 53016 220V ELEMENT (440V OVEN)

7 52304 ELEMENT GASKET

9 53007 CAVITY PROBE

11 51488 DOOR CATCH

12 52716 PERIMETER DOOR GASKET

13 36441 HI-LIMIT PROBE

15 39324 CAVITY VENT SOLENOID

16 R3664 WIRE RACK

17 55024 VENT LID

18 55057 SUCTION TUBE

11

9

17

15

28

Page 31

Maintenance

Second Level Programming

NOTE: The oven must be in the ON position in order to run the 2nd level programming.

Press Maint Key Scroll with ▲ or ▼ keys to “Factory Program”

Press Ok Enter Code “3228”

Press Ok Scroll to “Appliance Type”

Press Ok Use ► or ◄ to set to “Electric”

Press Ok Scroll to “Boiler Enable”

Press Ok Use ► or ◄ to set to “No”

Press Ok Scroll to “Quench Enable”

Press Ok Use ► or ◄ to set to “No”

Press Ok Scroll to “Exit”

Press Ok Scroll to “Service”

Press Ok Enter Service Code “7378”

Press Ok Scroll to “Diagnostic Output”

Press Ok

Press and hold each button below to

test the function listed on the right:

Temp Heat On (Fan High Fwd, Hot Air, Hot Air Enable, Hot Air Contactor)

Combi Fan Speed Gentle Forward (20 Hz)

Fan Fan Speed Low Forward (30 Hz)

Prog Fan Speed High Forward (40 Hz)

1 Fan Speed Turbo Forward (50 Hz)

4 Fan Speed High Reverse (-40 Hz)

7 Light

Light Spritzer

Esc Cooling Fan

2 Vent

5 Hot Air

8 Hot Air Enable

0 Quench

Time Cook Done

Press Ok to Exit Scroll to “Diagnostic Input”

Press Ok

Press and hold each button below to

test the input listed on the right:

Temp Fan Error (Open or Closed Drive At Speed Relay)

Combi Door (Open or Closed Door Switch)

Fan Cavity Probe Temp

Prog Cooling Fan Probe Temp

4 Core Probe Temp (Open if not inserted)

Press Ok to Exit Press Esc to Exit

Press Esc to Exit

See “Trouble Shooting Test Points” for output testing if necessary

(Component Tested)

(Input Tested)

