Page 1

BCSĆ6

ELECTRIC COOKING APPLIANCES

INSTALLATION - OPERATION - MAINTENANCE

BLODGETT COMBI

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331Ć5842, (802) 860Ć3700 Fax: (802)864Ć0183

PN R7701 Rev F (4/09)

E 2009 - Blodgett Combi

Page 2

A PERSONAL WORD

FROM BLODGETT COMBI

Congratulations on your purchase of a BLODGETT Combi appliance. We

firmly believe that your choice has been a wise one, and trust you will reĆ

ceive many years of excellent service from your new Combi.

You will find that cooking with Combi appliances saves time, labor and

extensive cleaning of both the kitchen and the unit.

With Combi appliances the quality, taste, consistency, and look of your

food are improved, thus endorsing the policy to which we've always adĆ

hered: For Better Cooking!"

Once you've had a chance to use your Combi, please tell us, your dealer

and colleagues about any creative and interesting applications you have

discovered; exchange ideas with other users. Be sure to advise us or

your dealer immediately should any mechanical or technical problems

be encountered (...we're here to help!) and above all Enjoy Cooking the

BLODGETT Combi Way!

For information on cooking, please refer to our separate cooking guide.

Page 3

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INĆ

STALLATION, OPERATING AND MAINTENANCE INĆ

STRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

The information contained in this manual is important for the proper

installation, use, and maintenance of this oven. Adherence to these

procedures and instructions will result in satisfactory baking results

and long, trouble free service. Please read this manual carefully and

retain it for future reference.

Errors: Descriptive, typographic or pictorial errors are subject to correcĆ

tion. Specifications are subject to change without notice.

Page 4

Your Service Agency's Address:

Model:

Serial Number:

Your oven was installed by:

Your startĆup inspection service was

performed:

Date:

ASAP:

Page 5

Table of Contents

Introduction

The Convection Steamer 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of the Convection Steamer 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steamer Features 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

Owner's Responsibilities 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Agency Approvals 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Utility Connections 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Utility Connections 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leg Attachment 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stacking 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Final Check Lists 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation

Standard Controls 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Push Button Power Saver" Control 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Spray Bottle Operating Procedure 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Preventive Maintenance 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decalcification 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Introduction

The Convection Steamer

Steaming āis āa wellĆknown cooking process freĆ

quently used in restaurant and institutional kitchĆ

ens. With the Blodgett Convection Steamer, it is

now possible to enjoy the many advantages of

steaming, some of which are:

Simplified Work Process

The work process is simplified since products are

prepared on or in steam table āpans āand trays.

Food can be cooked, stored, and transported with

āthe āsame āāpans. āSmall āamounts of product can be

processed efficiently; preĆcooked and conveĆ

nience foods can be rethermalized within minutes.

āMany frozen foods can be processed without preĆ

thawing. This flexibility in preparation reduces the

need for kettles and steam tables since there is no

need for large amounts of food to be kept warm for

long periods of time.

High Quality Foods

Today the improvement of food quality is more imĆ

portant than ever. With ātheā useāāā ofā steam,ā valuable

taste and aroma are preserved since steamed

foods retain their own natural taste. During the

steaming process foods retain the nutrients and

vitamins which are lost in water during boiling.

Therefore when compared, steamed foods have

much better color than foods that have been

boiled. āAlso,ā by using shallow containers the prodĆ

uct is not layered as deeply and mushing is

avoided.

Vitamin Retention

HOW STEAMING WORKS

The Blodgett Convection Steamer gently cooks

food using nonĆpressurized steam. Fresh steam is

directed into the unit from the generator. It is not

necessary to add water to foods during the steamĆ

ing process.

WHAT CAN BE STEAMED

Vegetables, side dishes, fish, meat, poultry, diet

foods, garnishes, dumplings, casseroles, meat

loaf, fruits, desserts and eggs.

In the Steam mode you can:

D steam

D defrost

D blanch

D poach

D rethermalize

In āthe āBlodgettā Convection Steamerā vitamins are not

destroyed. This is due to the shorter cooking times,

the use of less or little water and the use of a low temĆ

perature; slightly less than 212_F (100_C).

Firmness

With the use of steam, overcooking āisā notā a probĆ

lem and firmness can be individually controlled.

