Page 1

BLAKESLEE

Division of Blako Inc.

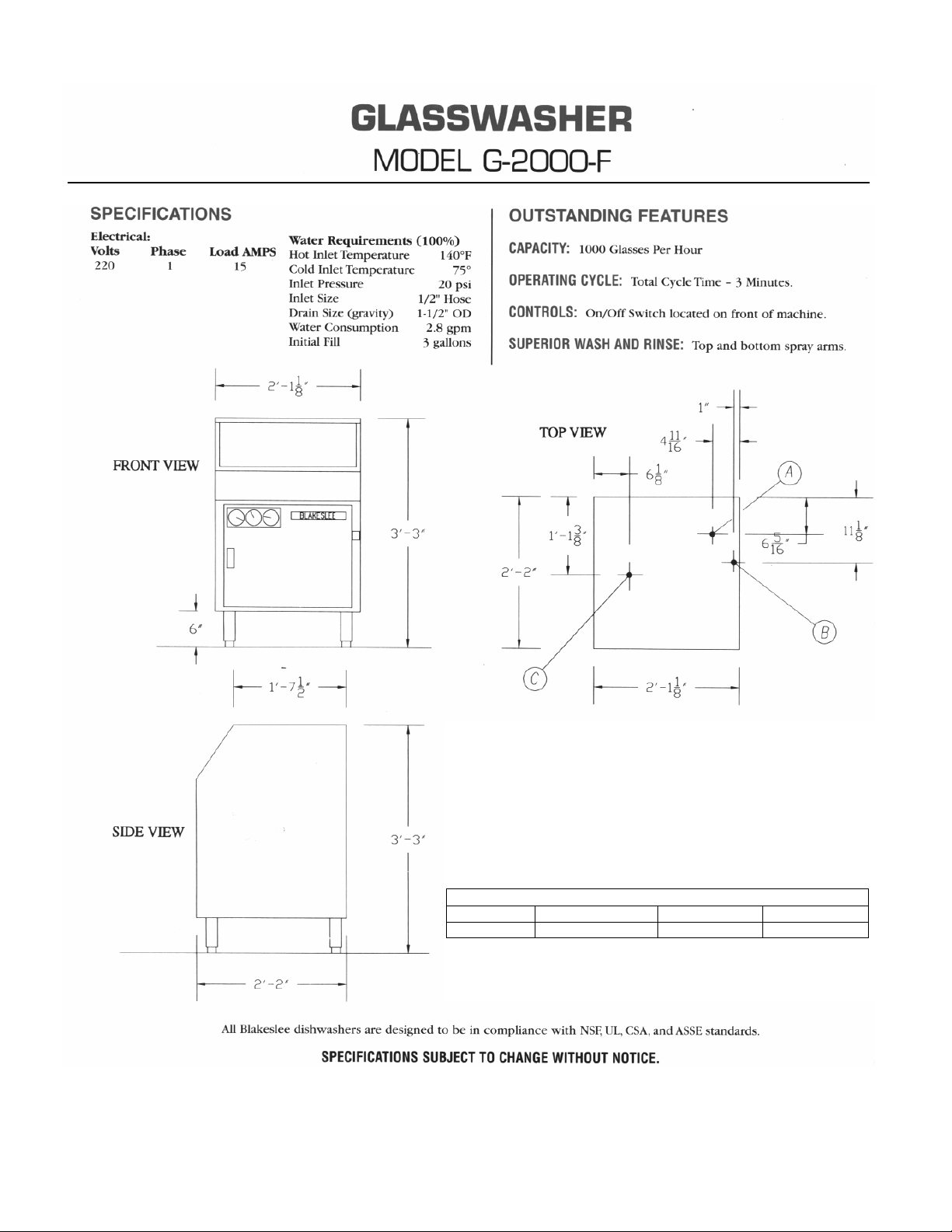

GLASSWASHER

MODEL G-2000-F

OWNERS

MANUAL

1844 South Laramie Avenue

Chicago, IL 60804

Phone (708) 656-0660

Fax (708) 656-0017

www.blakesleeinc.com

service@blakesleeinc.com

1149 Bellamy Road North Unit 19

Scarborough, Ontario Canada M1H1H7

Phone (416) 751-2625

Fax (416) 751-8539

Page 2

INDEX

PAGE

NO.

