Page 1

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SPECIFICATION SHEET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

OVEN AND ELECTRICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

KEY PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

BG3240 OVEN INSTALLATION KIT (51100) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

BG3240 SINGLE OVEN OPTION BASE KIT (34832) . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

BG3240 DOUBLE OVEN OPTION BASE KIT (34833). . . . . . . . . . . . . . . . . . . . . . . . . . . .9

BG3240 TRIPLE OVEN OPTION BASE KIT (OUTRIGGERS) (51139) . . . . . . . . . . . . . . .10

STANDARD FINGER CONFIGURATION (50593 REV C) . . . . . . . . . . . . . . . . . . . . . . . . .11

VIEW OF OVEN PANELS, WINDOW AND LEGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

PARTS FOR OVEN PANELS, WINDOWS AND LEGS. . . . . . . . . . . . . . . . . . . . . . . . . . . .13

VIEW OF RIGHT-HAND CONTROL COMPARTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . .14

PARTS FOR RIGHT-HAND COMPARTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

VIEW OF BLOWER AREA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

PARTS FOR BLOWER AREA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

VIEW OF BLOWER/MOTOR COMPARTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

PARTS FOR BLOWER/MOTOR COMPARTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

VIEW OF GAS BURNER & PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

PART FOR GAS BURNER & PIPING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

VIEW OF “SINGLE” BELT CONVEYOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

PARTS FOR “SINGLE” BELT CONVEYOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

VIEW OF “SPILT” BELT CONVEYOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

PARTS FOR “SPLIT” BELT CONVEYOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ.,

1-PHASE 3W 50141 REV. F2 US/UK/CANADA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

LADDER WIRING DIAGRAM, 208-240 VOLT 50/60 HZ.,

1-PHASE 3W 50141 REV. F1 US/UK/CANADA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52059 REV. D DN . . . . . . .28

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52065 REV. D DUT . . . . . . 29

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52053 REV. D FR . . . . . . . 30

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52055 REV. D GM . . . . . . .31

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52067 REV. D GK . . . . . . .32

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52061 REV. D IT . . . . . . . . 33

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52057 REV. D SP . . . . . . .34

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52063 REV. D SW . . . . . . .35

TABLE OF CONTENTS

2

Page 3

BLODGETT OVEN COMPANY

www.blodgett.com

1400 Toastmaster Drive, Elgin, IL USA 60120 • Phone: (847) 741-3300 • Fax: (847) 741-0015

MODEL BE3240 & BG3240

Electric/Gas Conveyor Oven

EXTERIOR CONSTRUCTION

Stainless steel front, top, bottom and sides

Aluminized steel back

Full drop down front window

INTERIOR CONSTRUCTION

Stainless steel outer plates

32" (813mm) stainless steel wire mesh conveyor belt

One single inlet blower in plenum for air circulation

Upper and lower air fingers

OPERATION

Heat transferred through forced convection (impingment)

Open vented baking compartment

Solid state digital controls to display set point and actual temperature as well

as belt speed

Electronic spark ignition control system (gas model)

Gas power type burner has mixer with adjustable shutter and sight window

(gas model)

Internal gas pressure regulator (gas model)

Tubular resistance elements (electric model)

Solid state speed control with motor feedback

Two circulation blower motors

3-30 minute bake time

STANDARD FEATURES

Field reversible belt direction

Large front loading door with window and stainless steel handle

Product stop

Cord set and plug (NEMA L6-15P) domestic gas ovens only

Folding removable conveyor belt assembly

Adjustable belt tensioning feature

Flexible gas hose with quick disconnect and restraining device

Oven start-up*

One year parts & labor warranty*

* For all international markets, contact your local distributor.

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

Twin belt - two 15" (381mm) wide belts

One year additional extended warranty*

Project

Item No.

Quantity

Blodgett conveyor oven with 32" (813mm) wide belt and 40" (1016mm)

baking zone length. Single, double or triple stack models.

All data is shown per oven section, unless otherwise indicated.

