Blitz GHUSLE, GWSK 2, GWS 2, GWUS 2, GWSKT Operating Instructions And Spare Parts List

...

Operating Instructions and Spare Parts

Rev. 0 126867 06/2018

Type

Serial number

Date

List for Suspended Pit Jacks

Original Operating Instructions in German

Series:

GHUSE / GHUSLE

Series:

GWS 2 / GWUS 2

Series:

GWSK 2 / GWSKT / GWSKTA

Series:

GH / GHL – GHS / GHSL

GHUS / GHUSL / GHUST

GHSP / GHLP

GHUSP / GHUSLP / GHUSTP

Series:

GHUSKTP

Series:

Blitz S 15 Vario

Operating Instructions for Suspended Jacks

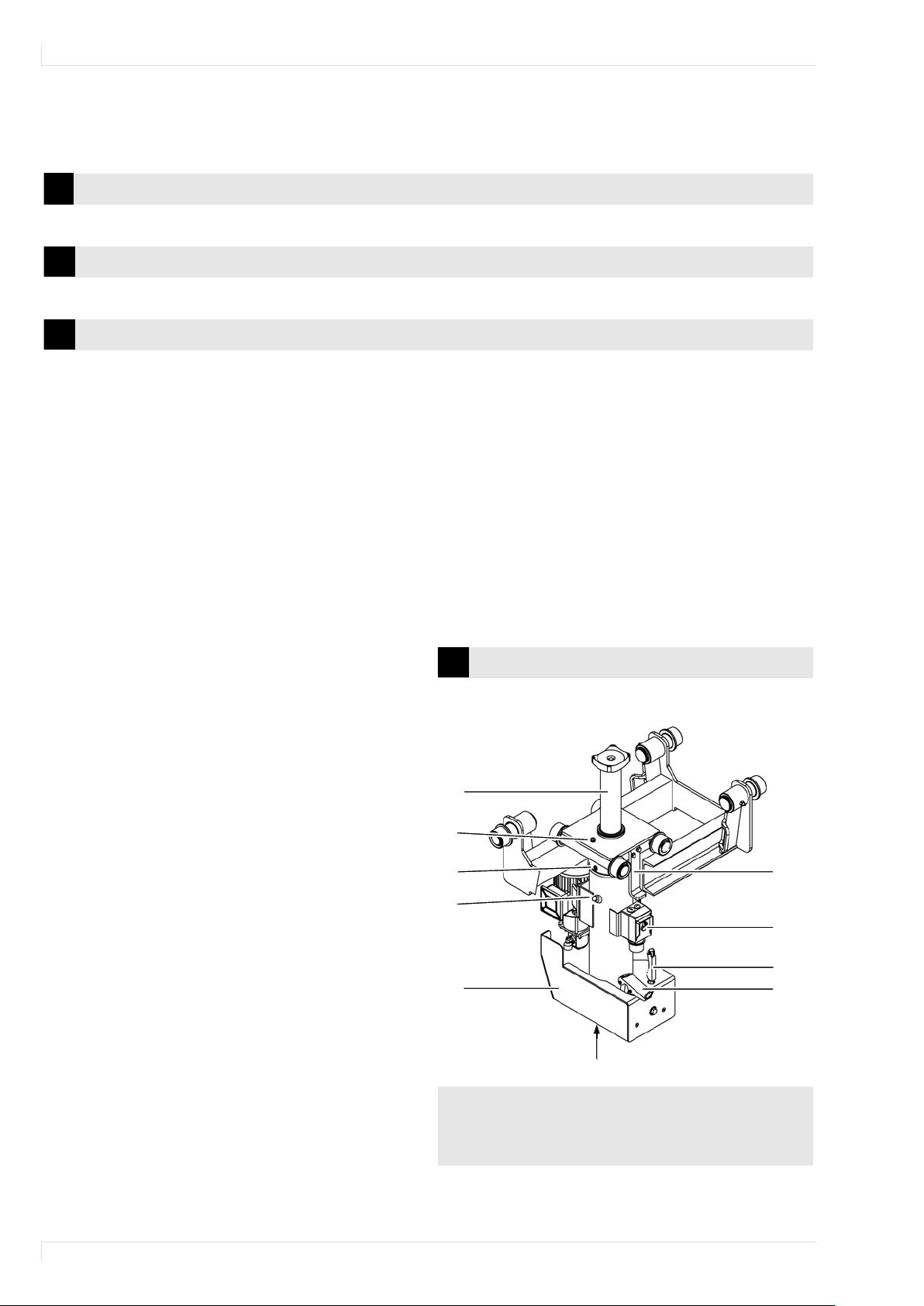

Component overview for all series

[1]

Tilt protection bar

[2]

Control elements

[3]

Drain valve

[10]

[4]

Manual pump

[9]

[5]

Oil drain plug load stroke

[8]

[7]

[1]

[6]

Compressed air supply

[2]

[7]

Oil dipstick load stroke

[3]

[8]

Oil drain plug retrieval

[11] [4]

[9]

Oil dipstick retrieval

[10]

Piston rod

[5]

[11] Cover

Series:

GHUSE

H

P

E

E

Concerning these operating instructions

These operating instructions apply to several series with three different construction methods:

Hydraulic (-pneumatic) construction

Pneumatic construction

Electrohydraulic construction

• Pictures or text sections marked with the symbols shown above only apply to the jacks of the respective construction.

• Position numbers [1] in the operating instructions always refer to the pictures shown here and the component

overview.

• Cross-references () must be taken into consideration.

