Page 1

SERVICE/PARTS MANUAL

ELECTRIC

BLAKESLEE

BLAKESLEE

Crockford Boulevard

FOOD

MIXERS

MODELS

DD-60

DD-80

1844 South Laramie Avenue

Chicago, IL 60804

Phone: (708) 656-0660

66

Scarborough Ontario, Canada M1R 3C3

Phone: (416) 751-2625

Page 2

INDEX

GENERAL INFORMATION 1

INSTALLATION INSTRUCTIONS 2

DESIGN AND USE OF BEATERS, WHIPS AND OTHER ACCESSORIES 3

MIXING INSTRUCTIONS 5

MIXING BOWL CAPACITY CHART 9

AVAILABLE BEATERS, WHIPS AND ACCESSORIES 12

OPERATION 15

PARTS SECTION - Follows page 15.

IMPORTANT -- Please list your Model and Serial Number below:

Model _______________________

Serial Number _______________

This information is required when ordering parts or requesting service information.

Page 3

GENERAL INFORMATION

Your Blakeslee Mixer is just one piece of equipment that provides extra profit in your operation.

Consistency of performance will reduce waste and maintain better control over yield.

Your Blakeslee-built mixer has been designed and engineered to assist you in the quick and easy

preparation of fine tasting, quality foods. It is a valuable machine deserving the same maintenance and

attention your other kitchen equipment now receives. By following the suggestions In this booklet, your

mixer will operate for many trouble-free years.

This booklet has been prepared to give you the necessary knowledge for correct operation,

load, and lubrication of your mixer.

The food service operator will also be able to save you labor during the cleaning proc ess due to the

smooth surfaces and the design of the Blakeslee mixer. Each beater, whip and attachment is engineered to

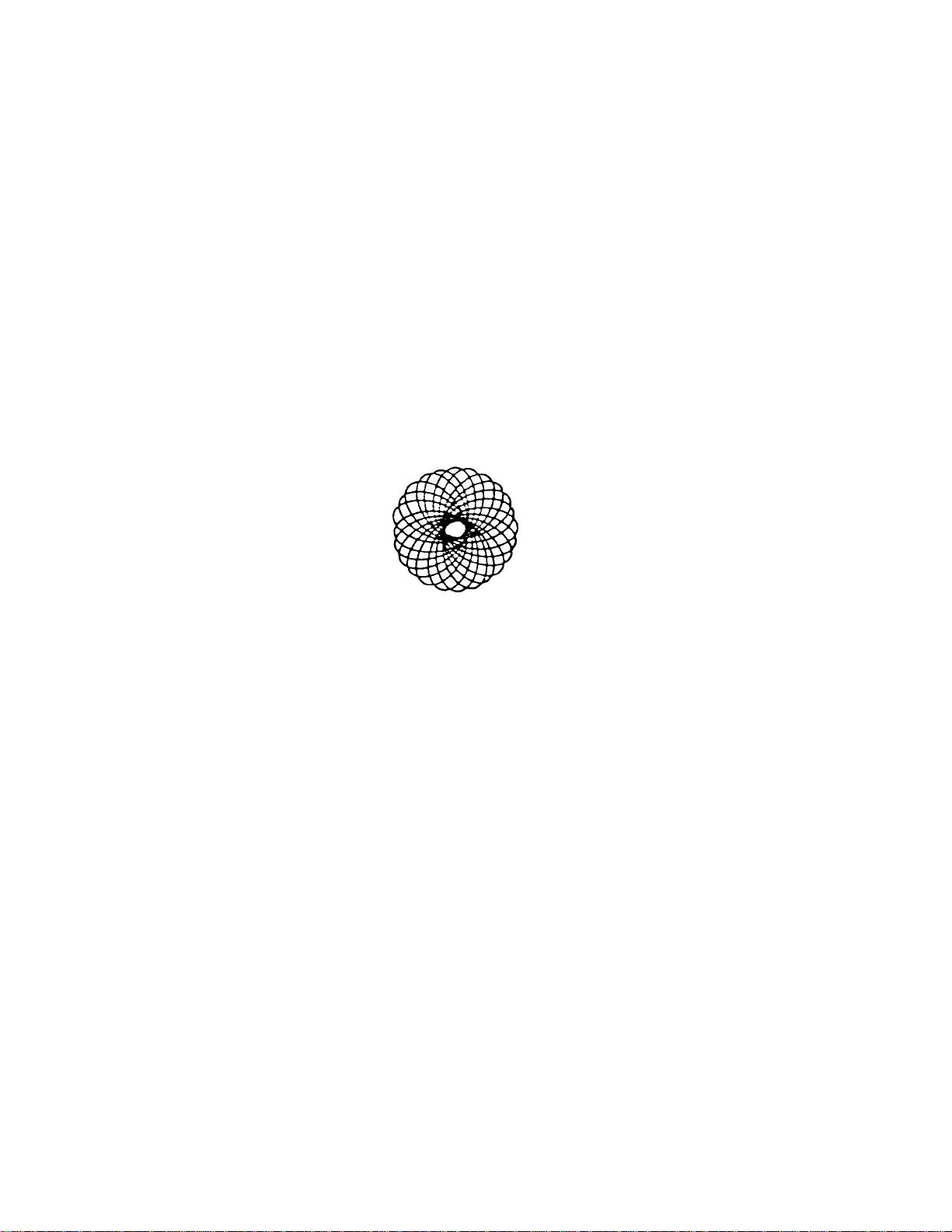

perform specific jobs for you. The planetary action of Blakeslee Mixers (beater travels around the

circumference of the bowl as it rotat es) assures you of a perfectly blended mix every time.