BE3240 & BG3240

3

SPECIFICATION SHEET

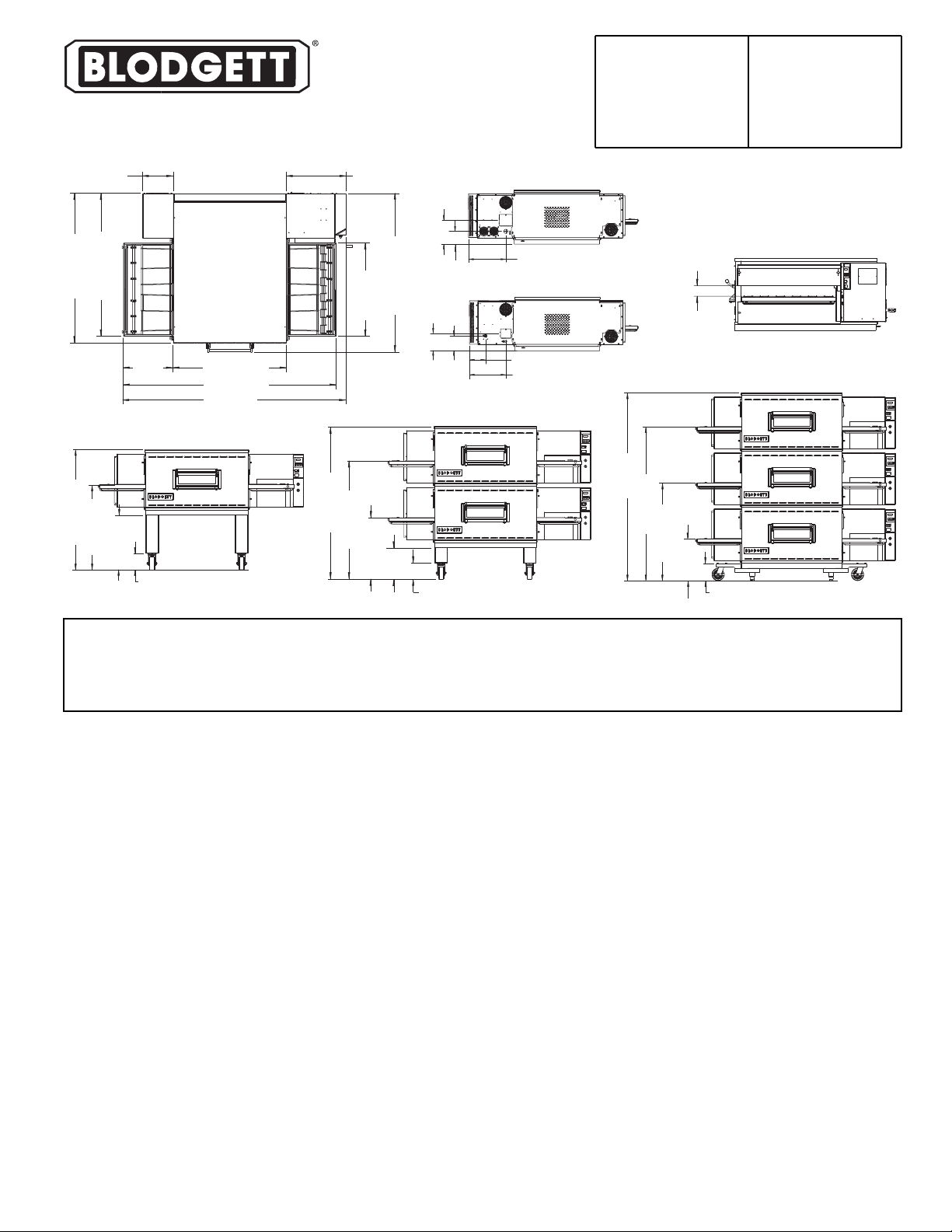

Page 4

DIMENSIONS ARE IN INCHES [MM]

TRIPLE

5 [127]

17-5/16

[440]

39-7/8 [1013]

62-1/4 [1581]

76 [1930]

TOP VIEW

11 [280]

21-1/2 [546]

53-1/2 [1359]

51-1/4 [1302]

57-13/16 [1468]

32 [813]

18

[457]

40-1/2 [1028]

76-1/2 [1943]

80 [2032]

6-1/2 [165]

22-1/2 [546]

33-7/8 [860]

47-5/16 [1202]

SINGLE

DOUBLE

60-7/8 [1546]

43-3/4 [1111]

24-13/16 [630]

12-1/2

[318]

6-1/2 [165]

END VIEW

3-7/8

[98]

6-1/2

(165)

1-1/2

(38)

17-5/8 (448)

BE3240 REAR VIEW

7-1/4

(184)

6-3/8

(162)

7-3/4 (197)

17-3/8 (441)

BG3240 REAR VIEW

BLODGETT OVEN COMPANY

www.blodgett.com

1400 Toastmaster Drive, Elgin, IL USA 60120 • Phone: (847) 741-3300 • Fax: (847) 741-0015

MODELS BE3240 & BG3240G

SHORT FORM SPECIFICATIONS

Provide Blodgett conveyor model BE3240 (electric) or BG3240 (gas) conveyor oven. Unit shall cook by means of forced, heated air. Unit shall be (single/double/triple) deck. Each deck

shall be fully independent, of stainless steel construction, and fully insulated on all sides. Provide with (electronic spark ignition gas fired/electrically heated) baking compartment with

one blower to evenly distribute heat across baking zone. Conveyor belt shall be 32" (813mm) wide and constructed of stainless steel wire mesh; baking zone length shall be 40"

(1016mm). Unit shall be provided with drop down front window. Control panel shall be solid state with 550°F (288°C) maximum thermostat and LCD display of 3-30 minutes adjustable

belt speed. Provide start-up inspection service by a factory authorized service agent. Provide options and accessories as indicated.

Printed in U.S.A. NOTE: FOR COMMERCIAL USE ONLY

NOTE: The company reserves the right to make substitutions of components without prior notice

APPROVAL/STAMP

P/N M10991 Rev D (1/06)

POWER SUPPLY (must have dedicated ground)

BE3240

Domestic 208 VAC, 50/60 hz, 3 ph, 75 amp, 3-wire plus ground

240 VAC, 50/60 hz, 3 ph, 65 amp, 3-wire plus ground

International 380 VAC, 50/60 hz, 3 ph, 41 amp, 3-wire plus N and ground

480 VAC, 50/60 hz, 3 ph, 32.5 amp, 3-wire plus N and ground

CE 380 VAC, 50 hz, 3 ph, 41 amp, 3-wire plus N and ground

BG3240

Domestic 208-240 VAC, 1 phase, 50/60 Hz., 4.1 amp., 2-wire plus ground

International 220-230 VAC, 1 phase, 50 Hz., 4.1 amp., 2-wire plus ground

MINIMUM ENTRY CLEARANCE:

Uncrated 25-3/4" (654mm)

SHIPPING INFORMATION:

Approx. Weight:

Single 1100 lbs. (499 kg)

Double 2200 lbs. (999 kg)

Triple 3300 lbs. (1498 kg)

DIMENSIONS:

Floor space 80" (2032mm) W x 60-1/2" (1537mm) L

Product clearance 3-7/8" (98mm)

Combustible wall clearance Left Right Rear

BE3240 0” (0mm) 0” (0mm) 3” (76mm)

BG3240 3" (76mm) 18” (457mm) 3” (76mm)

Belt width

Standard belt 32" (813mm)

Optional twin belt 15" (381mm) each

Baking zone length 40" (1016mm)

MAXIMUM INPUT: (per section)

BE3240 32.23 kW

BG3240 110,000 BTU/hr (32.23 KW) (116 MJ/hr)

GAS SUPPLY: (specify) Natural Propane

Oven per cavity 1/2" NPT 3/4" NPT

Main gas supply 2" line 1-3/8" line

Minimum Gas Pressure: 6" W.C. 11.0" W.C.