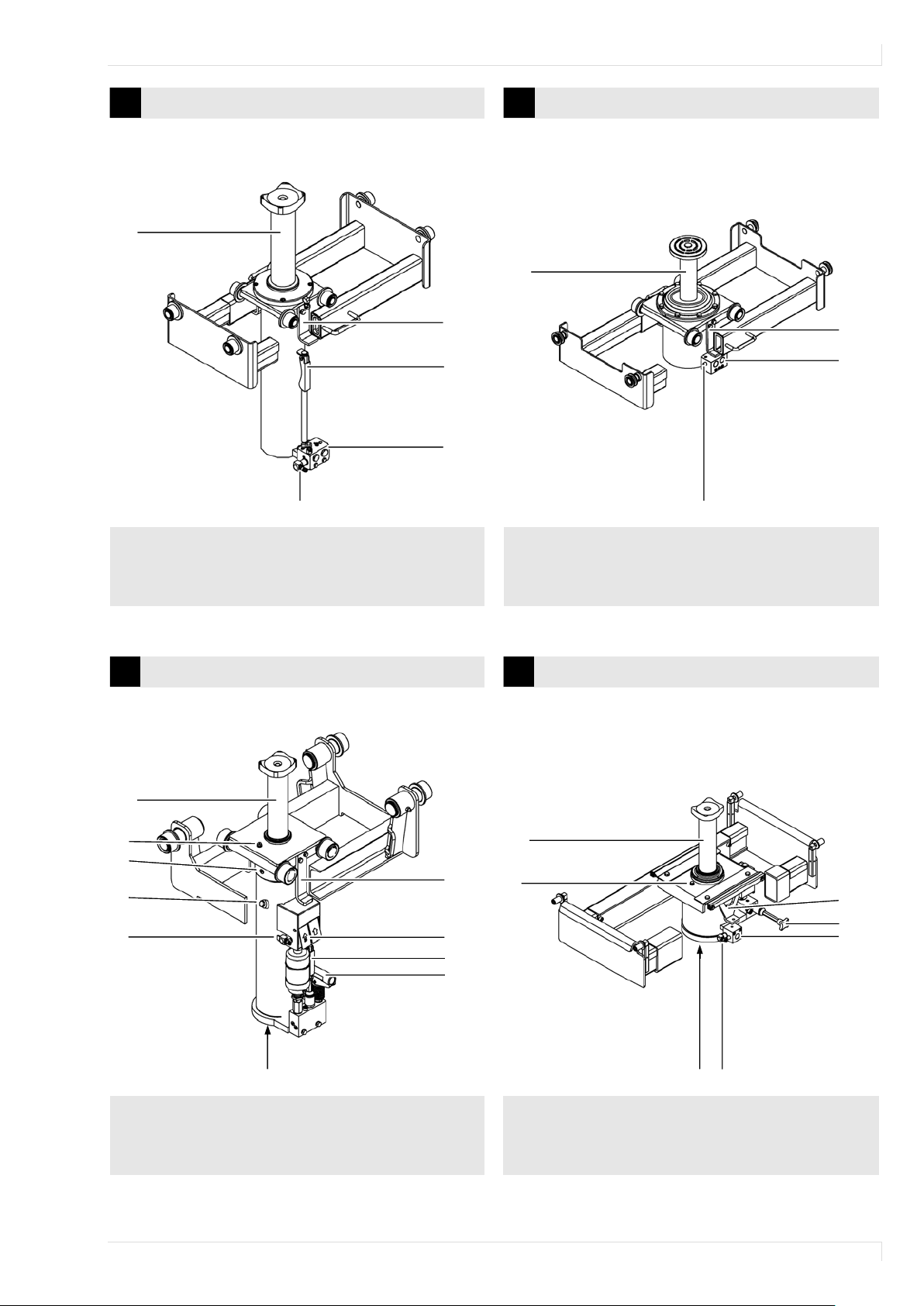

Overview of the Series

The overview shows a variant of each series.

2

/GHUSLE

Operating Instructions for Suspended Jacks

[10]

[1]

[10]

[1]

[2]

[3]

[2]

[6]

[6]

Series:

GWS 2

Series:

GWSK 2

[10]

[9]

[8]

[10]

[7]

[1]

[7]

[1]

[6]

[2]

[3]

[2]

[3]

[4]

[5]

[5] [6]

Series:

GH/GHL

GHUS/GHUSL/GHUST

GHSP/GHLP

Series:

GHUSKTP

P

P

H

H

GWUS 2

GWSKT GWSKTA

GHS/GHSL

GHUSP/GHUSLP/GHUSTP

3

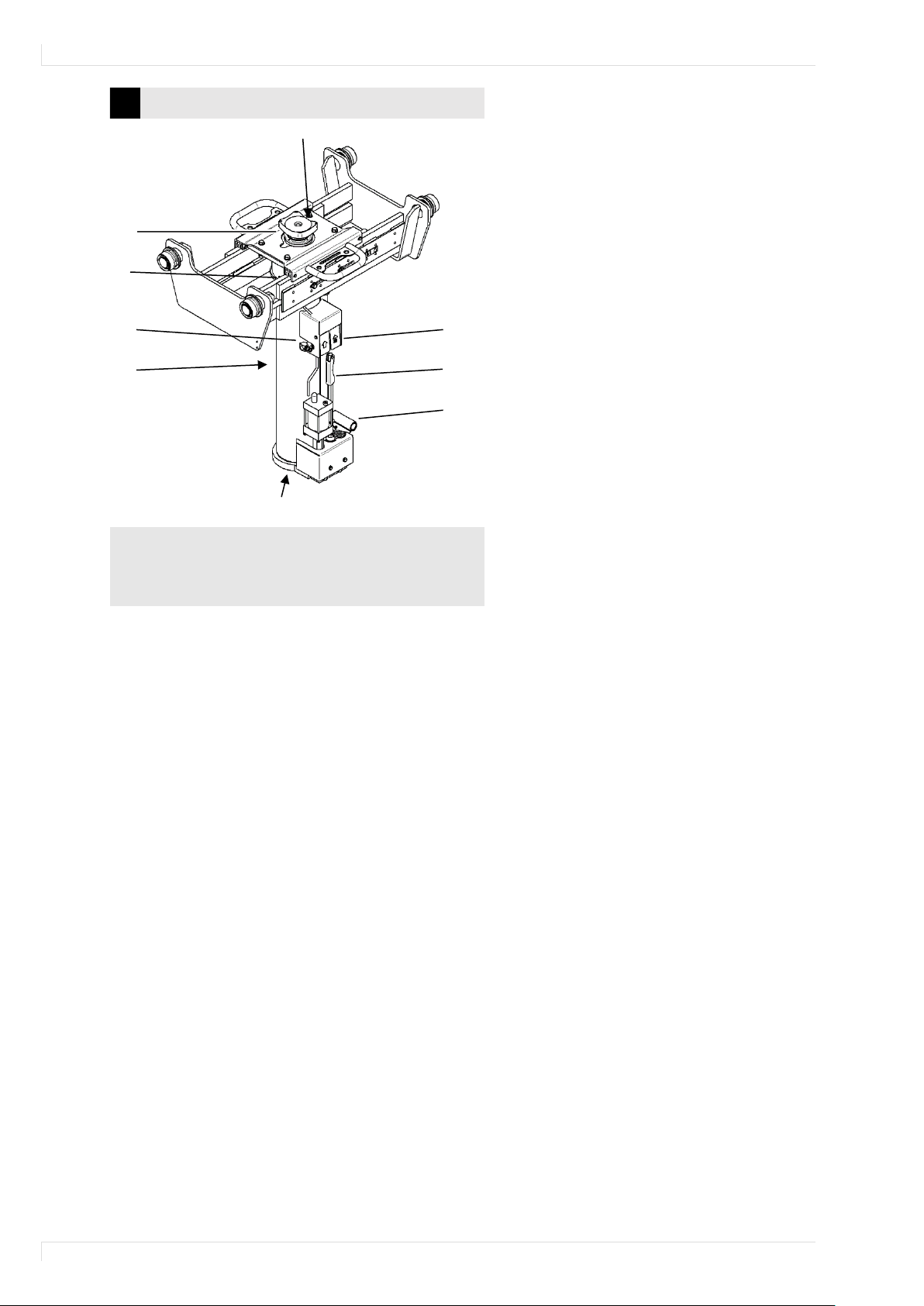

Operating Instructions for Suspended Jacks

[9]

[10]

[8]

[6]

[2]

[7]

[3]

[4]

[5]

Series:

Blitz S 15

H

Vario

4

Operating Instructions for Suspended Jacks

Table of Contents

1 Basic Safety Instructions ........................................................................................................ 6

1.1 Intended Use ................................................................................................................................................. 6

1.2 Basic Measures ............................................................................................................................................ 6

1.3 Safety-relevant Components ...................................................................................................................... 6

1.4 Explanation of Notes ................................................................................................................................... 6

2 Storage ......................................................................................................................................... 6

3 Technical Data ........................................................................................................................... 7

4 Transport, Installation and Assembly ................................................................................. 8

4.1 Make the Lifting Cylinder ready for Operation ........................................................................................ 8

4.2 Install and assemble Jack .......................................................................................................................... 9

4.3 Compressed Air Supply ............................................................................................................................ 12

4.4 Electrical Connection ................................................................................................................................ 12

5 Commissioning ........................................................................................................................ 12

6 Operation ................................................................................................................................... 12

6.1 Load Handling Device ............................................................................................................................... 12

6.2 Supporting Bridges and Trestles............................................................................................................. 13

6.3 Hazard Statements .................................................................................................................................... 14

6.4 Lift, lower and transport Loads ................................................................................................................ 15

