Page 1

BLAKESLEE

OWNER’S

MANUAL

Division of Blako Inc.

FLIGHT – TYPE DISHWASHER

I.R.S. INTEGRATED RECIRCULATING SYSTEM DESIGN

1844 South Laramie Avenue

Chicago, IL 60804

Phone (708) 656-0660

Fax (708) 656-0017

www.blakesleeinc.com

service@blakesleeinc.com

1149 Bellamy Road North Unit 19

Scarborough, Ontario Canada M1H1H7

Phone (416) 751-2625

Fax (416) 751-8539

Revised 8/2005

Page 2

NOTES

Page 3

CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

I DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

II OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

III CLEANING OF MACHINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

IV PREVENTATIVE MAINTENANCE AND MINOR REPAIR . . . . . . . . . . . . . . . . . . . . . . 18

V USE OF ADDITIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

VI PARTS LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Introduction

GENERAL.

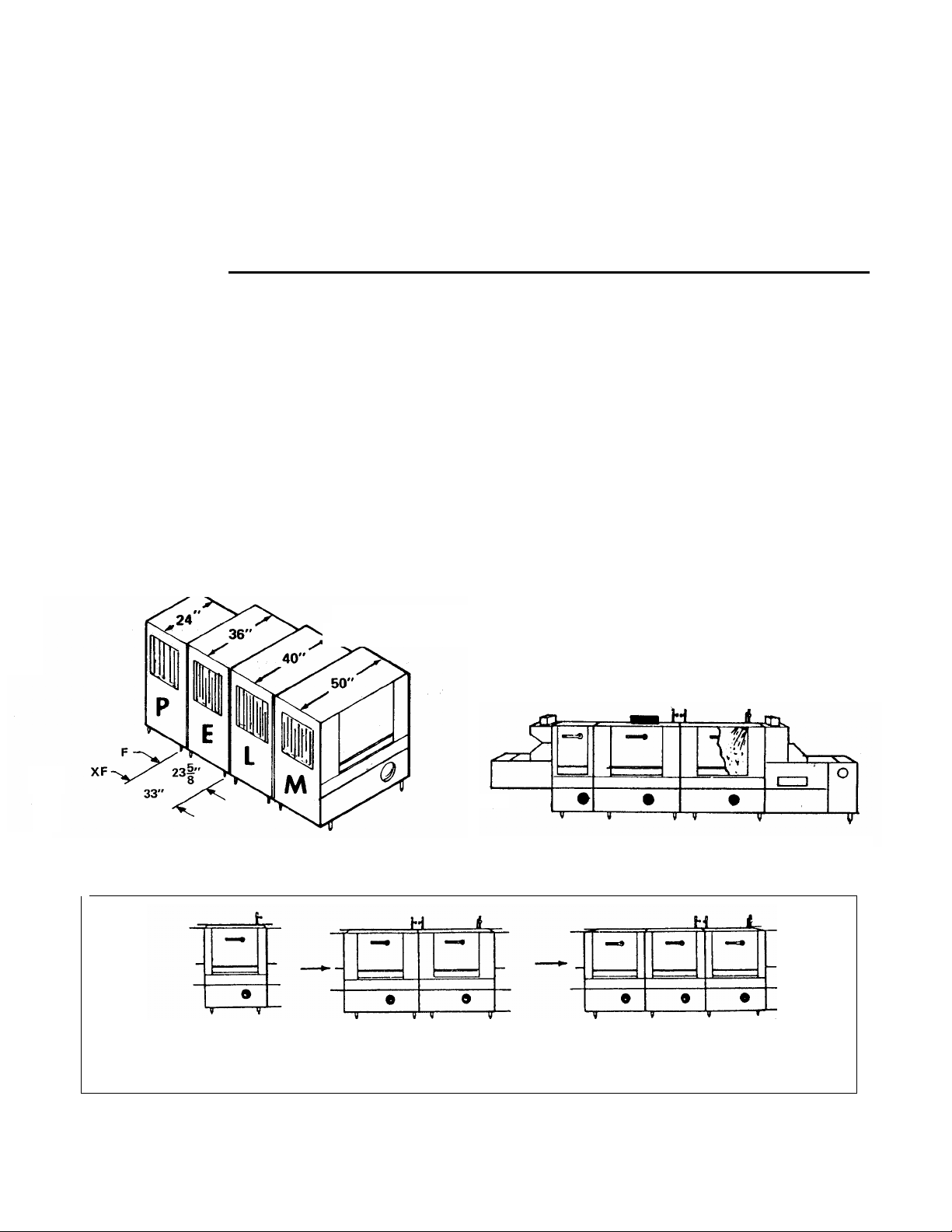

The Blakeslee Flight Type dishwashing machine is

available in many models. Each model is developed from

one or more of the five basic modules (or tanks) shown in

figure A. The P tank (24” long) which is the smallest is

used only as a PRE-WASH tank and is always fitted to

another tank as shown in figure B. The other four tanks

are identified by their length. Any E, L, or M module can

be a complete dishwasher in itself, or can be used as a

pre-wash, wash or power-rinse tank in a multi-tank unit

(see figure C). The Flight Type dishwasher is available in

two widths; the standard width machine has a 20-inch

conveyor; the extra wide model has a 30-inch conveyor.

EXPLANIATION OF MODEL DESIGNATION.

The Blakeslee Model designation indicates which tank, or

tanks, are used to build a particular machine. A Model F-E

FIGURE A. Dishwashing Machine Modules

Model F-E

Dishwasher indicates that a single E tank (36”

long) is the complete dishwasher. The Model FEE Dishwasher consists of two E tanks, one of

which is a wash tank and the other a power-rinse

tank. When a pre-wash is desired, the P tank is

added and the model becomes the F-PEE

Dishwasher. If a larger capacity dishwasher is

desired, a C, E, L, or M tank can be used as the

pre-wash in a three tank machine. When adding

the third tank to a F-EE machine, it becomes a

Model F-EEE Dishwasher.

CONVEYOR DIRECTION.

When your order was placed, you specified the

direction of conveyor travel. If the dishes enter the

machine on the left, we refer to the machine as

having L to R feed. Similarly, if the dishes enter

on the right, the machine has R to L feed. The

Illustrations included in this manual are of

machines with L to R feed, unless otherwise

noted.

FIGURE B. Dishwashing Machine with “P” Tank

Model F-EE Model F-EEE

F-L F-LL F-LLL

F-M F-MM F-MMM

FIGURE C. Dishwashing Machine Model Designations

1

Page 4

2

Page 5

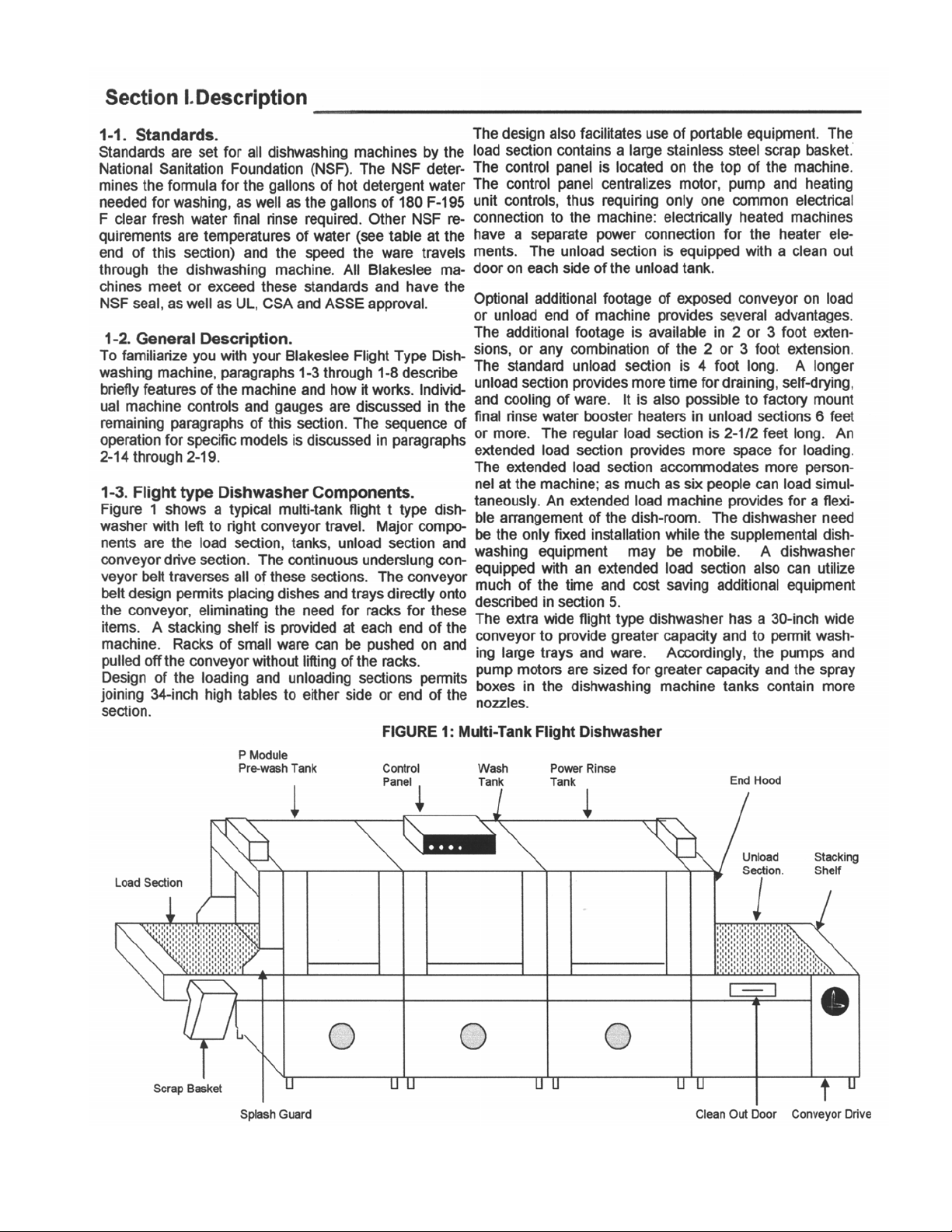

1-4. Single Tank Dishwashing Machine.

Figure 2 identifies the principle parts of a typical single

tank dishwashing machine. The machine shown has

Left to Right feed. The stainless steel tank is

supported on a sturdy base and has adjustable legs.

All interior parts are of stainless steel, or plastic

construction to resist effects of present day detergents

and cleaning chemicals. Curtains (26, figure 2) and a

splash guard (23) at the entrance and exit prevent

excessive splashing in the work room. A short curtain

(4) separates the washing and rinsing areas on

models without power-rinse tanks. All curtains are

easily removed for thorough cleaning. The large

access door (25) lifts to allow quick cleaning and

inspection of the dishwasher. The scrap trays (14)

slide out easily through the access door area. The

control panel (3) centralizes motor, pump, and heating

unit controls. Electrically heated machines have a

separate power connection for the heater elements.

1-5. Multi-Tank Dishwashing Machine.

Since Blakeslee dishwashing machines are developed

from the module concept, the multi-tank machine

includes all of the features outlined in the preceding

paragraph for the single tank machine.

The primary advantages of a multi-tank dishwashing

machine are the increased economy and capacity.

The inclusion of a pre-wash tank increases economy

by reusing overflow detergent wash water, thereby

reducing detergent cost. Similarly, the power rinse is

added to increase economy by pre-rinsing the dishes

with water accumulated from the fresh water rinse,

thereby reducing the amount of fresh final rinse water

needed to cleanse the already pre-rinsed dishes.

Capacity is increased by the addition of a full sized

pre-wash or power rinse tank since conveyor speeds

are then faster for multi tank dishwashers. (Note:

capacities are determined by the National Sanitation

Foundation.)

1-6. Wash Cycle.

Washing dishes requires two basic operations: first,

the washing second, the rinsing. This paragraph

describes the path of the wash water from the time it

enters the machine through the complete wash cycle.

This unit has auto-matic tank fill & water level control.

When the power switch is turned on, fresh water

enters the dishwashing machine at the fill valve (2,

figure 2) at the top of the machine. The water passes

through the vacuum breaker (1) to internal piping. The

vacuum breaker is a safety device designed to

prevent contaminated water from the dishwashing

machine being siphoned back into the fresh water

supply lines if water supply pressure fails. The internal

piping directs the water into the tank. When the tank is

filled to the proper level, and deter-gent added, a float

switch stops the fill, and turns on the tank heat. The

tank heat is controlled by a thermostat (12).