SPECIFICATIONS 1

SECTION I OPERATION 2

SECTION II DAILY CHECK-OUT 3

SECTION III CLEANING 4

SECTION IV TROUBLE SHOOTING 5

SECTION V PARTS ILLUSTRATIONS 7

WIRING DIAGRAM 16

CLEANING TOOL 18

WARRANTY 19

Page 3

(A) HOT WATER CONNECTION (1/2” N.P.T. FEMALE FITTING)

(B) COLD WATER CONNECTION (1/2” N.P.T. FEMALE FITTING)

(C) 1-1/2” O.D. DRAIN

NOTE: If your water pressure is over 25 psi; installation of a

pressure reducing valve is necessary.

It is recommended that check valves be installed in both incoming

water supplies.

APPROXIMATE SHIPPING INFORMATION

MODEL DIMENSIONS WEIGHT CUBE

G-2000-F 47” xX27” X 28.5 160 lbs. 21.0 Ft.

1

Page 4

SECTION I OPERATION

1-1 Water

The wash tank is equipped with a float assembly that

turns water off when proper level is achieved.

The water temperature is controlled by a heater and a

thermostat. The thermostat should be set to provide a

wash water temperature between 145° F /60° C and

160° F /71° C.

1-2 Filling Wash Tank

Ensure that the standpipe is in place. Put the toggle

switch in the “AUTO” position. This will also turn the

heater on. To start the conveyor and detergent pump,

put the main switch on the front of the machine in the”

ON” position.

Detergent is fed from the supply container into the

detergent tank in controlled amounts by the detergent

pump. Use detergent at strength of 0.35% or as

recommended by your chemical supplier to

accomplish the necessary cleaning job.

NOTE: Use a heavy-duty NON-CHLORINATED liquid

detergent manufactured specifically for glassware

washing machines.

Your chemical representative will test the solution to

insure the proper strength is recommended.

NOTE: Many of the detergents used in glass and

dishwashers are harmful to the skin in their

concentrated form. To prevent accidental exposure to

this danger, be sure all hoses are secure and clamped

after service to machine.

1-3 Chemical Settings

Approximate chemical settings can be obtained by

counting the revolutions of the injector rotors.

For detergent, one revolution per second equals

approximately .035% concentration.

For sanitizer, one revolution in 5 seconds equals

approximately .035% concentration

For rinse agent, on revolution in 8 seconds is

suggested.

1-4 Detergent Injector Adjustment

1. Install the detergent tank standpipe and switch tank

fill toggle switch to “AUTO” position. The detergent

feeder will now feed detergent into the detergent tank

with water fill.

2

2. To increase detergent volume, turn the detergent

adjustment screw clockwise.

3. To decrease detergent volume, turn the detergent

adjustment screw counter-clockwise.

1-4 Sanitizer Injector Adjustment

The sanitizer is automatically fed into the line through

the sanitizer injector. Injection is into the final rinse

sprays.

1. When a new sanitizer container is installed, push

the prime button in and hold until sanitizer feed tubes

are full.

2. Start the washer—take a sample from the final rinse

spray tubes.

3. To increase sanitizer volume, turn the detergent

adjustment screw clockwise.

4. To decrease sanitizer volume, turn the detergent

adjustment screw counter-clockwise.

NOTE: If iodophor is being used as a sanitizer, it is not

necessary to use a separate rinse agent. To turn the

rinse agent injector “OFF” in this case, turn the

adjustment screw counter-clockwise until the rotor

stops turning.

