Page 1

COMBI

X14E, BX14E,

BC

COMBINATION OVEN STEAMER

TROUBLESHOOTING MANUAL

BLODGETT COMBI

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05402 USA ~ Tel. (802) 658-6600 Fax (802) 652-2814

PN

52308 Rev B (12/15/2010)

Page 2

TABLE OF CONTENTS

Section 1 Controls

Standard Control Operation……………………………………………………………. 1-3

Standard Control Second Level Programming…………………………………………... 4

New Manual Control Operation……………………………………………………….. 5-7

New Manual Second Level Programming ……………………………………………...8-9

New Manual Control Factory Level Programming…………………………………. 10-11

MenuSelect Control Operation……………………………………………………….12-15

MenuSelect Control Second Level Programming……………………………………16-17

Notes……………………………………………………………………………………..18

Section 2 BCX14E Troubleshooting

Troubleshooting Guide……………………………………………………………….19-22

Incoming Power Supply ………..…………………………….………………………….23

Logic Board Dcv Test Points ………..…………………………………….…………….24

Cool Down Flow Chart ………..……………………………….………………………..25

Hot Air Operation Flow Chart ……….………………………………………………….26

Steam Operation Flow Chart ……….…………………………………………………...27

Combi Mode Operation Flow Chart ……….……………………………………………28

Door Switch Troubleshooting Flow Chart ………..……………………………………..29

Float Switch Troubleshooting Flow Chart ………..……………………………………..30

Convection Motor Direction Flow Chart ………………………………………………..31

Drain Valve Troubleshooting Flow Chart ...............................………………………….32

Logic Board LED Designations Flow ………………....…………………………….33-34

IFB (LED) Designations Flow ……………..………………………………....................35

Point to Point Troubleshooting……………………………………………………….36-39

Symbol Description ...…………………………………………………………………...40

Notes……………………………………………………………………………………..41

Section 3 Convection Motor Inverter Troubleshooting

Manual Control Inverter Programming………………………………………………42-43

enuSelect/New Manual Control Inverter Programming..………………………….44-45

M

Inverter Fault Codes and Stored Fault Codes ………………………………………46-47

Section 4 BCX14E Wire Schematics

Manual Control W-Floats 208V-240V P/n 50277…………..……..…………………….48

Manual Control W-Level Board 208V-240V P/n 52854 ………….…………………….49

New Manual Control W-Level Board 208V-240V P/n 53851…………..………………50

MenuSelect Control W-Floats 208V-240V P/n 51409…………..………………………51

MenuSelect Control W-Level Board 208V-240V P/n 52856....…………………………52

MenuSelect Control W-Level Board 480V P/n 53852…………………………………..53

Page 3

Section 5 BX14E Wire Schematics

New Manual Control 208V-240V P/n 53855……………………………………………54

MenuSelect Control 208V-240V P/n 51284……………………………………………..55

Section 6 Error Codes

Manual Control Error Codes……………………………………………………………..56

New Manual Control Error Codes……………………………………………………….57

MenuSelect Control Error Codes………………………………………………………...58

Lit-Sheets

L-927 Control panel LED Light Replacement……………………………………………...

L-938 Manual Control Water Sensor Upgrade Kit…………………………………………

L-939 MenuSelect Control Water Sensor Upgrade Kit…………………………………….

L-949 Element Drip Deflector Kit P/n 53550………………………………………………

Probe Chart

BCX14G with Manual Control

Part number 39800 located at the rear of the oven cavity below the blower motor a two

wire probe 1K value. At 75° 1090 ohm’s and at 300° 1575 ohm’s

BCX14G with MenuSelect Control

Part number 50310 located at the rear of the oven cavity below the blower motor a two

wire probe right angle 1K value. At 75° 1090 and at 300° 1575 ohm’s

(BX14G) with MenuSelect Control

Part number 50310 all the same as above for the BCX14G with MenuSelect Control.

(BX14G/BCX14G with the New Manual)

Part number 50310 all the same as the above for MenuSelect Controls.

(BX14G) with Manual Control

Part number 50636 located at the rear of the oven cavity below the blower motor a 4 wire

probe 1K value. At 75° 1090 ohm’s and at 300° 1575 ohm’s

Meat Probes

All Controls use the same Meat probes

Part number 39797 a 6” removable probe the plugs into the blue meat probe jack at the

bottom of the control panel.

This is a 1K probe at 75° 1090 ohm’s and at 300° 1575 ohm’

