Page 1

GAS CONVECTION INSTALLATION

FOURS A CONVECTION D’INSTALLATION

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS MUST BE POSTED IN A PROMINENT

LOCATION. THIS INFORMATION MAY BE OBTAINED BY CONTACTING YOUR LOCAL GAS SUPPLIER.

FOR YOUR SAFETY Do not store or use gasoline or other ammable vapors or liquids in the vicinity of this or any other

appliance.

The information contained in this manual is important for the proper installation, use, and maintenance of this oven.

Adherence to these procedures and instructions will result in satisfactory baking results and long, trouble free service.

Please read this manual carefully and retain it for future reference.

Errors: Descriptive, typographic or pictorial errors are subject to correction. Specications are subject to change without

notice.

AVERTISSEMENT: UNE INSTALLATION, UN AJUSTEMENT, UNE ALTERATION, UN SERVICE OU UN ENTRETIEN

NON CONFORME AUX NORMES PEUT CAUSER DES DOMMAGES A LA PROPRIETE, DES BLESSURES OU LA

MORT. LISEZ ATTENTIVEMENT LES DIRECTIVES D’INSTALLATION, D’OPERATION ET D’ENTRETIEN AVANT DE

FAIRE L’INSTALLATION OU L’ENTRETIEN DE CET EQUIPEMENT.

LES INSTRUCTIONS A RESPECTER AU CAS OU L’UTILISATEUR PERQOIT UNE ODEUR DE GAZ DOIVENT ETRE

AFFCHEES DANS UN ENDROIT BIEN VISIBLE. VOUS POUVEZ VOUS LES PROCURER AUPRES DE VOTRE

FOURNISSEUR DE GAZ LOCAL.

AVERTISSEMENT Ne pas entreposer ni utiliser de l’essence ni d’autres vapeurs ou liquides inammables dans le voi-

sinage de cet appariel, ni de tout autre appareil.

Les informations donnees dans le present manuel sont importantes pour installer, utiliser et entretenir correctement ce

four. Le respect de ces instructions et procedures permettra d’obtenir de bons resultats de cuisson et une longue duree

de service sans problemes. Veuillez lire le present manuel et le conserver pour pouvoir vous y reporter a l’avenir.

Erreurs: Les erreurs de description, de typographie ou d’illustration font l’objet de corrections. Les caracteristiques sont

sujettes a modications sans preavis.

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802) 864-0183

PN 54865 Rev D (3/14)

© 2014 - G.S. Blodgett Corporation

Page 2

DELIVERY AND LOCATION

DELIVERY AND INSPECTION

All Blodgett ovens are shipped in containers to prevent damage. Upon delivery of your new oven:

• Inspect the shipping container for external damage. Any evidence of damage should be noted on the delivery receipt

which must be signed by the driver.

• Uncrate the oven and check for internal damage. Carriers will accept claims for concealed damage if notied within

fteen days of delivery and the shipping container is retained for inspection.

The Blodgett Oven Company cannot assume responsibility for loss or damage suffered in transit. The carrier assumed full

responsibility for delivery in good order when the shipment was accepted. We are, however, prepared to assist you if ling

a claim is necessary.

OVEN LOCATION

The well planned, proper placement of your oven will result in long term operator convenience and satisfactory performance.

The following clearances must be maintained between the oven and any combustible or non-combustible construction.

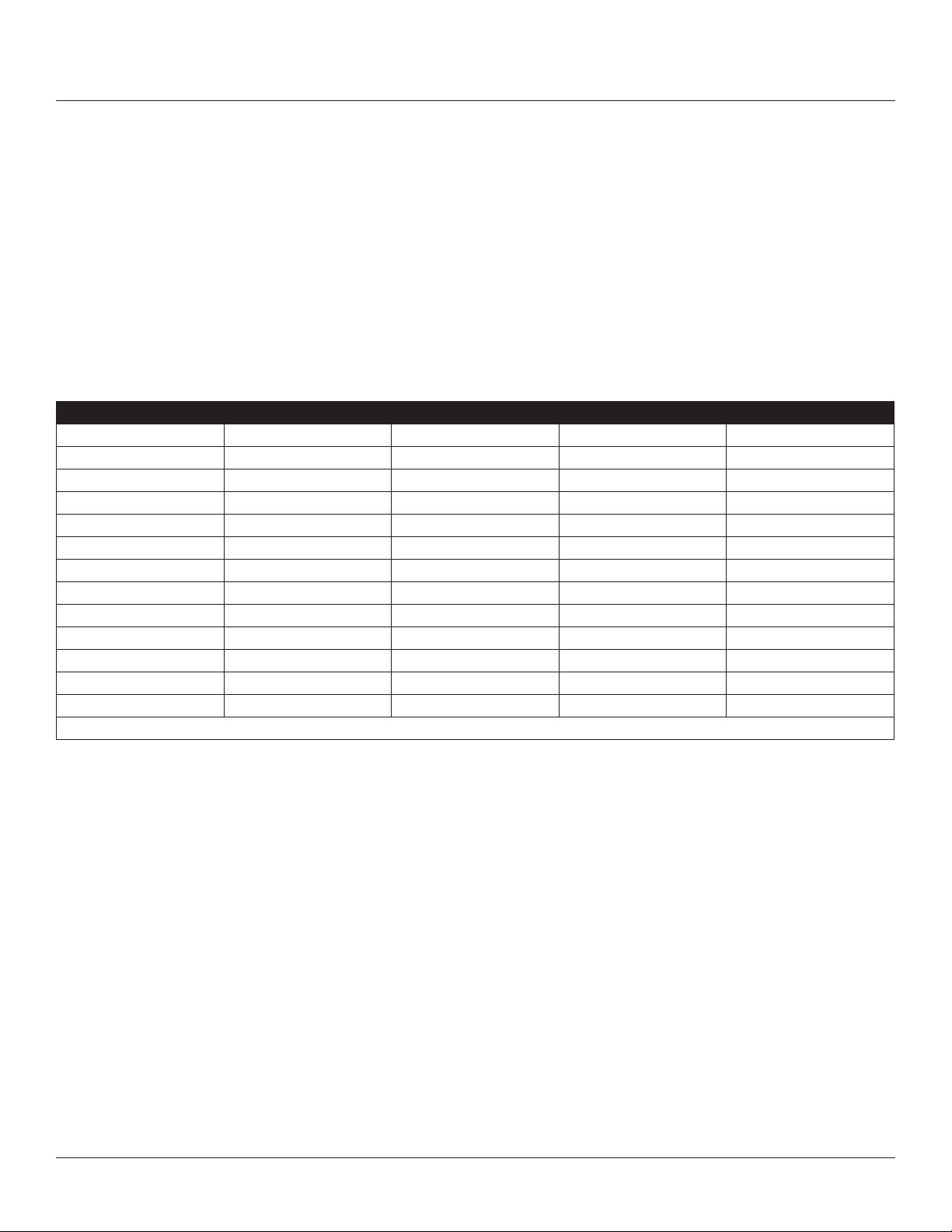

OVEN CLEARANCES

Model Right Side Left Side Back Bottom

DFG-100 XCEL 0” (0cm) 0” (0cm) 0” (0cm) 6” (15cm)

