Page 1

CNV14E AND CNV14G

CONVECTION OVEN

INSTALLATION -- OPERATION -- MAINTENANCE

CNV14E ET CNV14G

FOURS À CONVECTION

MANUEL D’INSTALLATION -- FONCTIONNEMENT -- ENTRETIEN

BLODGETT COMBI

www.blodgett.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN R10144 Rev A (10/01)

E 2001 --- Blodgett Combi

Page 2

A PERSONAL WORD FROM BLODGETT COMBI

QUELQUES MOTS DE BLODGETT COMBI

Congratulationson yourpurchase of a BLODGETT Combi appliance. We

firmly believe that your choice has been a wise one, and trust you will receive many years of excellent service from your new Combi.

You will find that cooking with Combi appliances saves time, labor and

extensive cleaning of both the kitchen and the unit.

With Combi appliances the quality, taste, consistency, and look of your

food are improved, thus endorsing the policy to which we’ve always adhered: “For Better Cooking!”

Once you’ve had a chance to use your Combi, please tell us, your dealer

and colleagues about any creative and interesting applicationsyou have

discovered; exchange ideas with other users. Be sure to advise us or

your dealer immediately should any mechanical or technical problems

be encountered(...we’re here to help!)and above all “EnjoyCooking the

BLODGETT Combi Way!

For information on cooking, please refer to our separate cooking guide.

Toutes nos félicitations sur votre achat d’appareil de Blodgett Combi.

Nous croyons fermement que votre choix est un choix raisonnable et

nous sommes certains que vous obtiendrez de nombreuses années

d’excellent service de votre nouveau four multi-usages.

Vous allez découvrir que la cuisson dans les appareils Combi économise

le temps, le travail et le degré de nettoyage de l’appareil aussi bien que

de la cuisine.

Avec les appareil de Combi, la qualité, le goût, la consistence et l’apparence des aliments sont améliorés, s’accordant, de ce fait, avec notre

politique ”Pour une meilleure cuisson !”

Une fois que vous aurez eu la chance d’utiliser notre Combi, informez

nous, votre concessionnaire et vos collègues, de toutes les applications

nouvelles et intéressantes que vous avez découvertes ; échangez vos

idées avec d’autres utilisateurs. N’hésitez pas à nous prévenir, ou votre

concessionnaire, de tout problème mécanique ou technique que vous

pourriez rencontrer (... nous sommes ici pour vous aider) et par-dessus

tout “Régalez-vous à cuisiner à la façon BLODGETT Combi!

Pour obtenir de plus amples informations sur l’art culinaire, veuillez consulter notre livre de cuisine séparé.

Page 3

IMPORTANT

WARNIN G:IMPROPER INSTALLATION,ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENAN C E CAN CAUSE PROPERTY DAMAGE, INJURY OR DEA TH.READ THE

INSTALLA TION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

AVERTI SSEMEN T: UNE INSTALLA TI O N , UN AJUSTEMENT, UNE ALTÉRATION, UN

SERVICE OU UN ENTRETIEN NON CONFORME AUX NORMES PEUT CAUSER DES

DOMMAGESÀ LA PROPRIÉTE,DES BLESSURES OU LA MORT. LISEZATTENTIVEMENT LES DIRECTIVES D’INST A L LATION, D’OPÉRATION ET D’EN TRETI ENAV A N T

DE FAIRE L’IN S TALLATION OU L’ENTRETIEN DE CET ÉQ UI P EMEN T.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS

MUST BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE

OBTAINED BY CONTACTING YOUR LOCAL GAS SUPPLIER.

LES INSTRUCTIONS À RESPECTER AU CAS OÙ L’UTILISATEUR PERÇOIT UNE

ODEUR DE GAZ DOIVENT ÊTRE AFFICHÉES DANS UN ENDROIT BIEN VISIBLE.

VOUS POUVEZ VOUS LES PROCURER AUPRÈS DE VOTRE FOURNISSEUR DE

GAZ LOCAL.

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity

of this or any other appliance.

AVERTISSEMENT

Ne pas entreposer ni ut ilis er de l’essence ni d’aut r es vapeurs ou liquides inf la mmables dans le voisinage d e cet appariel, ni de to ut autre appareil.

The information contained in this manual is important for the proper installation,

use, and maintenance of this oven. Adherence to these procedures and instructions will result in satisfactory baking results and long, trouble free service.

Please read this manual carefully and retain it for future reference.

Les informations données dans le présent manuel sont importantes pour installer,

utiliser et entret en ir correctement ce four. Le respect de ces instructions et procédures permettra d’obtenir de bonsrésultats de cuisson et une longue durée de service sans prob lèm es . Veuillez lire le présent manuel et le conserver pour pou voir

vous y reporter à l’avenir.

Errors: Descriptive, typographic or pictorial errors are subject to correction. Specifica-

tions are subject to change without notice.

Erreurs:Les erreurs de description, de typographie ou d’illustration font l’objet de

corrections. Les caractéristiques sont sujettes à modifications sans préavis.

Page 4

Your Service Agency’s Address:

Adressedevotreagencedeservice:

Model/Modèl:

Serial Number/Numéro de série:

Your appliance was installed by/

Installateur de votre four:

Your oven’s installation was checked by/

Contrôleur de l’installation de votre four:

Page 5

Table of Contents/Table des Matières

Introduction

Description of the Blodgett Combi

Convection Oven 2.....................

Installation

Agency Approvals 3....................

Owner’s Responsibilities 4...............

Oven Location and Ventilation 5..........

Leg Attachment 6......................

Stacking 7.............................

Oven Leveling 8........................

Plumbing Connections 9................

Electrical Connections 10................

Gas Connections 11.....................

Gas Hose Restraint 13...................

Adjustments 14.........................

Final Check Lists 15.....................

Operation

Safety Information for Gas Units 16........

Gas Controls 17.........................

Standard Controls 18....................

Optional Cook & Hold 19.................

Optional Meat Probe 22..................

Maintenance

Spray Bottle Operating Procedure 23......

Cleaning and Preventive Maintenance 24...

Introduction

Description du four à convection Combi 25.

Installation

Certifications 26.........................

Responsabilités du propriétaire 27.........

Emplacement du four et mise de

niveau et Ventilation 28...................

Montage des pieds 29...................

Superposition 30........................

Mise de niveau du four 31................

Raccordement de la plomberie 32.........

Raccordement à l’électricité 33............

Raccordement a u gaz 34.................

Câble d’immobilisation du tuyau à gaz 36..

Ajustements 37.........................

Liste de vérification finale 38..............

Fonctionnement

Renseignements sur la sécurité

des appareils au gaz 39..................

Commandes du gaz 40..................

Commandes standard 41................

Cuisson et Pause en Option 42...........

Sonde thermique optionnelle 46...........

Entretien

Procédure de fonctionnement du

pulvérisateur 47.........................

Nettoyage et entretien préventif 48........

Page 6

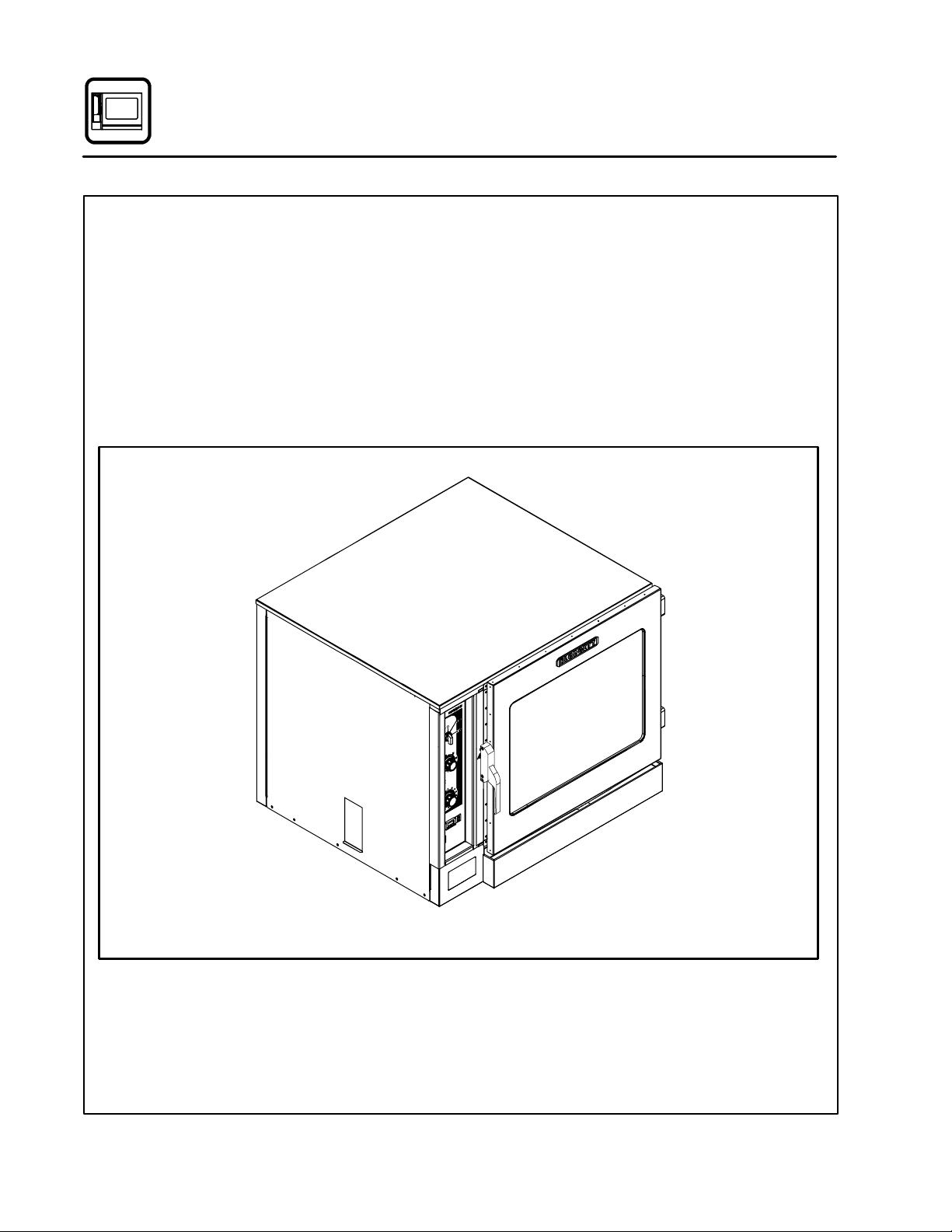

Introduction

Description of the Blodgett Combi Convection Oven

Cooking in the Combi Convection Oven differs

from cooking in a traditional deck or range oven

since heated air is constantly recirculated over the

product by a fan in an enclosed chamber. The

moving air continually strips away the layer of cool

air surrounding the product, quickly allowing the

heat to penetrate. The result is a high quality product, cooked at a lower temperature in a shorter

amount of time.

Blodgett Combi ovens are quality produced using

high-grade stainless steel with first class workmanship.

The two speed fan, which is guarded against accidental finger contact, is driven by a quiet and powerful motor.

The use of high quality insulation impedes excessive heat radiation and saves energy.

The oven has optional adjustable legs which

adapt easily to slightly uneven surfaces and optional floor stands which are designed for use with

all of the table models.

Figure 1

2

Page 7

Installation

Agency Approvals

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATIONAND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and are responsible for:

D

The installation or replacement of gas piping.

The connection, installation, repair or servicing

of equipment.

D

The installation of electrical wiring from the electric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experiencedinsuchwork,befamiliarwithallprecautions required and have complied with all requirements of state or local authorities having

jurisdiction.

U.S. and Canadian Installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1 ---Latest Edition,

the Natural Gas Installation Code CAN/CGAB149.1 or the Propane Installation Code, CAN/

CGA-B149.2 as applicable.

Reference: National Electrical Code, ANSI/NFPA

70---Latest Edition and/or Canadian Electrical

Code CSA C22.1 as applicable.

General Export Installations

Installation must conform with Local and National

installation standards. Local install atio n codes and/

or requirements may vary. If you have any questions

regarding the proper installation and/or operation of

your appliance, please contact your local distributor.

If you do not have a local distributor, please call

Blodgett Combi at 0011-802-860-3700.

3

Page 8

Installation

Owner’s Responsibilities

Installation responsibilities prior to service

startup inspection

You are entitled to a free start-up inspection service by our factory ASAP. Before a factory representative arrives to perform a startup procedure,

the owner must already have satisfied the following requirements.