NOTE: If chlorine is being used, a separate rinse

agent is required to prevent spotting.

1-5 Rinse Agent Injector Adjustment

1. When a new rinse agent container is installed, push

the prime button in and hold until sanitizer feed tubes

are full.

2. Start the washer—take a sample from the final rinse

spray tubes.

3. To increase rinse agent volume, turn the detergent

adjustment screw clockwise.

4. To decrease rinse agent volume, turn the detergent

adjustment screw counter-clockwise.

NOTE: The above only allows for testing the sanitizer

being fed. Actual sanitizing rinse solution should be

tested by your chemical supplier representative.

NOTE: To meet the requirement of N.S.F. standards,

iodophor in a concentration of 12.5 p.p.m. of chlorine

at 50 p.p.m. must be used in the final rinse.

Page 5

SECTION II DAILY CHECK-OUT

1. Clean machine. (See cleaning instructions on next page.)

2. Drain deflector is in position in drain.

3. Splash curtain is in position.

4. Right and left-hand trays are in position

5. Wash return screen for wash water is clean and in place.

6. Standpipe in the detergent tank is in place.

7. Bottom drain screen is in position.

8. Ensure that the mixing valve is adjusted.

9. Place the fill valve switch in “AUTO” position.

10. Wait for the detergent tank to reach the desired temperature.

(145° F /60° C and 160° F /71° C.)

11. Check the detergent, sanitizer, and rinse agent supply.

12. Switch the Glasswasher on.

3

Page 6

SECTION III CLEANING

Daily Cleaning Instructions:

1. Run glassware through the machine, and then clear the conveyor of glassware.

2. Turn the machine off.

3. Remove right and left-hand trays and splash curtain. Wash with hot soapy water, rinse thoroughly, and

then dry.

4. Remove the conveyor as follows:

• Remove sleeve in center of conveyor.

• Lift back of conveyor until it is free of drive gear.

• Raise front of conveyor and remove from wash section.

5. Remove drain deflector screens. Clean, wash and rinse areas with hot soapy water, rinse thoroughly,

then dry.

6. Replace drain deflector screens, conveyor, right and left-hand trays, and splash curtain. Ensure

conveyor is level and engaged with drive gear.

7. Turn auto fill switch to “OFF” position.

8. Remove wash return screen from below detergent tank. Clean and replace.

9. Turn fill switch to “AUTO” position.

10. Ensure there is product in the detergent, sanitizer, and rinse agent containers.

11. Check the detergent, sanitizer and rinse agent feed lines to ensure they are in place and securely

clamped.