DFG-100-ES 0” (0cm) 0” (0cm) 0” (0cm) 0” (0cm)

DFG-200-ES 0” (0cm) 0” (0cm) 0” (0cm) 0” (0cm)

DFG-100 2” (5cm) 2” (5cm) 0” (0cm) 6” (15cm)

DFG-200 6” (15cm) 6” (15cm) 6” (15cm) 6” (15cm)

Zephaire-100-G-ES 0” (0cm) 0” (0cm) 0” (0cm) 0” (0cm)

Zephaire-200-G-ES 0” (0cm) 0” (0cm) 0” (0cm) 0” (0cm)

Zephaire-100-G 2” (5cm) 2” (5cm) 0” (0cm) n/a

Zephaire-200-G 6” (15cm) 6” (15cm) 6” (15cm) 4.5” (11.4cm)

BDO-100-G-ES 0” (0cm) 0” (0cm) 0” (0cm) 0” (0cm)

SHO-100-G 2” (5cm) 2” (5cm) 0” (0cm) 6” (15cm)

DFG-50 6” (15cm) 6” (15cm) 6” (15cm) 6” (15cm)

12” (30cm) must be available on all oven sides and back for servicing.

NOTE: On gas models, routine servicing can usually be accomplished within the limited movement provided by the gas

hose restraint. If the oven needs to be moved further from the wall, the gas must rst be turned off and disconnected

from the oven before removing the restraint. Reconnect the restraint after the oven has been returned to its normal

position.

It is essential that an adequate air supply to the oven be maintained to provide a sufcient ow of combustion and ventilation air.

• Place the oven in an area that is free of drafts.

• Keep the oven area free and clear of all combustibles such as paper, cardboard, and ammable liquids and solvents.

• NSF requires 6” of clearance on the bottom and sides of the unit for cleaning. Do not place the oven on a curb base or

seal to a wall.

• The location must provide adequate clearance for the air opening into the combustion chamber.

Before making any utility connections to this oven, check the rating plate to be sure the oven specications are compatible

with the gas and electrical services supplied for the oven.

1. Pull out control panel. The rating plate attached to the inside of the control compartment.

GAS CONVECTION OVENS 2 INSTALLATION

Page 3

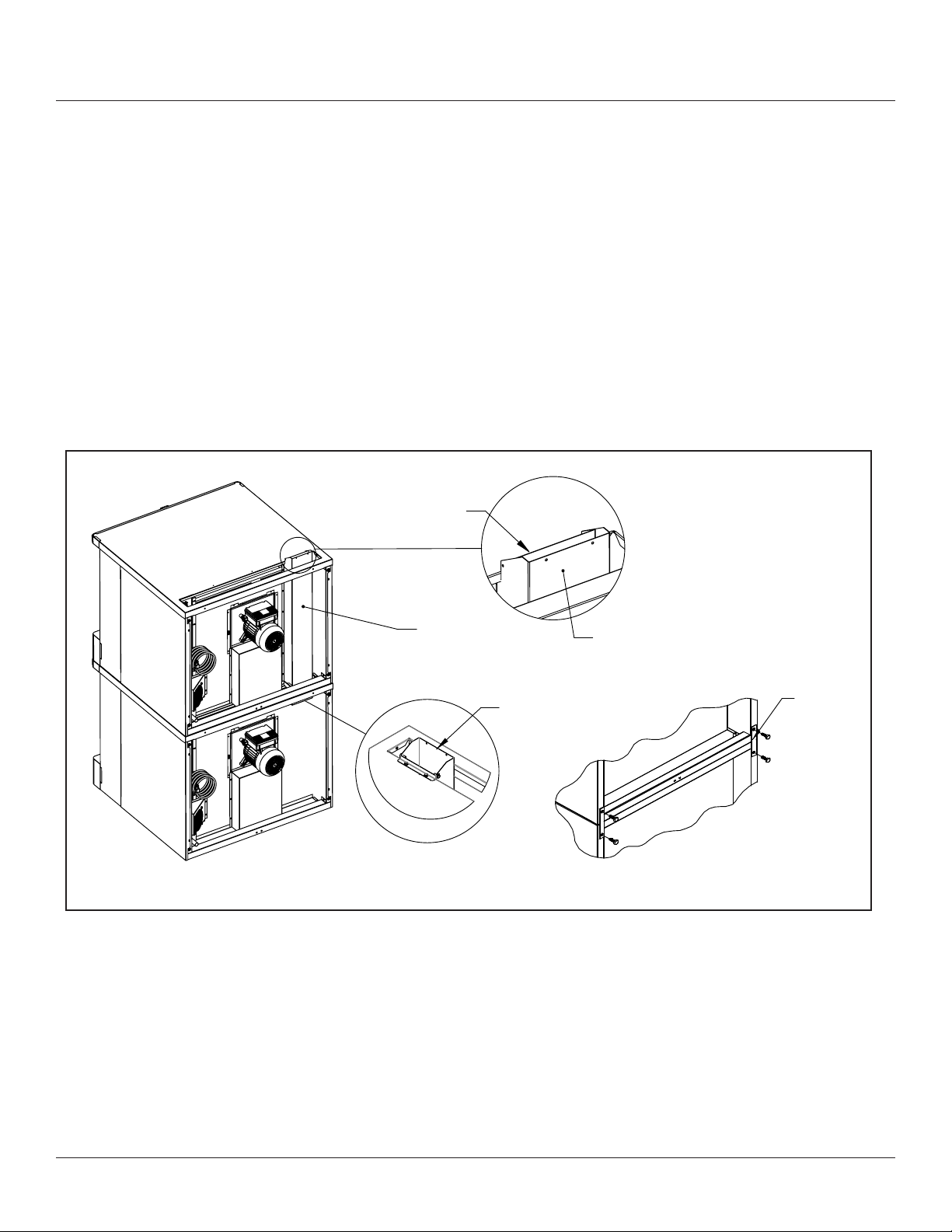

OVEN ASSEMBLY

LEG ATTACHMENT

1. Push the oven onto a lift with the bottom of the oven down.

2. Align the threaded stud in each leg with the nut located inside each bottom corner of the oven frame. Turn the legs

clockwise and tighten to the nearest full turn.

3. Align the two leg plate holes in each leg with those in the oven bottom. Secure each leg using two 1/2” bolts.

NOTE: If using casters see CASTER ASSEMBLY before proceeding.

