Blitz Master Wheel 50 Operating Instruction

Operating Instruction

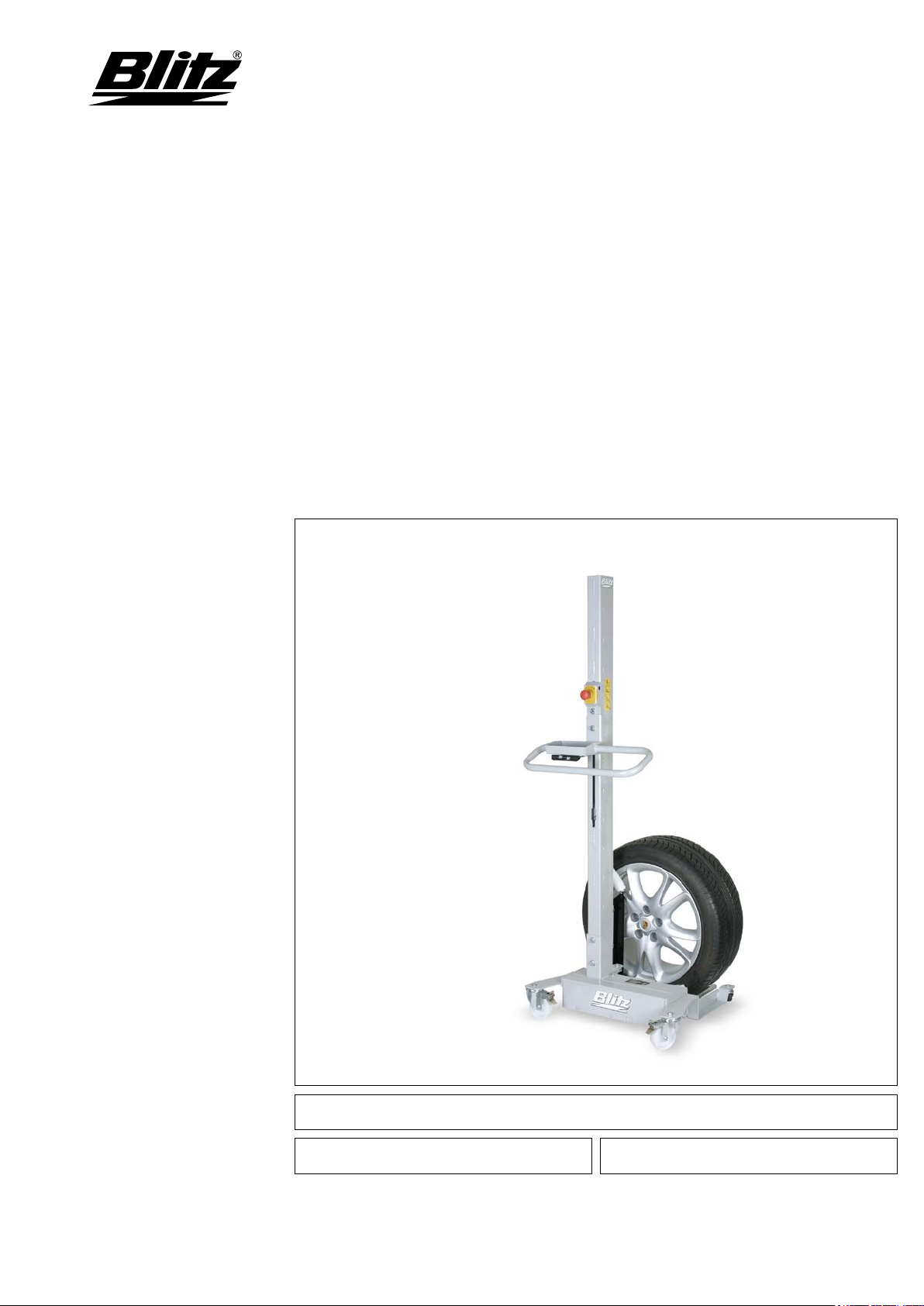

Mobile Wheel Carriage Master Wheel 50

Type

Serial number Date

Rev. D 106431 03/15

Operating Instruction

Table of Contents

Table of Contents

1 Saftey ..................................................... 2

1.1 Safety instructions in this manual ..... 2

2 Introduction .......................................... 3

2.1 Areas of operation .................................. 3

2.2 Warranty and liability ...........................3

2.3 Safety / accident prevention ................. 3

2.4 Instructions for adhering to the

operating instructions .......................... 4

2.5 Operator obligations .............................. 4

2.6 Dangers in handling the

Master Wheel 50 ..................................... 4

2.7 Maintenance work,

repairing faults, disposal ...................... 5

2.8 Special dangers ...................................... 5

3 Technical data ...................................... 6

4 Transport and assembly .................... 7

4.1 Assembling the feet ............................... 7

4.2 Assembling the sliding handle ........... 7

4.3 Assembling the wheel support ........... 7

5 Commissioning .................................... 7

1 Saftey

1.1 Safety instructions in this

manual

Danger

Risk to life and limb.

Warning

Material damage.

Information and tips.

6 Operation ............................................... 8

6.1 Charging the battery.............................. 8

6.2 Loading and unloading ......................... 8

6.3 Transporting the load ............................ 8

6.4 Lifting loads ............................................ 9

6.5 Lowering loads ....................................... 9

7 Faults / causes / rectification ......... 10

8 Maintenance and repair ................... 11

8.1 Electrical circuit diagram .................... 11

8.2 Periodic work ........................................ 11

8.3 Description of periodic work .............. 11

9 Safety examination ........................... 13

10 Appendix ............................................. 14

10.1 Adhesive notices .................................. 14

10.2 Safety examination .............................. 15

2

106431 03/15

Operating Instruction

Introduction

2 Introduction

Blitz lifting tools are the result of many years

of experience. The high quality standards

and the well-considered concept guarantee

reliability, durability and economic operations.

Please read these operating instructions carefully and adhere at all times to the contents in