29

Page 32

Maintenance

Troubleshooting

TEST POINTS USING CONTROL DIAGNOSTIC OUTPUTS

KEY OUTPUT COMPONENTS

Temp Heat On (Fan High Fwd, Hot Air, Hot Air Enable,

Hot Air Contactor) Hot Air

Temp Heat On (Fan High Fwd, Hot Air, Hot Air Enable,

Hot Air Contactor) Hot Air Enable

Temp Heat On (Fan High Fwd, Hot Air, Hot Air Enable,

Hot Air Contactor) Hot Air Contactor

7 Light Terminal Block 4

Light Spritzer Terminal Block 4

Esc Cooling Fan Terminal Block 4

2 Vent Terminal Block 4

5 Hot Air Terminal Block 4

8 Hot Air Enable Terminal Block 4

Time Cook Done Terminal Block 4

TEST POINTS TO RELAY BOARD

Black Lead Red Lead

Terminal Block 4

Pin #4k 4-Pin #4

Terminal Block 4

Pin #4

Terminal Block 4

Pin #4

Pin #4

Pin #4

Pin #4

Pin #4

Pin #4

Pin #4

Pin #4

Connector J6-Pin

#4-RD Wire

Connector J6-Pin

#8-BL Wire

Connector J20-Pin

#2-OR Wire

Connector J3-Pin

#4-RD Wire

Connector J18-Pin

#3-VI Wire

Connector J3-Pin

#11-GY Wire

Connector J2-Pin

#4-GY Wire

Connector J6-Pin

#4-RD Wire

Connector J6-Pin

#8-BL Wire

Connector J2-Pin

#2-No Wire

VOLTAGE

AC + DC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

24VDC

30

Page 33

TEST POINTS USING CONTROL DIAGNOSTIC OUTPUTS

Maintenance

Troubleshooting

KEY FAN CONTROL COMPONENTS

Combi Fan Speed Gentle Forward (20 Hz) J2 9-12

Fan Fan Speed Low Forward (30 Hz) J2 9-12

Prog Fan Speed High Forward (40 Hz) J2 9-12

1 Fan Speed Turbo Forward (50 Hz) J2 9-12

4 Fan Speed High Reverse (-40 Hz) J2 9-12

OUTPUT COMPONENTS J2.9 (BIT 0) J2.10 (BIT 1) J2.11 (FWD) J2.12 (REV)

Gentle Forward Outputs (20 Hz) 0v 0v 23Vdc Rtn 0v

Low Forward Outputs (30 Hz) 23Vdc Rtn 0v 23Vdc Rtn 0v

High Forward Outputs (40 Hz) 0v 23Vdc Rtn 23Vdc Rtn 0v

Turbo Forward Outputs (50 Hz) 23Vdc Rtn 23Vdc Rtn 23Vdc Rtn 0v

Gentle Reverse Outputs (-20Hz) 0v 0v 0v 23Vdc Rtn

Low Reverse Outputs (-30Hz) 23Vdc Rtn 0v 0v 23Vdc Rtn

High Reverse Outputs (-40Hz) 0v 23Vdc Rtn 0v 23Vdc Rtn

Turbo Reverse Outputs (-50Hz) 23Vdc Rtn 23Vdc Rtn 0v 23Vdc Rtn

TEST POINTS TO RELAY BOARD

Black Lead Red Lead

Terminal Block 4

See Chart Below

See Chart Below

See Chart Below

See Chart Below

See Chart Below

Pin #4

Terminal Block 4

Pin #4

Terminal Block 4

Pin #4

Terminal Block 4

Pin #4

Terminal Block 4

Pin #4

VOLTAGE

AC + DC

24VDC

24VDC

24VDC

24VDC

24VDC

31

Page 34

Maintenance

Sequence of Operation

Light

Cook Done

Vent

Cooling Fan

Hot Air

Hot Air

Enable

Hot Air

Contactor

Spritzer

When the Control is rst turned on, it begins to Preheat

the oven to 350?F by enabling the following relays. The

activated relays are associated with red LEDs which will

turn on when the control sends a call to the relay. Relays

are designated with a K, LEDs are designated with a D,

and Junctions are labeled with a J. In preheat the following LEDs will be lit:

D25 LED will come on as the Light relay, K6, is closed.

The cavity lights will remain on until the Light button is

pressed to turn them off. Check for 24 VDC output at J3.4,

which feeds the cavity lights on the red wire.

D31 LED will be lit as the Hot Air (Power On) relay is

enabled on this unit. The Hot Air relay is active whenever

the red light is on at the Power Button. Check for 24 VDC

output from K3 at J6.4 on the orange wire, which jumps to

the common for the K2 relay at J6.7. The K2 relay waits

for input from the Fan@Speed or Drive@Set Speed Relay, which is 24 VDC return at the grey wire in J11.4.

D35 LED shows the Hot Air Enable relay is activated when

the Fan@Speed Relay is closed at the Inverter sending

24 VDC return in at J11.4; this signal closes K2. Check for

24 VDC output at J6.8 on the blue wire, which jumps to

J20.1. J20.1 is the common to the K1 relay.

D37 LED is lit as the Hot Air Contactor relay is enabled

when there is a Call for heat. A call for heat is generated

when the cavity probe(or core probe when not in preheat)

reads resistance/temperature below the current set point,

which is 350?F during preheat. Check for 24 VDC at

J20.2, which is the K1 relay output that feeds the contactor coil on the orange wire.

