Page 1

COS-8G, COS-8GDS, BCS-8G, AND CNV-8G

GAS COOKING APPLIANCES

INSTALLATION -- OPERATION -- MAINTENANCE

COS-8G, COS-8GDS, BCS-8G, ET CNV-8G

APPAREILS DE CUISSON AU GAZ

MANUEL D’INSTALLATION -- FONCTIONNEMENT -- ENTRETIEN

BLODGETT COMBI

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN R8133 Rev D (6/01)

E 2000 --- Blodgett Combi

Page 2

A PERSONAL WORD FROM BLODGETT COMBI

QUELQUES MOTS DE BLODGETT COMBI

Congratulationsonyourpurchase ofaBLODGETTCombiappliance.We

firmlybelieve that yourchoicehasbeenawiseone,andtrustyouwillreceive many years of excellent service from your new Combi.

You will find that cooking with Combi appliances saves time, labor and

extensive cleaning of both the kitchen and the unit.

With Combi appliances the quality, taste, consistency, and look of your

food are improved, thus endorsing the policytowhichwe’vealwaysadhered: “For Better Cooking!”

Onceyou’vehad a chancetouseyour Combi, please tellus,yourdealer

andcolleaguesaboutanycreative andinterestingapplicationsyouhave

discovered; exchange ideas with other users. Be sure to advise us or

your dealer immediately should any mechanical or technical problems

beencountered(...we’rehereto help!)andaboveall“Enjoy Cookingthe

BLOD GETT Combi Way!

For information on cooking, please refer to our separate cooking guide.

Toutes nos félicitations sur votre achat d’appareil de Blodgett Combi.

Nous croyons fermement que votre choix est un choix raisonnable et

nous sommes certains que vous obtiendrez de nombreuses années

d’excellent service de votre nouveau four multi-usages.

Vousallezdécouvrir que lacuissondans lesappareils Combiéconomise

le temps, letravail etle degré de nettoyage de l’appareilaussi bien que

de la cuisine.

Avecles appareil de Combi,la qualité, le goût, la consistence et l’apparence des aliments sont améliorés, s’accordant, de ce fait, avec notre

politique ”Pour une meilleure cuisson !”

Une fois que vous aurez eu la chance d’utiliser notre Combi, informez

nous, votreconcessionnaire et voscollègues, de toutes les applications

nouvelles et intéressantes que vous avez découvertes ; échangez vos

idées avec d’autres utilisateurs. N’hésitez pas à nousprévenir, ou votre

concessionnaire, de tout problème mécanique ou technique que vous

pourriezrencontrer (... noussommes icipour vous aider) etpar-dessus

tout “Régalez-vous à cuisiner à la façon BLODGETT Combi!

Pourobtenirde plus amples informationssur l’artculinaire, veuillezconsulter notre livre de cuisine séparé.

Page 3

IMPORTANT

WARNIN G:IMPROPERINSTALLATION,ADJUSTMENT,ALTERATION,SERVICEOR

MAINTENAN C ECAN CAUSEPROPERTY DAMAGE,INJURY ORDEATH .READTHE

INSTALLA TION,OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

AVERTI SSEMEN T: UNE INSTALLATIO N , UN AJUSTEMENT, UNE ALTÉRATION, UN

SERVICEOU UN ENTRETIEN NON CONFORMEAUXNORMES PEUT CAUSERDES

DOMMAGESÀLAPROPRIÉTE,DESBLESSURESOULAMORT.LISEZATTENTIVEMENTLES DIRECTIVESD’INST A L LATION,D’OPÉRA TI O NET D’ENTRETIENAVANT

DE FAIRE L’IN S TALLATI O N OU L’ENTRETIEN DE CET ÉQUIPEMENT.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS

MUST BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE

OBTAINED BY CONTACTING YOUR LOCAL GAS SUPPLIER.

LES INSTRUCTIONSÀ RESPECTER AU CAS OÙ L’UTILISATEUR PERÇOIT UNE

ODEURDE GAZ DOIVENTÊTRE AFFICHÉES DANSUN ENDROITBIEN VISIBLE.

VOUS POUVEZ VOUS LES PROCURER AUPRÈS DE VOTRE FOURNISSEUR DE

GAZ LOCAL.

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or liquids in the vicinity

of this or any other appliance.

AVERTISSEMENT

Ne pas entreposer ni utiliser de l’essence ni d’autres vapeurs ou liquides inflammables dans le voisinage de cet appariel, ni de tout autre appareil.

The information contained in thismanual isimportant for the properinstallation,

use,and maintenanceofthisoven. Adherenceto theseproceduresand instructions will result in satisfactory baking results and long, trouble free service.

Please read this manual carefully and retain it for future reference.

Les informatio nsdonnées dans le présent manuel sont importantes pour installer,

utiliseret entret enircorrectementce four.Le respectde ces instructions et procédurespermettra d’obtenir de bonsrésultatsdecuissonetune longue durée deservice sans problèmes. Veuillez lire le présent manuel et le conserver pour pouvoir

vous y reporter à l’avenir.

Errors: Descriptive, typographic or pictorial errorsare subject to correction. Specifica-

tions are subject to change without notice.

Erreurs:Les erreurs de description, de typographie ou d’illustration font l’objet de

corrections. Les caractéristiques sont sujettes à modifications sans préavis.

Page 4

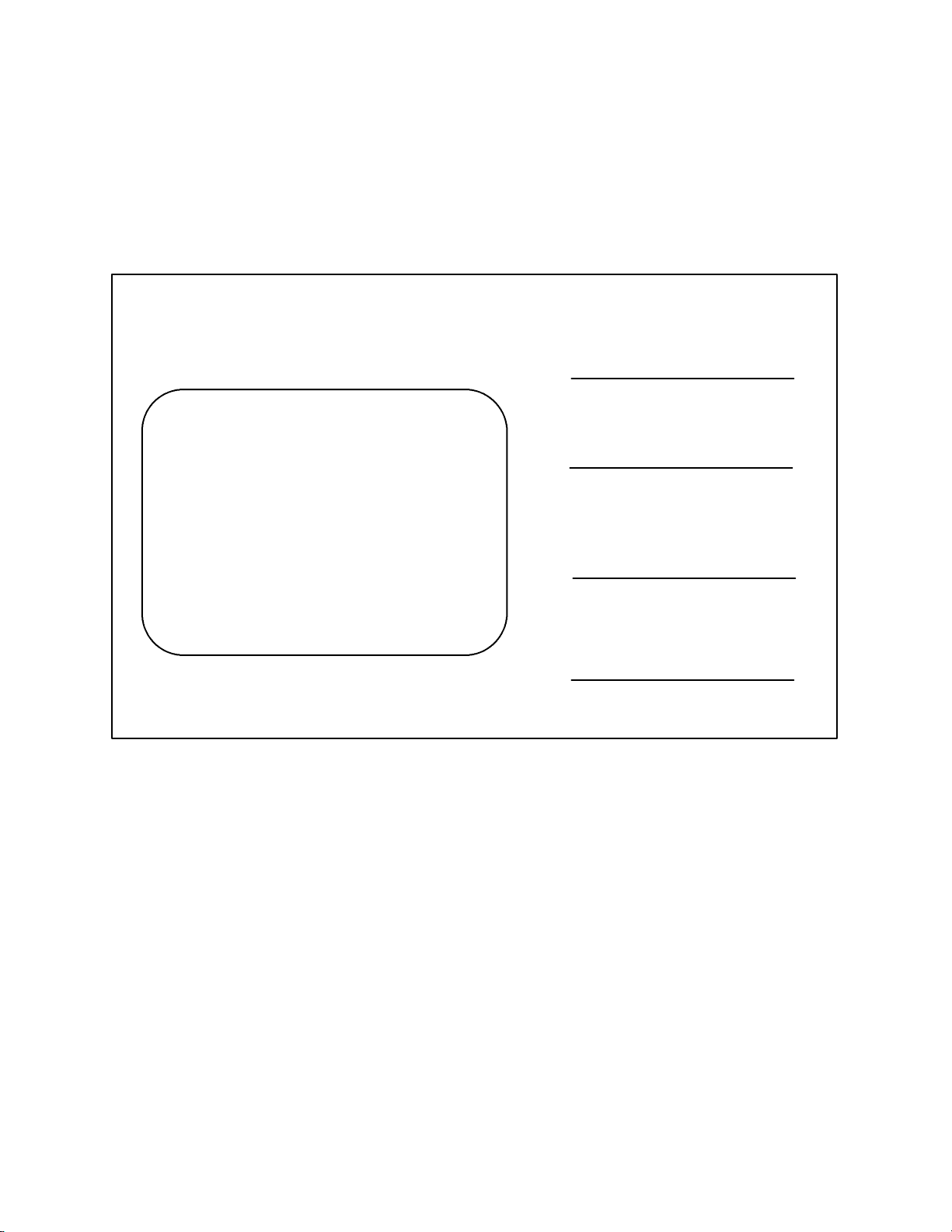

Your Service Agency’s Address:

Adressedevotreagencedeservice:

Model/Modèl:

Serial Number/Numéro de série:

Your oven was installed by/

Installateur de votre four:

Your oven’s installation was checked by/

Contrôleur de l’installation de votre four:

Page 5

Table of Contents/Table des Matières

Introduction

The Blodgett Combi Cooking Line 2......

Description of the Blodgett Combi

Cooking Line 3.........................

Oven Features 4.......................

Installation

Owner’s Responsibilities 5...............

Location and Ventilation 6...............

Agency Approvals 7....................

Utility Connections 8....................

Optional Leg A ttachment 13..............

Baffle Installation 14.....................

Stacking Instructions 15..................

Final Check and Adjustments 17..........

Final Check Lists 18.....................

Operation

Safety Information 19....................

Oven Start-Up 20........................

Combi-Oven/Steamer Standard Controls 21

Optional Combi-Oven/Steamer

Cook & Hold 23.........................

Convection Steamer Standard Controls 26.

Convection Oven Standard Controls 27....

Optional Convection Oven

Cook and Hold 28.......................

Optional Meat Probe 31..................

Maintenance

Spray Bottle Operating Procedure 32......

Cleaning and Preventive Maintenance 33...

Decalcification 34.......................

Introduction

Laligned’appareilsdecuisson

de Blodgett Combi 36....................

Description de la ligne d’appareils de cuis-

son de Blodgett Combi 38................

Caractéristiques 39......................

Installation

Responsabilités du propriétaire 40.........

Placement et Ventilation 41..............

Normes et Codes 42.....................

Branchement Utilitaires 43................

Retenue du Tuyau de Gaz 47.............

Fixation des pieds en Option 48...........

Installation du Déflecteur 49..............

Superposition - Assemblage

section double 50.......................

Vérification finale et derniers réglages 52...

Vérifications Finales 53...................

Utilisation

Informations de Sécurité 55...............

Mise en Marche du Four 56...............

Combi-Four/ étuve à Vapeur

Contrôles Standards 57..................

Combi-Four/ étuve à Vapeur

Cuisson et Pause en Option 59...........

Combi-Convection/étuve à

Vapeur Contrôles Standards 63...........

Combi-Four à Convection

Contrôles Standards 64..................

Combi-Four à Convection

Cuisson et Pause en Option 65...........

Sonde à Viande en Option 69.............

Entretien

Procédé de fonctionnement de la bouteille

vaporisatrice 70.........................

Entretien Préventif et Nettoyage 71........

Détartrage 72...........................

Page 6

Introduction

The Blodgett Combi Cooking Line

For quite some time, commercial cooking equipment has remained more or less unchanged.

There are kettles, deck ovens,t he good old range

with its legion of pots and many other extra

appliances. The result: time expenditure, excessive manual work, and countless cleaning processes.Thelastfew yearshavepavedthe wayfor

a revolutionin the equipment ofrestaurant and in stitutionalkitchens. Blodgett Combi is proud tooffer three different cooking platforms, one of which

is sure to match your needs. The B lodgett Combi

line includes:

D

The Blodgett Combi Convection Steamer

D

The Blodgett Combi Convection Oven

D

The Blodgett Combi-Oven/Steamer

AllBlodgettCombi appliancesimproveyour kitchen through:

D

increased productivity

D

a wider range of menu choices

D

a simplified cleaning process

The work process is simplified since products are

prepared on or in steam table pans and trays.

Foodcan be cooked, stored, and transportedwith

the same pans. Small amounts of product can be

processed efficiently; pre-cooked and convenience foods can be reheated within minutes.

COMBI CONVECTION OVEN

Cooking in the Combi Convection Oven differs

from cooking in a traditional deck or range oven

sinceheated airis constantlyrecirculated overthe

product by a fan in an enclosed chamber. The

movingaircontinuallystrips away thelayer ofcool

air surrounding the product, quickly allowing the

heatto penetrate. Theresult isa high qualityproduct, cooked at a lower temperature in a shorter

amount of time.

COMBI-OVEN/STEAMER

WiththeOven/Steameryouhave thechoiceoftwo

cooking processes: Steam and Hot Air, either...

D

Separately

D

Combined, or

D

InSequenceusingtwo orthreefunctionsduring

onecookingprocess.Wecallthiscombi-steaming and combi-baking.

For easy operation you can choose from three

modes:

Steam HotAir Combi

Steam &

Hot Air

In the Steam mode you can:

COMBI CONVECTION STEAMER

Steaming is a well known cooking process frequently used in restaurant and institutional kitchens.WiththeCombiConvectionSteamer,it isnow

possible to enjoy the many advantages ofsteaming including shorter cook times, higher product

quality and vitamin retention.

TheCombi ConvectionSteamer includesa builtin

steamgenerator.This unitincludes aninlet, funnel

assembly and valve lever for decalcification.