4

Page 7

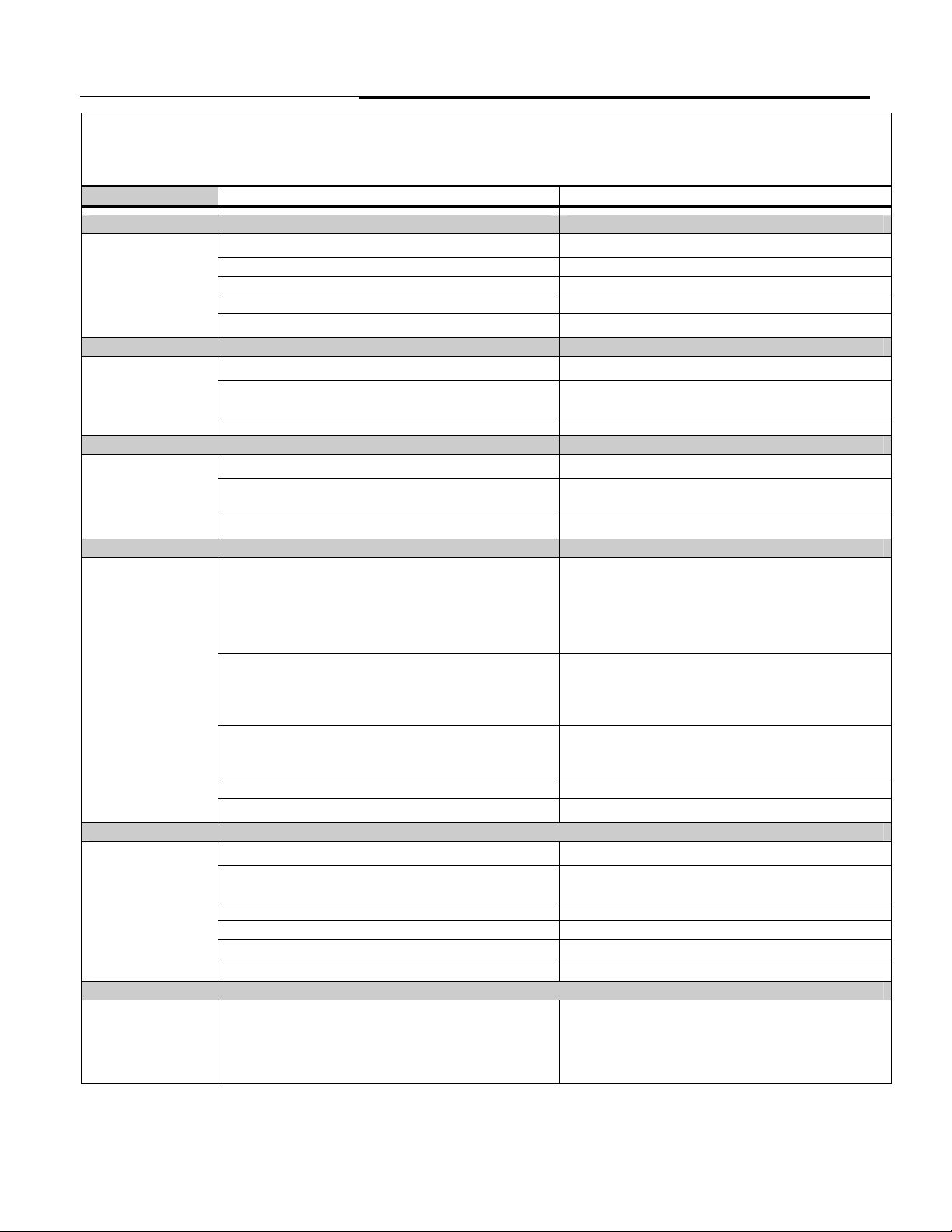

SECTION IV TROUBLE SHOOTING

Trouble shooting procedures are listed in the following table. Each trouble is followed by a list of possible causes

and suggested procedures to correct the cause.

In general, the procedures should be performed in the order in which they are listed.

Trouble Possible Cause Corrective Procedure

1. Conveyor does not turn

No power

Check the fuse on panel.

Drive motor burnt out Replace motor

Obstruction in wash or rinse section Remove the obstruction

Table limit switch not making contact or faulty Adjust micro-switch or replace if faulty

Conveyor not in position

2. Overspray from hood section

Splash curtain not in position

Washer running without any glasses on

Position properly

Reinstall splash curtain

Load conveyor with glasses

conveyor

Spray boxes plugged Clean thoroughly, use jet reamer provided

3. Chemical containers filling with water

Dirty rinse spray box

Element tube stretched; pinhole in tubing;

Refer to cleaning section

Replace tubing

loose hose ties

Worn flow washer in solenoid valve

4. Lack of pressure at wash spray tubes

No water in detergent tank

Replace flow washer

a. Make sure stand pipe is in place in tank

b. Check that the fill switch is in “AUTO”

position and that tank fills

c. Make sure that the float switch is operating

d. Check that the fill solenoid is operating

Pump not operating a. Check power supply to machine

b. Check pump capacitor, replace if

necessary

c. Replace pump if necessary

Pump defective a. Replace pump impeller if not working

correctly

b. Check for voltage drop

Wash spray box dirty Clean thoroughly, use jet reamer provided

Supply line plugged

5. Lack of pressure in spray boxes

Shut-off valve on supply line closed

Clear line of cause

Open valve

Low water pressure Have pressure taken on main cold water line

to machine. Pressure must be 25 p.s.i.

