Blitz MONSUN Fast R Operating Instructions Manual

Operating instructions

MONSUN Fast R Screw Compressors

Type

Serial number Date

1214

55 01

/

2015

Reg-Nr. 2014-10_S_en_2006/42/EG

.

EC Declaration of Conformity

according to EC directive 2006/42/EC on

machinery (Annex II A)

Name and address of the manufacturer

BlitzRotary GmbH

Hüfinger Str.55

78199 Bräunlingen, Germany

This declaration relates exclusively to the machinery in the state in which it was placed on the market, and

excludes components which are added and/or operations carried out subsequently by the final user. The

declaration is no more valid, if the product is modified without agreement.

Herewith we declare, that the machinery described below

product denomination Screw Compressor oilinjected

model / type

MONSUN Pro, Pro D, Pro S, Pro Navicon, Pro Navicon D, Pro Navicon S

Pro Eco, Pro Eco D, Pro Eco S

Fast, Fast D, Fast S, Fast R

Monsun, Monsun FU, Monsun D, Monsun S

Eco, Eco D, Eco G, Eco FU, Eco DFU, Eco GFU

machinery- / serial number .............................................

Year of manufacture 20 .............

complies with all key provisions of Machinery Directive 2006/42/EC.

Furthermore, the machine complies with the provisions of the Electromagnetic Compatibility Directive

2004/108/EC and the Low Voltage Directive 2006/95/EC

(safety standards have been met pursuant to Annex I, No. 1.5.1 of the Machinery Directive 2006/42/EC).

Furthermore, the machine complies with the provisions of the Simple Vessels Directive 2009/105/EC

Harmonised Standards used

EN 1012-1 : 2010 Compressors and vacuum pumps - Safety requirements

EN 60204-1: 2006+7/2007 Safety of machinery - Electrical equipment of machines

EN ISO 12100-1 : 2003 Safety of machinery - Basic concepts

EN ISO 12100-2 : 2003 Safety of machinery - Basic concepts

EN ISO 14121-1 : 2007 Safety of machinery - Risk assessment

Other technical standards and specifications used:

The person authorised to compile the relevant technical documentation:

BlitzRotary GmbH; Hüfinger Str. 55, 78199 Bräunlingen

Place, date:

Bräunlingen, 31.10.2014 ______________________

Frank Scherer

Geschäftsführer / Managing Director

__________________________________________________________________________________

2

IMPORTANT INFORMATION

Read all the operational instructions, safety recommendations and all warnings provided in the instruction manual.

Most accidents encountered when using the compressor are merely due to the failed observance of basic safety standards.

Accidents are prevented by foreseeing potentially hazardous situations and observing the appropriate safety standards.

The fundamental safety standards are listed in the “SAFETY” section of this manual and also in the section involving the use

and maintenance of the compressor.

Hazardous situations to be avoided in order to prevent serious personal injuries and machine damages are listed in the

“WARNINGS” section of the instruction manual or are actually printed on the machine.

Never use the compressor improperly but only as recommended by the Manufacturer.

The Manufacturer reserves the right to up-date the technical information given in this manual without notice.