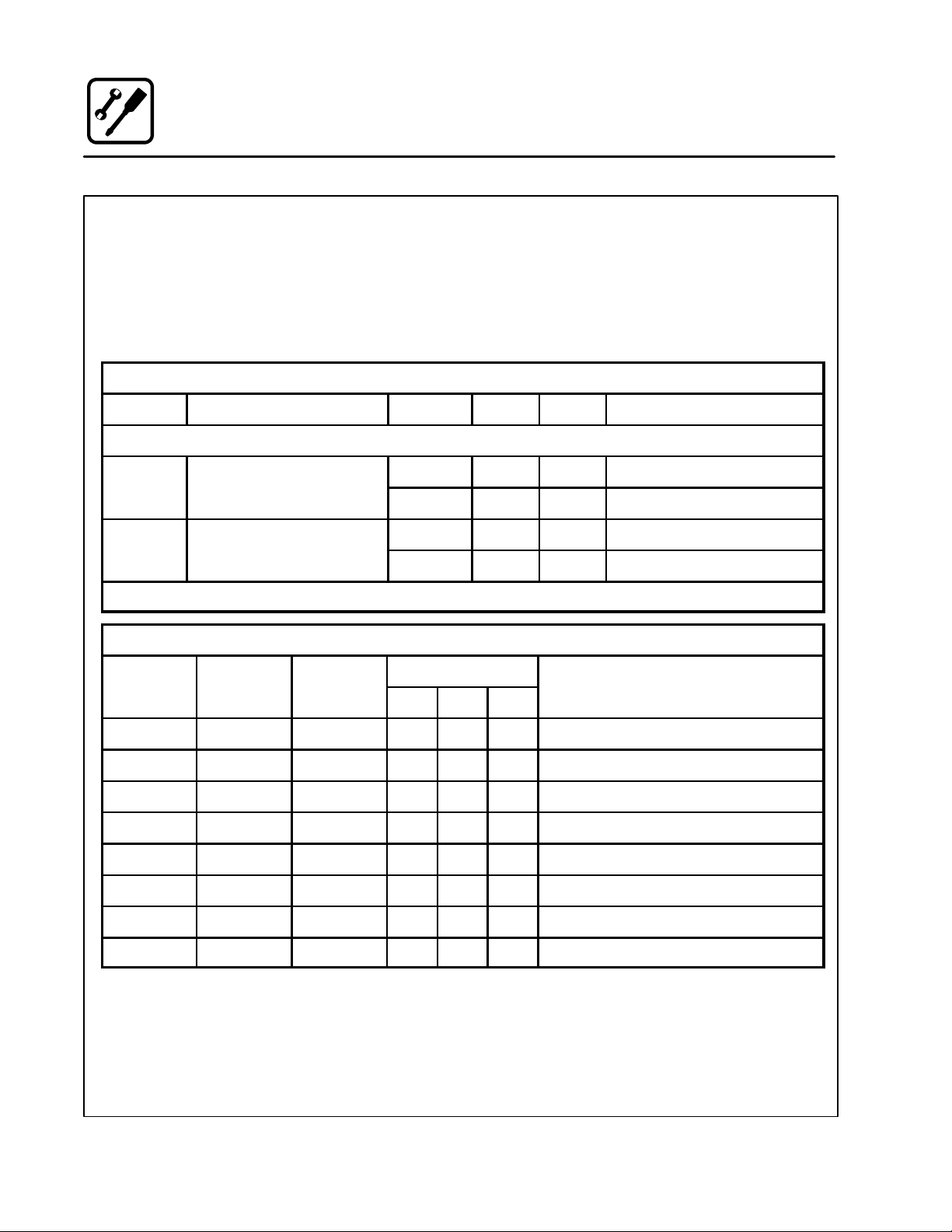

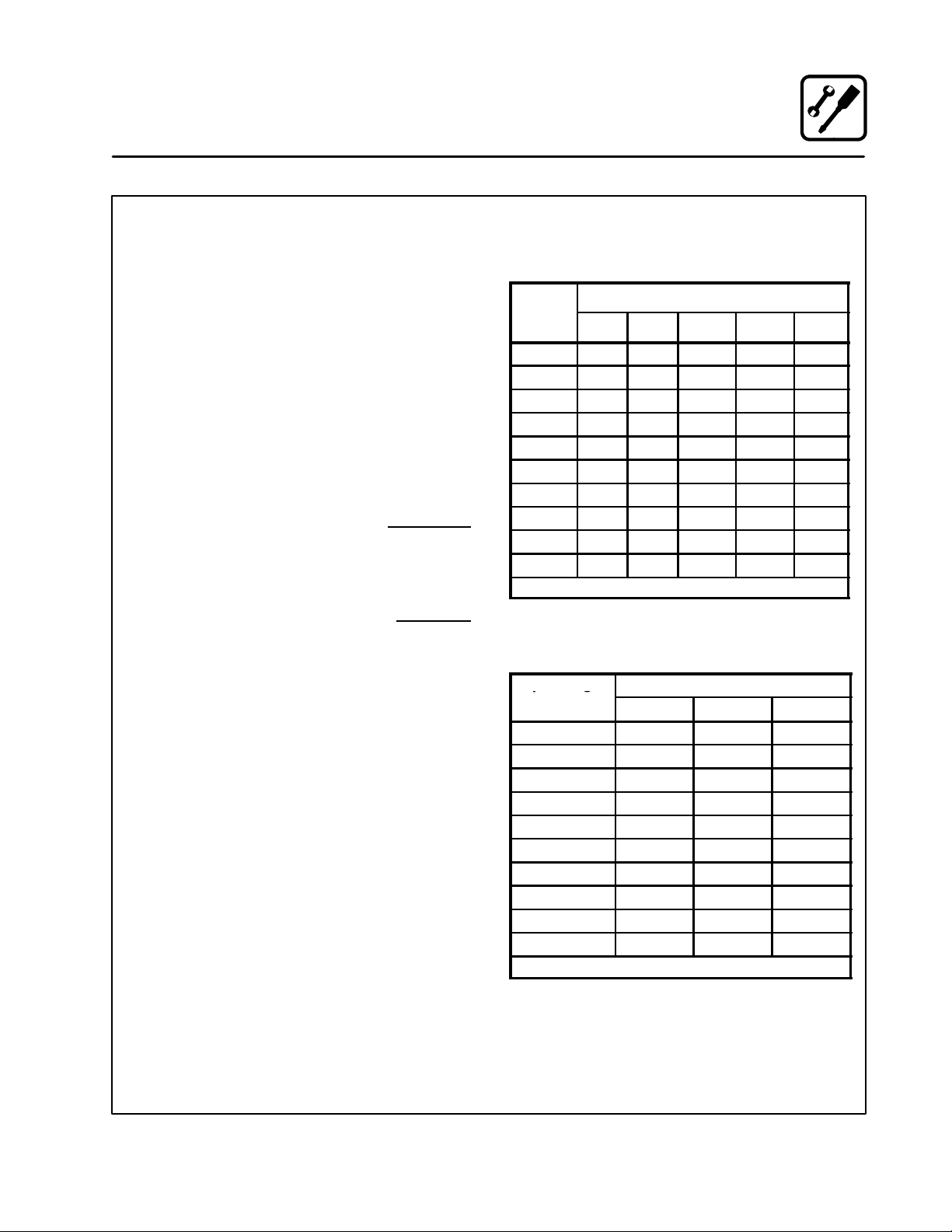

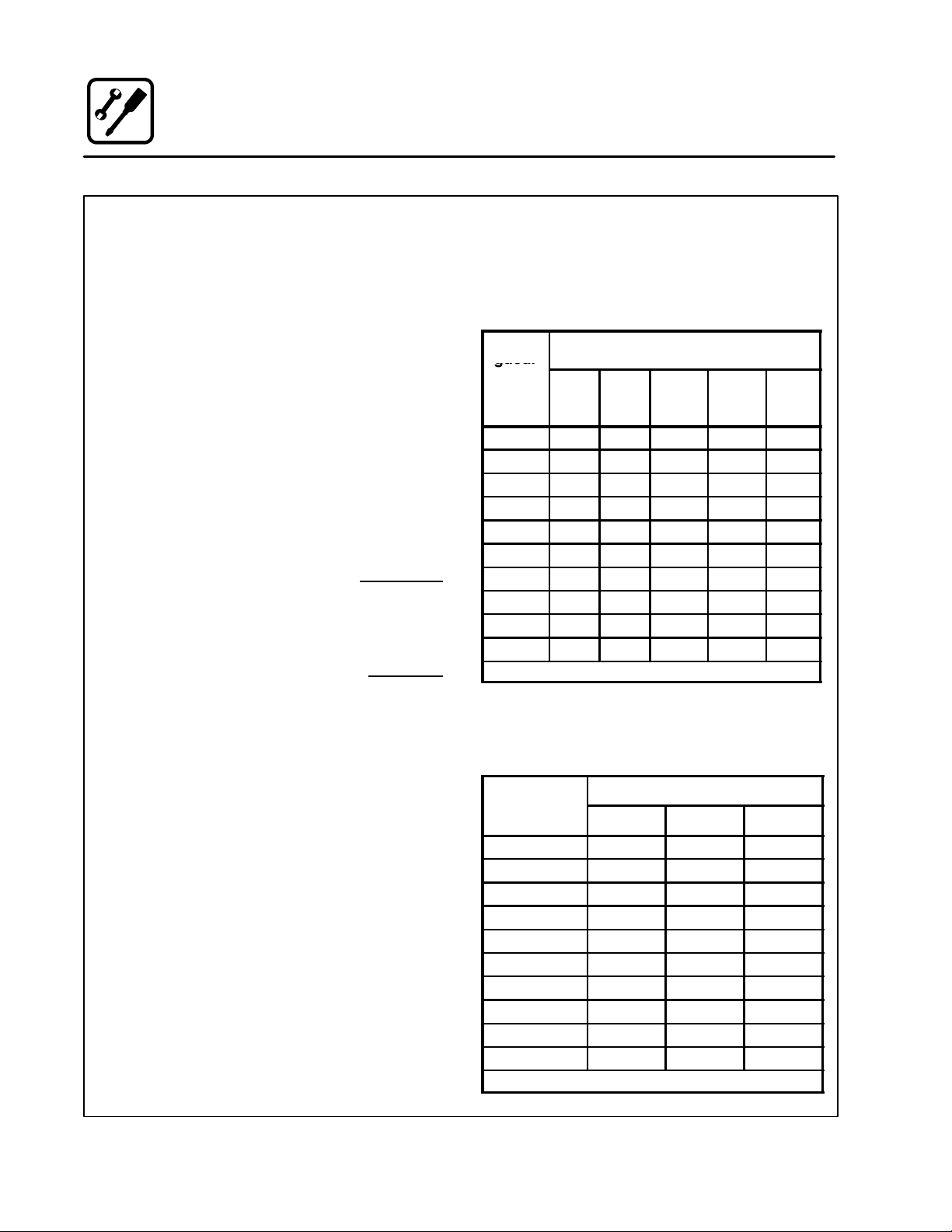

RATINGS -- GAS APPLIANCES -- CNV14G/AA

Gas Type Gas Input Voltage Phase Amps Motor

U.S. and Canadian Installations

Natural 65,000 BTU/Hr

Propane 65,000 BTU/Hr

3/4” FNPT connector for all U.S. and Canadian installations

RATINGS -- ELECTRIC APPLIANCES -- CNV14E/AA

Voltage Hz Phase

208-240 1 15 1/2HP 208-240VAC, 50/60 Hz

120 1 15 1/2HP 208-240VAC, 50/60 Hz

208-240 1 15 1/2HP 208-240VAC, 50/60 Hz

120 1 15 1/2HP 208-240VAC, 50/60 Hz

Max Load (amps)

1. Oven(s) are uncrated, stacked (if applies) and

put in place.

NOTE: Please refer to Leg Attachment and

Stacking.

Maximum shelf loading -- 100 lbs (45.5 Kg)

Motor

L1 L2 L3

208 60 1 89 89 --- 1/2HP 208-240VAC, 50/60 Hz

208 60 3 52 52 52 1/2HP 208-240VAC, 50/60 Hz

240 60 1 82 82 --- 1/2HP 208-240VAC, 50/60 Hz

240 60 3 47 47 47 1/2HP 208-240VAC, 50/60 Hz

480 60 3 23 23 23 1/2HP 208-240VAC, 50/60 Hz

380/220 50 3 25 25 25 1/2HP 208-240VAC, 50/60 Hz

415/240 50 3 27 27 27 1/2HP 208-240VAC, 50/60 Hz

400/230 50 3 26 26 26 1/2HP 208-240VAC, 50/60 Hz

4

Page 9

Installation

Oven Location and Ventilation

OVEN LOCATION

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

Certain minimum clearances must be maintained

between the oven and any combustible or noncombustible construction. See the table below.

In addition, the following clearances are recommended for servicing.

D

Oven body sides --- 12” (30cm)

D

Oven body back --- 12” (30cm)

NOTE: On gas models, routine servicing can usu-

ally be accomplished within the limited

movement provided by the gas hose restraint. If the oven needs to be moved further from the wall, the gas must first be

turned off and disconnected from the oven

before removing the restraint. Reconnect

the restraint after the oven has been returned to its normal position.

Left Side Heat Shield

Heat sources should not be near the air vents located on the left hand side of the gas appliance.

Consult the factory for optional protective side

heat shield.

CNV14 P/N R9527

MINIMUM REQUIRED

Oven

Model

Right

Side

CNV14E 1”

(25.4mm)4”(101.6mm)6”(152.4mm)

CNV14G 1”

(25.4mm)6”(152.4mm)6”(152.4mm)

CLEARANCES

Left

Side

Back

VENTILATION

The necessity for a properly designed and installed ventilation system cannot be over emphasized. The ventilation system will allow the unit to

function properly while removing unwanted vapors

and products of combustion from the operating

area.

The appliance must be vented w ith a properly designed mechanically driven exhaust hood. The

hood should be sized to completely cover the

equipment plus an overhang of at least 6” (15 cm)

on all sides not adjacent to a wall. The capacity of

the hood should be sized appropriately and provisions made for adequate makeup air.

WARNING!!

Failure to properly vent the oven can be

hazardous to the health of the operator;

and will result in operational problems,

unsatisfactory baking, and possible damage to the equipment. Damage sustained

as a direct result of improper ventilation

will not be covered by the Manufacturer’s

warranty.

U.S. and Canadian Installations

Refer to your local ventilation codes. In the absence of local codes, refer to the National ventilation code titled, “Standard for the Installation of

Equipment for the Removal of Smoke and Grease

Laden Vapors from Commercial Cooking Equipment”, NFPA-96- Latest Edition.

General Export Installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installationand/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

please call Blodgett Combi at 0011-802-860-3700.

5

Page 10

Installation

Leg Attachment

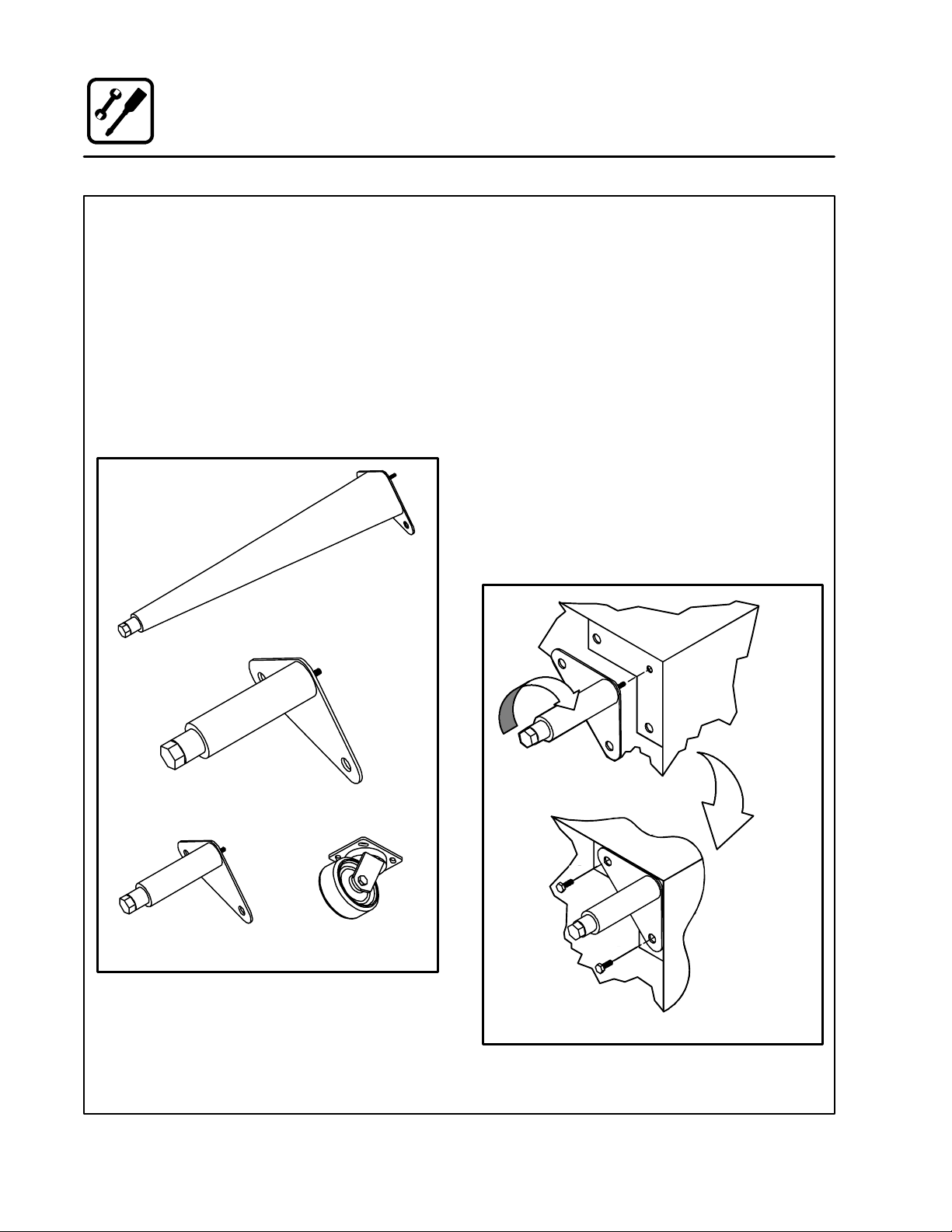

LEG OPTIONS

Legs are available in 4” (101mm), 6” (152mm) or

25” (635mm) lengths or low profile casters.