Also in preheat, the control will call for Fan High Speed

Forward by sending 23 VDC return on J2.10 and J2.11,

and 0 VDC on J2.9 and J2.12. Note: outside the ready

band, which is-10 to +25?F, in relationship to the set

point, the control automatically switches to high fan speed

and can be used only in high fan speed or turbo fan speed.

Once in ready band, all speeds are available.

Figure 16

32

Page 35

Maintenance

Sequence of Operation

After preheat the control can be operated in Manual Mode

or in one of the 100 programs. Each program can have

up to 6 steps and a hold. In each step the user can program Core Probe (Yes/No), Cook Time, Mode (Steam/

Combi/Reth/Hot A), Set Temp, Fan Speed (Gentle/Low/

High/Turbo), Fan Reverse (Manual/Auto), Fan Reverse

Time, and Vent Setting (Close/Open).

If Core Probe is “Yes”, the unit will look for the resistance

at the probe port on the front on the control. If Fan reverse

is set to Auto, the control will automatically reverse the fan

every 2 minutes while a time counting down. If it is set to

manual, the reverse time can be set. Also the Cook Time,

Cook Mode, Set Temp, Fan Speed, as well as Vent position, can be programmed for each step. When the Vent

is opened, D24 LED lights and 24 VDC is sent by K5 on

the grey wire at J2.4; no voltage is present when the vent

is closed.

If operating in Manual Mode, you can manually modify

the Fan Speed, the Vent Position, Core or Cavity Probe,

Time and Temp, Steam on Demand (not functional in

steam mode) and the Cook Modes: Hot Air, Combi,

Steam, and Retherm.

Hot Air uses the “call for heat” sequence mentioned

above.

Combi uses the same call for heat and the Water Spritzer

is cycled at 33% for the default setting, or 20 seconds on

40 Seconds off. The cycle rate can be adjusted from 0 to

100%. When the Water Spritzer is called for, D33 is lit,

and K8 sends out 24 VDC on the Violet wire at J18.3.

Steam uses the same call for heat and the Spritzer is cycled at 100%. In steam the lowest temperature setting is

85?F and the maximum temperature in the steam mode

is 225?F. Steam on demand is not available in Steam

mode because the control is cycling the Spritzer at 100%

already.

Retherm uses the Water Spritzer at a 25% duty cycle, or

15 seconds on 45 Seconds off, and the call for heat is set

at 250?F as the default temperature. The Water Spritzer

cycle rate can be adjusted from 10 to 90% and the Temperature can be set to 250 - 300?F.

When the Control calls for the fan to go Forward, J2.11

will have 23 VDC return and J2.12 will have 0 VDC. That

condition will invert when the fan call is for Reverse; J2.12

will have 23 VDC return and J2.11 will have 0 VDC. The

speeds are set by J2.9 and J2.10. 0 VDC on both is Gentle Speed, J2.9 with 23 VDC return and J2.10 with 0 VDC

is Low Speed, J2.9 with 0 VDC and J2.10 with 23 VDC

re- turn is High Speed, and 23 VDC return on J2.9 and

J2.10 is Turbo Speed.

The Cooling Fan is controlled by the probe located under

the Inverter heat sink; it is cycled on at 100?F. When the

Cooling Fan is called for, K4 Relay sends 24 VDC out at

J3.11 on a grey wire, and the call is indicated by LED D26.

The Cooling Fan is also activated at any time the timer is

counting down.

Cook Done is not used. Therefore no wire is located at

J2.2, where K14 sends 24 VDC when D21 is lit. However,

Cook Done is activated when the Timer goes off on the

control.