3

0

Foreword

4

0.1

How to read and use the instruction manual

4

0.1a

Importance of the manual

4

0.1b

Conserving the manual

4

0.1c

Consulting the manual

4

0.1d

Symbols used

4

1

General information

5

1.1

Identification data of the manufacturer and the compressor

5

1.2

Information on machine technical/maintenance service

5

1.3

General safety warnings

6

2

Preliminary machine information

8

2.1

General description

8

2.2

Intendedt use

8

2.3

Technical data

9

3

Transport, Handling, Storage

10

3.1

Transporting and handling the packed machine

10

3.2

Packing, unpacking and prepare to use

10

3.3

Storing the packed and unpacked compressor

11

4

Installation

12

4.1

Admitted surrounding conditions

12

4.2

Space required for maintenance

12

4.3

Positioning the compressor

12

4.4

Connecting the compressor to the sources of energy and relative inspections

13

4.4.1

Connecting to the electric mains

13

4.4.2

Connecting to the pneumatic mains

14

5

Using the compressor

15

5.1

Preparing to use the compressor

15

5.1.1

Operational principle

15

5.2

Control panel

16

5.3

Check the efficiency of the safety devices before starting

16

5.4

Starting the compressor

16

5.5

Stopping the compressor

17

6

Compressor maintenance

18

6.1

Instructions relative to inspections and maintenance jobs

18

6.1.1

Oil change

19

6.1.2

Replacing the oil filter cartridge

20

6.1.3

Replacing the filter cartridge oil separator

20

6.1.4

Replacing the air filter cartridge

21

6.1.5

Draining the condensate

21

6.1.6

Cleaning the air/oil radiator

22

6.1.7

Lubricating the electric motor

22

6.2

Diagnosing the alarm status/inconveniences-faults

23

7

Drawings and diagrams

25

7.1

Wiring diagrams

25

7.2

Pneumatic diagrams

28

0

Foreword

4

0.1

How to read and use the instruction manual

0.1.a Importance of the manual

This INSTRUCTION MANUAL has been written to guide you through the INSTALLATION, USE and MAINTENANCE of

the compressor purchased.

We recommend that you strictly observe all the indications given within as the ideal operational efficiency and lasting

wear of the compressor depend on the correct use and methodical application of the maintenance instructions given

hereafter.

Remember that when any doubts or inconveniences arise it is a good rule to always contact the AUTHORISED

SERVICE CENTRES. They are at your complete disposal for any explanations or jobs required.

The Manufacturer therefore declines all liabilities regarding the incorrect use and poor maintenance of the compressor.

The INSTRUCTION MANUAL is integral part of the compressor.

Ensure that any up-dates forwarded by the Manufacturer are actually added to the manual.

If the compressor is sold on at a later date the manual must be given to the new owner.

0.1.b Conserving the manual

Use and read the manual with care being careful not to damage any part of it.

Do not remove, tear or re-write any parts of the manual for any reason whatsoever.

Keep the manual in a dry and sheltered place.

0.1.c Consulting the manual

This instruction manual is made up of the following:

• FRONT COVER WITH MACHINE IDENTIFICATION

• DETAILED INDEX

• INSTRUCTIONS AND/OR NOTES ON THE COMPRESSOR

The model and serial number of the compressor to which the manual refers and that you have purchased is found on

the FRONT COVER.

The various SECTIONS in which all the notes relative to a certain subject are found in the INDEX.

All the INSTRUCTIONS AND/OR NOTES ON THE COMPRESSOR aim at pointing out safety warnings and

procedures required to use the compressor correctly.

0.1.d Symbols used

The SYMBOLS pointed out below are used throughout this manual and their purpose is that of drawing the operator’s

attention, informing the latter how to behave and how to proceed in each operational situation.

READ THE INSTRUCTION MANUAL

Read the use and maintenance manual carefully before installing and starting the compressor.

GENERAL HAZARDOUS SITUATION

An additional note will point out the type of hazard involved.

Meaning of the indications:

Warning!

This points out a potentially hazardous situation, which if ignored, could cause personal injury and machine damage.

Note!

This enhances crucial information.

RISK OF ELECTRIC SHOCK

Warning: the electrical power supply of the compressor must be disconnected before doing any jobs on the

compressor.

RISK OF SCOLDING

Warning: be careful when touching the compressor as some parts of it could be very hot.