7 Maintenance and Repair ....................................................................................................... 16

7.1 Maintenance Intervals ............................................................................................................................... 16

7.2 Perform Function Test............................................................................................................................... 16

7.3 Check Compressed Air Supply ................................................................................................................ 16

7.4 Top up Anti-Rust Oil .................................................................................................................................. 17

7.5 Check the Hydraulic Oil Level .................................................................................................................. 17

7.6 Perform Safety Test ................................................................................................................................... 17

7.7 Changing the Hydraulic Oil ...................................................................................................................... 18

7.8 Replacing Hydraulic Hoses ...................................................................................................................... 18

7.9 Drain the Condensate ............................................................................................................................... 18

7.10 Bleed the Jack ............................................................................................................................................ 18

7.11 Clean or replace the Pneumatic Control Valve ..................................................................................... 19

7.12 Replace Hydraulic Block .......................................................................................................................... 19

8 Troubleshooting ...................................................................................................................... 20

9 Decommissioning and Disposal ......................................................................................... 20

10 EC – Declaration of Conformity .......................................................................................... 21

11 Spare Parts Lists ..................................................................................................................... 22

5

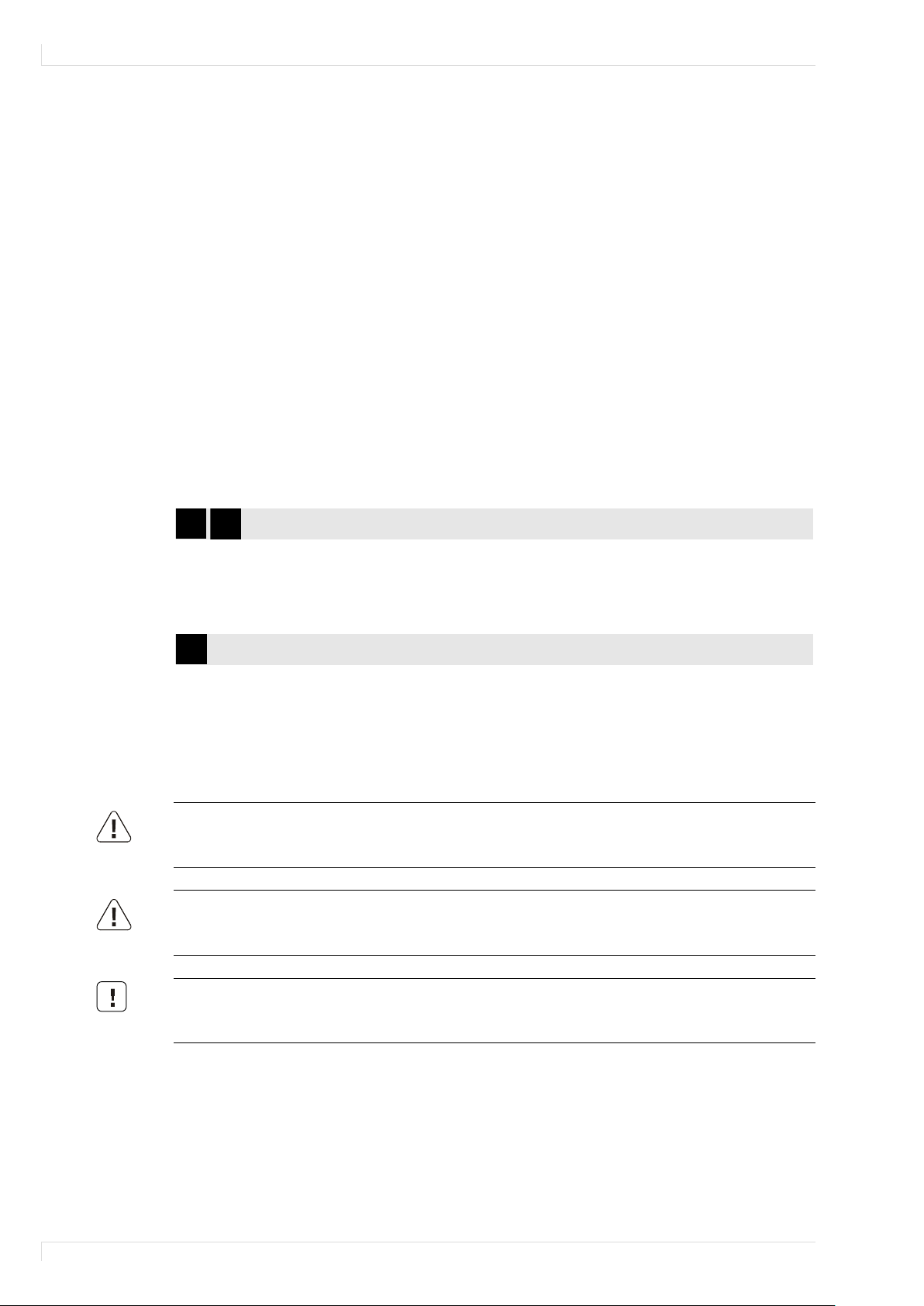

Operating Instructions for Suspended Jacks

H

E

P

1 Basic Safety Instructions

1.1 Intended Use

The jack is intended exclusively for partially lifting vehicles and for transporting vehicle parts

(engine, transmission). Any other use there of shall be considered as not intended use.

Always secure lifted vehicles with supporting bridges/A-frames.

1.2 Basic Measures

The lift may be used only by workshop personnel with corresponding training.

Work on electric, hydraulic, and pneumatic systems may be performed only by specialists.

Observe the operating instructions.

Always keep the operating instructions available at the place of use.

Observe all safety and danger notes on the lift and keep them legible.

The workshop operator must insure that all safety regulations are observed by the workshop

personnel.

Technological modifications of the lift are not permitted.

The operating instructions are a part of the product and must be handed over to a succeeding

user.

Observe the maintenance intervals.

1.3 Safety-relevant Components

• Hydraulic pressure limiting valve

• Hydraulic lowering brake valve

• Tilt protections [1] on the lifting cylinder

• Pull-out safety devices at the undercarriage ( 4.2, Positions A)

• Pressure limiting valve

• Throttle valve

• Tilt protections [1] on the lifting cylinder

• Pull-out safety device at the undercarriage ( 4.2, Positions A)

1.4 Explanation of Notes

DANGER

Risk of death and severe injury

Measures

WARNING

Risk of injury and material damage

Measures

CAUTION

Property damage

Measures

2 Storage

Store the jack in a dry place protected from the weather at an ambient temperature of -10 °C to +50

°C. Contact the manufacturer if storing for more than 6 months.