33

Page 36

Component Resistance Readings

PART NAME OHMS

24VDC Power Supply, Across +V & -V (Unwired DC Voltage) 326

24VDC Power Supply, Across L & N (Unwired Line Voltage) 0.6

Control Transformer (Primary) 25

Control Transformer (Secondary) 0.6

Element, (Single element) 24

Element, (At contactor) 32.5

Heating Contactor Coil 6

Water Solenoid Valve 178

Cooling Fan 3.7

Convection Motor Windings Blue to Black 6.2

Connection Motor Windings Brown to Black 6.2

Connection Motor Windings Brown to Blue 6.2

Circuit Breaker Trip Coil 3.7

Vent Solenoid 30

Step Down Transformer (Primary) 2

Step Down Transformer (Secondary) 1

NOTE: Readings may vary some based on meter capability and accuracy.

Probe Ohms Chart

TEMP

0 1000

20 1078

24 1090

30 1115

50 1195

60 1232

80 1310

93 1360

100 1386

120 1460

150 1575

180 1685

200 1758

230 1868

260 1978

PROBE OHMS

(P/N 51516)

Page 37

BK–10

BK–6

R–14

R–14

1

39796

1 2

1 2

Quench Soleno id_ B

Water Soleno id_ A

V–5

BL–10

Cavi ty _Vent _Rt n

BK–22GY_16

BK–9/BK–21

39324

+ –

Vent_Sol

1 2

M9616

Mtr_2

Cooling_ Blwr

1 2

+24 V, RD–23

Hot Ai r_24VDC

32–DR42–DR

RD–25

RD–26

RD–27

1_A

1_B

2_A

2_B

3_A

TB4

3_B

1_C

1_D

2_C

2_D

3_C

3_D

+24VDC Power Distribution

RD

RD–16

RD–15

RD–9

RD–10

Drv _Inpu t _Com

BK–12

BK–14

BK–9

BK–10

4_A

4_B

5_A

5_B

50952

Term_Blk_5p

4_C

4_D

5_C

5_D

BK

BK–26

50 L AKESIDE AVE. BURLINGTON, VERMONT 0540 1

G.S.BLODGETTCORPORATION

___

__–__–__

53512 C

DRAWINGNUMBE R REV

32MH

OF

1

SCALE

SHEET

09–13–10

09–13–10 NO NE

DATE

DATE

SCHEMATIC,HV100EM 440 V 14KW MENUSE LECT

MH

G. S. BLODGETT CORPORATION. UNPUBLISHED WORK. AL LRIGHTS RESERVED

BY

BY

APR

DWG

WITHOU T TH E EXPRESSWRITTEN PERMISSION OF THE G.S. BLODGETTCORPORATION .