D

The 4” (101mm) legs may be used when mounting on a counter.

D

The 6” (152.4mm) legs are used on the lower

section of a double stacked appliance.

D

The 25” (635mm) legs are used for a single appliance located on the floor.

NOTE: For safety reasons, casters must not be

used with the 25” (635mm) legs.

25” (635mm) Adjustable Leg

ATTACHMENT

1. Align the threaded stud on one of the front

legs to the bolt hole located in the bottomcorner of the appliance. Turn the leg clockwise

and tighten to the nearest full turn.

2. Align the leg plate holes with the bolt holes.

Secure with the two 1/2” bolts provided.

3. Repeat the above steps with the other front

leg. If low profile casters are used, install them

with the locking casters in the front of the oven.

The rear casters do not lock. Ensure that the

locksaresetonthefrontcasters.

4. Tip the oven up on the newly installed front

legs. If casters are used, check that the locks

aresetonthefrontcasters.Repeat the above

steps for the rear legs.

5. Except for appliances with casters, level the

oven by screwing the a dj ustable feet in or out

as necessary.

6” (152,4mm) Adjustable Leg

4” (101mm) Leg

Figure 2

Low Profile Casters

Figure 3

6

Page 11

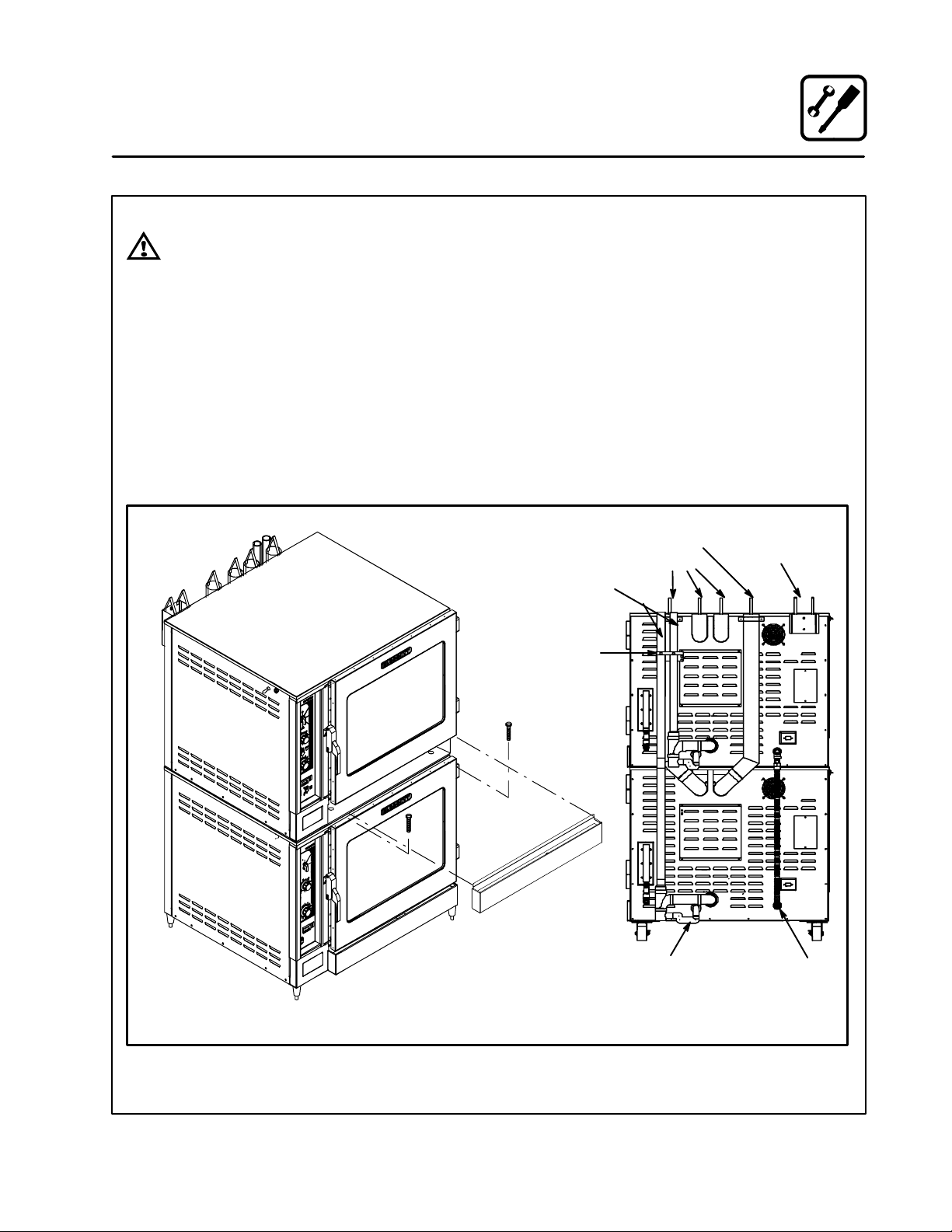

WARNING!!

Stacking should be performed by quali-

fied installation personnel only. The appliancesare heavy. Take careto use proper tools and techniques when lifting and

stacking appliances.

1. Remove the drip pan from the top appliance.

2. Attach the legs or casters to the bottom appliance.Seepage6.

3. Place the BC14 on the CNV14. Be sure all four

sides are flush.

4. Bolt the two appliances together using the

bolts provided.

Installation

Stacking

5. GAS APPLIANCES ONLY: Attach the flue

ventsasshown.

NOTE: For electric appliances proceed to

step 6.

6. Replace the drip pan.

7. Connect the gas (if applicable) and electrical.

Refer to pages 10---13.

NOTE: An optional gas manifold may be purchased

from Blodgett Combi. Order part number

R9570.

NOTE: An optional Drain Assembly/Steam Vent may

be purcha se d from Blodgett Combi. Order

part number R9251 for single or top ovens.

Order part number R9252 for bottom ovens.

Drain Assembly/Steam Vent

Optional

Mounting

Bracket

Drip Pan

BC14 on CNV14

Hot Air Flue

(BC14G &

CNV14G only)

1.125” I.D. Hose

from Drip Pan Drain

Rear View

Steam Generator

Flue

OptionalGas

Plumbing

Manifold

(BC14G &

CNV14G only)

Figure 4

7

Page 12

Installation

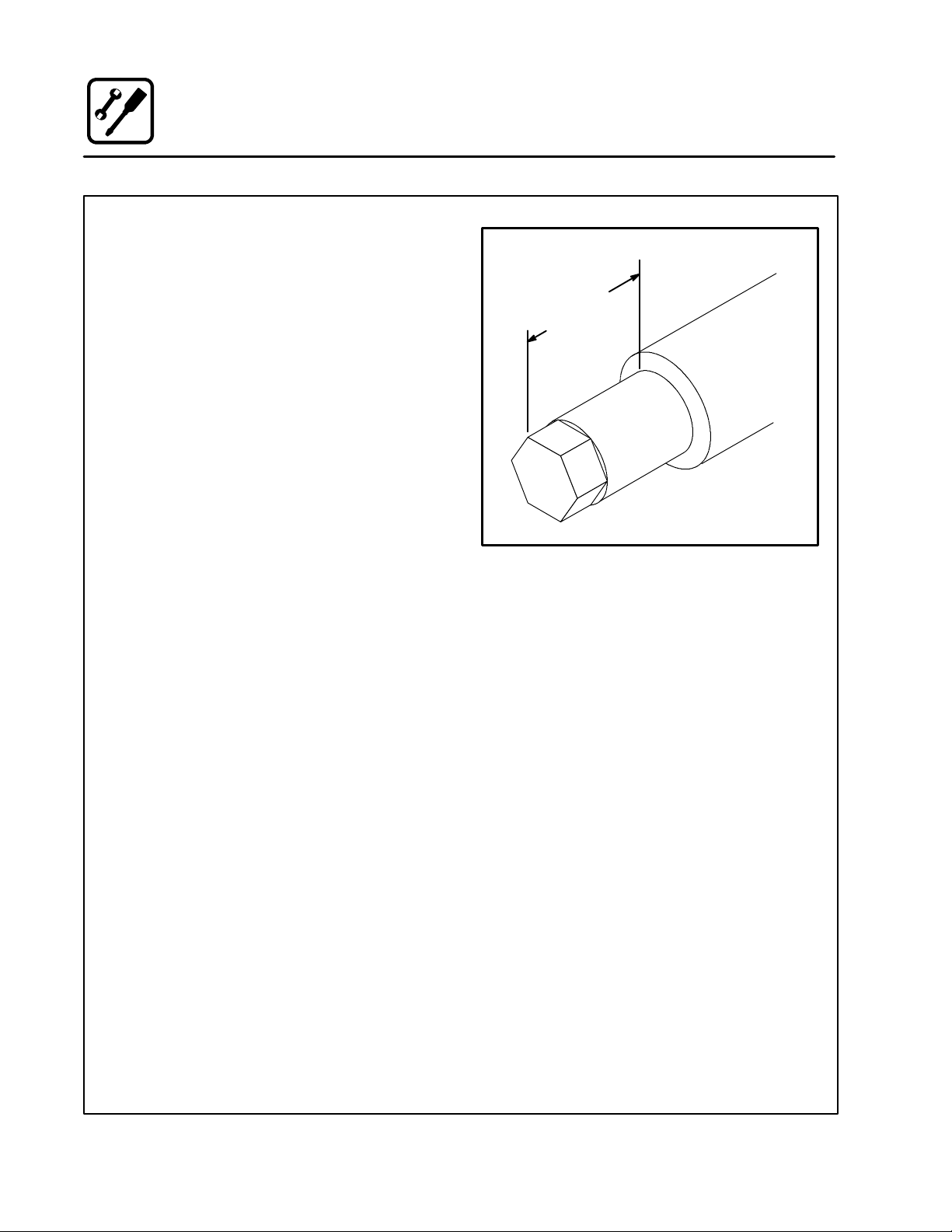

Oven Leveling

OVEN LEVELING

This oven should be set up in place.

With any stand or oven, be certain that the surface

is level, even and solid. A sloped or uneven base

may cause the appliance to function improperly.

Minor unevenness can be corrected by adjusting

the metal leg feet. The maximum adjustment of the

leg feet is 1-3/8” (35mm).

Maximum

Adjustment

1-3/8” (35mm)

Leg

Foot

Figure 5

8

Page 13

Installation

Plumbing Connections

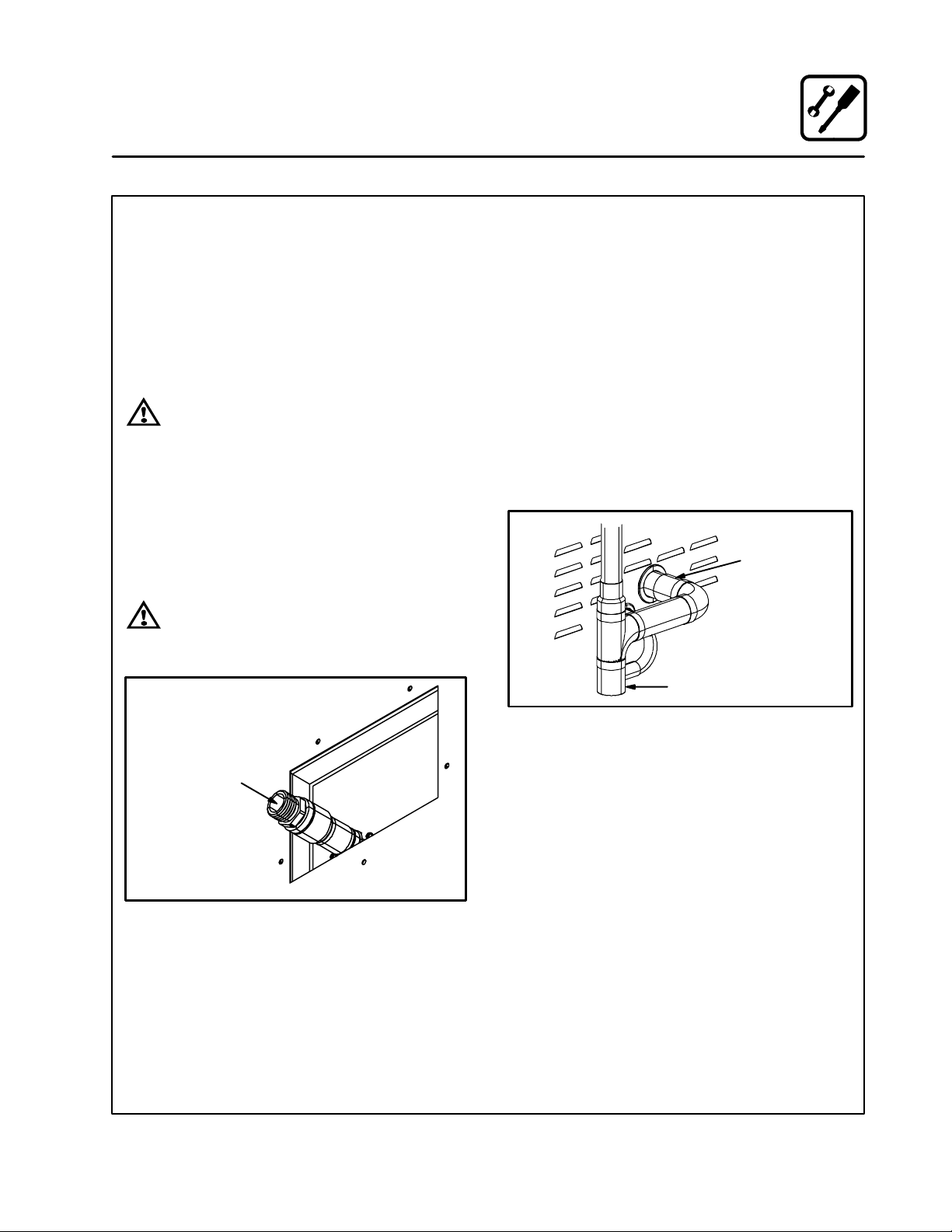

WATER CONNECTION -- CNV14E ONLY

NOTE: Hot water maximizes steam production but

is not required. Cold water may be supplied

to both inlets if hot water is not available.

Connect the appliance to quality water via a pressure hose with 3/4” (19mm) couplings. See

Figure 6 for connections. A shut off valve is to be

provided adjacent to the oven.