6

Operating Instructions for Suspended Jacks

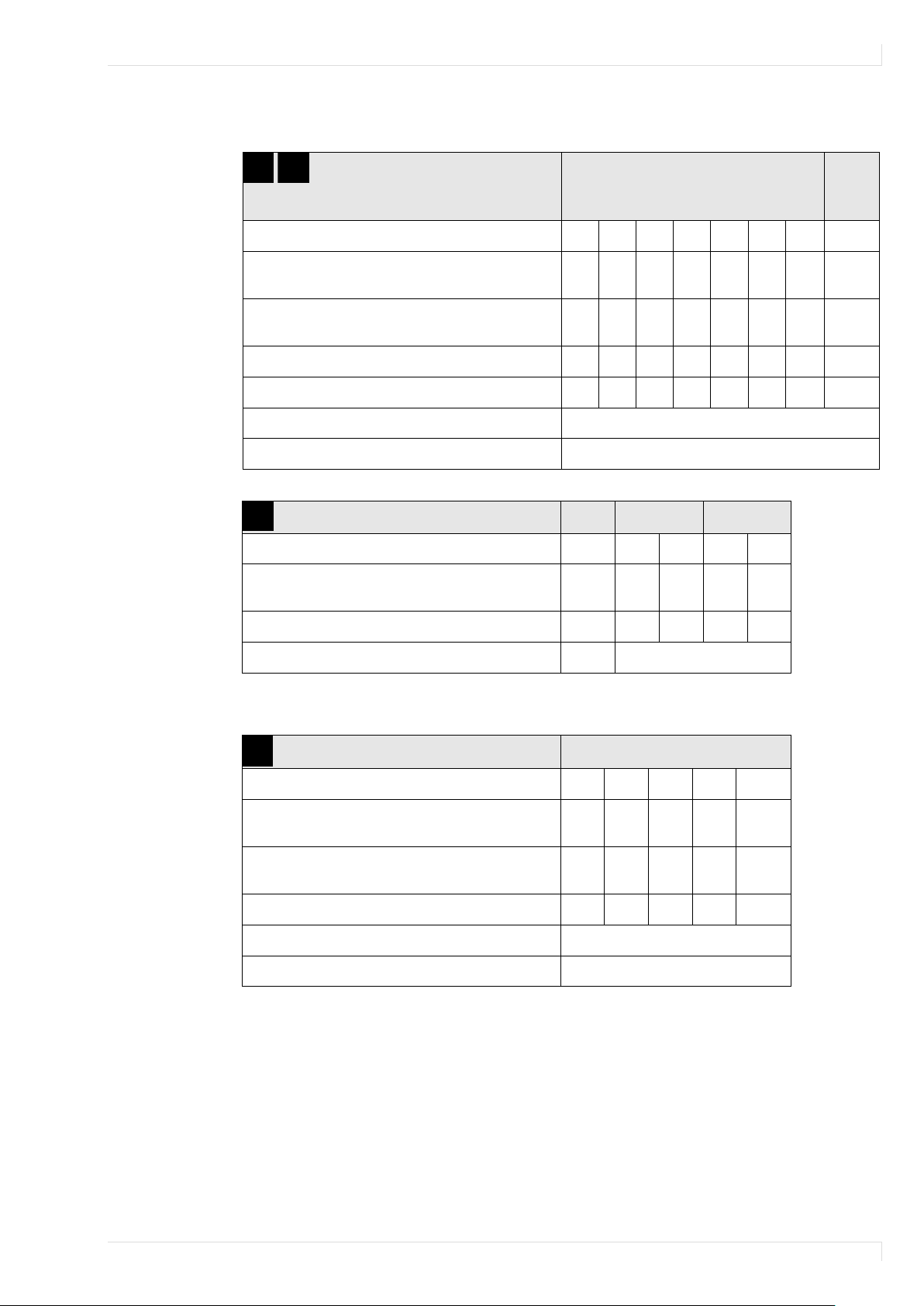

GH/GHL, GHS/GHSL,

GHUS/GHUSL/GHUST, GHSP/GHLP,

GHUSP/GHUSLP/SHUSTP

GHUSE/GHUSLE

Blitz S

15

VarioFit

Load capacity

t 4 6

10

15

16

20

30

15

Operating pressure pneumatically

bar

10

10

10

10

10

Operating pressure hydraulically

bar

80

120

199

235

130

Oil capacity container 1

l 5 5 5 5

12

Oil capacity container 2

L

1.2

1.2

1.2

1.3

2.1

2.1

2.1

1.6

Lifting height (L models)

mm

600 (800)

Max lowering speed at rated load

m/s

0.15

GWS 2

GWUS 2

GWSKT

GWSKTA

Load capacity

t 2 3/2.5

4/3.5

2/1.5

3/2.5

Operating pressure pneumatically

bar

12

10

14 8 10

Lifting height

mm

500

420

420

285

345

Max lowering speed at rated load

m/s

0.15

0.15

GHUSKTP

Load capacity

t

4/4

6/6

10/10

12/12

14/14

Operating pressure pneumatically

bar

10

10

10

10

10

Operating pressure hydraulically

Bar

70

105

175

210

245

Oil capacity container

l

4.1

4.1

4.1

4.1

4.1

Lifting height

mm

330

Max lowering speed at rated load

m/s

0.15

H

E

P

H

3 Technical Data

7

Operating Instructions for Suspended Jacks

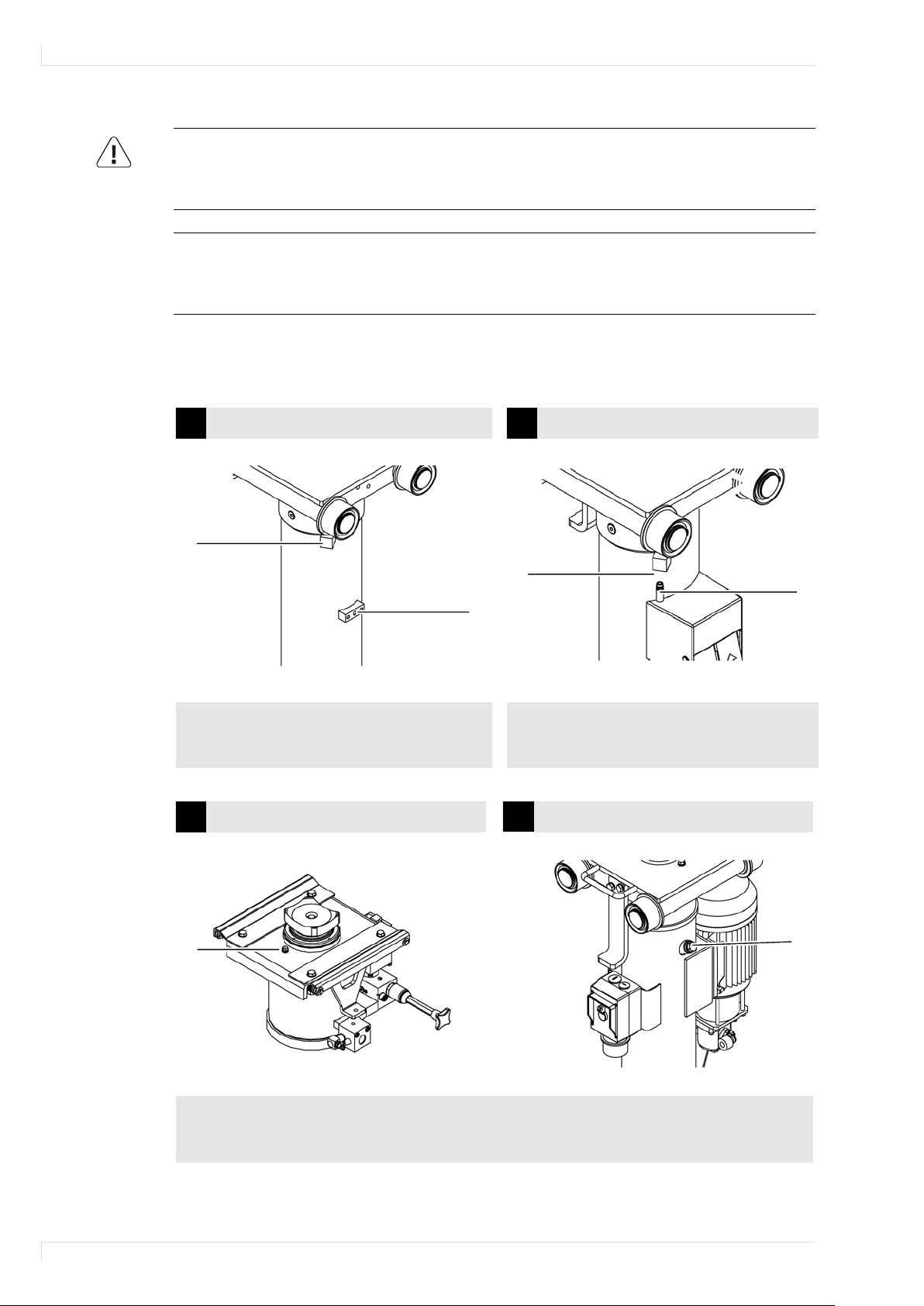

B

Remove cap A.