Diagram shows complete coverage of

bowl by planetary action of beaters

IMPORTANT - The mixers must be in gear for the mixer to start.

-1-

Page 4

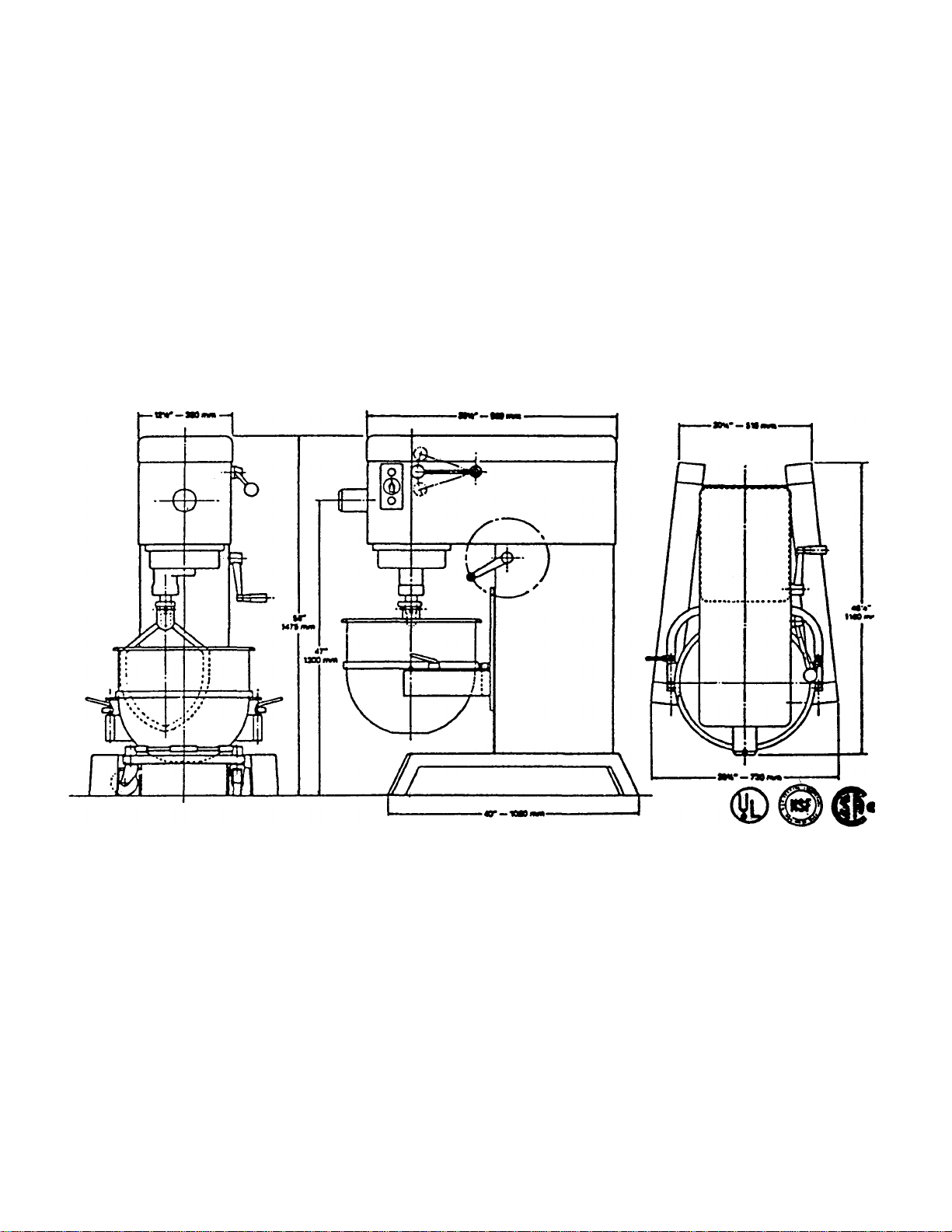

1. Place Mixer in correct location with proper clearance between wall and/or adjacent equipment.

2. Level machine with shims.

3. No bolting is required to the floor.

4. Connect electrical conduit to left side of machine. Check rotation of motor by arrow on planetary cover.

Planetary shaft should rotate as shown.

5. Checking the oil level Is not required due to the permanent lubrication used.

-2-

Page 5

DESIGN AND USE OF BEATERS, WHIPS & OTHER ACCESSORIES

Each beater and whip has been designed to do a particular type of work. Use only that beater or whip

for the work for which it was designed. For example: Never use a batter beater for mixing heavy

doughs. Always use an "H" or a "SPIRAL" dough hook for dough work.

Following are illustrations of the different types of beaters and whips with an explanation of the work

and the use for which they were designed.

BOWL EXTENSIONS

Extension Rims are merely vertical sided Splash Covers. They are not covers in form

but do provide higher side walls to prevent throw-out of ingredients. Usually they are

not recommended because they are often invitations to overloading a machine beyond

its point of maximum efficiency. Extension rims permit more air

to enter the bowl and prevents splash of light ingredients.

The true capacity of a Mixer is not the amount of material that can be put in the bowl of the amount of total

batch which can be mixed within the power of the motor. The true capacities and the most efficient

(therefore the best money makers) are the ideal loads which permit a Mixer to operate at peak efficiency,

so far as development, yield or aeration have their effect on the mixing operation.