D

steam

D

defrost

D

blanch

D

rethermalize

D

poach

In the Hot Air mode you can

D

roast

D

bake

D

braise

In the Combi mode you can:

D

defrost

D

reheat

D

proof*

D

roast

D

bake

D

cook & hold*

D

rethermalize

D

sous vide*

* with optional digital controls

The Combi-Oven/Steamer is offered in two models,

each with different steam producing systems.

D

The COS-8G model includes a built in steam

generator. This unitincludes an inlet, funnelassembly and valve lever for decalcification.

D

The COS-8GDS is a direct steam unit that is

connected to an external steam source.

2

Page 7

Introduction

Description of the Blodgett Combi Cooking Line

ABOUT THE COMBI LINE

Blodgett Combi appliances are quality produced

using high-grade stainless steel with first class

workmanship.

The use ofhigh qualityinsulation impedes excessive heat radiation and saves energy.

Optional adjustable legs adapt easily to slightly

unevensurfaces. Optional floor stands have been

designed for use with all of the table models.

Oven/Steamers and Convection Steamers

The high performance steam control system

makes it possibleto enjoy all of the advantages of

ahigh qualitysteamerat theflickof a switch.Fresh

steamenters theoven cavitywithoutpressureand

is circulated at high speed. This process enables

quickandgentlecookingandensures highquality

product while providing convenientworkingmethods.

Apatentedquench systemkeepsthe airint he unit

clean. Fumes are extracted from the appliance,

quenched,and directed outthroughthe condenser drain. The exhaust system is effective in all

cooking modes and results in better quality foods

and no flavor transfer. The fan, w hich isguarded

against accidental finger contact, is driven by a

quiet and powerful motor. The condenser draws

out excess steam from the appliance. Condensation and waste water, which result during steaming and cleaning, are continuously drained.

OPERATION

The practical oven door , with a viewing window,

has a wide swingradius and handlewhich can be

operated easily, even with wet or greasy hands.

Ease of operation is guaranteed through the simplearrangement of the controls. Graphic symbols

make the appliances easy for even inexperienced

kitchenstaffto operate.All modescanbe selected

with one switch. This includes the Cool Down

mode, which allows the oven cavity to cool down

rapidly with the door opened or closed.

Cleaningiskept to aminimum. The interiorcan be

sprayed with a cleaning solution to easilyremove

crusts and stains. The oven is designed for easy

care and is welded w ater tight so that the internal

cooking cavity may be rinsed with a hose after the

cleaning process.

3

Page 8

Introduction

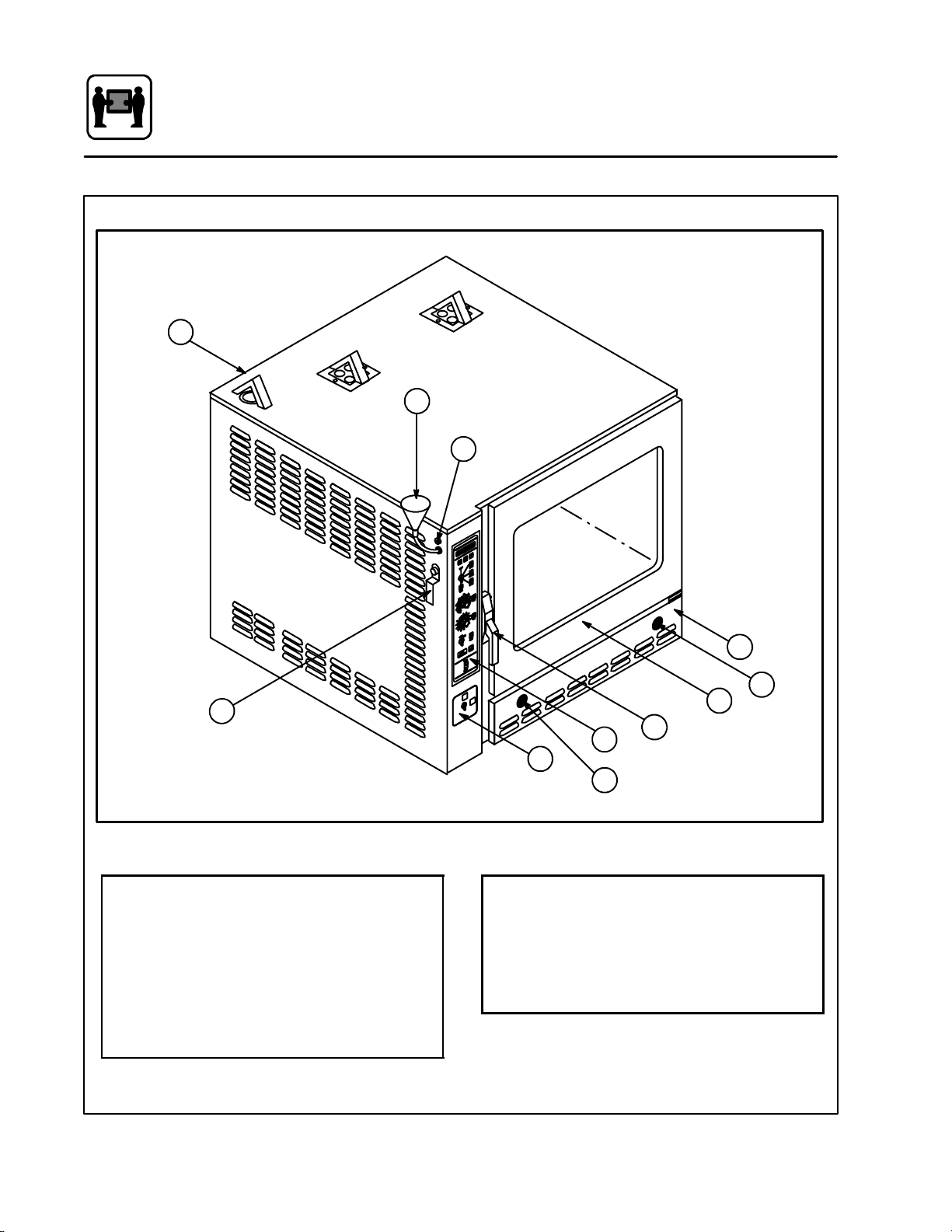

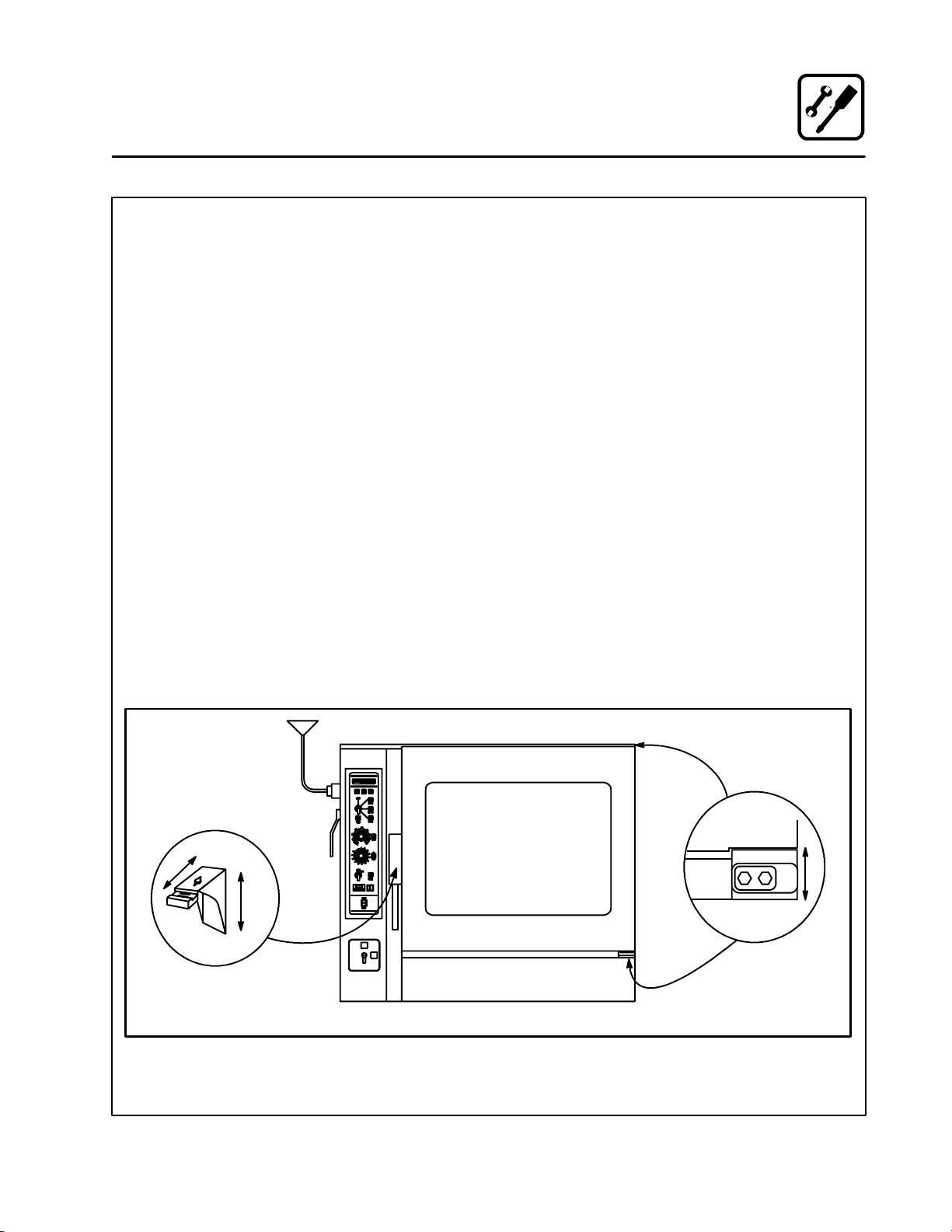

Oven Features

5

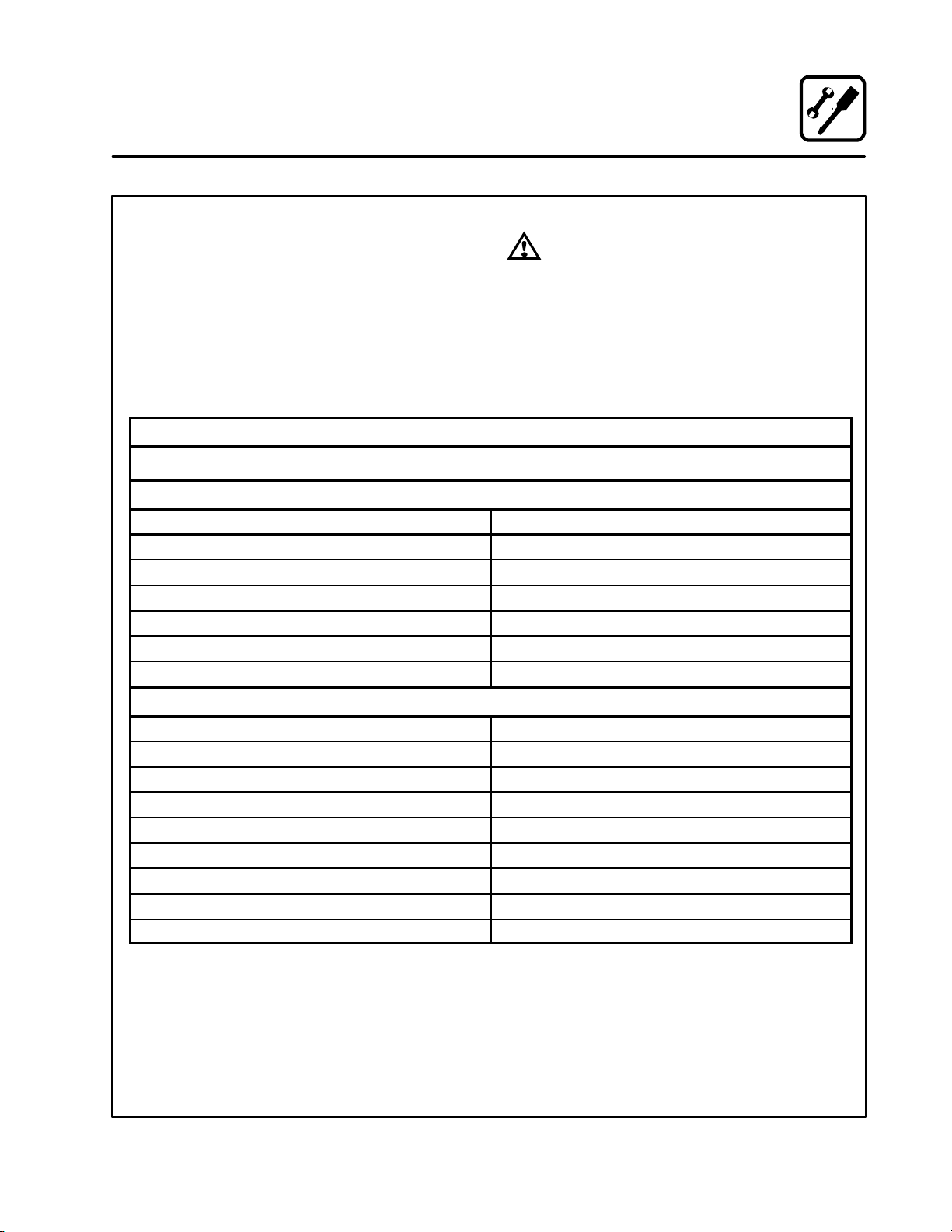

Standard Features

6

9

7

1

Control Panel

2 Oven Door

3 Drip Collector (self draining)

4 Door Handle

5 Vent (not shown)

6 Decalcifying Inlet & Funnel Assembly*

COS-8G Shown

Figure 1

3

2

1

8

10

7 Decalcifying Valve Lever*

8 Gas Shut Off Valve

9 Tilt Down Panel Screw

10 Removeable plugs provide access to

screws securing drip collector

* only on COS-8G and BCS-8G

4

10

4

Page 9

Installation

Owner’s Responsibilities

1. Oven(s)are uncrated, stacked (if applies)and

put in place.