WARNING!!

Operating the appliance without the water

regulator installed will invalidate your warranty.

Water must meet the following minimum requirements:

D

Total Dissolved Solids (TDS) content will not exceed 30 parts per million.

D

WaterPHmustbe7.0orhigher

WARNING!!

The use of poor quality water will invali-

date your warranty.

CNV-14E

DRAIN CONNECTION

The steam vent assemblies are constructed of 2”

DWV copper piping reduced to 1-1/2 DWV pipe. If

the vent system is not purchased as an option

(R9381), Blodgett Combi recommends plumbing

the oven as shown in Figure 7.

The steam vent should be run to an open floor

drain avoiding flexible hose that could sag and allow trapped water to accumulate. The customer

must supply the piping from the oven to the drain.

Connect the drip pan drain to the steam vent with

1.125 I.D. hose.

Use the drain vent assembly and a 2” ( 50.8mm)

pipe for drain connection.

Coupling

Customer supplied

2” (50.8mm) drain

waste vent piping

Figure 7

Cold

Water

Water Connections

Rear of Appliance

Figure 6

Specific water/drain connection for City of Los

Angeles

1. Each drain line from the appliance shall be

routedwithoutdipsorsagstoterminate

above the flood level rim of an approved indirect waste receptor.

2. The appliance shall be installed in accordance

with the manufacturer’ s printed instructions

and the LAPC and LAMC, 1999 editions.

3. A backflow protection device shall be installed

on the potable water system directly ahead of

the appliance. The backflow protection device

shall be any of the following: an approved pressure type vacuum breaker installed at least 12”

above the highest point of use, a double check

valve backflow preventer or a reduced pressure

principal backflow preventer.

9

Page 14

Installation

Electrical Connections

All Models

NOTE: Electrical connections must be performed

by a qualified installer only.

Before making any electrical connections to these

appliances, check that the power supply is adequate for the voltage, amperage, and phase requirements stated on the rating name plate mounted on

the appliance.

The circuit break er that is used to provide power

to this a ppliance must have a minimum of .076”

(3mm) contact spacing. The circuit breaker must

meet all Local and National installation standards.

All appliances must be installed in accordance

with Local or National Electrical codes.

A wiring schematic is located on the inside of the

removeable side panel.

NOTE: Disconnect the power supply to the ap-

pliancebeforeservicing.

WARNING!!

Improper installation will invalidate your

warranty.

Electric Models

A strain relief for the power supply cord is required.

The installer must supply a cord bushing that meets

all Local and National installation standards.

Gas Models

U.S. and Canadian Installations

A power cord (115V or 230V ) is supplied with a

plug attached. Plug the power cord into the desired receptacle.

Export Installations

A 230V 13 amp fused power cord is supplied w ith

a plug attached. Plug the power cord into the appropriate receptacle.

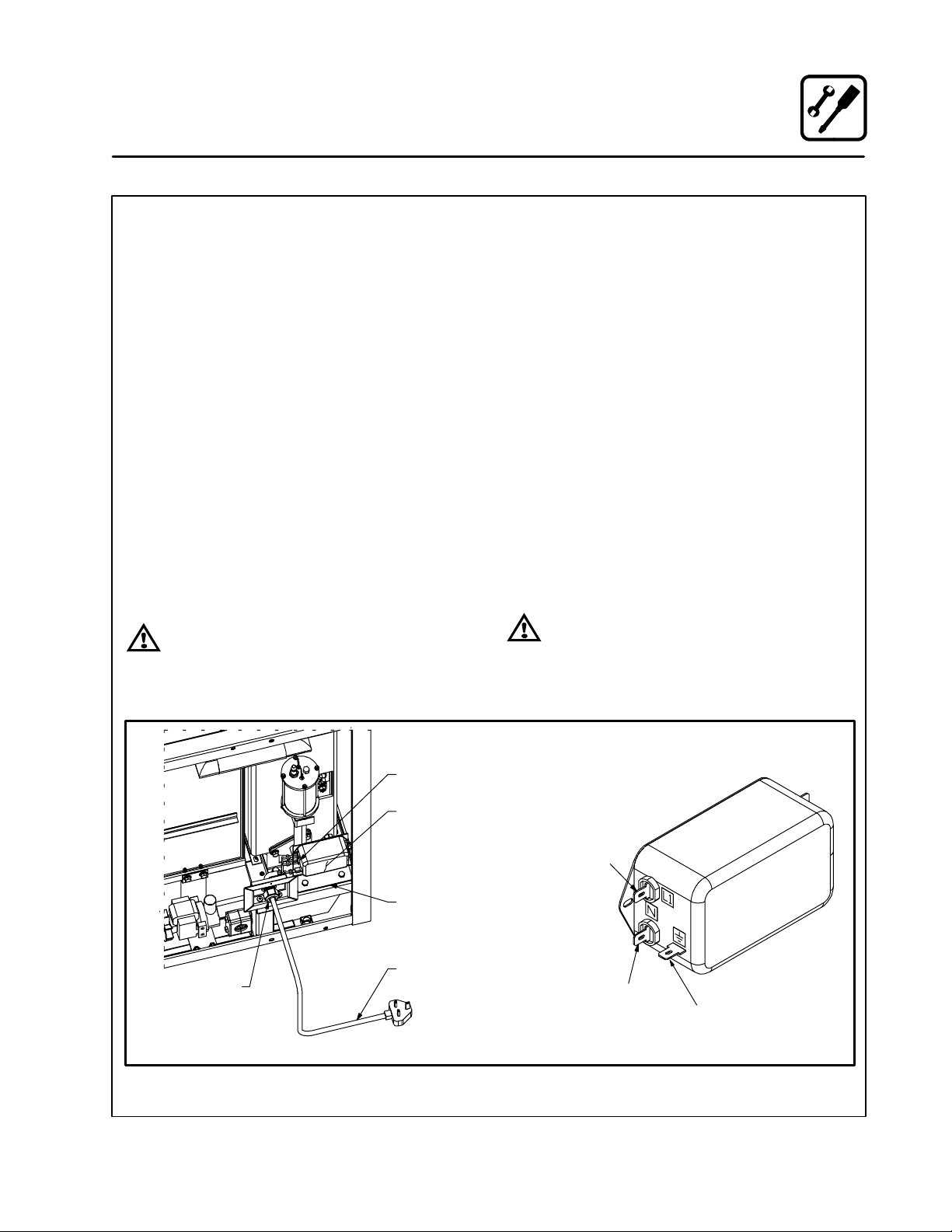

See Figure 8 for power cord routing and connections to the line filter.

WARNING!!

If the supply cord is damaged, it must be

replaced by a special cord or assembly

availablefrom themanufacturer or itsservice agent.

Strain Relief

Rear view of BC14G

with rear panel removed

Power Connections

Line Filter

Line Filter

Mounting Bracket

Power Cord with

13 amp fuse

Export Installations

Figure 8

10

Line Filter

L 1 --Brown wire

N --Blue wire

Ground Symbol --Green/Yellow wire

Page 15

Installation

L

t

h

p

g

Gas Connections

GAS PIPING

A properly sized gas supply system is essential for

maximum oven performance. Piping should be

sized to provide a supply of gas sufficient to meet

the maximum demand of all appliances on the line

without loss of pressure at the equipment.

Example:

NOTE: BTU values in the following example are

for natural gas.

You purchase a CNV14G to add to your existing

cook line.

1. Add the BTU rating of your current appliances.

Pitco Fryer 120,000 BTU

6 Burner Range 60,000 BTU

Deck Oven 50,000 BTU

Total 230,000 BTU

2. Add the BTU rating of the new oven to the total.

Previous Total 230,000 BTU

CNV14G 65,000 BTU

New Total 295,000 BTU

3. Measure the distance from the gas meter to

the cook line. This is the pipe length. Let’s say

thepipelengthis30’(9m)andthepipesize

is 1” (2.54 cm).

4. Use the appropriate table to determine the total capacity of your current gas piping.

The total capacity for this example is 375,000

BTU. Since the total required gas pressure,

295,000 BTU is less than 375,000 BTU, the

current gas piping will not have to be increased.

NOTE: The BTU capacities given in the tables are

for straight pipe lengths only. Any elbows

or other fittings will decrease pipe capacities. For example: a schedule 40 1-1/2” ell

fitting has an equivalent capacity of 4.2”

(10.2 cm) of straight pipe. Contact your local gas supplier if you have any questions.

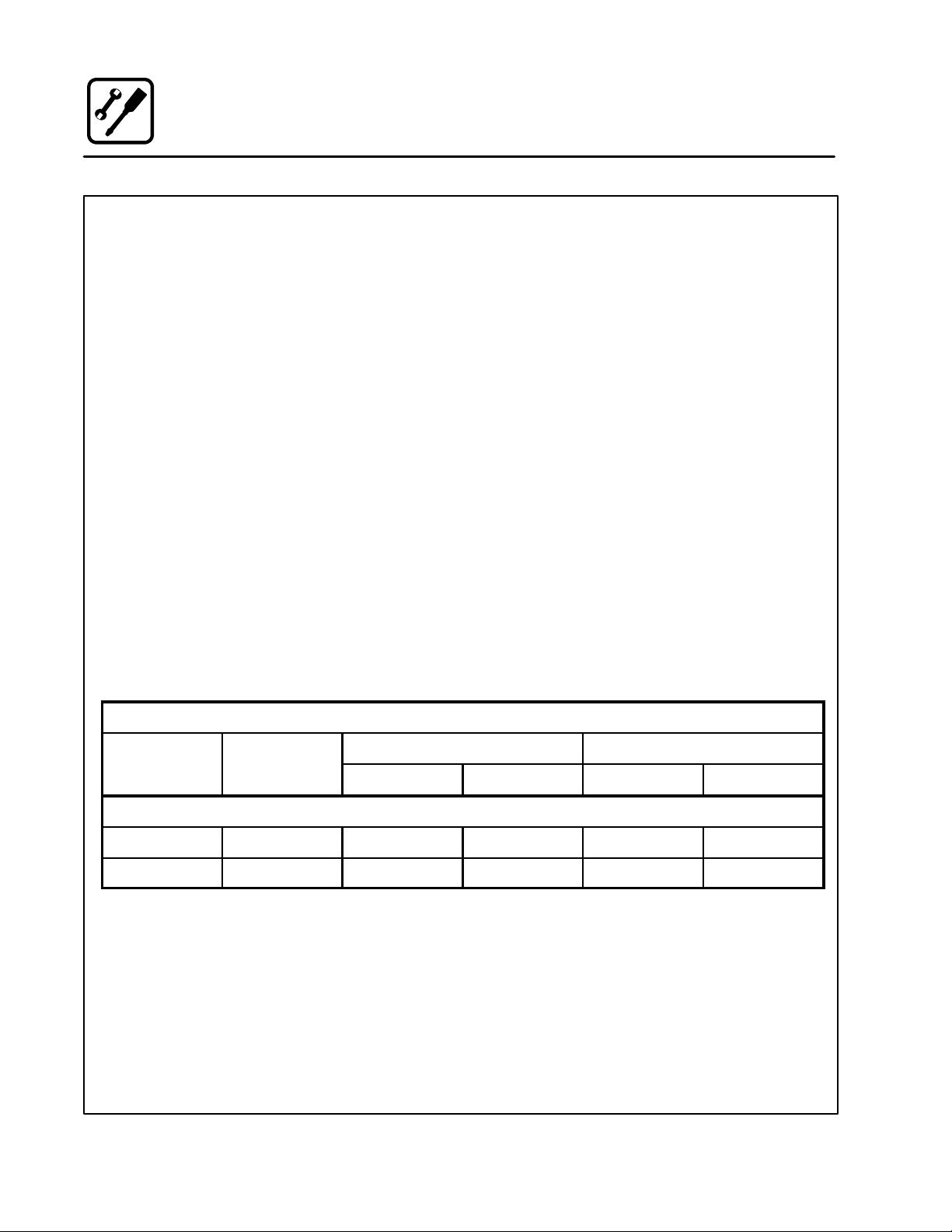

Maximum Capacity of Iron Pipe in Cubic Feet

of Natural Gas Per Hour

(Pressure drop of 0.5 Inch W.C.)

Pipe

eng

(ft)

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

From the National Fuel Gas Code Part 10 Table 10-2

Maximum Capacity of Pipe in Thousands of

BTU/hr of Undiluted P.P. Gas at 11” W.C.

(Pressure drop of 0.5 Inch W.C.)

Pipe Length

(ft)

10 608 1146 3525

20 418 788 2423

30 336 632 1946

40 287 541 1665

50 255 480 1476

60 231 435 1337

70 215 404 1241

80 198 372 1144

90 187 351 1079

100 175 330 1014

From the National Fuel Gas Code Part 10 Table 10-15

Nominal Size, Inches

3/4” 1” 1-1/4” 1-1/2” 2”

Inside Diameter, Inches

3/4” 1” 1-1/2”

11

Page 16

Installation

Gas Connections

PRESSURE REGULATION AND TESTING

The gas pressure to the appliance must be rated

for each a ppliance while the burners are on. A suf ficientgaspressuremustbepresentattheinletto

satisfy these conditions. Refer to the t able below

for correct gas pressure.

Each appliance has been adjusted at the factory

to operate with the type of gas specified on the rating plate attached to the right side of the appliance.

Each oven is supplied with a regulator to maintain

thepropergaspressure.The regulator is essen-

tial to the proper operation of the oven and

should not be removed.

DO NOT INSTALL AN ADDITIONAL REGULATOR

WHERE THE UNIT CONNECTS TO THE GAS

SUPPLY UNLESS THE INLET PRESSURE IS

GREATER THAN 14” W.C. (1/2 PSI) (37mbar).

The oven and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressuresinexcessof1/2psig(3.45kPa).

The oven must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas piping system at test pressures equal or less

than 1/2 psig (3.45kPa).

Prior to connecting the appliance, gas lines

should be thoroughly purged of all metal filings,

shavings, pipe dope, and other debris. After connection, the appliance must be checked for correct gas pressure.

U.S. and Canadian Installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1 ---Latest Edition,

the Natural Gas Installation Code CAN/CGAB149.1 or the Propane Installation Code, CAN/

CGA-B149.2 as applicable.

General Export Installations

Installation must conform with Local and National

installation standards. Local install atio n codes and/

or requirements may vary. If you have any questions

regarding the proper installation and/or operation of

your appliance, please contact your local distributor.

If you do not have a local distributor, please call

Blodgett Combi at 0011-802-860-3700.

GAS PRESSURE

Gas

Type Pressure

U. S . and Canadian Installation s

Natural 7 --- 14” W.C. .0531” dia .042” dia 3.5” W.C. 3.5” W.C.

Propane 12---14” W.C. .032” dia .026” dia 10.0” W.C. 10.0” W.C.