"SPIRAL" DOUGH HOOKS

(Available for 60 and 80 qt. bowls only)

Used for mixing bread .of roll dough of standard consistency, biscuits, meat loaf. etc. The

"SPIRAL" dough hook is a special dough hook for mixing heavy doughs such as white, graham

or rye bread, noodles, pret zels, Italian bread and pizza. Dough hooks should always be operated

at stow speed only. Do not use other types of beaters for dough work; doing so will result in

damage to either the beaters or to the mixer proper. Never exceed capacities as listed.

"PK" PASTRY KNIFE

Used for cutting flour and shortening together in pie dough, pastry shells and for cutting

lard or shortening into flour. The "PK" pastry knife should always be used for such work

so that pie crusts, etc. are mixed with as little rubbing as possible and so that the

shortening will be in small pieces to produce a flaky product.

-3-

Page 6

SPLASH COVERS

These items provide means for reducing splash of throw-out on certain mixers when, for reasons of

speed, the operator prefers to start in a higher speed or progress quickly to a high speed in order to

complete a batch. These are valuable accessories but would not be used to increase the mixing

capacity of any particular machine, beyond its recommended maximum. They are convenience

Items, not capacity increasers. The best functioning of Blakeslee Mixers depends on leaving room for proper

material aeration or manipulation. Use splash Covers or Extenders only for containing ingredients. They are

efficient for their intended use, but if a Mixer is overloaded and a Splash Cover is used, aeration is reduced due

to restriction in the area where air enters the mix. The capacity chart located on the column of the Mixer is a

good guide for maximum efficient use for the Mixer. Experience will have to dictate exact top capacity and

Splash Cover use under your own needs.

"B" BATTER BEATER

Furnished as part of standard equipment. Used for mixing batters such as cake and muffin batters,

creaming butter, mashing potatoes and vegetables, light cakes. Icings and the average run of light

work. Never use this beater for heavy dough work. When mashing potatoes , etc., it is advisable to

start with the bowl at Its lowest posi ion and then as the potatoes or other ingredient break up, the

bowl should be gradually raised to its working position. This procedure eliminates severe strain to

the beater and to the mixer proper and consequently adds to their life and efficiency.

"W" WIRE WHIP

Furnished as part of standard equipment. Used for whipping, creaming, beating eggs, meringues,

small amounts of mayonnaise, icings and for whipping milk or cream into mashed potatoes after

they have been broken up with "b" batter beater.

-4-

Page 7

MIXING INSTRUCTIONS

Operators have their own pet ways of operating their mixing machines, so no attempt will be made to set up

iron clad instructions, but there are certain general principles that should be followed in the various operations. These

general principles as listed below should be helpful to old and new operators.

GENERAL POINTS FOR PROPER OPERATION

NOTE: Refer to Mixing Chart before filling bowl.

1. Always start with the bowl in its lowest position.

NOTE: When mashing potatoes, kneading dough, or any operation of a similar nature, it is

adviseable to start the beating with the bowl at its lowest position and as the potatoes or

other ingredients break up, the bowl should be gradually raised to its working position. This

procedure eliminates seve re strain to the mixer and consequently adds to its life and

efficiency.

2. In general, start all mixing at slow speed.

3. Gradually raise bowl and its contents to working position.

4. Always return to the neture position when finishing a mix. ±

5. Bowl should be filled to at least half capacity for best results.

6. Make sure that bowl-to-beater clearance is about 1/8". Place a 1/8" layer of paper on

bottom of bowl to check bowl-to-beater clearance. See instructions on how to raise or

lower the beater lock should adjustment be necessary for proper bowl-to beater

clearance.

WHIPPING CREAM

The "W" wire whip (refer to Beaters 6 Whip chart) should be used for whipping cream. Cream to be

whipped should be 24 hours old, should contain 30% butter fat and should be well chilled, in fact near freezing

temperature is desirable, since the cooler the cream, the better the whipping. Warm cream may turn into butter

instead of whipped cream.

To prevent splashing out of the bowl. start whipping the

cream at slow speed and increase the speed as the cream thickens or use a "bowl splash cover" attachment on

the bowl.

EGG WHITES

Use the "W" wire whip and be sure that the eggs are at room temperature and that both the mixing bowl and

"W" wire whip are free from all traces of fact or oil, or egg whites won't whip. In some installations one bowl will be

kept and used exclusively for the oily type mixes. Start beating the eggs at low speed and gradually increase the

speed.

-5-

Page 8

MERINGUES

Use the "W wire whip. Meringues can be made perfect by the gradual addition of sugar to eggs which have

not been too stiffly beaten.

MASHING POTATOES

Use the "B batter beater and pre-heat the bowl and beater. Lower the mixing bowl before putting in the

potatoes to be mashed so that the breaking up starts with the bowl at its lowest position; then as the potatoes break

up, graudally raise the bowl to its working position. This procedure eliminates severe strain to the mixer and the batter

beater. Start the operation on low speed. When the potatoes have been broken up, stop the mixer and add the milk or

cream, butter and seasoning. Many operators like to change to the "W" wire whip or the "M" four wing whip for

whipping in the milk or cream since more of a whipping action is obtained to produce a fluffier mashed potato.