order to avoid unnecessary damage and risks.

2.1 Areas of operation

The Master Wheel 50 is exclusively designed

to lift, lower and transport car tyres in car

garages. In this, the load must not exceed the

load bearing capacity of the appliance. The

appliance must not be used in areas that are

exposed to the risk of explosion.

Warning

Any other use, or any use that exceeds

the described scope, is deemed to be

improper. This applies in particular to

climbing on to the appliance, driving

with the appliance or using it as a support stand.

2.2 Warranty and liability

Our “General terms of sales and supply”

apply. The operator has been in possession

thereof since the conclusion of the contract.

Warranty and liability claims for personal

and material damage are excluded if they are

based on one or more of the following circumstances:

• Improper use.

• Improper assembly, commissioning, op-

eration and maintenance of the appliance.

• Operation of the Master Wheel 50 while

the safety installations are defect or

improperly installed or non-functioning

safety and protective installations.

• Failure to adhere to the instructions in the

operating instructions concerning transport, storage, assembly, operation and

maintenance.

• Customer modifications to the Master

Wheel 50.

• Substandard monitoring of parts that are

subject to wear.

• Improperly implemented repairs.

• Catastrophes due to the influence of for-

eign bodies or acts of god.

BlitzRotary GmbH will not be made liable for

damage that results from improper use. The

operator carries the exclusive risk for this.

The following is also deemed necessary for

proper use

• Adherence to all instructions in these operating instructions

• Adherence to inspection and maintenance

work and the specified tests.

We will not accept customer services claims

or the costs of return transport in the event of

there being a failure to adhere to these listed

points. Therefore, please contact the manufacturing plant before organising any return

transport.

2.3 Safety / accident prevention

The Master Wheel 50 must only be operated

by qualified persons. Unauthorised persons

are prohibited from operating the appliance!

106431 03/15

3

Operating Instruction

Introduction

2.4 Instructions for adhering to the

operating instructions

• Knowledge of the fundamental safety in-

structions and the safety regulations is a

basic precondition for safe handling and

undisturbed operation of the short lifter.

• The operating instructions must be ad-

hered to by all persons that work on the

short lifter. This applies in particular to the

chapter on “Safety / accident prevention”.