Page 4

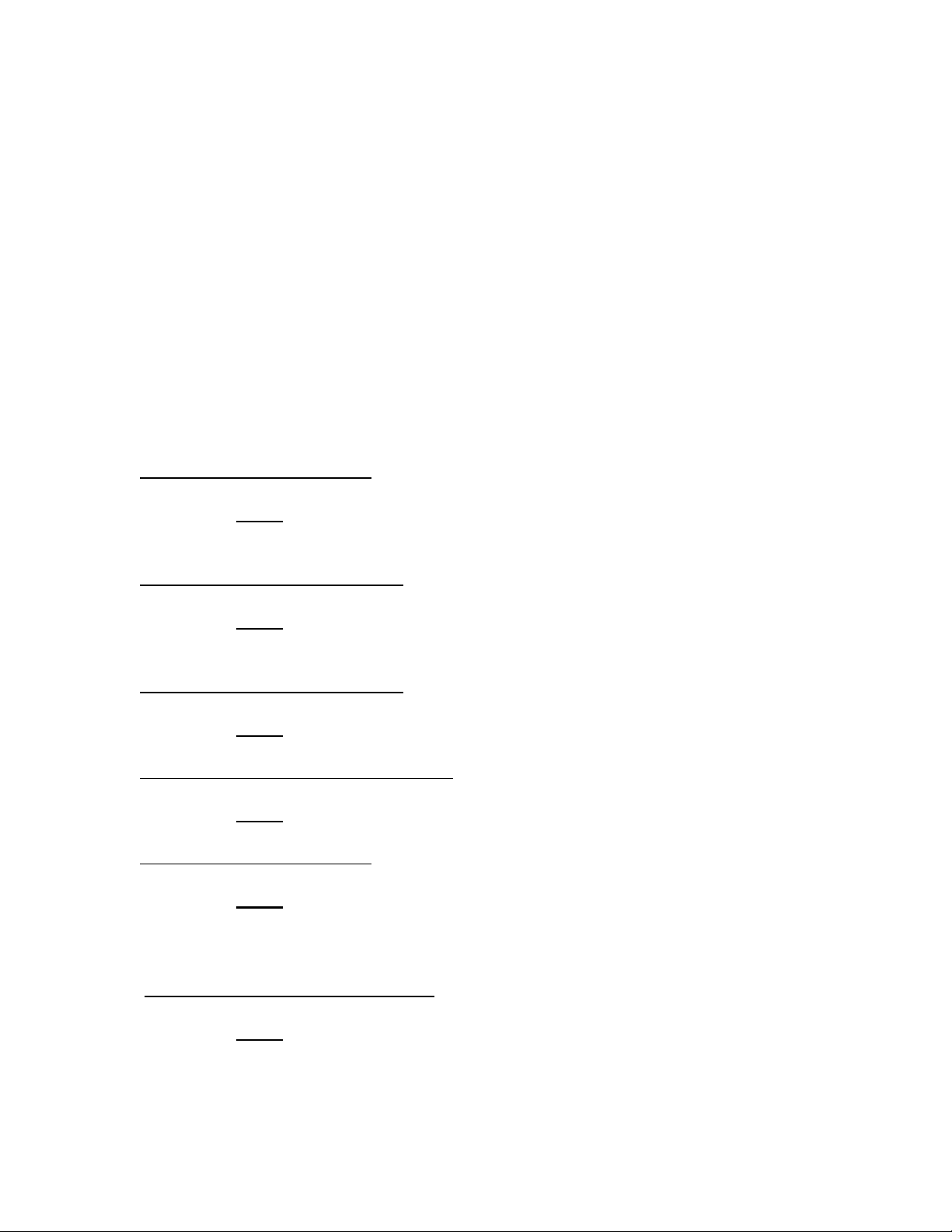

1

2

3

4

5

5

6

8

7

9

11

12

10

13

14

15

16

18

17

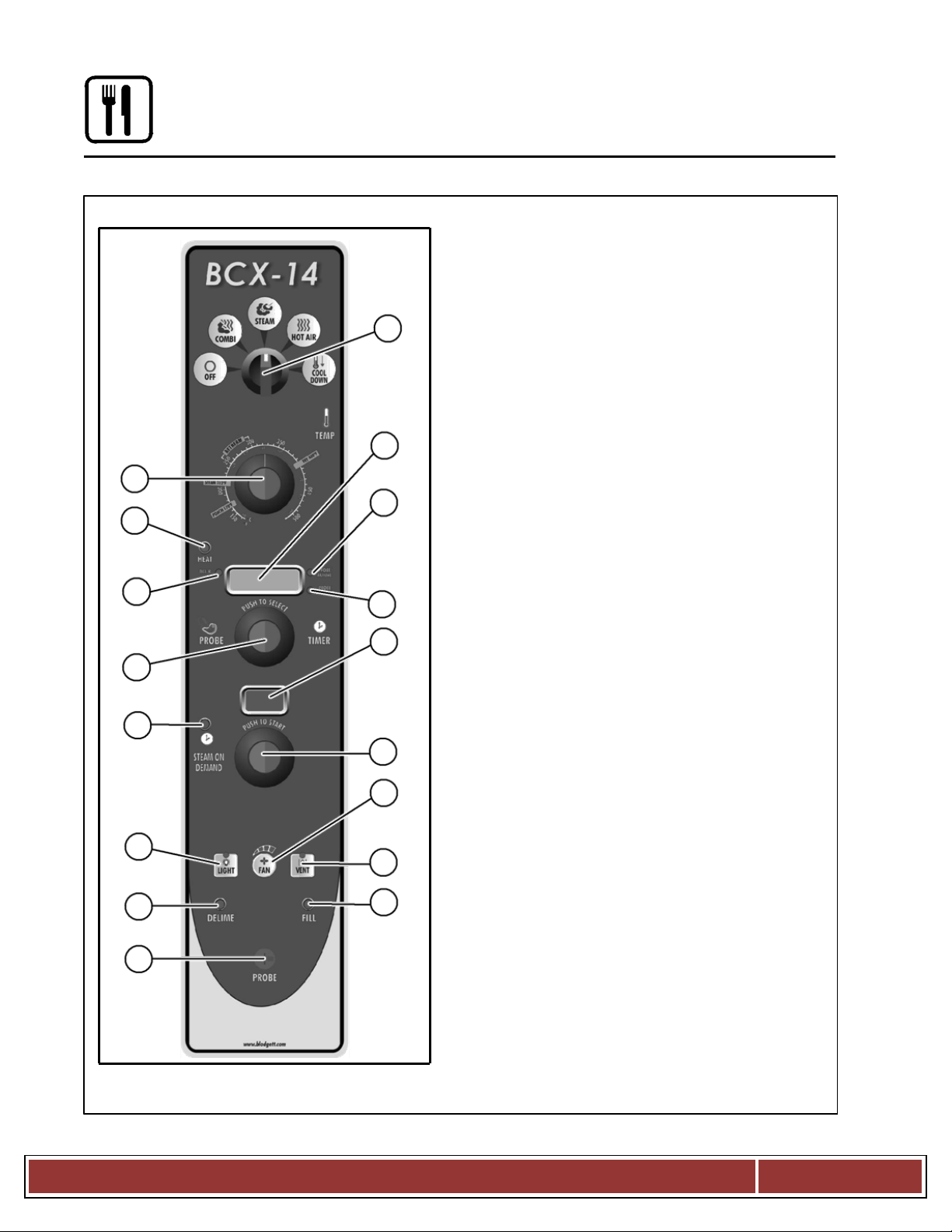

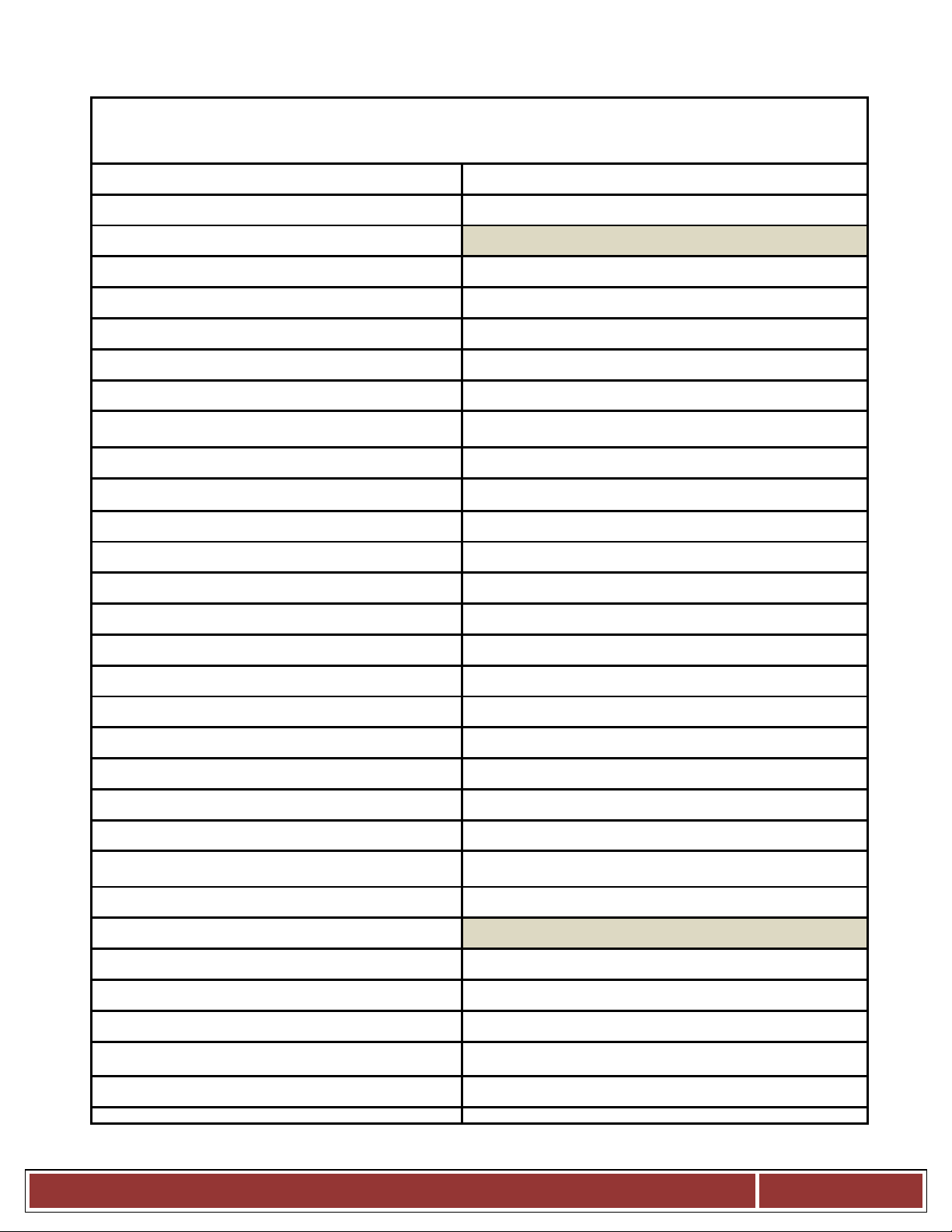

Operation

Standard Controls for Models BCX 14 and BX 14

CONTROLS IDENTIFICATION

1. POWER ON LAMP - when lit indicates

power to the unit is turned on.

2. MODE SELECTOR SWITCH - tur ns power to

the oven on or off. Allows selection of

Steam, Hot Air, Combi or Cool Down Modes.

3. TEMPERATURE DIAL - used to set

desired cooking temperature.

4. DISPLAY - displays time and temperature

in formation.

5. UP & DOWN ARROW KEYS - press to

enter values in the display.

6. ACTUAL TEMP KEY - press to display the

actual probe temperature during core cooking

or actual cavity temperature in timer mode.

7. TIME/PROBE TOGGLE KEY - used to

select either timer or probe cooking.

8. CLEAR/STOP KEY - use to clear or stop

the timer and silence the buzzer.

9. START KEY - press to start the timer.

10. STEAM ON DEMAND TIMER - used to set

duration for steam on demand.

11. STEAM ON DEMAND SWITCH - used to

initiate steam injection cycle.

12. STEAM ON DEM AND LAMP - lights when

steam on demand is activated.

13. LIGHTS SWITCH - used to turn the lights

on and off.

14. CAVITY VENT SWITCH - used to open or

close vent to release steam from cavity.

15. FAN SPEED SWITCH - used to select fan

speed.

16. PROBE CONNECTION - used to connect

the core temperature probe to the control.

17. FILL LAMP - illuminated until the steam

generator is filled with water.

NOTE: Model BX 14 ovens do not have a

18. DELIME LAMP (BCX 14 ovens only) Flashes when steam generator deliming

is needed. Remains steady when deliming

process is active.

CLEAN LAMP (BX 14 ovens only) - Flashes

when the unit has been in use for a

preprogrammed time and needs to be clean

fill lamp.

Blodgett Oven

Page 1

Page 5

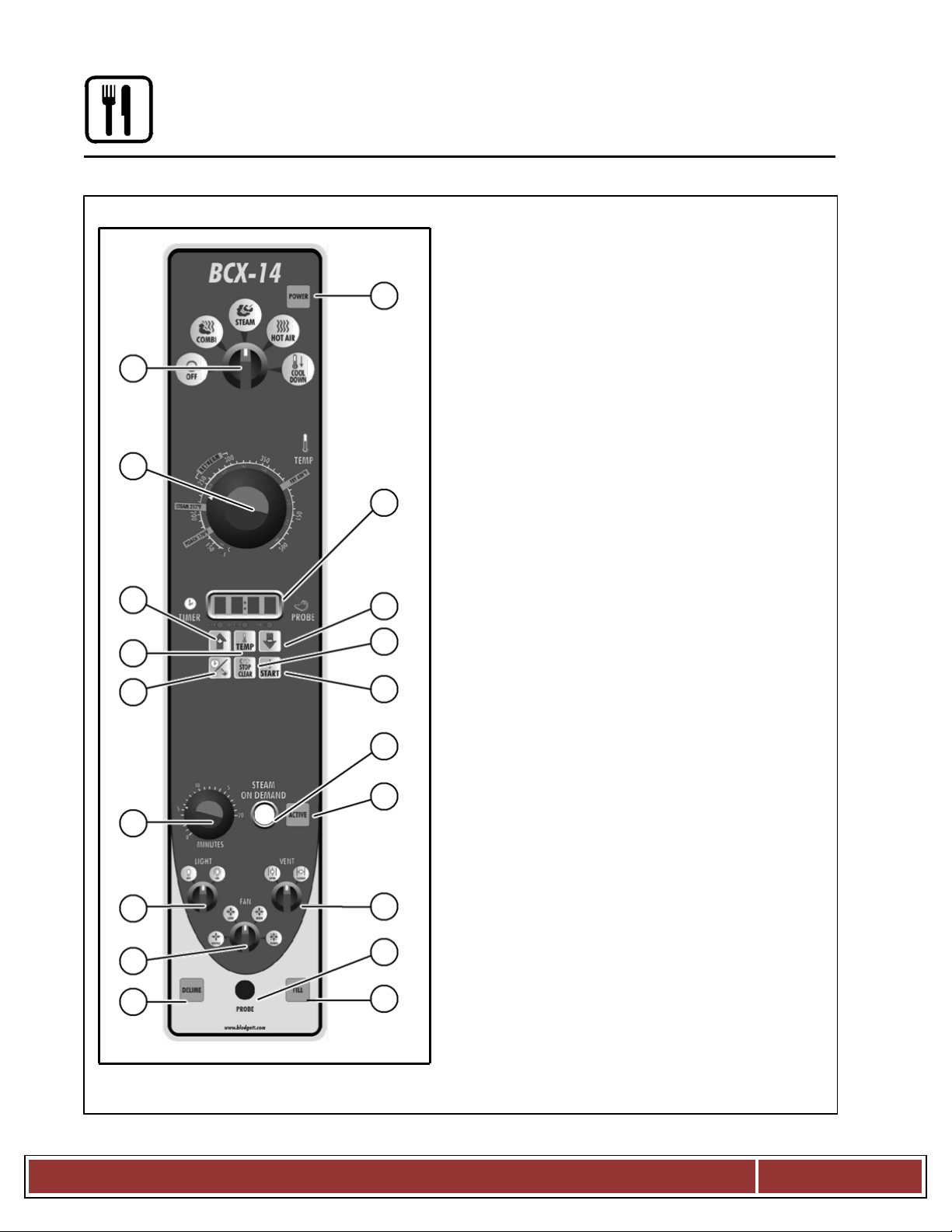

Operation

5

5

6

7

8

9

Standard Controls for Models BCX 14 and BX 14

TIMER COOKING

1. Press the TIMER/ PRO B E TOGGLE KEY (7)

to select the timer mode. The TIMER LED

below the display lights.

2. Turn the MODE SELECTOR Switch (2) to

the desired function.

3. Set the TEMPERATURE DIAL (3) to the de

sired cook temperature.

For Steam mode, set the temperature no

higher than 212_F (100_C).

For poaching, turn the temperature dial to

the POACH position, 180_F (82_C).

The optimum temperature for Combi

mode is 300 350_F (149 177_C).

4. When the oven has reached the cook

temperature, load the product.

5. Use the ARROW KEYS (5) to enter the desired

cook time in the display. You can clear the

display by pressing the CLEAR/STOP KEY (8).

6. Press the START KEY (9) to begin the timer.

The temperature, time and mode can be al

tered at any time during the cooking process.

To stop the timer, press the CLEAR/STOP KEY

(8).

7. When the timer reaches 00:00, the buzzer

sounds. Press the CLEAR/STOP KEY (8) to

silence the buzzer. Remove the product.

PROBE COOKING

1. Press the TIMER/PRO BE key (7) to select

the probe mode. The PROBE LED below

the display lights.

2. Use the ARROW KEYS (5) to enter the

desired final cook temperature in the

display. You can clear the display by

pressing the CLEAR/ STOP KEY (8).

3. Insert the core probe into the product. Load

product into the oven and close the door. Be

sure that the terminal end of the core probe is

outside of the oven and clear of the door.

4. Connec t the core probe to the P ROBE C ON

NECTION (16) at the bottom of the control.

5. The display gives the actual core probe

temperature.

6. When the product reaches the final cook

temperature the buzzer sounds.

COOL DOWN

NOTE: The unit can be cooled down rapidly

1. To cool down the oven cavity, open the

for steaming, cleaning, etc.

door and select Cool Down on the MODE

SELEC TOR Switch (2).

Blodgett Oven

Page 2

Page 6

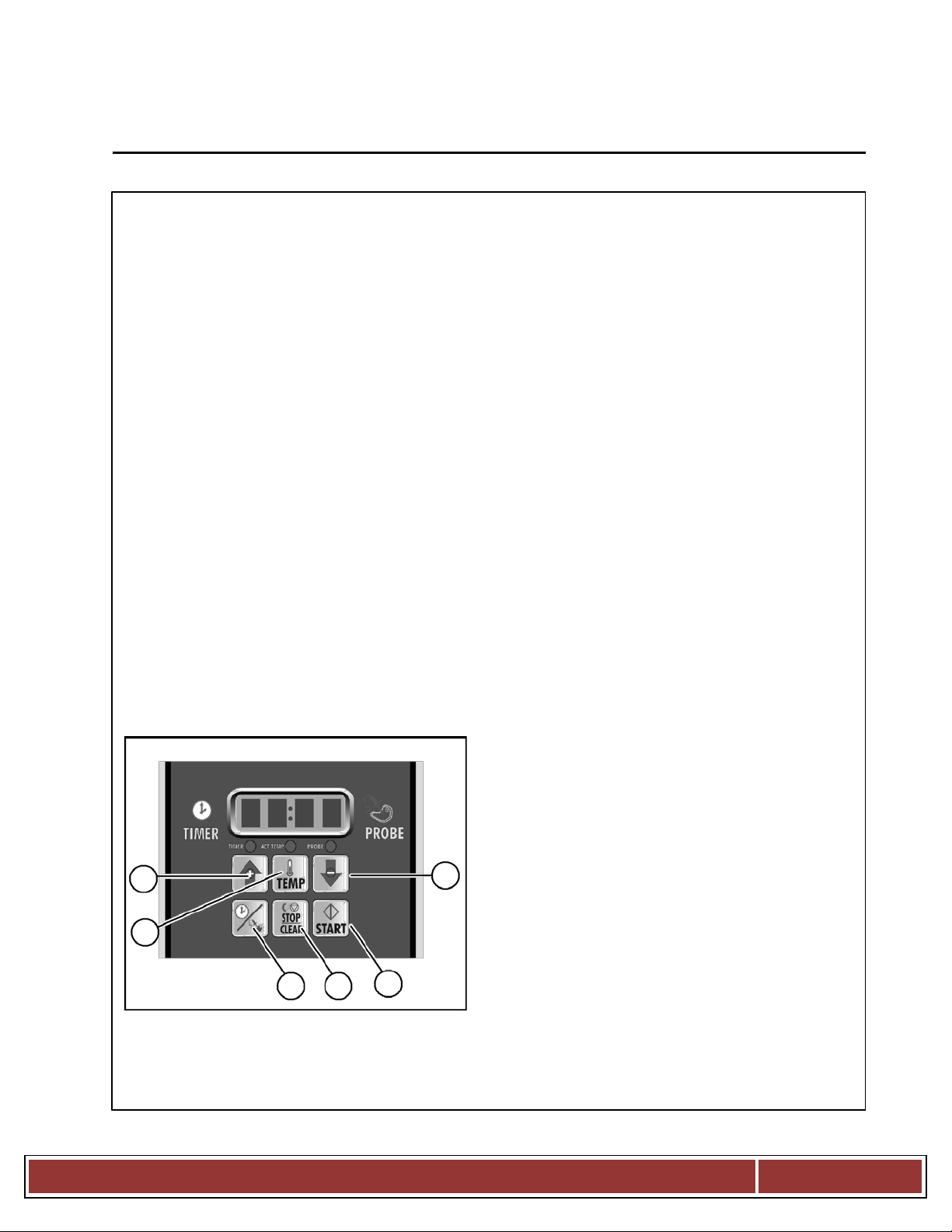

STEAM ON DEMAND

Uses for Steam On Demand:

How to set the Steam On Demand feature:

Most of the ideas came from our creative custom

While in the Hot Air or Combi mode, the unit can

ers. Experiment with this feature on your own and

let us know of any new uses.

be set to steam for a timed period. At the end of the

Add a minute or two at the beginning when

timed cycle the unit reverts back to the original set

D

baking bread for a shiny crust.

ting. Steam On Demand can be used at any time

during the cook cycle.