CAKE BATTERS AND COOKIE POUCH

Use "B" batter beater. Butter or shortening can be thoroughly creamed in about 10 minutes.. The butter or

shortening should be at room temperature. Alway s lower the bowl and start on slow speed and then gradually raise

the bowl to its working position. Sugar should be added to recipes at a medium speed. When all of the sugar has

been added, stop the mixer and scrape down the sides of the mixing bowl with a spatula to insure a smooth mix. Be

careful not to add sugar until the butter or shortening has been thoroughly creamed. Some recipes call for yolks and

whites to be beaten separately. This is not necessary with your Blakes -lee Mixer as the mechanical mixing is efficient

enough to allow the addition of whole eggs. When adding dry ingredients, stop the mixer occasionally and scrape the

upper part of the bowl with a spatula to make sure that every portion will beefficiently mixed into the recipe. Always

operate the mixer on slow speed while adding dry ingredients. Many operators use the Blakeslee-Built bowl extension

ring to help confine ingredients to the mixing bowl. Add dry ingredients alternately with liquid, staring and ending with

dry ingredients. .Do most of the beating before the flour and milk are added. Over beating after addition of these two

ingredients causes a sub-standard mixture.

6-

Page 9

MIXING DOUGH

Always use the spiral dough hook for mixing heavy doughs. Do not overload the mixer with too large

batches. (See the capacity chart of this booklet for capacities of the various size bowls.) When using the spiral

dough hook, the mixing should be started at low speed only with the bowl in the lowest position; then as the mixing

continues, the bowl should be gradually raised to its working position. Remember - an increased mixing time means

a decreased fermentation time. Weighing materials each mixing time will insure a standard product. Stop the mixer

occasionally to lower the dough mass from the hook and to scrape the bowl.

IMPORTANT In mixing heavy dough, be sure to use the dough hook, be sure not to overload the mixer (see

the capacity chart ), and be sure to start the mixer on low speed with the bowl In its lowest position.

BISCUIT MIX

Use "W" wire whip and bowl extension ring (to confine ingredients to bowl). Mix shortening and dry

ingredients until shortening is blended and mixture is granular in appearance. Turn off mixer. Scrape bowl down

with bowl knife. Store in covered can until ready for use. (Use beater or dough hook when adding liquid; start mixing

on slow speed and bowl In lowest position, then gradually raise to working position. Do not over mix.)

PASTRIES

Use the "PK" pastry knife, as pastries should be mixed with as little "rubbing" as possible. The "PK" pastry

knife leaves the shortening In small pices to produce as flaky product. Remember, over-worked dough makes tough

pastry, and working in too much flour tends to toughen pastry.

SWEET DOUGH

For best results use the "SD" sweet dough beater.

-7-

Page 10

ELECTRICAL

"Start-Stop" Push buttons are used to operate the mixer which are protected by rubber caps. There is a

thermal overload device with automatic resetting for protection, internally mounted. On all machines over

250 volts primary, a transformer is supplied to reduce, voltage to the pilot circuit.

A timer is available as an option which would shut off the machine in any speed after pre-set time has

expired. Normal operation is obtained by setting timer to "HOLD" position. When timer Is set at "O", the start

button, becomes a jog button, permitting intermittent operation at the push of a button.

LUBRICATION

The planetary and spiral-beveled gears are self-lubricated for life. The lubrication used is micromly

grease and must be re-applied if gears are ever replaced. While the transmission uses Mobil "delvic 1"

synthetic oil which should last the normal life of the mixer. No lubrication is required for the auxiliary

drive hub.

If lubrication is applied to the auxiliary hub a grease-like substance will possibly leak out causing damage to

the product.

Application of any lubrication Voids Warranty.

-8-

Page 11

Mixing Bowl Capacity Chart

Smaller bowls used

on

60

of

80

qt. machine

-9-

CAPACITY OF BOWL

(Finished Materials)

DD-60 DD -80

KITCHEN MATERIALS

Egg whites 1 1/2 qts. 1 1/2 qts. 2 qts. 2 1/2 qts.

Mashed potatoes 23 lbs 26 lbs. 42 lbs. 55 lbs.

Mayonnaise (qts. of oil) 12 qts. 13 qts. 18 qts. 24 qts.

Meringue (pts. of water) 2 pts. 2 1/4 pts. 3 pts. 6 pts.

Waffle or hot cake batter 12 qts. 13 qts. 24 qts. 32 qts.

Whipped cream 6 qts. 6 1/2 qts. 12 qts. 16 qts.

BAKE SHOP MATERIALS

Angel food (8-10 oz. cake) 22 lbs. 24 lbs. 45 lbs. 60 lbs.

Box or slab cake 30 lbs. 33 lbs. 52 lbs. 80 lbs.

Cup cakes 33 doz. 34 doz. 65 doz. 90 doz.

Layer cakes 30 lbs. 34 lbs. 60 lbs. 82 lbs.

30 qt. 40 qt. 60 qt. 80 qt.

Pound cake 30 lbs. 34 lbs. 52 lbs. 80 lbs.

Short sponge cake 23 lbs. 25 lbs. 45 lbs. 70 lbs.

Sponge cake batter 18 lbs. 20 lbs. 36 lbs. 54 lbs.

Sugar cookies 50 doz. 55 doz. 100 doz. 115 doz.

Bread or roll dough (60% AR) 45 lbs. 1

Heavy bread dough (55% AR) 30 lbs. 1

Noodle dough 10 lbs. 11 lbs. 15 lbs. 35 lbs.

Pie dough 27 lbs. 30 lbs. 50 lbs. 62 lbs.

Pizza dough (50% AR) 15 lbs. 1 18 lbs. 1 40 lbs. 1 55 lbs. 1

Raised doughnut dough (65% AR) 15 lbs. 2

Eggs & sugar (for sponge cake) 12 lbs. 13 lbs. 24 lbs. 36 lbs.