General information

1

5

1.1

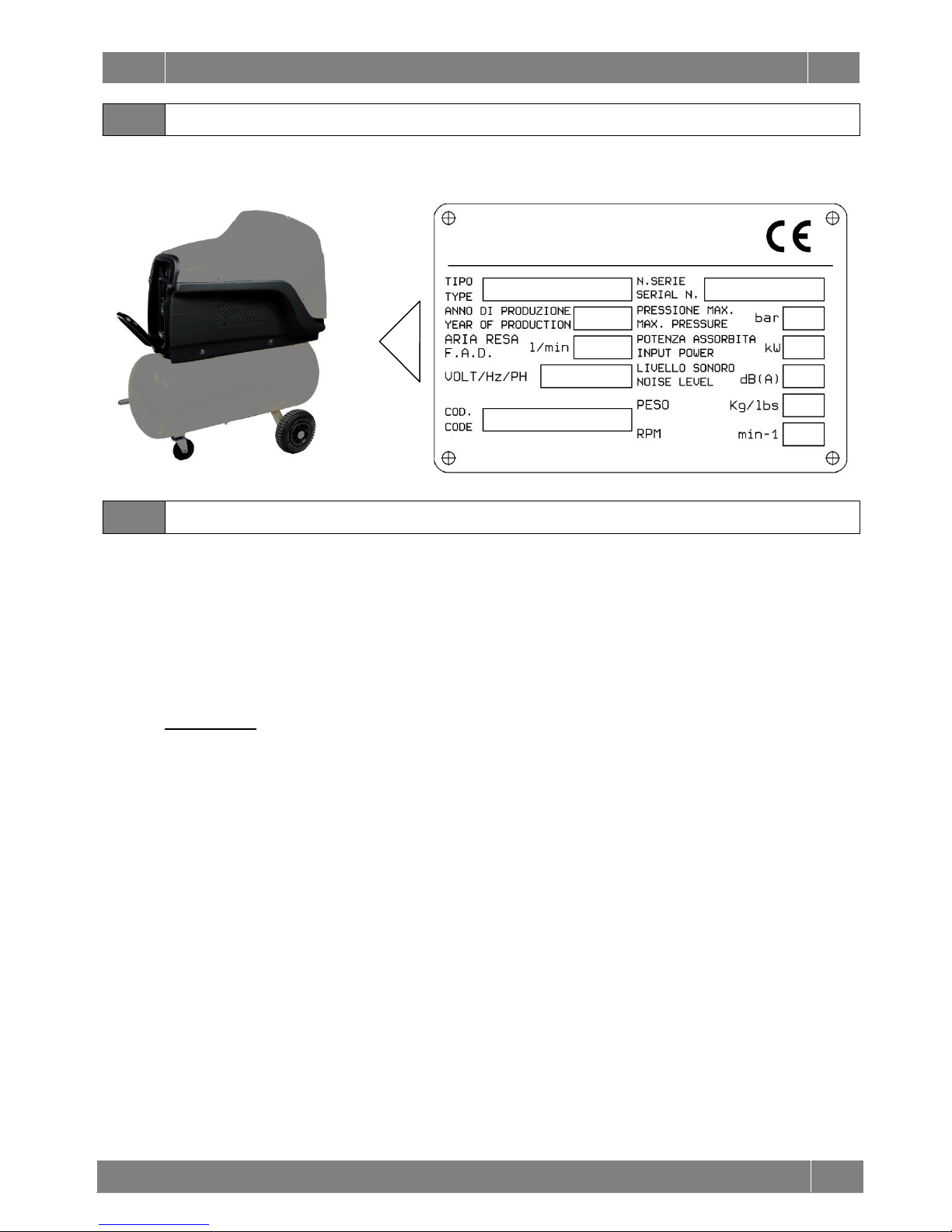

Identification data of the manufacturer and the compressor

COMPRESSOR IDENTIFICATION NAME PLATE.

(Silent electric rotary screw compressor on tank)

1.2

Information on machine technical/maintenance service

We remind you that our technical service department is at your complete disposal to help you resolve any problems

that may possibly be encountered, or to provide you with any other information necessary.

In the case of need contact:

Our CUSTOMER TECHNICAL SERVICE department or your local dealer.

The constant and efficient performance of the compressor is ensured only if original spare parts are used.

It's recommended to visit the producer web site

We recommend therefore that you strictly observe the indications provided in the MAINTENANCE section and to use

EXCLUSIVELY original spare parts.