Simultaneously Steaming Different Foods

There is no flavor transfer when cookingā āwithā ātheā

āConvection Steamer. For this reason, various

types of food with different cooking times can be

loaded or removed at any point during the steamĆ

ing process.

2

Page 7

Introduction

Description of the Convection Steamer

ABOUT THE CONVECTION STEAMER

Blodgett Convection Steamers are quality proĆ

duced using highĆgrade stainless steel with first

class workmanship.

The high performance fresh steam generator with

its control system makes it possible to enjoy all of

the advantages of a high quality steamer at the

flick of a switch. Fresh steam enters the steamer

cavity without pressure and is circulated at high

speed. This process enables quick and gentle

cooking and ensures high quality food while proĆ

viding convenient working methods. The steam

generator is completely automatic and protected

from running dry.

A patented quench system keeps the air in the

steamer clean. Fumes are extracted from the

appliance, quenched, and directed out through

the condenser drain. This exhaust system results

in better quality foods and no flavor transfer. The

fan, which is guarded against accidental finger

contact, is driven by a quiet and powerful motor.

The condenser draws out excess steam from the

appliance. Condensation and waste water, which

result during steaming and cleaning, are continuĆ

ously drained.

The use of high quality insulation impedes excesĆ

sive heat radiation and saves energy.

The Convection Steamer has optional adjustable

legs which adapt easily to slightly uneven surfaces

and optional floor stands which are designed for

use with all of the tabletop models.

STEAMER OPERATION

The practical door, with a viewing window, has a

wide swing radius and handle which can be operĆ

ated easily, even with wet or greasy hands.

NOTE: Some models may be supplied with a solĆ

id door.

Ease of operation is guaranteed through the simĆ

ple arrangement of the controls. Graphic symbols

make the appliance easy for even inexperienced

kitchen staff to operate. Steam can be selected

with one switch.

The steamer is designed for easy care and is

welded water tight so that the internal cooking

cavity may be rinsed with a hose after the steam

cleaning process. For more detailed instructions

refer to the Maintenance section of this manual.

3

Page 8

Introduction

Steamer Features

7

Standard Features

8

10

3

9

2

1 Control Panel (standard control shown)

2 Power Connection

3 Steamer Door (glass door shown)

4 DripĂCollectorĂ(removableĂforĂcleaning)

5 Door Handle

4

5

6

1

Figure 1

6 Door Contact Switch

7 VentĂ(not shown)

8 Decalcifying Inlet & Funnel Assembly

9 Decalcifying Valve Lever

10 Tilt Down Panel Release Screw

4

Page 9

Installation

y

Owner's Responsibilities

1. Steamer(s) are uncrated, stacked (if applies)

and put in place.

NOTE: Please refer to Leg Attachment and

Stacking Addendum.

2. The owner/operator must have the following

plumbing and electrical requirements met and

installed.

NOTE: Refer to the Utility Connection inforĆ

mation provided.

PLUMBING

Water

Building Water Pressure (min/max) 40 PSI min / 50 PSI max

Cold Water Connection 3/4" Hose Fitting, 3/8" ID hose minimum

Water Regulator Setting 35 PSI static - preset

Drainage Atmospheric Vented Drain

WARNING!!

Improper installation, adjustment, alterĆ

ation service or maintenance can cause

property damage, injury or death. Read

the installation, operation and mainteĆ

nance instructions thoroughly before

installing or servicing this equipment.

Drain Connection 2" Copper

Avg Water Drain Temp. Approximately 122_F (50_C)

ELECTRICAL

Electrical 9.4 kw

Amp/line (max)

3

Volt

208 26 45

240 23 40

By

Mode

Blower Motor .33 HP / .4 kW

Steam 9kw

Hot Air 9kw

Combi 9kw

Phase

1

Phase

5

Page 10

Location

Installation

The well planned and proper placement of your

appliance will result in long term operator conveĆ

nience and satisfactory performance.

The following clearances must be maintained beĆ

tween the unit and any combustible or nonĆcomĆ

bustible construction.