4. Level the oven by screwing the adjustable leg feet in or out as necessary.

6" (15 cm Legs Shown

Figure 1

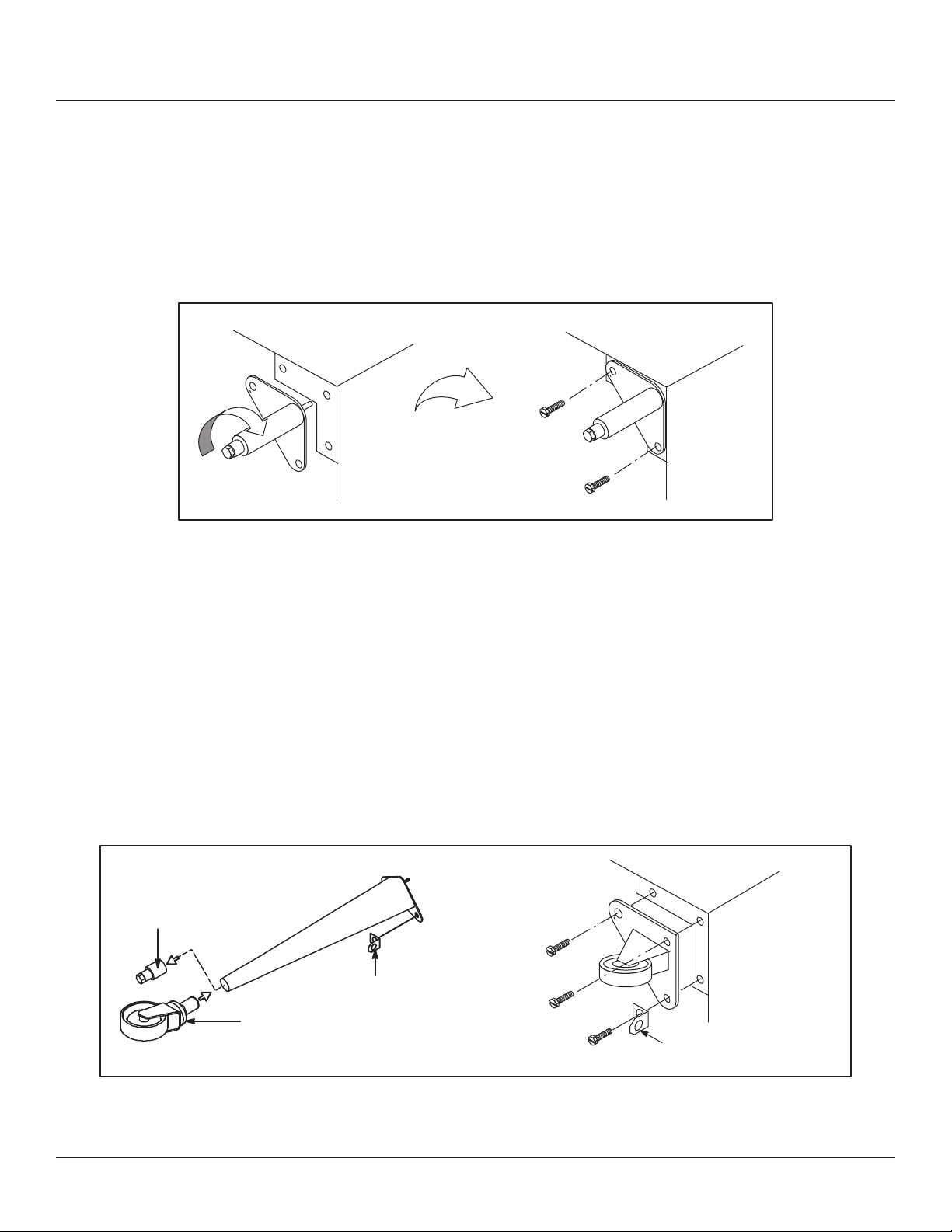

CASTER ASSEMBLY

NOTE: Install the locking casters on the front of the oven. Install the non-locking casters on the back of the oven.

NOTE: Use a gas hose restraint on all units with casters. See page 6.

Casters for Single and Double Stacked Ovens:

1. Attach the legs as described.

2. Pry the adjustable feet out of the legs.

3. Insert one caster into each leg as shown. Tighten the lock nuts to secure the casters.

Low Prole Casters for Double Stacked Ovens:

1. Align the three holes in each caster assembly plate with those in the oven bottom. Secure each caster using three 1/2”

bolts.

Adjustable

Leg Foot

Gas Hose

Restraint Bracket

Caster Assembly

Gas Hose Restraint Bracket

Figure 2

GAS CONVECTION OVENS 3 INSTALLATION

Page 4

OVEN ASSEMBLY

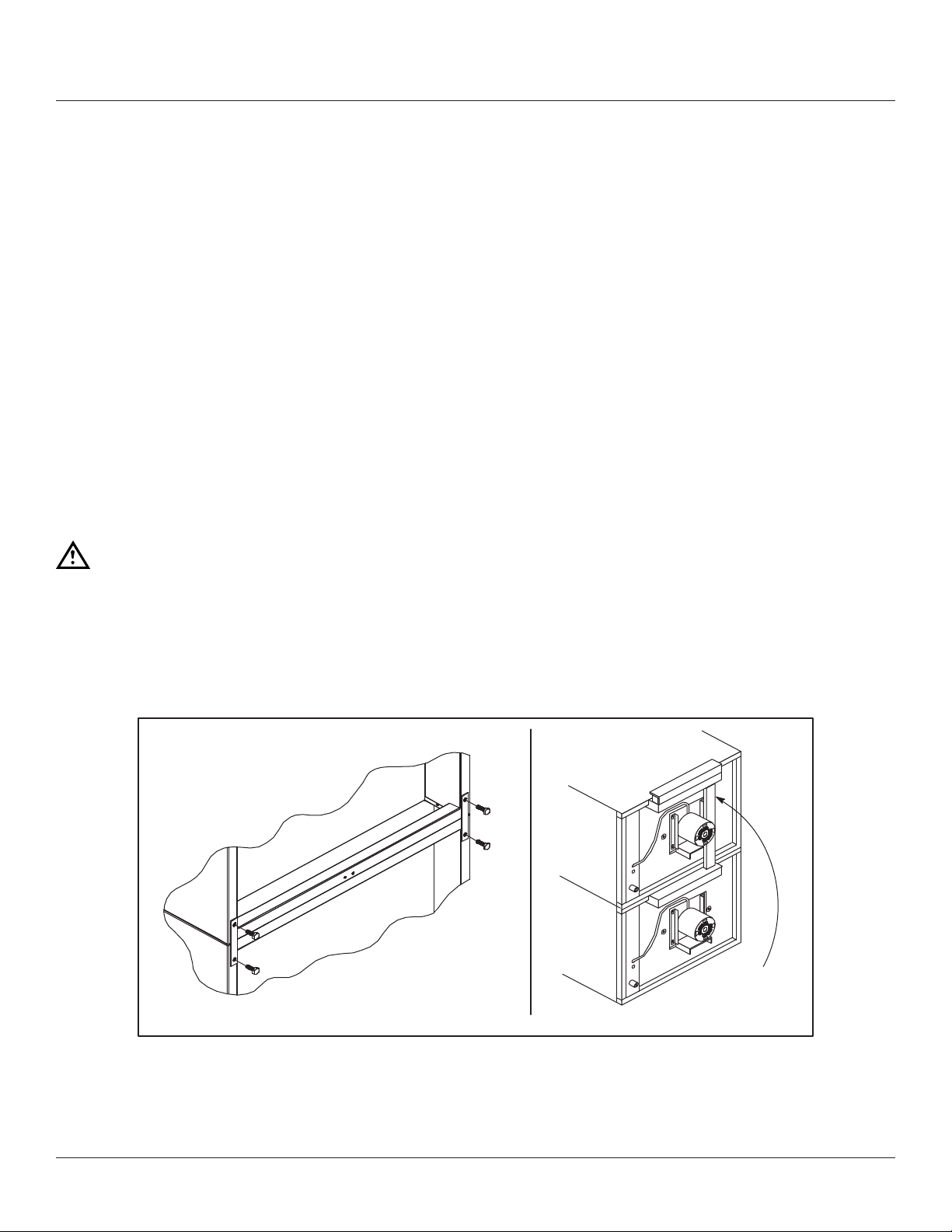

DOUBLE SECTION ASSEMBLY

NOTE: Old style ovens refer to units with painted exposed rear angle. New style ovens refer to units with rear angle iron

enclosed in steel.