NOTE: Refer to Leg Attachmentand Stacking

information provided.

2. The owner/operator must have the following

plumbing, electrical and gas requirements

met and installed.

NOTE: Refer to the Utility Connection infor-

mation provided.

ELECTRICAL

15 amp Nema 5-15 grounded outlet

PLUMBING

Water

Water Pressure (min/max) 50 PSI (345 kPa)

Cold Water Supply 3/4” Hose Fitting, 3/8” ID hose minimum

Hot Water Supply* 3/4” Hose Fitting*, 3/8” ID hose minimum

Drainage Atmospheric Vented Drain

Drain Connection 2” Copper

Average Water Drain Temperature 122_F/50_C

WARNING!!

Improper installation, adjustment, alter-

ation service or maintenance can cause

property damage, injury or death. Read

the installation, operation and maintenance instruction thoroughly before installing or servicing this equipment.

GAS PRESSURE

Orifice at Sea Level

Steam #13/64 (.203” dia) natural gas

Hot Air #54 (.055” dia) natural gas

Inlet Pressure to the Unit

Natural Gas 7---14” WC (1.74---3.48 kPa)

Propane 12---14” WC (2.98---3.48 kPa)

Pressure at the Manifold

Natural Gas 3.5” WC (.87 kPa)

Propane 10” WC (2.49 kPa)

*Not applicable with COS-8GDS and CNV-8G

5

Page 10

Installation

Location and V entilation

LOCATION

The well planned and proper placement of your

appliance will result in long term operator convenience and satisfactory performance.

The following clearances must be maintained between the unit, including hose assemblies, and any

combustible or non-combustible constructio n.

D

Ovens with cast ers --- 6” (15 cm)

D

Ovens without casters --- 12” (30 cm)

The following clearances are recommended, but

not required, for servicing.

D

Oven body sides --- 12” (30 cm)

D

Oven body back --- 12” (30 cm)

Place the unit in an area which is free of drafts and

accessible for proper operation and servicing.

Keep the oven area free and clear of all combustibles such as paper, cardboard, and flammable

liquids and solvents.

DO NOT place the oven on a curb base or seal to

the wall; either condition will prevent proper ventilationtothe blowermotors.Slightunevennesscan

be corrected with the adjustable legs.

The air vents on the left side of the unit must be

protected from h eat and steam or water sources.

Consult the factory for an optional protective side

heat shield kit if excessive ambient heat orsteam

is present on the left side of the unit.

D

COS-8G heat shield P/N R4514

D

COS-8GDS heat shield P/N R4514

D

BCS-8G heat shield P/N R4514

D

CNV-8G heat shield P/N R4514

Onallmodels, tripping theblower motor’s thermal

overload device indicates an excessive ambient

temperature at the back of the oven. This must be

corrected to prevent permanent damage to the

oven. All motor bearings are permanently lubricated by the manufacturer; there is no need for

additional lubrication during the operational lifetime of the motors.

VENTILATION

The necessity for a properly designed and installed ventilation system cannot be over emphasized. The ventilation system will allow the unit to

function properly while removing unwanted vaporsand productsof combustionfrom the operating area.

The appliance must be ventedw ith a properlydesigned mechanically driven exhaust hood. The

hood should be sized to completely cover the

equipmentplus an overhang of at least 6” (15 cm)

on all sides not adjacent to a wall.The capacityof

the hood should be sized appropriately and provisions made for adequate makeup air.

WARNING!!

Failure to properly vent the oven can be

hazardous to the health of the operator;

and will result in operational problems,

unsatisfactorybaking,and possibledamage to theequipment. Damage sustained

as a direct result of improper ventilation

will not be coveredby theManufacturer’s

warranty.

U.S. and Canadian Installations

Refer to your local ventilation codes. In the absence of localcodes, refer to the Nationalventilation code titled, “Standard for the Installation of

Equipment for the Removal of Smoke and Grease

Laden Vapors from Commercial Cooking Equipment”, NFPA-96- Latest Edition.

General Export Installations

Installationmust conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questionsregarding the proper installationand/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

pleasecall BlodgettCombiat 0011-802-860-3700.

6

Page 11

Installation

Agency Approvals

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIEDINSTALLATIONANDSERVICEPERSONNEL

ONLY. INSTALLATION OR SERVICE B Y OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN A ND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and are responsible for:

D

The installation or replacement of gas piping.

The connection, installation, repair or servicing

of equipment.

D

Theinstallationofelectricalwiringfromthe electric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experienced in such work, be familiar with all precautions required and have complied with allrequirements of state or local authorities having

jurisdiction.

U.S. and Canadian Installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1---Latest Edition,

the Natural Gas Installation Code CAN/CGAB149.1 or the Propane Installation Code, CAN/

CGA-B149.2 as applicable.

Reference: National Electrical Code, ANSI/NFPA

70---Latest Edition and/or Canadian Electrical

Code CSA C22.1 as applicable.

This equipment is to be installed in compliance

withthe Basic Plumbing Code of the Building Offi-

cials and Code Administrators International Inc.

(BOCA) and theFood Service Sanitation Manual of

the Food and Drug Administration (FDA).

General Export Installations

Installationmust conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questionsregarding the proper installationand/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

pleasecall BlodgettCombiat 0011-802-860-3700.

7

Page 12

Installation

Utility Connections

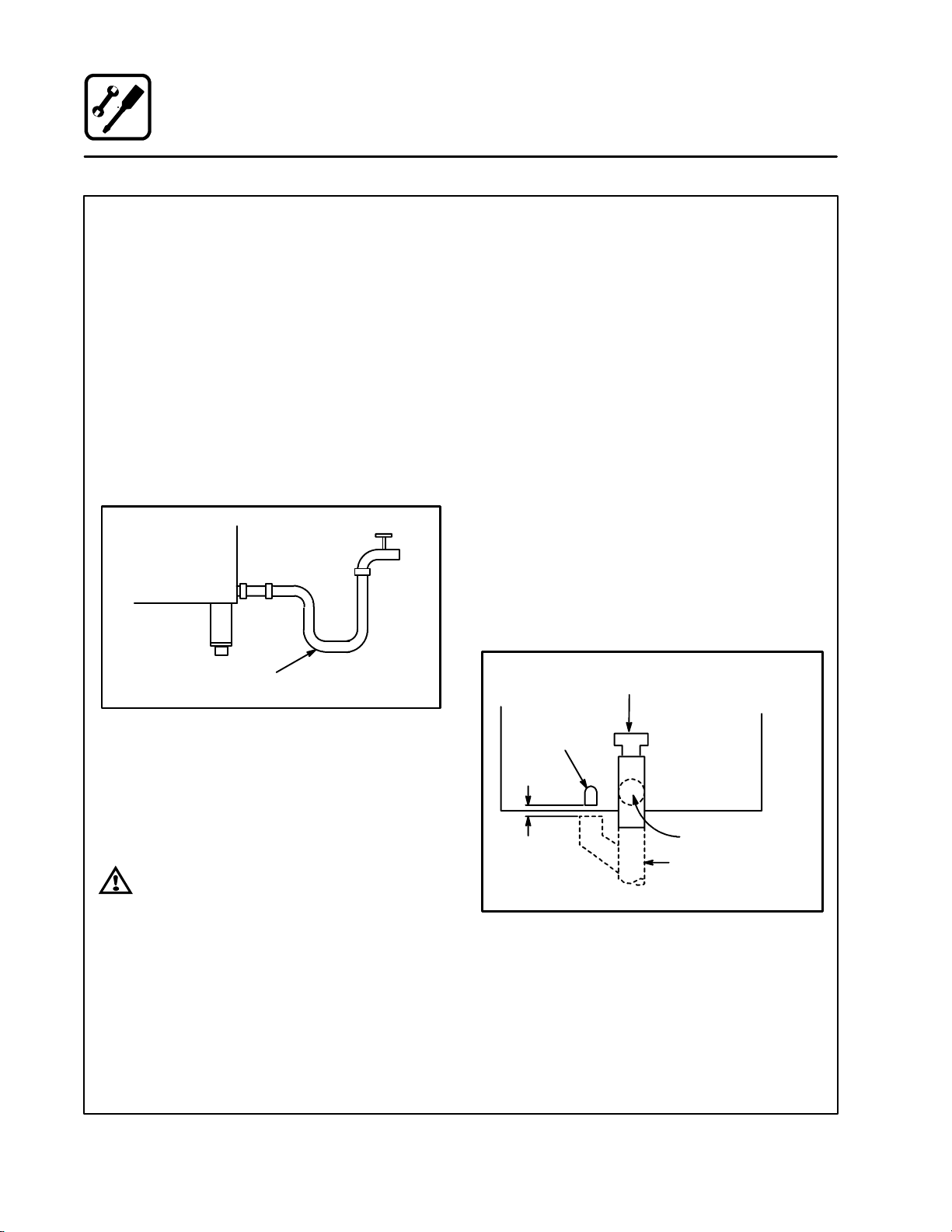

HOT AND COLD WATER CONNECTION

NOTE: Hot water maximizes steam production but

is notrequired.Cold water may be supplied

to both inlets if hot water is not available.

COS-8G and BCS-8G --- Connectthe appliance to

qualitycold water via a pressure hose with 3/4” couplings. Cold water is connected to the left solenoi d/

pressure regulator, as viewed from the rear of the

unit. Hot water connection, right solenoid/pressure

regulator, to the boiler is recommended. Shut off

valves must be provided adjacent to the oven.

COS-8GDS and CNV-8G --- Connect these units

to quality coldw ater viaa pressurehose with 3/4”

couplings.

1/2” appliance hose

With 3/4” hose fittings

DRAIN CONNECTION

A 2” (5 cm) copper pipe with standard drain pitch

mustberuntoanopendrainorconnectedtoa

standpipe equipped with a vent.

NOTE: The waste water can also bedirected to a

nearbyfloor drain. Flexible hose which allows trapped water to accumulate in

sagged runs must be avoided.

1. Find the drain connections on the lower rear

of the unit.

2. Using the band coupling provided, attach

coupling clamps to the drain connection.

3. Create the drip pan drain connection as

shown. A separate drain connection for the

drip pan is also possible.

NOTE: The open end of the drain should be

installed fac ing the floor . Copper line used

for installation to an open drain or floor sink

must be supplied by the installer.

CAUTION! Use of an inline trap will causedrain

backup

Plumbersupplied

breather vent and tee

Figure 2

Water must meet the following minimum requirements:

D

Total Dissolved Solids (TDS) content willnot exceed 30 parts per million.

D

Water PH must be 7.0 or higher

WARNING!!

The use of poor quality water will invali-

date your warranty.

Drip pan drain

1” air g ap

Main drain

Plumbersupplied

connection to lower unit

or drain system

Figure 3

8

Page 13

Installation

Utility Connections

STEAM CONNECTION

NOTE: COS-8GDS only.

Connect the appliance to a 200 psi maximum external steam source per local or state codes. The

steam must be clean, potable and fit for human

consumption. Failureto connect this appliance to

asuitablesteamsource willrevoketheapprovalof

NSF.

ELECTRICAL CONNECTION

Beforemaking any electricalconnectionsto these

units, check that the powersupply is adequate for

the voltage, amperage, and phase requirements

stated on the rating name plate mounted on the

unit.

Wiring diagrams are located on the inside of the

louvered side panel.

All units are equipped for operation on 115V 15

amp 1Φ 60Hz., 2 conductor cable with ground.

Wiring from the power source to this unit must be

aminimum of#16 AWG CU. strandedwire or larger.

NOTE: DISCONNECT THE POWER SUPPLY TO

THEUNITBEFORESERVICING!

U.S. and Canadian installation

All units, when installed, must be electrically

groundedin accordance with localcodes or inth e

absenceoflocalcodes, withtheNationalElectrical

Code, ANSI/NFPA70---Latest Edition and/or Canadian Electrical Code CSA C22.1 as applicable.

General Export Installations

Installationmust conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questionsregarding the proper installationand/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

pleasecall BlodgettCombiat 0011-802-860-3700.

WARNING!!

Improperelectricalinstallationwill invali-

date your warranty.

WARNING!!

This appliance is equipped with a 115V,

three-prong (grounding) plug for your

protection against shock hazard and

shouldbe pluggeddirectlyintoa properly

grounded three-prong receptacle. DO

NOT cut or remove the grounding prong

from this plug.

9

Page 14

Installation

L

t

h

p

g

Utility Connections

GAS PIPING

Aproperlysized gas supplysystem isessentialfor

maximum oven performance. Piping should be

sized to provide a supplyof gassufficient to meet

themaximum demandof allapplianceson theline

without loss of pressure at the equipment.

Example:

NOTE: BTU values in the following example are

for natural gas.

You purchase a COS-8G to add to your existing

cook line.

1. Addthe BTUratingofyourcurrentappliances.

Pitco Fryer 120,000 BTU

6 Burner Range 60,000 BTU

Deck Oven 50,000 BTU

Total 230,000 BTU

2. Add the BTU ratingof the new oven to the total.

Previous Total 230,000 BTU

COS-8G (for steam) 90,000 BTU

New Total 320,000 BTU

3. Measure the distance from the gas meter to

the cookline. This is the pipelength.Let’s say

thepipelengthis30’(9m)andthepipesize

is 1” (2.54 cm).

4. Use the appropriate table to determine the total capacity of your current gas piping.

The total capacity for this example is 375,000

BTU. Since the total required gas pressure,

320,000 BTU is less than 375,000 BTU, the

current gas piping will not have to be increased.