D Steamer right side - 1" (2.54 cm)

D Steamer left side - 4" (10 cm) with casters

12" (30 cm) without casters

D Steamer back - 4" (10 cm)

NOTE: For models with hose assemblies on the

back of the unit, the hose must be 1" (2.54

cm) from the wall.

If optional casters are not used, the following

clearances are recommended for service.

D Steamer sides - 12" (30 cm)

D Steamer back - 12" (30 cm)

Place the unit in an area which is free of drafts and

accessible for proper operation and servicing.

Keep the oven area free and clear of all combusĆ

tibles such as paper, cardboard, and flammable

liquids and solvents.

DO NOT place the oven on a curb base or seal to

the wall; either condition will prevent proper ventiĆ

lation to the blower motors. Slight unevenness can

be corrected with the adjustable legs.

Heat sources must not be located near the air

vents on the left hand side of the unit. Consult the

factory for an optional protective side heat shield

kit if a warm surface or water source is to the left

of the unit. If excessive ambient temperature or a

water source is present a heat shield must be addĆ

ed to the left hand side of the oven to protect the

unit from excessive heat or water

D BCSĆ6 heat shield P/N R9047

On all models, tripping the blower motor's thermal

overload device indicates an excessive ambient

temperature at the side of the oven. This must be

corrected to prevent permanent damage to the

oven. All motor bearings are permanently lubriĆ

cated by the manufacturer; there is no need for

additional lubrication during the operational lifeĆ

time of the motors.

6

Page 11

Installation

Agency Approvals

THE INSTALLATION INSTRUCTIONS CONĆ

TAINED HEREIN ARE FOR THE USE OF QUALIĆ

FIED INSTALLATION AND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE STEAMER AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and responsible for:

D the installation of electrical wiring from the elecĆ

tric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experiĆ

enced in such work, familiar with all precautions

required, and have complied with all requirements

of state or local authorities having jurisdiction.

U.S. and Canadian installations

All steamers, when installed, must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70-Latest Edition and/or CanaĆ

dian National Electric Code C22.2 as applicable.

Appliance is to be installed with backflow prevenĆ

tion in accordance with applicable federal, provĆ

ince and local codes.

General export installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your Blodgett Convection Steamer,

please contact your local distributor. If you do not

have a local distributor, please call Blodgett Combi

at 0011Ć802Ć860Ć3700.