The sump thermometer (16) indicates the wash water

temperature. The wash cycle begins when the water is

heated and the conveyor is manually started. The pump

(20) directs the wash water through the riser weldment

(27) at the rear of the machine. Upper spray tubes and a

lower spray box are attached to the vertical riser.

Nozzles on each spray tube, and spray box direct wash

water at the dishes. Scrap trays (14) on either side of the

lower spray box prevents dislodged food particles falling

into the tank. The water return’s to the tank where it is

ready to start the wash cycle again. A hollow standpipe

(18) permits overflow water to flow down the drain. The

standpipe permits overflow water to skim heavy soil, etc.,

that floats on top of the wash water, and carry it down

the drain.

1-7. Final Rinse Cycle.

The final rinse water must always be fresh and hot

(within a range of 180 F to 195 F). Hot rinse water enters

the dishwashing machine at the strainer (10) and final

rinse solenoid valve (9). The water travels through the

vacuum breaker (7) and comes in contact with the final

rinse thermometer (6). The thermometer indicates the

temperature of the water entering the spray pipes (5).

The spray pipes contain small nozzles sized and

positioned for application of an even spray across the

conveyor. Final rinse water is never allowed to run

continuously. The final rinse photo-sensor (22) located

on the entrance of the machine controls the solenoid (9)

turning it on to coincide with the ware entering the final

rinse.

1-8.Quick Start.

Quick Start utilizes the 180° water from the final rinse as

an additional source to fill the tanks This system is

designed to give you a much shorter start-up time by

significantly decreasing the time necessary for the water

to come up to temperature. See paragraph 2-1.

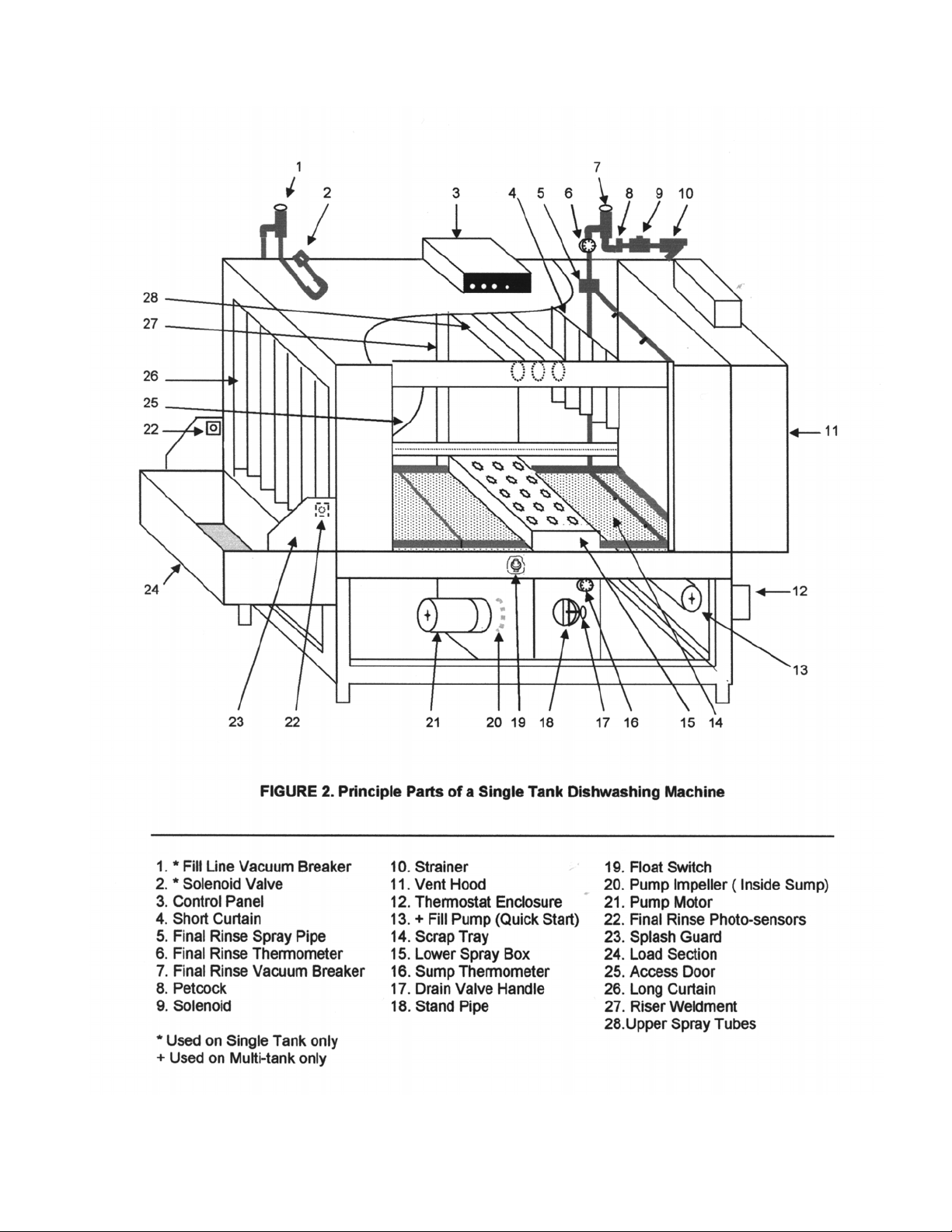

1-9. Conveyor Drive Mechanism.

The underslung links of the conveyor belt are supported

by ½ inch stainless steel rods for standard and x-wide

machines. Rollers located on the ends of the rods

engage the drive sprockets attached to the shafts at

each end of the dishwashing machine. Figure 3A shows

the 48 tooth drive chain sprocket that is mounted in the

head shaft in the conveyor drive section. The chain is

driven by a ½ HP motor through a speed reducer.

A micro switch in the drive unit provides overload

protection for the conveyor. If a conveyor jam occurs,

the drive chain exerts a force on the lever arm, (see

figure 3A). The lever arm moves to trip the micro switch

open, causing the conveyor to stop. A spring is

connected to the lever arm and spring tension is

adjusted at the time of installation. Spring tension is set

so that when a fully loaded conveyor jams, the micro

switch opens.

3

Page 6

4-

Page 7

As the stop plate moves under the stacking shelf, it trips

the conveyor unload switch open and the conveyor

stops. After the clean item is removed from the

conveyor, the stop plate returns to its extended position

and conveyor operation automatically resumes.

FIGURE 3A. Drive Assembly

FIGURE 3B. Conveyor Stop Plate

The tail shaft in the load section is supported in

bearings which are mounted in take-up blocks. These

blocks can be moved by turning take-up screws to

remove slack from the conveyor belt. This adjustment

is performed at time of installation and the take up

screws are set in position with locking screws.

The stacking shelf on the conveyor drive section is a

part of the conveyor stop mechanism. When clean

ware or racks reach the discharge end of the conveyor

the conveyor stops. The clean item presses a spring

loaded stop plate. (See Figure 3B) this is the actuator

for the micro switch.

5

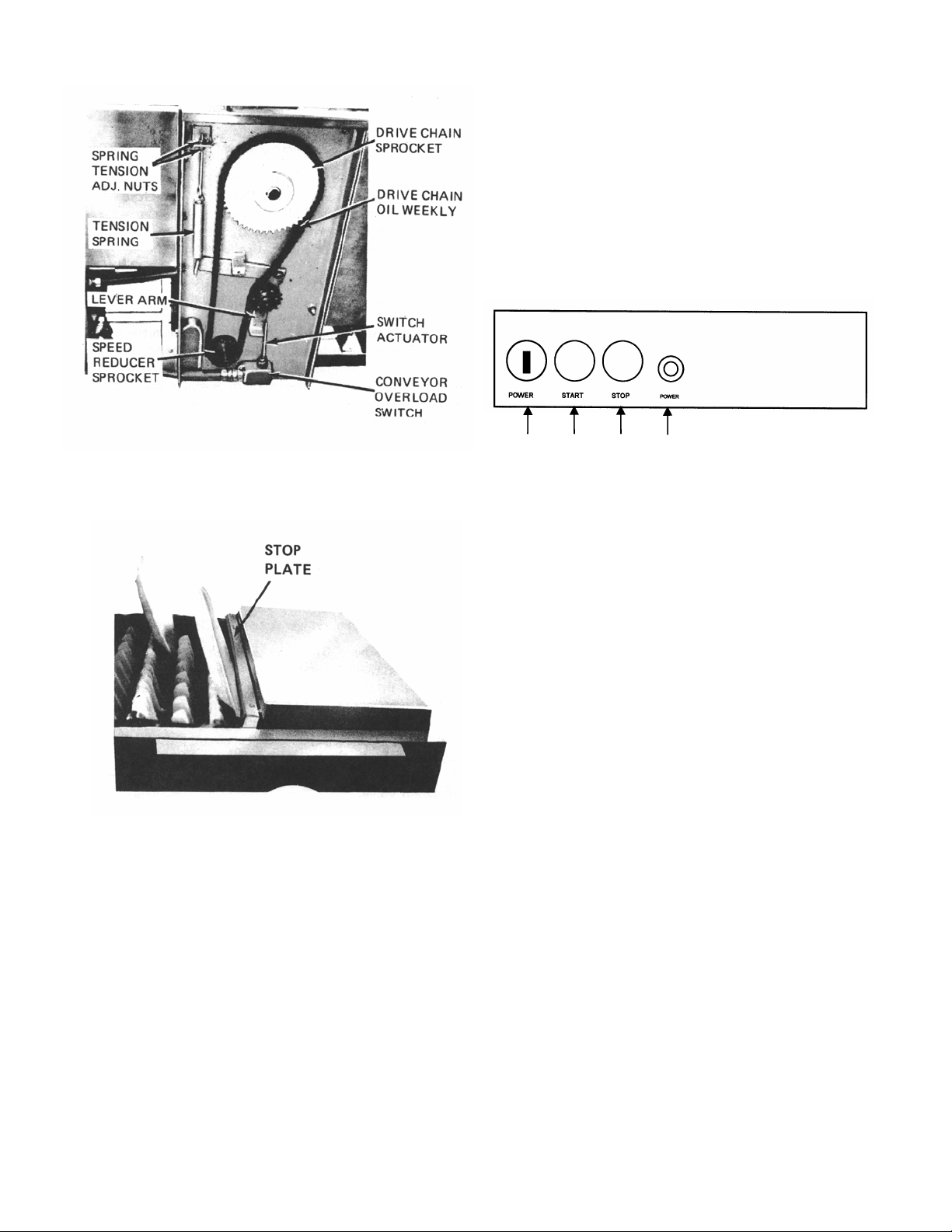

1-9. EXPLANATION OF CONTROLS.

1-10. Control Panel.

The control panel (figure 4) contains the motor switches,

and indicator light. These controls are used as follows:

1 2 3 4

FIGURE 4. Control Panel

1. Power on/off switch

2. Pumps & Conveyor start switch

3. Pumps & Conveyor stop switch

4. Power on indicator light

a. All Blakeslee flight conveyor dishwashers are

equipped with a door safety switch. The large inspection

door must be closed and the switch lever extended to

actuate the switch before any power can reach the

control panel.

b. The power ON/OFF selector switch provides electrical

power to the control panel. (1 figure 2)

c. The START and STOP pushbutton switches(2 and 3,

Figure 2) are the panel controls for the conveyor and

pumps electrical circuit. The START switch (2) is

pressed to start the pumps and conveyor drive motors,

and to provide electrical power to the final rinse limit

switch and solenoid valve when needed. Pressing the

STOP switch (3) disconnects power from the conveyor

and pumps electrical circuit and stops the conveyor and

pump motors.

d. Power light – Controlled by ON/OFF selector

switch. Light is on when switch is on.

e. Automatic low water cut-off. This circuit connects the

power supply to the pump and heat control circuits. If

this circuit is not operational, the pumps and heating

units will not operate. As the tank fills, the float ball

moves up. When there is approximately 2-1/2 inches, of

water in the tank the float switch (23 Figure 2) will close

and this circuit becomes operational. The pumps can

then be started and the tank heat will come on.

Page 8

The tank heat pilot lamp will not light unless the Low

Water Cut-Off circuit is operational. If the tank is

emptied or if the tank water level falls below 2-1/2

inches, the float will come down, opening the switch

and stopping the pumps and turning off the tank

heat. In the multi-tank machine, there is a float in

each tank except the P module pre-wash tank. If

one tank empties, the pumps and heat will not

operate for any of the tanks. Refilling the tanks will

automatically reconnect the pump and heat circuits.

1-11. Auxiliary Conveyor Start/Stop Switches

(OPTIONAL).