D

Kick start large loads such as 20 or more chick

NOTE:

Steam On Demand

is not available

in ens. By starting large loads with 5 to 8 minutes

of steam you help the oven recover and cut the

steam mode.

cooking time by more than 10%.

1. Set

the desired •steam

on" time with

the

D

Bake bagels without boiling. By starting raw ba

STEAM ON DEMAND TIMER (10).

gels with 1 to 2 minutes of steam you can

2. Press the STEAM ON DEMAND S WI TCH (11).

achieve a beautiful crust.

The STEAM ON DEMAND LAMP (12) lights.

D

Cream caramel is great at 230_F to 250_F in the

Combi mode using 2 min utes of on demand

steam.

11

D

When cooking chicken wings, try setting the

oven in the Combi mode at 375_F and use 3

minutes of Steam On Demand. This method will

10

12

stop the tips from burning. Total cooking time is

approximately 12 minutes.

D

Pork ribs tend to pull off the bone better when

using 5 to 8 minutes of Steam On Demand. Try

ribs in the Combi mode at 350_F.

Operation

Standard Controls for M odel s BCX 14 and BX 14

Blodgett Oven

Page 3

Page 7

B l o d g e t t O v e n

Page

4

Standard Control Second Level Programming

3. Press and Hold

for 5 seconds and release

or

Combi Manual Control Temp. (BP# 39673)

Instructions For +7° Temperature Offset

Recommended: Read instructions before programming. If each step is not

conducted within 9 seconds, the control will lock up and the programming

sequence will have to be restarted from step 1

1. Power oven off

. Power on oven in Combi Mode

2

4. Press and hold

5. Toggle

6. Press and release

7. Toggle

8. Press and release

9. Press

until "2 X X X" is displayed. Where "X X X" are any number

until Screen displays "P 3 X X" where "X X" are any number

for 5 seconds and release

PROBE LED will begin to Flash

until Screed displays "P 2 0 7"

TIMER LED will begin to flash

10. Press and release PROBE LED will begin to flash

11. Toggle or until Screed displays "P 3 0 0"

12. Do not touch oven for 10 seconds. "0 0 0" will appear. Temp. offset is now programmed

13. Turn off oven and turn back on

Page 8

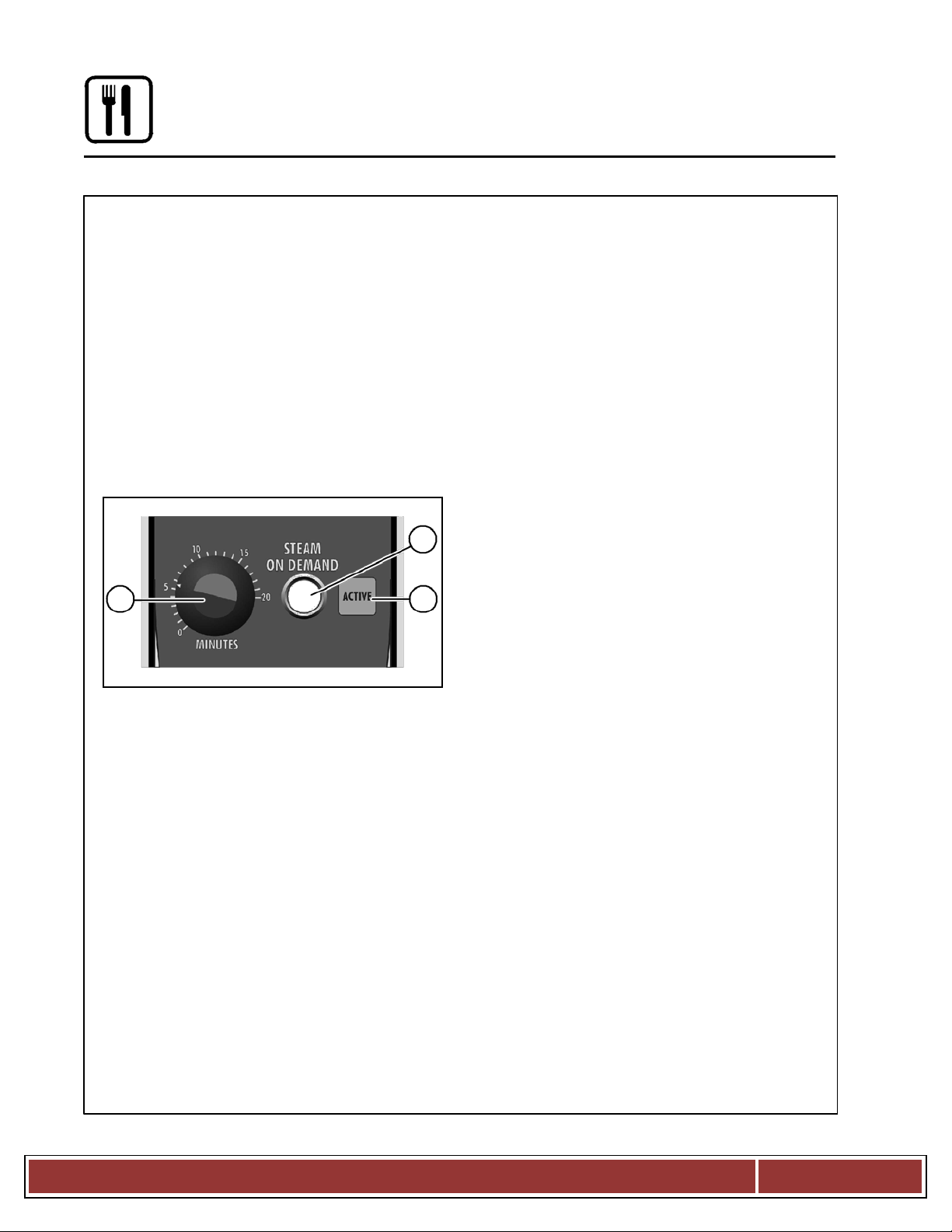

1

2

3

6

4

5

7

9

8

10

11

13

12

14

15

16

17

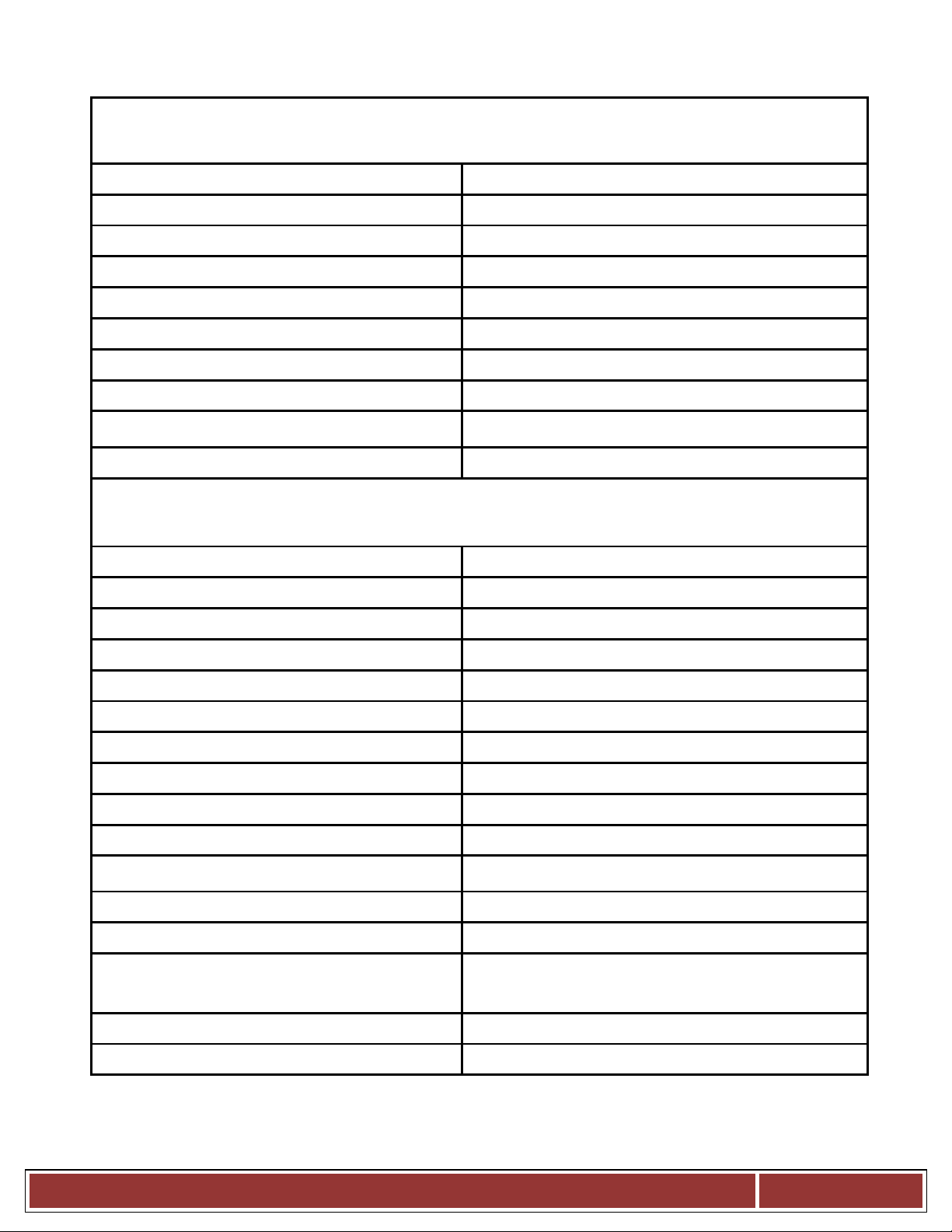

Operation

Standard Controls for Models BCX 14 and BX 14

CONTROLS IDENTIFICATION

1. MODE SELECTOR SWITCH - tur ns power to

the oven on or off. Allows selection of

Steam, Hot Air, Combi or Cool Down Modes.

2. DISPLAY - displays time and temperature

in formation.

3. TEMPERATURE DIAL - used to set

desired cooking temperature.

4. HEAT LAMP - lights when the oven is

calling for heat

5. TIMER LED - lights when the cook time is

displayed

6. PROBE ACTUAL LED - lights when the

actual probe temperature is displayed

7. PROBE SETPO INT LED - lights when the

core set point temperature is displayed

8. TIMER/PROBE KNOB - use to select and

set either cook time or probe temperature

9. STEAM ON DEM AND DISPL AY - displays

the steam on demand time

10. STEAM ON DEM AND LAMP - lights when

steam on demand is activated.

11. STEAM ON DEMAND KNOB - use to set

duration for steam on demand

12. LIGHTS KEY - press to turn the oven

lights on and off

13. FAN SPEED KEY - used to select fan speed.

14. CAVITY VENT KEY - used to open or

close vent to release steam from cavity.

15. DELIME LAMP (BCX 14 ovens only) Flashes when steam generator deliming

is needed. Remains steady when deliming

process is active.

16. FILL LAMP - illuminated until the steam

generator is filled with water.

NOTE: Model BX 14 ovens do not have a

17. PROBE CONNECTION - used to connect

the core temperature probe to the control.

fill lamp.

Blodgett Oven

Page 5

Page 9

Standard Controls for Models BCX 14 and BX 14

TIMER COOKING

1. Press the TIMER/PROBE KNOB (8) to select

the timer mode. The TIMER LED lights.

2. T urn the MODE SELECTOR Switch (1) to

the desired function.

3. Set the TEMPERATURE DIAL (3) to the de

sired cook temperature.

For Steam mode, set the temperature no

higher than 212_F (100_C).

For poaching, turn the temperature dial to

the POACH position, 180_F (82_C).

The optimum temperature for Combi

mode is 300 350_F (149 177_C).

4. When the oven has reached the cook

temperature, load the product.

5. Rotate knob to enter the desired cook

time in the display. You can clear the

display by rotating counter clockwise. The

timer begins on its own.

6. The temperature, time and mode can be

altered at any time during the cooking

process.

7. When the timer reaches 00:00, the buzzer

sounds. Press or rotate the TIMER/PROBE

KNOB (8) counter clockwise to silence the

buzzer. Remove the product.

Operation

PROBE COOKING

1. Press the TIMER/PROBE knob (8) to

select the probe set point mode. The

PROBE SET POINT LED (7) lights.

2. Rotate the knob to enter the desired final

cook temperature in the display.

3. Insert the core probe into the product. Load

product into the oven and close the door. Be

sure that the terminal end of the core probe is

outside of the oven and clear of the door.

4. Connec t the core probe to the P ROBE C ON

NECTION (17) at the bottom of the control.

5. The display gives the actual core probe

temperature by pressing the TIMER/PROBE

knob

(8) again.

6. When the product reaches the final cook

temperature the buzzer sounds.

COOL DOWN

NOTE: The unit can be cooled down rapidly

1. To cool down the oven cavity, open the

for steaming, cleaning, etc.

door and select Cool Down on the MODE

SELEC TOR Switch (1).

