Blitz MONSUN Pro Operating Instructions Manual

Operating instructions

MONSUN Pro Screw Compressors

Type

Serial number Date

Operating instructions

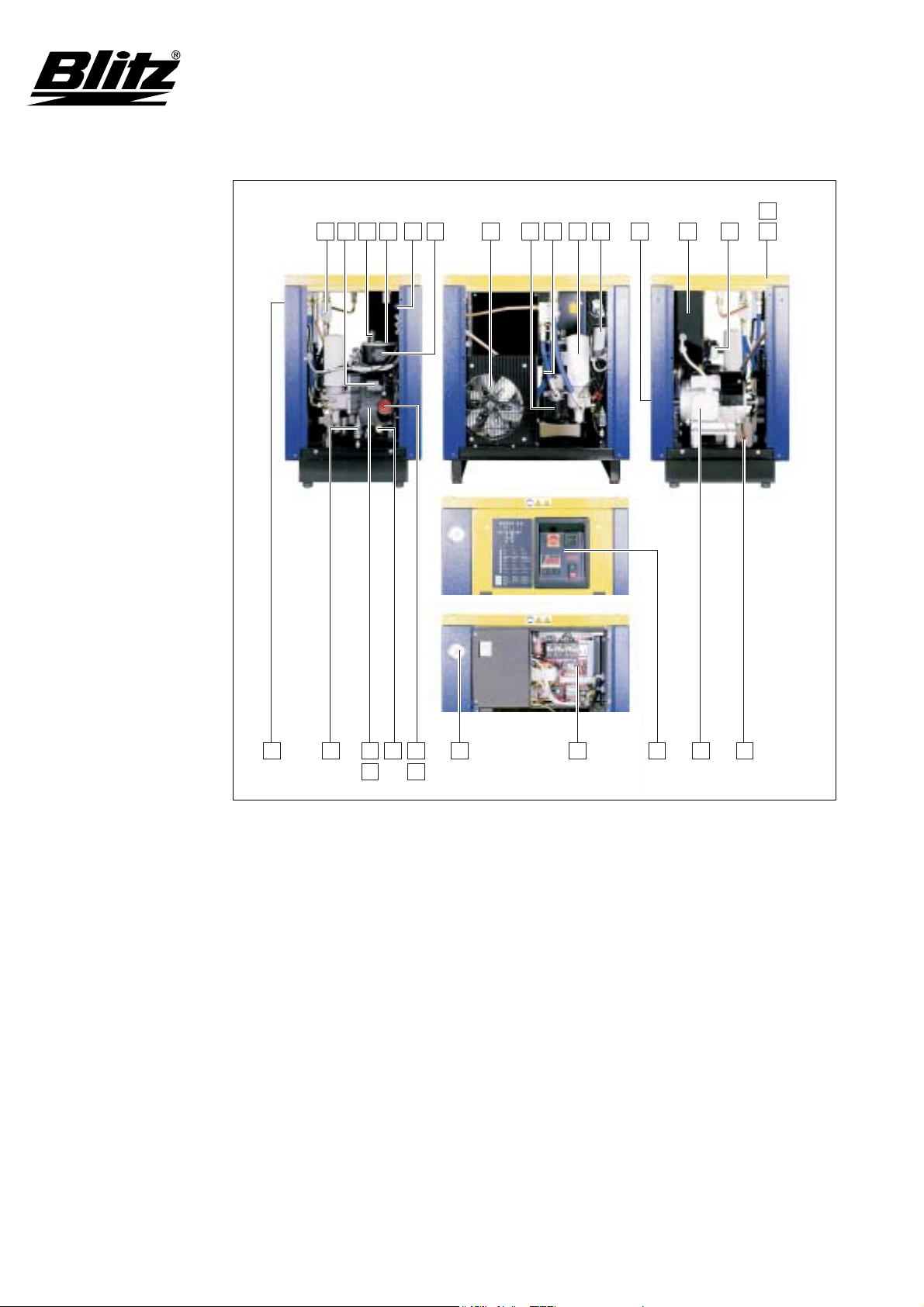

Component overview

31 2223 24

20 3231116

27

5

10 12131533

26

1

19

Fig. 1: Component overview

1 Compressor

2 Compressed air / oil reservoir 19 Spring mounted adjusting screw for V-belt

3 Oil high-precision separator cartridge 20

4 Electric motor 22

5 Fan 23

6 Control device 24

8 Name plate 25 Compressed-air outlet with cut-off valve

10 Pressure detector 26

11 Safety valve 27

12 Switch box 29

13 Oil thermostat 30 Reset key oil – temperature alarm

15

Plug / oil and condensation water drain

valve (enclosed)