NOR ANY IN FORMATION CONTA INED H EREINM AYBE COPIED ORUSED,INW HOLE ORIN PART,

THISDR AW ING IS THE PROPERTY OF G.S. BLOD GETT CORPO RATION.NEITHERTHISDRAWING

Title

___

MH

MH

03–23–12

__–__–__

11–10–10

BK–15

2

Mtr _Rev_Ena_L

Mtr _Fwd_Ena_L

Mtr _Spd_Sel_Bit_0_Ena_L

Mtr _Spd_Sel_Bit_1_Ena_L

Hotai r_24Vd c

Light _Pwr

GY–18

GY–19

GY–14

GY–17

BL–10

RD–24

Vent

+24VDC

+24VDC

+24VDC

Quench

Chemical_Pump

Spd_Sel_Bit_0

Spd_Sel_Bit_1

J2.1

J2.2

3

Fwd_Ena_L

J2.3

J2.4

J2.5

J2.6

J2.7

J2.8

J2.9

J2.10

RD–5

RD–22

Lights

+24VDC

Rev_Ena_L

J3.1

J2.11

J2.12

+24VDC

24VAC

Cir_Pump

J3.2

J3.3

J3.4

J3.5

J3.6

J3.7

J3.8

J3.9

52–DR52–DR

GY–9

BL–11

V–5

RD–20/RD–21

OR–23

DRV_Ok

Oven_On

Oven_On

DRV_Ok

Cooling_Fan

J6.1

J3.10

J3.11

J3.12

+24VDC

J6.2

J6.3

J6.4

J6.5

J6.6

J6.7

J6.8

J6.9

J6.10

Relay Outputs

+24VDC

+24VDC

+24VDC_Rtn

Spritzer_Sol

Cavity_Drain–

Cavity_Drain+

J6.11

J6.12

J18.1

J18.2

J18.3

J18.4

J18.5

J18.6

J18.7

J18.8

J18.9

J18.10

J18.11

HEAT CONTACTOR[1..2]

OR

OR/BK–1, 22awg twisted pai r

BK

BK–14

BL–11

RD(RD/Y/BK–1)

Y(RD/Y/BK–1)

BK(RD/Y/BK–1)

RS232 Out

RS232 In

+24VDC

Heat_Ena

HEAT_CONTACTOR_A1

HEAT_CONTACTOR_A2

+24VDC_Rtn

+24VDC

Rinse_Pump

+24VDC

Door_Lock

J20.1

J20.2

J20.3

J20.4

J20.5

J20.6

J20.7

J20.8

J18.12

J20.9

J20.10

J20.11

J20.12

Buzzer

J13.1

J13.2

DGND

DGND

J14.1

J14.2

J13.3

Shield Wire

PWM OUT

PWM OUT

DGND

J5.1

J5.2

J5.3

J14.3

PWM RS232 Buzzer

RD/BK–1[1..2]

RD/BK–1, 22 awg twisted pair

–

–

–

–

___–___

___–___

–

–

.015 .03 1 .005

.XXX .XX ANGULAR HOLE

TOLERANCES UN LESS OTHERWISESPECIFIED

2

DRIVEAND SHIELDED CABLE TOM OTOR AND COM

NEW TITLE BLOCK; ADD ED EMI FILTER TO MOTOR

CHANGED J19 TO J7 TO MATCH I NTERFACEBOARD.

IMPROVEDD EPICTION OF I NVERTERDRIVE WIRING.

B10–158

B12–011

–

–

C

B

MATL

GAGE

REV ECN ETADSNOISIVE YBRPAR

3

VFD – Relay Interface Module

U5

Digital Inputs Analog Inputs

J11.1

J11.2

J11.3

J11.4

J11.5

J11.6

J11.7

J11.8

J11.9

J11.10

J1.1

J1.2

J1.3

J1.4

J1.5

J1.6

J1.7

J1.8

J1.9

J1.10

J15.1

J15.2

J15.3

J15.4

J15.5

J15.6

J15.7

J15.8

Hi_Lmt_Trip

Door_Closed_H

Drv_@Setspd_L

SSR_HeatSink_H

Door_Latched_H

Safety_Sw_Closed_H

Y–6

GY–15

BK–13/BK–14

J41.1

J41.2

J41.3

J41.4

J41.5

J41.7

J41.8

J8.1

J8.2

J8.3

J8.4

J8.5

J8.6

J8.7

J8.8

J17.1

J17.2

J17.3

J17.4

J17.5

J17.6

J17.7

J17.8

J16.1

J16.2

J16.3

J16.4

J16.5

J16.6

J16.7

J41.6

Oven Prb

Oven Prb

Product_Prb

Product_Prb

Ctrl_Zone_Prb

Ctrl_Zone_Prb

J16.8

24VAC_Pwr

J7.1

RD(RD/WH –2)

J7.2

J7.3

RD/WH –2[1..2]

WH(RD/ WH–2)

RD/WH–2, 22awg twisted pair

Product

RT4

OR

39797 (6”)

t

WH/BK–2, 22awg twisted pai r

BL/BK–1, 22awg twisted pai r

4

WH/BK–1, 22awg twisted pai r

Inv ert er_H .S.