Maximum Gas Pressure: 12" W.C. 14" W.C.

4

Page 5

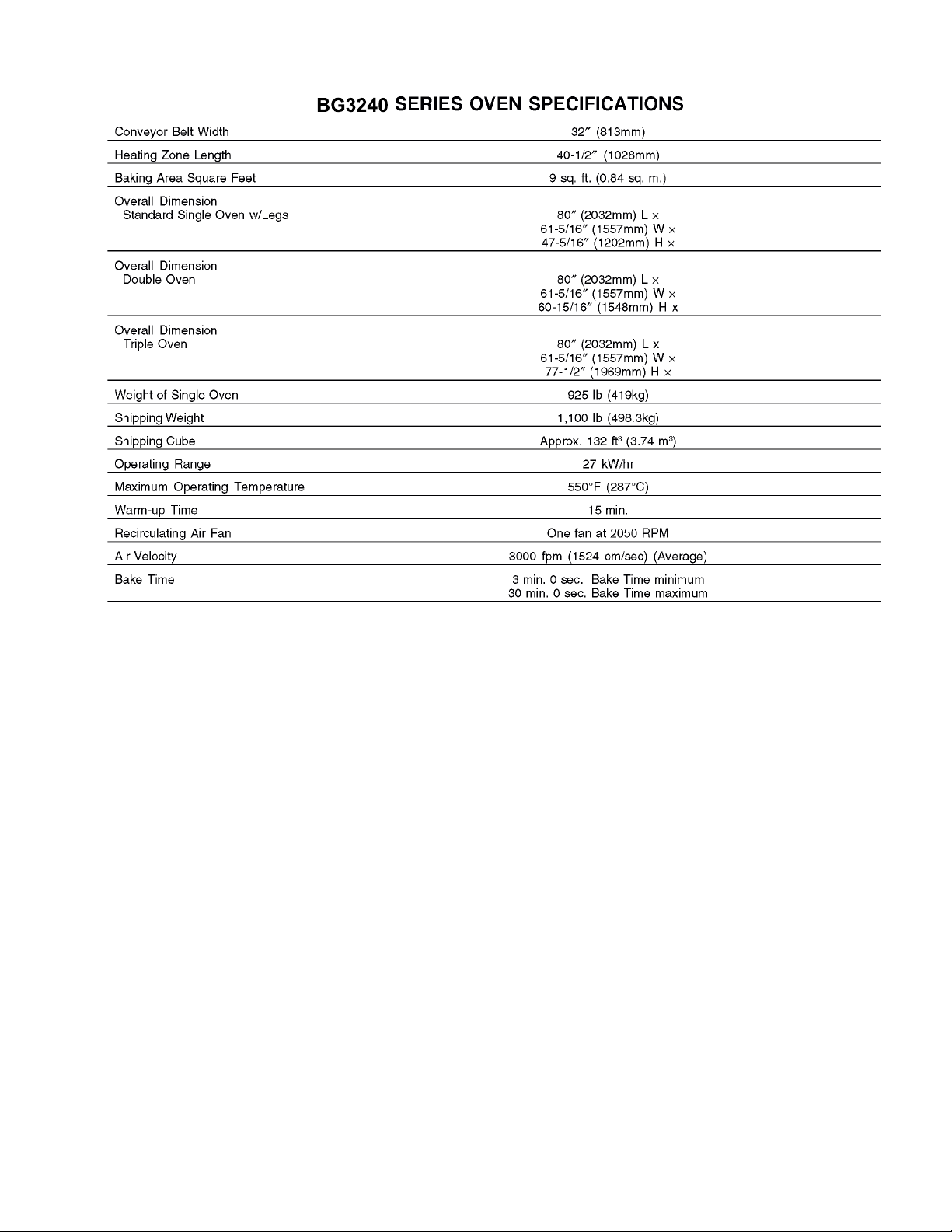

OVEN AND ELECTRICAL SPECIFICATIONS

5

Page 6

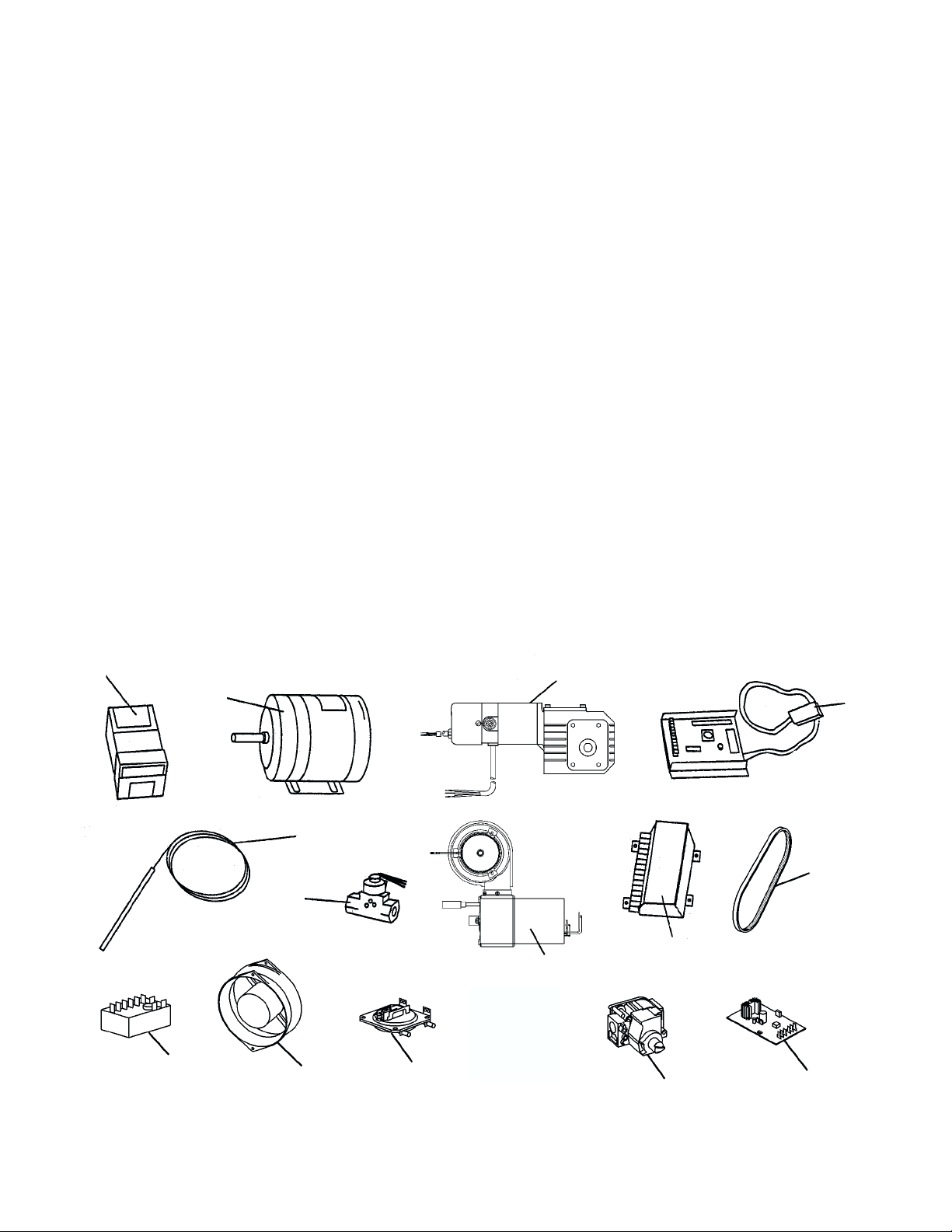

KEY PARTS

BG3240-SERIES GAS OVEN KEY PARTS

ITEM PART NO. ENGLISH DESCRIPTION QUANTITY

1 58504 Temperature Controller 1

2 44687 Blower/Fan Motor 1

3 47797 Conveyor Drive Motor, Standard Speed 1 or 2