The following instructions apply to stacking two new style ovens.

1. Secure the short legs to the bottom sections as described.

2. Place the upper section in position on top of the lower oven.

3. Attach the stacking brackets using the remaining 5/16” bolts shipped with the ovens.

4. Attach the ue connector.

The following instructions apply to stacking a new style oven on an old style oven.

1. Secure the short legs to the bottom sections as described.

2. Place the upper section in position on top of the lower oven.

3. Attach the stacking brackets using the remaining 5/16” bolts shipped with the ovens.

4. Drill a clearance hole for a 5/16” bolt in the angle iron of the old style oven. Use the holes in the stacking brackets as a

pilot.

5. Attach the stacking brackets to the old style oven with the 5/16” bolts and nuts provided in the kit.

6. Attach the ue connector.

WARNING!!

When stacking ovens be sure to remove the single oven ue boxes prior to attaching three-piece connec-

tor.

OVEN LEVELING

After assembly, the oven should be leveled and moved to the operating location.

1. The oven can be leveled by adjusting the feet or casters located on the bottom of each leg.

Flue Connector

Figure 3

GAS CONVECTION OVENS 4 INSTALLATION

Page 5

OVEN ASSEMBLY

DOUBLE SECTION ASSEMBLY - ES MODELS

1. Secure the short legs to the bottom sections as described.

2. Place the upper section in position on top of the lower oven.

3. Attach the stacking brackets using the remaining 5/16” bolts shipped with the ovens.

4. Attach the draft diverter to the bottom oven. DO NOT install the draft diverter guard on the bottom oven.

5. Install the ue riser on the top oven. The bottom of the ue riser slides down over the draft diverter on the bottom oven.

Secure with 12 screws.

6. Install the ue riser guard as shown below.

OVEN LEVELING

After assembly, the oven should be leveled and moved to the operating location.

1. The oven can be leveled by adjusting the feet or casters located on the bottom of each leg.

Flue Riser Guard

Flue Riser

Draft Diverter

DFG-100-ES Shown

Figure 4

Flue Riser

Stacking

Brackets

GAS CONVECTION OVENS 5 INSTALLATION

Page 6

VENTILATION

WARNING!!

Failure to properly vent the oven can be hazardous to the health of the operator and may result in operational problems, unsatisfactory baking and possible damage to the equipment. Damage sustained as a

direct result of improper ventilation will not be covered by the manufacturer’s warranty.

CANOPY TYPE EXHAUST HOOD

A mechanically driven, canopy type exhaust hood is the preferred method of ventilation.

The hood should be sized to completely cover the equipment plus an overhang of at least 6” (15 cm) on all sides not adja-

cent to a wall. The distance from the oor to the lower edge of the hood should not exceed 7’ (2.1m). The total makeup and

exhaust air requirements for hood capacity should be approximately 30 CFM (.85 m3) for each oven section.

Installing the canopy hood draft diverter

Ovens ordered for hood venting are supplied with a draft diverter. Install the draft diverter as follows:

1. Place the diverter over the ue connector with the open area facing the front of the oven.

2. Secure both ends with the sheet metal screws provided.

Draft Diverter

Front of

Oven

Figure 5

ES Models

1. Place the draft diverter on the oven back and slide it up through the rectangular hole in the oven body top. Secure to the

oven body back with four screws.

2. Secure the draft diverter guard to the draft diverter with four screws.

Draft

Diverter

Front of

Oven

Draft Diverter

Guard

Figure 6

GAS CONVECTION OVENS 6 INSTALLATION

Page 7

VENTILATION

DIRECT FLUE ARRANGEMENT

When the installation of a mechanically driven exhaust hood is impractical the oven may be vented by a direct ue arrangement.

WARNING!!

It is essential that the direct ue be installed as follows. Incorrect installation will result in unsatisfactory

baking and oven damage.

The ue must be class B or better. The height of the ue should rise 6-8 ft (2-2.5 m) above the roof of the building or any

proximate structure. Never direct vent the oven into a hood. The ue should be capped with a UL Listed type vent cap to

isolate the unit from external environmental conditions.

The direct vent cannot replace air consumed and vented by the oven. Provisions must be made to supply the room with

sufcient make-up air. Total make-up air requirements for each oven section should be approximately 30 CFM (.85 m3) per

section. To increase the supply air entering the room, a ventilation expert should be consulted.

Installing the draft hood

Ovens ordered for direct venting are supplied with a draft hood. Install the draft hood as follows:

1. Place the draft hood over the ue connector.

2. Secure both ends with the sheet metal screws provided.

Flue

Figure 7

ES Models

1. Install draft diverter using the screws provided as shown below.

2. Place the draft hood over the draft diverter.

3. Secure both ends with the sheet metal screws provided.

Drafthood

Two screws

Draft diverter

in back

Draft Hood

Front of Oven

Flue

One

screw

One screw

into frame

Front of

Oven

Figure 8

GAS CONVECTION OVENS 7 INSTALLATION

Page 8

UTILITY CONNECTION

GAS PRESSURE REGULATION AND TESTING

Each oven has been adjusted at the factory to operate with the type of gas specied on the rating plate.

GAS RATINGS

Natural Gas Propane

Min Max Min Max

Inlet Pressure

W.C. 7.0 10.5 11.0 13.0

kPa 1.742 2.61 2.74 3.23

Manifold Pressure

W.C. 3.5 10.0

kPa .87 2.49

• Inlet Pressure - the pressure of the gas before it reaches the oven.

• Manifold Pressure - the pressure of the gas as it enters the main burner(s).

• Min - the minimum pressure recommended to operate the oven.

• Max - the maximum pressure at which the manufacturer warrants the oven’s operation.

Each oven is supplied with a regulator to maintain the proper gas pressure. The regulator is essential to the proper opera-

tion of the oven and should not be removed. It is preset to provide the oven with 3.5” W.C. (0.87 kPa) for natural gas and

10.0” W.C. (2.50 kPa) for Propane at the manifold.

DO NOT INSTALL AN ADDITIONAL REGULATOR WHERE THE OVEN CONNECTS TO THE GAS SUPPLY UNLESS

THE INLET PRESSURE IS ABOVE MAXIMUM.

Prior to connecting the oven, gas lines should be thoroughly purged of all metal lings, shavings, pipe dope, and other

debris. After connection, the oven should be checked for correct gas pressure.

The oven and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig (13.85” W.C., 3.45 kPa).

The oven must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any

pressure testing of the gas piping system at test pressures equal or less than 1/2 psig (13.85” W.C., 3.45 kPa).