In addition to the conveyor controls on the control

panel, auxiliary SRART/STOP pushbutton switches

are factory installed at convenient customer

selected locations. These auxiliary switches

operate in the same manner as described in

paragraph 1-10c. Operating personnel can start or

stop the conveyor by pushing the appropriate button

on the control panel or any of the auxiliary stations.

1-12. Conveyor Unload Micro Switch.

The conveyor unload micro switch is under the

unload stacking shelf. This switch is tripped open

when clean ware reaches the discharge end of the

conveyor. When the switch is tripped, the conveyor

stops. Removing the clean item from the conveyor

automatically restarts the conveyor.

1-13. Conveyor Overload Micro Switch.

The conveyor overload micro switch is located in the

drive unit. This switch is automatically actuated

when the conveyor binds or is jammed. When this

occurs, the conveyor stops. After the cause of the

jam is determined and corrected, conveyor

operation is resumed by pressing the conveyor

START switch.

1-14. Final Rinse Photo-sensor and Solenoid

Valve.

The final rinse photo-sensor (22, Figure 2) When an

object moving on the conveyor breaks the infrared

beam between the sensors a signal is sent to the

microprocessor starting the final rinse timer. The

final rinse circuit is timed to activate the solenoid

valve (9 Figure 2) as the first item enters the final

rinse area and turn off the solenoid as the last item

leaves the final rinse area. The microprocessor

resets each time the infrared beam is broken

allowing the machine to stay in operation until the

final item is washed.

6

1-15. Drain Valve.

Each tank of the dishwashing machine is equipped with a

drain valve (18, figure 2). The drain valve handle is turned

clockwise ½ turn for the full closed position. This valve

must be closed when the tank is filled and must remain

closed while the dishwasher is operated. To empty the

tank, the drain valve is turned counter-clockwise ½ turn to

the open position. Each drain valve is equipped with a

screen. The screen requires frequent cleaning, as outlined

in paragraph 3-3.

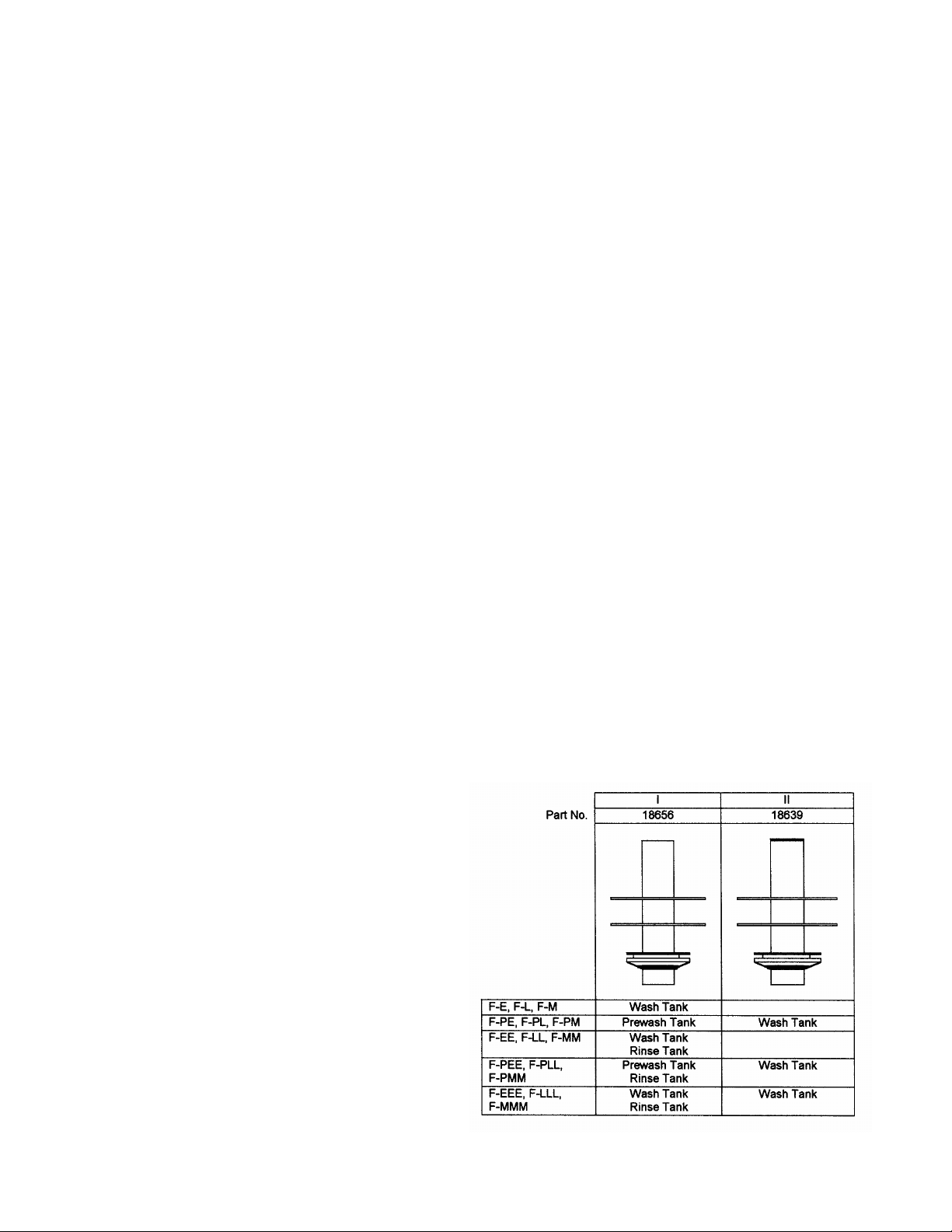

1-16. Standpipe.

A hollow stainless steel drain standpipe (22, figure 1) fits

into the drain valve seat in each tank. The standpipe is

sealed by a rubber drain plug which fits over the standpipe

and is secured by two stainless steel retaining rings. There

are two standpipe styles; the configuration used in a

particular tank is determined by the dishwashing machine

model as shown in figure 5. The standpipe must be

removed when cleaning the drain strainer. It is important

that the correct standpipe is installed in each tank.

For tanks equipped with standpipe style I, the length of the

standpipe determines the water level in the tank in which it

is mounted. When the water reaches the top of the

standpipe, it spills into the hollow standpipe and flows

through to the drain. This also permits overflow water to

skim heavy soil, etc, that floats on top of the wash water,

and carry it down the drain.

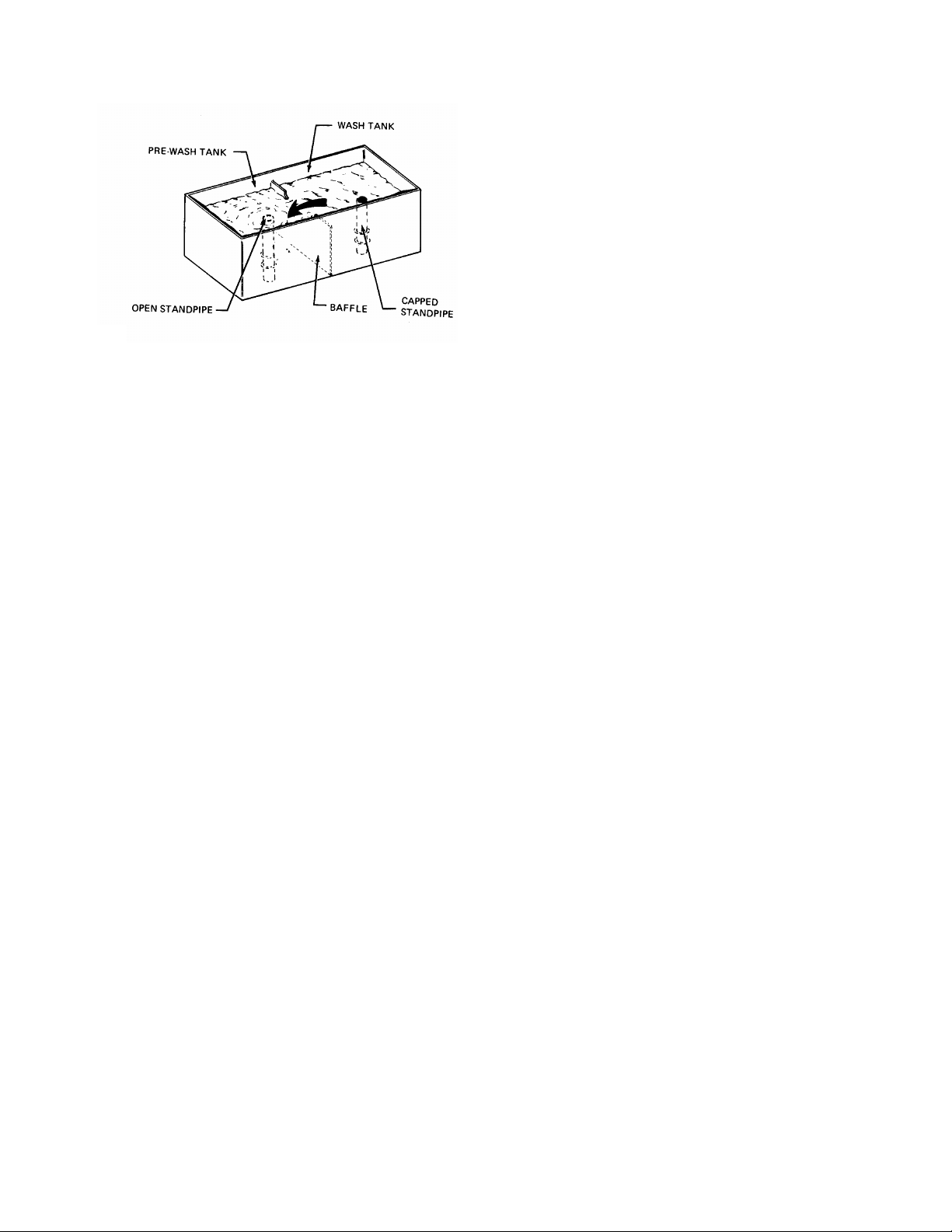

On standpipe style II, the top of the standpipe is capped.

These standpipes are used in wash tanks of machines

which include a pre-wash tank. This capped standpipe

prevents the excess water to drain. Instead, the excess

water flows over the cut out portion of the baffle (in the

tank common to both the wash and pre-wash tanks) into

the pre-wash tank, as indicated in figure 5 A. The pre-wash

tank is equipped with the style I standpipe.

FIGURE 5. Standpipes

Page 9

D. GAS. The gas heating system includes a gas control

valve and a separate low water cut-off float switch. Gas

enters the valve and is directed to the mixer heads on

the burners. Two burners are arranged along the bottom

rear of the tank. Burner orifice sizes are set at the factory

and usually require no further adjustments; larger or

smaller orifices for certain special gas B.T.U. outputs are

available. Safety devices include a gas flue, safety pilot

and built-in pressure regulator (natural gas only). Gas

will not flow through the gas control valve unless the pilot

light is lit, and there is water in the tank. Therefore, the

operator must check periodically that the pilot light has

not gone out, and relight it when necessary (refer to

paragraph 2 – 6) The gas control is actuated by the

control panel ON/OFF switch (1 figure 2) and is

FIGURE 5 A.

Baffle between Wash and Pre-wash Tanks only

1-17. Heaters.

A. ELECTRIC. The electric heating system is

controlled by the ON/OFF switch (6, figure 2) and is

monitored with a thermostat. This heating system

includes a contactor. The co ntactor is located toward

the rear of the machine on the right side (as viewed

when facing the access door). Some machines are

equipped with optional common connection electric

heat junction box. A separate power supply, properly

fused, must be connected to the contactor of each

heated tank.

After the switch is turned ON, no other control of the

system is required by the operator. The HEAT

indicator light (6) will glow when the heat circuit is on,

providing all tanks are filled with water.

B. STEAM INJECTOR. This heating system is

automatically controlled with a thermostat and

solenoid valve. Steam enters a strainer, passes

through the solenoid valve and a check valve and

enters the steam water heaters in the tank. The

solenoid valve is actuated by the control panel

ON/OFF switch (1, figure 4) and is monitored with a

thermostat. After the switch is turned ON, no other

control of the system is required by the operator. The

HEAT indicator light (6) will glow when the heat circuit

is on.

C. STEAM COIL. The steam coil heating system is

automatically controlled with a thermostat and

solenoid valve. Steam enters a strainer, passes

through the solenoid valve and enters the steam coil in

the tank where heat transfers to the tank water. A

steam trap at the coil exit connects to the condensate

drain. The solenoid valve is actuated by the control

panel ON/OFF switch (1, figure 2) and is monitored

with a thermostat. After the switch is turned ON no

other control of the system is required by the operator.

monitored with a thermostat. The HEAT indicator light

(6) will glow when the heat circuit is on, providing all

tanks are filled with water.