Fondant icing 18 lbs. 20 lbs.. 36 lbs. 45 lbs.

Marshmallow icing 3 lbs. 3 lbs. 5 lbs. 7 lbs.

Shortening & sugar creamed 24 lbs. 26 lbs. 48 lbs. 55 lbs.

RECOMMENDED SPEEDS

50 lbs. 1

40 lbs. 1

17 lbs. 2 30 lbs. 3 40 lbs.. 3

70 lbs. 2 105 lbs. 2

60 lbs. 2 80 lbs. 2

1- First speed

2- Second speed

3- Third Speed

Page 12

MIXER CAPACITY

When mixing any of the above products with an absorption rate lower than listed, the batch size should be decreased proportionately to insure

60 mixer has a pizza dough capacity

the batch size must

30 pounds of dough. However, while the mixer is capable of handling a larger batch, a change in speed will affect development of the products

1.

Divide the AR of the batch to be mixed by the AR listed on the cap

-

40 lbs Rated Batch Size

A mixer capacity chart is provided as a guide for controlling the batch sizes. The capacities listed take into account the amount of product

which can be contained in a particular size bowl and the type of dough or product to be mixed and it's own unique properties which affect

mixer performance.

Also considered and noted on the chart is the batch absorption rate-the ratio of the weight of water to the weight of flour expressed as a

percentage. The absorption rate (AR) measures how heavy a batch is or the density of the batch. In fact, the capacities listed on the capacity

chart for the products listed below are based on the following absorption rates:

PRODUCT ABSORPTION RATE

Heavy bread dough 55%

Medium bread dough 60%

Light bread dough 65%

Pizza dough 50%

Raised donut dough 65%

efficient mixing of the product and eliminate the possibility of over-loading your mixer. For example: An DDof 40 pounds at first speed based on AR of 50% according to the capacity chart. If the batch to be mixed has an AR of 45%,

be reduced to compensate for the difference. The size of the reduction is computed as follows:

acity chart.

45% Actual AR

50% Rated AR

=90%

2. Multiply the rated batch size by the percentage obtained in step 1.

The result is the maximum batch size of the DD—60 mixer for pizza

dough with a 40% AR.

X 90%

36 Ibs. Max. Cap @45% AR

Another factor often overlooked is the ability of your mixer to operate at a higher speed. For example, the DD-60 has a 60 pound capacity of

heavy bread dough with an AR of 50% in second speed. The batch could be mixed in third speed but the batch must be reduced by half to 30

pounds. Conversely, a batch may be increased by half to 90 pounds if first speed were used proveded the bowl is large enough to hold another

and may result in quality being sacrificed for quantity.

-10-

Page 13

Your Blakeslee mixer is designed and intended to mix your products in the most efficient

way possible. There is no need for you to sacrifice individual characteristics when using

your Blakeslee mixer. Care should be taken during your batch mixing. When results are

exactly to your liking note carefully the time of operation and the speed setting. Under

the same conditions your Blakeslee mixer will perform exactly the same, day after day,

providing uniformity of your product.

A WORD OF CAUTION; DO NOT OVERMIX. Overmixing can adversely affect the texture of the

product you are mixing. You will also discover there is often a saving in the time

required for each mixing operation, and that even delicate products usually mixed by hand

can be adapted to your mixer.

-11-

Page 14

Available Beaters, Whips and Accessories

40

QT.

Steel Tinned

40

QT. M-3-98525

Steel Tinned

60 QT

. M-0-98270

Steel

Tinned

40

QT. M-O-98508

Stainless Steel

80

QT. M-0-98272

Steel Tinned

60

QT. M-O-98108

Stainless Steel

60

QT.

80 QT.

7

40

QT.

Steel Tinned

M-0-9910

0

60 Qt

U.S.D.A. approved

-12-

CAP. PART NO. DESCRIPTION CAP. PART NO. Description

BOWLS— Smaller bowls can be used on 50 or 80 Qt. Mixers "W" WIRE WHIPS-Part No. includes spindle.

with Adaptor shown below.

30 QT.

Steel Tinned

30 QT. M-O-98523 Steel Tinned

30 QT. M-O-98513 Stainless Steel

60 QT. M-O-98107 Steel Tinned

Used on M-3-99058 Steel Tinned

60 QT.

Used on M-3-99059 Stainless Steel

80 QT.

80 QT. M-3-98022 Bowl Tinned

80 QT. M-3-98023 Stainless Steel

*Requires bowl adaptor

BOWL ADAPTORS

30 QT.

& M-0-99040 Used on 60 QT Mixer

40 QT.

30 QT.

&

40 QT.

Used on 80 QT Mixer

30 QT.

40 QT. M-0-98506 Stainless Steal

60 QT. M-0-98271 Stainless Steel

80 QT. M-0-98021 Stainless Steel

"H" DOUGH HOOKS-Part No. Include spindle.

M-0-98501

Stainless Steel

30 QT.

30 QT.

40 QT. M-0-98522 Aluminum

"SPIRAL" DOUGH HOOKS-Part No. includes spindle.

M-0-9851

60 QT. M -0-98269 Aluminum

80 QT. M -0-98020 Aluminum

Steel Tinned

Aluminum

"B" BATTER BEATERS- Part No. Include spindle

30 QT. M-0-98521 Aluminum

40 QT. M-0-98515 Aluminum

60 QT.

60 QT.

80 QT.

80 QT.

used on M -0-98268 Aluminum

80 Qt

M-0-98268

M-0-98019

Aluminum

Chrome plated

U.S.D.A. approved

Aluminum

Chrome plated

Page 15

60 QT.

Stainless Steel

carrying.