The use of NON ORIGINAL spare parts automatically annuls the guarantee.

1

General information

6

1.3

General safety warnings

Nota! Le operazioni che troverete dentro questo manuale sono state scritte per assistere l’operatore

durane l’utilizzo e le operazioni di mantenimento del compressore.

IMPORTANT INSTRUCTIONS FOR THE SAFE USE OF THE COMPRESSOR

WARNING: THE INAPPROPRIATE USE AND POOR MAINTENANCE OF THIS COMPRESSOR MAY CAUSE

PHYSICAL INJURY TO THE USER. YOU ARE RECOMMENDED TO CAREFULLY FOLLOW THE INSTRUCTIONS

PROVIDED HEREAFTER TO AVOID SUCH RISKS.

1. DO NOT TOUCH MOVING PARTS

Never put your hands, fingers or other parts of the body near moving parts of the compressor.

2. NEVER USE THE COMPRESSOR WITHOUT THE SAFETY GUARDS FITTED

Never use the compressor without all the safety guards fitted perfectly in their correct place (i.e. panelling, belt

guard, safety valve). If these parts are to be removed for maintenance or servicing purposes, ensure that they

are put back in their original place perfectly before using the compressor again.

3. ALWAYS WEAR SAFETY GOGGLES

Always wear goggles or equivalent eye protection means. Never direct compressed air towards any part of your

body or that of others.

4. PROTECT YOURSELF AGAINST ELECTRIC SHOCKS

Avoid accidentally touching the metal parts of the compressor with your body, such as pipes, the tank or metal

parts connected to earth. Never use the compressor where there is water or in damp rooms.

5. DISCONNECT THE COMPRESSOR

Disconnect the compressor from the electric power supply and completely discharge the pressure from the tank

before carrying out any service, inspection, maintenance, cleaning, replacing or inspection jobs of each part.

6. ACCIDENTAL START-UP

Never move the compressor while it is connected to the electrical power supply or when the tank is pressurised.

Ensure that the main switch is turned OFF before connecting the compressor to the electrical power supply.

7. STORE THE COMPRESSOR APPROPRIATELY

When the compressor is not in use, it must be stored in a dry room away from atmospheric agents. Keep it out

of children’s reach.

8. OPERATIONAL AREA

Keep the work area clean and remove any tools that are not required. Keep the work area sufficiently

ventilated. Never use the compressor in the presence of flammable liquids or gas. The compressor may

produce sparks while running. Do not use the compressor where there may be paints, gasoline, chemical

compounds, glues and any other flammable or explosive material.

9. KEEP THE COMPRESSOR OUT OF CHILDREN’S REACH

Prevent children or anyone else from touching the power supply cable of the compressor. All outsiders must be

kept at a safe distance from the operational area.

10. WORK CLOTHES

Do not wear unsuitable clothing, ties or jewellery as these may get caught up in moving parts. Wear caps to

cover your hair if necessary.

11. PRECAUTIONS FOR THE POWER SUPPLY CABLE

Do not disconnect the power supply plug by pulling on the cable. Keep the cable away from heat, oil and sharp

edges. Do not stand on the electrical cable or squash it under heavy weights.

12. LOOK AFTER THE COMPRESSOR WITH CARE

Follow the maintenance instructions. Inspect the power supply cable on a periodic basis and if damaged it must

be repaired or replaced by an authorised service centre. Visually check the outside appearance of the

compressor, ensuring that there are no visual anomalies. Contact your nearest service centre if necessary.

13. ELECTRICAL EXTENSIONS FOR OUTDOOR USE

When the compressor is used outdoors, use only electrical extensions manufactured for outdoor use and

marked as such.

14. WARNING

Pay attention to everything you do. Use your common sense.

Do not use the compressor if you are tired. The compressor must never be used if you are under the effect of

alcohol, drugs or medicines, which could make you tired.