Remove cap A.

D

Replace cap D with the supplied ventilation screw.

H

H

H

E

4 Transport, Installation and Assembly

DANGER

Risk of death and severe injury from improper transport

Always transport the lift table with suitable hoisting and transport devices (e.g. forklift or crane).

Never stay under suspended loads.

Safety notes

Hoist the jack at viable spots only.

Move the lifting cylinder horizontally and with the operating elements at the top.

Secure moving and loose parts.

4.1 Make the Lifting Cylinder ready for Operation

Note variants of the hydraulic construction.

Without operating elements

With operating elements

A

In addition, replace cap B with the supplied

ventilation screw.

A

For jacks with retrieval, connect hose C.

C

D

8

Operating Instructions for Suspended Jacks

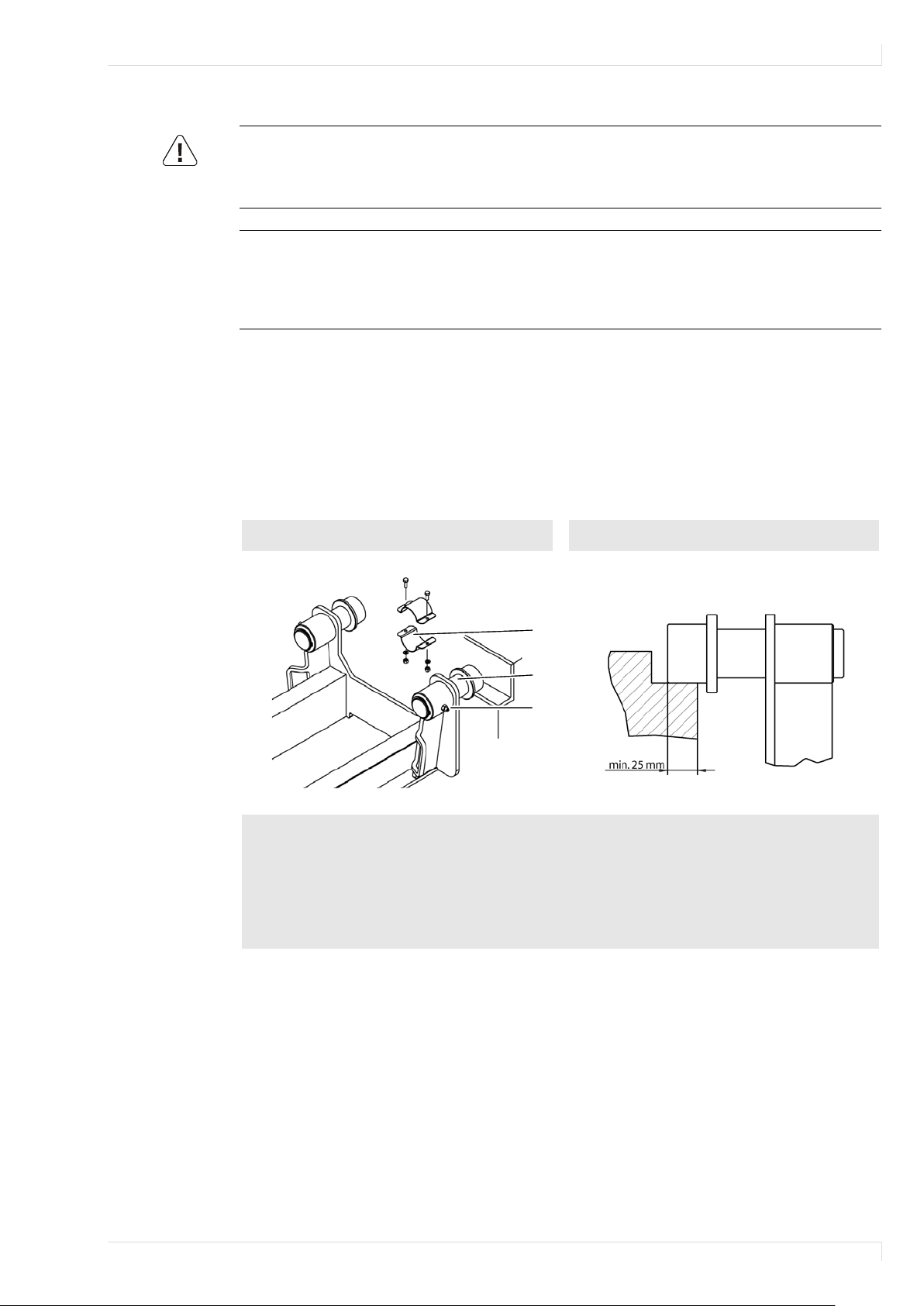

A

B

Insert undercarriage in rails.

undercarriage and replace the tilt protection bracket on both sides.

4.2 Install and assemble Jack

WARNING

Risk of injury and material damage by crashing jacks

Install jack only on level and solid ground, which has the necessary load-bearing capacity.

Use jack only on load-bearing and parallel rails.

Safety notes

Use jack only with castors that fit the rails.

Only use the jack in the workshop pit or lift for which it was made.

If the distance between the rails of vehicle lifts (e.g. scissor lifts) changes due to alternating load,

additional fuses need to be requested from the manufacturer.

There are five types of undercarriages:

• Undercarriages with sliding axles (adjustable)

• Undercarriages with telescopic carriers (adjustable)

• Single-piece undercarriages (rigid)

• Two-piece undercarriages (rigid)