Blodgett Oven

Page 6

Page 10

Operation

Standard Controls for Models BCX 14 and BX 14

STEAM ON DEMAND

How to set the Steam On Demand feature:

While in the Hot Air or Combi mode, the unit

can be set to steam for a timed period. At the

end of the timed cycle the unit reverts back to

the original set ting. Steam On Demand can

be used at any time during the cook cycle.

NOTE: Steam On Demand is not available in

1. Turn the STEAM ON DEMAND KNOB (11) to

2. Press the STEAM ON DEMAND KNOB (11).

steam mode.

set the desired length of time. The time is

displayed in the STEAM ON DEMAND

DISPLAY

(9).

The STEAM ON DEMAND LAMP (10) lights.

Uses for Steam On Demand:

Most of the ideas came from our creative

customers. Experiment with this feature on

your own and let us know of any new uses.

D Add a minute or two at the beginning when

baking bread for a shiny crust.

D Kick start large loads such as 20 or more

chickens. By starting large loads with 5 to 8

minutes of steam you help the oven recover

and cut the cooking time by more than 10%.

D Bake bagels without boiling. By starting

raw bagels with 1 to 2 minutes of steam you

can achieve a beautiful crust.

D Cream caramel is great at 230_F to 250_F in the

Combi mode using 2 minutes of on demand

steam.

D When cooking chicken wings, try setting the

oven in the Combi mode at 37 5_F and use 3

minutes of Steam On Demand. This method

will stop the tips from bur ning. Total cooking

time is approximately 12 minutes.

D

Pork ribs tend to pull of f th e bone better when

using 5 to 8 minutes of Steam On Demand.

Try ribs in the Combi mode at 350_F.

Blodgett Oven

Page 7

Page 11

Se

rvice

Level Programming

BCX, BX – NEW MANUAL CONTROL

Code: 7378

(The oven needs to be in the “OFF” position)

Press the Timer Dial Till “0000” Is Displayed

Turn the Dial: Scroll the flashing # to (7)000

Press the Dial to Enter Scroll the flashing # to 7(3)00

Press the Dial to Enter Scroll the flashing # to 73(7)0

Press the Dial to Enter Scroll the flashing # to 737(8)

Press the Dial to Enter Scroll to (DIAG) Diagnostics

Press the Dial to Enter

“D-01” Is Displayed

(Cavity Heat Relay)

Press the Dial to Enter Turn Dial CW to “ON”

Turn Dial CCW to “OFF”

Press the Dial to EXIT

(CONTINUE) (FOLLOW STEPS ABOVE)

Scroll the Dial to D-02 Boiler Heat Relay

D-03 Water High Level Switch Status

D-04 Water Low Level Switch Status

D-05 Drain Relay

D-06 Fill Relay

D-07 Steam Relay

D-08 Quench Relay

D-09 Motor-Reversals Relay Gently

D-10 Motor Gently

D-11 Motor Low

D-12 Motor High

D-13 Motor Turbo

D-14 Door Status

D-15 Lights Relay

D-16 Delime Pump Relay

D-17 Software Flash Number

D-18 Software Number

D-19 Software Download Number

B l o d g e t t O v e n

Page 8

Page 12

Se

rvice

Level Programming

BCX, BX NEW MANUAL CONTROL

Code: 7378

(The oven needs to be in the “OFF” position)

D-20 SIB Software Number

D-21 Cavity Set Temperature

D-22 Cavity ACT Temperature

D-23 Cooling Fan Probe Temperature

D-24 Quench Probe Temperature

D-25 Core Probe Temperature

D-26 Boiler Tank Temperature

D-27 Main Switch

D-28 Fan Feedback Input

D-29 Cook Done relay

D-30 Vent relay

D-33 Cool Fan Relay

D-34 Hot Air relay

D-35 Hot Air Enable Relay

D-37 All Relays

D-38 Display and LED Test

END End Of Diagnostic Test

Press Dial to Exit

B l o d g e t t O v e n

Page 9

Page 13

Factory

Level Programming

BCX, BX – NEW MANUAL CONTROL

Code: 3228

(The oven needs to be in the “OFF” position)

Press the Timer Dial Till “0000” Is Displayed

Turn the Dial: Scroll the flashing # to (3)000

Press the Dial to Enter Scroll the flashing # to 3(2)00

Press the Dial to Enter Scroll the flashing # to 32(2)0

Press the Dial to Enter Scroll the flashing # to 322(8)

Press the Dial to Enter “P-01” Is Displayed

Press the Dial to View Turn Dial to: (F)

Press the Dial to Retune Turn Dial to: P-02

(CONTINUE) (FOLLOW STEPS ABOVE)

P-## “ Set To “

(P-02) Cool Down Temp 100F

(P-03) Ready Beep ON

(P-04) Fan Reverse Time 6:00

(P-05) Cook Done Beeper Yes

(P-06) Delime Interval 30 Hours

(P-07) Flush Interval 24 Hours

(P-08) Appliance Type Gas

(P-09) Machine Type BCX / BX

(P-10) Max Steam On Demand

20

(P-11) Min Hot Air Set Point 140F

(P-12) Max Hot Air Set Point 500

(P-13) Min Steam Set Point 85F

(P-14) Max Steam Set Point 225F

(P-15) Max Core Probe Pull Temp 200F

(P-16) Upper Hot Air Hysteresis 1F

(P-17) Lower Hot Air Hysteresis 1F

(P-18) Upper Steam Hysteresis 1F

(P-19) Lower Steam Hysteresis 1F

B l o d g e t t O v e n

Page 10

Page 14

Factory

Level Programming

BCX, BX NEW MANUAL CONTROL

Code: 3228

(The oven needs to be in the “OFF” position)

(P-20) Upper Ready Band 25F

(P-21) Lower Ready Band 10F

(P-22) Cavity Probe Offset 0F

(P-23) Core Probe Offset -2F

(P-24) Spritzer Solenoid Duty Cycle

(P-25) User Response Timeout

33

5

(P-26) Sleep Mode Timeout 1

(P-27) Counter Start Delay 2

(P-28) Quench Probe Yes

(P-29) SCK Address 30

(P-31) ACT Oven Temp Display

No

(P-32) Remote Beeper Yes

Press Dial to Exit Scroll to END

Press Dial to Exit End Of Factory Programming

B l o d g e t t O v e n

Page 11

Page 15

Blodgett Oven

Page 12

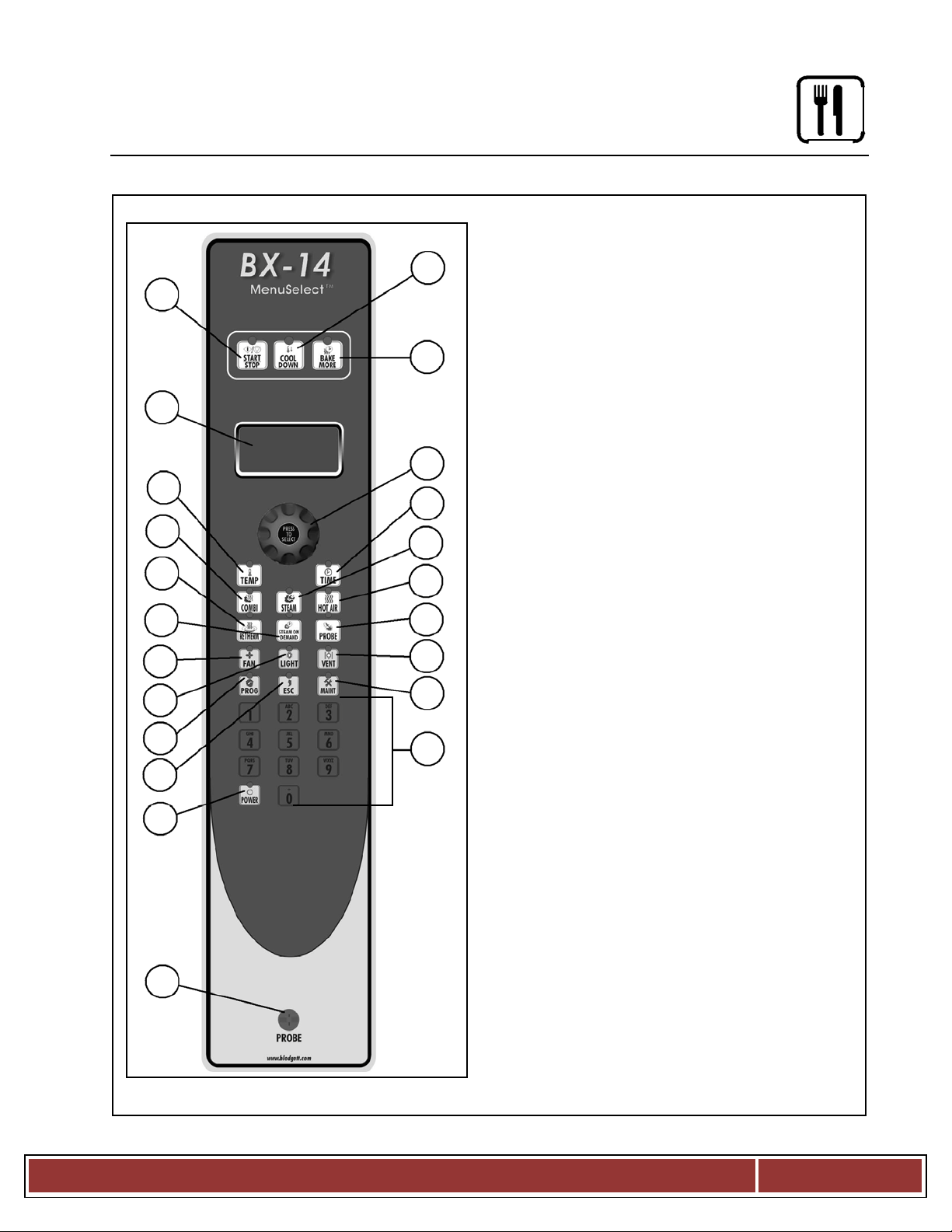

Operation

MenuSelect Control for Models BCX 14 and BX 14

CONTROL DESCRIPTION

2

1.

START/ ST O P K E Y press to start, cancel or

pause the bake

1

2.

COOL DOWN KEY initiates oven cool down

cycle

3.

BAKE MORE KEY press at the end of a bake

3

cycle to add additional bake time in one

Minute increments.

4.

DISPLAY displays ti me o r temperature and

4

other information related to oven function and/

Or programming.

5.

DIAL used to enter set points, time, and pro

5

Programmable settings. Also used to select

6

the programmed product.

6.

TEMP KEY used to set or change the bake

7

temperature

8

9

7.

TIME KEY used to set or change the bake

Time.

11

10

8.

COMBI KEY press to enter combi mode

9.

STEAM KEY press to enter steam mode

12

13

16

11.

RETHERM KEY press to enter Retherm

14

mode, this mode uses steam to reheat frozen

or precooked product. Retherm has a

15

19

temperature limit of 250 300_F.

12.

STEAM ON DEMAND KEY used to initiate

17

Steam injection cycle.

20

13.

PROBE KEY press to use core pr obe cooking

18

14.

FAN KEY press to select the fan speed

15.

LIGHT KEY press to turn the lights on and off.

21

16.

VENT KEY press to manually open and close

the oven vent

17.

PROGRAM KEY press to enter product pro

gramming and save programmed settings.

during programming

19.

MAINTENANCE KEY press to enter manager

programming and save programmed settings

22

20.

ALPHA/NUMERIC KEYPAD used to program

Recipes.

21.

POWER KEY used to place control in and out

of standby mode.

22.

CORE PROBE CONNECTION plug core

temperature probe in here when using

Probe cooking

10. HOT AIR KEY press to enter hot air mode

18.

ESCAPE KEY press to back up one step

Page 16

Blodgett Oven

Page 13

Operation

MenuSelect Control for Models BCX 14 and BX 14

OVEN STARTUP

1. Be sure the gas shutoff sw itch and/or circuit

breaker switch below the control panel are

in the on position. The display flashes OFF

PRESS POWER KEY TO START.

NOTE: If the real time clock and auto wake

up functions are enabled the

display reads PRES S POWER KEY

2. Press the POWER KEY (21). The display

reads PREHEAT and the oven heats to the

last manual set temperature in the hot air

mode. The display flashes READY / IDLE

and the alarm beeps 5 times when the

oven is at temperature and ready to bake.

TO START AUTO START.

MANUAL COOKING

1. Turn the DIAL (5) until the display reads

MANUAL.

2. Press the TIME KEY (7). Rotate the dial, or

use the alpha/numeric keypad to enter the

desired bake time. Pr ess the center of the

dial to set the bake time.

NOTE: Time is set in one minute increments

using the dial. To set time in less

than one minute increme nts use the

3. Press the TEMP KEY (6). Rotate the dial, or

use the alpha/numeric keypad to enter the

de sired bake temperature. Press the center

of the dial to set the bake temperature. The

oven preheats to the new temperature.

NOTE: Temperature is set in 5 degree

4. Press the desired mode key, combi,

steam, hot air or Retherm.

If Combi or Retherm are selected, rotate

the dial, or use the alpha/numeric keypad

to enter the desired percentage of steam.

NOTE: Retherm has a temperature limit of

5. When the display flashes READY / IDLE,

open the doors. Load the product.

alpha/ numeric keypad.

increments using the dial. To set

time in less than 5 degree

increments use the alpha/numeric

keypad.