Gas Connection

2.5” (64 mm)

2.88” (73 mm) ES Models

Gas Connection

3.75” (85.7 mm)

3.375 (86 mm) DFG-200-ES & Zephaire 200-G-ES Models

3” (76 mm) ES Models

Figure 9

GAS CONVECTION OVENS 8 INSTALLATION

Page 9

UTILITY CONNECTION

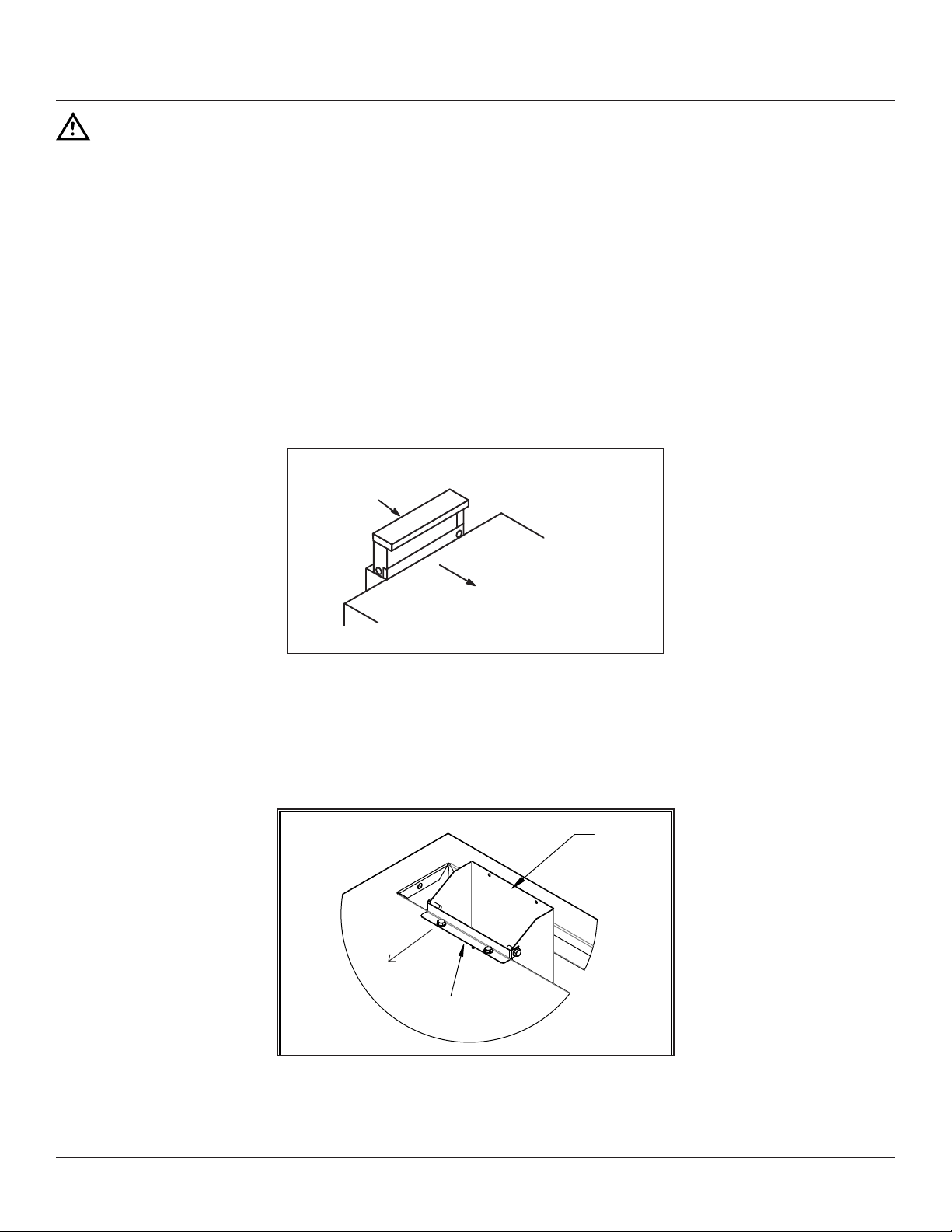

GAS HOSE RESTRAINT

If the oven is mounted on casters, a commercial exible connector with a minimum of 3/4” (1.9 cm) inside diameter must

be used along with a quick connect device. The restraint, supplied with the oven, must be used to limit the movement of the

unit so that no strain is placed upon the exible connector. With the restraint fully stretched the connector should be easy

to install and quick connect.

The restraint (ie: heavy gauge cable) should be 1,000 lb. (453 kg) test load and should be attached without damaging the

building. DO NOT use the gas piping or electrical conduit for the attachment of the permanent end of the restraint! Use anchor bolts in concrete or cement block. On wooden walls, drive hi test wood lag screws into the studs of the wall.

1. Mount the supplied bracket to the leg bolt just below the gas inlet.

2. Attach the clip on restraining cable to the mounting bracket.

WARNING!!

If the restraint is disconnected for any reason it must be reconnected when the oven is returned to its original position.

Back of Oven

Restraint Cable

Bracket

Double stacked unit shown. Use the

same procedure for single units.

Figure 10

ELECTRICAL CONNECTION

Wiring diagrams are located in the control compartment and on the back of the oven. This oven is supplied for connection

to 115 volt grounded circuits. The electric motor, indicator lights and related switches are connected through the 6’ electric

supply cord found at the rear of the oven.

WARNING!!

This appliance is equipped with three prong grounding type plug for your protection against shock hazard

and should be plugged directly into a properly grounded three prong receptacle. DO NOT cut or remove

the grounding prong from this plug.

THE BLODGETT OVEN COMPANY CANNOT ASSUME RESPONSIBILITY FOR LOSS OR DAMAGE SUFFERED AS A

RESULT OF IMPROPER INSTALLATION.

ELECTRICAL SPECIFICATIONS

Hz Volts Phase Amps Electrical Connection

U.S. & Canadian Installations

60 115 1 6 Cord set provided

General Export Installations

50 220-240 1 3 Size per local code

GAS CONVECTION OVENS 9 INSTALLATION

Page 10

INITIAL STARTUP

The following is a check-list to be completed by qualied personnel prior to turning on the appliance for the rst time.

• Open the manual shut-off valve at the rear of the oven.

• Remove the control panel and combustion covers.

• Turn the combination valve’s manual shut-off to the on position.

• Turn the selector switch to Cook, and the thermostat to 500ºF (260ºC).

The oven main burner lights, and the Oven Ready Light comes on. With the main burner on, check the following.

• Verify there are no gas leaks, by checking all gas connections with a soapy water solution.

• Set thermostat to 350-400ºF (149-204ºC) to check oven calibration. Adjust as necessary.

• Verify that the inlet pressure is correct. The inlet pressure can be checked at the pressure tap located on the combina-

tion valve’s inlet side.

• Verify that the manifold pressure is correct. The manifold pressure can be checked at the pressure tap located on the

manifold.

• If the above pressure readings are set to the recommended pressure requirements, allow the oven to burn-off for 2

hours. If the pressure readings are not set correctly, turn off the oven and readjust accordingly.

WARNING!!

The break in procedure burns off excess oils present in the metals during fabrication. Smoke may be pro-

duced. Proper ventilation is required.