Inlet

Orifice Size at Sea Level Manifol d Pressure

Hot Air Steam Hot Air Steam

12

Page 17

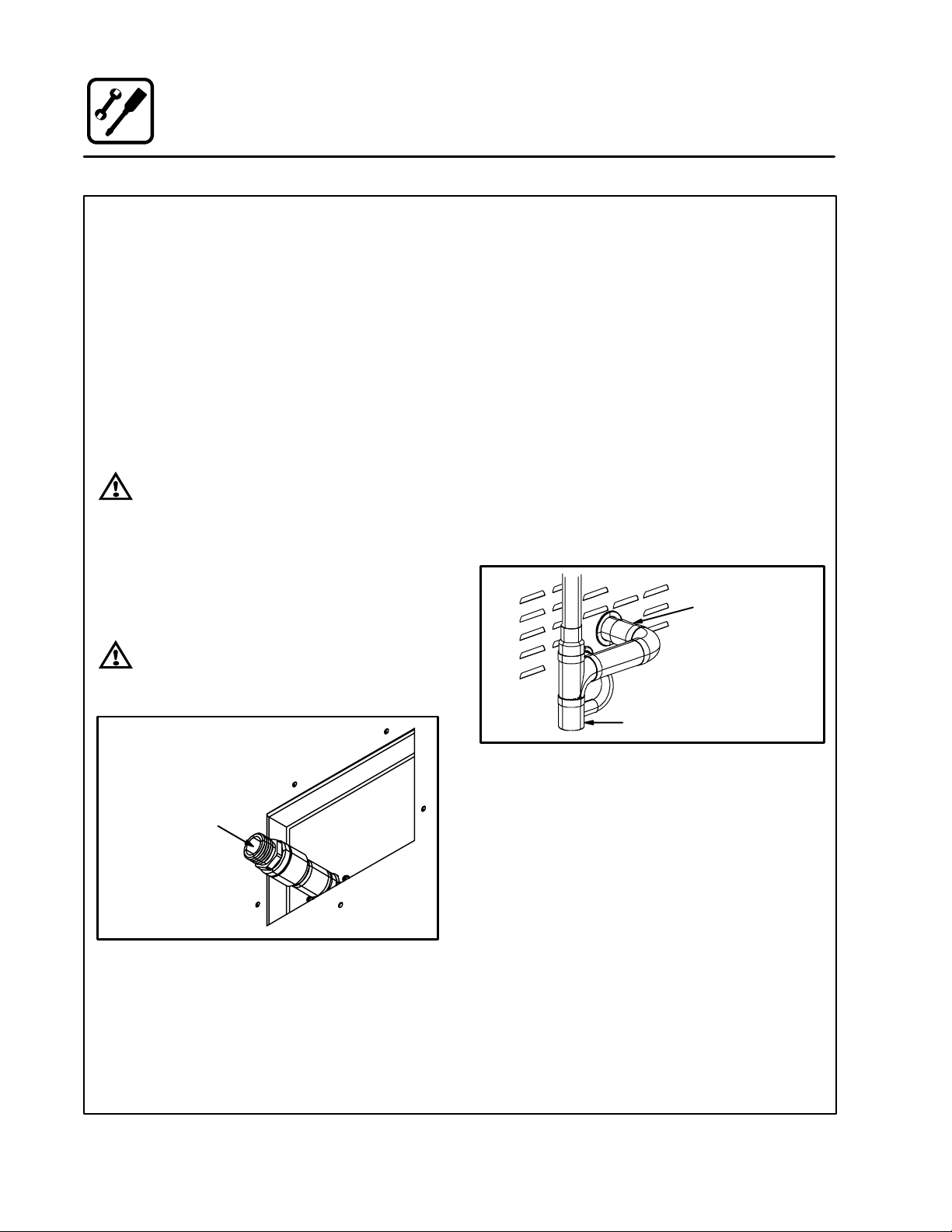

Installation

Gas Hose Restraint

If the appliance is mounted on casters, a commercial flexible connector with a minimum of 3/4” (1.9

cm) inside diameter must be used along with a

quick connect device.

The restraint, supplied with the appliance, must be

used to limit the movement of the appliance so that

no strain is placed upon the flexible connector. The

restraint should be fastened to the base frame of

the oven as close to the flexible connector as possible. It should be short enough to prevent any

strain on the connector. With the restraint fully

stretched the connector should be easy to install

and quick connect.

The restraint (ie: heavy gauge cable) should be attached without damaging the building. DO NOT

use the gas piping or electrical conduit for the attachment of the permanent end of the restraint!

Use anchor bolts in concrete or cement block. On

wooden walls, drive hi test wood lag screws into

the studs of the wall.

WARNING!!

If the restraint is disconnected for any rea-

son it must be reconnected when the appliance is returned to its original position.

U.S. and Canadian installations

The connector must comply with the Standard for

Connectors for Movable Gas Appliances, ANSI

Z21.69 or Connectors For Moveable Gas Appliances CAN/CGA-6.16 and a quick disconnect

device that complies with the Standard for QuickDisconnect Devices for Use With Gas Fuel, ANSI

Z21.41 or Quick Disconnect For Use With Gas Fuel

CAN 1-6.9. Adequate means must be provided to

limit the movement of the appliance without depending on the connection and the quick disconnect device or its associated piping.

A drip leg must be used at each appliance. Refer

to NFPA54/ANSI Z223.1 - Latest Edition (National

Fuel Gas Code) for proper drip leg installation.

General export installations

Installation must conform with Local and National

installation standards. Local install atio n codes and/

or requirements may vary. If you have any questions

regarding the proper installation and/or operation of

your appliance, please contact your local distributor.

If you do not have a local distributor, please call

Blodgett Combi at 0011-802-860-3700.

Attachment Plate

(secure with leg mount bolt)

Gas Hose

Quick Connect

Gas Supply Line

Restraint

Installation of Gas Hose and Restraint

(Single Section Shown)

Figure 9

13

IMPORTANT: Cable restraint should

be fastened as close as possible to the

flexibleconnector and short enough to

prevent any strain on the flexible connector.

At maximum stretch of shortened restraint, the flexible connector should

be easy to install and quick to connect.

Page 18

Installation

Adjustments

Before applying power to the appliance for the first

time, check for the following conditions:

j

All electrical safety provisions have been adhered to and the electrical connections are

correct.

j

The bake enhancer and holder are in their

proper positions.

j

The pan holders are inserted into the oven

cavity.

DOOR ADJUSTMENT

The door catch may be adjusted in two directions,

in and out, and up and down, using the following

procedure:

1. Adjust up and down by loosening the two

bolts holding the catch to the face of the appliance. See Figure 10 (A).

2. Make adjustments so that the leading face of

the latch is centered in the opening of the handle assembly.

3. Tighten the bolts so t hat there is no further

movement.

4. Adjust in and out by loosening the bolt on top

of t he catch. See Figure 10 (B).

5. The adjustment face is stepped so that movement is limited with the bolt tightened properly.

6. The adjustment is correct when the door

closes firmly and no steam leaks from the gasket.

The hinges can also be adjusted as follows:

1. Be certain the latch is a dj usted properly.

2. Adjust hinges so that the door back and the

appliance face are parallel. See Figure 10 (C).

3. The adjustment is correct when no steam

leaks through the gasket.

Door

B

A

Figure 10

14

C

Oven

Page 19

WARNING!!

Final check list must be performed by a

qualified installer only.

ELECTRICAL CONTROL COMPARTMENT

j

Voltage to appliance matches rating plate

PLUMBING FINAL CHECK -- CNV14E ONLY

j

Incoming water pressure w ithin appliances of

specification

j

Atmospheric vented drain in place

j

Water solenoid properly bracketed and not

leaking

j

Water feed lines intact without leaks

j

Optional Spray Hose connected properly.

Connect the optional spray hose to the fill solenoid as shown.

Installation

Final Check Lists

OVEN OPERATIONAL TESTS

NOTE: Checkstobemadebycustomerorautho-

rized service agent.

Cool Down Mode

j

Check that the fan runs with the door open.

Hot Air Mode

Turn to HOT AIR mode and set thermostat to

400_F (204_C) and verify:

j

Heat demand light is on

j

Oven is heating properly

j

Heat lights shuts off at 400_F (204_C) and

oven maintains 400_F (204_C).

j

Fan shuts off with door open.

Cold Water Supply

To

Oven Fill

Manifold

Figure 11

Hose and Spray

Option

15

Page 20

Operation

Safety Information for Gas Units

THE INFORMATION CONTAINED IN THIS SECTION IS PROVIDED FOR THE USE OF QUALIFIED

OPERATING PERSONNEL. QUALIFIED OPERATING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONTAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE OVEN AND/OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPERATIONOF THE EQUIPMENT DESCRIBED. ADHERENCE TO THE PROCEDURES RECOMMENDED HEREIN WILL ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLE-FREE SERVICE.

Please take the time to read the following safety

and operating instructions. They are the key to the

successful operation of your Blodgett Combi appliance.

SAFETY TIPS

For your safety read before operating

What to do if you smell gas:

D

DO NOT try to light a ny appliance.

D

DO NOT touch any electrical switches.

D

Use an exterior phone to call your gas supplier

immediately.

D

If you cannot reach your gas supplier, call the

fire department.

What to do in the event of a power failure:

D

Turn a ll switches t o o ff.

D

DO NOT attempt to operate the appliance until

the power is restored.

NOTE: In the event of a shut-down of any kind, al-

low a five (5) minute shut off period before

attempting to restart the oven.

General safety tips:

D

DO NOT use tools to turn off the gas control. If

the gas cannot be turned off manually do not try

to repair it. Call a qualified service technician.

D

If the oven needs to be moved for any reason,

the gas must be turned off and disconnected

fromtheappliancebeforeremovingtherestraint cable. Reconnect the restraint after the

oven has been returned to its original location.

D

DO NOT remove the control panel cover unless

the oven is unplugged.

16

Page 21

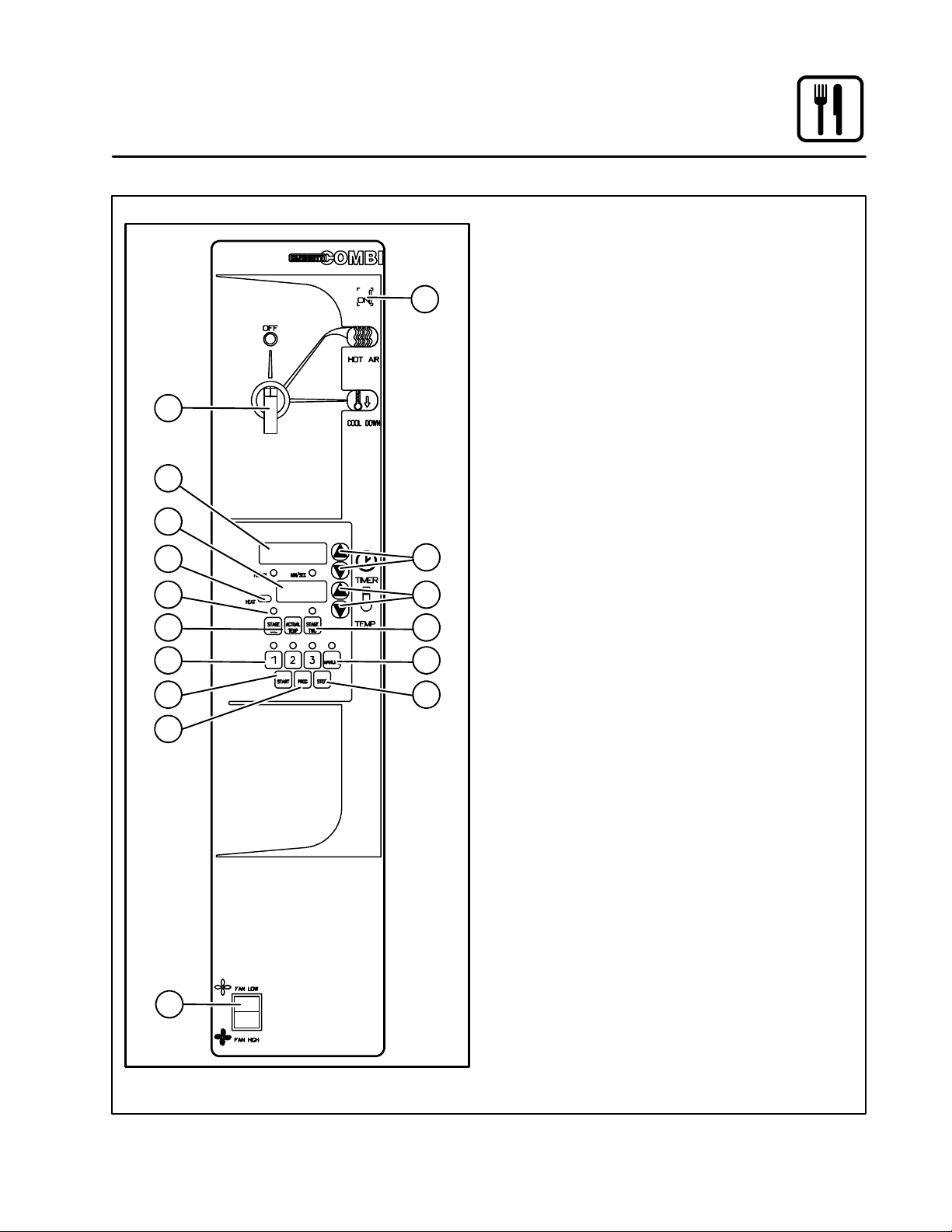

CONTROLS IDENTIFICATION

The gas controls are located behind the small

door under the control panel.

1. MANUAL GAS VALVE --- Us e t o t u r n g a s on

or off.

See View A

Operation

Gas Controls

2. GAS ON POSITION --- Turn the knob to this

position to open the gas valve.

3. GAS OFF POSITION --- Turn the knob to this

position to close the gas valve.