1-18. Line Strainers.

A. FINAL RINSE SYSTEM. The final rinse system

includes a strainer (10, figure 1) to protect the solenoid

valve (9, figure 1) from dirt. A good preventive

maintenance program must include periodic cleaning of

the strainer screen (refer to paragraph 3-5).

B. STEAM INJECTOR HEATING SYSTEM. This system

includes a solenoid valve protected with a strainer.

Periodic cleaning of the strainer is recommended (refer

to paragraph 3-5). The strainer is located at the steam

inlet side of the solenoid valve.

C. STEAM COIL HEATING SYSTEM. This system

includes a solenoid valve protected with a strainer.

Periodic cleaning of the strainer is recommended (refer

to paragraph 3-5). The strainer is located at the steam

inlet side of the solenoid valve.

1-19. Venting and End Hoods.

The end hoods are attached to the inlet and exit of the

dishwashing machine to reduce water splash and

exhaust the steam from the dishwashing machine area.

Exhausting the steam reduces the humidity in the

dishwashing department which contributes to more

efficient working conditions and quick self-drying of

dishes. Each hood must be connected to a ventilating

duct; vent opening on the hood is 4 x 16 inches.

Figure 1 shows the standard full-length unload end hood

with 10 inch wide side panels and standard load-end

hood. Extended full-length load and unload end hoods

with up to 16-inch wide side panels are available as an

option. Extended hoods provide more space for steam

collection and additional splash protection.

A damper in the hood is adjustable to control the

exhaust volume. To adjust the damper, place a wrench

on the flat of the damper rod and loosen the stop nut on

the side of the hood and turn the damper rod; tighten the

stop nut to lock the damper in position while holding rod

in position with wrench.

7

Page 10

The best damper position will vary according to the

size of the dishwashing room and machine. Allow

majority of steam to escape without loss of water

temperature in tanks. NOTE: if damper is open too

much heat will be lost from the tank.

CAUTION: Do not vent into wall or ceiling or

concealed space of a building.

1-20. Splash Guards.

Figure 1 shows splash guards attached to either the

end hoods or the end of the tank. These splash

guards are designed to divert water that is not

contained by the end hoods back into the load and

unload tanks.

1-21. GAUGES

1-22. Sump Thermometer.

Each tank of the dishwashing machine is equipped

with a sump thermometer (19, figure 1). This

thermometer indicates the temperature of the water in

the tank. NSF requirements for water temperatures

are indicated in the table at the end of this section.

After the dishwashing machine is filled with water and

the heating unit is turned on, the sump thermometer

should be observed periodically to assure that the

proper temperatures are being maintained.

1-23. Final Rinse Thermometer.

The final rinse thermometer (6, figure 1) is located

above the last tank of the dishwashing machine. This

thermometer indicates the temperature of the final

rinse water entering the machine. An NSF requirement

for final rinse water is 180 F – 195 F. Heating the final

rinse to 180 F is generally accomplished with a

booster heater. This heater was either purchased with

the dishwashing machine, or was part of the regular

kitchen equipment.

The heat from the final rinse water assures sanitation

and assists in heating the ware for rapid drying. During

dishwashing operation, the final rinse thermometer

should be observed periodically to assure that proper

temperature is being maintained.

8

1-24. Water Temperature Chart.

TYPE OF

MACHINE

OPERATION NSF MINIMUM

TEMPERATURE

SINGLE

TANK

SINGLE

TANK

W/PREWASH

2 TANK

2 TANK

W/PREWASH

3 TANK

Wash

Final Rinse

Prewash

Wash

Final Rinse

Wash

Power Rinse

Final Rinse

Prewash

Wash

Power Rinse

Final Rinse

Prewash

Wash

Power Rinse

Final Rinse

160 F

180 F - 195 F

110 F - 140 F

160 F

180 F - 195 F

150 F

160 F

180 F – 195 F

110 F – 140 F

150 F

160 F

180 F

110 F – 140 F

150 F

160 F

180 F – 195 F

1-25. Final Rinse Pressure Gauge. (OPTIONAL)

Properly heated final rinse water under pressure

between 15 to 25 psi (flow pressure) will effectively rinse

away detergent. The optional gauge is used to monitor

this flow pressure. Flow pressure is the indicated water

pressure with all final rinse valves open and the final

rinse in operation.

1-25-A. Final Rinse Pressure Gauge Petcock.

The final rinse system is equipped with a ¼- inch N.P.T.

petcock (8, figure 1). This device is used in conjunction

with detergent reps. & health inspectors test equipment.

Be sure petcock is closed (valve lever horizontal) before

removing plug to install equipment.

Page 11

Section II. Operation

5. Turn the ON/OFF switch in the control panel (1,

figure 2) on. The dishwashing machine will begin

filling. The fill indicator light should come on. Multi

tank machines fill using the rinse tank fill and the final

rinse. Water is pumped from the rinse tank to fill the

wash tank. See Quick Start paragraph 1-8. Quick

start is optional on single tank machines.

6. The machine will automatically stop filling when the

water reaches its proper level. At this point the heat

indicator light should come on.

7. Observe sump thermometers; minimum operating

temperatures are indicated on the thermometers, and

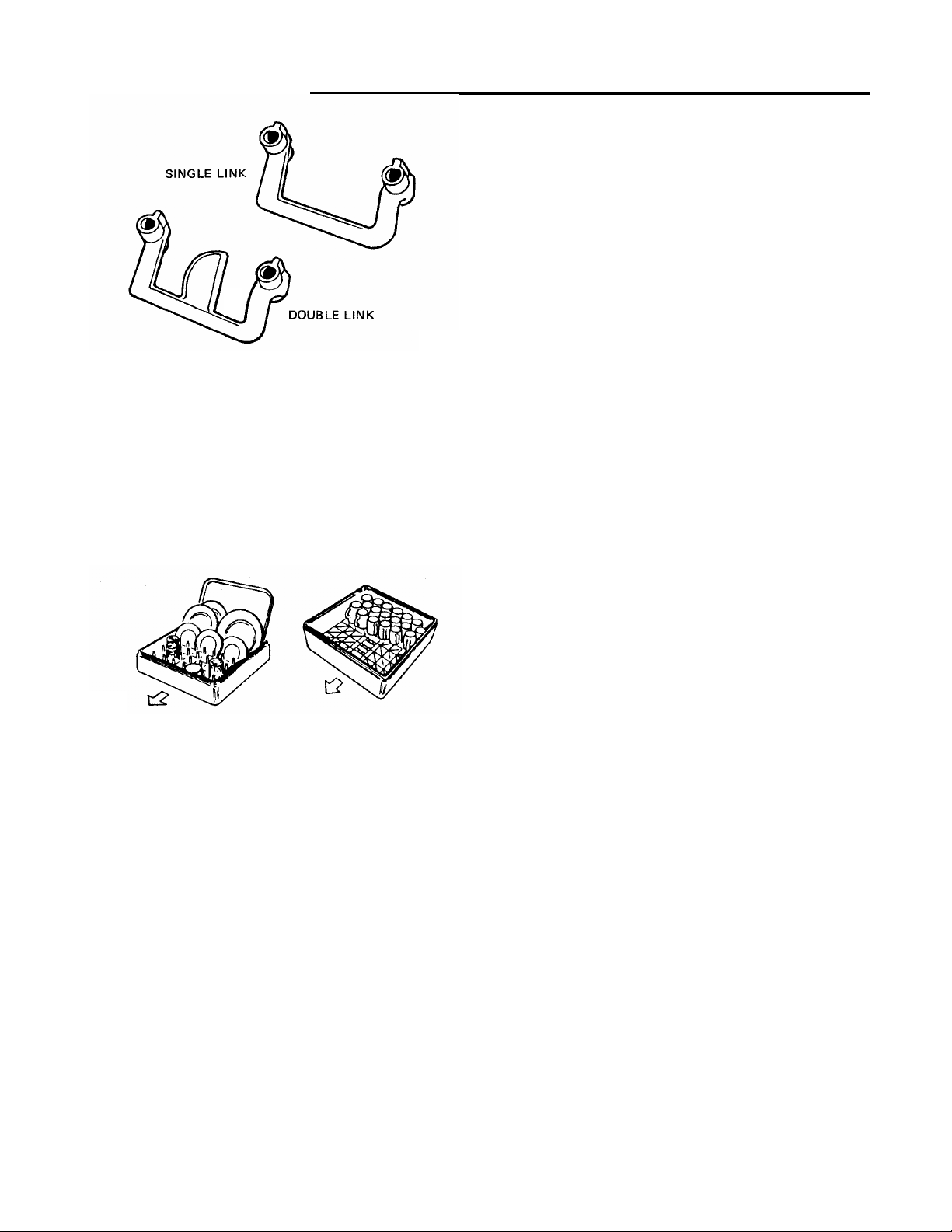

FIGURE 6. Flight Type Conveyor Link

Two types of racks are recommended: the multipurpose rack and the combination rack. There are

more holes in the bottom of the combination rack than

in the multi-purpose rack. The multi-purpose rack is

used for washing plates, saucers, trays (14 x 18 inch

maximum) and any ware except silverware. The

combination rack is used for washing silverware and

small ware such as cups, bowls and glasses.

MULTI-PURPOSE RACK COMBINATION RACK

PART NO. W-0-16428 PART NO. W-0-16429

FIGURE 7. Proper Loading of Racks

2-1. PREPARING MACHINE FOR OPERATION.

Perform the following steps to insure proper

dishwasher operation.

1. Check that clean scrap trays are in position on either

side of lower spray boxes. Be sure the curtains are in

position at dishwasher entrance, between the wash

and rinse areas of tanks, and at dishwasher exit.

2. Close tank drain valves and access doors.

3. Put correct amount of detergent in detergent

dispenser box. Observe the recommendations of the

detergent manufacture.

4. Be sure the door safety switch is pulled out so the

inspection door cannot be opened.

9

in the table at the end of section I.

8. Press the start switch on the control panel.

The dishwasher is now ready for loading.

2-2. LOADING MACHINE.

2-3. Conveyor Links.

The underslung conveyor links are suspended

between Stainless steel cross rods to form a flat belt

surface for easy loading and unloading. The double

link shown in figure 6 accommodates all regu lar and

extra-heavy ware that does not require racks. Platter

and tray sizes up to 14 x 18 inches maximum can be

placed directly in the links. Some dishwashing

machines, equipped with pre-flushers and used

primarily for washing trays, are equipped with a single

link conveyor belt. The slightly wider spacing of the

single link is especially suitable for trays, but does

accommodate other ware as well.

When loading the conveyor links, observe the

following: Place dishes in links with the soiled surface

tilted up. Place oblong items, such as platters and

trays, with the long side in the link. For example, to

wash a 14 x 18 inch tray, place the tray with the 18

inch side in the link.

2-4. OPERATING THE DISHWASHER.

Observe the following instructions to obtain maximum

performance from the dishwashing machine. Also

refer to paragraph 2-7 for helpful suggestions.

1. Whenever possible, instruct bus boys or wait staff

to stack the soiled dishes according to sizes as they

are brought to the soiled dish table.

2. Remove by hand, rubber scraper, or pre-washing

as much food particles left on the dishes as possible.

This will reduce pollution of water, insure the cleanest

possible wash water and lower detergent costs.

Page 12

3. Load the conveyor links and racks as described in

paragraphs 2-3 and 2-4. Slide the racks of soiled ware

onto the conveyor. Continue loading the machine with

soiled ware as fast as the conveyor allows.

4. Clean ware must be removed from the unload

section continuously. When ware is not removed from

the conveyor, the conveyor micro switch is tripped

causing the conveyor to stop.

5. Scrape and rack more dishes and “feed” the racks of

soiled ware to the machine as fast as it will take them

6. Continually check wash and rinse temperatures.

NOTE: For machines equipped with gas heating units, a

decreasing temperature may be caused by the pilot light

going out. Check that the pilot light is lit; when

necessary; relight as outlined in paragraph 2-6.

7. Be sure enough detergent is being added to the wash

water to keep it at an effective strength if an automatic

dispenser is not being used.

8. Repeat steps 2 through 8 until all dishes have been

washed.

10. Stop dishwasher (paragraph 2-5) and perform the

daily cleaning (paragraph 3-1).

2-5. STOPPING MACHINE AFTER OPERATION.

To stop the dishwasher, observe the following.

