Page 1

BLODGETT OVEN COMPANY

www.blodgett.com

1400 Toastmaster Drive, Elgin, IL USA 60120

Phone: (847) 741-3300 • Fax: (847) 741-0015

MODEL BG2136

Gas Conveyor Oven

EXTERIOR CONSTRUCTION

Stainless steel front, top, sides, and interior

Fully insulated on bottom, top, front, and rear

Easy serviceable access to all components

Front and top surfaces are cool to the touch

Full drop down front window

Aluminized finished steel back

INTERIOR CONSTRUCTION

Stainless steel outer (finger) plates

18” (457mm) wide stainless steel wire mesh conveyor belt

36” (915mm) long bake chamber

Two blower inlets in the plenum for forced air circulation supplying top and bot-

tom air flow

Standard or Customer specific finger set that allows control of 8 heat zones

inside the bake chamber. Finger set consists of manifolds, inner plates, outer

plates and blank plate(s).

OPERATION

Solid state digital controls to display set point and actual bake chamber tem-

perature(s) as well as bake time.

Maximum Temperature is 550 degrees F (one degree increment)

Modulating gas valve maintains accurate bake chamber temperature

Electronic spark ignition control system

Atmospheric type burner

Internal gas pressure regulator

3 – 30 minute bake time (one second increment)

Product clearance 3 ½” (889mm)

Heat transferred through forced directed hot air impingement

Open vented baking chamber

Two blower cooling fans

Easy to clean – no tools required

Project

Item No.

Quantity

Blodgett gas fired conveyor oven with 18” (457mm) wide conveyor belt and

36” (915mm) long baking zone length. Single, double or triple stack models.

All data is shown per oven section, unless otherwise indicated.

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

High speed conveyor (1-10 minute bake time)

76” (1930mm) long conveyor in lieu of standard 60”

(1524) long conveyor

9” (228mm) Twin stainless steel wire mesh conveyor

belt with individually adjustable bake time settings

Stacking kit to properly stack a BG2136 on top of an

existing SG2136G

One year additional extended warranty*

BG2136

STANDARD FEATURES

Energy reduction system provides an efficient heating

system that improves cooking results and saves energy

Impingement deluxe dual air return that improves cook-

ing results and saves energy

Solid state controls

Temperature controller’s built in auto tune feature

improves overall conveyor oven performance

Microprocessor-controlled conveyor speed with motor

feedback

Large front loading door with window and stainless steel

handle

Portable stand (single, double, triple stack ovens)

Stackable to three high

Stainless steel under shelf on single and double stack

ovens

Removable folding conveyor frame and belt assembly

Removable 8” (203mm) shelf extension (entrance end)

Adjustable conveyor belt tension

Field reversible conveyor belt direction

Product stop (exit end)

¾” by 48” coated gas hose, restraint cable, and manual

on/off gas valve

6’ cord with NEMA L6-20P plug (shipped loose)

One year parts and labor warranty

Start Up by our Authorized Service Provider to activate

the warranty (USA and Canada only)*

* For all international markets, contact your local distributor.