Gas Control

Panel Door

View A

1

3

Figure 12

2

17

Page 22

Operation

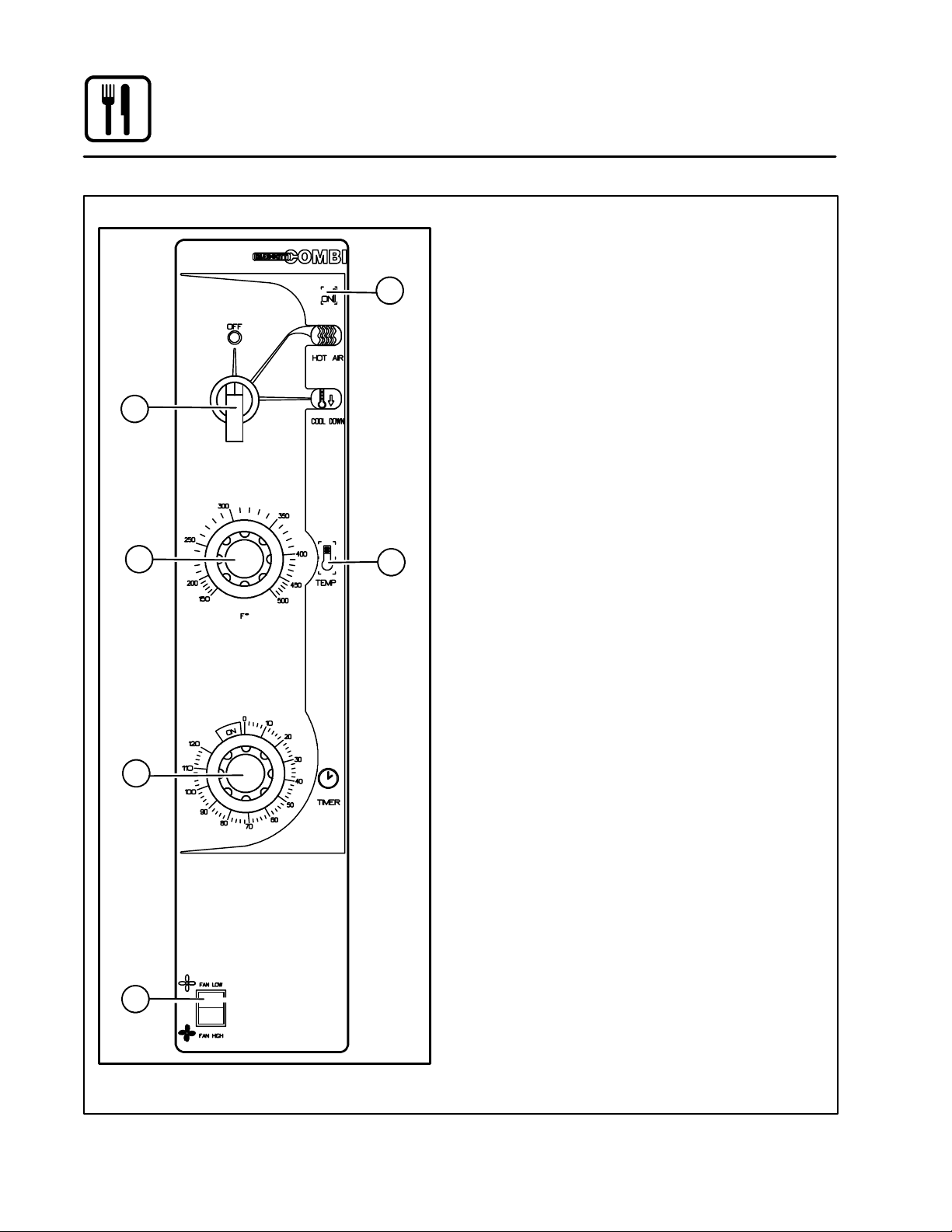

Standard Controls

2

CONTROLS IDENTIFICATION

1. POWER ON LIGHT --- when lit indicates pow-

1

er to the unit is turned on.

2. SELECTOR SWITCH --- allows selection of

Hot Air or Cool Down Mode.

3. TEMPERATURE DIAL --- used to set desired

cooking temperature.

4. HEATING INDICATOR LIGHT --- l i g h t s w h e n

the Hot Air heating is in operation.

5. TIMER DIAL --- used to set desired cook time.

6. FAN SPEED SWITCH --- u s e d t o s e l e c t L OW

or HIGH speed

OPERATION

3

5

4

1. Turn the SELECTOR switch (2) to HOT AIR.

2. Load product into the oven when ready.

3. Turn the TEMPERATURE DIAL (3) to the desired temperature.

4. Turn the TIMER DIAL (5) to the desired cook

time.

5. At the end of the specified time period, the

buzzer sounds and the a ppliance shuts off automatically. Move the timer to the STAY ON

positionto stop the buzzer and restart the unit.

6. Turn the SELECTOR switch (2) to the COOL-

DOWN position.

6

Figure 13

18

Page 23

1

2

3

5

6

8

9 10

11 12

13 14

15

4

7

Operation

Optional Cook & Hold

CONTROLS IDENTIFICATION

1. POWER ON LIGHT --- when lit indicates pow-

er to the unit is turned on.

2. MODE SELECTOR SWITCH --- c o n t r o l s p o w -

er to the oven and selection of hot air and cool

down modes. The convection fan runs with

theswitchinhotairorcooldown.

3. TIM E DISPLAY --- g i v e s c o ok t i m e .

4. TIM E ARROW KEYS --- press to enter cook

time from 00:00 to 99:59.

5. TEMPERATURE DISPLAY --- g i v e s c o o k t e m -

perature.

6. HEAT LIGHT --- when lit indicates hot air is in

operation.

7. TEMPERATURE ARROW KEYS --- pr e s s t o

enter cook temperature from 140---500_F

(60 --- 2 6 0 _C).

8. STAGE ONE LED --- when lit indicates opera-

tion or programming of stage one for the current product. Cook cycles may contain one or

two different stages.

9. ACTUAL TEMP KEY --- press to displayactual

oven temperature

10. STAGE TWO KEY --- press to enter stage two

cook time and temperature.

11. PRODUCT KEYS --- three programmable keys.

12. MANUAL PRODUCT KEY --- d e f a u lt p r o d u c t

key used for manual and programmed cooking.

13. START KEY --- press to begin a cook cycle.

14. STOP KEY --- press to silence audible alarms

and pause or cancel cook cycles.

15. PROGRAM KEY --- press to enter program-

ming mode and save programmed settings.

16. FAN SPEED SWITCH --- u s ed t o s e l e c t LO W

or HIGH speed

16

Figure 14

19

Page 24

Operation

Optional Cook & Hold

MANUAL OPERATION

1. Turn the SELECTOR SWITCH (2) to HOT AIR.

The LED above the manual key lights.

2. Press the TEMPERATURE ARROW KEYS (7)

to set the stage one cook temperature.

3. Press the TIME ARROW KEYS (4) to set the

stage one cook time.

4. Press the STAGE TWO KEY (10).

NOTE: Stage two can be used for either a

hold mode or a second cook temperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

5. Press the TEMPERATURE ARROW KEYS (7)

to set the stage two cook temperature.

6. Press the TIME ARROW KEYS (4) to set the

stage two cook time.

7. Press the START KEY (13) to begin the cook

cycle. The STAGE ONE LED (8) lights. The

TIME DISPLAY (3) counts down the stage one

cook time.

If stage two is selected an alarm sounds a t the

end of stage one. The time display counts

down the stage two cook time.

8. When all cook stages are complete the TIME

DISPLAY (3) flashes 00:00, the TEMPERATURE DISPLAY (5) flashes 0 and an audible

alarm sounds. Press the STOP KEY (14) to silence the alarm. The control maintains the

stage one cook temperature.

9. Turn the SELECTOR SWITCH (2) to OFF to

shut down the oven.

NOTE: Time and temperature settings may be

changed at any time during manual operation. Press the time arrow keys to change

the cook time. Press the temperature arrow keys to change the cook temperature.

PROGRAMMED OPERATION

NOTE: See page 21 for programming instruc t io ns.

1. Turn the SELECTOR SWITCH (2) to HOT AIR.

2. Press t he desired PRODUCT KEY (11). The

LED above the selected key lights.

3. Press the START KEY (13) to begin the cook

cycle. The STAGE ONE LED (8) lights. The

TIME DISPLAY (3) counts down the stage one

cook time.

NOTE: Press the STOP KEY (14) once to pause

an active stage one cycle. Press the

START KEY (13) to resume.

NOTE: Press the STOP KEY (14) twice to can-

cel an active stage one cycle.

4. An alarm sounds a t the end of stage one The

time display counts down the stage two cook

time.

NOTE: Press the STOP KEY (14) once to can-

cel an active stage two cycle. Stage

two cycles cannot be paused.

5. When all cook stages are complete, the TIME

DISPLAY (3) flashes 00:00, the TEMPERATURE DISPLAY (5) flashes 0 and an audible

alarm sounds. Press the STOP KEY (14) to silence the alarm. The control maintains the

stage one cook temperature.

20

Page 25

Operation

Optional Cook & Hold

PROGRAMMING THE PRODUCT KEYS

1. Turn the SELECTOR SWITCH (2) to HOT AIR.

2. Press the desired PRODUCT KEY (11).

3. Press and hold the PROGRAM KE Y (15) for

five seconds. The control beeps. The product

key LED and STAGE ONE LED (8) light.

4. Press the TEMPERATURE ARROW KEYS (7)

to set the stage one cook temperature.

5. Press the TIME ARROW KEYS (4) to set the

stage one cook time.

6. Press the STAGE TWO KEY (10).

NOTE: Stage two can be used for either a

hold mode or a second cook temperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

7. Press the TEMPERATURE ARROW KEYS (7)

to set the stage two cook temperature.

8. Press the TIME ARROW KEYS (4) to set the

stage two cook time.

9. Press and hold the PROGRAM KEY (15) to

save the program settings.

PROGRAMMING THE MANUAL KEY

NOTE: The manual key may be used for manual

andprogrammedcooking.

1. Turn the SELECTOR SWITCH (2) to HOT AIR.

2. Press the MANUAL KEY (12). The LED above

the manual key lights.

3. Press the TEMPERATURE ARROW KEYS (7)

to set the stage one cook temperature.

4. Press the TIME ARROW KEYS (4) to set the

stage one cook time.

5. Press the STAGE TWO KEY (10).

NOTE: Stage two can be used for either a

hold mode or a second cook temperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

6. Press the TEMPERATURE ARROW KEYS (7)

to set the stage two cook temperature.

7. Press the TIME ARROW KEYS (4) to set the

stage two cook time.

8. Press and hold the PROGRAM KEY (15) to

save the program settings.

NOTE: Time and temperature settings may be

changed at any time during operation of a

programmed manual key. Press the time

arrow keys to changethe cook time. Press

the temperature arrow keys to change the

cook temperature.

21

Page 26

Operation

Optional Meat Probe

CONTROLS IDENTIFICATION

1. MEAT PROBE SWITCH --- c o n t r o l s p ow e r t o

the meat probe.

2. MEAT PROBE CONTROL --- u s e to se t t h e d e -

sired probe temperature. Indicates the actual

temperature of the product

3. MEAT PROBE CONNECTOR --- re c e p t a c l e

for the plug in meat probe.

NOTE: For sanitation purposes it is recom-

mended that the meat probe remain

plugged into the front panel receptacle at all times.

OPERATION

Measuring the product core temperatures during

long roasting periods is very practical. It is especiallyimportant for products such as Roast Beef to

reach a specific internal temperture.

Place the probe through to the middle of the product’s thickest section. B e sure the probe does not

touch any bone and the tip is not in a fat pocket.

These conditions can ca use inaccurate readings.

1. Set the MODE SELECTOR Switch to Hot Air.

2. Turn the MEAT PROBE Switch (1) to ON.

3. Toset the desired core temperature press and

hold the * BUTTON (4) on the MEAT PROBE

CONTROL (2).

Use the up arrow key (6) to increase the setpoint temperature. Use the down arrow key

(5) to decrease the setpoint temperature.

4. Set the TIMER to STAY ON. The cooking process runs automatically.

When the selected core temperature is

reached, the buzzer will sound and the ap pliance shuts off automatically.

The temperature and mode can by changed

at any time during the process.

5. Shut the appliance off by setting all switches

to OFF.

NOTE: When setting the internal temperature, be

sure to allow for carry-over cooking after

the roast is removed from the oven

3

1

2

4 5 6

Figure 15

22

Page 27

Maintenance

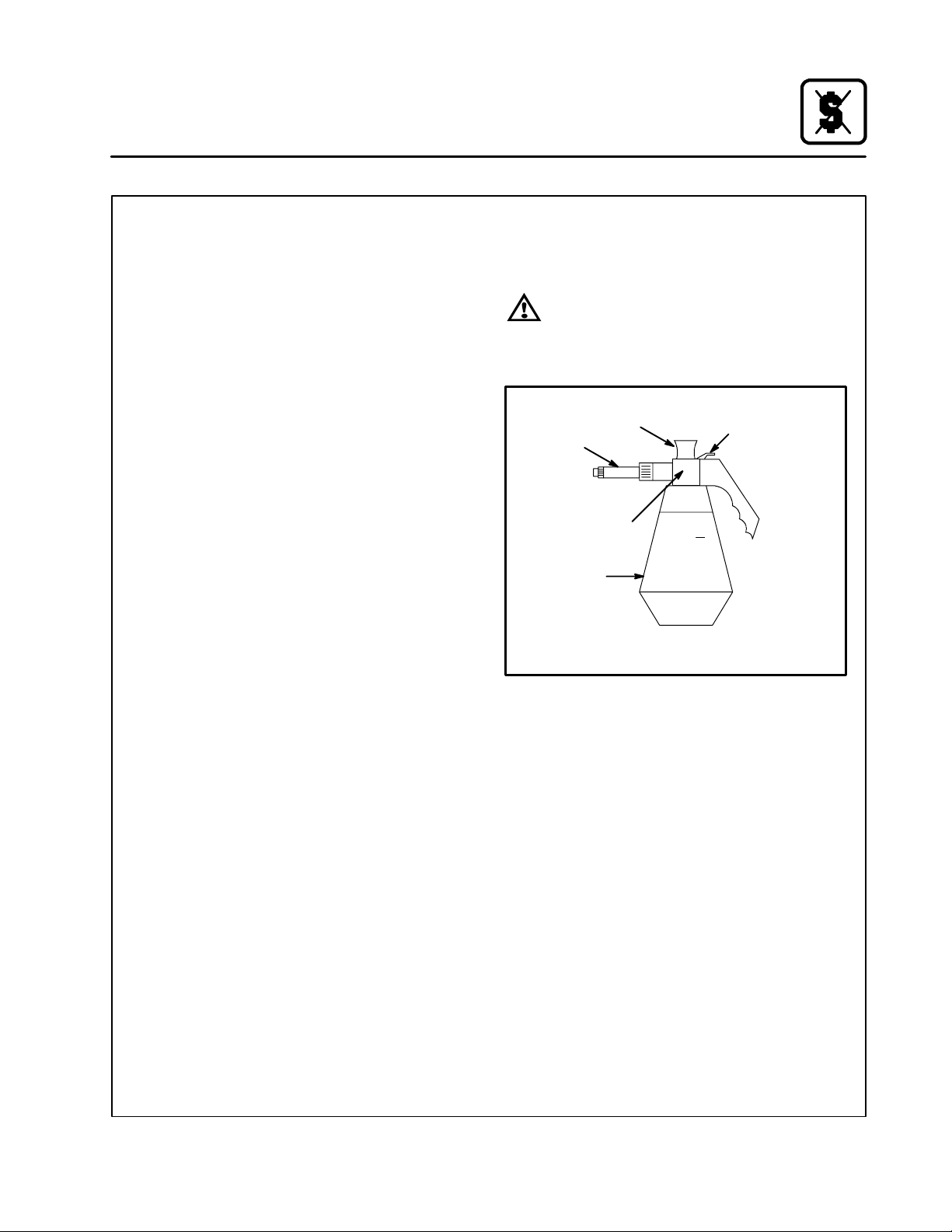

Spray Bottle Operating Procedure

NOTE: Use good, non-toxic industrial stainless

steel cleaner. DO NOT use corrosive cleaners on the Oven/Steamer.

1. Unscrew the sprayerheadandfill thecontainer to the MAX mark. Screw the head assembly

on firmly to ensure an airtight seal. The liquid

must be clean and free from foreign matter. Do

not overfill - space must be left for compressing air.