ADJUSTMENTS ASSOCIATED WITH INITIAL INSTALLATION

Each oven, and its component parts, have been thoroughly tested and inspected prior to shipment. However, it is often

necessary to further test or adjust the oven as part of a normal and proper installation. These adjustments are the responsibility of the installer, or dealer. Since these adjustments are not considered defects in material or workmanship, they are

not covered by the Original Equipment Warranty. They include, but are not limited to:

• calibration of the thermostat

• adjustment of the doors

• burner adjustments

• leveling

• testing of gas pressure

• tightening of fasteners.

No installation should be considered complete without proper inspection, and if necessary, adjustment by qualied

installation or service personnel.

GAS CONVECTION OVENS 10 INSTALLATION

Page 11

LIVRAISON ET IMPLANTATION

LIVRAISON ET INSPECTION

Tous les fours sont expédiés en conteneurs. A la réception de votre four Blodgett vous devez:

• Vérier que les emballages ne sont pas abimés. Toute défection dans l’emballage doit être notée sur l’accusé de

reception de la marchandise; celui-ci doit être signé par le chauffeur.

• Sortir le four de son emballage et vérier son bon état. Les transporteurs n’acceptent les réclamations et plaintes que

si elles sont faites dans les quinze jours qui suivent la livraison et si l’emballage a été conservé an d’être inspecté.

La Blodgett Oven Co., n’est pas responsable des dégâts subis pendant le transport. Le transporteur est seul responsable de la livraison du matériel en bon état lorsque l’expédition a été acceptée. Néanmoins, nous sommes à

votre disposition pour vous aider à composer votre dossier de réclamation.

IMPLANTATION DU FOUR

L’implantation correcte et bien étudiée du four sera à l’avantage à long terme de l’opérateur et permettra d’obtenir un rendement satisfaisant. Les espaces de dégagement ci-dessous doivent être prévus entre le four et toute construction combus-

tible ou non.

DÉGAGEMENTS DE FOUR

Modèle Côté droit Côté gauche Arrière du four Dessous du four

DFG-100 XCEL 0” (0cm) 0” (0cm) 0” (0cm) 6” (15cm)

DFG-100-ES 0” (0cm) 0” (0cm) 0” (0cm) 0” (0cm)

DFG-200-ES 0” (0cm) 0” (0cm) 0” (0cm) 0” (0cm)

DFG-100 2” (5cm) 2” (5cm) 0” (0cm) 6” (15cm)

DFG-200 6” (15cm) 6” (15cm) 6” (15cm) 6” (15cm)

Zephaire-100-G-ES 0” (0cm) 0” (0cm) 0” (0cm) 0” (0cm)

Zephaire-200-G-ES 0” (0cm) 0” (0cm) 0” (0cm) 0” (0cm)

Zephaire-100-G 2” (5cm) 2” (5cm) 0” (0cm) n/a

Zephaire-200-G 6” (15cm) 6” (15cm) 6” (15cm) 4.5” (11.4cm)

BDO-100-G-ES 0” (0cm) 0” (0cm) 0” (0cm) 0” (0cm)

SHO-100-G 2” (5cm) 2” (5cm) 0” (0cm) 6” (15cm)

DFG-50 6” (15cm) 6” (15cm) 6” (15cm) 6” (15cm)

12” (30cm) doit être disponible sur tous les côtés et dos de four pour l’entretien

REMARQUE: L’entretien régulier peut en général être effectué dans les limites du déplacement que permet la chaîne

de retenue. Si le four doit être plus écarté du mur, l’alimentation en gaz doit être coupée et la canalisation

débranchée du four avant d’enlever la chaîne. Celle-ci doit être utilisée pour empêcher d’exercer toute contrainte sur le coupleur de gaz.

Il est essentiel qu’une circulation d’air adéquate au four soit maintenue pour apporter un débit d’air de combustion et de

ventilation sufsant.

• L’emplacement ne doit pas avoir de courants d’air.

• Maintenez la zone du four libre et dégagée de tous matériaux combustibles tels que le papier, le carton, ainsi que les

liquides et solvants inammables.

• Le NSF exige 6”; du dégagement du fond et des côtés de l’unité pour le nettoyage. Ne placez pas le four sur une

base de bord ou le joint à un mur.

• L’emplacement doit permettre un dégagement adéquat pour l’ouverture de ventilation dans la chambre de combus-

tion.

Veuillez vérier le tableau de spécications avant d’effectuer tout branchement sur ce four an de vous assurer ques les

spécications de ce four sont compatibles avec le gaz d’arrivée au four.

FOURS A CONVECTION 11 D’INSTALLATION

Page 12

MONTAGE DU FOUR

ASSEMBLAGE DES PIEDS

1. Pousser le four, couché sur le dos, sur un élévateur.

2. Alignez le goujon leté du pied sur le trou de vis prévu dans le coin avant du fond de caisse. Vissez le pied, dans le sens

des aiguilles d’une montre, jusqu’au dernier tour complet possible.

3. Alignez les deux orices de la plaque du pied sur les trous prévus au bas du four. Fixez le pied à l’aide de deux boulons

de 12.7 mm (1/2 po).

REMARQUE: Si des roulettes sont utilisées, voir MONTAGE DES ROULETTES avant de continuer.

4. Si nécessaire, mettez le four de niveau en vissant ou en dévissant la vis de niveau des pieds réglables.

Illustré : pieds de 15 cm (6”)

Figure 11

MONTAGE DES ROULETTES

REMARQUE: Installer les roulettes à frein sur le devant du four. Installer les roulettes sans frein à l’arrière.

REMARQUE: Si le four est monté sur roulettes, un connecteur commercial exible doit être utilisé. Voir le page 13.

Roulettes pour four simple ou pour four superposés :

1. Placer les pieds comme décrit.

2. Desserrer l’écrou de blocage des embouts au bas de chaque pied réglable. Retirer les embouts.

3. Insérer une roulette dans chaque pied, comme illustré. Serrer les écrous de blocage pour xer les roulettes.

Roulettes de bas prole pour deux fours superposés :

1. Aligner les trois trous dans chaque plaque de l’ensemble de roulette avec les trous dans le fond du four. Fixer chaque

roulette à l’aide de trois boulons de 12.7 mm (1/2 po).

Embouts de pied

ajustables

Cornière de

retenue du câble

Ensemble de roulette

Cornière de retenue du câble

Figure 12

FOURS A CONVECTION 12 D’INSTALLATION

Page 13

MONTAGE DU FOUR

MONTAGE DE LA SECTION DOUBLE

REMARQUE: Les vieux modèles de fours sont ceux qui ont un cadre arrière peinturé. Les nouveaux modèles de fours

sont ceux avec un cadre arrière enfermé en acier.

Les instructions suivantes sont applicable a l’assemblage de deux nouveaux modèles de fours..

1. Fixez les pieds de courte longueur au bas de la section inférieure comme décrit.

2. Posez la section supérieure par-dessus la section inférieure.

3. Fixez les ferrures de montage superposé au moyen des autres boulons de 5/16 po expédiés avec les fours.

4. Raccordez le connecteur de carneau.

Les instructions suivantes sont applicables a l’assemblage d’un nouveau modèle de four (le four supérieur) avec

un vieux modèle de four (le four inférieur).