• Transverse and height-adjustable undercarriages

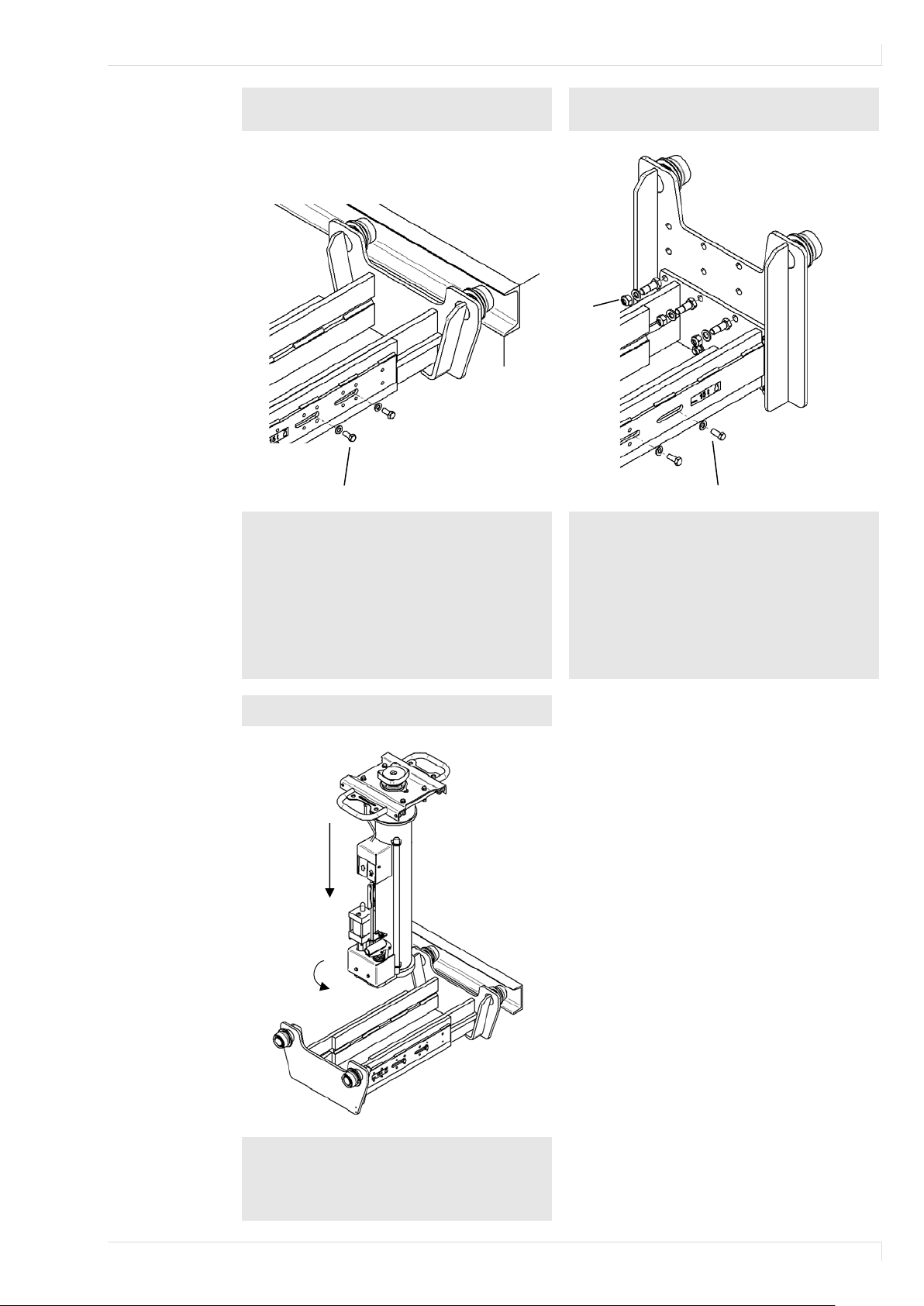

Undercarriages with sliding axles

Standard castors

C

Pull out sliding axes B evenly and set the track width.

Tighten set threaded pins C.

Check the secure support of the castors (standard castors min. 25 mm) over the entire length of

the rails.

Adjust enclosed clamping collars A and attach externally to sliding axles B.

Dismantle the tilt protection bracket [1] on the lifting cylinder, insert the lifting cylinder into the