2. Tobuilduppressure,pumpapproximately20

full strokes when the container is filled with liquid. The higher the pressure, the finer the

spray. If the container is only partially filled,

then more pumping is required to compress

the additional air space.

3. Tospray, depress the trigger with your thumb.

4. After a period of spraying, the pressure will

drop. Restore the pressure by operating the

air pump.

5. Release pressure after use by inverting the

spray head and depressing the trigger or by

slowly unscrewing the spray head assembly

which will allow air to escape from around the

filling aperture.

6. After use, rinse the spray bottle with clean water and check that the hole in the nozzle is perfectly clean and clear. Warm water (not hot)

used with a household detergent is a useful

cleaning agent for this purpose.

NOTE: Further information can be found in the in-

struction leaflet supplied with your spray

bottle.

WARNING!!

Protective clothing and eyewear should

be worn while using cleaning agents.

Spray

Head

Pressure

Vessel

Clean the pump 2 or 3 times per week with warm water

Pressure Pump

Pump

MAX

Spray Trigger

Figure 16

Complete Spray Bottle --- P/N R0006

Spray Head Repair Kit --- P/N R6332

23

Page 28

Maintenance

Cleaning and Preventive Maintenance

CLEANING THE INTERIOR

Daily cleaning of the appliance is essential for sanitation, and to ensure against operational difficulties. Use an oven cleaning detergent in conjunc tion with the supplied spray bottle.

NOTE: DO NOT use corrosive cleaners!

1. Cool the oven down to 140_F(60_C).

2. Fillthespraybottleand pump air intothecontainer w ith the pressure pump.

3. Spray the interior of the oven with a cleaning

solution.

NOTE: Never spray water into the unit when

the temperature is above 212_F

4. Let the cleaner work for 10 to 20 minutes with

the oven off.

5. Rinse the oven interior with the hose and

spray assembly.

NOTE: The interior cavity should never be

scoured or scraped.

CLEANING THE EXTERIOR

The exterior of the appliance may be cleaned and

kept in good condition with a light oil. Saturate a

cloth and wipe the appliance when it is cold;wipe

drywithacleancloth.

WARNING!!

DO NOT spray the outside of the appliance

with water or clean with a water jet.

PREVENTIVE MAINTENANCE

The best preventive maintenance measures are

the proper initialinstallationof the equipment and

a program for cleaning and deliming the appliance

routinely. The Oven/Steamer requires no lubrication. Contact the factory, the factory representative or a local Blodgett Combi service company to

perform maintenance and repairs should they be

required.

24

Page 29

Introduction

DescriptiondufouràconvectionCombi

Lacuissondansunfouràconvectiondiffèredela

cuisson dans un four de cuisine ordinaire en ce

sens que de l’air chaud circule en perma nence a utour de l’aliment cuit, sous l’effet d’ un ventilateur

enfermé dans une enceinte spéciale. Le mouve ment continu de l’air,en éliminant constamment la

couche d’air froid qui se formerait autrement autour de l’aliment, permet la pénétration plus rapide

de la chaleur. Il en résulte un aliment de qualité

comparable à ceux préparés dans un four ordinaire, mais cuit à température inférieure et en moins

de temps.

Les fours Combi de Blodgett sont des appareils

haut de gamme fabriqués en acier inoxydable de

première qualité en faisant appel à des procédés

supérieurs.

Le ventilateur à deux vitesses est doté d’un dispositif de protection pour les doigts et alimenté par

un puissant moteur silencieux.

L’isolant de haute qualité empêche un rayonnement thermique excessif et aide à conserver

l’énergie.

En option, des pieds réglables et des supports

permettent d’adapter le four aux surfaces inégales

et à tous les modèles de table.

Figure 1

25

Page 30

Installation

Certifications

LES PRÉSENTES CONSIGNES D’INSTALLATION

SONT DESTINÉES AU PERSONNEL D’INSTALLATION ET D’ENTRETIEN QUALIFIÉ SEULEMENT. TOUTE INSTALLATION OU TOUT ENTRETIEN EFFECTUÉ PAR DES PERSONNES NON

COMPÉTENTES POURRAIENT ENDOMMAGER

LE FOUR OU CAUSER DES BLESSURES.

Le terme personnel d’installation qualifié désigne

une personne, une entreprise, une société ou une

organisation assumant, elle-même ou par l’entremise d’un représentant, les responsabilités suivantes :

D

la pose ou le remplacement des tuyaux de gaz.

Le raccordement, la mise en service, la réparation ou l’entretien du matériel.

D

La pose du câblage électrique à partir du compteur, de la boîte de distribution principale ou de

la prise jusqu’à l’appareil.

Le personnel qualifié doit détenir de l’expérience

dans ces domaines, connaître toutes les mesures

de sécurité pertinentes et respecter les normes de

la province ou des autorités locales.

Mises en service américaines et canadiennes

La mise en service doit respecter les normes locales ou, en l’absence de tels normes, les règlements suivants : National Fuel Gas Code,

NFPA54/ANSI Z223.1 --- dernière édition, le Code

d’installation du gaz naturel CAN/CGA-B149.1 ou

le Code d’installation du propane, CAN/CGAB149.2,selonlecas.

Référence : National Electrical Code, ANSI/NFPA

70 --- dernière édition ou le Code canadien de

l’électricité CSA C22.1,selonlecas.

Mise en service dans les autres pays

L’installation doit respecter les normes nationales

et locales, qui varient selon le pays. Si vous avez

des questions sur les méthodes d’installation acceptables ou sur le fonctionnementde votre appareil, veuillez communiquer avec votre détaillant.

S’il n’y a aucun détaillant dans votre région, veuillez communiquer avec Blodgett Combi au

0011-802-860-3700.

26

Page 31

Installation

Responsabilités du propriétaire

Responsabilités de l’installation avant l’inspection de mise en service

Vous avez droit à une inspection de mise en service

gratuite effectuée dès que possible par notre représentant. Avant que cette personne se présente pour

effectuer la mise en service, vous devez vous assurer de satisfaire déjà aux exigences suivantes :

CARACTÉRISTIQUES TECHNIQUES -- APPAREILS AU GAZ -- CNV14G/AA

Type d e gaz Entrée Ten sio n Phase Intensité Moteur

Installations canadiennes et américaines

Naturel 65 000 BTU/h

Propane 65 000 BTU/h

Connecteur de 3/4 po FNPT pour toutes les installations canadiennes et américaines

CARACTÉRISTIQUES TECHNIQUES -- APPAREILS ÉLECTRIQUES -- CNV14E/AA

Ten sio n Fréquence Phase

208-240 1 15 1/2 HP 208-240 V c.a., 50/60 Hz

120 1 15 1/2 HP 208-240 V c.a., 50/60 Hz

208-240 1 15 1/2 HP 208-240 V c.a., 50/60 Hz

120 1 15 1/2 HP 208-240 V c.a., 50/60 Hz

Charge maximale

(ampères)

1. Le four est déballé, empilé (s’il y a lieu) et mis

en place.

REMARQUE: Veuillez consu lte r la section Mon-

tage des pieds et Superpositio n .

Charges maximales sur une tablette -- 45.5 kg

(100 lb)

Moteur

L1 L2 L3

208 60 1 89 89 --- 1/2 HP 208-240 V c.a., 50/60 Hz

208 60 3 52 52 52 1/2 HP 208-240 V c.a., 50/60 Hz

240 60 1 82 82 --- 1/2 HP 208-240 V c.a., 50/60 Hz

240 60 3 47 47 47 1/2 HP 208-240 V c.a., 50/60 Hz

480 60 3 23 23 23 1/2 HP 208-240 V c.a., 50/60 Hz

380/220 50 3 25 25 25 1/2 HP 208-240 V c.a., 50/60 Hz

415/240 50 3 27 27 27 1/2 HP 208-240 V c.a., 50/60 Hz

400/230 50 3 26 26 26 1/2 HP 208-240 V c.a., 50/60 Hz

27

Page 32

Installation

Emplacement du four et mise de niveau et Ventilation

EMPLACEMENT DU FOUR

Il est important de bien choisir l’emplacement de votrefourafind’enaugmenterlesperformanceset

l’utilité.

Vous devez conserver un dégagement minimal entre le four et toute construction combustible ou non

combustible. Consultez le tableau ci-dessous.

De plus, il est recommandé de respecter les dégagements suivants pour l’entretien.

D

Parois latérales du four --- 30 cm (12 po)

D

Paroi arrière du four --- 30 cm (12 po)

REMARQUE:Pour les modèles à gaz, il est habi-

tuellement possible d’effectuer l’entretien courant sans être gêné par le

dispositif de retenue du tuyau à gaz.

S’il devient nécessaire d’éloigner da vantagelefourdumur,vousdevez

d’abord fermer l’alimentation de gaz

et débrancher le tuyau du four avant

de retirer le câble d’immobilisation.

Remettezle câble en place lorsquele

four est remis à sa position normale.

Écran thermique -- côté gauche

Il ne doit y avoir aucune source de chaleur à proximitédesorificesd’aérationsituésducôtégauche

de l’appareil à gaz. Communiquez avec le fabri cant pour obtenir un écran thermique additionnel

(offert en option) adapté au four BC14.

CNV14 Numéro de pièce R9527

DÉGAGEMENT ACCEPTABLE

Modèle

du fo ur

CNV14E 25,4 mm

CNV14G 25,4 mm

Côté droit Côté

gauche

101,6 mm

(1 po)

(1 po)

(4 po)

152,4 mm

(6 po)

Arrière

152,4 mm

(6 po)

152,4 mm

(6 po)

VENTILATION

On ne saurait trop insister sur la nécessité de prévoir un système d’aération bien conçu. Un tel

système permettra au four de bien fonctionner,

tout en évacuant les vapeurs et produits de com bustion gênants de la zone d’utilisation.

L’extraction des fumées de combustion de l’appareil

doit se faire au moyen d’un groupe d’aspiration à

commande mécanique. Celui-ci doit être dimensionné de façon à ce qu’il recouvre entièrement l’appareil, tout en dépassant d’au moins 15 cm de tous

les côtés qui ne sont pas contigüs à un mur . Le

groupe doit avoir la capacité qui convient et un appointd’airadéquatdoitêtreprévu.

AVERTISSEMENT!!

Une mauvaise extraction des fumées de

combustion du four peut mettre en danger la santé de l’opérateur. Elle aura

également pour résultats des problèmes

de fonctionnement, une cuisson laissant

à désirer et de possibles dég â ts subis par

le matériel. Les dégâts résultant directement d’une aération inadéquate ne seront

pas couverts par la garantie offerte par le

fabricant.

Mises en service américaines et canadiennes

Se reporter aux codes locaux de la ventilation. En

l’absencedecodeslocaux,sereporteraucode

national de la ventilation intitulé “Normes pour

l’installation d’équipements pour l’enlèvement des

fumées et vapeurs grasses provenant d’équipements commerciaux pour la cuisine”, NFPA ---96 --Édition la plus récente.

Mise en service dans les autres pays

L’installation doit respecter les normes nationales

et locales, qui varient selon le pays. Si vous avez

des questions sur les méthodes d’installation acceptables ou sur le fonctionnementde votre appareil, veuillez communiquer avec votre détaillant.

S’il n’y a aucun détaillant dans votre région, veuillez communiquer avec Blodgett Combi au

0011-802-860-3700.

28

Page 33

Installation

Montage des pieds

OPTIONS

Les pieds sont offerts en différentes longueurs :

101 mm (4 po), 152 mm (6 po) ou 635 mm (25 po)

ou avec des roulettes basses.

D

Les pieds de 101 mm (4 po) s’adaptent lorsque

l’appareil est monté sur un comptoir.

D

Les pieds de 152,4 mm (6 po) sont adaptés à la

section inférieure lorsque deux appareils sont

empilés.

D

Les pieds de 635 mm (25 po) sont utilisés pour

un seul appareil installé sur un plancher.

REMARQUE:Pour des raisons de sécurité, vous ne

devez pas utiliser des roulettes avec

les pieds de 635 mm (25 po).

Pied réglable de 635 mm (25 po)

MONTAGE

1. Alignez le goujon fileté situé sur l’un des pieds

avant avec le trou de boulon situé au coin inférieur de l’appareil. Tournez le pied dans le

sens horaire et serrez jusqu’au tour complet

le plus proche.

2. Alignezlestrousdelaplaquedemontagedu

pied avec les trous de boulon. Fixez solidement au moyen des deux boulons de 1/2 po

fournis.

3. Répétez les étapes précédentes pour l’autre

pied avant. Si vous utilisez des roulettes bas-

ses, installez les roulettes à frein à l’avant du

four. Les roulettes arrière ne se bloquent pas.

Assurez-vous que les roulettes avant sont

bloquées.

4. Penchez le four vers l’avant sur les pieds avant

que vous venez d’installer. Si vous venez d’in-

staller des roulettes, assurez-vousque les roulettes avant sont bien bloquées. Répétez les

étapes précédentes pour les pieds arrière.

5. Pour mettre le four de niveau (sauf pour les

modèles dotés de roulettes), vissez ou dévissez les pieds réglables selon le cas.

Pied réglable de 152,4 mm (6 po)

Pied réglable de 101 mm (4 po)

Figure 2

Roulettes basses

Figure 3

29

Page 34

Installation

Superposition

ATTENTION !!

Seul un installateur qualifié peut effectuer

la superposition des appareils. Les appareils sont lourds. Assurez-vous d’utiliser

des outils et des méthodes appropriés

pour soulever et superposer les appareils.

1. Retirez le bac d’égouttage de l’appareil du

haut.

2. Posez les pieds ou les roulettes sur l’appareil

du bas. Consultez la page 29.

3. Placez le BC14 sur le CNV14. Assurez-vous

que les quatre côtés sont bien alignés.

4. Boulonnez les deux appareils ensemble au

moyen des boulons fournis.

5. APPAREILS À GAZ SEULEMENT : Fixez les

évents à gaz tel qu’illustré.

REMARQUE:Pour les appareils électriques,

passez à l’étape 6.

6. Remettez le bac d’égouttage.

7. Raccordez le gaz (s’il y a lieu) et l’alimentation

électrique. Consultez les pages 33---36.

REMARQUE:Un collecteur de gaz optionnel est of-

fert par Blodgett Combi. Comman dez la pièce numéro R9570.

REMARQUE:Un Assemblage de Drain/Évent à va-

peur optionnel est aussi offert par

Blodgett Combi. Commandez la pièce

numéro R9251 pour les fours simples

et les fours du dessus dans le cas de

fours superposés. Commandez la pièce numéro R9252 pour les les fours du

basdanslecasdefourssuperposés.

BC14 sur CNV14

Les fours du gaz Évent à air chaud

(BC14G & CNV14G seulement)

Assemblage de

Drain/Évent à vapeur

optionnel

Plaque de

fixation

Bac

d’égouttage

Tuyau de 1,125 po de

diamètre intérieur provenant

du drain du bac d’égouttage

Vue arrière

Évent du générateur

de vapeur

Collecteur de Gaz

optionnel

(BC14G & CNV14G

seulement)

Figure 4

30

Page 35

MISE DE NIVEAU DU FOUR

La préparationdu four doit se faire à l’emplace-

ment choisi.