• The rules and regulations that apply at the

place of operation must also be adhered to

in addition to the safety instructions in the

operating instructions.

2.5 Operator obligations

The operator is obligated to only allow such

persons to work on the system as

• are aware of the fundamental regulations

concerning work safety and accident prevention and have been instructed in the

handling of the system

• have read, understood and confirmed by

signature the safety chapter and warnings

in these operating instructions.

2.6 Dangers in handling the Master

Wheel 50

Danger

The Master Wheel 50 must only be

operated for its designated purpose in

perfect and safe working order.

Faults that may affect the safety must

be rectified immediately.

The appliances are designed and constructed

on the basis of state of the art technology and

the recognised technical safety regulations.

Nonetheless, improper use may result in a

risk for the life and limb of the operator or in

material damage.

• Keep the area in which the Master Wheel

50 moves free.

• Persons must not enter the area in which

the Master Wheel 50 moves!

• Do not exceed the maximum load bearing

capacity.

• Do not climb on to the Master Wheel 50,

travel with it or climb on to the load!

• Carry out lifting, lowering and moving

evenly. Observe the load during transport.

Organisational measures

• Keep the operating instructions accessible

at all times at the place of operation of the

short lifter.

• In addition to the operating instructions,

general statutory and other binding regulations concerning accident prevention

and environmental protection must be

observed and publicised!

• Monitor at least occasionally during operation that the staff operate the appliance

in accordance with the safety and danger

instructions!

• Use personal safety equipment whenever

necessary or specified in regulations!

• Observe all safety and danger instructions

on the wheel assembly trolley!

• Ensure that all safety and danger instructions on the wheel assembly trolley are

legible!

• Do not make any changes, additions or

modifications to the wheel assembly trolley which may impede the safety without

the approval of the manufacturer! This applies in particular to welding load-bearing

components.

• Spare parts must conform to the technical

requirements specified by the manufacturer. Only original parts can guarantee this.

• Periods prescribed or specified in the

operating instructions for cyclic examinations / inspections must be adhered to!

• Switch off and secure the Master Wheel 50

immediately in the event of faults! Rectify

any faults immediately!

• Never operate the appliance in areas that

are exposed to the risk of explosion.

• Only use the appliance on an even, firm

surface.

• Only move the appliance when this would

not endanger any persons.

4

106431 03/15

Operating Instruction

Introduction

2.7 Maintenance work, repairing

faults, disposal

• Adhere to the setting, maintenance and

inspection work and deadlines specified in

the operating instructions, including the

replacement of parts and equipment!

This work must only be carried out by

qualified personnel.

• Always tighten screw connections that

were loosened during maintenance and

servicing work!

• Make sure that operating materials, fuels

and spare parts are disposed of safely and

in an environmentally friendly manner!

2.8 Special dangers

• Separate the charging device from the

Master Wheel 50 and the electric mains

before the start of repair work.

• Remove voltage from the appliance at all

times before the start of repair work; to do

this, remove the plug from the battery.

• Do not confuse the electrical connections!

Oils, greases and other chemical substances

Observe the safety instructions that apply to

the product when handling oils, greases and

other chemical substances!