16 Pressure reservoir name plate

17 Oil level indication 33 Visual wear indication (suction filter car-

17

2

18

18 Oil filler neck

31 Reset key oil – protective motor switch

32

30

tension

Suction stop valve

Relief valve

Suction filter

Oil filter

(optional)

Compressed-air aftercooler

Oil cooler

Master pressure gauge

alarm

Dust preliminary filter

tridge)

4

6298

25

104485 • 03/03

Operating instructions

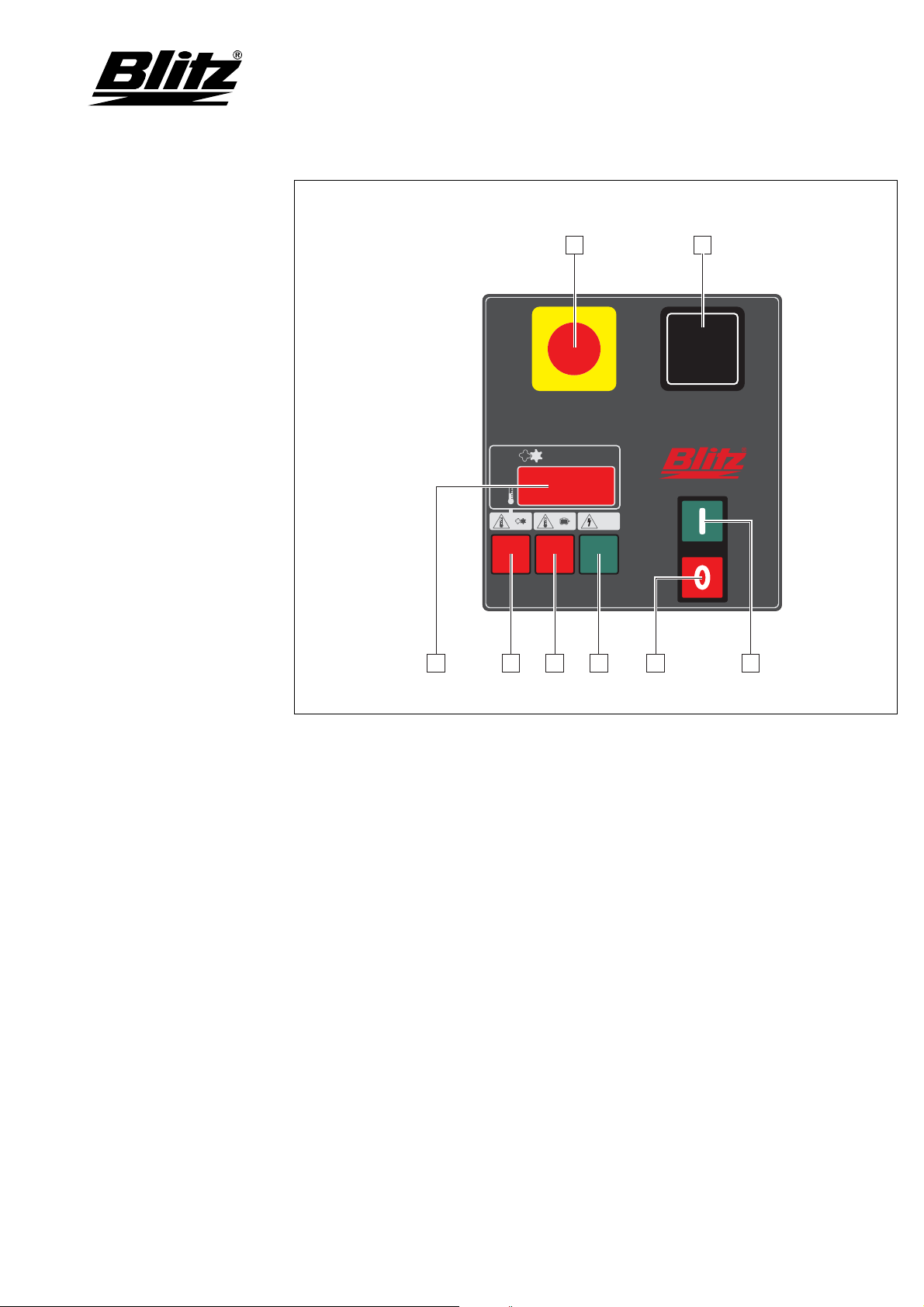

MONSUN Pro operating elements

8

20

7

0000000h

3 4 56 2

Fig. 2: Operating elements

1 Power switch

2 Circuit-breaking key

3 Red flashing: Oil temperature approaches the maximum value of 105°C

Permanent red: Oil temperature alarm, compressor shuts down

4 Permanent red: Protective motor switch alarm, compressor shuts down

5 Permanent green: System is energised

6 Temperature indication Oil temperature in °C

7 Counter for operating

hours

8 Emergency stop

1

104485 • 03/03 1

Operating instructions

Table of contents

MONSUN Pro operating elements

Table of contents

Component overview

MONSUN Pro operating elements

Fundamental safety instructions.......2

1

1.1 Designated use........................................ 2

1.2 Fundamental measures.......................... 2

1.3 Description of symbols and notes ........ 2

2 Transport and storage ......................... 2

2.1 Transport .................................................. 2

2.2 Storage...................................................... 2

3 Mounting ................................................3

3.1 Mounting conditions............................... 3

3.2 Compressed-air port ...............................4

3.3 Electrical connection ..............................4

3.4 Checking the rotating direction ............5

4 Operation................................................ 7

4.1 Safety instructions .................................. 7

4.2 Switching the unit on ............................. 7

4.3 Start-up after an extended idle time..... 7

4.4 Weekly check ........................................... 7

4.5 Switching the unit off .............................7

4.6 Remote control ........................................8

4.7 Original BLITZ accessories.................... 8

5 Inspection and servicing.....................9

5.1 Safety instructions .................................. 9

5.2 Checking and topping up the oil level . 9