1. Press the STOP button.

2. Turn ON/OFF switch to the OFF position.

3. Open drain valve.

4. Clean machine (paragraph 3-1)

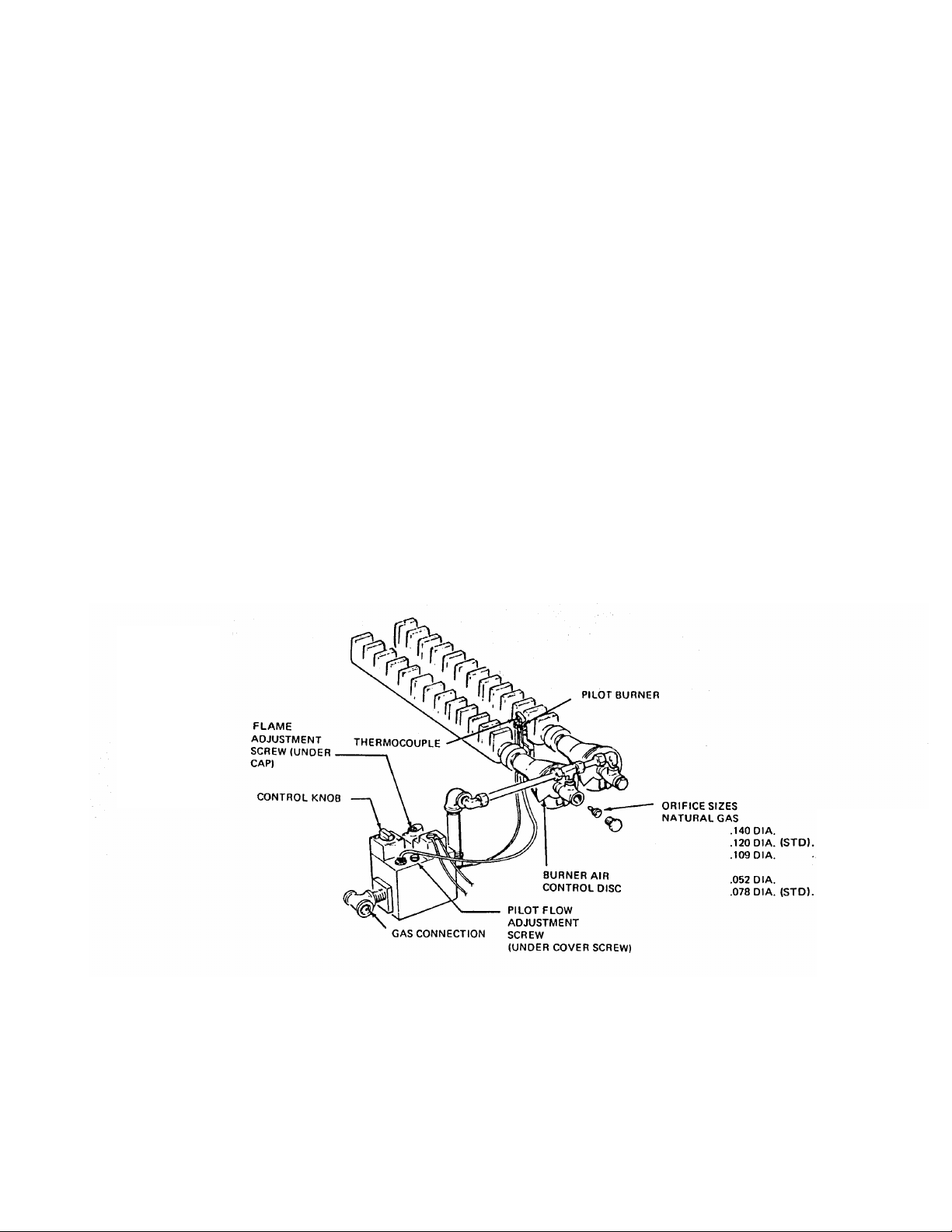

2-6 GAS PILOT LIGHTING INSTRUCTIONS.

The pilot burner is accessible from the right side of

the machine. Figure 8 shows the gas heat unit and

identifies the pilot burner and pilot lighting button.

Use a fireplace match, or a long piece of rolled – up

paper, to light the pilot burner as follows;

1. Slightly depress control knob if at PILOT position

and turn clockwise to OFF. Wait 5 minutes for all

unburned gas to vent. REMEMBER that LP gas does

not vent upward naturally.

2. Turn the control knob to PILOT, depress it

completely, and light the pilot burner. The knob must

be held down about one minute before the pilot

burner will stay lit after releasing the knob.

3. Turn the knob to ON. Gas burners should ignite. If

not, repeat above sequence.

10

Page 13

2-.7 HELPFUL HINTS

2-8. Proper Use of Flight Type Dishwashing

Machine.

The Flight Type dishwashing machine provides a direct

load, single-handling method of cleaning dishes. Since

this is a random load system, all sorting and stacking

can be eliminated before loading. The machine operators or waitresses simply remove the soiled dishes

from the container (tote box, tray, etc.) used to bring

the soiled ware into the dish room, scrape soil into

appropriate containers, and load the item in the

conveyor link or rack. Cups, glasses and miscellaneous

items like creamers, butter dishes, etc. are placed in

suitable racks. When a rack is full, it is placed on the

conveyor at random. Silverware is placed in a soak

sink. When a rack full of silverware is accumulated, it

is placed at random on the conveyor belt. Sorting and

stacking is done at the unload end. Clean ware can be

stacked on storage shelves or on portable carts for the

transportation to other areas in the dish room.

To obtain full advantage of the direct-load system, the

following equipment should be provided at the load end

of the machine: a suitable soil container (scrapping

trough, disposer, etc.); silver soak sink; and shelves (or

some convenient method) for loading racks and for

storing empty racks. For peak periods of operation,

shelves for temporary storage of entire tote boxes or

trays full of soiled ware are also convenient on the load

end of the machine.

2-9. Loading Precautions.

The dishwashing machine is built for washing dishes

and other tableware only, not for pots, pans or other

kitchen equipment. Any item that cannot be placed “in”

the conveyor link or dish racks without falling over

should not be cleaned in this machine.

Load racks properly. Glasses, cups and creamers

should be placed face down in the racks.

Care must be used not to overfill a silver rack. The

bottom of the rack must be visible in several areas

through the silver ware. If not, the rack is overfilled and

poor results will be obtained.

Small ware (saucers, dessert dishes etc.) that are

placed directly in the conveyor belt will not actuate the

conveyor stop mechanism. All small ware must be

placed in racks in order to trip the stop mechanism.

2-10. Dish Handling Techniques – Flight Machine

with regular Load Section

LOADING OPERATIONS. The Flight Type machine is

designed for the direct-load, single chandelling system

of cleaning dishes: whenever possible, use the

machine as described in paragraph 2-8. When the size

or layout of the dish room limits activity at the load

section, it may be necessary to perform the scraping or

rack loading operations at a separate location. When

rack loading is performed away from the load section,

consider establishing a soiled dish table. Instruct your

busboys or wait staff to arrange the soiled ware on the

dish table in an orderly manner as the ware is brought

to the table. There should be designated places for

depositing scraps, napkins, and soiled ware. In many

instances, cups, glasses, butter dishes, etc., can be

placed directly in the appropriate rack by the bus boys

or wait staff. Mobile equipment can be helpful to

convey the soiled ware to the dishwashing machine.

SCRAPING DISHES. Do a good job of removing left

over food from the dishes. Scrape dishes by hand, with

a rubber scraper, or by pre-washing before placing

them in the conveyor links or racks. Doing this job

properly helps to maintain cleaner wash water.

2-11. Dish Handling Techniques – Flight

Machine with Extended Load Section

LOADING OPERATIONS. The extended load machine

is best used as described in paragraph 2-8. The

extended load section provides ample space for

performing all of the loading operations and

accommodates three or more personnel at the same

time. The extended load machine is usually purchased

with optional equipment or arranged with existing

equipment, such as scraping trough, rack loading and

storage shelves, and a pre-flushing system. For proper

and efficient use of Blakeslee option items refer to

section V.

SCRAPING DISHES. Heavy soil must be removed

from the dishes before loading them into the links or

racks; a minimum of pre-scraping is required. A

machine equipped with a pre-flusher requires

practically no pre-scraping.

2-12 Detergents.

Detergents should be used according to the detergent

manufacturer’s recommendations. Their representative

knows the capabilities of their detergents and can

determine the proper treatment of your water for proper

use with their product. The wash water must be kept at

an effective strength to obtain good washing results.

Use a good detergent. Never use a foaming soap or

soap flakes. Ask your local detergent man for his help

and heed his advice.

2-13. BRIEF DESCRIPTION OF SEQUENCE OF

OPERATION.

The sequence of operation for various dishwasher

models is described in paragraph 2-14 through 2-16

and represented in figures 9 through 13. Many of the

parts referred to in these descriptions are shown in

figure 1 of this manual.

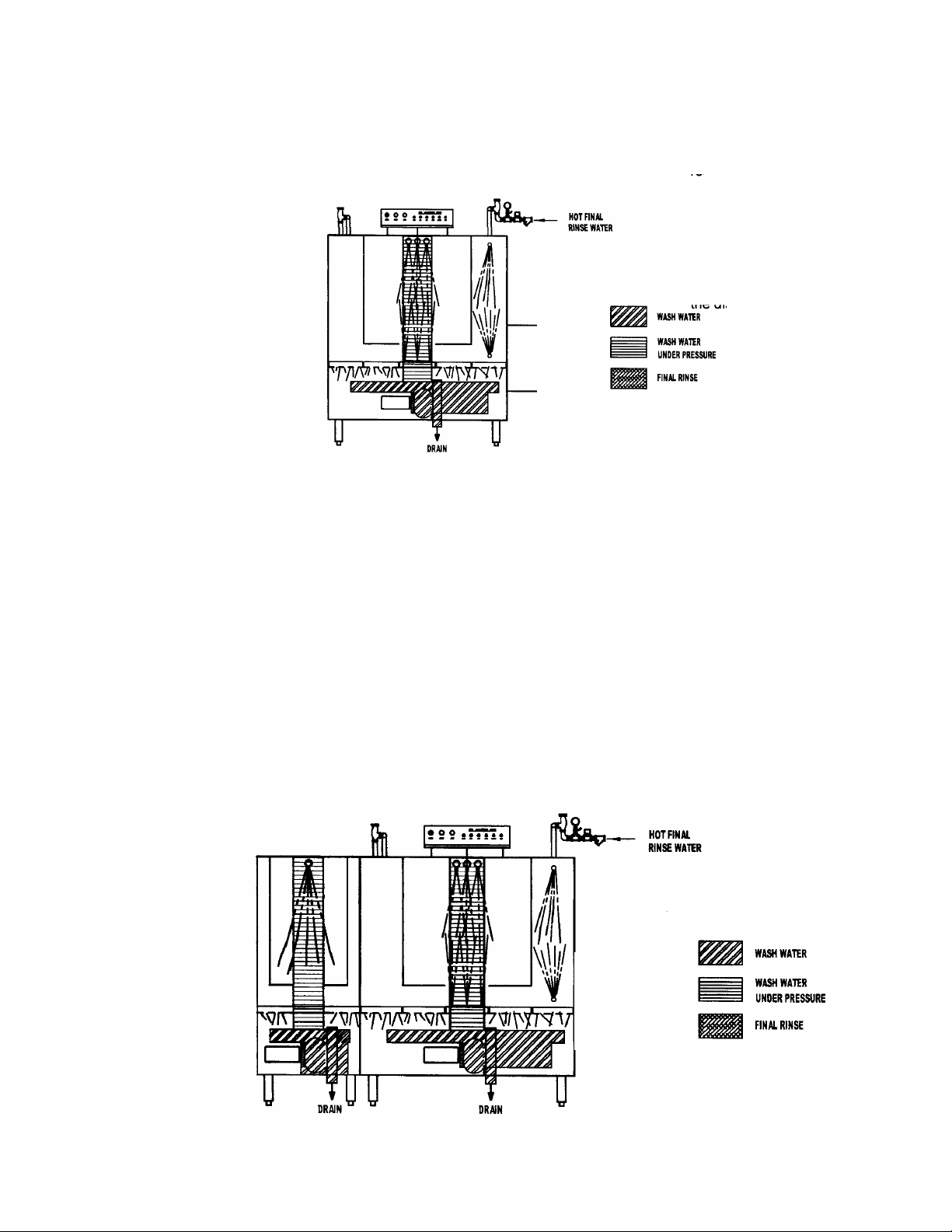

2-14 Single Tank Dishwashing Machine. (See Fig. 9)

WASH CYCLE. The pump directs the wash water

through the riser weldment at the rear of the machine to

upper spray arms and to a lower spray box. Nozzles on

the spray arms, and spray box direct the wash water at

the dishes.