NOTE: The BTU capacitiesgiveninthe tables are

for straight pipe lengths only. Any elbows

orother fittingswill decreasepipe capacities. For example: a schedule 40 1-1/2”ell

fitting has an equivalent capacity of 4.2”

(10.2cm) ofstraight pipe.Contactyourlocalgas supplierif youhave anyquestions.

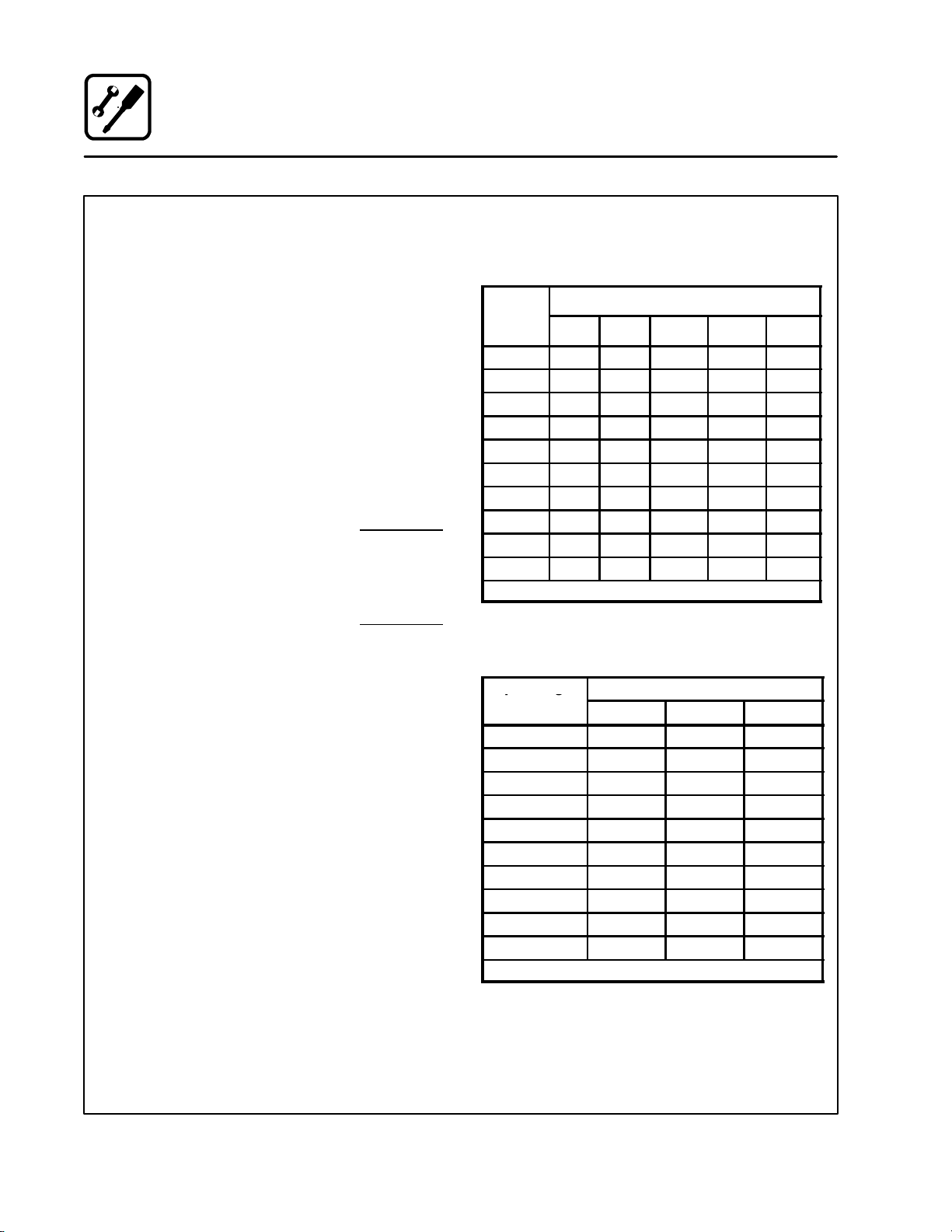

Maximum Capacity of Iron Pipe in Cubic Feet

of Natural Gas Per Hour

(Pressure drop of 0.5 Inch W.C.)

Pipe

eng

(ft)

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

From the National Fuel Gas Code Part 10 Table 10-2

Maximum Capacity of Pipe in Thousands of

BTU/hr of Undiluted P.P. Gas at 11” W.C.

Pipe Length

From the National Fuel Gas Code Part 10 Table 10-15

3/4” 1” 1-1/4” 1-1/2” 2”

(Pressure drop of 0.5 Inch W.C.)

(ft)

10 608 1146 3525

20 418 788 2423

30 336 632 1946

40 287 541 1665

50 255 480 1476

60 231 435 1337

70 215 404 1241

80 198 372 1144

90 187 351 1079

100 175 330 1014

Nominal Size, Inches

Inside Diameter, Inches

3/4” 1” 1-1/2”

10

Page 15

Installation

Utility Connections

PRESSURE REGULATION AND TESTING

The gas pressure to the appliance must be rated

for 7” W.C. for natural gas and 12---14” W.C. for

propane gas for each unit while the burners are

on. A sufficient gas pressure must be present at

the inlet to satisfy these conditions.

Eachunit hasbeen adjustedat thefactorytooperate with the type of gas specified on the rating

plate attached to the right side of the unit.

Each oven issupplied with a regulator to maintain

the propergas pressure. The regulator isessen-

tial to the proper operation of the oven and

shouldnotberemoved.It ispreset toprovidethe

oven with 3.5” W.C. (0.87 kPa) for natural gas and

10.0” W.C. (2.50 kPa)for Propanewhile the flame

is on.

DO NOT INSTALL AN ADDITIONALREGULATOR

WHERE THE UNIT CONNECTS TO THE GAS

SUPPL Y UNLESS THE INLET PRESSURE IS

GREATER THAN 14” W.C. (1/2 PSI)

The oven and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressuresinexcessof1/2psig(3.45kPa).

The oven must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas piping system at test pressures equal or less

than 1/2 psig (3.45kPa).

Prior to connecting the unit, gas lines should be

thoroughly purged of all metal filings, shavings,

pipedope, and other debris. Afterconnection, the

unit s hould be checked for correct gas pressure.

U.S. and Canadian installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1---Latest Edition,

the Natural Gas Installation Code CAN/CGAB149.1 or the Propane Installation Code, CAN/

CGA-B149.2 as applicable.

General Export Installations

Installationmust conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questionsregarding the proper installationand/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

pleasecall BlodgettCombiat 0011-802-860-3700.

11

Page 16

Installation

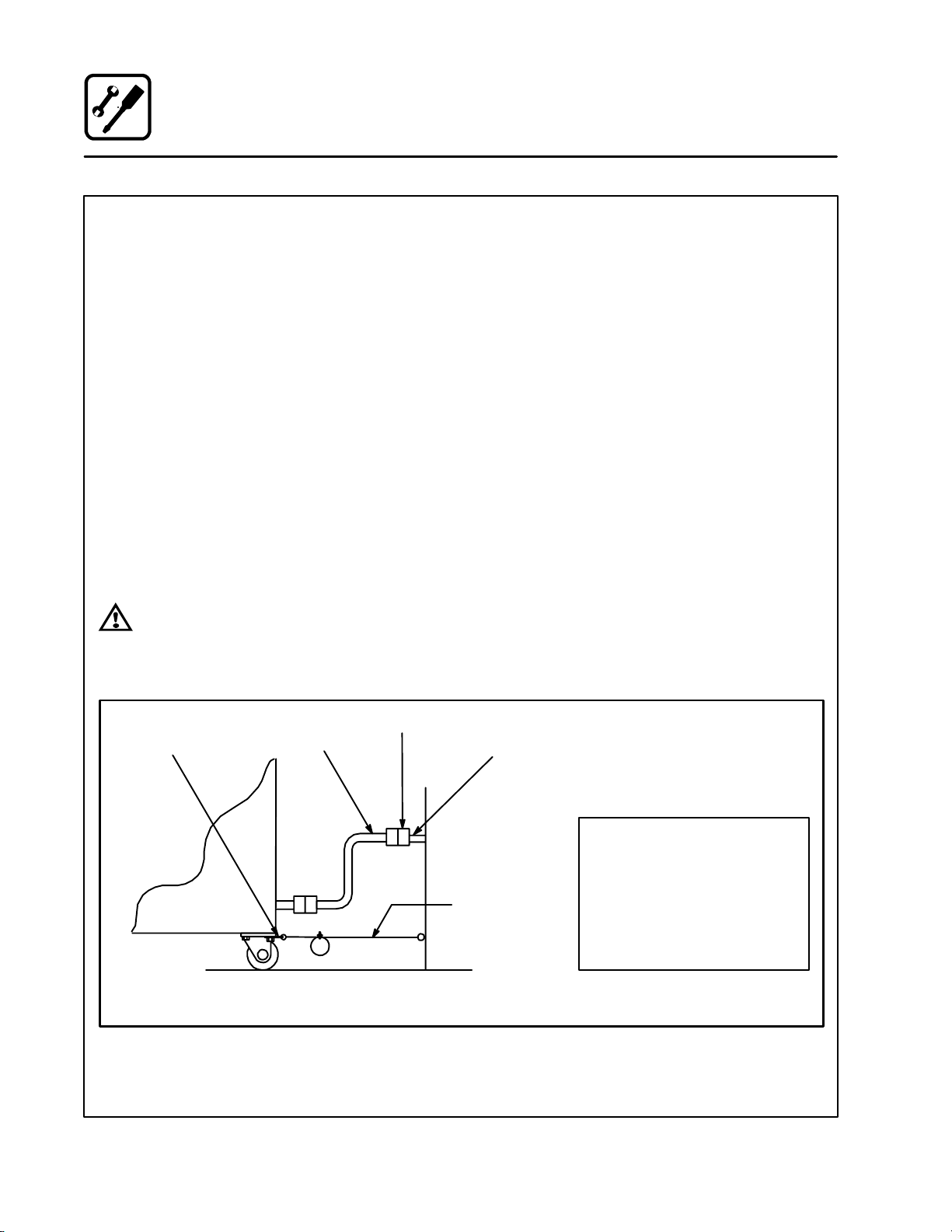

Gas Hose Restraint

If the unit is mounted on casters, a commercial

flexible connector with a minimum of 3/4”(1.9 cm)

inside diameter must be used along with a quick

connect device.

Therestraint,suppliedwiththe appliance,mustbe

used to limit the movement of the unit so that no

strain is placed upon the flexible connector. The

restraint should be fastened to the base frame of

the ovenas close to the flexibleconnector as possible. It should be short enough to prevent any

strain on the connector. With the restraint fully

stretched the connector should be easy to install

and quick connect.

Therestraint (ie:heavygauge cable)should beattached without damaging the building. DO NOT

use the gas piping or electrical conduit for the attachment of the permanent end of the restraint!

Use anchorbolts in concrete or cement block. On

wooden walls, drive hi test wood lag screws into

the studs of the wall.

WARNING!!

If the restraint is disconnected for any

reason it must be reconnected when the

unit is returned to its original position.

U.S. and Canadian installations

The connector mustcomply with the Standard for

Connectors for Movable Gas Appliances, ANSI

Z21.69 or Connectors For Moveable Gas Appliances CAN/CGA-6.16 and a quick disconnect

device that complies with the Standard for QuickDisconnect Devices for Use With Gas Fuel, ANSI

Z21.41or Quick Disconnect For UseWithGasFuel

CAN 1-6.9. Adequate means must be provided to

limit the movement of the appliance without depending on theconnection and the quick disconnect device or its associated piping.

A drip leg must be used at each appliance. Refer

to NFPA54/ANSI Z223.1 - Latest Edition (National

Fuel Gas Code) for proper drip leg installation.

General export installations

Installationmust conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questionsregarding the proper installationand/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

pleasecall BlodgettCombiat 0011-802-860-3700.

Attachment Plate

(securewith leg mount bolt)

Gas Hose

Quick Connect

Gas Supply Line

Restraint

Installation of Gas Hose and Restraint

Figure 4

12

IMPORTANT: Cable restraint should

be fastened as close as possibleto the

flexibleconnectorand short enoughto

prevent any strain on the flexible connector.

At maximum stretch of shortened restraint, the flexible connector should

beeasytoinstallandquickto connect.