3A 47799 Conveyor Drive Motor, High Speed 1 or 2

3B 45017 Kit, Brushes, Springs & Caps 1

3C 50265 Pickup, Sensor 1

4 58323 Conveyor Speed Control 1

5 33812-3 Thermocouple 3

6 41647 Modulating Gas Valve 1

7 50275 Burner & Motor Assembly 1

8 50239 Ignition Control Module (kit) 1

9 See RPM Kit Blower Belt, page 19 1

10 33983 High Limit Control Module 1

11 36451 Cooling Fan 2

12 50610 Air Switch 2

13 50274 Control Valve, Gas, 1/2" 1

14 31651 Signal Amplifier

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

6

KEY PARTS

Page 7

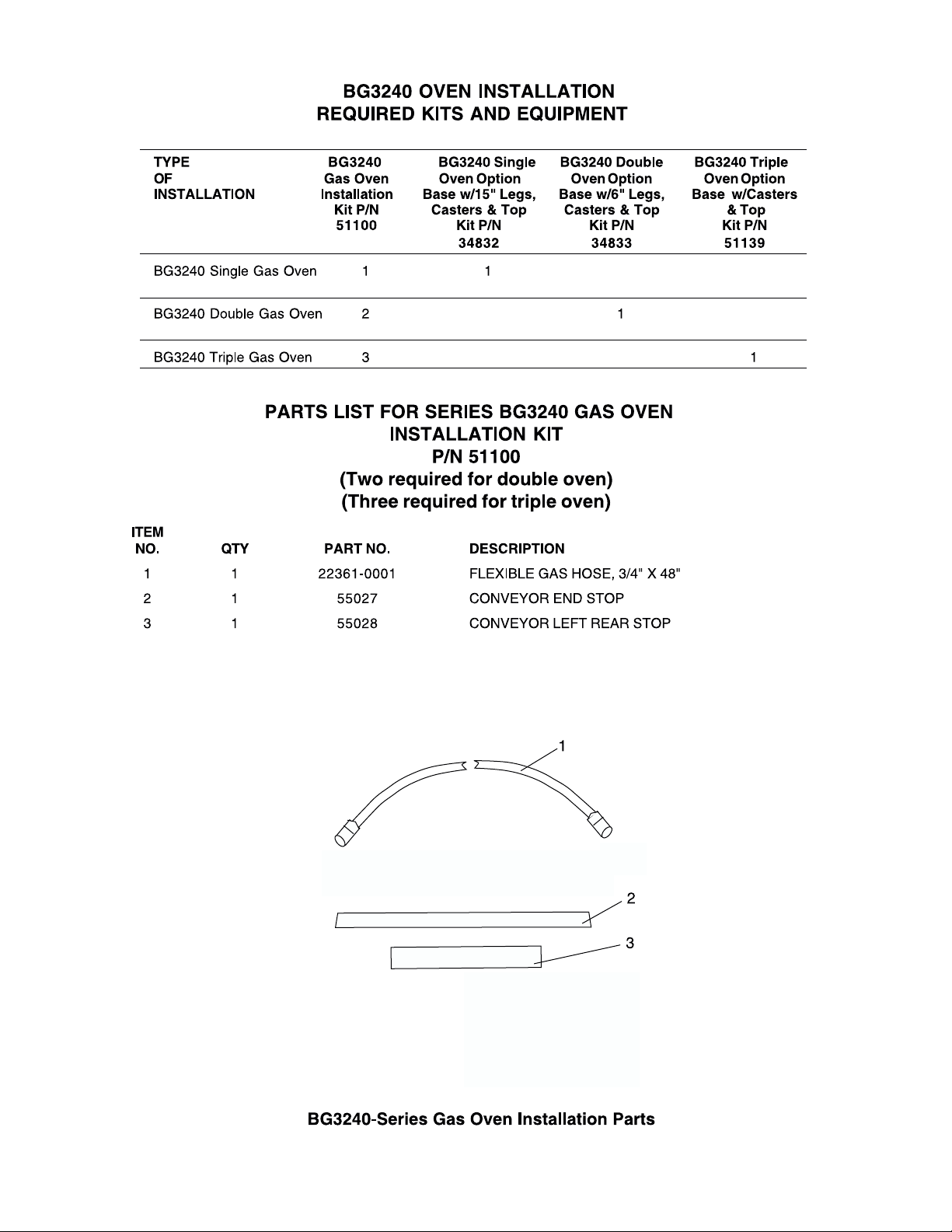

BG3240 OVEN INSTALLATION KIT (51100)

7

Page 8

� �

�

�

�

8

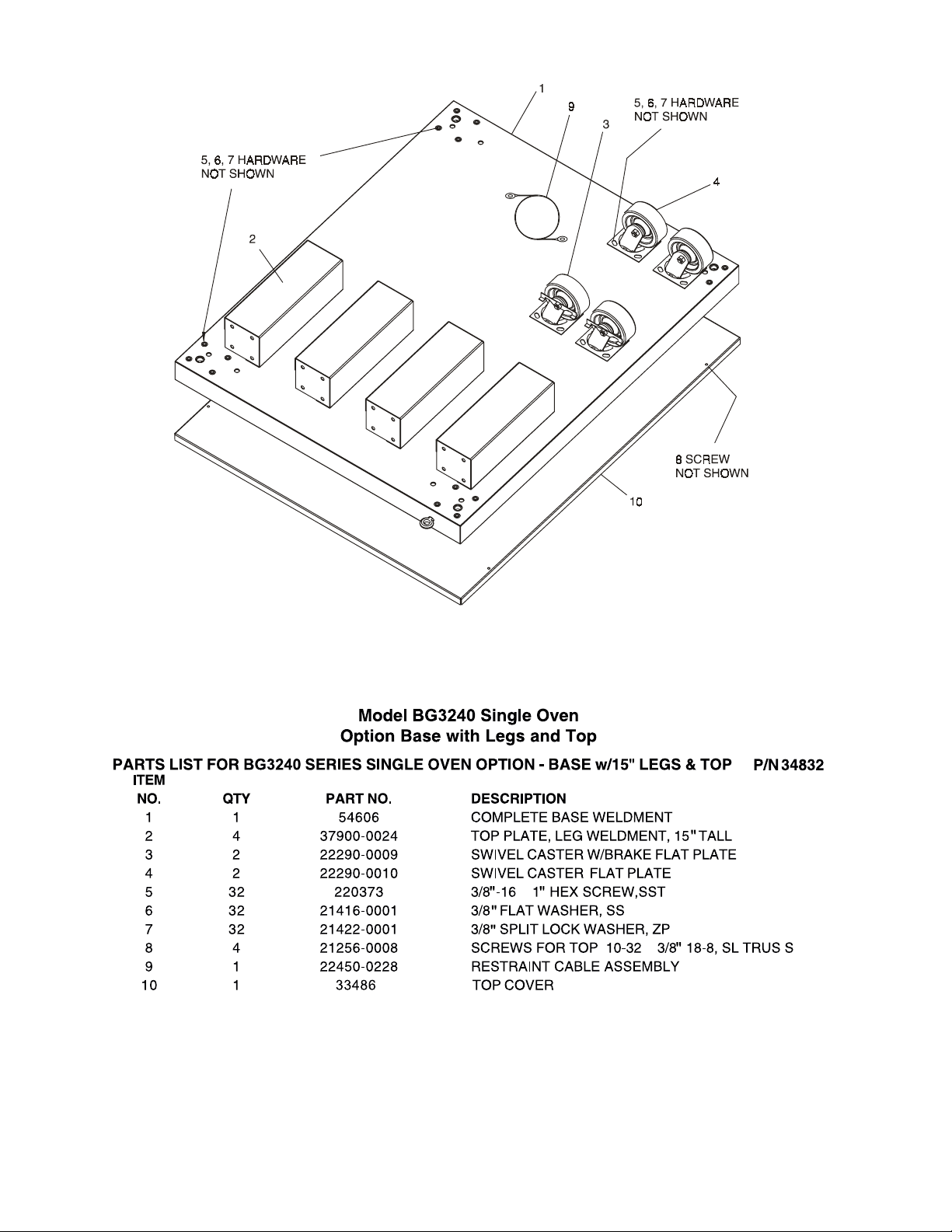

BG3240 SINGLE OVEN OPTION BASE KIT (34832)