15. CHECK FAULTY PARTS OR AIR LEAKS

Before using the compressor again, if a safety guard or other parts are damaged, they must be checked

carefully to evaluate whether they may operate as established in complete safety.

Check the alignment of moving parts, hoses, gauges, pressure reducers, pneumatic connections and every

other part that may be crucial for the normal operational efficiency of the compressor. All damaged parts must

be properly repaired or replaced by an authorised service centre or replaced following the instructions provided

in instruction manual.

General information

1

7

16. USE THE COMPRESSOR EXCLUSIVELY FOR THE APPLICATIONS SPECIFIED IN THIS INSTRUCTION

MANUAL.

The compressor is a machine that produces compressed air.

Never use the compressor for purposes other than those specified in the instruction manual.

17. USE THE COMPRESSOR CORRECTLY

Operate the compressor in compliance with the instructions provided in this manual. Do not allow children to

use the compressor or those who are not familiar with it.

18. ENSURE THAT EACH SCREW, BOLT AND GUARD IS FIRMLY SECURED IN PLACE.

19. KEEP THE IN-TAKE GRIDS CLEAN

Keep the motor ventilation grids clean. Regularly clean these grids if the work area is particularly dirty.

20. OPERATE THE COMPRESSOR AT THE RATED VOLTAGE

Operate the compressor at the voltage specified on the electric data plate. You could damage or burn-out the

motor and other electric components if the compressor is operated at a higher or lower voltage than its rated

voltage.

21. NEVER USE THE COMPRESSOR IF IT IS FAULTY

If the compressor is noisy or vibrates excessively when running or it seems to be faulty, stop it immediately and

check its efficiency or contact your nearest authorised service centre.

22. DO NOT CLEAN PLASTIC PARTS USING SOLVENTS

Solvents such as gasoline, thinners, gas oil or other compounds that contain hydrocarbons may damage the

plastic parts. Clean them with a soft cloth and soapy water or other suitable liquids.

23. USE ORGINAL SPARE PARTS ONLY

The use of non-original spare parts involves the annulment of the guarantee and the abnormal running

conditions of the compressor. Original spare parts are available c/o the authorised dealers.

24. DO NOT MODIFY THE COMPRESSOR

Do not modify the compressor. Contact an authorised service centre for all repairs required. An unauthorised

modification may impair the efficiency of the compressor and may also cause serious accidents for those who

do not have the technical skill required to make such modifications.

25. TURN THE COMPRESSOR OFF WHEN IT IS NOT IN USE

When the compressor is not in use turn the main ON/OFF switch OFF (position “0”).

26. DO NOT TOUCH HOT PARTS OF THE COMPRESSOR

To avoid scolding do not touch pipes, the motor or any other hot part.

27. DO NOT DIRECT THE JET OF AIR DIRECTLY TOWARDS THE BODY

To avoid all risks never direct the jet of air towards people or animals.

28. DO NOT STOP THE COMPRESSOR BY PULLING ON THE POWER SUPPLY CABLE

Use the “O/I” (ON/OFF) buttons of the control panel to stop the compressor.

29. PNEUMATIC CIRCUIT

Use recommended pneumatic hoses and tools that can withstand the same or a higher pressure than the

maximum running pressure of the compressor.

30. SPARE PARTS

Use only original and identical spare parts to replace worn or damaged ones.

Repairs must be made exclusively by authorised service centres.

31. CORRECT USE OF THE COMPRESSOR

The operator must be perfectly familiar with all the controls and compressor characteristics before starting to

work with the machine.

32. MAINTENANCE JOBS

The use and maintenance jobs of the commercial components fitted on the machine, but not indicated in this

manual, are indicated in the enclosed documents.

33. DO NOT UNSCREW THE CONNECTION WHEN THE TANK IS PRESSURISED

Do not unscrew the connection for any reason whatsoever with the tank pressurised without first checking if the

tank is discharged.

34. DO NOT MODIFY THE TANK

It is prohibited to intentionally drill, weld or deform the compressed air tank.