Page 17

Installation

Optional Leg Attachment

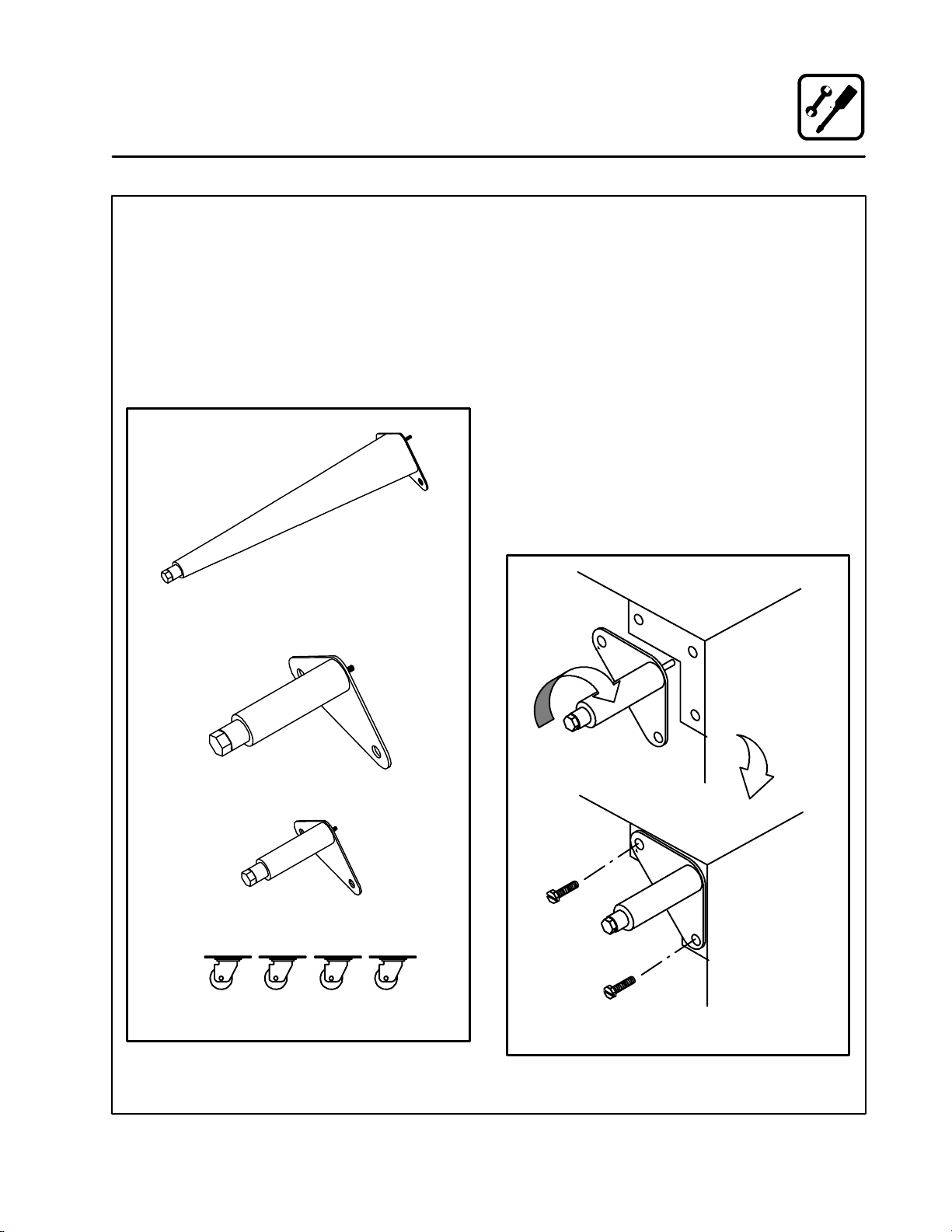

LEG OPTIONS

Legs are available in 4” (10 cm), 6” (15 cm) or 25”

(64 cm) lengths or low profile casters. The 4” legs

are for counter top installations. The 6” legs are

usedonthelowersectionofa doublestackedunit.

The 25” legs are used for a single oven located on

the floor .

NOTE: For safety reasons, casters must not be

used with the 25” (64 cm) legs.

25“ (64 cm) Adjustable Leg

LEG ATTACHMENT

NOTE: If low profile casters are used, install the

locking casters on the front of the oven.

The rear casters do not lock. Be sure the

locks are set on the front casters.

1. Alignthethreadedstud theeachlegto thebolt

holes located in the unit’s bottom corners.

Turn the legs clockwise and tighten to the

nearest full turn.

2. Align the leg plate holes with the bolt holes.

Secure with the two 1/2” bolts provided.

3. Tip the oven up on the legs. If casters are

used, check that the locks are set on the front

casters.

4. Except forunits with casters, levelthe ovenby

screwing the adjustable feet in or out as necessary.

6” (15 cm) Adjustable Leg

4” (10 cm) Leg

Low Profile Casters

Figure 5

6” (15 cm) Legs Shown

Figure 6

13

Page 18

Installation

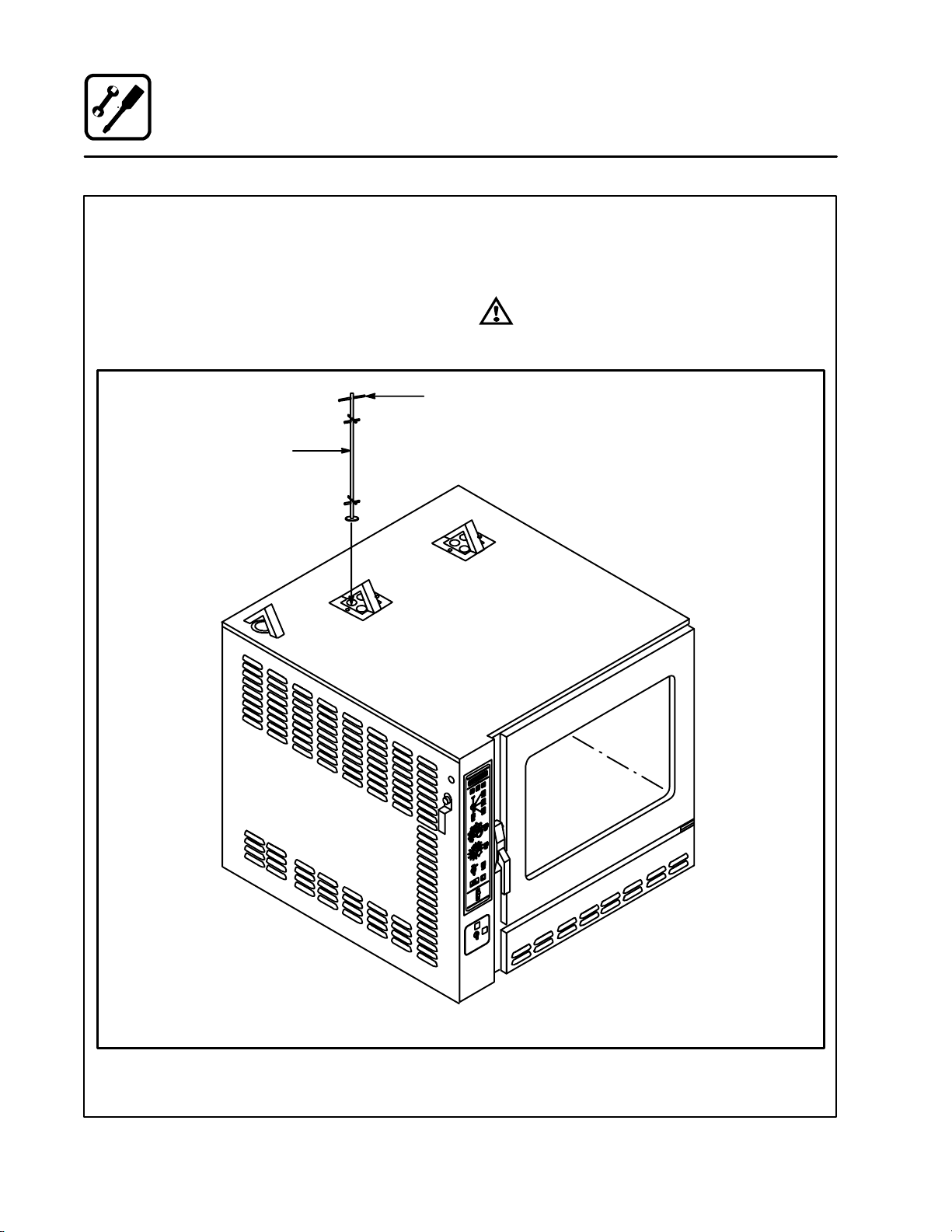

Baffle Installation

NOTE: Does not apply to BCS-8G convection

steamer.

1. Inserta baffleintoeachheatexchange tubeas

shown. There are eight baffles per oven. The

baffles are packed in a cartoninside theoven

cavity.

SupportPin

Baffle

NOTE: The baffle support pin shouldbe rest-

ing on top of the heat exchange tube

when the baffle is fully inserted.

WARNING!!

Failure to install the baffles will result in

reduced heating efficiency of the oven.

COS-8G Shown

Figure 7

14

Page 19

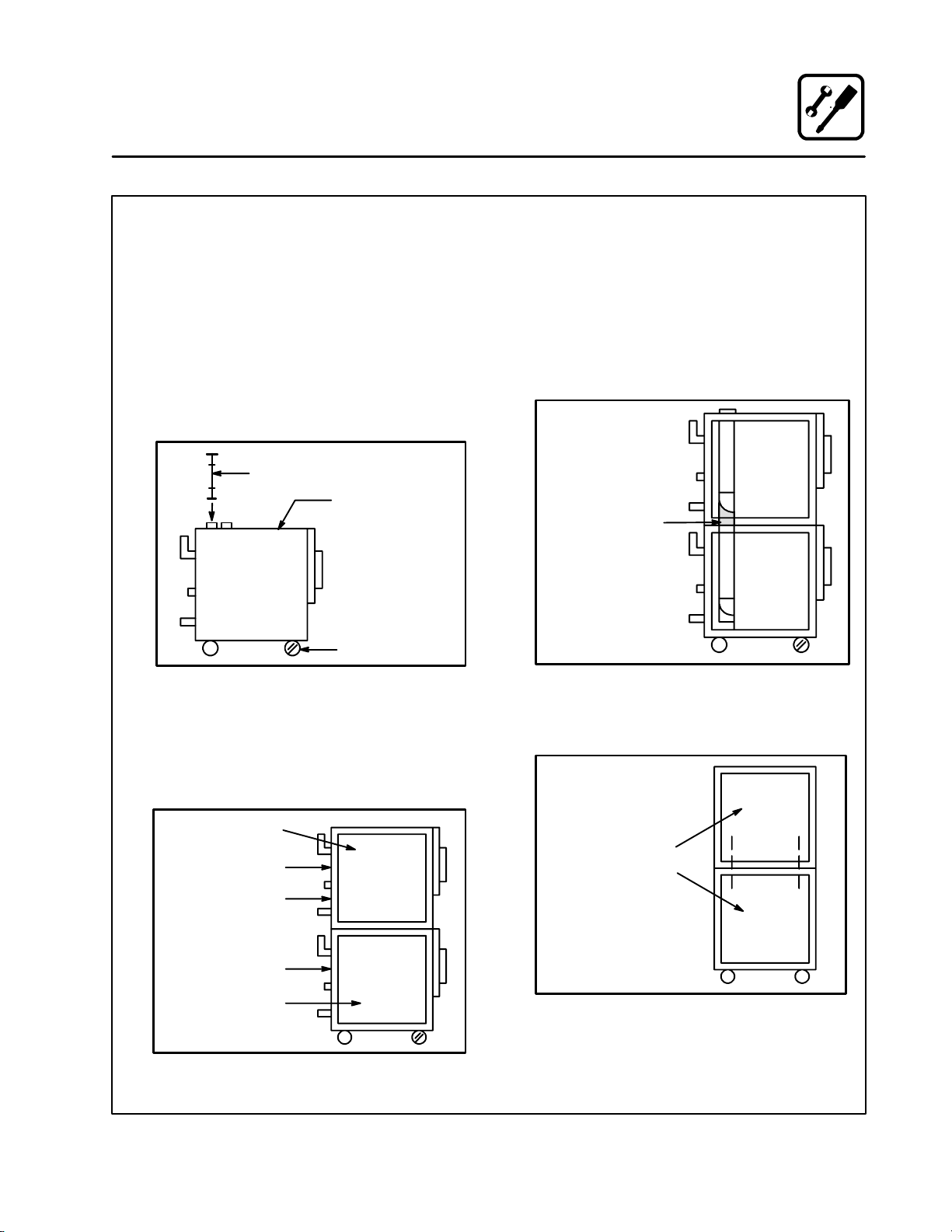

STACKING

1. Install6”(15cm) legsorcasters onthebottom

unit, using the three 1/2” bolts provided. If

castersare used, be sure thatthe casters with

brakesarelocatedonthe frontofthe ovenand

the gas hose restraint has been installed.

2. Oven/Steamers and Convection Ovens only

Install a baffle (8 per unit) into each heat exchange tube on both top and bottom units.

NOTE: For installation of convection steamers

proceed to step 3.

Baffle (not applicablefor

Convection Steamers)

DO NOT remove

body top

Installation

Stacking Instructions

4. COS-8G and BCS-8G only --- Remove the

upperunit’s steamgenerator flue bottomcap.

Install the steam generator flue adapter between the lower and upper units’ steam generator.

NOTE: For convection ovens (CNV-8G) and

direct steam units (COS -8GDS) proceed to step 5.

Remove plug

Install adapter flue

Caster with brakes

Figure 8

3. Lift and mount the upper unit onto the lower

unit.Flushtheedgeson allfoursides.Remove

the side panel and body back of both units.

Save the screws. Remove the lower body

back from the top unit.

Remove

louvered panel

Removebody back

Remove

lower body back

Removebody back

Remove

louvered panel

Figure 9

Figure 10

5. Bolt the upper and lower units together using

the 1/2” bolts provided.