5.3 Changing the oil ....................................10

5.4 Changing the oil filter ........................... 10

5.5 Draining the condensation water .......11

5.6 Cleaning the oil cooler and the

compressed-air aftercooler .................. 11

5.7 Checking safety valve ........................... 11

5.8 Changing oil high-precision separator

cartridge.................................................. 11

5.9 Checking and changing the suction

filter cartridge ........................................ 11

5.10 Checking and adjusting the V-belt ..... 12

5.11 Notes on systems equipped with water

cooling system....................................... 12

5.12 Tighten the screw connections........... 12

5.13 Checking electric terminals................. 12

5.14 Relubricating/replacing motor

mounting ................................................ 12

5.15 Cleaning dust preliminary filter. .........12

6 Maintenance schedule....................... 13

7 Trouble shooting ................................15

7.1 Malfunction, compressor generally.... 15

Technical annex

104485 • 03/03 1

Operating instructions

Fundamental safety instructions

1 Fundamental safety instruc-

tions

1.1 Designated use

The compressor system is intended exclusively for the generation of compressed air.

Any other use shall be considered an undesignated use.

1.2 Fundamental measures

• Never point compressed air at persons.

• Observe these operating instructions.

• Keep these operating instructions avail-

able at the location of use at all times.

• Please observe the regular maintenance

intervals (refer to chapter 6 “Maintenance

schedule”).

• Use original BLITZ parts and approved

operating material only.

• Do not use compressed air for breathing

without corresponding treatment.

• Do not modify the system.

• Use mounting parts and devices down-

stream from the compressor which have

been designed for the maximum operating

overpressure of the compressor.

• In your capacity as proprietor, please ensure that all safety regulations are observed by the operating staff.

• Do not use the compressor as a climbing

aid.

1.3 Description of symbols and

notes

Danger

Mortal danger and risk of injury.

Caution

Damage to property.

Information and tips.

2 Transport and storage

2.1 Transport

Danger

Mortal danger caused by incorrect

transport.

• Do not hold the compressor at its

cladding elements as you lift it.