7

Page 12

Installation

Utility Connections

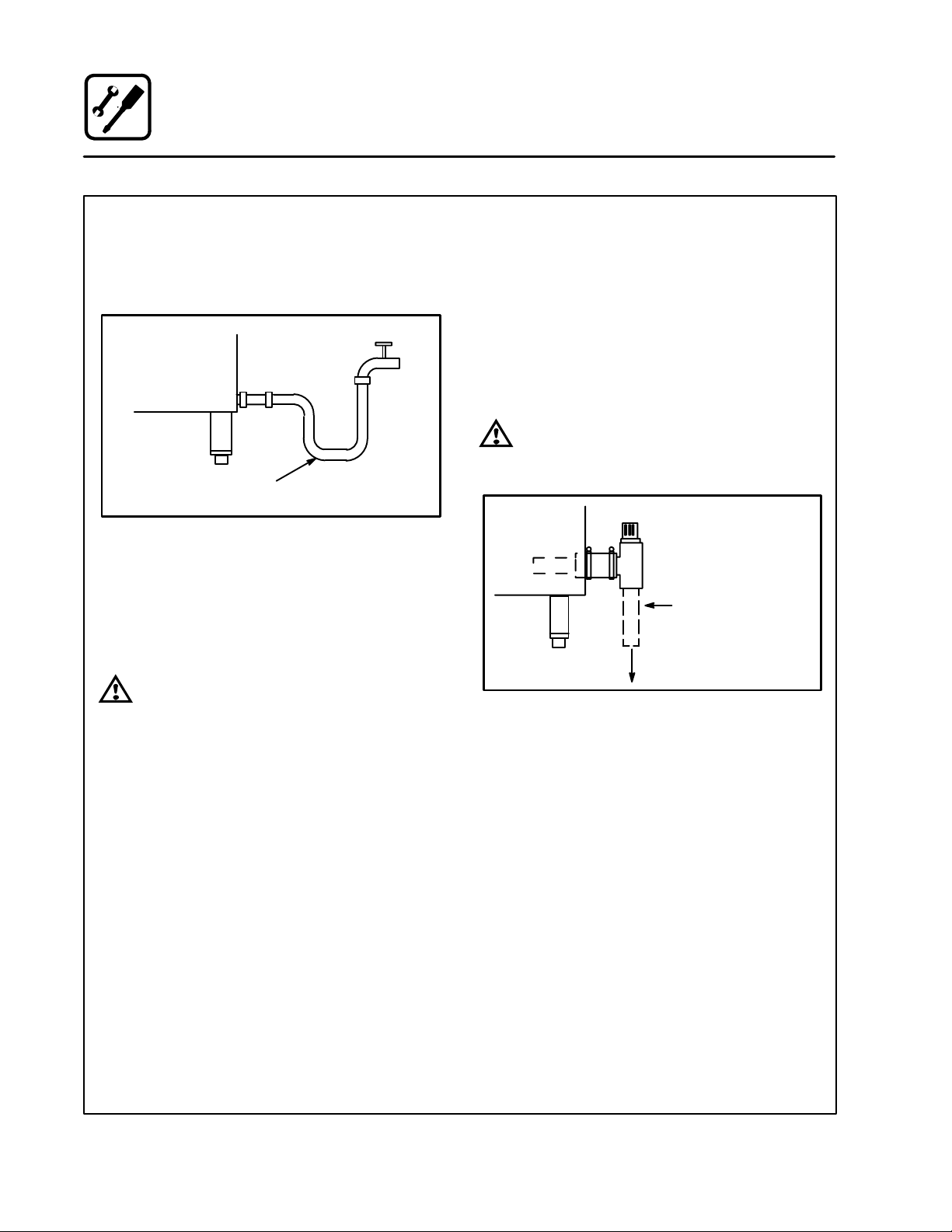

COLD WATER CONNECTION

Connect the appliance to quality water via a presĆ

sure hose with 3/4" couplings. A shut off valve is

to be provided adjacent to the steamer.

1/2" appliance hose

With 3/4" hose fittings

Figure 2

Water must meet the following minimum requireĆ

ments:

D Total Dissolved Solids (TDS) content will not exĆ

ceed 30 parts per million.

D Water PH must be 7.0 or higher

WARNING!!

The use of poor quality water will invaliĆ

date your warranty.

DRAIN CONNECTION

The Drain Vent assembly, included with the unit,

and a 2" (5 cm) copper pipe with standard drain

pitch, must be run to an open drain or connected

to a standpipe equipped with a vent.

NOTE: The waste water can also be directed to a

nearby floor drain. Flexible hose which alĆ

lows trapped water to accumulate in

sagged runs must be avoided.

WARNING!!

Failure to install the drain kit provided will

invalidate your warranty.

2" (5 cm) Drain

(Customer Supplied)

To Drain

Figure 3

8

Page 13

Installation

Utility Connections

ELECTRICAL CONNECTION

Before making any electrical connections to these

units, check that the power supply is adequate for

the voltage, amperage, and phase requirements

stated on the rating name plate mounted on the

right side of the unit.

Wiring diagrams are located on the inside of the

louvered side panel.

WARNING!!

Disconnect the power supply to the unit

before servicing.

U.S. and Canadian installations

All steamers, when installed, must be electrically

grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70-Latest Edition and/or CanaĆ

dian National Electric Code C22.2 as applicable.

General export installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

please call Blodgett Combi at 0011Ć802Ć860Ć3700.

NOTE: ALL MANUAL RESETS SHOULD BE REĆ

STORED BEFORE CONNECTING POWER

TO THE APPLIANCE.

WARNING!!

Improper installation will invalidate your

warranty.

9

Page 14

Installation

Leg Attachment

LEG VARIATIONS

Legs are available in 4" (101mm), 6" (152mm) āor

25" ā(635mm) ālengths āāor āālow profile casters. The 6"

legs are used on the lower section of a double

stacked unit. The 4" legs may be used with the opĆ

tional stands if additional height is required or

when mounting on a counter. The 25" legs are

used for a single unit located on the floor.

NOTE: For safety reasons, casters must not be

used with the 25" legs.