Bolt through holes

closest to oven center

Rear view of oven

Figure 11

15

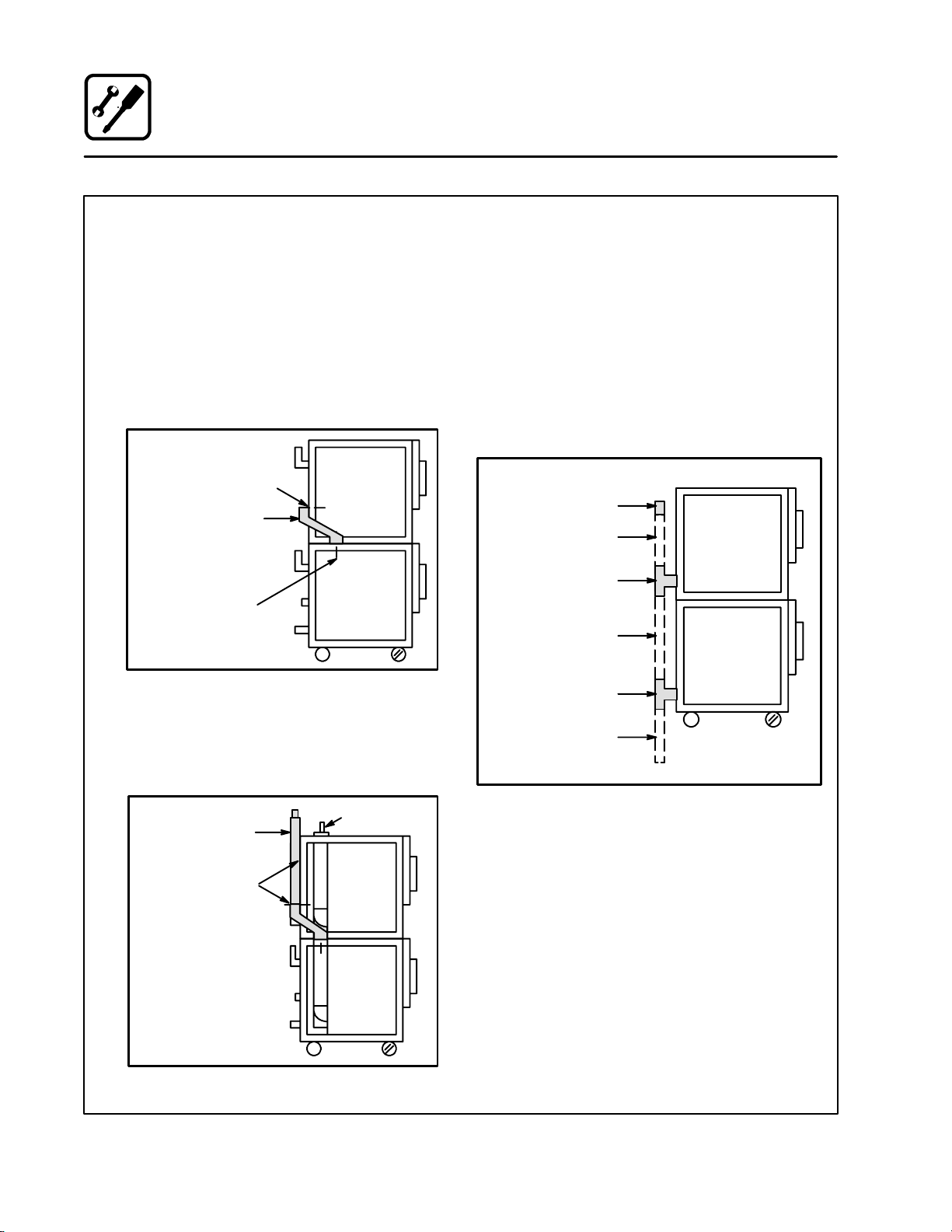

Page 20

Installation

Stacking Instructions

FLUE INSTALLATION

NOTE: Convection Steamers do not require tran-

sition and vertical flues. If installing a Convection Steamer proceed to Plumbing.

1. Install the transition flues between the units.

Use three 10-24 screws to attach each flue to

the lower unit’s body top. Reattach the body

backs to the appropriate units. Secure the

transition flues to the lower bodyback using

the sheet metal screws provided.

Secure the transition flues

to the lower bodyback

using sheet metal screws

Transition flue

Attach with three

10-24 screws at base

of transition flue

PLUMBING

NOTE: The installationplumber is responsiblefor

connection to the drain. Usea 24” section

onthetopunitTeetoraisethebreathervent.

NOTE: DO NOT manifold the drains together

when stacking a CNV-8G with a COS-8G,

BCS-8G or COS-8GDS.

1. Attach copper Tee, gray hose and clamps to

the drain outlet of both units.

2. Install suitable tubing to the floor drain from

the drip pan outlet on the rear of the unit.

Breather vent

Plumber installed

connection 24” long

Tee, hose and clamps

Plumber installed

connection

2. Install vertical flues using sheet metalscrews

provided. Drill through the body back of the

top unit using the vertical flue mounting holes

as pilot holes. Attach the vertical flues to the

body back using sheet metal screws provided.

Attach flue cap to the upper unit.

Flue cap

Vertical flue

Attach the vertical

flues to the body

back using sheet

metal screws

Figure 12

Tee, hose and clamps

Plumber installed

connection to drain

Figure 13

16

Page 21

Installation

Final Check and Adjustments

BEFORESWITCHINGTHEAPPLIANCEON

Beforeapplying power to the unit forthe first time,

check for the following conditions:

j

All electrical safety provisions have been adhered to and the electrical connections are

correct.

j

Water is connected, turned on and all of the

connections are water tight.

j

Check all gas fittings at the site with leak

detection solution.

NOTE: COS-8G and BCS-8G units only --- The

first time the unit is turned on, or after the

unit has been OFF for 5 hours and then

turned on, it will automatically flush the

steam generator for a period of 75 seconds. The steam generator will then fill to

the proper water level. The unit is now

ready for operation.

DOOR ADJUSTMENT

The doorcatch maybe adjusted in twodirections,

in and out, and up and down, using the following

procedure:

1. Adjust catch up and down by loosening the

two bolts holding the catch to the face of the

unit (A).

2. Make adjustments so that the leadingface of

the catch is centered in the opening of the

handle assembly.

3. Tighten the bolts so that there is no further

movement.

4. Adjust catch in and out by loosening the bolt

on the top of the catch (B).

5. The adjustment face is stepped so that movement is limited with the bolt tightened properly.

6. The adjustment is correct when the door closes

firmly and no steam leaks from the gasket.

The hinges can also be adjusted as follows:

1. Be certain the catch is adjusted properly.

2. Adjust hinges so that the door back and the

unit face are parallel (C).

3. The adjustment is correct when no steam

leaks through the gasket.

Oven

B

A

COS-8G shown

Figure 14

17

Door

C

Page 22

Installation

Final Check Lists

ELECTRICAL CONTROL COMPARTMENT

115 volt single phase to unit.

j

Remove side panel

j

Reset high limit thermostats

j

Check fuses

j

Reinstall side panel

PLUMBING FINAL CHECK

j

Incoming water pressure within 50 PSI (minimum)

j

Water solenoids are properly bracketed and

not leaking

j

24”atmosphericstandpipe vent/drainproperly installed

j

Water feed lines intact without leaks

j

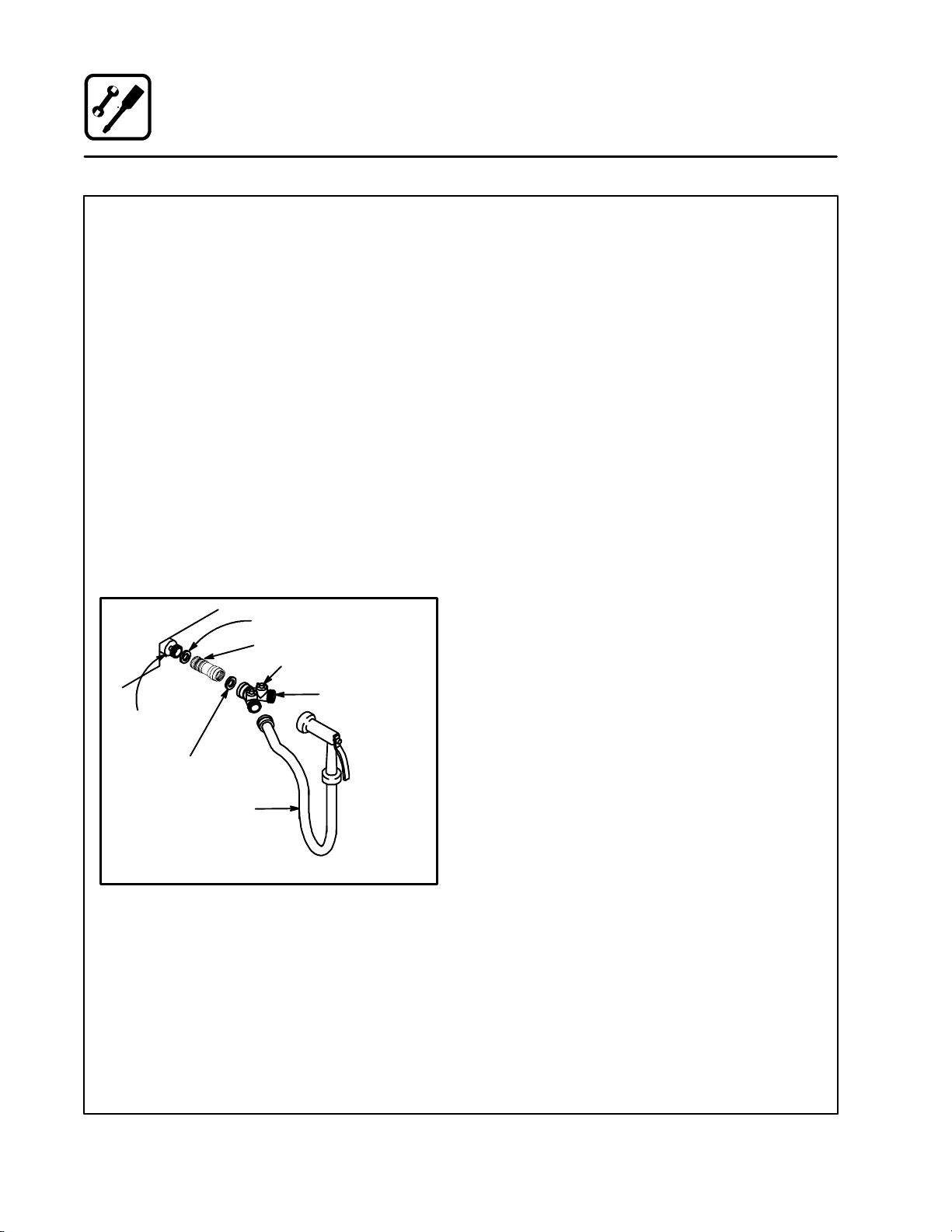

Spray hose connected properly

Washer

Regulator Assembly

“Y” Fitting

Cold water supply

Fill

Solenoid

Washer

Hose and Spray

Spray Hose Connection

Figure 15

j

Check for leaks using leak detection solution

j

Units with casters must use the gas hose restraint provided with the flexible hose

OVEN OPERATIONAL TESTS

NOTE: Checkstobemadebycustomerorautho-

rized service agent.

Cool Down Mode (if applicable)

j

Turn Switch toCOOL DOWN position and verify

that the motor operates with the door open.

Combi Mode (if applicable)

Turn to COMBI mode, set thermostat to 350_F

(177_C) and verify:

j

Steam generator flushes and fills

j

Steam generator preheats to 175_F(79_C)

then switches to hot air

j

When hot air reaches 350_F (177_C) hot air

shuts off and steam comes on

Steam Mode (if applicable)

Remove control panel, set to STEAM mode and

verify:

j

Check timer operation in both positions

1. Set timer in position other than ON, timer

should count down

2. Set timer in ON position, oven should operate continuously without timer

j

Run light (power light) turns on

j

Unit produces steam, window fogs, door seal

does not leak

j

Quenching system working

Hot Air Mode (if applicable)

GAS FINAL CHECK

j

Inletpressurestothe applianceare7---14”WC

forNaturalgas or12---14”WCforPropanegas

j

Manifold pressures are 3.5” WC for Natural

gas or 10.0” WC for Propane gas

j

Gas line properly secured

Turn to HOT AIR mode and set thermostat to

400_F (205_C) and verify:

j

Heat demand light is on

j

Oven is heating properly

j

Heat lights shuts off at 400_F (205_C) and

oven maintains 400_F (205_C)

18

Page 23

Operation

Safety Information

THE INFORMATION CONTAINED IN THIS SECTIONISPROVIDEDFORTHEUSE OFQUALIFIED

OPERATING PERSONNEL. QUALIFIED OPERATING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONTAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE OVEN A ND/ OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPERATIONOFTHE EQUIPMENTDESCRIBED.ADHERENCE TO THE PROCEDURES RECOMMENDED HEREIN WILL ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLE-FREE SERVICE.

Please take the time to read the following safety

andoperatinginstructions.Theyare the keyto the

successful operation of your Blodgett Combi gas

appliance.

SAFETY TIPS

For your safety read before operating

What to do if you smell gas:

D

DO NOT try to light a ny appliance.

D

DO NOT touch any electrical switches.

D

Use an exterior phone to callyour gas supplier

immediately.

D

If you cannot reach your gas supplier, call the

fire department.

What to do in the event of a power failure:

D

Turn all switches to off.

D

DO NOT attempt to operate the unit until the

power is restored.

NOTE: In the event of a shut-downof any kind, al-

low a five (5) minute shutoff period before

attempting to restart the oven.

General safety tips:

D

DO NOT use tools to turn off the gas control. If

thegas cannotbe turned offmanuallydo nottry

to repair it. Call a qualified service technician.

D

If the oven needs to be moved for any reason,

the gas must be turned off and disconnected

from the unit before removing the restraint

cable. Reconnect the restraint after the oven

has been returned to its original location.

D

DONOT remove the control panel coverunless

the oven is unplugged.

19

Page 24

Operation

Oven Start-Up

INITIAL OVEN START-UP

1. TurnthemanualgasvalvetoON.

STEAM MODE (if applicable)

NOTE: For direct steam units, skip steps 4---6.

1. Turn the mode selector switch to STEAM.

2. The combustion blower turns on.

3. The green POWERIndicator lampon thefront

control panel lights.

4. The steam generator flushes and drain automaticallyfor75 secondsiftheunithas beenoff

for at least 5 hours.

5. The steamgenerator beginsto fill.The FILLindicator lamp on the front control panel blinks.

6. When thesteam generatoris filledtothe properlevel,theconvectionblowerandPOWERindicator lamp turn on.

7. Severalrelay contacts change state. Aclick is

heard when the gas valve opens.