Rinse solenoid will not operate Replace coil if necessary

Rinse solenoid strainer plugged Clean or replace

Spray boxes plugged Clean thoroughly, use jet reamer provided

Supply line plugged

6. Continual flow of water through detergent tank or spray boxes with machine off

Solenoid valve not seating

Clear line of cause

a. Turn off water supply

b. Take apart and clean thoroughly

c. If above does not cure, replace plunger

and seat

5

Page 8

7. Hot water below required temperature in detergent tank

Thermostat set too low

Heater not on Check for power from switch to thermostat

Heater burned out Replace heater, Check float to insure heater

Thermostat defective Replace thermostat

Incoming water too cold Incoming water should be at 145° F /63° C

Rinse temperature should be a minimum of

8. Water on floor

Pump seal leaking

Rinse drain in wash chamber plugged Clear obstruction, clean machine

Wash drain in wash chamber plugged Clear obstruction, clean machine

Wash return screen in detergent tank plugged Clean screen

Drain screen under detergent tank plugged Clean screen

Main drain plugged

10. Sanitizer not feeding

No sanitizer in the container

Sanitizer crystallized or turned to gel, plugging

lines

Strainer at end of feed line in container

plugged

Sanitizer pump defective Replace pump

No sanitizer being fed Chemical adjustment set to low. Turn screw

Adjustment screw does not affect feed rate

11. Rinse agent not feeding

No rinse agent in the container

Rinse agent crystallized or turned to gel,

plugging lines

Strainer at end of feed line in container

plugged

Sanitizer pump defective Replace pump

No sanitizer being fed Chemical adjustment set to low/ Turn screw

Adjustment screw does not affect feed rate

6

Increase temperature by turning thermostat

clockwise

replace switch if necessary

is exposed when operating

minimum at supply for wash temperature.

Check supply

75° F. /24° C. To increase rinse temperature,

open mixing valve on inlet plumbing

Replace pump

Clean drain

Refill the container

Clean feed lines and sanitizer feeder, flush

with hot water. Use a fresh supply of

sanitizer

Remove feed line from container and clean

strainer

clockwise to increase rate of feed

Replace chemical injector control board

Refill the container

Clean feed lines and rinse agent feeder, flush

with hot water. Use a fresh supply of

sanitizer

Remove feed line from container and clean

strainer

clockwise to increase rate of feed

Replace chemical injector control board

Page 9

SECTION V PARTS

PROTECT YOUR EQUIPMENT

USE GENUINE BLAKESLEE PARTS

7

Page 10

MAIN ASSEMBLY

8

Page 11

ITEM

NO.

PART

NO.