• Only use suitable lifting gear with the

corresponding weight-bearing capacity

(for data on weight, please refer to

chapter “Technical annex”).

• Fasten and secure the system with

belts at the corresponding points.

• Secure swivelling and loose parts.

• Transport the compressor by means of

crane hooks, fork-lift truck and elevating truck only.

• Never remain under suspended loads.

• Depressurise the compressor prior to

any transport.

2.2 Storage

Store the compressor in a dry location protected against weather influence. Ambient

temperature: -10°C to +50°C.

Please order the BLITZ conservation instructions in case of storage of over six months.

For information on recommissioning

after an extended idle time, please refer to chapter 4.3.

2 104485 • 03/03

Operating instructions

Mounting

3 Mounting

3.1 Mounting conditions

!

Check the compressor for damage during

transport.

Ambient conditions

Danger

Mortal danger and explosion hazard

when caustic, inflammable or poisonous gases are drawn in.

• Do not operate the compressor in explosive surroundings or in the vicinity

of open flames and flying sparks.

Caution

Wrong mounting will cause damage to

the compressor.

• Ensure sufficient ventilation of the

compressor room.

• Do not operate the compressor in the

open.

• Systems with a capacity exceeding 40

kW must be installed in such a way

that no combustible objects or materials are in the immediate proximity.

• Systems with a capacity exceeding 100

kW should be installed in a separate

room.