250 300_F.

6. Press the START/STOP KEY (1) to begin the

bake cycle. The timer counts down and the

display alternates between the cooking

mode and the name of the product.

PROGRAMMED COOKING

1. Turn the DIAL (1) until the name of the

product is highlighted. Press the center of

the dial to select. The oven preheats to the

programmed temperature in the correct

cooking mode. The display flashes READY /

IDLE and the alarm beeps 5 times when the

oven is at temperature and ready to bake.

2. Open the doors. Load the product.

3. Press the START/STOP KEY (1) to begin the

bake cycle. The timer counts down and the

display alternates between the cooking

mode and the name of the product.

PROBE COOKING

1. Press the PROBE key (13) to select the

probe mode. The display reads CORE

PROBE COOK & HOLD. Turn the dial to

select either YES or NO . Press the center

of the dial to se lect.

If YES is selected, Cook & Hold has been

enabled. In the Cook & Hold mode, the

oven cavity lowers to the product pull

temperature as the product cooks.

If NO is selected, Cook & Hold has not

been enabled the cavity maintains the

cook temperature.

2. Turn the DIAL to enter the desired product pull

temperature in the display. Press the center of

the dial to save the pull temperature.

3. Press the TEMP KEY (6). Rotate the dial, or

use the alpha/numeric keypad to enter the

de sired bake temperature. Press the center

of the dial to set the bake temperature. The

oven preheats to the new temperature.

NOTE: Temperature is set in 5 degree incre

ments using the dial. To set time in

less than 5 degree increments use

the alpha/numeric keypad.

Page 17

Blodgett Oven

Page 14

MenuSelect Control for Models BCX 14 and BX 14

4. Press the desired mode key, combi,

steam, hot air or Retherm.

If Combi or Retherm are selected, rotate

the dial, or use the alpha/numeric keypad

to enter the desired percentage of steam.

NOTE: Retherm has a temperature limit of

5. Insert the core probe into the product. Load

product into the oven and close the door. Be

sure that the terminal end of the core probe is

outside of the oven and clear of the door.

6. Connect t he core probe to the PR OBE CON

NECTION (22) at the bottom of the control.

NOTE: Do not connected the probe before

7. The display gives the actual core probe tem

perature as well as the oven set temperature.

8. When the product reaches the pull

temperature the buzzer sounds.

9. Press t he START/ST OP KEY (1) to silence

the buzzer.

If using Cook & Hold - The cav ity tempe ra

ture continues to drop to the product pull

temperature and the display counts up,

telling the operator long the product has

been held. Disconnect the core probe and

remove the product when ready.

If not using Cook & Hold - The cavity re

mains at the cook temperature. The

display does not count up. Disconnect the

core probe and remove the product when

the buzzer sounds.

250 300_F.

the cook mode has been selected.

DURING ANY COOK CYCLE

Steam On Demand

While in the Hot Air, Combi or Retherm

modes, the unit can be set to steam for a

timed period of up to 20 minutes. At the end

of the timed cycle the unit reverts back to the

original setting. Steam On Demand can be

used at any time during the cook cycle.

1. Press the STEAM ON DEMAND KEY (12).

2. Rotate the dial, or use the alpha/numeric key

pad to enter the desired steam on demand

Operation

time. Press the center of the dial to

initiate Steam on Demand cycle.

NOTE: Steam on Demand time is set in one

minute increments using the dial. To

set time in less than one minute incre

3. The Steam on Demand LED flashes until

the steam time has expired.

Venting Moisture from the Oven Cavity

1. Press the VENT KEY (16). This manually

opens the vent until the key is pressed

again to close it.

Pause a Bake Cycle

1. To pause a cook cycle, p ress the START/

STOP KEY (1). The LED on the start/stop

key flashes. The bake cycle will pause

until the key is pressed again.

Cancel a Cook Cycle

1. To cancel the cook cycle, press and hold

the START/STOP KEY (1).

ments use the alpha/numeric keypad.

AT THE END OF ANY COOK CYCLE

1. An alarm sounds, the display reads DONE.

2. If more bake time is desired, press the BAKE

MORE KEY (3). This will add an additional one

minute of time for each press of the key.

3. When you are satisfied with the bake, press

the START/STOP KEY (1) to silence the alarm.

Open the door to remove the product.

OVEN SHUTDOWN

1. Press the COOL DOWN KEY (2). The

display reads AUTO COOL DOWN

ACTUAL TEMP. To speed up the cool

down process, open the doors and press

the VENT KEY (16) to open the vent.

2. When the oven has cooled down, the display

reads OFF PRESS POWER KEY TO START.

NOTE: The lights shut off and the vent

closes automaticall y at the end of

the cool down cycle.

Page 18

Blodgett Oven

Page 15

Operation

MenuSelect Control for Models BCX 14 and BX 14

PRODUCT PROGRAMMING

Entering the Program Mode

1. Press the PROGRAM KEY (17). If the control

is password protected, the display reads EN

TER CODE. Use the alpha/numeric keypad

to enter the manager pass code 3124, then

press the center of the dial to enter the

program mode.

Naming a Product Recipe

NOTE: Use the following procedure to name a

new product or edit the name of an

1. For a new recipe, turn the dial to the first open

2. Use the dial to scroll down to Edit Name.

3. Turn the dial or use the alpha/numeric keypad

4. Press the PROG KEY (17). With SAVE

existing product.

product. Press the center of the dial to select.

To edit an existing name, rotate the dial to

the name to be changed. Press the center

of the dial to select.

Press the center of the dial to enter the

edit name menu.

to select the first character. Press the center of

the dial to advance to the next character. Re

peat for all remaining characters.

NOTE: Product names may be up to 10

characters long and can contain

spaces. Use the #1 key to insert

spaces in a recipe name.

NOTE: To select letters using the keypad,

press the appropriate key once if you

need the first letter on the key, twice

for the second and three times for the

third. For example to enter the letter L

press the #5 key three times.

highlighted, press the dial to save the

product name.

Programming a Product Recipe

NOTE: The control can hold 99 recipes. Each rec

1. Turn the dial to highlight the name of the

2. The display reads PRODUCT NAME: ST AGE 1.

3. Rotate the dial, or use the alpha/numeric key

4. Rotate the dial to select the desired

5. Rotate the dial, or use the alpha/numeric

6. Rotate the dial to select the desired fan speed.

ipe may have up to 6 cooking stages.

product to be programmed. Press the

center of the dial to select the product.

Press the center of the dial to select the stage.

pad to enter the desired bake time. Press the

center of the dial to set the bake time.

NOTE: Time is set in one minute increments

using the dial. To set time in less

than one minute increme nts use the

alpha/ numeric keypad.

cooking mode. Choose from combi,

steam, hot air or Retherm. Press the

center of the dial to set the cook mode.

If Combi or Retherm are selected, rotate

the dial, or use the alpha/numeric keypad

to enter the desired percentage of steam.

key pad to enter the desired cook

temperature. Press the center of the dial

to set the bake temperature.

NOTE: Temperature is set in 5 degree incre

ments using the dial. To set time in

less than 5 degree increments use

the alpha/numeric keypad.

NOTE: Retherm has a temperature limit of

250 300_F.

Choose from gentle, low, high or turbo. Press

the center of the dial to set the fan speed.

Page 19

BCX, BX – MENUSELECT CONTROL

Service Level Programming

(The oven needs to be in the “ON” position)

Press the Maint Key Scroll to “SERVICE”

Press the Dial to Enter Enter Service Code “7378”

Press the Dial to Enter Scroll to “Diag Output”

Press the Dial to Enter

Press and hold # button to test

Temp Heat

Combi Fan Speed Gentle Fwd

Fan Fan Speed Low Fwd

Prog Fan Speed High Fwd Forward

1 Fan Speed Turbo Fwd

4 Fan Speed High Rev

7 Light

Light Spritzer

ESC Cooling Fan

2 Vent

5 Hot Air

8 Hot Air Enable

Component Function Test:

0 Quench

Hot Air Delime

Probe Heat Boiler

Vent Fill

Maint Drain

(Press the Dial to Exit) Scroll to “Diag Input”

Press the Dial to Enter

Press and hold buttons to test

Temp Fan Error

Combi Door

Fan Cavity Probe Temp

Component Function Test:

B l o d g e t t O v e n

Page 16

Page 20

BCX, BX MENUSELECT CONTROL

Service Level Programming

(The oven needs to be in the “ON” position)

Prog Cooling Fan Probe Temp

1 Quench Probe Temp

4 Core Probe Temp

7 Boiler Probe Temp

Steam Water Hi Level SW

Steam on Demand Water Low Level SW

“Press the Dial to Exit” Scroll to Exit

Press the Dial to Exit Scroll to Exit Press (“Dial”)

Factory Level Programming

(The oven needs to be in the “ON” position)

Press the Maint Key Scroll to Factory Program

Press the Dial to Enter Enter the Factory Code “3228”

Press the Dial to Enter Scroll to “Appliance Type”

Press the Dial to Enter Turn Dial to set Gas or Electric

Press the Dial to Enter

Scroll to “Cavity Probe Offset”

Press the Dial to Enter Turn the Dial to Set the Offset

Press the Dial to Enter

Scroll to ”Core Probe Offset”

Press the Dial to Enter Turn the Dial to set the Offset

Press the Dial to Enter

Scroll to Exit

Press the Dial to Exit Scroll to Exit again

Press the Dial to Exit the

Program Level.

B l o d g e t t O v e n

Page 17

Page 21

B l o d g e t t O v e n

Page

18

Notes:

Page 22

BCX14E

BCX14E TROUBLESHOOTING GUIDE

In this troubleshooting guide, the schematic is

broken down into areas. This allows the oven to be

checked in sections.

When troubleshooting, tilt the control panel down

for access to use your voltmeter. The main control

circuit voltage for all BX / BCX and CNVX model

ovens is 24DC volts. Once the problem is

determined be sure to power the oven down before

disconnecting connections.

NOTE: Always troubleshoot Combi ovens in the

following sequence: COOL DOWN, HOT AIR,

STEAM and then COMBI. Reference the text that

follows with the appropriate troubleshooting

schematic to help you troubleshoot each mode.

DC VOLTAGE TEST POINTS

1. At the DCV power supply should be (2)

+24Dcv and (2) -24Dcv_Rtn connections, when

115Acv is applied to the power supply there

will be a small green light on at the power

supply and it should always have 24Dcv

between the plus and minus points.

2. Locate the logic board small connector J1 using

your voltmeter checking for 24Dcv between

terminals (J1-1) 24Dcv Rtn

verify true 24Dcv input to enable the logic

board during the power up.

3. The J1 connector between (J1-1) -24Dcv Rtn

and (J1-4) +24dcv will be the best (Test points).

When troubleshooting any problems, if your

looking for a low signal test between (J1-4)

+24Dcv RD to the low input searching for, or if

your looking for a +24Dcv_H positive leg of

power check between (J1-1) -24Dcv_Rtn and

the high signal searching for. (See FIGURE 1)

4. Checking for 24Dcv at the IFB relay board J7

connector between (J7-1) to (J7-2).

5. NOTE: While troubleshooting the 24Dcv circuit

with the wire schematic you will see that most

all of the control switching is to a (Low)

24Dcv_Rtn. Also while reviewing the wire

schematic you will see the wires labeled as a

(High) or (Low) input such as (Oven_On_L) for

the low input and (Door_Closed_H) for a high

input/output.

to (J1-4) +24Dcv to

6. Acv/Dcv. See the incoming power supply flow

chart (FIGURE 1).

NO OPERATION WITH THE MODE SWITCH

IN COOL DOWN

1. Verify that the control panel circuit breaker is in

the on position.

2. Check the outlet for proper power supply.

3. Remove the LH body side panel and inspect the

motor inverter control to see if it is powered up

with 115Acv and if there are any error codes

present if so, see the attached fault code list for

troubleshooting. The display will show 00 if

there are no fault codes present while the motor

is not running. If no codes are present continue

or if a code is present see the programming fault

code troubleshooting flow chart section 4

(FIGURE 1) page 9-1.

4. Locate the logic board small vertical RH

connector J1 using your voltmeter checking for

24Dcv between (J1-4) to the mode switch

terminal # 4 voltage should be present, if not

investigate the mode switch. Also check

between the J1 connector (J1-4) to the inverter

connector BK-12 wire at CM2 for 24Dcv, if no

voltage check the IFB relay board connector J3.

5. To bypass the mode switch and wire harness

use your voltmeter set to the 10amp red fuse

side with the black in COM then set your meter

to DC amps, now your meter is a fused jumper

wire. Now jump between the logic board J1

connector (J1-1) to the motor speed inverter

GY-19 low signal at terminal # 2 of the inverter.

This should activate the inverter power up. See

the cool down operation troubleshooting flow

chart (FIGURE 3).

NO OPERATION WITH THE MODE SWITCH

IN HOT AIR

1. Verify that the convection motor is running with

the door fully closed. If not see door switch

troubleshooting flow chart (FIGURE 7).

2. Verify that the thermostat has powered up,

counted down and displaying a set temperature

along with the heat indicator light activated.

3. Remove the LH body side panel and tilt the

control panel down for troubleshooting access.