25" Adjustable Leg

LEG ATTACHMENT

NOTE: If low profile casters are used, install the

locking casters on the front of the oven.

The rear casters do not lock. Be sure the

locks are set on the front casters.

1. Align the threaded stud the each leg to the bolt

āholesā locatedāāā ināā ātheā āāunit'sā bottom ācorners.

Turn the legs clockwise and tighten to the

nearest full turn.

2. Align the leg plate holes with the bolt holes.

Secure with the two 1/2" bolts provided.

3. Tip the oven up on the legs. If ācastersā are

āused, checkā thatā the locksā areā setā on ātheā front

casters.

4. Except for units with casters, level the oven by

screwing the adjustable feet in or out as necĆ

essary.

6" Adjustable Leg

4" Leg

Low Profile Casters

Figure 4

6" (15 cm) Legs Shown

Figure 5

10

Page 15

1. Install the casters as directed.

2. Center āthe upper āunit on top of the lower secĆ

tion.

3. Remove āthe āscrews from the rear āaccess āpanĆ

el āand remove the access panel from the botĆ

tom unit.

4. Carefully āremove āthe āfan āāplug āand disasĆ

semble the steam vent.

NOTE: The fan plug connector can be easily

damaged

5. Alignā theā two rear bolt holes in the lower secĆ

tion with the two threaded holes in the upper

section.

6. Insertā a ābolt from the bottom up through each

of the two holes and tighten securely.

7. Reassemble the steam vent and reconnect

the fan plug. Reinstall the rear access panel

on the lower unit.