9

Operating Instructions for Suspended Jacks

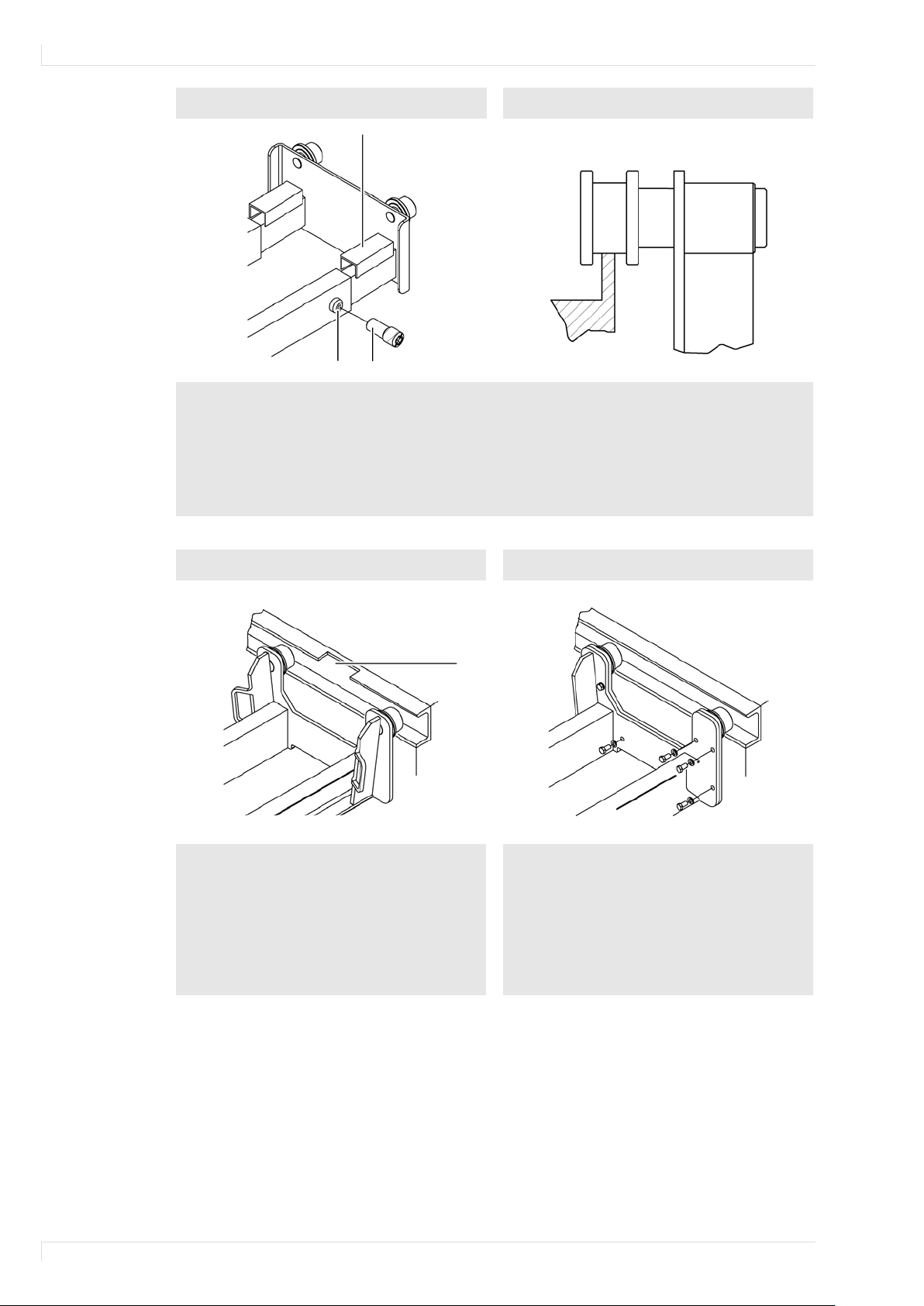

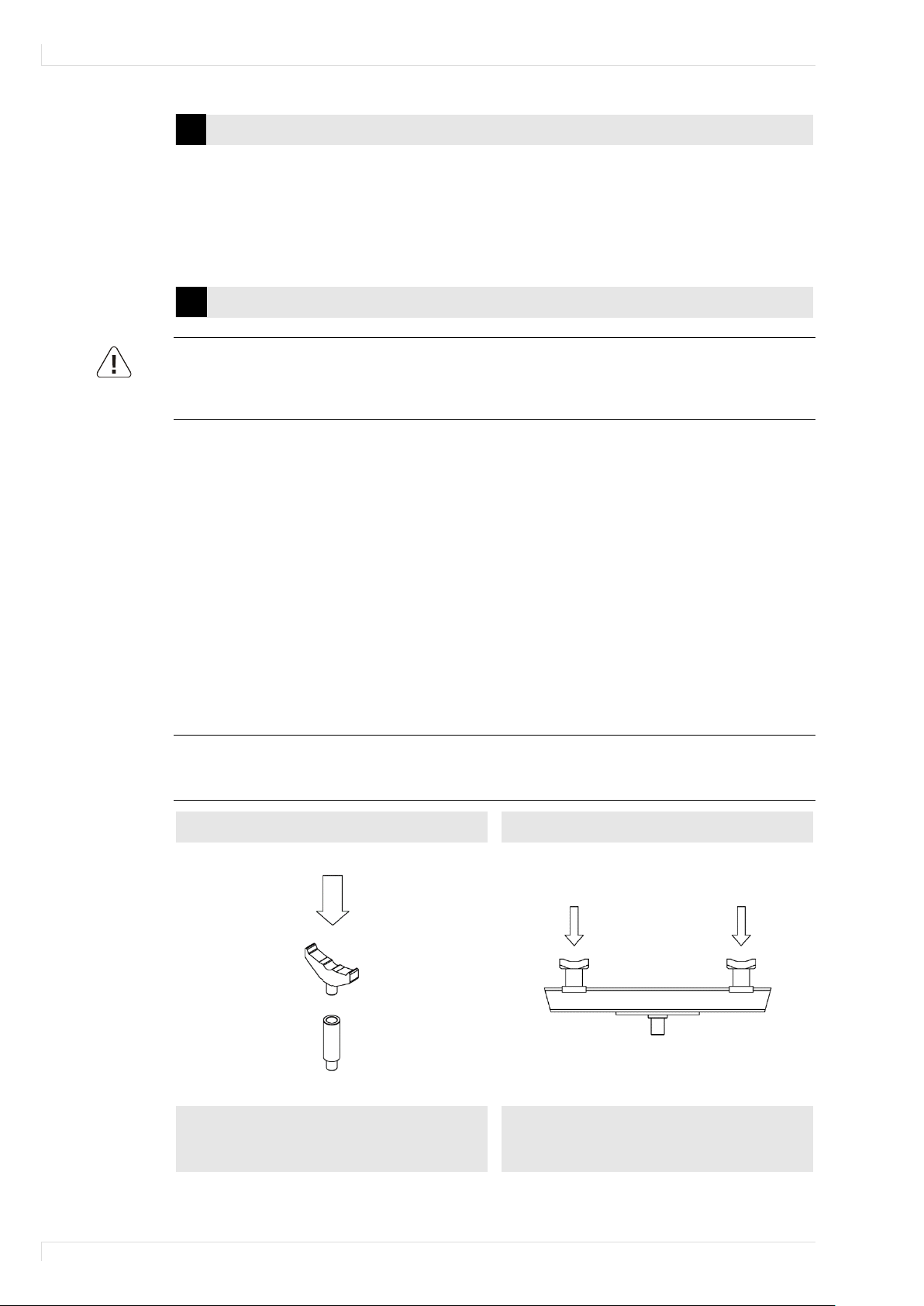

Undercarriages with telescopic carriers

C

B

A

Insert undercarriage in rails and set track width.

undercarriage and replace the tilt protection bracket on both sides.

Single

Two

E

Insert undercarriage via installation opening E

Dismantle the tilt protection bracket [1] on the

protection bracket on both sides.

Insert undercarriage components in rails and

Dismantle the tilt protection bracket [1] on the

protection bracket on both sides.

Remove threaded pins A and drill hole B to 8 mm.

Install threaded pins A with thread outwards and tighten.

Check the secure support of the castors (standard castors min. 25 mm) over the entire length of

the rails.

Adjust and place U profiles C.

Dismantle the tilt protection bracket [1] on the lifting cylinder, insert the lifting cylinder into the

-piece undercarriages

-piece undercarriages

Special castors

10

into rails.

Check the secure support of the castors

(standard castors min. 25 mm) over the entire

length of the rails.

lifting cylinder, insert the lifting cylinder into

the undercarriage and replace the tilt

firmly connect with enclosed screws.

Check the secure support of the castors

(standard castors min. 25 mm) over the entire

length of the rails.

lifting cylinder, insert the lifting cylinder into

the undercarriage and replace the tilt

Operating Instructions for Suspended Jacks

Transverse and height

undercarriage

B

A A

Insert undercarriage in rails and set track

Secure the undercarriage width with screws A

Screw side plates to desired height on the

cure the undercarriage width with screws A

(2 pcs. per side) to 30 Nm.

Lift the jack into the undercarriage and lower

Set jack down on the undercarriage

A

B

Transversely adjustable undercarriage

width.

Check the secure support of the castors

(standard castors min. 25 mm) over the entire

length of the rails.

(2 pcs. per side) to 30 Nm.

-adjustable

undercarriage.

Tighten all screws B with a torque wrench to

80 Nm.

Insert undercarriage in rails and set track

width.

Check the secure support of the castors over

the entire length of the rails.

Se

Transversely adjustable undercarriage

it (A) until the operating element [2] is just

below the guide rails

Turn the jack 90° (B)