Page 2

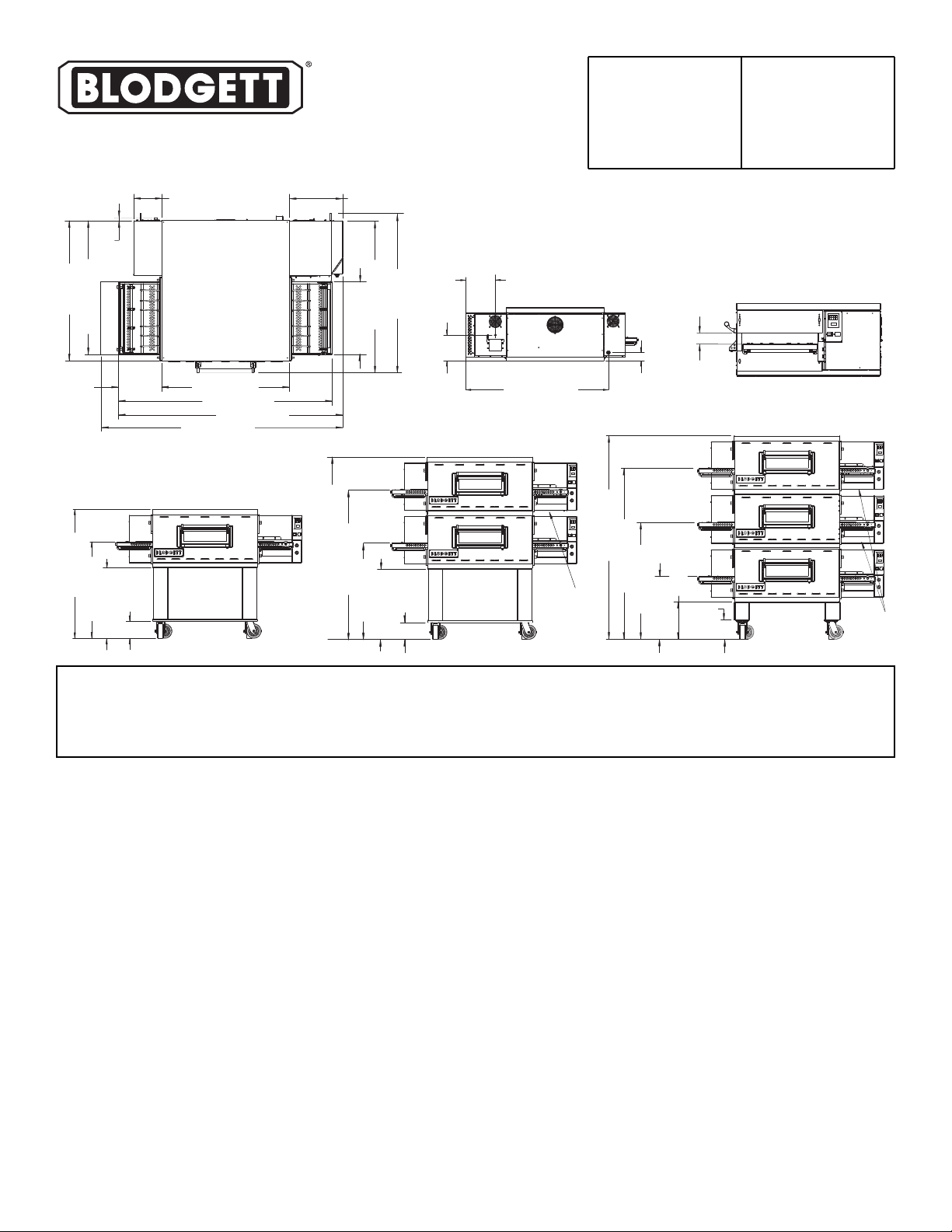

DIMENSIONS ARE IN INCHES [MM]

END VIEW

3-1/2

(89)

43-1/2 [1105]

33-3/16 [843]

24 [610]

5-13/16

[148]

SINGLE

11 (280)

Electrical junction box

52-7/8 (1343)

9-1/8

(231)

3-3/8 (86)

Gas inlet

REAR VIEW

51-5/16 [1303]

62-1/2 [1588]

5-13/16

[148]

33 [838]

24-1/2 [622]

DOUBLE

Heat

Guard

69-1/2 [1765]

40 [1016]

58-1/4 [1480]

21-3/4 [552]

12-1/2 [318]

6-11/16

[170]

TRIPLE

Heat

Guards

40 [1016]

37-15/16 [964]

7-11/16 [195]

7/8

[22]

15-1/16 [383]

46 [1169]

20 [508]

36 [914]

60-1/2 [1537]

63-7/16 [1611]

12-3/16

[310]

TOP VIEW

71-7/16 [1815]

Rear

Front

43-3/8 [1102]

BLODGETT OVEN COMPANY

www.blodgett.com • 1400 Toastmaster Drive, Elgin, IL USA 60120 • Phone: (847) 741-3300 • Fax: (847) 741-0015

MODEL BG2136

SHORT FORM SPECIFICATIONS

Provide Blodgett conveyor model BG2136 (gas) conveyor oven. Unit shall shall cook by means of forced, heated air. Unit shall be (single/double/triple) deck. Each deck shall be fully

independent, of stainless steel construction, and fully insulated on all sides. Provide with electronic spark ignition gas fired and baking compartment with two blowers to evenly distribute heat across baking zone. Conveyor belt shall be single - 18" (457mm) belt constructed of stainless steel wire mesh; baking zone length shall be 36" (915mm). Unit shall be provided with drop down front window. Control panel shall be solid state with 550°F (288°C) maximum thermostat and LCD display of 3-30 minutes adjustable belt speed. Provide startup inspection service by a factory authorized service agent. Provide options and accessories as indicated.

Printed in U.S.A. NOTE: FOR COMMERCIAL USE ONLY

APPROVAL/STAMP

P/N M10990 Rev H (5/08)

POWER SUPPLY (must have dedicated ground)

BG2136 208-240 VAC, 50/60 Hz, 1 ph, 6 amp., 2-wire plus ground

This current draw is an average value for normal operation. The initial amperage draw on oven start up may exceed the listed value.

MINIMUM ENTRY CLEARANCE:

Uncrated 19-1/2" (495mm)

SHIPPING INFORMATION:

Approx. Weight:

Single 658 lbs. (299 kg)

Double 1255 lbs. (570 kg)

Triple 1866 lbs. (846 kg)

Crate Size:

BG2136 60" L x 49" W x 42" H (1524 x 1245 x 1067 mm)

DIMENSIONS:

Floor space 60" (1524mm) W x 46" (1069mm) L

Product clearance 3-1/2" (89mm)

Recommended minimum wall clearance

Left and right side 1" (25mm)

Rear 3” (76mm)

Baking zone

Width 18" (457mm)

Length 36" (914mm)

MAXIMUM INPUT: (per section)

BG2136 75,000 BTU/hr

GAS SUPPLY: (specify) Natural Propane

Oven per cavity 3/4" NPT 3/4" NPT

Main gas supply 2" line 1-1/2" line

Minimum gas pressure: 6" W.C. 11" W.C.

Maximum gas pressure: 12" W.C. 14" W.C.

NOTE: Blodgett Oven, in accord with its policy to continually improve its products, reserves the right to change materials or specifications without notice. Such revisions do not entitle the buyer to corresponding changes, improvements, additions, or replacements for previously purchased equipment.

Loading...

Loading...