B l o d g e t t O v e n

Page 19

Page 23

BCX14E

BCX14E TROUBLESHOOTING GUIDE

4. Checking for logic board input/output LED

indicators, in the hot air mode the amber input

LED’s #6 and #9 need to be on along with the

green output LED #13. Verify LED’S with the

logic board LED designation flow chart

(FIGURE 11).

5. Also look for LED indicator inputs at the (IFB)

relay board, the CR3 relay LED (D31), CR2

relay LED (D21) and the CR1 relay LED (D11)

will all need to be on. If not check all

connectors and the 24Dcv inputs at the J7

connector per the wire schematic. Verify

LED’S with the IFB LED indicator designation

flow chart (FIGURE 12).

6. If all of the above are good continue testing

checking at the lower of the two Dcv 24V

power supplies for a lighted small green light

along with checking for 24Dcv output.

7. Next go directly the (K1) hot air contactor and

measure the coil voltage between A1 & A2 for

24dcv volts, if not check A1 at the coil to the J1

connector at the logic board J1-1 for 24dcv and

if okay check A2 coil to logic board J1-4 for

24dcv.

8. In either case no voltage go the IFB relay board

and check for 24dcv at J4 connector between

J4-1 and J4-2 for 24dcv from the power supply,

good check from J4-6 to logic board J1-1 for

24dcv output to the contactor coil.

NO OPERATION WITH THE MODE SWITCH

IN STEAM

1. Verify that the convection motor is running

with the door closed. If not see door switch

troubleshooting flow chart (FIGURE 7).

2. Verify that the thermostat has powered up,

counted down and displaying a set temperature

along with the heat indicator light activated.

3. Remove the LH body side panel and tilt the

control panel down for troubleshooting access.

4. Check for logic board input/output LED

indicators, in the steam mode the amber input

LED’s # 3 and # 6 need to be on along with the

green output LED # 10. Verify LED’S with the

LED designation flow chart (FIGURE 11).

5. Look for LED indicator inputs present at the

IFB relay board, looking for the CR3 relay

LED (D31), CR2 relay LED (D21) and the

6. CR7 relay LED (D71) should be on. If not

check IFB connector J7 between (J7-1) to (J7-

2) for 24Dcv input see wire schematic. Verify

LED’S with the IFB LED indicator flow chart

(FIGURE 12).

7. If all of the above is good continue testing

checking at the lower of the two power

supplies for a lighted small green light along

with checking for 24dcv output.

9. Next go directly the (K2) steam contactor and

measure the coil voltage between A1 & A2 for

24dcv volts, if not check A1 at the coil to the J1

connector at the logic board J1-1 for 24dcv and

if okay check A2 coil to logic board J1-4 for

24dcv.

10. In either case no voltage go the IFB relay board

and check for 24dcv at J6 connector between

J6-1 and J6-2 for 24dcv from the power supply,

good check from J6-5 to logic board J1-1 for

24dcv output to the contactor coil.

NO OPERATION WITH THE MODE

SWITCH IN COMBI

1. Verify that the convection motor is running with

the door fully closed. If not see door switch

troubleshooting flow chart (FIGURE 7).

2. Verify that the thermostat has powered up,

counted down and displaying a set temperature

along with the heat indicator light is activated.

3. Remove the LH body side panel and tilt the

control panel down for troubleshooting access.

4. Checking for logic board input/output LED

indicators, in the Combi mode the amber input

LED’s #2 and #6 need to be on along with the

green output LED #13 and then #10 for 45

seconds intervals of steam while in Combi.

Verify LED’S with the LED designation flow

chart (FIGURE 11).

5. Look for LED indicator inputs at the (IFB) relay

board, looking for the CR3 relay LED (D31),

CR2 relay LED (D21), CR1 relay LED (D11)

will all need to be on and CR7 relay LED (D71)

will be on during a 45 second steam on time. If

not check all connectors and the 24Dcv input at

the J7 connector per the wire schematic #50277

between (J7-1) to (J7-2). Verify the LED inputs

with the IFB LED indicator designation flow

chart (FIGURE 12).

B l o d g e t t O v e n

Page 20

Page 24

BCX14E

BCX14E TROUBLESHOOTING GUIDE

8. If all of the above is good continue testing

checking at the lower of the two power supplies

for a lighted small green light along with

checking for 24dcv output.

9. Next go directly the (K1) hot air contactor and

measure the coil voltage between A1 & A2 for

24dcv volts, if not check A1 at the coil to the J1

connector at the logic board J1-1 for 24dcv and

if okay check A2 coil to logic board J1-4 for

24dcv.

10. Hot air contactor will mostly control the Combi

mode along with the logic board switching

from hot air contactor to steam contactor for on

and off for about 45 seconds as long as the

boiler has come above the preheat temp of 180°

already.

11. In either case no voltage go the IFB relay board

and check for 24dcv at J4 connector between

J4-1 and J4-2 for 24dcv from the power supply,

good check from J4-6 to logic board J1-1 for

24dcv output to the contactor coil.

NO FILLING OF THE STEAM BOILER

1. Verify the water pressure and flow of the water

pressure through the pressure regulator.

2. Verify that the control panel circuit breaker is in

the on position.

3. Check for 24Dcv at the power supply with the

mode switch in the off position, green light ON.

4. Shut the water supply off, then at the IFB board

locate the flush switch in the center RH of the

relay board and press and hold it for 45 seconds

while checking for water flow out the drain.

5. After doing so disconnect the float wires (mark

as needed) check for continuity, both floats are

normally closed and open when are floats full.

6. If floats are closed re-connect the float wires

and turn the water supply back on. At this point

with the mode switch still in the off position the

logic board LED indicators amber input # 8 and

green output # 15 should be on activating the

fill solenoids.

7. No water filling yet check the IFB fill enable

CR8 relay LED (D81), if not on check the relay

board J8 connector at (J8-1) to (J8-2) for 24dcv.

8. See the float switch troubleshooting flow chart

(FIGURE 8).

OVER FILLING OF THE STEAM BOILER

1. Turn off the control panel circuit breaker to see

if the water over filling continues in the oven.

2. If water stopped when power was off, turn the

circuit breaker back on and check for the fill

light on the control panel and look at the logic

board for LED indicators. If LED’s amber

input # 8 and green out put # 15 are on this

would indicate the (LLC) low level cut float is

in the closed position and will not open. Repair

or replace floats switch as needed.

3. Check both float switches for normally closed

when empty and open when steam generator is

full. (If they do not open repair or replace floats

as needed.

4. See the float switch troubleshooting flow chart

(FIGURE 8).

CONVECTION MOTOR WILL NOT

REVERSE DIRECTIONS.

1. This oven comes equipped with the feature of

the convection motor reversal after every six

minutes of motor run time in all modes except

for the cool down mode.

2. When any mode but cool down is activated the

motor should start up counter clockwise.

3. Check for 24dcv at the TMR1 timer between

A1 to A2. When verified test between A1 to #

16 for 24dcv after six minutes 24dcv will

switch from terminal #16 to # 18. (If voltage

does not switch remove the wire from #18 and

retest the timer for switching.

4. What ever the out come the motor speed

inverter is looking for a 24Dcv_Rtn_L input

from the timer to either terminal #5 or #6 at the

motor speed inverter to reverse directions.

5. See the motor reverse troubleshooting flow

chart (FIGURE 9).

DOOR SWITCH TROUBLESHOOTING

1. The door switch is a proximity switch that is

activated by the metal of door when it is closed

therefor-proper adjustment is needed.

2. The door switch is located at the lower left

corner with the door open the switch will be

B l o d g e t t O v e n

Page 21

Page 25

BCX14E

BCX14E TROUBLESHOOTING GUIDE

protruding out ½ inch, inspect the switch for

any damage and for proper adjustment.

3. There are three wires from the door switch that

go directly to the IFB connector J5.

4. Check for 24Vdc active at the IFB relay board

at the connector J5 from (J5-3) to (J5-4).

5. If the door switch has 24Vdc going to it when

the door is closed the back of the door switch

will light up to indicate the door switch has

been activated and the blower motor should

began running.

6. At this point check for +24Vdc_H output from

the IFB connector J5 from (J5-2) to (J5-5). If

the voltage is present and the door switch is

closed now look for an LED indicator at the

IFB relay board CR2 relay (D21). See door

switch troubleshooting flow chart (FIGURE 7).

DRAIN VALVE TROUBLESHOOTING AND

OPERATION

1. The drain valve will always remain in the

closed position during all mode operations.

2. If the oven boiler is below 150 degrees and

after somewhere between 3-5 hours of non use

the logic board will activate the drain valve

motor to open and drain the boiler down then it

will close the drain valve motor and then refill

the boiler to the low level float switch.

3. When troubleshooting the drain valve motor

operation there is a small stem switch on the

right side of the IFB relay board. This can be

depressed to activate the drain valve motor,

while holding the switch (In) the drain valve

motor open fully to drain the boiler down and

when the switch is released the drain valve

motor will return to the normally closed

position. (Caution of a hot boiler).

4. See Troubleshooting (FIGURE 10).

NO STEAM ON DEMAND

1. While depress the steam on demand button

verify at the logic board LED indicators amber

input # 4 and green output # 12.

2. No LED input check for a 24dcv-Rtn_L input

to the logic board at the J3 connector at (J3-7)

of the logic board. If there is no input

24Dcv_Rtn_L signal go to the steam on

demand switch SW10 and check for a

24Dcv_Rtn_L signal at BK-7 of the switch to

Logic Board J1 connector (J1-4).

NO DELIME PUMP OPERATION

1. The delime pump can be tested with the oven

placed in the cool down, when you press and

hold the steam on demand button for a few

several seconds 24Vdc should be applied

directly the delime pump.

2. Verify when you activate the steam on demand

button, at the logic board LED indicators

amber input #4 and green output #12 light up.

3. If no voltage is found during the first test at the

delime pump, go to the IFB relay board J8

connector and test between (J8-1) to (J8-2)

24Vdc should be present.

4. Continued testing, check for 24Vdc to the R-12

wire at the delime pump testing from the J8

5. IFB connector (J8-2) to the R-12 wire. If

voltage is good this would mean the red

+24Vdc is good now check between the V-13

wire at the delime pump to check the

24Vdc_Rtn_L input from the J8 connector test

between (J8-1) to V-13. If no voltage inspect

the IFB relay board for damage.

MOTOR SPEED INVERTER PRGRAMING

1. Every motor speed inverter has been

programmed from the factory however for

some reason if it lost it’s programming it can

be reprogrammed manually.

2. You will see on the inverter drive the green

(Run) and red (Stop/Reset) buttons, below

those two buttons there is a door that will open

up to gain access to the programming keys

need to reprogram the inverter drive.

3. Behind the access door the programming keys

are (FUNC.), (#1⇑⇑⇑⇑ ), (#2 ⇓⇓⇓⇓) and (STR).

4. To program the inverter drive back to the

factory settings (See the attached programming

flow chart (Figure 3).

5. See Inverter fault code & stored fault codes

flow chart section 4 (FIGURE 1) page 4-1.

B l o d g e t t O v e n

Page 22

Page 26

BCX14E

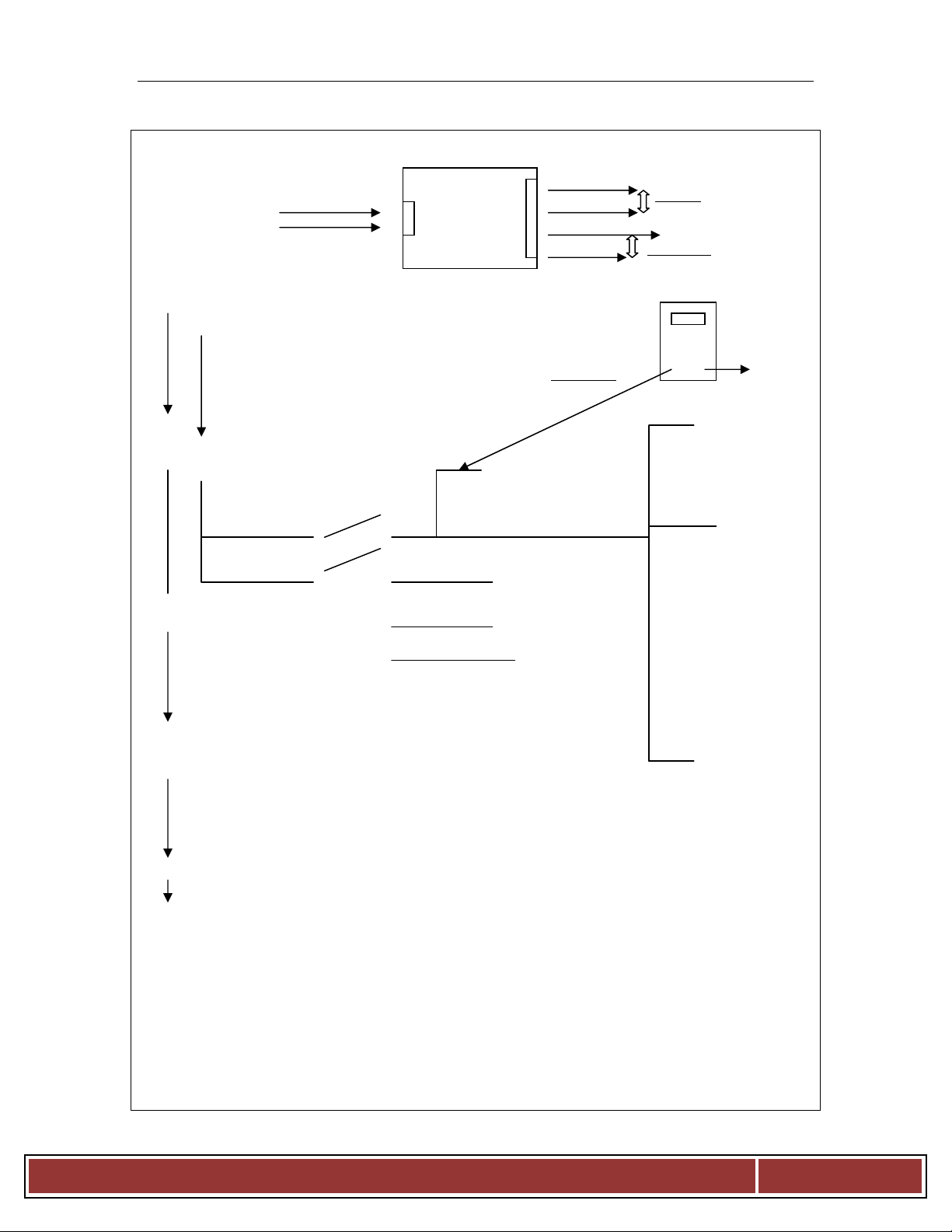

BCX14E INCOMING POWER SUPPLY CHECK

24dcv Power Supply

115 24dcv

Incoming ACV + + 24dcvRtn A. 24Vdc to J7 at (IFB)

L -

N + 24dcv

- 24dcvRtn B. 24Vdc to J1 connector

Switch Closed

+24Vdc

24Vdc Rtn

Logic Board

J1 Conn.