11

Operating Instructions for Suspended Jacks

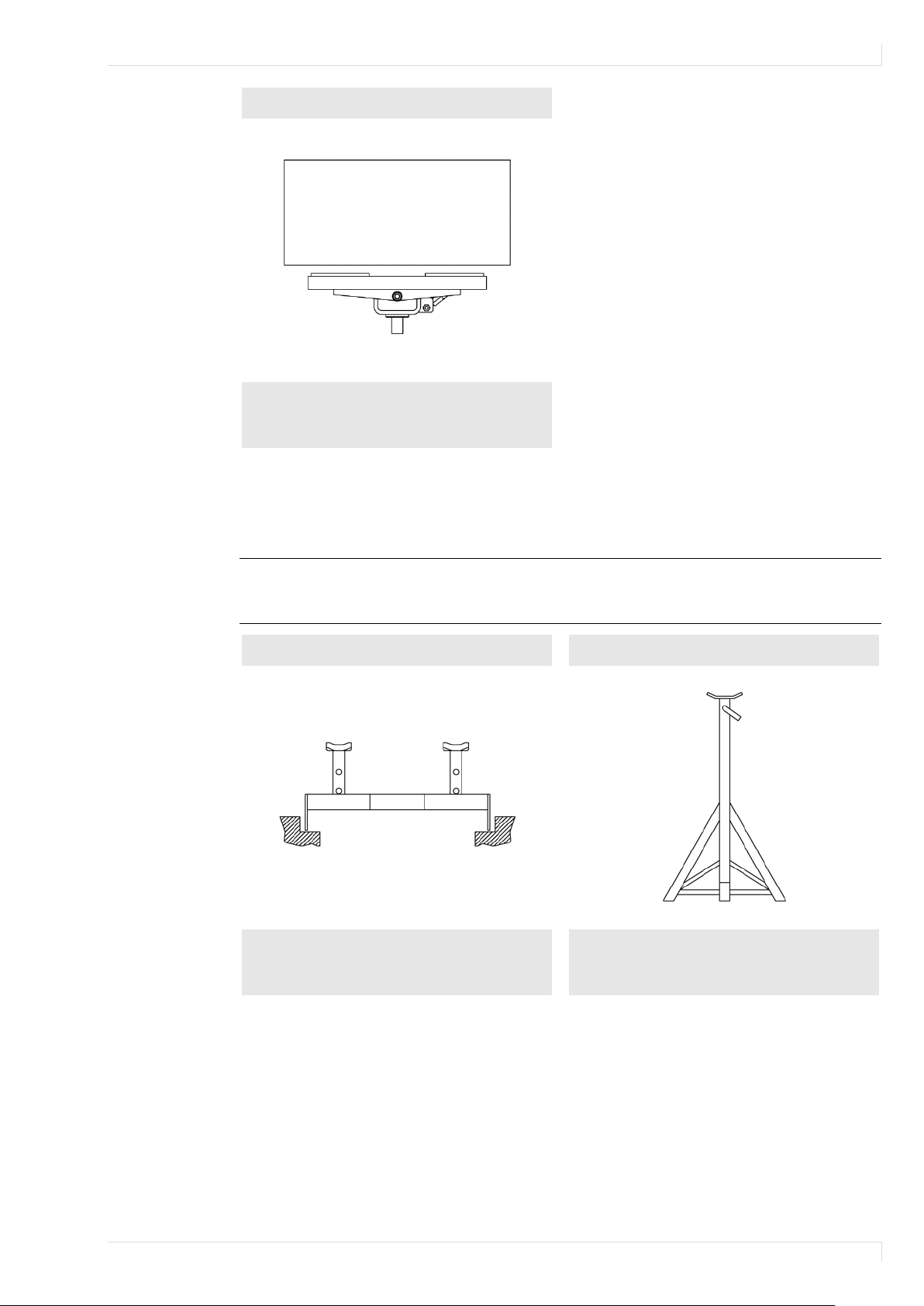

Support plate and extension

Traverse

Lift vehicles at one point.

Carefully lift vehicles at two points.

H

E

4.3 Compressed Air Supply

The compressed air supply must be provided via a maintenance unit consisting of water separator

and pressure reducer. Attach the maintenance unit directly to the jack.

• Supply pressure: max. 10 bar

4.4 Electrical Connection

WARNING

Risk of injury and material damage due to electric shock

The electrical connection and the protective measures in force in the country are to be installed

and checked by a specialist.

The electrical connection must consist of a cable with a five-pin CEE coupling 16 A, which is

connected to a 400V/50Hz mains. A motor-protective circuit-breaker of 3.8 A must be present.

The manufacturer recommends a suitable cable suspension.

5 Commissioning

Before first operation:

Connect compressed air supply or electrical connection to the jack.

Check the hydraulic oil level. ( 7.5)

Perform the safety test. ( 7.6)

6 Operation

6.1 Load Handling Device

Safety notes

Do not stack extensions.

Always use the manufacturer’s original load handling devices with suitable spigots.

12

Operating Instructions for Suspended Jacks

Remove, install and transport vehicle parts

Trestle

For use in workshop pits.

For use on workshop floors,

e.g. under lifts.

Transmission plate

safely.

For poorly accessible load application points on the vehicle use special support plates and an

extension, if necessary. For more information on all load handling devices, contact the manufacturer.

6.2 Supporting Bridges and Trestles

Safety notes

Ensure the secure support of the supporting bridges/trestles over the entire length of the

workshop pit or workshop floors.

Supporting bridge

For more information on all load handling devices, contact the manufacturer.

13

Operating Instructions for Suspended Jacks

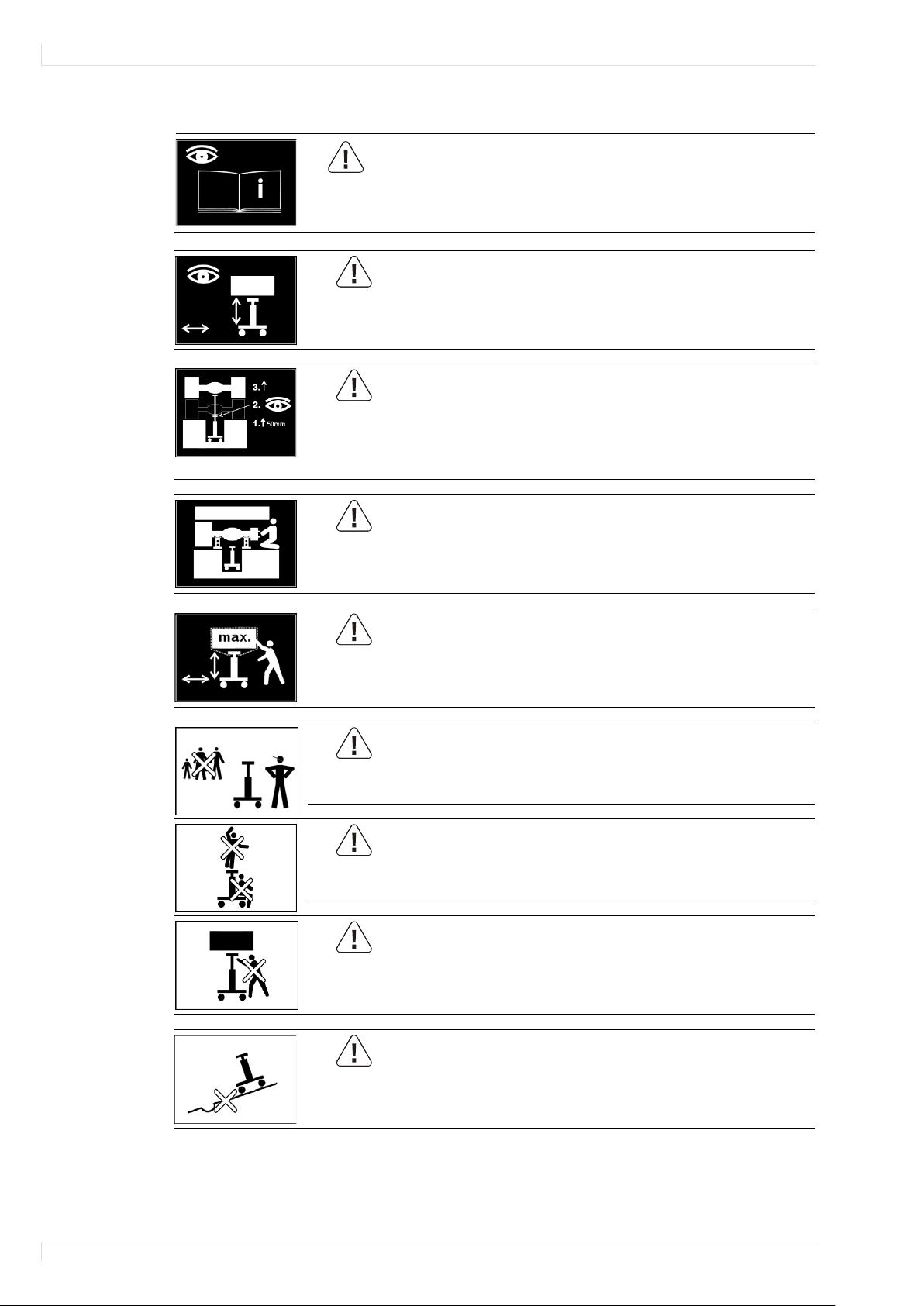

6.3 Hazard Statements

Observe the operating instructions.

Operate the lift only when there is no risk for persons.

Always observe lifting and lowering movements.

Use the lift only in a safety-technologically correct condition.

The safe vehicle support should always be checked after briefly lifting it.

Always use suitable load handling devices.

Attach load handling devices only to horizontal, level and load-bearing

Load application points, which are specified by the vehicle manufacturer.

Always secure lifted vehicles with supporting bridges/A-frames.

Do not exceed the max. load-bearing capacity of the lift.

Secure the vehicle part with chains or belts.

Transport vehicle parts only in lowered condition.

The lift may be used only by workshop personnel with corresponding training.

Lifting of persons and climbing onto the lift and the load are not permitted.

Never stay under suspended loads.

Use jack only on level and firm ground.

CAUTION

DANGER

DANGER

DANGER

DANGER

CAUTION

CAUTION

CAUTION

CAUTION

14

Loading...

Loading...