Page 9

�

�

�

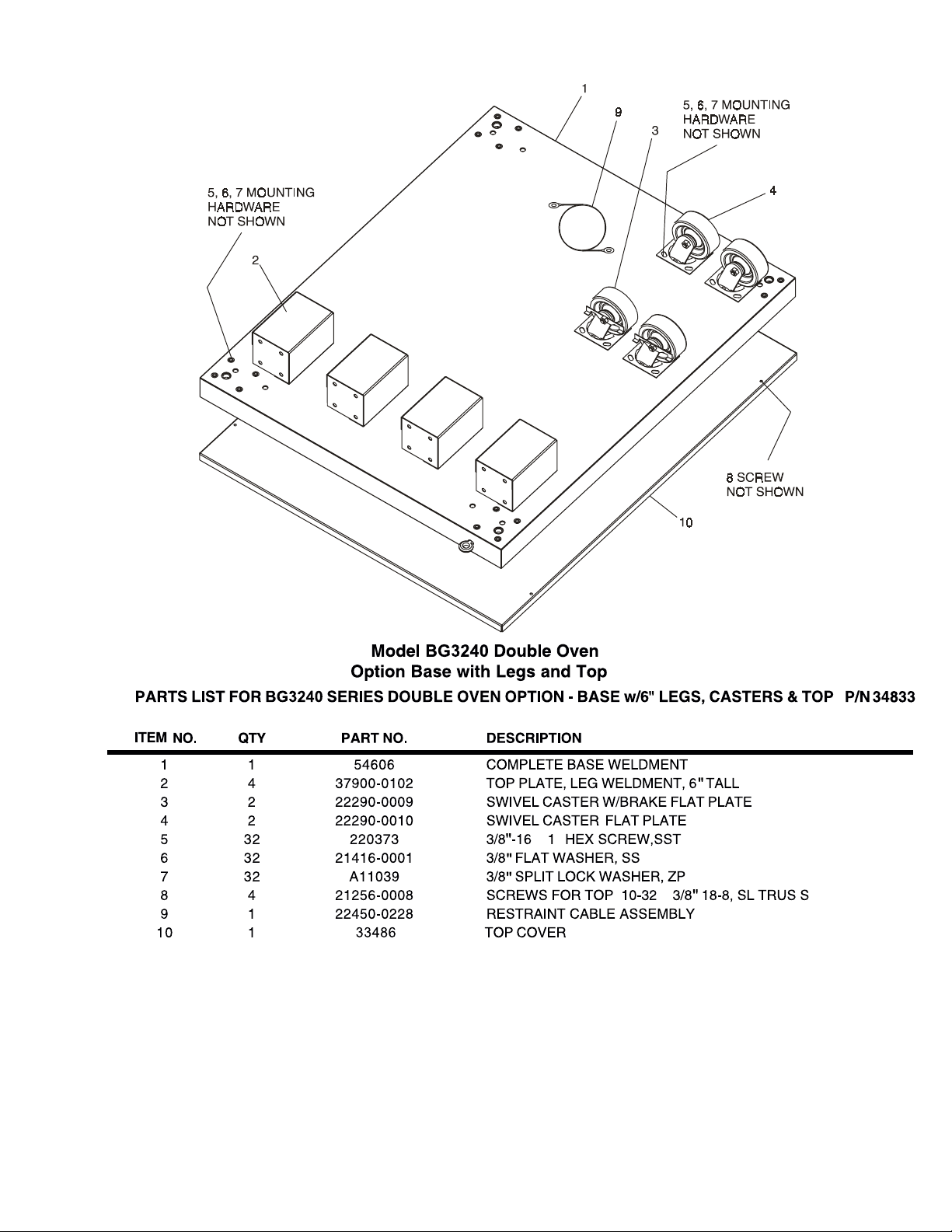

BG3240 DOUBLE OVEN OPTION BASE KIT

9

(34833)