"SD" SWEET DOUGH BEATERS-

60 QT. Stainless Steel 40 QT. M-0- 99477 Stainless Steel

80 QT. M-0-97681 Steel Tinned 60 QT. M-0- 99119 Stainless Steel

"PK" PASTRY KNIFE-Part No. Includes spindle. BOWL EXTENSIONS

60 QT. M-0-98509 Steel Tinned

"M" FOUR WING WHIPS - Part. No. includes spindle.

CAP. PART NO. DESCRIPTION CAP. PART NO. DESCRIPTION

Part Nos. includes spindle.

30 QT. M-0-98520 Steel Tinned

30 QT.

40 QT. M-0-98516 Stainless

60 QT. M-0-98504 Steel Tinned 30 QT. M-0- 99491 Stainless Steel

80 QT.

30 QT. M-0-98518 Steel Tinned

30 QT.

40 QT. M 0-98519 Steel Tinned

40 QT.

60 QT. N/A Stainless Steel

80 QT. M-0-97677 Steel Tinned

60 QT.

Stainless

Stainless Steel 80 QT. M-0- 99120 Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

SPLASH COVERS

30 QT. M-2-99493 Ring Stainless Steel

40 QT. M-2-99474 Ring Stainless Steel

60 QT. M-0-98524 Ring Stainless Steel

80 QT. M-0-98514 Ring Stainless Steel

40 QT. Stainless Steel

60 QT. Painted Aluminum

30 QT.

30 QT.

40 QT.

60 QT. M-0-98502 Steel Tinned BOWL TRUCKS— Allows bo wl to be transported without

80 QT. M-0-97674 SteeI Tinned

80 QT.

M-0-98500

M-0-98505 Steel Tinned

Steel Tinned

Stainless Steel

Stainless Steel

30 QT. 3-7125 Painted Steel

40 QT. 3-7125 Painted Steel

80 QT.

RECEIVING PAN BRACKET- Accommodates 10" x 16"

pan. Used instead of plastic bag.

60 QT.

80 QT.

M-1-15094

Painted Aluminum

(Pan Not Included)

(Pan Not Included)

-13-

Page 16

CAP. PART NO. DESCRIPTION CAP.

Above lncludes Knife

ACCESSORIES FOR

60 & 80

QT. MEAT CHOPPER

vegetable slicer

M-1-1905 End Plate,

3/8"

Perforations

9"VEGETABLE SLICER (UNIVERSAL HUB)

MEATCHOPPER (UNIVERSAL TYPE HUB)

PART NO DESCRIPTION

Complete with Slicer

Plate & Hopper Front

M-0-20581 9" Vegetable Slicer

60 & 80 M-0-20447 Meat Chopper Assy

QT. (Doubled Tinned)

& 1/8" Plate and Pusher M-0-20578 Pusher (Used w/tubular

9" Cheese Shredder

M-0- 99731 Complete with Hub & Shaft

5/16" Shredder Plate and

Hopper Front.

front only)

M-0-20595 Adjustable Slicer Plate 9"

(FOR BOTH BLAKESLEE & UNIVERSAL HUBS)

furnished w/Universal Hub

M-1-1904 End Plate, 1/4"

Perforations OPTIONAL-EQUIPMENT FOR M-0-20581 SLICER

Perforation M-0-20599 Hub & Shaft Assy

M-1-1906 End Plate. 1/2"

M-1-1901 Knife

M-1-1902 End Plate. 1/8" M-3-15071 Grater Disc

Perforations M-2-15088 3/32" Shredder Disc.

M-1-1903 End Plate, 3/16" M-2-15021 3/16" Shredder Disc.

Perforations

Plates to fit above:

M-2-15019 5/16" Shredder Disc.

M-2-15072 1/2" Shredder Disc.

Page 17

OPERATION

(RPM)

(RPM)

In order for your mixer to perform at top efficiency at all times, it is necessary that you follow the

recommendations as laid down by the designing engineers. Give your mixer the same attention you would

give your automobile and your BLAKESLEE-BUILT Mixer will give you many years of satisfactory service.

SPEED SELECTION

Speed for the beater and auniliary attachments are varied by the use of a four speed transmission.

When changing speeds one must first push the '"stop" button and allow mixer to come to a complete

stop before changing. NOTE: The mixer must be in gear in order for the mixer to start.

There is an exclusive locking gear feature to prevent damage to (he transmission and planetary gears if

inadvertantly changed while operation.

The available speeds are as such:

SPEEDS AGITATOR AUX. DRIVE SPEED

FIRST 55 105

SECOND 100 190

THIRD 175 300

FOURTH 310 575

BOWL LIFT

The bowl is raised to working position by means of a power switch or crank handle located on

the right side of the machine. The bowl lift is adjusted to stop at the proper working position

before the Mixer is shipped from the factory and therefore no further adjustment should be

necessary.

-15-

Page 18

FIGURE 1. COLUMN WELDMENT, UPPER HOUSING, MAIN SHAFT AND ELECTRICAL

COMPONENTS

16

Page 19

FIGURE 1. COLUMN WELDMENT, UPPER HOUSING, MAIN SHAFT AND ELECTRICAL

1 97763

Column Weldment

1 31

98076

Cover for Controller

1

COMPONENTS

Item

No.