1 76973 UPPER SPRAY BOX 2

2 77019 UPPER SPRAY BOX BRACKET 2

3 76962 LOWER SPRAY BOX 4

4 No Longer Used

5 76152 O-RING 1

6 75953 TRAY-R.H. 1

7 75954 TRAY-L.H. 1

8 75967 CENTER CO

9 76066 TURNTABLE WELDME

10 76000 ROLLER ASSEMBLY 4

11 76035 CURTAIN 1

12 76155 CURTAIN ROD 1

13 76156 DEFLECTOR SCREEN 2

14 76027 MAIN SWITCH 1

15 75937 LEG WELDMENT ASS’Y.-FRONT 1

16 75938 LEG WELDMENT ASS’Y.-REAR 1

17 75919 DOOR 1

18 76023 DOOR HA

* 76024 MAGNETIC CATH 1

19 76026 S/S SLIP HINGE 2

20 75944 SIDE PANEL-R.H. 1

21 75945 SIDE PANEL-L.H. 1

22 75940 TOP COVER 1

23 75964 VACUUM BREAKER ACCESS COVER 1

24 75939 BACK PANEL 1

25 75965 SWITCH MOUNTING BRACKET 1

26 75972 SWITCH ACTUATO

27 76467 MICRO SWIT

28 75973 STOP ARM 1

29 75982 WASTE BOX 1

30 75983 WASTE TRA

MAIN ASSEMBLY

DESCRIPTION

LUMN 1

NDLE 1

CH 1

Y 1

9

QTY

REQ

NT 1

R 1

Page 12

GAUGES, SENSORS AND DETERGENT PUMP

10

Page 13

GAUGES, SENSORS AND DETERGENT PUMP

ITEM

NO.

PART

NO.

DESCRIPTION

QTY

REQ

1 75920 GUAGE MOUNTING PLATE 1

2 70155 THERMOMETER 2

3 70156 PRESSURE GAUGE 1

4 18865 FLOAT SWITCH 1

5 76040 PROBE 1

6 75960 HEATING ELEMENT COVER 1

7 97990 HEATING ELEMENT COVER-TOP 1

8 75912 CONTROL BOX 1

9 75917 CONTROL BOX COVER 1

10 76037 TOGGLE SWITCH 1

11 07768 THERMOSTAT 1

12 76029 DETERGENT PUMP 1

NOT SHOWN

98849 TUBING 6

4” LENGTH

11

Page 14

ITEM

NO.

1 75986 DETERGENT TANK 1

2 75955 DRAIN TANK WELDMENT 1

3 76031 HEATING ELEMENT 1

4 76819 LOWER SCRAP TRAY 1

5 75960 HEATING ELEMENT COVER 1

6 75927 STAND PIPE 1

7 76822 UPPER SCRAP TRAY 1

8 75952 DETERGENT TANK FRONT COVER 1

9 75950 DETERGENT TANK REAR COVER 1

PART

NO.

DESCRIPTION

12

QTY

REQ

Page 15

WASH / RINSE FILL PLUMBING ARRAINGMENT

ITEM

NO

1 70286 3/8 Pipe To ½ Hose 2

2 76033 3/8 Solenoid 2

3 18528 ½ Pipe Plug 1

4 76055 3/8 Check Valve 1

5 76044 3/8 Male Tee 3

6 76041 3/8 X ½ Reducer Coupling 3

7 71312 3/8 Pipe Plug 1

8 76053 3/8 Line Strainer 2

9 70395 3/8 Close Nipple 2

10 76054 3/8 Ball Valve 1

11 70205 3/8 x 90 Elbow 1

PART

NO.

DESCRIPTION QTY

REQ

13

Page 16

CHEMICAL INJECTOR PLUMBING

ITEM

NO

PART

NO.

DESCRIPTION

QTY

REQ

1

1 76052 ½”-3/8” BELL REDUCER COUPLING 1

2 70395 3/8” CLOSE NIPPLE 1

3 76048 3/8” CROSS 1

4 76045 90° ELBOW 3/8” MALE to 1/4” TUBE 1

5 72631 BRASS MALE CONNECTOR 3/8” MALE to ¼” TUBE 1

6 72561 ¼” FLARED NUT 1

7 760006 MIXING ADAPTOR 1

8 76039 INJECTOR KIT 1

9 76049 90° ELBOW ¼” MALE PIPE to 3/8” HOSE BARB 1

10 76050 BRASS COUPLER ¼” MALE PIPE to ½” HOSE BARB 1

11 70201 3/8 ‘ VACUUM BREAKER 1

12 76041 ½”-3/8” BRASS REDUCER COUPLING 1

13 76046 3/8” MALE PIPE to ½” HOSE BARB 1

14

Page 17

5

7

WASH PUMP AND DRIVE

ITEM

NO

1 76030 WASH PUMP 1

2 75970 PUMP MOUNTING BRACKET 1

3 76049 90° ELBOW ¼” MALE PIPE TO 3/8” HOSE BARB 1

4 76032 DRIVE MOTOR 1

5 76927 DRIVE SPROCKET 1

6 76034 SPRING 1

7 77510 MOTOR COVER 1

PART

NO.