Page 10

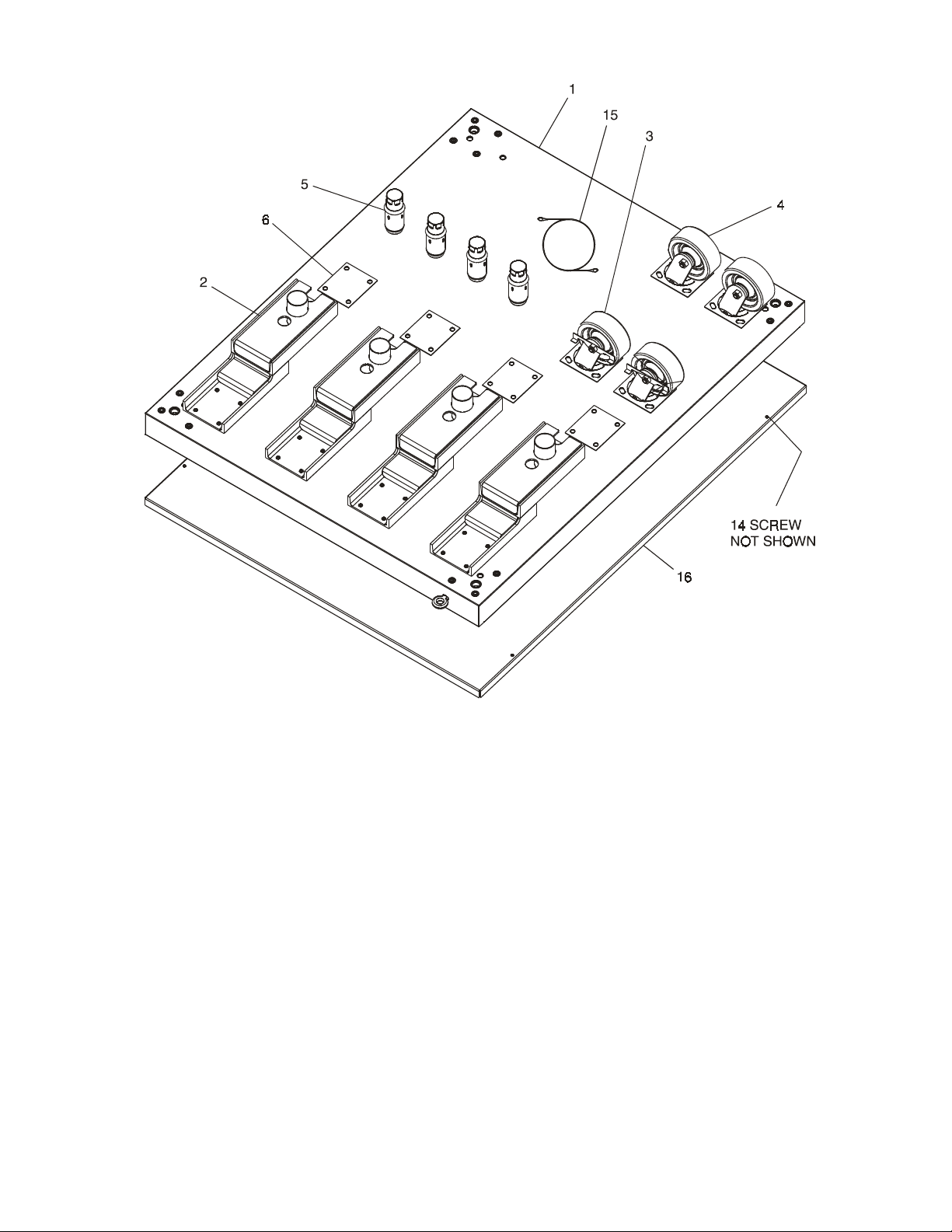

PARTS LIST FOR PS540 SERIES TRIPLE OVEN OPTION - BASE w/CASTERS & TOP

P/N 51139

ITEM

NO. QTY PART NO. DESCRIPTION

1 1 54606 COMPLETE BASE WELDMENT

2 4 45209 QUAD OUTRIGGER WELDMENT

3 2 22290-0009 SWIVEL CASTER, W/BRAKE FLAT PLATE

4 2 22290-0010 SWIVEL CASTER, FLAT PLATE

5 4 45206 INSERT,QUAD ADJUSTMENT FOOT

6 4 45205 SPACER,QUAD CASTER

14 4 21256-0008 SCREWS FOR TOP 10-32 × 3/8″ 18-8, SL TRUS S

15 1 22450-0228 RESTRAINT CABLE ASSEMBLY

16 1 35900-0011 TOP COVER

Model BG3240 Triple Oven

Option Base with Outriggers and Top

BG3240

33486

BG3240 TRIPLE OVEN OPTION BASE KIT

10

(OUTRIGGERS) (51139)

Page 11

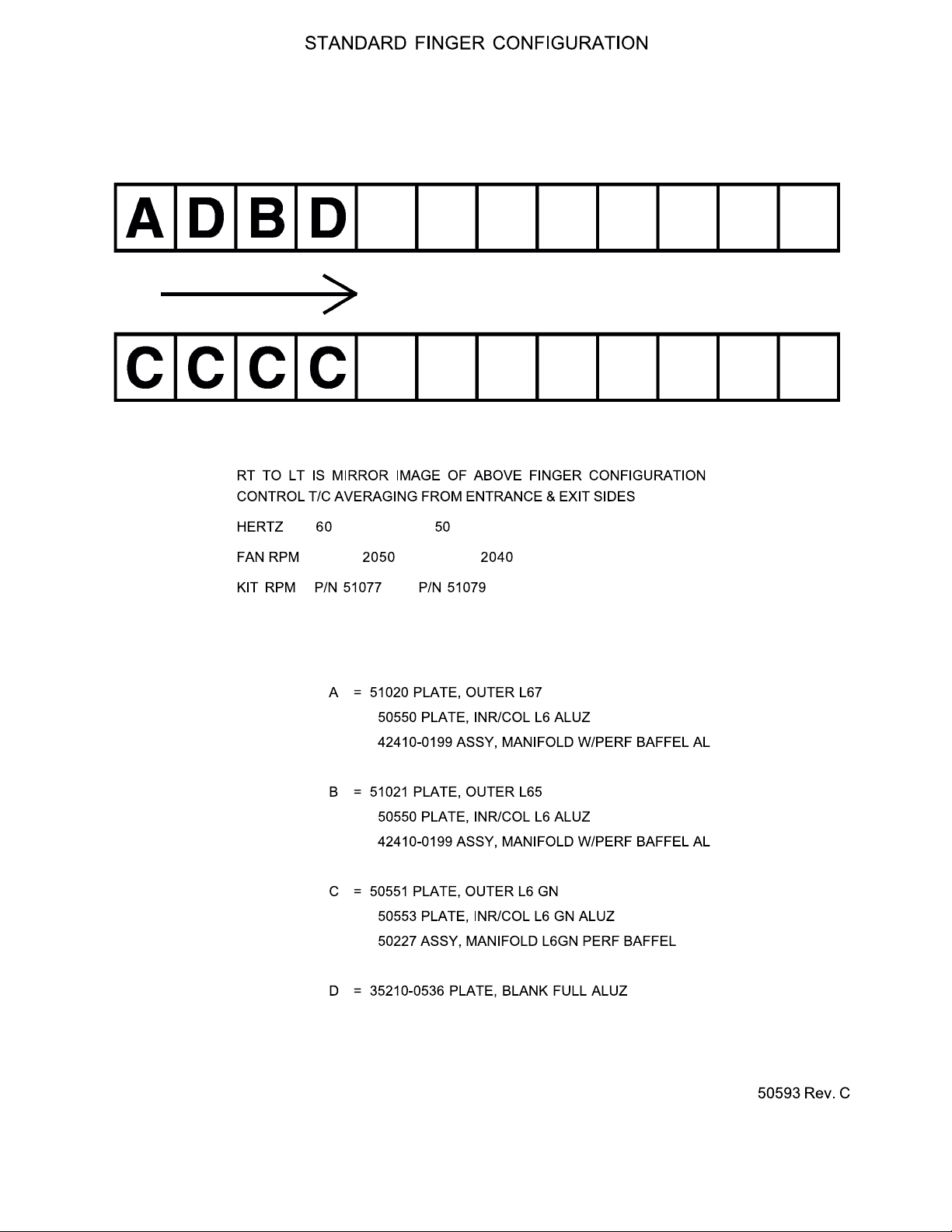

11

STANDARD FINGER CONFIGURATION (50593 REV C)

Page 12

12

VIEW OF OVEN PANELS, WINDOW AND LEGS

Page 13

13

PARTS FOR OVEN PANELS, WINDOWS AND LEGS

Page 14

14

VIEW OF RIGHT-HAND CONTROL COMPARTMENT

Page 15

15

PARTS FOR RIGHT-HAND COMPARTMENT

Page 16

View of BLOWER AREA

3A (NOT SHOWN)

NEVER SEIZE LUBRICANT

16

VIEW OF BLOWER AREA

Page 17

Parts for BLOWER AREA

ITEM QTY. P/N DESCRIPTION

1 1 51157 PULLEY, 1GRV 3.0PD AK32H, 3.25″ DIA.