11

Page 14

Trays on either side of the lower spray box prevent

dislodged food particles falling into the tank. The water

returns to the tank, where it is ready to start the wash cycle

again. The hollow standpipe permits overflow water to flow

down the drain and acts as a surface skimmer.

FINAL RINSE CYCLE. Hot final rinse water enters

the machine at the strainers and solenoid valve. The

water travels through the vacuum breaker and enters

the spray pipes. Nozzles on the spray pipes direct

the rinse water at the dishes.

FIGURE 9. Single Tank Water Distribution Diagram

2-15. Single tank with P-Module Pre-Wash (See Fig.11).

PRE-WASH CYCLE. The pre-wash tank is filled with

overflow water from the wash tank. The pre-wash water is

pumped through the riser weldment at the rear of the

machine where it enters an upper spray arm. (a lower

spray arm is available as optional equipment) Nozzles on

the spray arm direct the pre-wash water at the dishes. A

scrap tray below the conveyor track prevents dislodged

food particles falling into the tank. The water returns to the

tank, where it is ready to start the pre-wash cycle again.

The hollow standpipe permits overflow water to flow down

the drain.

WASH CYCLE. The pump directs the wash water

through the vertical riser at the rear of the machine to

upper spray pipes, and to a lower spray box. Nozzles

on the spray arms and spray box direct the wash

water at the dishes. Scrap trays on either side of the

lower spray box prevent dislodged food particles

falling into the tank. The water returns to the tank,

where it is ready to start the wash cycle again. The

capped standpipe prevents the overflow water

flowing down the drain. Instead, the water is forced

to overflow into the pre-wash tank.

FINAL RINSE CYCLE. The final rinse cycle for this

machine is identical to the final rinse cycle described

in paragraph 2-12.

12

FIGURE10. Single Tank with P- Module Pre-Wash Water Distribution Diagram

Page 15

2-16. Two Tank Dishwashing Machine (See Fig. 11).

WASH CYCLE. The pump directs the wash water

through the riser pipe at the rear of the machine to

upper spray pipes and to a lower spray box. Nozzles on

each spray arm and spray box direct the wash water at

the dishes. Scrap trays on either side of the lower spray

box prevent dislodged food particles falling into the

tank. The water returns to the tank, where it is ready to

start the wash cycle again. The hollow standpipe

permits overflow water to flow down the drain.

POWER RINSE CYCLE. The pump directs the rinse

water through the riser weldment at the rear of the

machine to upper spray arms and a lower spray box.

Nozzles on each spray arm and spray box direct the

rinse water at the dishes. Scrap trays on either side of

the lower spray box prevent dislodged food particles

falling into the tank. The water returns to the tank,

where it is ready to start the rinse again. The hollow

standpipe permits overflow water to flow down the

drain. The rinse water is replenished with used final

rinse water.

FINAL RINSE CYCLE. Hot final rinse water enters the

machine at the strainer and solenoid valve. The water

travels through the vacuum breaker and enters the

spray pipes. Nozzles on the spray pipes direct the rinse

water at the dishes. The used final rinse water falls into

the power rinse tank.

FIGURE 11. Two Tank Water Distribution Diagram

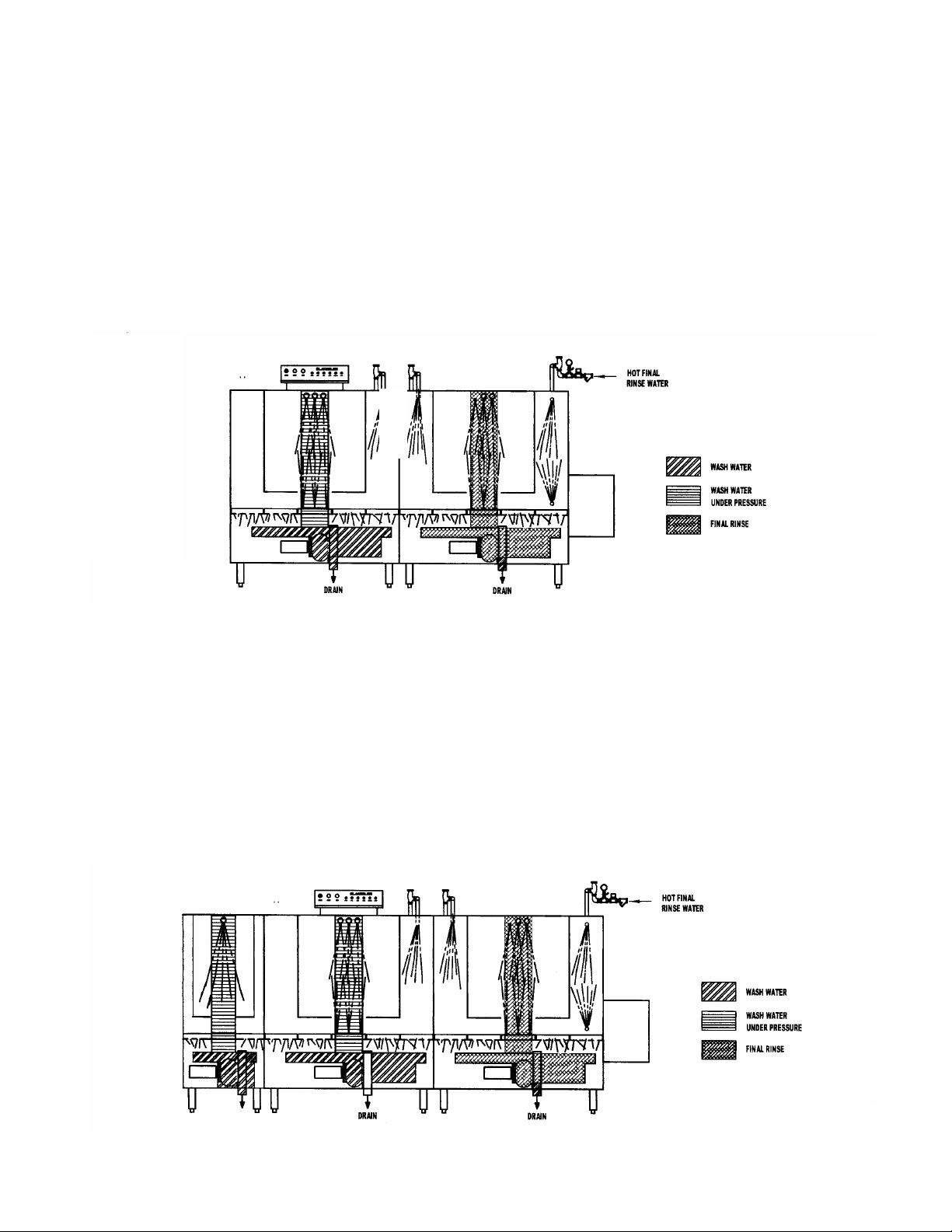

2-17. Two Tank with P-Module Pre-Wash (See Fig.12).

PRE-WASH CYCLE. The pre-wash cycle for this machine is

identical to the pre-wash cycle described in paragraph 2-13.

WASH CYCLE. The pump directs the wash water through

the riser weldment at the rear of the machine to upper spray

arms and a lower spray box. Nozzles on each spray arm and

spray box direct the wash water at the dishes. Scrap trays

on either side of the lower spray box prevent food particles

falling into the tank. The water returns to the

tank, where it is ready to start the wash cycle

again. The capped standpipe prevents the

overflow water flowing down the drain. Instead,

the water is forced to overflow into the pre-wash

tank.

POWER RINSE CYCLE. The power rinse cycle

for this machine is identical to the power rinse

cycle described in paragraph 2-14.

FINAL RINSE CYCLE. The final rinse cycle for

this machine is identical to the final rinse cycle

described in paragraph 2-14.

FIGURE 12. Two Tank with P – Module Pre-wash Water Distribution Diagram

13

Page 16

FIGURE 13. Three Tank Water Distribution Diagram

2-18. Three Tank Dishwashing Machine (See Fig. 13).

PRE-WASH CYCLE. The pre-wash tank is supplied with

overflow water from the wash tank. The pre-wash water is

pumped through the riser pipe at the rear of the machine

where it enters upper spray pipes and lower spray box.

Nozzles on each spray pipe and spray box direct the prewash water at the dishes. Scrap trays on either side of the

lower spray box prevent dislodged food particles falling into

the tank. The water returns to the tank, where it is ready to

start the pre-wash cycle again.

14

The hollow standpipe permits overflow water to flow

down the drain.

WASH CYCLE. The wash cycle for this machine is

identical to the wash cycle described in paragraph 2-

15.

POWER RINSE CYCLE. The power rinse cycle for

this machine is identical to the power rinse cycle

described in paragraph 2-14.

FINAL RINSE CYCLE. The final rinse cycle for this

machine is identical to the final rinse cycle described

in paragraph 2-14.

Page 17

Section III Cleaning of Machine

g

3-1. DAILY CLEANING

After each meal period and at the end of each day, the

dishwashing machine should be stopped and the

following cleaning procedures performed. A hose

attached to a faucet in the hot water supply line makes

the cleaning of your machine and dish tables much

quicker and easier. The hose can be stored neatly

coiled on a hook beneath the dish tables.

1. Stop the dishwashing machine as outlined in

paragraph 2-5. Check that heaters are off, tanks are

drained, and drain valves are open.

2. For a machine with regular load section, lift the clean

out door at the end of the section and remove soil from

inside the section. Clear the beehive strainer on the

drain to the scrap basket. Close the clean out door and

hose down the interior of the load section. Leave the

scrap basket in the machine during this operation.

For a machine with extended load section, hose the

interior of load section directing the scraps to the

opening in the load section that connects to the soil

container (trough disposer or basket, recirculator, etc.).

Clean the auxiliary equipment after the dishwashing

machine has been cleaned; cleaning instructions for

Blakeslee equipment is included in Section V.

3. Lift the clean out door on each side of the unload

section and remove soil from inside the section. Clear

the beehive strainer on the drain to the scrap basket.

Close the clean out door and hose down the interior of

the unload section.

4. Remove curtains and scrub them in a sink (see figure

14). The curtains can be installed in the dishwasher to

dry, but it is best to hang them elsewhere. The

dishwashing machine will dry and air out better without

the curtains in place.

5. Remove scrap trays and empty them into a sink.

Flush the trays with a hose or clean them with a scrub

brush. When emptying the trays, do not knock them on

disposal cans; knocking the trays will bend them out of

shape and they will not fit properly in the dishwasher.

FIGURE 14 Scrubbing Curtains

6. Check and clean the spray box/tubes as necessary. To

remove them refer to figure 14 and loosen the pilot screws

retaining the spray box/tubes. Slide the spray box and

tubes out of the machine. Check the gasket and seals for

signs of wear (paragraph 4-6). Dislodge anything stuck in

the nozzles by pushing the material back and into the box

or tube. Wash the spray box or tube, flushing the

materials out of the inlet hole.

FIGURE 14 Spray Box Mountin

7. Hose and scrub the inside of the dishwashing machine.

Do not direct hose up into the end hood ventilating ducts.

Use a damp cloth to wipe hood condensate baffle clean.

8. Remove access doors from each tank and clean both

sides of the door, a lip at the bottom tends to collect soil;

be sure to clean this area.

9. Clean the drain screen as outlined in paragraph 3-3.

10. Install the clean spray box and tubes in position in the

machine (refer to figure 14). Be sure to position the upper

spray tubes with the nozzles pointing down. When

installing the tubes and spray box, tighten pilot screw

finger tight only; do not apply excessive pressure.

11. Leave access doors open and leave scrap trays and

curtains on the dish table until preparing the machine for

operation. This allows the dishwashing machine to dry

and the operator will know that the machine has been

thoroughly cleaned.

12. Clean and fill detergent dispenser.

15

Page 18

3-2. PERODIC CLEANING.

The frequency with which the following cleaning

procedures should be performed depends on the hours of

dishwasher operation and the condition of the water in

your area. When intervals are specified (once a week,

once a month, etc.) they are recommended minimum

intervals and should be performed at least as often as

specified.

3-3. Drain Screen

The drain valve for each tank of the dishwashing machine

is equipped with a cylindrical stainless steel screen (6,

figure 15). When this screen is clogged with food

particles, the tank does not drain as quickly as it should.

Thorough pre-scraping of the ware will minimize screen

clogging. Cleaning of the screen should be performed

after a daily cleaning. Clean the screen in each tank as

follows:

1. Check that the heater is off and the tank is drained.

Position the drain valve in the closed position.