DESCRIPTION

15

QTY

REQ

Page 18

15

DETERGENT

PUMP

RINSE WASH

MAIN

POWER

WIRING DIAGRAM

16

Page 19

WIRING DIAGRAM PARTS LIST

SYM PART NO. DESCRIPTION QTY

DP 76029 Detergent Pump 1

TR 76537 Solid State Timer 1

FLO. 18865 Float Switch 1

PR 75292 Power Relay 1

M2 76030 Wash Pump 1

M1 76032 Drive Motor 1

SW 76467 Limit Switch 1

SOL 76033 Solenoid Valve 2

MSW 76027 Rocket Switch 1

SSW 20833 Toggle Switch 1

THS 07768 Thermostat 1

HE 76031 Heater 1

CAP 76038 Capacitor 1

RT 76913 Resistor 1

17

Page 20

CLEANING TOOL

PART

NO.

DESCRIPTION

QTY

REQ

76159 JET REAMER 1

18

Page 21

USA

Date of Installation

Serial

No.

Model

No.

Your new Blakeslee Glasswasher is warranted for one year from date of installation shown above

against defective materials and workmanship. If any defects are found within the warranty period;

parts, and labor involved with their replacement will be covered free of charge. Service must be

performed by a Blakeslee authorized service agency. All labor to be performed during regular working

hours. Overtime premium will be charged to the customer. All warranty parts are shipped by surface

transportation. If other means of transportation is requested the customer is required to pay the

premium. This warranty does not apply to damages resulting from errors in installation on the part of

other contractors, nor does it apply to machines which have been subject to accident, misuse, or

abuse. It is understood that Blakeslee’s warranty obligation with respect to machines located outside

of the United States or located in the state of Alaska is limited to the furnishing of replacement parts

only. In the state of Hawaii, repair labor is provided free of charge; travel time and expenses paid by

the customer. On the island of Oahu, repair labor, travel time and expenses are provided free of

charge. This is the entire and only warranty of Blakeslee. We neither assume nor authorize anyone

else to assume for us any other obligation or liability in connection with Blakeslee Machines.

Limited Warranty

● In no case can this warranty exceed eighteen (18) months from the date of shipment from our plant

at Chicago, Illinois

CANADA

Your new BLAKESLEE Glasswasher is warranted for one year from the date of installation shown

above* against defective materials and workmanship. If any defects are found within the warranty

period; parts, and labor involved with their replacement will be covered free of charge. Service must

be performed by a Blakeslee authorized service agency. All labor to be performed during regular

working hours. Overtime premium will be charged to the customer. Travel time and distance to

perform repairs over 100 Km. from the nearest authorized service agency will be charged to the

customer. All warranty parts are shipped by surface transportation. If other means of transportation is

requested the customer is required to pay the premium. This warranty does not apply to damages

resulting from errors in installation on the part of other contractors, nor does it apply to machines

which have been subject to accident, misuse, or abuse. This is the entire and only warranty of

Blakeslee. We neither assume nor authorize anyone else to assume for us any other obligation or

liability in connection with Blakeslee Machines. It is understood that BLAKESLEE’S guarantee

obligation with respect to machines located outside of Canada is limited to furnishing of replacement

parts only.

Date of Installation

Serial

No.

Model

No.

Limited Warranty

● In no case can this warranty exceed eighteen (18) months from the date of shipment from our plant

at Scarborough, Ontario.

Loading...

Loading...