KBKB

All Prob es: 1K RTD

4

Prb2_2Prb1_2

51516

t

RT2

W

Prb1_1 Prb2_1

Cav i ty

BK–13/BK–14

+24 VDC_RTN

Drv@SetSpd_L

Hi_Lim it _Trip_H

5

U2

FRONTPAN ELUSB SOCKET

WH(RD/WH–1)

RD(RD/WH–1)

123

123

123

VCC+

USB1

DATA–

DATA+

4

4

J38

J2

GND

USB PORT

D D

J37

RD/WH–1 [1 ..2]

AUX_Brd_DGND

AUX_Brd_+5Vdc_Sw_Pwr

AUX_Brd_SW1_Ena_L

AUX_Brd_SW2_Ena_L

AUX_Brd_SW3_Ena_L

AUX_Brd_D3_Ena_L

AUX_Brd_D1_Ena_L

AUX_Brd_D2_Ena_L

RD/WH–1, 22awg twisted pair

V–3

V–4

V–5

V–6

V–7

V–8

R–11

Bl–12

In_1

In_2

In_3

In_4

In_5

In_6

In_7

Com

Out_1

Out_2

Out_3

Out_4

Out_5

Out_6

+24Vdc

J4

Signal I/O 24VAC_PWR SCK_COMM

O/IyaleRO/IxuAO/IgolanA

121110

Com

Out_7

Out_8

J12

53487 US Navy

C C

Harness PN: 50178

98765432187654321

J41

AN–1

AN–2

AN–3

MenuSelect Control: 53486 General Market

5

4

Y(RD/Y/BK–1)

3

2

AN–4

1

J5

RD(RD/Y/BK–1)

BK(RD/Y/BK–1)

Y–6

SW5

SPST

RD–3/RD–23 RD–3

+24 VDC

B B

RT1

A A

52307 39783 ( 4”)

t

5

Page 38

DRKB

53512 C

WH

1

WH–3

RD–3

BK–3

T1

A2

6T35T24

1L12L23

8

K1_Aux

7

L3

A1

K1

52717

Heat Con tact or

WH BK

RD

440V configuration

14KW Heating Element Assembly

53016, 220V, 2.33KW (X6) 14KW total , 19A nominal

D0119 (X 2)

1

2

1

2

Halogen Lamp –12V

, 18awg

G.S.BLODGETTCORPORATION

, 18awg

___

RD, 200

__–__–__

DRAWINGNUMBE R REV

33MH

OF

1

SHEET

SCALE

09–13–10

09–13–10 NO NE

DATE

DATE

SCHEMA TIC,HV100EM440V 14KW MENUSE LECT

MH

G.S. BLODGETT CORPORATION. UNPUBLISHED WORK. AL L RIGHTS RESE RVED

BY

BY

APR

WITHOUT THE EXPRESSWRITTENPERMISSION OF THE G.S. BLODGETT CORPORATION.

NORANY INFORMATION CO NTAINED HEREINMAYBE COPIED ORUSED,INWHOLE ORINPART,

THISDRAWING IS THE PROPERTY OF G.S.BLODGETTCORPO RATION. NEITHERTHISDRAWING

DWG

50 LAKES IDEAVE. BURLINGTON, VERMONT0540 1

Title

___

MH

MH

03–23–12

__–__–__

11–10–10

Cavi ty_Vent _Rtn

.015 .03 1 . 005

.XXX .XX ANGULAR HOLE

TOLERANCESUNLESS OTHERWISESPE CIFIED

OR

BK

2

OR/BK–1

HEAT_CONTACTOR[1..2]

GY

GY

N.C.