Assurez-vous que la surface de l’emplacement

choisiest de niveau, plane et solide. Une base inégale ou en pente pourrait empêcher le four de

fonctionner correctement. Il est possible de compenser une surface qui n’est que légèrement inégale en ajustant les pieds en métal. L’ajustement

maximal est de 35 mm (1-3/8 po).

Installation

Mise de niveau du four

Réglage

maximal de

35 mm

(1-3/8 po)

Pied

Embase

Figure 5

31

Page 36

Installation

Raccordement de la plomberie

RACCORDEMENT À L’EAU -CNV14E SEULEMENT

REMARQUE:L’utilisation d’eau chaude maximise

la production de vapeur, mais elle

n’est pas obligatoire. Les deux entrées peuvent recevoir de l’eau froide

si l’eau chaude n’est pas disponible.

Raccordez l’appareil à une source d’ eau propre

au moyen d’un boyau de pression muni de raccordsde19mm93/4po).ConsultezlaFigure6

pour le raccordement. Prévoyez l’installation d’un

robinet d’a rrêt à proximité du four.

ATTENTION !!

L’utilisation de l’appareil non équipé du

régulateur d’eau annule votre garantie.

L’eau doit respecter les normes suivantes :

D

La quantité de matières totales dissoutes(MTD)

ne doit pas dépasser 30 parties par million.

D

Le pH de l’eau doit être égal ou supérieur à 7,0.

ATTENTION !!

L’utilisation d’une eau de qualité inférieu-

re annule votre garantie.

CNV14E

RACCORDEMENT DU DRAIN

Les évents à vapeur se composent de tuyaux de cuivre de 2 popour système d’égout se rétrécissant à

1-1/2 po. Si vous n’avez pas acheté le système d’aération optionnel (P/N R9381), Blodgett Combi vous

recommande de modifier le four selon les indications de la Figure 7.

Acheminez l’évent à vapeur jusqu‘à un fossé de

drainage dans le plancher et évitez d’utiliser des

boyaux qui pourraient s’affaisser et entraîner des

accumulationsd’eau. Le client est responsable de

fournirlatuyauterieraccordantlefouretledrain.

Raccordezledraindubacd’égouttageàl’éventà

vapeur au moyen d’un tuyau de 1,125 po de diamètre intérieur.

Pour raccorder le dra in, utilisez l’ensemble

d’évent de drain et un tuyau de 50,8 mm (2 po).

Raccord

Tuyau de système d’égout de

50,8mm(2po)fourniparleclient

Figure 7

Eau froide

Raccordement à l’eau

Vuearrièredel’appareil

Figure 6

Raccordement à l ’eau et à l’égout particulier à

la ville de Los Angeles

1. Chaque conduite de vidange raccordée à

l’appareil doit être acheminée sans déclivité

ou fléchissement pour se terminer au-dessus

du niveau de trop-plein d’un récipient d’eaux

usées indirectes homologué.

2. L’appareil doit être installé conformément aux

instructions imprimées du fabricant et aux éditions de 1999 du LAPC et du LAMC.

3. Un dispositif de protection antirefoulement doit

être installé sur le réseau d’eau potable, directement en amont de l’appareil. Ce dispositif doit

être l’un des suivants : un reniflard de type antivide homologué installé à au moins 12 po audessus du point le plus élevé, un disconnecteur

à deux clapets de non-retour ou un disconnecteur hydraulique principal à pression réduite.

32

Page 37

Installation

Raccordement à l’électricité

Tous les modèles

REMARQUE:Seulun technicienqualifié peut effec-

tuer le raccordement à l’électricité.

Avant de procéder a u raccordement à l’électricité

des appareils, assurez-vous que la source d’alimentation est conforme aux spécifications de tension, d’intensité et de phase indiquées sur la plaque signalétique de l’appareil.

Le disjoncteur raccordé à cet appareil doit être

doté de contacts espacés d’au moins 0,076 po (2

mm). Le disjoncteur doit respecter toutes les normes d’installation nationales et locales.

L’installation de tous les appareils doit se conformer aux codes d’électricité nationaux et locaux.

Le schéma de câblage se trouve à l’intérieur du

panneau latéral amovible.

REMARQUE:Débranchez la source d’alimentation

électrique de l’appareil avant de procéder à l’entretien.

ATTENTION !!

Une installation non conforme annule vo-

tre garantie.

Modèles électriques

Le cordon d’alimentation nécessite un protecteur de

cordon. Le responsable de l’installation doit fournir

un manchon pour le cordon qui respecte les normes

d’installation nationales et locales.

Modèles à gaz

Installations canadiennes et américaines

Un 115V ou 230V cordon d’alimentation muni

d’une fiche est fourni avec l’appareil. Branchez la

fichedansuneprisedecourantappropriée.

Installationsdansd’autrespays

Un 230V cordon d’alimentation à fusible de 13 ampères muni d’une fiche est fourni avec l’appareil.

Branchez la fiche dans une prise de courant appropriée.

Consultez la Figure 8 pour connaître le cheminement du cordon d’alimentation et les connexions

au filtre de ligne.

ATTENTION !!

Si le cordon d’alimentation est endomma-

gé, remplacez-le par un cordon spécial

ou un dispositif fourni par le fabricant ou

par un réparateur reconnu.

Connexions d’alimentation

Filtre de ligne

Ferrure de fixation

du filtre de ligne

Cordon d’alimentation avec

Protecteur

de cordon

Vue arrière du BC14G sans le panneau arrière

fusiblede13ampères

Filtre de ligne

L 1 --- F i l b r u n

N --- F i l b l e u

Symboledemiseàla

masse -- - Fil vert/jaune

Mise en service dans les a utres pays

Figure 8

33

Page 38

Installation

gueur

dut

Raccordement au gaz

CONDUITE DE GAZ

Il est essentiel d’avoir un circuit d’ a limentation en

gaz approprié afin que le four puisse donner un

rendement maximal. Les dimensions de la tuyauterie doivent permettre d’assurer une alimentation

en gaz suffisant pour satisfaire à la demande maximale de tous les appareils en service, et ce sans

pertedepression.

Exemple :

REMARQUE: Les valeurs indiquées en BTU à titre

d’exemple s’appliquent au gaz naturel.

Supposons que vous achetiez un appareil CNV14G

pour accroître votre capacité de cuisson.

1. Additionnez les puissances nominales en

BTU des appareils déjà en place.

Friteuse Pitco 120 000 BTU

Cuisinière à 6 éléments 60 000 BTU

Four à pont 50 000 BTU

Total 230 000 BTU

2. À ce total, ajoutez la puissance nominale en

BTU du nouveau four.

Total précédent 230 000 BTU

CNV14G 65 000 BTU

Nouveau total 295 000 BTU

3. Mesurezladistanceducompteurdegaz

jusqu’aux appareils de cuisson pour obtenirla

longueur du tuyau. Supposons que la longueur de tuyau soit de 30 pi (9 m) et que le

tuyau possède un diamètre de 1 po (2,54 cm).

4. Utilisez la table de calcul appropriée pour déterminer la capacité totale de votre conduite

de gaz actuelle.

Dans cet exemple, la capacité totale est de 375

000 BTU. Puisque la pression totale de gaz nécessaire est de 295 000 BTU, donc inférieure à

375 000 BTU, il n’est pas nécessaire pour l’instant

d’augmenter la tuyauterie actuellement en place.

REMARQUE:Les capacités en BTU indiquées

dans ces tableaux sont valables pour

les tuyaux droits seulement. L’ajout

de coudes et de raccords courbés

diminue la capacité de la tuyauterie.

Par exemple, un raccord en L de nomenclature 40 de 1-1/2 po possède

une capacité équivalente à un tuyau

droit de 4,2 po (10,2 cm). Renseignez-vous auprès de votre fournis-

seur en gaz local si vous avez des

questions à ce sujet.

Capacité maximale en gaz naturel d’une

tuyauterie en fer en pieds cubes à l’heure

(Chute de pression de 0,5 po de colonne d’eau)

Lon-

gueur

du

tuyau

(pi)

10 360 680 1 400 2 100 3 950

20 250 465 950 1 460 2 750

30 200 375 770 1 180 2 200

40 170 320 660 990 1 900

50 151 285 580 900 1 680

60 138 260 530 810 1 520

70 125 240 490 750 1 400

80 118 220 460 690 1 300

90 110 205 430 650 1 220

100 103 195 400 620 1 150

Extrait du National Fuel Gas Code, partie 10, tableau 10-2

Capacité maximale de la conduite en milliers de

BTU/h de gaz PP non dilué à 11 po de colonne

(Chute de pression de 0,5 po de colonne d’eau)

Longueur

uyau

(pi)

10 608 1 146 3 525

20 418 788 2 423

30 336 632 1 946

40 287 541 1 665

50 255 480 1 476

60 231 435 1 337

70 215 404 1 241

80 198 372 1 144

90 187 351 1 079

100 175 330 1 014

Extrait du National Fuel Gas Code, partie 10, tableau 10-15

Dimensions nominales (po)

3/4po1po 11/4po11/2po2po

d’eau

Diamètre interne (po)

3/4 po 1po 11/2po

34

Page 39

Installation

Raccordement au gaz

RÉGULATION DE LA PRESSION ET ESSAIS

Évaluez la pression d’alimentation du gaz pour

chaque appareil lorsque les brûleurs sont allumés. Il doit y avoir une pression suffisante à l’entrée pour répondre aux normes. Consultez le t ableau ci-dessous pour connaître la pression de

gaz qui convient.

Chaque appareil est réglé en usine de manière à

fonctionner avec le type de gaz indiqué sur la plaque signalétique située du côté droit de l’appareil.

Chaque four est muni d’un détendeur qui maintient le gaz à la bonne pression. Ce détendeur est

essentiel au bon fonctionnement du four et ne

doit jamais être débranché.

N’INSTALLEZ PAS UN DEUXIÈME DÉTENDEUR

AU POINT DE CONNEXION DU GAZ À MOINS

QUE LA PRESSION D’ALIMENTATION SOIT SUPÉRIEURE À 14 PO DE LA COLONNE D’EAU (1/2

LB/PO2) (37 mbars).

Pendant les essais de pression, débranchez le

four ainsi que son robinet d’arrêt de la tuyauterie

d’alimentationen gaz si la pression d’ essai est supérieure à 1/2 lb/po

Isolez le four de la tuyauterie d’alimentation en gaz

en fermant son robinet d’arrêt pendant les essais de

2

(3,45 kPa).

pression de la tuyauterie de gaz si la pression d’essai est égale ou inférieure à 1/2 lb/po

Avant de raccorder les tuyaux d’alimentation en gaz

de l’appareil, videz complètement les tuyaux de toutes particules métalliques et de tout déchet. Après

le branchement, inspectez l’appareil afin de vous

assurer que la pression de gaz est appropriée.

Installations américaines et canadiennes

L’installation doit respecter les normes locales ou,

en l’absence de telles normes, les règlements suivants : National Fuel Gas Code, NFPA54/ANSI

Z223.1 - -- dernière édition, le Code d’installation du

gaz naturel CAN/CGA-B149.1 ou le Code d’installation du propane, CAN/CGA-B149.2,selonlecas.

Installation dans les autres pays

L’installationdoit respecter les normes nationales

et locales. Les normes d’installation locales ou les

règlements peuvent varier. Si vous avez des questions concernant les méthodes d’installation acceptables ou sur le fonctionnementde votre appareil, veuillez communiquer avec votre détaillant

local. S’il n’y a aucun détaillant local dans votre région, veuillez communiquer avec Blodgett Combi

au 0011-802-860-3700.

2

(3,45 kPa).

Type d e gaz Pression

d’alimentation

Installations américaines et canadiennes

Naturel 7---14 po de

colonne d’eau

Propane 12---14 po de

colonne d’eau

Dimensions de l’orifice au

Air chaud Vapeur Air chaud Vapeur

0,0531 po de

diamètre

0,032 po de

diamètre

PRESSION DE GAZ

niveau de la mer

0,042 po de

diamètre

0,026 po de

diamètre

35

Pression d’admission

3,5 po de co-

lonne d’eau

10,0 po de co-

lonne d’eau

3,5 po de co-

lonne d’eau

10,0 po de co-

lonne d’eau

Page 40

Installation

Câble d’immobilisation du tuyau à gaz

Si l’appareil est monté sur des roulettes, utilisezun

connecteur flexible ordinaire dont le diamètre interne est d’au moins 1,9 cm (3/4 po) ainsi qu’un

raccord rapide.

Le câble d’ immobilisation fourni avec l’appareil

doit être utilisé pour limiter le mouvement de l’appareil de manière à ce que le connecteur flexible

ne subisse aucune tension. Attachez le câble au

bâti du four le plus près possible du connecteur

flexible. Le câble doit être assez court pour empêcher toute tension sur le connecteur. Lorsque le

câble est pleinement étiré, il devrait être facile d’installer le connecteur et de le brancher à l’aide du

raccord rapide.

Le câble (de fort calibre) doit être installé sans endommager l’immeuble. N’UTILISEZ PAS la

conduite de gaz ou les câbles électriques pour ancrer l’extrémité permanente du câble d’immobilisation! Utilisez des boulons d’ancrage vissés

dans le béton ou dans un bloc de béton. Pour les

murs de bois, utilisez des vis d’ancrage robustes

dans les montants des murs.

ATTENTION !!

Si le câble est enlevé pour quelque raison

que ce soit, installez-le de nouveau une

fois l’appareil remis en place.

Installations américaines et canadiennes

Le connecteur doit respecter la norme Standard

for Connectors for Movable Gas Appliances, ANSI

Z21.69 ou Connectors For Moveable Gas Appliances CAN/CGA-6.16 et le raccord rapide doit res-

pecter la Standard for Quick-Disconnect Devices

for Use W ith Gas Fuel, ANSI Z21.41 ou Quick Disconnect For Use With Gas Fuel CAN 1-6.9.Pré-

voyezdes mesures adéquates pour limiterle mouvement de l’appareil sans compter exclusivement

sur le connecteur et le ra ccord rapide ou sur la

conduite connexe.

Chaque appareil doit être muni d’un collecteur de

condensats. Consultez NFPA54/ANSI Z223.1 -

dernière édition (National Fuel Gas Code) pour

connaître les méthodes d’installation d’un collecteur de condensats.

Installation dans un autre pays

L’installation doit respecter les normes nationales

et locales. Les normes d’installation locales ou les

règlements peuvent varier. Si vous avez des questions concernant les méthodes d’installation acceptables ou le fonctionnement de votre appareil,

veuillez communiquer avec votre détaillant local.

S’il n’y a aucun détaillant dans votre région, veuillez communiquer avec Blodgett Combi au

0011-802-860-3700.

Plaque de fixation (fixez au

boulon de montage dupied)

Raccord rapide

Tuyau à g a z

Installation du tuyau à gaz et du câble d’immobilisation

(Single Section Shown)

Conduite d’alimentation

en gaz

Câble d’immobilisation

Figure 9

36

IMPORTANT : Attachez le câble