Incoming powers from the DC power supply control (B.24Vdc.) J1-4

Red

J1 ∧ TMR1 (Timer)

P1 ∧ ∧ J1 A2

∧ P1< < < Oven_On_L

1+3 #2 Logic Board

0 0 J1-6

Logic Board J3

5,7,9 0 0 #6 Combi (J3-1)

J1-4 Logic board 0 #8 Steam (J3-2)

0 #10 Convection (J3-6)

J2-2 Temp control TC1

+24Vdc (Temp Control)

J2-1

Control panel lights

(DS5)

Pwr_On

(DS6)

Heat_Demand

(DS9)

Steam_Demand

(DS8)

Delime

(DS7)

Low_Water

+24

Dcv

B l o d g e t t O v e n

Page 23

Page 27

BCX14E

BCX14E LOGIC BOARD ( J1 ) CONNECTOR VOLTAGE TEST POINTS

LOGIC BOARD VOLTAGE TEST POINTS AT (J1 CONNECTOR)

From (J1-1) BK 24Dcv_Rtn_L to (J1-4) RD +24Dcv_H

(Always live with circuit breaker On)

Trouble shooting test points!

Your volt meter leads should insert

right into the LH side of the J1

connector through a hole provided

from the factory for test points.

This connector will provide the

best test points while testing for a

24Dcv_Rtn_L, with your meter

Red lead into (J1-4)-RD +24Dcv

and your Black lead testing for the

24Dcv_Rtn_L.

Or your meter Black lead into the

(J1-1)-BK 24Dcv_Rtn_L and your

Red lead testing for a +24Dcv_H.

24DCV

- +

J3

J4

J1-4 RD

J1

J1-1 BK

J

B l o d g e t t O v e n

Page 24

Page 28

BCX14E

T3

BCX14E COOL DOWN MODE OPERATION TROUBLESHOOTING

J3

Connector

24Dcv_Rtn_L 24Dvc_Rtn_L

Switch Closed

1&3 4

Mode_Sw

+24dcv

- +

J1-4

J1 Connector

Logic Board

Inverter Drive

24Dcv_L

MOTOR

J3-1 Motor_Fwd_Ena

J3-2 Motor_Rev_Ena

J3-3 Spd_Sel_0

J3-4 Spd_sel_1

J3-5 Drv_@SetSpd

J3-7 Inv_Com

ACV

115Ac

NEU

1

2

3

4

5

L

11

12

CM2

T1

T2

B l o d g e t t O v e n

Page 25

Page 29

BCX14E

J1-6

Com

J4-6 J4

-

2

BCX14E HOT AIR FLOW CHART

+24Vdc_H

Logic Board

24Vdc_Rtn_L J1 TMR1

CR1

24Vdc_Rtn A2 15

+24Vdc

Oven On Oven_On_L

Logic Board

Logic Board J4

1+3 o o #2 J3

Mode_Sw

5,7,9 o o #10 (J3-6) Heat_Demand_In

(Switch Closed)

TC1

Logic Board J2-1

J1-4 Red

24Dcv

- +

J1 Connector

IFB

Conv_Heat_Ena_L

+24Vac_H

24Vac_Rtn_L

Pwr_On K1

Heat_Demand

Steam_Demand

24Acv

- +

-24V_DcvRtn

Power supply

Delime

T1

Transformer

24Vac_Rtn

# 6

J1-1

J1-4

Input

Amber

LED

# 6 &

# 9

Green

Output

LED

# 13

J4-2

J4-1

24Vdc_Rtn

No

J1-7

J4-1

Hot Air

CONTACTOR

A1 #7

A2 #8

B l o d g e t t O v e n

Page 26

Page 30

BCX14E

J1-6

#7

#14

Com

J6-5 J6

-

2

BCX14E STEAM FLOW CHART

+24Vdc_H

Logic Board

24Vdc_Rtn_L J1 TMR1

CR1

24Vdc_Rtn_L A2 15

+24Vdc_H

Oven On Oven_On_L

Logic Board

Logic Board J4

1+3 o o #2 J3

Mode_Sw

5,7,9 o o #8 (J3-2) Heat_Demand_In_L

(Switch Closed)

TC1

Logic Board J2-1

24Dcv

- +

J1-1 BK

J1 Connector

IFB

Boiler_Ena_L

+24Vac_H

24Vac_Rtn_L

Pwr_On T2

Heat_Demand

Steam_Demand

24Acv

- +

24Dcv_Rtn

Delime T2 Transformer Power supply

24Vac_Rtn # 6

J1-1

J1-4

Input

Amber

LED

# 3 &

#6

#11

Green

Output

LED

# 10

J4-6

J4-1

24Vdc_Rtn

No

J1-12

J6-1

STEAM

CONTACTOR

A1 #7

A2 #8

B l o d g e t t O v e n

Page 27

Page 31

BCX14E

J1-6

Com

J4-6 J4

-

2

A2 #8

BCX14E COMBI FLOW CHART

+24Vdc_H

Logic Board

24Vdc_Rtn_L J1 TMR1

CR1

24Vdc_Rtn_L A2 15

+24Vdc_H

Oven On Oven_On_L

Logic Board

Logic Board J4

1+3 o o #2 J3

Mode_Sw

5,7,9 o o #6 (J3-1) Heat_Demand_In_L

J2-1

IFB Heat_Ena_L

Boiler_Ena_L

+24Vac_H

24Vac_Rtn_L

Pwr_On T2

Heat_Demand

Steam_Demand T1

Delime

- 24vDcv_Rtn

J1-1

J1-4

Input

Amber

LED

# 2 &

# 6

#7

#11

Green

Output

LED # 13

& #10

J4-6

J4-1 J4-2

24Vdc_Rtn

No

J1-7

J1-12

J6-5

J4-1

Hot Air

CONTACTOR

A1 #7

Steam

CONTACTOR

A1 #7

A2 #8

B l o d g e t t O v e n

Page 28

Page 32

BCX14E

BCX14E DOOR SWITCH TROUBLESHOOTING

IFB

Door_Sw_Pwr_H

Door_Sw_Rtn_L

Door_Closed_H

J1-1 BK

J1 Connector

Logic Board

BK J5 Connector

BR BL

Output when door is closed

Switch will be lighted

Logic Board

J1 Connector

J1-1 BK +24Dcv_H

TMR1

IFB 13

Door_Closed_H

Y-5

CR1

Y-10

A1

J2 Connector

+24Dcv

- +

+24Dcv

- +

Y-10

J2-1

J5-3

J5-4

J5-5

B l o d g e t t O v e n

Page 29

Page 33

BCX14E

BCX14G FLOAT SWITCH TROUBLESHOOTING

J8

+24Dcv_H

24Dcv_Rtn

IFB

Relay Board

SW3

The Flats are normally closed

HI_Lvl_Float_Sw

and open when the boiler is

full.

V-3 o o R15

+24Dcv should always be

applied to the float wires R-15

that activates the fill solenoid’s

relay at the IFB which applies a

24Dcv_Rtn_L to complete the

o o R15

power circuit for the water fill

BL-6

solenoid’s till the float opens.

Troubleshooting the floats drain

SW2

the boiler with the flush switch

Lo_Lvl_Float_Sw

at the IFB and check both floats

to verify normally closed and

after boiler fill up floats open.

+24Dcv_H

24Dcv_Rtn_L V-5 R-14

Fill_Solenoid_A

24Dcv_Rtn_L BL-10 R-14

Fill_Solenoid_B

J8-1

J8-2

J8-3

J8-4

J8-5

J8-6

B l o d g e t t O v e n

Page 30

Page 34

BCX14E

T3

#6

BCX14E MOTOR REVERSE DIRECTION TROUBLESHOOTING

J3

Connector

IFB

24Dcv_Rtn_L

1&3 2

Mode_Sw

18 15

16

A2 A1

J1

J1-3

24Dvc_L

J1-4

I

F

B

Door_Closed_H

J2

J1-1

Inverter Drive

I

F

B

CR1

GY-12

24Dcv_L

14 13

#9

#5

#10

MOTOR

J3-1 Motor_Fwd_Ena

J3-2 Motor_Rev_Ena

J3-3 Spd_Sel_0

J3-4 Spd_sel_1

J3-5 Drv_@SetSpd

J3-7 Inv_Com

ACV

115Ac

NEU

1

2

3

4

5

L

11

12

CM2

T1

T2

B l o d g e t t O v e n

Page 31

Page 35

BCX14E

BCX14E DRAIN VALVE OPERATION TROUBLESHOOTING

J8

+24Dcv_H

24Dcv_Rtn

IFB

Relay Board

Drain_Closed_H

Drain_Open_H

The drain valve in its normally

closed position should always

have 24Dcv_Rtn_L input along

with the +24Dcv_H out put

from the IFB J8 connector to

the motorized drain valve.

The drain valve opens when the

+24Dcv_H switches from J8-8

BK-20

to J8-9 then it should switch

back to close.

The drain valve will only open

when the logic board sends an

output signal to the IFB after

oven is cold and 4-5 hours of

non use, or when the flush

switch is activated at the IFB.