Installation

Stacking

Figure 6

11

Page 16

Installation

Adjustments

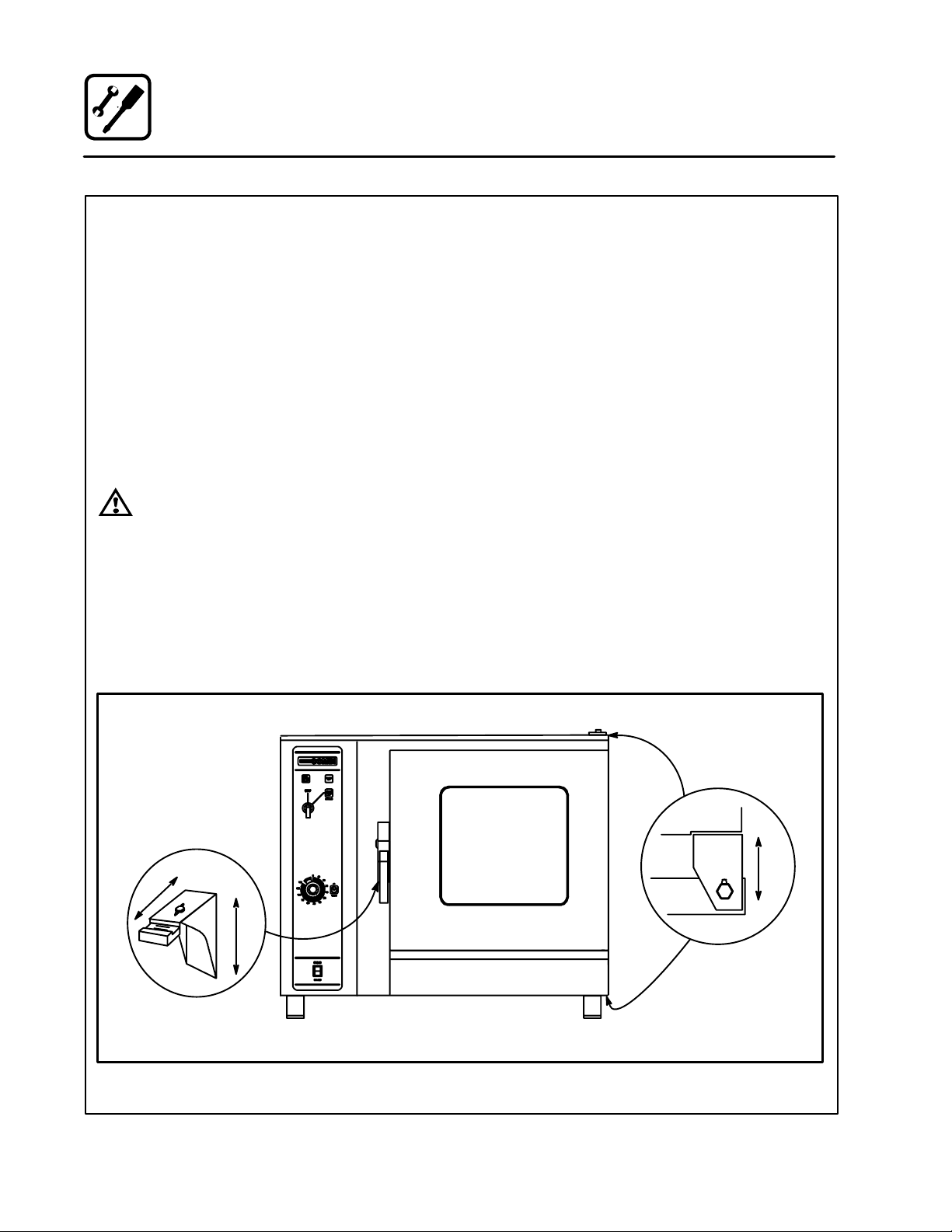

BEFORE SWITCHING THE APPLIANCE ON

Before applying power to the unit for the first time,

check for the following conditions:

j All āelectricalā safety provisions have been adĆ

hered to and the electrical connections are

correct.

j Water is connected, turned on and all of the

connections are water tight.

j The āāgrease āfilter āand āholder āare āin ātheir proper

positions.

j The āpanā holders are āinserted āinto the steamer

cavity.

WARNING!!

If the fan turns in the wrong direction, the

appliance will not function properly and

can be damaged.

NOTE: When the unit is turned on, or after it has

been OFF for 5 hours and then turned on,

āthe steam generator āautomatically flushes

for 75 seconds. The steam generator then

fills to the proper water level. The unit is

now ready for operation.

DOOR ADJUSTMENT

The door latch may be adjusted in two directions,

in and out, and up and down, using the following

procedure:

1. Adjust up and down by loosening the two boltsā

holdingā theā latch to the face of the unit (A).

2. Make āadjustmentsā soā thatā theā leadingā face of

the latch is centered in the opening of the hanĆ

dle assembly.

3. Tighten the bolts so that there is no further

movement.

4. Adjust in and out by loosening the bolt on top

of the latch (B).

5. The āāadjustment āāface āāis āstepped āso āthat moveĆ

ment is limited with the bolt tightened properly.

6. The āadjustment āis ācorrect āwhen āthe ādoor closes

firmly and no steam leaks from the gasket.

The hinges can also be adjusted as follows:

1. Be certain the latch is adjusted properly.

2. Adjustā hinges āso āthatā the door back and the

unit face are parallel (C).

3. The adjustment is correct when no steam

leaks through the gasket.

Steamer

C

B

A

Figure 7

12

Door

Page 17

Installation

Final Check Lists

ELECTRICAL CONTROL COMPARTMENT

Applied voltage to unit voltage/phase suitable for

appliance specified.

j Remove side panel

j Set motor protector (F2) to on position (480V

only)

j Adjust motor protector to maximum

j Reset high limit thermostat F6

j Check fuses

j Reinstall side panel

PLUMBING FINAL CHECK

j Incoming water pressure within 40 PSI (miniĆ

mum) - 50 PSI (maximum)

j Atmospheric vented drain in place

j Water solenoid properly bracketed and not

leaking

j Water feed lines intact without leaks

j Water pressure regulator is set to 35 psi

j Spray hose connected properly

STEAMER OPERATIONAL TESTS

NOTE: Checks to be made by customer or authoĆ

rized service agent.

Turn on STEAM mode and verify (control panel reĆ

moved):

j Check timer operation in all three positions

1. Set timer to OFF position, buzzer should

sound

2. Set timer in position other than OFF or

STAY ON, timer should count down

3. Set timer in STAY ON position, steamer

should operate continuously without timer

j Run light (power light) turns on

j Unit produces steam, window fogs, door seal

does not leak

j Quenching system working

Fill

Solenoid

Washer

Washer

Regulator Assembly

Y" Fitting

Cold water supply

Hose and Spray

Spray Hose Connection

Figure 8

13

Page 18

Operation

Standard Controls

1

3

CONTROLS IDENTIFICATION

1. LOW WATER FILL LIGHT - during the fill

cycle, this light remains on until the water in

the steam generator is at the proper level and

up to temperature. During normal operation the

light should not be on. If the light comes on,

2

check the water level in the steam generator.