2. Remove the 3 wing nuts (20, figure 15) and pull the

drain case door (21) from the drain case. A gasket (22)

between the case and the door acts as a seal to prevent

leakage. If it is necessary to pry the door from the case,

be careful to avoid damaging the gasket.

CAUTION: The tank must be empty of water before

removing the drain case door. When drain case contains

hot water and the door is removed, the hot water will exit

at the door hole and could cause serious injury. If drain

screen is completely clogged, manually remove water

with a container through the access door from top of tank.

To gain access to the screen to unclog it, lift standpipe by

pulling it up, turning drain valve handle at the same time.

3. Lift drain standpipe (1) straight up to gain access to the

screen.

4. Lift the screen straight up off of the drain valve seat

(10) and clean it in a sink with a brush A bent or deformed

screen should be replaced with a new one.

5. Clean drain case interior and flush the drain valve with

clear water.

6. Install clean screen (6) on drain valve seat (10).

7. Lower the standpipe (1) into the drain valve seat. Do

not drop standpipe into position.

8. Be sure door gasket is in place on drain case, (22).

With the drain valve knob in closed position (white arc at

the (bottom), install the door on the case, locating the

cam on the knob shaft between the two collars on the

standpipe. The three mounting holes in the gasket and

door are not spaced equally and therefore the gasket and

door holes must be matched to the case studs

16

9. Assemble the three wing nuts (20) on the case studs,

applying equal pressure to the wing nuts until they are

snug; do not tighten these nuts with a wrench.

FIGURE 15. Standpipe and Drain Valve Shaft

1. Stand Pipe 12. Thermometer

2. Retaining Ring 13. Cam Shaft Assy.(14-18)

3. Washer 14. Cam Shaft

4. Drain Plug 15. Stop Pin

5. Washer 16. O-Ring

6. Screen 17. Knob

7. Screen retainer 18. Hex Nut

8. Stand Pipe Guide 19. Spacer

9. Hex Head Bolt 20. Wing Nut

10. Drain Seat 21. Door

11. Cam Shaft Assy. 22. Door gasket

3-4. Low Water Cut-Off Float.

For proper operation of the low water cut-off system, the

float in each tank must be free of detergent scum and lime

deposits. Daily cleaning and deliming will keep the float

reasonably clean. CAUTION: Do not use steel wool

cleaning pads.

Page 19

3-5. Line Strainers

Every dishwashing machine is equipped with a strainer

in the final rinse system (10, figure 2). In addition, each

steam heated machine (steam injector or steam coil) is

also equipped with a strainer at the steam inlet. The

following instructions apply to all of the strainers.

DELIMING REMOVABLE DISHWASHER PARTS.

The daily cleaning procedures will reveal when it is

necessary to delime such items as final rinse nozzles

and spray boxes.

Recommended procedure is to soak these parts in a

large sink containing a deliming product. Follow the

instructions of the deliming product manufacturer for

mixing the solution and length of time soaking. After

soaking, be sure to wash with detergent and rinse all

parts thoroughly to neutralize any deliming solution

remaining on the parts.

DELIMING DISHWASHING MACHINE. Cleaning of

the dishwashing machine interior with an appropriate

deliming preparation should be performed as

necessary to remove accumulated deposits in order to

FIGURE 16. Steam Injector Line Strainer

Once a month, clean the strainer as follows. Unscrew

the brass cap and remove the strainer screen. Brush

the screen or flush out dirt with fresh water. Install the

screen and attach the brass cap securely. A worn

screen should be replaced with a new one.

3-6. Final Rinse Nozzles.

Every 3 to 4 months, check and clean rinse nozzles as

necessary. If lime deposits have formed on the nozzles,

the nozzles should be removed from the spray pipes and

placed in a deliming solution (refer to paragraph 3-9).

3-7. Electric Heating Elements.

Lime deposits on electric heating elements cause poor

heating and premature burn out of the element. The

tank must be delimed as soon as lime scale starts to

build up on the element.

3-8. Steam Heating Coil.

A buildup of lime scale on steam heating coils drastically

reduces their heating efficiency. The tank must be

delimed as soon as lime scale is noticed on the coils.

3-9. Deliming Solution Precautions.

Some deliming preparations contain muriatic acid.

Muriatic acid is corrosive to skin as well as to clothing

and metals; it is very harmful if splashed in the eyes.

When using this acid, caution must be exercised and

maintain optimum machine performance. Most

dishwasher detergent representatives will instruct

owners on proper deliming procedures. When

deliming the machine, observe the following:

1. Turn on power to fill the dishwashing machine

tank(s) half full of water, turn off power. Then

add deliming solution, following the detergent

manufacturer’s recommendations.

2. After the deliming solution has been added to

the half filled tank(s), turn on power to

continue filling tank.

3. The conveyor must be operating during the

deliming process.

4. Allow the deliming solution to circulate for 15

minutes. If this15 minute operation is not

sufficient to remove deposits, operate for not

more than an additional 15 minutes.

Occasionally, there will be places in the

machine where some deposits still remain;

remove the softened-up deposit with a putty

knife or wire brush.

5. Turn off power and drain the Tank(s). Then

immediately refill the tanks with fresh water

and add detergent. Operate the machine 10

to 15 minutes to neutralize any solution left in

machine.

6. Drain the tank(s) again and flush them out

with a hose. NOTE: Certain deliming

solutions have a very high concentration of

acid that is harmful to vital components of your

machine (pump seals, plastic links, etc.) Be

sure to check with your detergent

representative or the manufacturer deliming

solution before using. If in doubt, contact your

local Blakeslee representative.

personnel should be acquainted with the risks and

hazards.

17

Page 20

Section IV Preventive Maintenance and Minor Repair

4.1 PREVENTATIVE MAINTENANCE.

A good preventive maintenance program ensures that

the dishwashing machine is kept in good operating

condition and lessens the chances of break-down.

Preventive maintenance means making systematic

inspections and adjustments at regular intervals. These

procedures should be performed as soon as the need

becomes apparent or at the specified intervals. More

frequent inspections and adjustments should be if

experience indicates that shorter intervals are required

due to operating conditions. In addition to the periodic

cleaning procedures of Section III, the inspections and

adjustments of paragraph 4-2 through 4-16

4-2. LUBRICATION.

The pump and drive motors contain ball bearings and do

not require lubrication. The conveyor drive chain and

gear reducer must be lubricated or checked as described

in the following paragraphs. CAUTION: When applying

lubricant, secure or lock main power in the OFF position.

Power must be off to the machine during lubrication

procedures to avoid accidental conveyor operation which

could result in physical harm to maintenance personnel.

4-3. Conveyor Drive Chain

Once a month, oil the drive chain (see figure 3).

Remove drive section panel and apply a few drops of oil

to the drive chain. Use straight 20-20w oil. Replace the

drive section panel.

4-3. Conveyor Drive Gear Reducer.

Once a month check gear reducer oil level. The oil plug

and oil drain plug are located on the gear reducer as

shown in (figure 17). The oil level should never be higher

than the upper plug. To add oil, remove the air vent and

fill screw (figure 17) and add oil through the vent hole.

Use a high quality compounded worm gear oil, Mobil

Extra Hecla Super or a comparable oil recommended by

your lubricant supplier. Install the air vent and fill screw.

After the first 100 hours of operation, and then after

every 2500 hours of operation or every 6 months,

change oil. Place a suitable container beneath the oil

drain plug. Remove plug and allow oil to drain from the

gear reducer. Install drain plug and fill reducer with fresh

oil until the oil starts to come out of the oil level plug.

Install level plug.

4- 4. V-BELT TENSION ADJUSTMENT

The conveyor drive gear reducer is driven by a notched

V-belt from the drive motor. The average belt will stretch

after a period of time. After the first 50 hours of

operation, and then periodically as experience indicates,

check the v-belt tension. Figure 18 indicates the proper

tension; belt deflection is ½ inch when a 3-pound force is

applied.

18

FIGURE 17. Conveyor Drive Gear Reducer and

Motor

To adjust the tension, loosen the locknut see figure

18) to permit turning the adjustment rod. Turn the rod

clockwise to tighten the belt; turn counterclockwise to

loosen the belt. Tighten the locknut after turning the

rod to maintain the proper tension.

FIGURE 18. Conveyor Drive Belt Tension

4-5. PREVENTING LEAKAGE.

The spray box gaskets and standpipe drain plug are

subject to wear, which results in leakage. The

following paragraphs contain replacement instructions

for these and similar items. Part numbers for

replacement parts are listed in Section VI of this

manual. For servicing of other leaks, contact your

local Blakeslee service agency.

4-6. Spray Box Gaskets

Poor washing results occur when the spray box/tube

gaskets or seals are worn and leaking. When the

spray box/tube is removed for cleaning, check the

gasket and seals (see figure 14) for signs of wear. If

they are worn or out of shape, replace with new ones.

To minimize gasket wear, when installing the spray

box and tubes after cleaning, do not apply excessive

pressure to the pilot screw.

Page 21

4-7. Stand Pipe Drain Plug

When cleaning the drain strainer (paragraph 3-3), check

the stand pipe drain plug (4, figure 15) for signs of wear.

If the plug is nicked or badly grooved, replace with a new

one. NOTE: Before installing new drain plug, apply a

light film of silicon sealant to the entire exterior

circumference of the plug groove.

4-8. Drain Cleanout Door Gasket

When leakage occurs around the drain case door, the

problem may be a worn drain cleanout door gasket.

However, first be sure the door was properly installed

(paragraph 3-3, steps 8 and9). When the drain strainer

is cleaned, check the gasket for signs of wear. If gasket

is worn, replace with a new one.

4-9 Impeller Guard

This unique device consists of a guard housing encircling

the pump intake and positioned ¾” from sump wall,

providing a circular opening that is larger than the

opening of the pump intake, Thus creating no restrictions

for water flow. Inside the circular guard housing there is

a guard disk of smaller dimension which allows

additional passage of water flow with minimum

restrictions. The location of guard housing and disc is

such that there is no straight entrance into the impeller

4-11. Flame Adjustments for Gas-Heated Tanks.

After the dishwashing machine is installed and gas

connections are made, the pilot and burner should be

adjusted to obtain desired tank temperatures. Refer

to paragraph 2-6 for pilot lighting instructions.

PILOT FLAME ADJUSTMENT. The pilot flame should

envelope 3/8 to ½ inch of the top of the thermocouple.

Remove the cover screw to gain access to the pilot

flow adjustment screw; see figure 8. Turn the

adjustment screw clockwise to decrease pilot flame;

turn counterclockwise to increase pilot flame. Be sure

to replace cover screw after adjustment to prevent

possible gas leakage.

BURNER FLAME ADJUSTMENT. The burner flame

must only touch the tank. On natural gas machines,

minor burner adjustment can be made by adjusting

the pressure regulator of the gas valve; on L.P. gas

machines, the customer’s gas pressure regulator can

be changed for minor adjustment. Each burner is

equipped with an orifice spud See figure 8). If a

proper flame cannot be obtained by making minor

adjustments, the orifice spud size must be changed.

Contact your local Blakeslee agency for assistance, or

to order the appropriate size spud.

4-12. Thermostat Settings

An adjustable thermostat is furnished for each heated

tank of the dishwashing machine. A typical thermostat

is shown in figure 19. The thermostat is adjusted by

turning the adjusting screw with a screwdriver; turn

clockwise to increase tank water temperature and

counterclockwise to decrease the temperature. Some

adjusting screws are mounted on a temperature scale.

However, setting the screw at a specific temperature

on the scale does not necessarily mean the sump

thermometer will register that same temperature, since

the thermostat temperature sensing element and

thermometer are not mounted together. The

thermometer indication is the temperature to observe;

consider the adjusting screw scale as reference

settings. Thermostat settings are an owner

Figure 19. Impeller Guard Installed in Sump

4-10. MINOR REPAIR

The following repair procedures are adjustments or

replacements to be performed only when necessary, not

on a periodic basis. Part numbers for replacement parts

are listed in Section VI of this manual.

responsibility and are not covered under warranty.

Thermostat Adjusting

Screw

FIGURE 20. Thermostat Adjustment

19

Page 22

4-13. Control Box Fuse

1

The control panel fuse is a 3.2 ampere Slo-Blo fuse,

located as shown in figure 21. With the main power

turned off, open the control box cover and inspect the

fuse. If fuse is suspected to be blown, replace with a

new one of the same capacity. Fuse is held in position

with spring clamps.

NOTE: Simple problems like blown fuses are not

covered under warranty. However if the machine

continues to blow fuses, call your local Blakeslee Service

Agency.