Applied safety standards

DIN EN 292 / DIN EN 294 / EN 349 /

EN 418 / EN 811 / EN 50099 /EN 1494

106431 03/15

5

Operating Instruction

Technical data

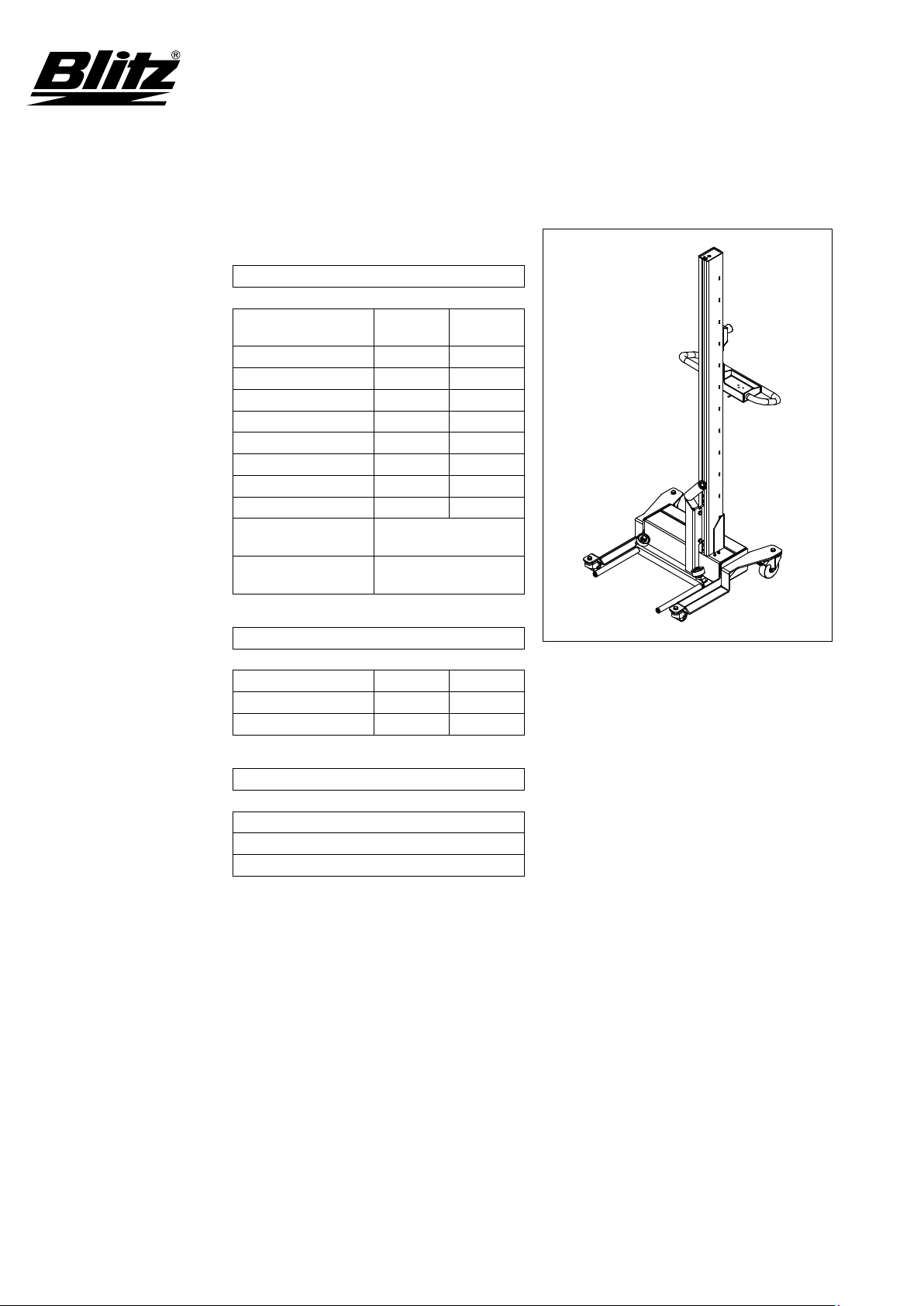

3 Technical data

Master Wheel 50

Load bearing capacity

Stroke mm 1400

Weight kg 60

Length mm 690

Width mm 730

Height mm 1860

Volume db(A) <75

Vibration m/s2 <2,5

Temperature range °C +10 - +40

Wheel dimensions

min.

Wheel dimensions

max.

Tab. 1:

Battery set

Quantity Units 2

Voltage V 24

Capacity Ah 7,2

Tab. 2:

Charger

kg 60

185/80

325/35

Fig. 1:

Safety installations

• Emergency off

• Up: power limitation 11 A= 60 kg

• Down: power limitation 4 A= 10 kg

• Spindle cover

• Electrical safety 16 A T

Adapter: EU,US,UK

Primary: 100-240V/ 47-63Hz/65W

Secondary: 24V, 1A, 24W

Tab. 3:

6

106431 03/15

Loading...

Loading...