24Dcv_Rtn_L

OR-17

5

1

Y-9 3

J8-1

J8-2

J8-8

J8-9

B l o d g e t t O v e n

Page 32

Page 36

BCX14E

LOW FLOAT LEVEL LED'S

BOILER PREHEAT TO 185F

AMBER

- INPUT LED'S

AMBER

- INPUT LED'S

GREEN OUTPUT LED'S

GREEN OUTPUT LED'S

HOT AIR MODE LED'S

STEAM MODE LED INDICATORS

AMBER

- INPUT LED'S

AMBER

- INPUT LED'S

GREEN OUTPUT LED'S

GREEN OUTPUT LED'S

BCX14E LOGIC BOARD LED INDICATOR DESIGNATIONS

LED On = INPUT

LED

Flush Disable (above 140F) J2-2

1

Combi Mode J3-1

2

Steam Mode J3-2

3

Steam On Demand J3-7

4

Spare input J3-8

5

Heat Demand J4-1

6

Boiler High limit J4-5

7

Boiler Lo_Lvl_Float

8

Convection Heat J3-6

9

DESCRIPTION

LED On = OUTPUT

10 Boiler Heat On

Delime lamp Flashing / Delime Oven

11

Steam On Demand Lamp J4-3

12

13 Convection Heat On J4-3

14 Drain Valve On J3-10

15 Boiler Fill Enable, J2-3

16 Delime Solenoid, J2-5

17 Spare Output, J3-5

LED On = INPUT

LED

Flush Disable (above 140F) J2-2

1

Combi Mode J3-1

2

Steam Mode J3-2

3

Steam On Demand J3-7

4

Spare input J3-8

5

Heat Demand J4-1

6

Boiler High limit J4-5

7

Boiler Lo_Lvl_Float

8

Convection Heat J3-6

9

DESCRIPTION

LED On = OUTPUT

10 Boiler Heat On

Delime lamp Flashing / Delime Oven

11

Steam On Demand Lamp J4-3

12

13 Convection Heat On J4-3

14 Drain Valve On J3-10

15 Boiler Fill Enable, J2-3

16 Delime Solenoid, J2-5

17 Spare Output, J3-5

LED On = INPUT

LED

Flush Disable (above 140F) J2-2

1

Combi Mode J3-1

2

Steam Mode J3-2

3

Steam On Demand J3-7

4

Spare input J3-8

5

Heat Demand J4-1

6

Boiler High limit J4-5

7

Boiler Lo_Lvl_Float

8

Convection Heat J3-6

9

DESCRIPTION

LED On = OUTPUT

10 Boiler Heat On

Delime lamp Flashing / Delime Oven

11

Steam On Demand Lamp J4-3

12

13 Convection Heat On J4-3

14 Drain Valve On J3-10

15 Boiler Fill Enable, J2-3

16 Delime Solenoid, J2-5

17 Spare Output, J3-5

LED On = INPUT

LED

Flush Disable (above 140F) J2-2

1

Combi Mode J3-1

2

Steam Mode J3-2

3

Steam On Demand J3-7

4

Spare input J3-8

5

Heat Demand J4-1

6

Boiler High limit J4-5

7

Boiler Lo_Lvl_Float

8

Convection Heat J3-6

9

DESCRIPTION

LED On = OUTPUT

10 Boiler Heat On

Delime lamp Flashing / Delime Oven

11

Steam On Demand Lamp J4-3

12

13 Convection Heat On J4-3

14 Drain Valve On J3-10

15 Boiler Fill Enable, J2-3

16 Delime Solenoid, J2-5

17 Spare Output, J3-5

B l o d g e t t O v e n

Page 33

Page 37

BCX14E

COMBI MODE LED'S

STEAM ON DEMAND LED'S

AMBER

- INPUT LED'S

AMBER

- INPUT LED'S

GREEN OUTPUT LED'S

GREEN OUTPUT LED'S

DRAIN VALVE OPEN LED'S

ACTIVE DELIME PUMP LED

AMBER

- INPUT LED'S

AMBER

- INPUT LED'S

GREEN OUTPUT LED'S

GREEN OUTPUT LED'S

BCX14E LOGIC BOARD LED INDICATOR DESIGNATIONS

LED On = INPUT

LED

Flush Disable (above 140F) J2-2

1

Combi Mode J3-1

2

Steam Mode J3-2

3

Steam On Demand J3-7

4

Spare input J3-8

5

Heat Demand J4-1

6

Boiler High limit J4-5

7

Boiler Lo_Lvl_Float

8

Convection Heat J3-6

9

DESCRIPTION

LED

1

2

3

4

5

6

7

8

9

LED On = INPUT

DESCRIPTION

Flush Disable (above 140F) J2-2

Combi Mode J3-1

Steam Mode J3-2

Steam On Demand J3-7

Spare input J3-8

Heat Demand J4-1

Boiler High limit J4-5

Boiler Lo_Lvl_Float

Convection Heat J3-6

LED On = OUTPUT

LED On = OUTPUT

10 Boiler Heat On > (45 Seconds) 10 Boiler Heat On

Delime lamp Flashing / Delime Oven

11

Steam On Demand Lamp J4-3

12

13 Convection Heat On J4-3

14 Drain Valve On J3-10

15 Boiler Fill Enable, J2-3

16 Delime Solenoid, J2-5

17 Spare Output, J3-5

Delime lamp Flashing / Delime Oven

11

Steam On Demand Lamp J4-3

12

13 Convection Heat On J4-3

14 Drain Valve On J3-10

15 Boiler Fill Enable, J2-3

16 Delime Solenoid, J2-5

17 Spare Output, J3-5

LED On = INPUT

LED

Flush Disable (above 140F) J2-2

1

Combi Mode J3-1

2

Steam Mode J3-2

3

Steam On Demand J3-7

4

Spare input J3-8

5

Heat Demand J4-1

6

Boiler High limit J4-5

7

Boiler Lo_Lvl_Float

8

Convection Heat J3-6

9

DESCRIPTION

LED On = OUTPUT

10 Boiler Heat On

Delime lamp Flashing / Delime Oven

11

Steam On Demand Lamp J4-3

12

13 Convection Heat On J4-3

14 Drain Valve On J3-10

15 Boiler Fill Enable, J2-3

16 Delime Solenoid, J2-5

17 Spare Output, J3-5

LED On = INPUT

LED

Flush Disable (above 140F) J2-2

1

Combi Mode J3-1

2

Steam Mode J3-2

3

Steam On Demand J3-7

4

Spare input J3-8

5

Heat Demand J4-1

6

Boiler High limit J4-5

7

Boiler Lo_Lvl_Float

8

Convection Heat J3-6

9

DESCRIPTION

LED On = OUTPUT

10 Boiler Heat On

Delime lamp Flashing / Delime Oven

11

Steam On Demand Lamp J4-3

12

13 Convection Heat On J4-3

14 Drain Valve On J3-10

15 Boiler Fill Enable, J2-3

16 Delime Solenoid On, J2-5

17 Spare Output, J3-5

B l o d g e t t O v e n

Page 34

Page 38

BCX14E

Boiler Heat

D11)

Heat Enable

CR8 (D81)

Fill Enable

CR10 (D101)

Boiler Drain

(D9)

CR2 (D21)

Door Closed

Oven On

Cooling Fan

CR5 (D51)

Vent

(D8)

Lights

BCX14E IFB RELAY BOARD LED DESIGNATIONS

BCX14 Interface Board

LED Designations

Part # 39672

Lights On

#1

indicate (Energized Relays) active circuits as labeled.

J1 J2

#1

J3

J4

CR1 (

CR3 (D31)

CR4 (D41)

CR6 (D61)

Quench Sol.

CR7 (D71)

Delime Sol.

#1

J8

J7 J6 J5

B l o d g e t t O v e n

Page 35

Page 39

B l o d g e t t O v e n

Page

36

BCX14E - Trouble shooting test points

Test Points

Voltage

(Lower)

(Lower)

3

1

/

3

(+V) Red +24vdc_H

BCX2 (Logic Board) /

V) Black 24vdc_Rtn

1

Test Points

(Top) Heat

(Top) Heat

Boiler High Limit /

Boiler High Limit /

Hot Air High Limit /

Hot Air High Limit /

Test Points

Mode Switch to

Motor Speed Inverter to

IFB Relay Board to

Motor Speed Inverter to

~ (Bottom) DC Voltage Power Supply Test Points ~

# Component

1

2

3

4

5

6

DC Power Supply

DC Power Supply

BCX2 (Logic Board)

BCX2 (Logic Board)

DC Power Supply

DC Power Supply

(IFB) Relay Board

~(Top) Heat DC Voltage Power Supply Test Points 2 ~

# Components Testing

1

2

DC Power Supply

DC Power Supply

Black lead Red Lead

Power supply (N) Power supply (L)

Power supply (-V) Power supply (+V)

J1 Connector (J1-1) BK-

24vdc_Rtn

J1 Connector (J1-1) BK-

24vdc_Rtn

(-

terminal at power supply

J7 Connector (J7-2) Black J7 Connector (J7-1) Red

J1 Connector (J1-4) RD-

+24vdc_H

terminal at power supply

J1 Connector (J1-4) RD-

+24vdc_H

Black lead Red Lead

Power supply (N) Power supply (L)

Power supply (-V) Black Power supply (+V) Red

AC + DC

115 VAC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

Voltage AC

+ DC

115 VAC

24 VDC

3

4

5

6

Hot Air Contactor

Hot Air Contactor

Hot Air Contactor

Hot Air Contactor

~ Cool Down Operation at Low Speed ~

# Components Testing

1

2

3

4

5

Motor Speed Inverter

BCX2 (Logic Board)

BCX2 (Logic Board)

BCX2 (Logic Board)

BCX2 (Logic Board)

Contactor Coil (A2) Black Wire

Contactor Coil (A2) Black Wire

Contactor Coil (A2) Black Wire

Contactor Coil (A2) Black Wire

Boiler High limit ( Red Wire )

Boiler High limit ( Yellow Wire )

Hot Air High limit ( Red Wire )

Hot Air High limit ( Orange Wire )

Black lead Red Lead

( N ) ( L )

Mode SW Terminal #4

Inverter Terminal #CW2

( IFB ) Connector J3 (J3-7) J1 Connector J1-4

( Inverter ) Terminal #2 & #3 ( Inverter ) Connector J1-4

J1 Connector J1-4

J1 Connector J1-4

24 VDC

24 VDC

24 VDC

24 VDC

Voltage AC

+ DC

115 VAC

24 VDC

24 VDC

24 VDC

24 VDC

Page 40

B l o d g e t t O v e n

Page

37

Test Points

Test Points

~ Hot Air Mode with Heat Light Active ~

# Components Testing

1

2

3

5

6

7

8

9

BCX2 (Logic Board)

BCX2 (Logic Board)

BCX2 (Logic Board)

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

RH Contactor Hot Air

~ Steam Mode with Heat Light Active ~

# Components Testing

Black lead Red Lead

J3 Connector (J3-6) GY-3 J1 Connector (J1-4) RD-1

J4 Connector (J4-1) V-6 J1 Connector (J1-4) RD-1

J4 Connector (J4-2) Y-1 J1 Connector (J1-4) RD-1

J4 Connector (J4-2) W-2 J4 Connector (J4-1) RD-2

J4 Connector (J4-2) W-2 J4 Connector (J4-3) OR-22

J4 Connector (J4-2) W-2 J4 Connector (J4-4) OR-22

J4 Connector (J4-2) W-2 J4 Connector (J4-6) BL-1

HA Contactor (A2) White HA Contactor (A1) Red

Black lead Red Lead

Voltage AC

+ DC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

Voltage AC

+ DC

1

2

3

4

5

6

8

9

BCX2 (Logic Board)

BCX2 (Logic Board)

BCX2 (Logic Board)

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

LH Contactor Steam

J3 Connector (J3-2) GY-2 J1 Connector (J1-4) RD-1

J4 Connector (J4-1) V-6 J1 Connector (J1-4) RD-1

J4 Connector (J4-6) BL-2 J1 Connector (J1-4) RD-1

J6 Connector (J6-2) W-1 J6 Connector (J6-1) RD-1

J6 Connector (J6-2) W-1 J6 Connector (J6-3) Y-3

J6 Connector (J6-2) W-1 J6 Connector (J6-4) Y-3

J6 Connector (J6-2) W-1 J6 Connector (J6-5) RD-16

Steam Contactor (A2) White Steam Contactor (A1) Red

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

Page 41

B l o d g e t t O v e n

Page

38

~ Combi Mode with Heat Light Active ~

Test Points

2

Test Points

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

5

( IFB ) Relay Board

10

# Components Testing

1

2

3

4

5

6

7

8

9

10

BCX2 (Logic Board)

BCX2 (Logic Board)

BCX2 (Logic Board)

BCX2 (Logic Board)

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

RH Contactor Hot Air

( IFB ) Relay Board

Black lead Red Lead

J3 Connector (J3-1) GY-1 J1 Connector (J1-4) RD-1

J4 Connector (J4-1) V-6 J1 Connector (J1-4) RD-1

J4 Connector (J4-2) Y-1 J1 Connector (J1-4) RD-1

J4 Connector (J4-6) BL-

(Active 25%)

J4 Connector (J4-2) W-2 J4 Connector (J4-1) RD-2

J4 Connector (J4-2) W-2 J4 Connector (J4-3) OR-22

J4 Connector (J4-2) W-2 J4 Connector (J4-4) OR-22

J4 Connector (J4-2) W-2 J4 Connector (J4-6) BL-1

HA Contactor (A2) White HA Contactor (A1) Red

J6 Connector (J6-2) W-1 J6 Connector (J6-1) RD-1

J1 Connector (J1-4) RD-1

Voltage

AC + DC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

24 VDC

11

12

13

14

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

LH Contactor Steam

~ Boiler Float Level Troubleshooting ~

# Components Testing

1

2

3

4

5

6

7

( IFB ) Relay Board

(Hi_Lvl Float Closed)

(Hi_Lvl Float Open)

(Lo_Lvl Float Closed)

(Lo_Lvl Float Open)

(Hi_Lvl Float Closed)

(Lo_Lvl Float Closed)

J6 Connector (J6-2) W-1 J6 Connector (J6-3) Y-3

J6 Connector (J6-2) W-1 J6 Connector (J6-4) Y-3

J6 Connector (J6-2) W-1 J6 Connector (J6-5) RD-16

Steam Contactor (A2) White Steam Contactor (A1) Red

Black lead Red Lead

J8 Connector (J8-2) BK-4 J8 Connector (J8-1) RD-4

J8 Connector (J8-2) BK-4 J8 Connector (J8-3) V-3

J8 Connector (J8-2) BK-4 J8 Connector (J8-3) V-3

J8 Connector (J8-2) BK-4 J8 Connector (J8-4) BL-6

J8 Connector (J8-2) BK-4 J8 Connector (J8-4) BL-6

J8 Connector (J8-5) V-

(To Fill Solenoid)

J8 Connector (J8-6) Bl-

(To Fill Solenoid)

J8 Connector (J8-1) RD-4

J8 Connector (J8-1) RD-4

24 VDC

24 VDC

24 VDC

24 VDC

Voltage

AC + DC

24 VDC

24 VDC

0 VDC

24 VDC

0 VDC

24 VDC

24 VDC

Page 42

B l o d g e t t O v e n

Page

39

Test Points

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

( IFB ) Relay Board

Test Points

1

~ Delime Pump Troubleshooting ~

Test Points

1

( IFB ) Relay Board /

~ Drain Valve Troubleshooting ~

# Components Testing

1

2

3

4

5

( IFB ) Relay Board

(Drain Valve Closed)

(Drain Valve Closed)

(Drain Valve Open)

(Drain Valve Open)

~ Steam on Demand Troubleshooting ~

# Components Testing

1

BCX2 (Logic Board)

Black lead Red Lead

J8 Connector (J8-2) BK-4 J8 Connector (J8-1) RD-4

J8 Connector (J8-9) Y-9 J8 Connector (J8-1) RD-4