1. Fixez les pieds de courte longueur au bas de la section inférieure comme décrit.

2. Posez la section supérieure par-dessus la section inférieure.

3. Fixez les ferrures de montage superposé au moyen des autres boulons de 5/16 po expédiés avec les fours.

4. Forez un trou pour un boulon de 5/16” dans le cadre du vieux modèle du four. Untilisez les trous dans les agrafes

d’empilage.

5. Fixez les agrafes d’empilage au vieux modèle du four a l’aide de boulons 5/16” et des écrous qui se trouve dans le

trousseau d’assemblage.

6. Raccordez le connecteur de carneau.

AVERTISSEMENT!!

Lors de la superposition de deux fours simples, il est nécessaire d’enlever les boîtes de carneau des unités simples avant l’installation du connecteur à trois pièces.

MISE À NIVEAU DU FOUR

Après assemblage le four doit être mis à niveau et installé à son emplacement d’utilisation.

1. Le four peut être mis à niveau en ajustant les vis de mise à niveau ou les roulettes en bas de chaque pied.

Le Connecteur

Figure 13

FOURS A CONVECTION 13 D’INSTALLATION

Page 14

MONTAGE DU FOUR

MONTAGE DE LA SECTION DOUBLE

1. Fixez les pieds de courte longueur au bas de la sec-

tion inférieure comme décrit.

2. Posez la section supérieure par-dessus la section inférieure.

3. Fixez les ferrures de montage superposé au moyen

des autres boulons de 5/16 po expédiés avec les

fours.

4. Fixez le déecteur de tirage au four bas. NE PAS installer le projet de dérivation garde sur le fond du four.

5. Installer la colonne montante de fumée sur le dessus

du four. Le bas de la colonne montante de combustion glisse vers le bas sur le déecteur de tirage sur la

partie inférieure du four. Fixer avec 12 vis.

6. Installer la colonne montante garde de combustion,

comme indiqué ci-dessous.

Combustion

garde montante

MISE À NIVEAU DU FOUR

1. Après assemblage le four doit être mis à niveau et

installé à son emplacement d’utilisation.

2. Le four peut être mis à niveau en ajustant les vis de

mise à niveau ou les roulettes en bas de chaque pied.

Combustion

montante

Divertisseur d’air

DFG-100-ES montré

Figure 14

Combustion

montante

Les ferrures

de montage

superposé

FOURS A CONVECTION 14 D’INSTALLATION

Page 15

VENTILATION

AVERTISSEMENT:

Un mauvais système d’aération peut aboutir à un mauvais fonctionnement du four, des résultats de cuisson peu satisfaisants; il peut également abîmer l’appareil.Les dégâts causés par une mauvaise ventilation

ne sont pas couverts par la garantie du fabricant.

HOTTE D’ÉVACUATION TYPE VOÛTE

La méthode de ventilation la meilleure est celle qui utilise une hotte de ventilation adéquate à mécanique.

La hotte doit être conçue pour couvrir la totalité de l’appareil à ventiler avec en plus un surplomb se 15 cm (6”) de chaque

côté de l’appareil non adjacent au mur. La distance du plancher à l’extremité la plus basse de la hotte ne doit pas dépasser

sept 2.1m (7’).Le volume total d’air neuf et d’évacuation à considérer lors de la détermination de la capacité de hotte nécessaire est d’environ 30 CFM (.85 m3) pour chaque section de four.

Installation du déviateur de tirage

Les fours commandés pour hotte d’évacuation sont fournis avec un déviateur de tirage. Installer le déviateur de tirage

comme suit :

1. Placer le déviateur au-dessus du connecteur de cheminée avec la partie ouverte tournée vers l’avant du four..

2. L’assujettir des deux côtés avec les vis à tôle fournies.

Divertisseur d’air

Avant du four

Figure 15

Modèles ES

1. Placer le déviateur de tirage sur la partie arrière du four et le faire glisser vers le haut à travers l’orice rectangulaire qui

se trouve sur le dessus du bâti du four, puis l’assujettir à la partie arrière du bâti du four avec les quatre vis.

2. Assujettir l’élément de protection du déviateur de tirage à celui-ci avec les quatre vis.

Divertisseur

d’air

Avant

du four

Élément de

protection du

déviateur de

tirage

Figure 16

FOURS A CONVECTION 15 D’INSTALLATION

Page 16

VENTILATION

EN PRISE DIRECTE

Quand l’installation d’une hotte aspirante mécanique est impossible ou peu pratique à réaliser, on peut ventiler le four au

moyen d’une installation en prise directe.

AVERTISSEMENT!!

Quand on utilise un système à prise directe il faut absolument suivre le schéma. Une installation de ventilation à prise directe qui est défectueuse donnera des résultats de cuisson peu satisfaisants et causera

des dégâts prématurés aux éléments brûleurs.

La cheminée doit être de classe B ou mieux). La hauteur de la cheminée doit dépasser de 2 à 2,5 m (6-8’) le haut du toit du

bâtiment ou autre structure proche. Ne jamais diriger la ventilation du four dans une hotte. La cheminée doit être chapeautée avec une coiffe de type homologué UL, pour isoler la cheminée des intempéries extérieurs.

Dans ce cas îl est important de fournir assez d’air secondaire car l’installation à pris directe ne peut pas renouveler l’air

absorbé et ventilé par le four. Le volume total d’air neuf et d’évacuation à considérer lors de la détermination de la capacité

de hotte nécessaire est d’environ 30 CFM (.85 m3) pour chaque section de four. Pour augmenter la circulation d’air dans la

pièce, un expert en ventilation doit être consulté.

Installation de la hotte de tirage

Les four commandés pour la ventilation directe sont fournis avec une hotte de tirage. Installer la hotte de tirage comme suit :

1. Placer la hotte de tirage au-dessus du connecteur de cheminée.

2. L’assujettir des deux côtés avec les vis à tôle fournies.

Cheminée

Hotte de tirage

Avant du four

Figure 17

Modèles ES

1. Installez la hotte de tirage en utilisant les vis fournies, comme indiqué ci-dessous.

2. Placer la hotte de tirage au-dessus du divertisseur d’air.

3. Fixez les deux extrémités avec les vis à tôle fournies.

Cheminée

Hotte de tirage

Deux vis

Divertisseur d’air

à l’arrière

Une vis dans le

châssis

Une vis

Avant

du four

Figure 18

FOURS A CONVECTION 16 D’INSTALLATION

Page 17

BRANCHEMENT D’UTILITE

RÉGLAGE ET TEST DE PRESSION DE GAZ

Tous les fours sont réglés en usine en fonction du type de gaz spécié sur la plaque signalétique.

SPECIFICATIONS POUR GAZ

Gaz Naturel Gaz Propane

Min Max Min Max

Pression à l’entrée

W.C. 7.0 10.5 11.0 13.0

kPa 1.742 2.61 2.74 3.23

Pression au collecteur

W.C. 3.5 10.0

kPa .87 2.49

• Pression à l’entrée - Pression du gaz d’arrivée, avant l’entrée du four.

• Pression au Collecteur - Pression du gaz à l’entrée du ou des brûleurs principaux.

• Min - Pression recommandée pour le fonctionnement du four.