2. POWER ON LIGHT - Indicates the unit is in

Steam mode.

3. MODE SELECTOR SWITCH - Turns power

to the steamer on or off. Allows selection of

steam mode.

4. TIMER DIAL - Used to set desired steam

time. Some models may be supplied with a

push button reset switch.

5. FLUSH/DRAIN SWITCH - Used to flush/

drain the steam generator during decalcificaĆ

tion.

OPERATION

1. Turn the mode selector switch to STEAM.

2. The green POWER Indicator lamp on the front

control panel lights.

3. The steam generator flushes and drain autoĆ

matically for 75 seconds if the unit has been off

4

5

for at least 5 hours.

4. The steam generator begins to fill. After two

minutes, the FILL indicator lamp on the front

control panel blinks. The convection blower

and POWER lamp turn off.

5. When the steam generator is filled to the propĆ

er level, the convection blower, interior lights

and POWER indicator lamp turn on.

6. Steam fills the cavity and is controlled by a

nonĆaccessible internal thermostat.

Figure 9

14

Page 19

Operation

Push Button Power Saver" Control

CONTROLS IDENTIFICATION

1. LOW WATER FILL LIGHT - during the fill

cycle, this light remains on until the water in

the steam generator is at the proper level and

up to temperature. During normal operation the

light should not be on. If the light comes on,

1

3

2

check the water level in the steam generator.

2. POWER ON LIGHT - Indicates the unit is in

Steam mode.

3. MODE SELECTOR SWITCH - Turns power

to the steamer on or off. Allows selection of

steam mode.

4. RESET PUSH BOTTON - Turns on steamer

when door is closed. Must be pushed to start

steamer every time the door is opened.

5. FLUSH/DRAIN SWITCH - Used to flush/

drain the steam generator during decalcificaĆ

tion.

4

5

OPERATION

1. Turn the mode selector switch to STEAM.

2. The green POWER Indicator lamp on the front

control panel lights.

3. With the door closed, push and release the

RESET button. The steamer comes one and

begins steaming.

4. Open the door to shut off the steamer.

Figure 10

15

Page 20

Maintenance

Spray Bottle Operating Procedure

1. Unscrewāā ātheā āāsprayerāāā āhead āāāāandāāā āfillā āāāthe containĆ

er to the MAX mark. Screw the head assembly

āon āfirmlyā toā āensureā āan āāairtight seal. The liquid

must be clean and free from foreign matter. Do

not overfill Ć space must be left for compressĆ

ing air.

2. To build up pressure, pump approximately 20

full strokes when the container is filled with liqĆ

uid. The higher the pressure, the finer the

spray. If the container is only partially filled,ā

then āmoreā pumping āāis āārequired āto compress

the additional air space.

3. To spray, depress the trigger with your thumb.

4. After a period of spraying, the pressure will

drop. Restore the pressure by operating the

air pump.

5. Release pressure after use by inverting the

spray head and depressing the trigger or byā

slowly āunscrewing ā theā spray āhead assembly

āwhichā willā allow āairā toā escape āfrom around āāāthe

filling aperture.

6. Afterā use,ā rinse āthe āsprayā bottleā withā clean waĆ

ter and check that the hole in the nozzle is āperĆ

fectly āclean āand clear. Warm water (notā hot)ā

usedā withā aā household ādetergent is a useful

cleaning agent for this purpose.

NOTE: Further information can be found in the inĆ

struction leaflet supplied with your spray

bottle.

Service Parts:

Complete spray bottle P/N R0006

Spray nozzle repair kit P/N R6332

WARNING!!

Protective clothing and eye wear should

be worn while using cleaning agents.