2 97793 Mixer Foot 4 32 * Screw 4

3 97803 Column Panel Front 1 33 97579 Contactor-25 Amp with 120 v

4 7580 1/4-20 S.S. R.H. 3

5 97849 Lg. Hex HD Cap Screw-5/8-18

6 97807 Flat Washer 5/8" 1

7 97700 Housing-Bearing Weldment 1

8 97843 Label Instructions 1

9 97278 Label-on/off w/timer 1

9A 97315 Label on/off without timer 1

10 96858 Label, Blakeslee Logo 1

11 97779 Housing-Transmission Weldment 1 34B 97292 Overload Thermal Relay-Range

12 97846 LG.H.SHCS 5/8-11 nc x 1-1/2"lg 4

13 98399 Key 1/4 x 1/4x4" 1 34 C 97293 Overload Thermal Relay-Range

14 97816 Shaft Main Drive 1

15 98402 Key 2 35 97709 Bracket for Controller 1

16 7858 LG. Hex Hd. Machine Screw

17 07524 Lockwasher 3/8" 1 38 8132 Nut Hex 10-32 1

18 97702 Bevel Gear Support 1 39 7285 Lockwasher-SpIit 10 1

19 97838 Ring Retaining 1

20 97733 Spiral Bevel Gear 1 40 98082 Cover 1

21 97833 Transmission Cover 1 41 97276 Contact Block-Normally Open 1

22 7564 Locknut 1/2" 1 42 97275 "Start" Push Button-operator 1

23 97307 Handy Electrical Box & Cover

24

25

26 13965 Nipple-close 1/2" NPT-1-1/2 lg 1

27

28 97847 Cap Screw Lg. Hex HD-3/4 x 10

29 03584 3/4 Lock Washer 4 48 98081 Hold Down Bracket 1

30 03184 3/4 Flat Washer 4 49 08132 10-32 NUT 2

Part No. Description No.

N.F.x 1-1/4 1

3/8-24 x 1" 1 37 97709 Bracket for Controller 1

complete (includes items 23 & 24) 1

Handy Electrical Box 1

Handy Electrical Box Cover 1

Screw 18-32 x 3/8" lg 1

NC x 2" 4

Reqd.

Item No. Part No. Description No.

oil coil 1

33A 97289 Contactor-22 Amp with 240 v

oil coil 1

33 B 97299 Contactor-22 Amp with 480 v

34 97300 Overload Thermal Relay-Range

34A 97290 Overload Thermal Relay-Range

36 08132 10-32 NUT 2

43 97933 Timer-5 minutues w/hold circuit 1

44 97274 "Stop" Push Button 1

45 97277 Contact Block-Normally Closed 1

46 97663 Bracket for Timer 1

47 97669 Screw 6-40 x 1/2" Lg. R.H.

50 07957 TRANSFORMER

oil coil 1

2.5 to 3.9 1

7.0 to 10 1

10 to13 1

18 to 25 1

98083 Timer-15 minutes w/hold circuit 1

15258 Timer-30 minutes w/hold circuit 1

for timer 2

Reqd.

*NOT AVAILABLE SEPARATELY INCLUDED W/

P/N 98075. COVER FOR CONTROLLER

17

Page 20

FIGURE 2. BOWL SUPPORT. BOWL SUPPORT CRANK AND

BOWL LOCKDOWN ASSY

18

Page 21

FIGURE 2. BOWL SUPPORT, BOWL SUPPORT CRANK AND BOWL

LOCKDOWN ASSY

Item No. Part

No.

1 97799 POST 1 17 97811 BOWL, Clamp Handle 1

2 97798 RETAINER, Post 1 18 97795 SCREW, Elevator 1

3 97819 PLATE. Back-up 1 19 * SCREW. Allen 5/16-18 x 4

4 97846 CAPSCREW.Soc.Hd. 1

5 97837 BEARING, "Rulon" 2 21 98639 THRUST BRG 1

6 97769 BOWL. Support Elevator 1 22 16323 NUT, 3/8" 2

6A 98152 BOWL, Support Elevator 1 24 97797 PLATE. Post Support 1

7 98154 BOWL. Support Rear Shield 1 26 97846 CAPSCREW.Soc.Hd. 1

7A 98156 BOWL, Support Rear Shield 1 27 17224 TIMKEN CUP 1

8 97800 BOWL. Rear Retainer (for 80 Qt) 1 29 97802 COLLAR 2

8A 98159 BOWL, Rear Upper Retainer 1 30 97827 GEAR 2

8B 98159 BOWL, Rear Lower Retainer 1 32 97796 BOWL, Rising Shah 1

9 97761 BOWL. Clamp Stud 1

10 97822 SPRING, Pressure Die 1 35 05996 LOCKWASHER. 5/16" 4

11 7115 NUT. Hex 3/8.18 1 36 10660 BOLT 4

12

13

07521 LOCKWASHER 1 37 97845 PIN, Grooved 1

98157 BOWL, Support Side Shield 1 38 97760 CRANKHANDLE, Complete 1

13A 98155 BOWL, Support Side Shield 1 40 07840 SPRING, Compression 1

14 98963 PIN 1 42 97836 ROLL PIN 1

15 95290 WASHER 1

16 97818 BOWL HUB 1

Description No. Reqd. ltem

No.

5/18-11 NC x 1-1/2" Ig.

Weldment {for 80 01)

Weldment (for 60 Qt)

(for 80 Qt )

((or 60 Qt)

(for 60 Qt)

(for 60 Qt)

20 3181 COLLAR. 3/4" 1

23 16095 BOLT 1

25 98170 LOCKWASHER, 5/8" 4

28 17225 BEARING 1

31 98400 KEY 1

33 * SETSCREW. 1/4-27 x 4

3/8".24 x 4" Ig.