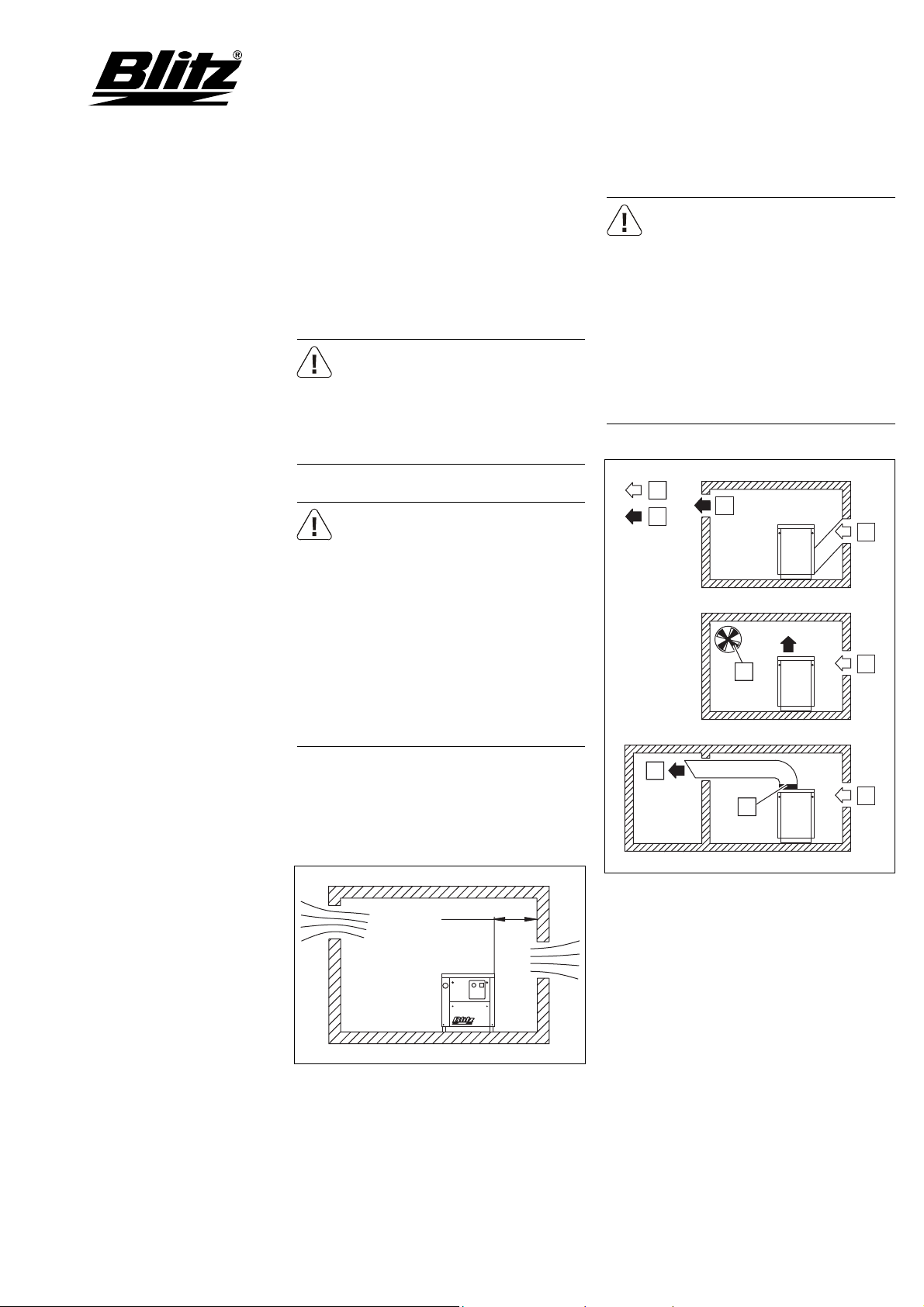

The space between the compressor and the

wall has to be at least 60 cm (cf. fig. 3: Location). The compressor has to be easily accessible from all sides. The ambient temperature

must be between 3°C and 40°C.

Cooling and exhaust air

Danger

Mortal danger and explosion hazard

during suction.

• Ensure that the compressor draws in

only clean air which is free from noxious constituents. Noxious substances

are liable to accumulate in the lubricating oil of the compressor. They may

cause explosions in the system and severe damages.

• Do not allow objects or pieces of clothing of persons going past to be sucked

in by the intake air flow.

1

2

C

B

D

E

A

A

A

+3°C - +40 °C

Fig. 3: Location

> 60 cm

Fig. 4: Room ventilation

1 Intake air

2 Exhaust air

A Air inlet

B Air outlet

C Ventilation duct

D Exhaust fan

E Elastic connecting piece

3104485 • 03/03

Operating instructions

Mounting

The overall length of all intake air ducts and

exhaust air ducts must not exceed 4 m; one

baffle is permissible. In case of ducts exceeding this length or in case of several baffles,

filters, grids etc., a booster fan must be installed. In this case, please contact your technical adviser.

For further information on the required ventilation cross sections, please refer to the

Technical Annex.

Ground

!

Place the compressor on a horizontal and

plane surface.

The ground has to have a suitable loadbearing capacity. BLITZ offers special solutions for inclined surfaces.

BLITZ recommends the use of rubber-metal

connections to prevent vibrations.

3.2 Compressed-air port

The connection to the compressed-air ductwork system may be carried out only by

trained experts or by staff members of BLITZ

Company.

Danger

Danger of injury by pressure in the

pipes.

• Vent the pipes to which the compressor is connected.

Use a flexible hose to connect the

compressor to the supply network.

Thus, stress cracks and sound bridges

are prevented.

• Compressed-air lines, filters, aftercoolers

and vessels must be equipped with an outlet for the accumulated condensation water at their lowest spots. These outlets

must allow to observe the draining condensation water. Condensation water may

contain oil! In draining the condensate, all

applicable regulations on the disposal of

waste water must be complied with.

• Remove all securing devices before

mounting the conduits.

• Use only suitable supply lines and couplings which are designed for the intended

working pressure. Do not use any defect

components.

• Supply lines must not be subjected to

stress or tension.

Observe the technical data for the connection

of compressed air (cf. chapter “Technical

annex”).

3.3 Electrical connection

The connection to the electrical power system

may be carried out only by adequately trained

expert.

Danger

Mortal danger caused by electric voltage but also by rotating wheels, Vbelts, and fan blades.

• Test runs are permissible only if all

parts of the casing are closed (exception: check of the rotating direction).

Compressor systems have to be fitted with a

power switch or a plug connection to interrupt

the power supply. Compressor systems with a

motor capacity of more than 3 kW or 16 Amps

have to be fitted with a lockable power switch

and upstream fuses.

In this respect, please refer to the circuit diagram in the chapter titled

“Technical annex” or in the switch

cabinet as well as to the following

connection conditions.

Check and retighten where appropriate

all electric terminals before first commissioning.

4 104485 • 03/03

Loading...

Loading...