35. IF THE COMPRESSOR IS USED FOR PAINTING JOBS

a) Do not work in closed rooms or near free flames.

b) Ensure that the room in which you are working is sufficiently ventilated.

c) Wear face and nose mask.

36. DO NOT PUT OBJECTS OR PARTS OF THE BODY IN THE PROTECTION GRIDS

Do not put objects or parts of the body in the protection grids to prevent physical injuries and damage to the

compressor.

KEEP THESE USE AND MAINTENANCE INSTRUCTIONS CAREFULLY AND GIVE THEM TO

PERSONNEL WISHING TO USE THE COMPRESSOR!

WE RESERVE THE RIGHT TO MAKE MODIFICATIONS WHERE NECESSARY WITHOUT

NOTICE.

2

Preliminary machine information

8

2.1

General description

The rotary screw compressor has been specifically designed aiming at minimising maintenance and labour costs.

The outside cabinet is completely covered in sound-proof and oil-proof panelling thus ensuring its extended and lasting

wear.

The components have been arranged so that all vital parts can be easily reached for maintenance purposes simply by

opening dedicated panels with quick-release locking devices.

The filters and adjustment and safety devices (oil filter, air filter, oil separator filter, regulator valve, minimum pressure

valve, max. pressure safety valve, thermostat, belt tightener, screw compression unit, pressure switch and oil separator

tank emptying and filling taps) are all fitted on the same side.

The dryer series has been devised with the intention of enclosing a complete compressed air system in one compact

machine. It is indeed connected to a dryer that is capable of supplying dry air to ensure the perfect and lasting use of

the tools.

Note! The tanks of the compressors have been manufactured in compliance with the EEC/2009/105

Directive for the European market.

The compressors have been manufactured in compliance with the EC/2006/42 Directive for the

European market.

Note! Check your model on the identification nameplate fitted on the compressor. It is also

indicated in this manual.

ADVISED LUBRICANTS

Always use oil for turbines with approximately 46 cSt at 40°C and a pour point of at least -8 +10°C. The flash point

must be greater than +200°C.

NEVER MIX DIFFERENT OIL QUALITIES.

SCREW OIL

OIL ISO VG D46

Use oil with VG32 rating for cold climates and VG68 for tropical climates.

It is advisable to use synthetic oils for very hot and humid climates.

2.2

Intended use

The silent rotary screw compressors have been designed and manufactured exclusively to produce compressed air.

EVERY OTHER USE, DIFFERENT AND NOT FORESEEN BY ALL INDICATED, RELIEVES THE MANUFACTURER

OF POSSIBLE CONSEQUENT RISKS.

In any event the use of the compressor different to that agreed in the purchase order RELIEVES THE

MANUFACTURER FROM ALL LIABILITIES WITH REGARD TO POSSIBLE MATERIAL DAMAGE AND

PERSONAL INJURY.

The electrical system is not designed for the use in environments subject to explosion or for flammable products.

NEVER DIRECT THE JET OF AIR TOWARDS PEOPLE OR ANIMALS. NEVER USE THE

COMPRESSED AIR PRODUCED BY LUBRICATED COMPRESSORS FOR RESPIRATORY

PURPOSES OR IN PRODUCTION PROCESSES WHERE THE AIR IS IN DIRECT CONTACT

WITH FOODSTUFFS UNLESS IT HAS BEEN FIRST FILTERED AND CONDITIONED FOR SUCH

PURPOSE.