8. The steam generator main burner ignites.

9. Steam fills the cavity and is controlled by a

non-accessible internal thermostat.

HOT AIR MODE (if applicable)

1. Turn the mode selector switch to Hot Air.

2. The convection blower turns on.

3. Set the hot air thermostat to the desired temperature.

4. Thethermostat lamplights,indicatingthe cavitytemperature isbelow the desired set point.

5. Twoseriesofclicksareaudibleasthehotair

pilot burners and main burners ignite.

6. When the cavity temperature reaches the desiredsetpoint,the temperatureindicatorlamp

goes off. The main burners shut off.

COMBI MODE (if applicable)

NOTE: For direct steam units, skip steps 5---8.

1. Turn the mode selector switch to COMBI.

2. The combustion blower turns on.

3. The green POWER indicator lamp on the front

control panel lights.

4. Set the HotAir thermostat to the desired temperature.

5. The steam generator flushes and drain automaticallyfor75 secondsiftheunithas beenoff

for at least 5 hours.

6. The steam generator begins to fill. After two

minutes the FILL indicator lamp on the front

control panel blinks. The convection blower

and POWER lamp do not shut down.

7. When thesteam generatoris filledtothe proper level, several relay contacts change state.

A click is heard when the gas valve opens.

8. When thesteam generatorcomes up to apredetermined temperature, the hot air t hermostat lamp illuminates, indicating the cavity

temperature is below the desired set point.

9. Twoseriesofclicksareaudibleasthehotair

pilot burners and main burners ignite.

10. When the cavity temperature reaches the desiredsetpoint,the temperatureindicatorlamp

goes off. The main burners shut off.

11. The steam and hot air burners toggle back

and forth responding to the thermostat set

points.

20

Page 25

Operation

Combi-Oven/Steamer Standard Controls

CONTROLS IDENTIFICATION

1. LOW WATER FILL LIGHT --- during the fill

cycle, this light remains on until the water in

2

1

4

7

3

65

the steam generator is atthe properlevel and

up totemperature.During normaloperationthe

light should not be on. If the light comes on,

check the water level in the steam generator.

NOTE: COS-8GDS, the direct steam unit,

does not have a low water fill light.

2. DON’T STEAM LIGHT --- indicates the unit is

too hot to operate in the steam mode. Place

the unit inthe CoolDown mode until the tem peratureisbelow230_F (110_C)andopenthe

door. This lightdoes not inhibitsteam production.

3. POWER ON LIGHT --- indicates the unit is in

Steam, Hot Air or Combi.

4. MODE SELECTOR SWITCH --- t urns pow er

to the oven on or off. Allows selection of

Steam, Hot Air, Combi or Cool Down Modes.

5. TEMPERATURE DIAL --- used to set desired

cooking temperature.

6. HEATING INDICATOR LIGHT --- lights when

the Hot Air heating is in operation.

7. TIMER DIAL --- used to setdesired cooktime.

8. FLUSH/DRAIN SWITCH --- used to flush/

drain the steam generator for decalcification.

NOTE: COS-8GDS, the direct steam unit,

does not have a flush/drain switch.

8

COS-8G with Meat Probe Shown

Figure 16

21

Page 26

Operation

Combi-Oven/Steamer Standard Controls

OPERATION

1. Turn the MODE SELECTOR Switch (4) to the

desired function.

The POWER ON Light (3) illuminates.

2. Set theTIMER(7) forthe desired cookingtime

orsetittoSTAY ON. The buzzer sounds and

the unit shuts off when the time has expired.

3. For the HOT AIR and COMBI modes, set the

TEMPERATURE Dial (5) to the desired cook

temperature. The HEATINGINDICATORLight

(6) illuminates and stays lit until the desired

temperature is reached. Thetemperature dial

doesnot operateduring theSTEAM portionof

the COMBI mode.

4. The selected mode operates automatically.

Thetemperature,timeandmodecanbealtered at any timeduring the cooking process.

The operation can be stopped by the use of

the Mode Selector Switch or by opening the

door .

5. At the end of the s pecified time period, the

6. To cool down the oven cavity, switch the

7. The mode selector switch is also the main

buzzersoundsandthea pplianceshuts offau tomatically. Move the TIMER (7) to the STAY

ON positionto stop the buzzer and restart the

unit.

MODE SELECTOR Switch (4) to COOL

DOWN. In the Cool Down mode neither the

temperaturedialorthe timerwill beoperational. The blower will function with the door open

or closed.

power switch. In the OFF position the appliance is not operational.

22

Page 27

1

4

5

7

8

10

11

13

15

18

COS-8G Shown

Operation

Optional Combi-Oven/Steamer Cook & Hold

CONTROLS IDENTIFICATION

1. LOW WATER FILL LIGHT --- during the fill

cycle, this light remains on until the water in

the steam generator is atthe properlevel and

2

3

6

9

12

14

16

17

up totemperature.During normaloperationthe

light should not be on. If the light comes on,

check the water level in the steam generator.

NOTE: COS-8GDS, the direct steam unit,

does not have a low water fill light.

2. DON’T STEAM LIGHT -- - when lit indicates the

unit is too hot to operate in the steam mode.

3. POWER ON LIGHT --- when lit indicates power to the unit is turned on.

4. MODE SELECTOR SWITCH --- controls power to the oven and selection of steam, hot air

and combi modes. The convection fan runs

withthe switchin steam, hot air, combi orcool

down.

5. TIME DISPLAY --- shows cook time.

6. TIME ARROW KEYS --- press to enter cook

time from 00:00 to 99:59.

7. TEMPERATURE DISPLAY --- shows cook

temperature.

8. HEAT LIGHT --- when lit indicates hot air or

steam is in operation.

9. TEMPERATURE ARROW KEYS --- press to

enter cook temperature from 120---212_F

(48 --- 100_C) for steam and 140---500_F

(60 --- 260_C) for hot air/combi.

10. STAGE ONE LED --- when lit indicates operation or programming of stage one for the current product. Cook cycles maycontain oneor

two different stages.

11. ACTUALTEMP KEY --- presstodisplayactual

oven/steamer temperature

12. STAGE TWO KEY --- press to enter stage tw o

cook time and temperature.

13. PRODUCT KEYS - -- three programmablekeys.

14. MANUAL PRODUCT KEY -- - default product

key used for manual and programmed cooking.

15. START KEY --- press to begin a cook cycle.

16. STOP KEY --- press to silenceaudible alarms

and pause or cancel cook cycles.

Figure 17

23

Page 28

Operation

Optional Combi-Oven/Steamer Cook & Hold

17. PROGRAM KEY --- press to enter programming mode and save programmed settings.

18. FLUSH/DRAIN SWITCH --- Used to flush/

drain the steam generator for decalcification.

NOTE: COS-8GDS, the direct steam unit,

does not have a flush/drain switch.

MANUAL OPERATION

1. Turn the SELECTOR SWITCH (4) to the desired mode. The LED above the manual key

lights.

2. PresstheTEMPERATUREARROWKEYS(9)

to set the stage one cook temperature.

3. Press the TIME ARROW KEYS (6) to set the

stage one cook time.

4. Press the STAGE TWO KEY (12).

NOTE: Stage two can be used for either a

holdmode or asecond cooktemperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

5. PresstheTEMPERATUREARROWKEYS(9)

to set the stage two cook temperature.

6. Press the TIME ARROW KEYS (6) to set the

stage two cook time.

7. Press the START KEY (15) to begin the cook

cycle. The STAGE ONE LED (10) lights. The

TIME DISPLAY (5) counts down the stageone

cook time.

Ifstage twois selectedan alarm soundsatthe

end of stage one. The time display counts

down the stage two cook time.

8. When all cook stages are complete the TIME

DISPLAY (5) flashes 00:00, the TEMPERA-

TURE DISPLAY (7) flashes 0 and an audible

alarm sounds. Press the STOP KEY (16) tosilence the alarm. The control maintains the

stage one cook temperature.

9. Turn the SELECTOR SWITCH (4) to OFF to

shut down the oven/steamer.

NOTE: Time and temperature settings may be

changedat any time during manual operation. Press the time arrow keys to change

the cook time. Press the temperature arrow keys to change thecook temperature.

PROGRAMMED OPERATION

NOTE: See page 25 for programming instruc-

tions.

1. Turn the SELECTOR SWITCH (4) to the desired mode.

2. Press the desired PRODUCT KEY (13). The

LED above the selected key lights.

3. Press the START KEY (15) to begin the cook

cycle. The STAGE ONE LED (10) lights. The

TIME DISPLAY (5) counts down the stageone

cook time.

NOTE: Press the STOPKEY (16) once to pause

an active stage one cycle. Press the

START KEY (15) to resume.

NOTE: Press the STOP KEY (16) twice to can-

cel an active stage one cycle.

4. An alarm sounds at the end of stage one The

time display counts down the stage two cook

time.

NOTE: Press the STOP KEY (16) once to can-

cel an active stage two cycle. Stage

two cycles cannot be paused.

5. When all cook stages arecomplete, the TIME

DISPLAY (5) flashes 00:00, the TEMPERATURE DISPLAY (7) flashes 0 and an audible

alarm sounds. Press the STOP KEY (16) tosilence the alarm. The control maintains the

stage one cook temperature.

24

Page 29

Operation

Optional Combi-Oven/Steamer Cook & Hold

PROGRAMMING THE PRODUCT KEYS

NOTE: Each product key can hold two programs:

onefor steam and one for hot air/combi. Hot

air programs can be used in combi.

1. Turn the SELECTOR SWITCH (4) to the desired mode.

2. Press the desired PRODUCT KEY (13).

3. Press and hold the PROGRAM KEY (17) for

five seconds. The control beeps. Theproduct

key LED and STAGE ONE LED (10) light.

4. PresstheTEMPERATUREARROWKEYS(9)

to set the stage one cook temperature.

5. Press the TIME ARROW KEYS (6) to set the

stage one cook time.

6. Press the STAGE TWO KEY (12).

NOTE: Stage two can be used for either a

holdmode or asecond cooktemperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

7. PresstheTEMPERATUREARROWKEYS(9)

to set the stage two cook temperature.

8. Press the TIME ARROW KEYS (6) to set the

stage two cook time.

9. Press a nd hold the PROGRAM KEY (17) to

save the program settings.

PROGRAMMING THE MANUAL KEY

NOTE: The manual key may be used for manual

cooking and programmed for two products, one for steam andone for hotair/combi. Hot air programs can be used in combi.

1. Turn the SELECTOR SWITCH (4) to the desired mode.

2. Press the MANUAL KEY (14). The LED above

the manual key lights.

3. PresstheTEMPERATUREARROWKEYS(9)

to set the stage one cook temperature.

4. Press the TIME ARROW KEYS (6) to set the

stage one cook time.

5. Press the STAGE TWO KEY (12).

NOTE: Stage two can be used for either a

holdmode or asecond cooktemperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

6. PresstheTEMPERATUREARROWKEYS(9)

to set the stage two cook temperature.

7. Press the TIME ARROW KEYS (6) to set the

stage two cook time.

8. Press a nd hold the PROGRAM KEY (17) to

save the program settings.

NOTE: Time and temperature settings may be

changed at any time during operation of a

programmed manual key. Press the time

arrowkeysto changethecook time.Press

the temperaturearrow keys to change the

cook temperature.

25

Page 30

Operation

Convection Steamer Standard Controls

1

3

4

2

CONTROLS IDENTIFICATION

1. LOW WATER FILL LIGHT --- during the fill

cycle, this light remains on until the water in

the steam generator is atthe properlevel and

up totemperature.During normaloperationthe

light should not be on. If the light comes on,

check the water level in the steam generator.

2. POWER ON LIGHT --- when lit indicates power to the unit is turned on.

3. MODE SELECTOR SWITCH --- t urns pow er

to the steamer on or off.

4. TIMER DIAL --- used to set desired cooking

time.

5. FLUSH/DRAIN SWITCH --- used to flush/

drain the steam generator during decalcification.

OPERATION

NOTE: Before the first use of the appliance, daily

or after the unit has been idle for 5 hours,

preheat with the STEAM functionapproximately 1-2 minutes.

1. Turn the SELECTOR SWITCH(3) to STEAM.

2. Set the TIMER (4) for the desired steaming

timeorsetittoSTAYON.Thebuzzersounds

and the unit shuts off when the time has expired.

3. Move the Timer switch to the STAY ON position to stop the buzzer and restart the unit.

4. Turn the SELECTOR SWITCH (3) to OFF to

shut down the steamer.

5

BCS-8G shown

Figure 18

26

Page 31

CONTROLS IDENTIFICATION

1. POWER ON LIGHT --- when lit indicates power to the unit is turned on.

2. SELECTOR SWITCH --- allows selection of

Hot Air or Cool Down Mode.

3. TEMPERATURE DIAL --- used to set desired

cooking temperature.

4. HEATING INDICATOR LIGHT --- lights when

the Hot Air heating is in operation.

5. TIMER DIAL --- used to setdesired cooktime.

Operation

Convection Oven Standard Controls

1

OPERATION

1. Turn the SELECTOR switch (2) to HOT AIR.

2. Load product into the oven when ready.

3. Turn the TEMPERATURE DIAL (3) to the desired temperature.

4. Turn the TIMER DIAL (7) to the desired cook

time.

5. At the end of the s pecified time period, the

buzzersoundsandthea pplianceshuts offau tomatically. Move the timer to the STAY ON

positiontostopthe buzzerandrestart theunit.

6. Turn the SELECTOR switch (2) to the COOL-

DOWN position.