Pressure Pump

Spray Head

Pump

MAX

Pressure

Vessel

Clean the pump 2 or 3 times per week with warm water

Spray Trigger

Figure 11

16

Page 21

Maintenance

Cleaning and Preventive Maintenance

CLEANING THE INTERIOR

Daily cleaning of the appliance is essential for sanĆ

itation and to ensure against operational difficulĆ

ties. Use an oven cleaning detergent in conjuncĆ

tion with the supplied spray bottle.

On stainless interiors, deposits of baked on splatĆ

ter, oil, grease or light discoloration āmay ābe āreĆ

moved āwith āa good non toxic industrial stainless

steel cleaner. Apply cleaners when the unit is cold

and always rub with the grain of the metal. The

racks, rack supports and the blower wheel may be

cleaned either in the unit or removed āand āsoaked

in a solution of ammonia and water.

NOTE: DO NOT use corrosive cleaners!

1. Cool āāthe āappliance down to 140_F (60_C) or,

if the āunitāā has āābeenā āidle, āāturnā the steam modeā

onā foār 3 āto ā4ā minutesā inā order āāāto warm the interiĆ

or surfaces.

2. Fill āāāāātheāāā āsprayāāā ābottleā āāandāāā pump āāāairā āāintoāā āthe conĆ

tainer with the pressure pump.

3. Spray āāthe āinteriorā of āātheāā unitā with a cleaning soĆ

lution.

NOTE: Never spray water into the unit when

the temperature is above 212_F.

4. Let āthe ācleanerā āworkāā for āā10ā toā 20 minutes withāāāāā

the āāāāunitā āāāāoff.āāā āForā āādifficult cleaning allow to work

over night.

5. Set the timer for 15 to 20 minutes. Turn ātheā

āmodeā āāselector switch to Steam. This will softĆ

en all burned on residue.

6. Rinseāā āāthe interiorā āāāwithāāāāā the hose and spray asĆ

sembly.

7. Setā āāātheā āāāmode āāāselectorāāā toā āāsteam āāāforā anotherā five

minutes to flush out the interior and remove all

detergent residue.

NOTE: The āinterior ācavity ā should ā never ā be

scoured or scraped.

CLEANING THE EXTERIOR

Exteriors may be cleaned and kept in good condiĆ

tion with a stainless steel polish.

NOTE: DO NOT spray the outside of the appliance

with water.

PREVENTIVE MAINTENANCE

The best preventive maintenance measures are:

D the āāāproper āāinitial āāinstallation āāof āāthe equipment

D deliming the steam generator (if applicable)

D a program for routine cleaning.

These units requires no lubrication. Contact the

factory, a factory representative or a local Blodgett

Combi service company to perform maintenance

and repairs should they be required.

WARNING!!

Disconnect the appliance from the power

supply before servicing or cleaning.

17

Page 22

Maintenance

Decalcification

1. Turn the Mode Selection Switch (1) to the

STEAM mode. Wait until steam is produced.

This will ensure that the water in the steam

generator is hot.

2. Turn the Mode Selection Switch (1) to the

COOL DOWN mode and leave the door open.

Let the oven compartment cool to 150_F

(66_C). This ensures that the Drain/Flush

switch will function in STEP 8.

3. Turn the Mode Selection Switch (1) to OFF.

4. In a suitable size container, mix together the

deliming solution and tap water. Refer to the

following chart for the proper mixture:

Deliming

Model

BCSĆ6 12 oz. 3 quarts

NOTE: These volumes are approximate. You

may need slightly more or less water

depending on your site.

5. Remove the Deliming Port Cap from the DeĆ

liming Inlet (5). Attach the supplied Funnel

and Hose Assembly (3) to the deliming inlet.

6. Open the Deliming Port Valve (2) and pour in

the deliming mixture. Stop pouring when the

funnel stops draining. This is the correct

amount for your site.

Solution Tap Water

7. Shut the Deliming Port Valve (2). Screw on the

Deliming Port Cap. Let the mixture stand for 20

minutes. In areas of the country with hard waĆ

ter, allow the mixture to stand for 1 hour maxiĆ

mum.

8. Depress and hold the Drain/Flush Switch (4)

in the FLUSH position for 90 seconds. This

completes the deliming procedure.

3

open

2

close

1

4

Figure 12

18

Page 23

INSERT

WIRING DIAGRAM

HERE

Loading...

Loading...