• Max - Pression maximale à laquelle le fabricant garantit le fonctionnement du four.

Pour maintenir la bonne pression de gaz, chaque four est livré avec un régulateur. Le régulateur est essentiel pour le fonctionnement correct du four et il ne doit pas être retiré. Il est préréglé pour alimenter le four avec une pression de gaz naturel

au collecteur de 0,87 kPa (3,5” WC [à la colonne d’eau]) et une pression de propane au collecteur de 2,50 kPa (10,5 WC).

NE PAS INSTALLER DE RÉGULATEUR SUPPLÉMENTAIRE OÙ LE FOUR SE CONNECTE SUR L’ALIMENTATION DE

GAZ SAUF SI LA PRESSION D’ENTRÉE EST AU-DESSUS DU MAXIMUM.

Avant le raccordement du four, veillez à bien purger les conduites de gaz de toutes rognures métalliques, limaille, bavures

d’enduit et autres débris. Après le raccordement, vériez la pression du gaz.

Le four et sa vanne d’arrêt individuelle doivent être déconnectés du système d’alimentation en cas de test des conduites à

pression manométrique supérieure à 1/2 psi (13.85 po à la colonne d’eau ou 3.45 kPa).

En cas de test à pression manométrique de 1/2 psi (13.85 po à la colonne d’eau ou 3.45 kPa) ou moindre, le four doit être

isolé du système par la fermeture de sa vanne d’arrêt manuelle individuelle.

Branchement de Gaz

2.5” (64 mm)

2.88” (73 mm) Modéles ES

Branchement de Gaz

3.75” (85.7 mm)

3.375 (86 mm) DFG-200-ES & Zephaire 200-G-Modéles ES

3” (76 mm) Modéles ES

Figure 19

FOURS A CONVECTION 17 D’INSTALLATION

Page 18

BRANCHEMENT D’UTILITE

RETENUE DU TUYAU DE GAZ

Si le four est monté sur roulettes, un connecteur commercial exible ayant un diamètre intérieur minimum de 1,9 cm (3/4”)

doit être utilisé avec un dispositif de connexion rapide.La retenue, fournie avec le four, doit servir à limiter les mouvements

de l’unité de façon qu’aucune tension ne soit placée sur le connecteur exible. Quand la retenue est entièrement étendue,

le connecteur doit être facile à installer et à connecter rapidement.

Ce dispositif (qui consiste en un câble de gros calibre) doit supporter une charge d’épreuve de 1,000 lb. (453 kg) et doit être

accroché au mur pour empêcher d’endommager celui-ci. NE vous servez PAS de la canalisation de gaz ni d’une canalisation d’électricité pour y accrocher l’extrémité xée à demeure du dispositif de retenue! Servez-vous de boulons d’ancrage

dans le béton ou les parpaings. Sur les murs en bois, utilisez des tire-fond à bois à résistance élevée que vous enfoncez

dans les montants du mur.

1. Monter la cornière fournie sur le boulon du pied juste au-dessous de l’arrivée de gaz.

2. Fixer l’attache sur le câble de retenue sur la cornière.

AVERTISSEMENT!!

Si la retenue est déconnectée, quelqu’en soit la raison, elle doit être reconnectée quand le four est remis à

sa position d’origine.

Arrière du four

Cornière de retenue

du câble

Unité à deux fours superposés montrée.

Utiliser le même procédé pour les unités

simples avec des pieds de 64 cm (25”).

Figure 20

RACCORDEMENT ÉLECTRIQUE

Les diagrammes de câblage se trouvent dans le coffret de commande et à l’arrière du four.Ce four est équipé pour connexion sur un circuit de prise de terre de 115 volts. Le moteur électrique, les voyants lumineux et les commutateurs apparentés

sont connectés par le l de branchement de 1,8 m (6’) qui se trouve à l’arrière du four.

AVERTISSEMENT!!

Pour votre protection contre les risques d’électrocution, cet appareil est doté d’une che a trois broches

avec l de terre et doit etre branché directement dans une prise a trois trous adéquatement mise a la terre.

Ne coupez ou ne retirez en aucun cas la broche de terre de la che.

LA SOCIÉTÉ BLODGETT NE SAURAIT ÊTRE TENUE POUR RESPONSABLE DES PERTES OU DOMMAGES SUBI PAR

SUITE DE L’INSTALLATION INCORRECTE DE FOURS.

SPÉCIFICATIONS ÉLECTRIQUES

Hz Volts Phase Amps Connexion

Installation É-U et Canada

60 115 1 6 Ensemble du cordon electrique fourni

Installation à l’export

50 220-240 1 3 Calibre suivant code local

FOURS A CONVECTION 18 D’INSTALLATION

Page 19

MISE EN MARCHE INITIALE

Les points de la liste qui suit doivent être contrôlés par un personnel qualié avant la première mise en marche de l’appareil.

• Ouvrez la vanne d’arrêt manuelle combinée à l’arrière du four.

• Enlevez les couvercles du tableau de commande et de combustion.

• Tourner la vanne d’arrêt manuel à combinaison sur la position marche.

• Mettez le sélecteur en position Cook (cuisson) et la temperature à 260ºC (500ºF).

Les voyants du brûleur principal du four et le voyant du four prêt s’allument. Quand le brûleur principal est en marche, vérier ce qui suit.

• Vériez l’absence de fuites de gaz par l’application d’une solution d’eau savonneuse sur tous les raccords des con-

duites de gaz.

• Réglez le four sur 350-400ºF (149-204ºC)F pour vérier l’étalonnage. Ajuster si nécessaire.

• Vériez si la pression a l’entrée est conforme au niveau recommandé. Cette pression se vérie au niveau de la prise

de pression prévue du côté a vanne de combinaison.

• Vériez si la pression au collecteur est conforme au niveau recommandé. Cette pression se vérie au niveau de la

prise de pression prévue du côté sortie des brûleurs principaux.

• Si le relevé de pression sont conformes du valeur recommandé, laissez chauffer le four pendant deux heures. S’il est

inacceptable, procédez aux réglage requis.

AVERTISSEMENT

Les ruptures dans le procédé brûlent les excès d’huile présents dans le métal pendant la fabrication. De la

fumée peut en résulter. Une ventilation correcte est requise.

RÉGLAGES À FAIRE LORS DE L’INSTALLATION INITIALE

Chaque four ainsi que ses composants ont été soigneusement testés et inspectés avant d’être expédiés. Cependant, il est

bien souvent nécessaire de faire des vérications et des réglages sur place au moment de l’installation initiale. Ceci est un

procédé normal. De tels réglages sont sous la responsabilité du vendeur ou de l’installateur et ne sont pas imputables à des

défauts de fabrication ou de matériau. Par conséquent, ces réglages ne sont pas couverts par la garantie de l’équipment

d’origine. Ces réglages comprennent, sans s’y limiter:

• le calibrage du thermostat

• le réglage des portes

• réglage du brûleur

• la mise de niveau

• la vérication de la pression du gaz

• le serrage des boulons

On ne peut considérer une installation achevée tant qu’un personnel qualié n’a pas procédé à sa vérication com-

plète et fait les réglages nécessaires s’il en est besoin.

FOURS A CONVECTION 19 D’INSTALLATION

Loading...

Loading...