2 1 48855 WELDMENT, BRG BRACKET PS540G

3 22 220373 SCREW, HH 3/8″ - 16 × 1″ SS T

3A A/R 17110-0017 NEVER SEIZE LUBRICANT - USED ON ITEMS 3 & 7

APPLIED TO THREADS BEFORE REINSTALLING

4 A/R A11039 SPLIT LOCK WASHER 3/8″ ZP

5 A/R 21416-0001 FLAT WASHER 3/8″ SS

6 2 22072-0025 BEARING, PILLOW BLOCK 5/8″

7 8 21326-0002 SCREW, HX HD GRS 3/8″ - 16 × 5-1/2″

8 6 2000203 SCREW ,HX W/HD 10 - 32 × 3/8″ ZC

9 1 48872 BACK WALL SHROUD

10 1 48803 AIR INLET RING

11 8 35900-0108 FAN ORIFICE STAND OFF TUBE

12 1 50643 FAN DRIVE SHAFT

13 1 21651-0010 KEY, SQ 3/16″ × 3/16″ × 1.00″ STL

14 1 48862 AXIAL FAN, 14″ DIAMETER

15 1 51110 INR/OTR BACK WELDMENT

16 1 50222 SPECIAL BUSHING, 5/8″ ID - 3/16″ × 3/32″ KEY

17 2 35323 COUPLING, COLLAR SPLIT 5/8″ DIAMETER

18 4 50271 ROLL PIN, PLN 5/32″ × 7/16″

17

PARTS FOR BLOWER AREA

Page 18

View of BLOWER/MOTOR COMPARTMENT

VIEW OF BLOWER/MOTOR COMPARTMENT

18

Page 19

Parts for BLOWER/MOTOR COMPARTMENT

ITEM QTY. P/N DESCRIPTION

1 1 28021-0047 INTERLOCK SWITCH 10A NO2P

2 1 28021-0061 MOMENTARY SWITCH - 10A NO 2 POLE

3 1 44687 MOTOR 1/2 HP

4 1 49953 MOTOR MOUNTING BRACKET WELDMENT

5 1 50449 MOTOR SUPPORT BRACKET

6 8 1513D8805 SCREW, HEX HD 3/8″-16 × 3/4″ - NP

7 8 21422-0001 LOCK WASHER, SPLIT 3/8″ ZP

8 8 21416-0001 FLAT WASHER SS 3/8″

9 4 A3896 MACHINE SCREW, HEX HD 5/16″-18 × 1″ 18-8

10 4 3023A8807 FLAT WASHER 5/16″ SAE NP

11 4 21126-0004 HEX NUT SS 5/16-18

12 4 21421-0004 LOCK WASHER 5/16″

13 1 36451 COOLING FAN 230V AC

14 1 31497 FINGER COOLING FAN GUARD

15 1 33812-3 THERMOCOUPLE, TYPE “J” SHIELDED 9.50 × 60″ (TEMP CONTROL)

16 1 21651-0010 KEY - MOTOR, 3/16″ X 3/16″ X 1″

17 1 SEE CHART MOTOR, PULLEY

18 1 SEE CHART BUSHING, SPLIT

19 1 SEE CHART BELT, GRIP NOTCH

RPM KIT HERTZ MOTOR PULLEY MTR PULLEY P/N BELT SIZE BELT RPM OF

P/N W/SPLIT BUSHING SPLIT BUSH P/N DESCRIPTION P/N FAN

50545 50 AK51H PULLEY, 4.95″ 51161 AX63 34259 2300

H 5/8 SPLIT BUSHING 50222

51079 50 AK46H PULLEY, 4.45″ 51160 AX62 50584 2040

H 5/8 SPLIT BUSHING 50222

50544 60 AK44H PULLEY, 4.25″ 51159 AX61 50450 2300

STANDARD H 5/8 SPLIT BUSHING 50222

51077 60 AK39H PULLEY, 3.75″ 51158 AX61 50450 2050

OPTIONAL H 5/8 SPLIT BUSHING 50222

SLOW BRAKE

51403 50 AK56H PULLEY, 5.45″ 51404 AX62 50584 2485

H 5/8 SPLIT BUSHING 50222

19

PARTS FOR BLOWER/MOTOR COMPARTMENT

Page 20

20

VIEW OF GAS BURNER & PIPING

Page 21

21

PART FOR GAS BURNER & PIPING

Page 22

22

VIEW OF “SINGLE” BELT CONVEYOR

Page 23

23

PARTS FOR “SINGLE” BELT CONVEYOR

Page 24

24

VIEW OF “SPILT” BELT CONVEYOR

Page 25

25

PARTS FOR “SPLIT” BELT CONVEYOR

Page 26

����-�

26

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 50141 REV. F2 US/UK/CANADA

Page 27

27

LADDER WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 50141 REV. F1 US/UK/ CANADA

Page 28

28

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52059 REV. D DN

Page 29

29

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52065 REV. D DUT

Page 30

30

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52053 REV. D FR

Page 31

31

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52055 REV. D GM

Page 32

32

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52067 REV. D GK

Page 33

33

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52061 REV. D IT

Page 34

34

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52057 REV. D SP

Page 35

35

WIRING DIAGRAM, 208-240 VOLT 50/60 HZ., 1-PHASE 3W 52063 REV. D SW

Page 36

Loading...

Loading...