4-14. Motor Overload Relay

Each motor in the dishwashing machine is protected

with thermal overload relays. These relays will

automatically reset when the relay has cooled down.

The motor thermal overload relay tripped for a reason.

For example, if one or all of the conveyor motor relays

opened, a jammed conveyor may have been the

cause. Once the jam is released and the relay has

reset, the conveyor should operate. Similarly, the

pump motor overload relays may be tripped due to a

foreign object caught in the pump impeller. Removing

the object should remedy the situation. However, if

the same relay opens again shortly after operation is

resumed, the cause has not been found and

corrected. Do not continue resetting the relay; call

your local Blakeslee Service Agency for assistance.

NOTE: Resetting motor overloads is not covered

under warranty.

16

15

o o o o

o o o o o o o o o o o o o o o o o o o o o o o o o o o o o

o o o o o o o o o o o o o o o o o o o o o o o o o o

11

L1 L2 L3

o o o

6

o o o o o o o o

o

o

o

o

o o

o o

10

14

9

o

6

8

o

6

6 6

6 6

7

12

13

7

2 3 4 5

FIGURE 21. Control Panel

1. Rinse Timer 7. Auto Fill Timer - 2 12. Auto Cut-Off Timer

2. Power Switch 8. Door Safety Switch 13. 24 Volt Power Supply

3. On Switch Contact Block 9. Contactors - 4 14. Transformer, Output 115 Volt

4. Off Switch Contact Block 10. Auxiliary Contactors - 2 15. Fuse 3.2 Amp. Slow Blow

5. Relays - 7 11. Overload Relays - 4 16. Reset Switch

6. Indicator Light

20

Page 23

4-16. TROUBLE SHOOTING.

Trouble shooting procedures are listed in the following table.

Each trouble is followed by a list of possible causes and

suggested procedures to correct the cause.

Trouble Possible Cause Corrective Procedure

In general, the procedures should be performed

in the order in which they are listed.

Machine will not start Main power supply off Turn on main power supply

Fuse blown – main supply Replace fuse or fuses

Fuse blown – control panel Replace fuse

Improper power supplied to machine Check incoming line voltage

Tanks not completely filled with water Fill all tanks with water

Tanks do not heat up NOTE: Electrically heated machines ha v e separate supply line voltage feed to

heating element contactors and should have a separate circuit breaker.

Power supply turned off Check circuit breaker

Low water float not satisfied Make sure tank is full of water

Thermostats set at improper

Check thermostats and adjust

temperature

Gas not turned on Check gas line valve – turn on

Pilot light not lit Light pilot light

Steam not turned on Check steam supply (boiler) to assure it

is operational

Low steam pressure Boost boiler pressure up to 15-25 lb.

flow pressure

Clogged steam line strainers Check all steam line strainers and clean

Pumps do not start All tanks not completely filled with water Fill all tanks with water

Float switch inoperable or stuck in down

position

Check by lifting float ball. Clean foreign

material from between float and stem.

Conveyor wont run Power not on Turn on conveyor start switch

“V” belts slip Adjust “V” belt tension (1/2” deflection of

belt)

Is “V” belt broken Replace “V” belt

Conveyor unload switch in open position Remove ware from unload section;

check that stop plate is released

Conveyor overload relay tripped Will reset automatically after cooling –

check for jam

Conveyor safety stop switch is not

Release jam that is tripping switch

released

Conveyor jammed and

wont move

Silverware caught in conveyor belt Remove and instruct operators on

proper loading

Broken underslung link Replace underslung link

Poor Final Rinse Water not turned on Check to assure rinse water supply is

turned on

Line strainer dirty and clogged Remove line strainer screens and clean

Low water pressure Check incoming water pressure and

adjust to15-25 lb. flow pressure

Rinse micro switch not working Check rinse actuator lever to assure it is

activating the rinse micro switch - adjust

Rinse temperature low Adjust hot water booster

Excessively hard water Install water treatment equipment

Rinse nozzles clogged Remove rinse nozzles, clean and

reassemble

21

Page 24

Trouble Possible Cause Corrective Action

Final rinse temperature low Booster not turned on Check circuit breaker for electrically

heated boosters

Thermostats set improperly Adjust thermostats as needed

Excessive water pressure Reduce water pressure to 15-25 lb.

flow pressure

Steam pressure low Boost up steam pressure at boiler

Steam line strainer clogged Remove line strainer screen, clean

and reassemble

Electrical & steam heated

boosters do not maintain 180°

Temperature at final rinse

Tanks not holding water Drains are not closed properly Check drain handles to assure drains

Plugs on standpipes worn Refer to paragraph 4-7

Standpipes in wrong tanks Refer to paragraph 1-12 and figure 4

Standpipes not positioned properly on

Poor washing results Pump(s) not running Press pump start button

Pump(s) running backwards Check arrow on pump motor. Consult

Spray box/tube nozzles clogged Remove spray box/tubes, clean &

Spray box/tubes seals leaking Remove Gaskets/seals, if worn or out

Upper spay tube in upside down Remove spray tube & replace

Tank temperature low Check thermostats and adjust if

Detergent dispenser empty Fill Dispenser

Detergent dispenser inoperative Contact detergent representative

Dish poorly scrapped Remove all heavy soil before putting

Dirty wash water Drain tanks and refill

Tanks foaming Poor pre-scraping of ware Scrape ware before putting into

Tank water excessively dirty Drain tanks and refill

Excessive amount of detergent being

Racks will not pass through

machine

Improper racks being used Replace type of rack being used.

22

140° water not being fed to booster Increase incoming water temperature

to 140° to inlet side of booster

are in closed position

Remove cleanout cover and replace

drain can shaft

assuring the drain cam shaft is

located between the two collars on

the standpipe

Blakeslee technical support for

assistance if necessary

reinstall

of shape, replace

correctly

necessary

into machine

machine

Contact detergent representative for

used

assistance

Racks not in correctly Check racks for proper alignment to

conveyor tracks

Check with your local Blakeslee

Representative

Page 25

Section V. Use of Additional Equipment

5-1. GENERAL 5-2. HOT WATER BOOSTER.

This section contains information regarding proper use

and maintenance of extra equipment available from

Blakeslee for dishwashing machines. The information

included here is for additional equipment purchased

most frequently. It is not a complete listing of every

option available. The additional equipment is listed

below with the corresponding paragraph number.

Equipment Paragraph

Automatic Tray Unloader

Econo-Blower

End Hoods

Fresh Water Prerinse

Hot Water Booster

Loading Shelf

Overshelves

Preflusher

Preflusher with Flush-veyor

Tray Guides

Tray Retainer

Troughs

5-45

5-41

5-13

5-32

5-2

5-24

5-16

5-31 The S2 Heat Exchanger is used on all single and

5-36

5-51

5-23

5-25

The hot water booster is used to raise the final rinse

water temperature recommended by the National

Sanitation Foundation and required by many health

departments. To attain this temperature, the water

supply to the booster must be maintained at 140° F.

The booster is supported on a sturdy floor stand with

adjustable legs for installation

Underneath the dish table. A choice of either a steam

or an electric heater is offered. If the supply

temperature of the water is lower than 140° F, an

oversized booster must be used. In some cases, it is

necessary to connect 2 boosters in series. The

machine capacity ratings are based on a 50°

temperature rise.

5-3. STEAM HOT WATER BOOSTER.

multi-tank systems.

FUGURE 22. Steam Hot Water Booster

1. Steam Inlet Strainer 5. Pressure Gauge

2. Solenoid Valve 6. Pressure Relief Valve

3. Strainer 7. Steam Trap

4. Pressure Regulator

23

Page 26

5-4. Controls

STEAM LINES. The steam inlet is equipped with a

line strainer (1, figure 21) and solenoid valve (2); the

solenoid valve is controlled by an electric thermostat.

A steam trap (7) on the steam outlet assures efficient

heating. Periodic cleaning of the strainer is

recommended. No operator control of this system is

required.

HOT WATER INLET LINE. The inlet piping contains a

line strainer (3), pressure regulator (4), pressure

gauge ( 5), and pressure relief valve (6). Periodic

cleaning of the line strainer is recommended. The

pressure regulator is adjustable (paragraph 5-6). The

pressure gauge indicates the flow pressure of the final

rinse water when the final rinse is in operation. The

gauge should be observed periodically to assure good

final rinse action. Good final rinse results are obtained

when the flow pressure is between 15 and 25 P.S.I.

HOT WATER OUTLET LINE. The thermostat sensing

bulb is in the hot water outlet line. See paragraph 5-6

for adjustment

5-5. Cleaning.

Line strainers. The water outlet and steam line

strainers protect the solenoid valves from dirt. Every

month, clean the strainers as described in paragraph

3-5. Be sure water and steam supplies are turned off

and pipes are cool.

Lime deposits if lime deposits are a problem in your

area, every 9 to 12 months delime the booster heat

exchanger. Remove the heat exchanger and

submerge it in a tub of deliming solution. Follow the

instructions of the deliming product manufacturer for

mixing the solution and for length of time of soaking;

48 to 60 hours of soaking time is generally required.

After soaking, be sure to wash and rinse the heat

exchanger thoroughly before installing it on the

booster.

5-6. Adjustments.

THERMOSTAT. Observe the instructions of paragraph

4-12 for adjusting the thermostat settings.

PRESSURE REGULATOR. If the final rinse flow

pressure is not between 15 and 25 psi, adjust the

pressure regulator (4, figure 21) observe the following.

Loosen the ½” lock nut. Start the conveyor and

activate the final rinse. With the final rinse water

flowing through the pressure regulator, adjust to the

correct pressure. After the proper pressure is

attained, hold the ½” square head screw in place and

tighten the lock nut. To increase the flow pressure,

turn the screw clockwise. Turning the screw

counterclockwise will decrease the pressure.

24

5-7. Installation.

Position the booster so that the pressure gauge can be

observed by machine operator. Use the adjustable feet

on the booster to level the unit.

BOOSTER LOCATION. Booster location with respect to

the steam supply, hot water supply and dishwashing

machine is important for efficient booster operation.

Position the booster as close to these items as possible.

If the booster is positioned 20 feet or more from the

dishwasher, though the final rinse water is 180° F when

it leaves the booster, the exposed piping through which

the water travels will cool the water. The same situation

applies to the booster hot water supply. Similarly, when

steam is carried over a long distance through an

exposed pipe, a pressure loss and temperature loss

results. The booster cannot operate efficiently with long

distances of exposed piping. If the booster is located a

great distance from the dishwasher, it is recommended

that an optional final rinse low temperature control be

installed in the dishwasher.

BOOSTER TO DISHWASHER CONNECTIONS. Final

rinse piping is3/4 inch NPT. Connect wires of steam

solenoid (2, Figure 21) to the control panel terminals (as

noted in wiring diagram). Protect the wires with a ½ inch

conduit.

SUPPLY AND CONDENSATE CONNECTIONS. When

connecting the hot water and steam inlet piping, include

a shut-off valve at each inlet. The water piping you

connect must be a minimum of ¾ inch. The steam pipe

must be a minimum of 1 ½ inch. Pipe size must be

increased on runs over 50 ft.

The hot water inlet tee is ¾ inch NPT. The steam inlet

strainer is 1 inch NPT. We suggest supply pipes be

wrapped with insulation material. The condensate

return is ½ inch NPT.

NOTE: Your condensate return line must always be

pitched down. For condensate return lines that are level

or going uphill, a condensate return pump must be used.

SUPPLY PRESSURE AND TEMPERATURE

REQUIREMENTS. Booster output (180° F water) is

measured in gallons per minute (gpm). The output

requirement for a particular machine is the sum of the

final rinse water 9 (in gpm) plus make up water (in gpm);

makeup water requirement is approximately 2 gpm. To

obtain a desired output, inlet water temperature and

steam supply pressure must correspond as indicated in

the booster chart (page 22). For example, the S2

booster is capable of providing 10 gpm (600 gph) of

191° F final rinse water when the inlet water temperature

is 140° F and the flowing steam supply is 5 pounds. If

the inlet water temperature is 120°F to provide 10 gpm

of water at 191° F the steam flow pressure would have

to rise to 11 pounds. The booster chart is included to

assist you in making sure adequate supply conditions

are available for effective booster operation.

Page 27

S2 Heat Exchanger

1” Co nn. ¾” Conn. Water Temperature

Steam Water Flow 100° F IN 120° F IN 140° F IN

PSIG GPM OUT° F OUT° F OUT° F

4 200 205 209

5 195 200 205

6 190 195 201

7 186 192 199

8 181 188 195