2

3

5

4

27

Figure 19

Page 32

Operation

Optional Convection Oven Cook and Hold

CONTROLS IDENTIFICATION

1. POWER ON LIGHT --- when lit indicates pow-

2. MODE SELECTOR SWITCH --- controls pow-

1

3. TIME DISPLAY --- gives cook time.

4. TIME ARROW KEYS --- press to enter cook

2

3

5

6

8

9

11

13

4

7

10

12

14

15

5. TEMPERATURE DISPLAY --- gives cook tem-

6. HEAT LIGHT --- when lit indicates hot air is in

7. TEMPERATURE ARROW KEYS --- press to

8. STAGE ONE LED --- when lit indicates opera -

9. ACTUALTEMPKEY --- pressto displayactual

10. STAGE TWO KEY --- press to enter stage tw o

11. PRODUCT KEYS - -- three programmablekeys.

12. MANUAL PRODUCT KEY --- default product

13. START KEY --- press to begin a cook cycle.

14. STOP KEY --- press to silenceaudible alarms

15. PROGRAM KEY --- press to enter program-

er to the unit is turned on.

ertotheovenandselection of hot air andcool

down modes. The convection fan runs with

the switch in hot air or cool down.

time from 00:00 to 99:59.

perature.

operation.

enter cook temperature from 140---500_F

(60 --- 260_C).

tion or programming of stage one for the current product. Cook cycles maycontain oneor

two different stages.

oven temperature

cook time and temperature.

key used for manual and programmed cooking.

and pause or cancel cook cycles.

ming mode and save programmed settings.

Figure 20

28

Page 33

Operation

Optional Convection Oven Cook & Hold

MANUAL OPERATION

1. Turn the SELECTOR SWITCH (4) to HOT AIR.

The LED above the manual key lights.

2. PresstheTEMPERATUREARROWKEYS(9)

to set the stage one cook temperature.

3. Press the TIME ARROW KEYS (6) to set the

stage one cook time.

4. Press the STAGE TWO KEY (12).

NOTE: Stage two can be used for either a

holdmode or asecond cooktemperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

5. PresstheTEMPERATUREARROWKEYS(9)

to set the stage two cook temperature.

6. Press the TIME ARROW KEYS (6) to set the

stage two cook time.

7. Press the START KEY (15) to begin the cook

cycle. The STAGE ONE LED (10) lights. The

TIME DISPLAY (5) counts down the stageone

cook time.

Ifstage twois selectedan alarm soundsatthe

end of stage one. The time display counts

down the stage two cook time.

8. When all cook stages are complete the TIME

DISPLAY (5) flashes 00:00, the TEMPERATURE DISPLAY (7) flashes 0 and an audible

alarm sounds. Press the STOP KEY (16) tosilence the alarm. The control maintains the

stage one cook temperature.

9. Turn the SELECTOR SWITCH (4) to OFF to

shut down the oven.

NOTE: Time and temperature settings may be

changedat any time during manual operation. Press the time arrow keys to change

the cook time. Press the temperature arrow keys to change thecook temperature.

PROGRAMMED OPERATION

NOTE: See page 30 for programming instruc tio n s.

1. Turn the SELECTOR SWITCH (4) to HOT AIR.

2. Press the desired PRODUCT KEY (13). The

LED above the selected key lights.

3. Press the START KEY (15) to begin the cook

cycle. The STAGE ONE LED (10) lights. The

TIME DISPLAY (5) counts down the stageone

cook time.

NOTE: Press the STOPKEY (16) once to pause

an active stage one cycle. Press the

START KEY (15) to resume.

NOTE: Press the STOP KEY (16) twice to can-

cel an active stage one cycle.

4. An alarm sounds at the end of stage one The

time display counts down the stage two cook

time.

NOTE: Press the STOP KEY (16)once to can-

cel an active stage two cycle. Stage

two cycles cannot be paused.

5. When all cook stages arecomplete, the TIME

DISPLAY (5) flashes 00:00, the TEMPERATURE DISPLAY (7) flashes 0 and an audible

alarm sounds. Press the STOP KEY (16) tosilence the alarm. The control maintains the

stage one cook temperature.

29

Page 34

Operation

Optional Convection Oven Cook & Hold

PROGRAMMING THE PRODUCT KEYS

1. Turn the SELECTOR SWITCH (4) to HOT AIR.

2. Press the desired PRODUCT KEY (13).

3. Press and hold the PROGRAM KEY (17) for

five seconds. The control beeps. Theproduct

key LED and STAGE ONE LED (10) light.

4. PresstheTEMPERATUREARROWKEYS(9)

to set the stage one cook temperature.

5. Press the TIME ARROW KEYS (6) to set the

stage one cook time.

6. Press the STAGE TWO KEY (12).

NOTE: Stage two can be used for either a

holdmode or asecond cooktemperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

7. PresstheTEMPERATUREARROWKEYS(9)

to set the stage two cook temperature.

8. Press the TIME ARROW KEYS (6) to set the

stage two cook time.

9. Press a nd hold the PROGRAM KEY (17) to

save the program settings.

PROGRAMMING THE MANUAL KEY

NOTE: The manual key may be used for manual

andprogrammedcooking.

1. Turn the SELECTOR SWITCH (4) to HOT AIR.

2. Press the MANUAL KEY (14). The LED above

the manual key lights.

3. PresstheTEMPERATUREARROWKEYS(9)

to set the stage one cook temperature.

4. Press the TIME ARROW KEYS (6) to set the

stage one cook time.

5. Press the STAGE TWO KEY (12).

NOTE: Stage two can be used for either a

holdmode or asecond cooktemperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

6. PresstheTEMPERATUREARROWKEYS(9)

to set the stage two cook temperature.

7. Press the TIME ARROW KEYS (6) to set the

stage two cook time.

8. Press a nd hold the PROGRAM KEY (17) to

save the program settings.

NOTE: Time and temperature settings may be

changed at any time during operation of a

programmed manual key. Press the time

arrowkeysto changethecook time.Press

the temperaturearrow keys to change the

cook temperature.

30

Page 35

Operation

Optional Meat Probe

NOTE: The meat probe is not available for the

Combi Convection Steamer.

CONTROLS IDENTIFICATION

1. MEAT PROBE SWITCH

Controls power to the meat probe.

2. MEAT PROBE CONTROL

Use to set the desiredprobe temperature. In-

dicates the actual temperature of theproduct

3. MEAT PROBE CONNECTOR

Receptacle for the plug in meat probe.

NOTE: For sanitation it is recommended that

the meat probe remain plugged into

the front panel receptacle at all times.

OPERATION

Measuring the product core temperatures during

long roasting periods is very practical. It is especiallyimportant forproductssuch as RoastBeef to

reach a specific internal temperture.

Placethe probe through tothe middle ofthe product’s thickest section. B e sure theprobe does not

touch any bone and the tip is not in a fat pocket.

These conditions can ca use inaccurate readings.

1. Set the MODE SELECTOR Switch to the desired function.

2. TurntheMEATPROBESwitch(1)toON.

3. To set thedesired coretemperature press the

blue SET BUTTON (4) on the MEAT PROBE

CONTROL (2).

Use the up arrow key (6) to increase the setpoint temperature. Use the down arrow key

(5) to decrease the setpoint temperature.

Press the set button again to store the set point.

4. Set the TIMER to STAY ON. The cooking process runs automatically.

When the selected core temperature is

reached, the buzzer will sound and the appliance shuts off automatically.

The temperature and mode can by changed

at any time during the process.

5. Shut the appliance off by setting the mode

switch to OFF.

NOTE: When setting the internal temperature, be

sure to allow for carry-over cooking after

the roast is removed from the oven

1

2

3

Figure 21

31

WATLOW

1

2

RDY

SET

4 5 6

Page 36

Maintenance

Spray Bottle Operating Procedure

1. Unscrewthesprayerheadandfillthecontainerto theMAX mark. Screwthe headassembly

on firmly to ensure an airtight seal. The liquid

mustbeclean andfree fromforeignm atter. Do

not overfill - space must be left for compressing air.

2. Tobuilduppressure,pumpapproximately20

fullstrokeswhen the containeris filledwith liquid. The higher the pressure, the finer the

spray. If the container is only partially filled,

then more pumping is required to compress

the additional air space.

3. To spray,depressthe triggerwith your thumb.

4. After a period of spraying, the pressure will

drop. Restore the pressure by operating the

air pump.

5. Release pressure after use by inverting the

spray head and depressing the trigger or by

slowly unscrewing the spray headassembly

which willallow air to escape from aroundthe

filling aperture.

6. Afteruse, rinse thespray bottlewith cleanwaterand check thatthe holein thenozzleisperfectly clean and clear. Warm water (not hot)

used with a household detergent is a useful

cleaning agent for this purpose.

NOTE: Further informationcan be found in the in-

struction leaflet supplied with your spray

bottle.

Service Parts:

Complete spray bottle P/N R0006

Spray nozzle repair kit P/N R6332

WARNING!!

Protective clothing and eye wear should

be worn while using cleaning agents.

PressurePump

Spray Head

Pump

MAX

Pressure

Vessel

Clean the pump 2 or 3 times per week with warm water

Spray Trigger

Figure 22

32

Page 37

Maintenance

Cleaning and Preventive Maintenance

CLEANING THE INTERIOR

Daily cleaningof the appliance isessentialfor sanitation and to ensure against operational difficulties.Use a non-causticoven cleaningdetergent in

conjunction with the supplied spray bottle.

NOTE: DO NOT use corrosive cleaners!

Oven/Steamers and Convection Steamers

1. Cool the appliance down to 140_F(60_C) or,

ifthe unit has beenidle, turn the steam mode

until the window fogs.

2. Fillthespraybottleandpumpairintothecon-

tainer w ith the pressure pump.

3. Spray the interior of the unit with the cleaning

solution.

NOTE: Never spray water into the unit when

the temperature is above 212_F.

4. Let the cleaner work for10 to 20 minuteswith

the unit off.

5. Set the timer for 15 to 20 minutes. Turn the

mode selector switch to Steam. This willsoften all burned on residue.

6. Rinse the interiorwith the hoseand spray as-

sembly.

7. Setthemodeselectortosteamforanotherfive

minutesto flushouttheinteriorand remove all

detergent residue.

NOTE: The interior cavity should never be

scoured or scraped.

Convection Ovens

1. Cool the oven down to 140_F(60_C).

2. Fillthespraybottleandpumpairintothecontainer w ith the pressure pump.

3. Spray the interior of the oven with a cleaning

solution.

NOTE: Never spray water into the unit when

the temperature is above 212_F

4. Let the cleaner work for10 to 20 minuteswith

the oven off.

5. Rinse the oven interior with the hose and

spray assembly.

NOTE: The interior cavity should never be

scoured or scraped.

CLEANING THE EXTERIOR

Exteriorsmay be cleaned and kept in goodcondition with a stainless steel polish.

NOTE: DO NOTspraytheoutsideoftheappliance

with water.

PREVENTIVE MAINTENANCE

The best preventive maintenance measures are:

D

the proper initial installation of the equipment

D

deliming the steam generator (if applicable)

D

a program for routine cleaning.

These units requires no lubrication. Contact the

factory,a factoryrepresentative ora localBlodgett

Combi service company to perform maintenance

and repairs should they be required.

33

WARNING!!

Disconnect the appliance from the power

supply before servicing or cleaning.

Page 38

Maintenance

Decalcification

NOTE: ThisprocedureappliestomodelsCOS-8G

and BCS-8G only.

1. TurntheModeSelectionSwitch(1)tothe

STEAM mode. Wait until steam is produced.

This will ensure that the water in the steam

generator is hot.

2. TurntheModeSelectionSwitch(1)tothe

COOL DOWN mode and leave the door open.

Let the oven compartment cool to 150_F

(66_C). This ensures that the Drain/Flush

switch will function in STEP 8.

3. TurntheModeSelectionSwitch(1)toOFF.

4. In a suitable size container, mix together the

deliming solution and hot tap water. Refer to

the following chart for the proper mixture:

Deliming

Model

COS-8G 24 oz. 2 gallons

BCS-8G 24 oz. 2 gallons

NOTE: These volumes are approximate. You

mayneedslightlymore orless hotwater depending on your site.

5. Remove the Deliming Port Cap from the Deliming Inlet (5). Attach the supplied Funnel

and Hose Assembly (3) to the deliming inlet.

6. Open the Deliming Port Valve (2) and pour in

the deliming mixture. Stop pouring w hen the

Solution

Hot Tap Water

funnel stops draining. This is the correct

amountforyoursite.

7. Shut the DelimingPortValve(2). Screw onthe

DelimingPortCap.Let themixturestandfor20

minutes. In areas of the country with hard water, allow the mixture to stand for 1 hour.

8. Depress and hold the Drain/Flush Switch (4)

in the FLUSH position for 90 seconds. This

completes the deliming procedure.

3

2

1

5

open

close

4

Figure 23

34

Page 39

COS-8G, COS-8GDS, BCS -8G et CNV-8G

ApparielsdeCuissonauGaz

Manuel D’Installation --- Fonctionnement --- Entretien

35

Page 40

Introduction

Laligned’appareilsdecuissondeBlodgettCombi

Depuis un certain temps le matériel de cuisson

commerciale est resté plus ou moins inchangé. Il

y a des bouilloires,des foursouverts, des bonnes

vieillescuisinièresavec leurs régiments de casseroleset denombreux autresappareils. Lerésultat:

gaspillage de temps, excès de travail manuel, et

des processus de nettoyage interminables. Ces

quelques dernières années ont préparées la voie

pour une révolution dans l’équipement des cuisines de restaurants et de collectivités. Blodgett

Combi est heureux de vous présenter trois nouveaux appareils de cuisson, parmi lesquels vous

trouverezcertainement votre bonheur. La ligne de

Blodgett Combi comprend les appareilssuivants:

D

Combi-convection/étuve à vapeur Blodgett

D