BK

GY

1 2

39332

L3

Gnd

L1

Cir_Mtr, 3p , 4 po le

L2

BL

BKBK

MTR1

Shield Wire

WH

GY/BK–1 twisted pair

3

BK

WH

RD

Shield Wire

V/T2

U/T1

W/T3

52680

Programmed

Yaskawa

S/L2

4

5

BR–16BR–6

BL–16

N

L1

LOAD

LINE

N

GND

L1

BL–6

GR/Y–2

BR–6

BL–6

18awg, 600v

Shielded Cable

GY/BK–1 [1..2]

A22: 010 – Hi_Spd Freq = 40hz

A21: 001 – Lo_Spd Freq = 30hz

A20: 000 – V_Lo_Spd Freq = 20hz

A23: 011 – V_Hi_Spd Freq = 50hz

binary select:

Pre_Set Speeds:

MC

MB

MA

AC

AM

AC

+V

A1

SC

S5

J1000

INVERTER

DRIVE

S4

S3

S2

S1

B1B2R/L1

V–11

GY–IN3

GY–IN4

GY–IN2

BK–L

GY–IN5

BK–CM2

GY–IN1

52706

150W, 400 OHM

BRAKINGRES ISTOR

53902

EMI FILTER

BK–L/CM2

101112

12

BK(GY/BK–1)

BK–13

GY(GY/BK–1)

123456789

1234567891011

GY–18

GY–19

GY–20

GY–14

GY–17

GY–15

BK–12/BK–13

BK–12

Drv_Faul t_L

Mtr@SetSp d_L

Mtr_ Fwd_Ena_L

Mtr _Rev_Ena_L

Drv_Inpu t _Com

Mtr_Spd_Sel_Bit_0_Ena_L

BK(GY/BK–1)

GY(GY/BK–1)

Mtr_Spd_Sel_Bit_1_Ena_L

GY/BK–1 twisted pair

RD–2

WH–2

BK–2

RD–6/RD–3

RD–3, 24VDC

BK–5

T1

T2

T3

A2A1

CB2

25 A

52446

Fast Trip Curve

L2

L1

Trip Coil

L3

SW4

36441

Cavity Hi_Limit

Cavi ty_Hi _Lmt

RD/BK–1 [1..2]

OR–5, 22awg, 300V

22awg twisted pair

R

R

Bk

OR–6

24VAC_2[0..2]

24Vac [0..2]

RD/WH–1, 22awg twisted pair

RD/WH–2, 22awg twisted pair

WH–2

RD–2

RD–1

WH–1

WH–3

RD–3

Hi_Limi t_Trip_H

24VAC_2[0..2]

RD/WH–3, 22awg twisted pair

T1

0IN

220V

380V

WH–1, 10awg, 600V

RD–1, 10awg, 600V

BK–1, 10awg, 600V

0OUT

51453

440V

480V

24356

T1

TRANSFORMERPOWER, STEPDOWN

RD–9, 14awg, 600V

WH–9, 14awg, 600V

F1

51454

51455

F2

FUSE HOLDER

RD–8, 14awg, 600V

WH–8, 14awg, 600V

1_C

1_D

2_C

2_D

3_C

R11092

TB1

Field Wir ing Term Blk

3_D

1_A

1_B

2_A

2_B

3_A

3_B

2X Fuse, 7A

BL–1, 14awg, 600V

CB1

Gnd_1 Gnd_2

52185

15 Amp

BR–1, 14awg, 600V

BK–22

2

–

–

IMPROVEDDEPICTION OF INVERTERDRIVEWIRING.

CHANGED J19 TO J7 TO MATCH INTERFACEBOARD.