Preliminary machine information

2

9

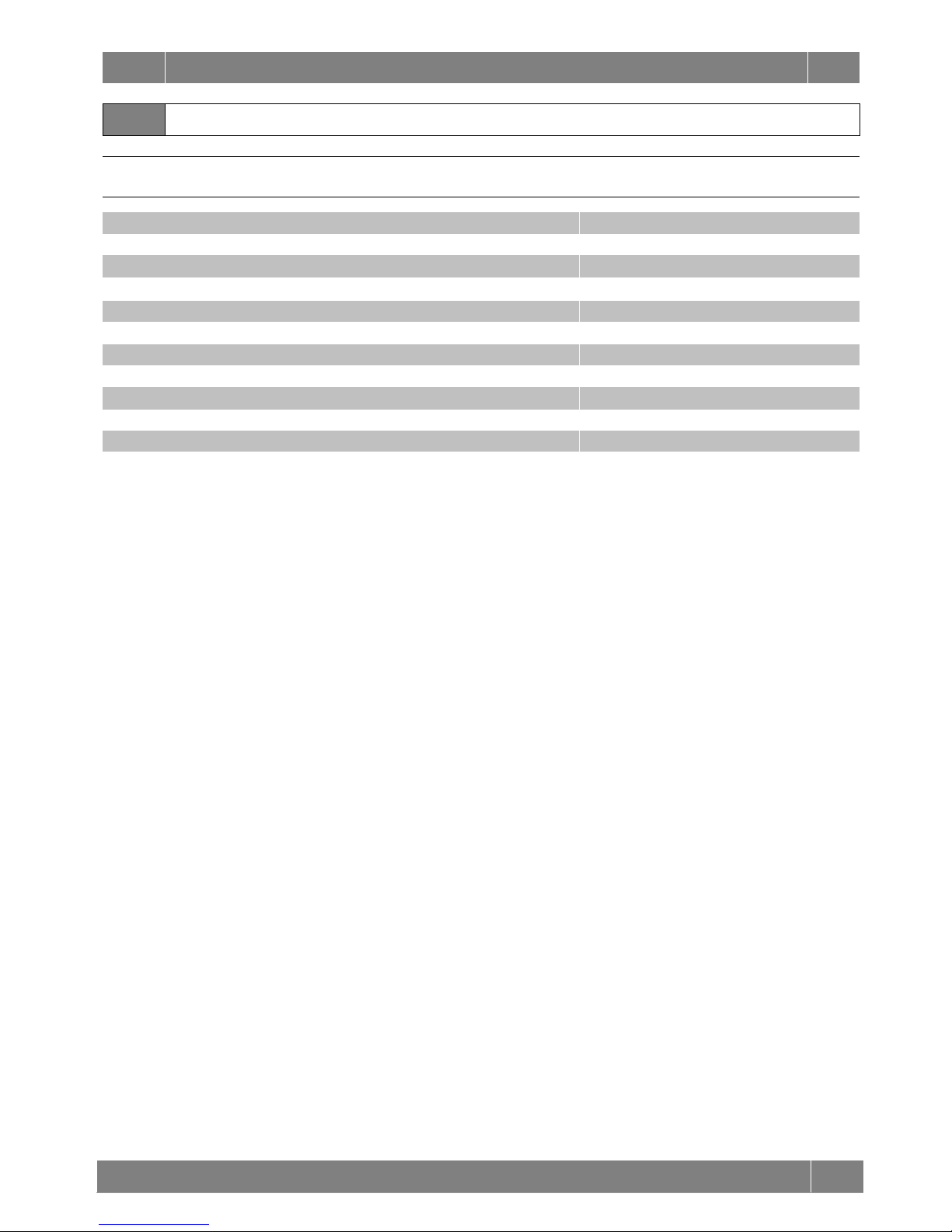

2.3

Technical data

MODEL

Hp 3 ( 2,2kW )

Max. pressure

bar/psi

@50 Hz

9 – 130.5

@60 Hz

7,5 - 109

Free air delivered ISO 1217 MAX

l/min - cfm

@50 Hz

300 – 10.6

@60 Hz

310 – 10.9

Air outlet fitting R ½ G

Oil q.ty

l

2

Oil residue in air

ppm

<3

Output

HP / kW

3 / 2,2

Service

S1

Max starts p/hour

N°

10

Ambient temperature range

°C (min/max)

5/40

Noise level*

dB (A)

59

* Sound level measured in a free range at a distance of 4 m: ±3dB(A) at the maximum working pressure

Loading...

Loading...