DRIVEAND SHIELDEDCABLE TO MOTORAND COM

NEW TITLEBLOCK; ADDED EMI FILTER TO MOTOR

–

–

L1_C

L1_D

L2_C

L2_D

L3_C

L3_D

___–___

B10–158

B12–011

___–___

–

50956

TB3

L1_A

L1_B

L2_A

L2_B

R

Bk BK, 200

–

–

Term_Blk_3p

L3_A

L3_B

T.B. Oven, Rear

–

C

B

MATL

REV ECN ETADSNOISIVE YBRPAR

GAGE

RD–5

BK–3

Light_Pwr

RD/BK–2[1..2]

BK–3, 24VDC_RTN

22awg twisted pair

3

Bk

–

+

+

–L

CON4

M9608

24Vdc Power Supply

N

Gnd

123

4

BR–6

BL–6

14awg, 600V

Transformer_Mu lt itap

BL–4, 22awg, 600V

BR–4, 22awg, 600V

GR/Y–2

L1_C

L1_D

L2_C

L2_D

Gnd_C

Gnd_D

38605

TB2

L1_A

GR/Y–1

BL–2, 14awg, 600V

Term_Blk_AC_Gnd_3p

L1_B

Gnd_A

Gnd_B

L2_A

L2_B

5

BL–3, 22awg, 600V

BR–3, 22awg, 600V

BR–2, 14awg, 600V

D D

C C

B B

A A

Page 39

L ED

L ED

L ED

Red LEDS – T100

C21535

DRAWIN G NUM BER REV

31M H

O F

SCALE

SHEET

09 –13–10

09 –13–10 N O N E

Switches – MEC

#1052612,12m m key_cap

2

3

SW 3

50 L AKES ID E AVE . B UR L IN G TO N , VE RM O NT 0540 1

TH IS DR A W IN G IS TH E P RO PE RT Y OF G. S. BL O D G ETT CO RP O RAT ION . NEIT H ER T H IS DR AW IN G

1

D3

D2

D1

4

2

3

SW 2

1

4

2

3

SW 1

1

4

G.S. BLOD GETTCO RPORATION

___

___

__ –__ –__

__ –__ –__

–

–

–

–

DATE

DATE

SCH EM A T IC, HV 100 EM 440 V 14 K W M ENU SEL ECT

M H

G. S. BLO D GE TT C O RPO RA TI O N. UN PU BL IS H ED W ORK . A L L R IG HT S R ESE RVED

W IT H O U T TH E EXPR ESS W RITT EN PER M I SSIO N OF TH E G. S. BL O DG ETT COR PO RAT IO N .

N OR A N Y INFO R M A T IO N C O N T AIN E D HE RE IN M AY BE C OP IED O R U SED , IN W H O LE OR IN P AR T,

M H

03 –23– 12

CHAN GE D J 19 TO J 7 T O M A TCH I NT E RFA C E BOA RD .

IM P ROVE D DEP ICT IO N O F I N VE RT ER D RI V E W IRI N G.

BY

BY

AP R

D W G

Tit l e

M H

11 –10– 1 0

.015 . 03 1 .005

.XXX . XX A N GU LA R H OL E

TOLE R A NC ES UN LE S S O TH E RW ISE SPEC IF I ED

DR IVE AND SH IEL D ED CABLE TO M O TO R A ND CO M

NEW TI TLE BLO C K; ADD ED EM I F IL TE R TO M OT O R

___–__ _

B1 0–15 8

B1 2–01 1

___–__ _

–

–

R2

330

R3

R1

10K

10K

R4

R5

10K

R6

330

For Refere nce Only

330

123456789

J5

P5

1234567891011

V–3

V–4

V–5

V–6

V–7

AU X _B rd_ D 3_ Ena_ L

AU X _B rd_ D 1_ Ena_ L

AU X _B rd_ D 2_ Ena_ L

AU X_ Br d_ SW 1_ Ena_ L

101112

733 –34 2

WA GO

12

733 –31 2

V–8

R– 11

Bl– 12

Harness PN : 50178

A UX _ Br d_ D G N D

AU X_ Br d_ SW 2_ Ena_ L

AU X_ Br d_ SW 3_ Ena_ L

AU X _B rd_ + 5 Vd c _Sw _ Pw r

To VFD Control ler Aux I/O

–

–

B

C

M A T L

REV EC N ETADSNOISIVER A P R BY

GA G E

Loading...

Loading...