(for 60 Qt)

(for 80 Qt)

34 97825 FLANGE, BEARING 2

39 97794 NUT. for Elevator Screw 1

41 97817 WASHER 1

Part No. Description No. Reqd.

6/16 Ig.

6/8-11 NC x 1-1/2" lg.

1/4" Ig.

* NOT AVAILABLE SEPARATELY

INCLUDED W/ P/N 97825 FLANGE BRG. P/N 03181 COLLAR

AND P/N 97827 GEAR

Page 22

Itern

Part No. Description

No.

1 97777 MOTOR BASE WELD'MT 1

2 98006 SUPPORT BRACKET WELD'MT 2

3 98011 SCREW. Hex. Hd. 1/2-13 x 1" lg.. 3

4 12838 WASHER. Flat 9/16 I.D. x 3

6 98012 SCREW, Hex. Kd. 1/2-13 x 3" lg. 1

6 98004 STOP BRACKET 1

1-1/4" O.D. x 1/18" thk.

FIGURE 3. MOTOR MOUNTING BRACKET ASSY

20

No.

Reqd.

Page 23

ltem No. Part No. Description

1 97714 TRANSMISSION 1 17 08523 SEALING WASHER 2

2 97281 GEAR WHEEL 1 18 14082 ROLLER 4

3 97284 HUB 1 20 70411 SWITCH MOUNTING PLATE 1

4 * SCREW. SET 1 21 70403 FLAT WASHER 1

5 98398 KEY 1 22 97836 ROLL PIN 1

6 * WASHER. LOCK 5/16" 3 23 12122 6-32 ROUND HEAD MACHINE 4

7 * BOLT. 5/16"-18 X 2" LG. 3

8 97282 FLEX GEAR 1 24 70152 LIMIT SWITCH 2

9 + BOLT. 3/16-24 X 1" LG. 3 25 05587 FLAT WASHER 11/32" X 3/8" 4

10 + WASHER. LOCK 3/16" 3 26 14784 BOLT 5/16" X 3/4" LC 2

11 97283 HUB. 7/8" DIA. WITH 1 27 05996 LOCKWASHER 5/16" 2

12 98400 KEY 1 29 97813 HUB 1

13 97289 GEAR WHEEL 1 30 97810 SHAFT 1

14 97298 2 H.P. MOTOR. 115/230V. 1 PH

14A 97660 2 H.P. MOTOR. 230/460V..3PH

14B 15126 2 H.P. MOTOR, 208/230/

15 99730 SHOULDER SCREW 2 * INCLUDED IN P/N 97284 ASSEMBLY

1/4" KEYWAY

460V. 3PH

70404 ROLLER 2 * INCLUDED IN P/N 97283 ASSEMBLY

No.

Reqd.

Item No. Part No. Description

19 70409 SWITCH MOUNTING PLATE 1

28 14786 HEX NUT 5/16"-18 2

31 97826 KNOB 1

SCREW

21

No.

Reqd.

Page 24

FIGURE 5. AUXILIARY HUB ASSY

1

Item

Part No. Description

No.

1 98483 ADAPTOR, for Attachment

2 14784 BOLT. 5/16-18 x 3/4" Ig.

3 05996 LOCKWASHER. 5/16 "

4 97817 WASHER

5 97734 GEAR PINION, Spril Bevel

6 97804 CONNECTOR, for

Attachment Drive

7 97738 PIN, Spring 2

8 98484 ADAPTOR, for Attachment 1

9 98378 SLEEVE. Bearing "Rulon" 1

No.

Reqd.

1

1

1

Item

No.

Part No. Description

10 88379 ADAPTOR, Bearing Attachment 1

11 98377 HUB ATTACHMENT 1

12 18761 DRIVE CAP, Auxillary 1

13 98015 SCREW ASSY. Wing Hd. 1

1

1

14 97815 RETAINING PLATE, 1

Attachment Hub

22

No.

Reqd.

Page 25

FIGURE 6. LOWER PLANETARY AND BEARING HOUSING ASSY

Item

No.

1 98349 LABEL DIRECTION ARROW 1 9 97700 BEARING HOUSING 1

2 97832 COVER 1

3 97831 GEAR PLANETARY 1 10 97779 TRANSMISSION HOUSING 1

4 97842 PINION 1

5 97809 SPACER 1 11 97848 CAP SC REW.Soc.Hd. 4

6 97824 BEARING ROLLER (Includes 2*

7 99191 CONE *

8 99190 CUP *

Part No. Description No. Reqd. ltem No. Part No. Description No. Reqd.

ltem 7 and 8)

WELDMENT

WELDMENT

5/8-11 NCx 1-1/2" lg.

23

Page 26

FIGURE 7. PLANETARY AND BEATER SHAFT ASSY

Item

No.

1 97849 CAP SCREW.Hex.Hd. 1 6 97850 BEARING. Ball 1

2 98094 SETSCREW 2 8 97851 BEARING, Ball 1

3 97852 SEAL 1 9 97842 PINION 1

4 97857 PIN 1 10 98402 KEY. 1/4 x 1/4 x 1-1/4 1

5 97830 SHAFT AGITATOR 1 11 97835 RING. Retaining 1

Part No. Description No. Reqd. Item No. Part No. Description No. Reqd.

5/8-18 N.D.X 1-1/4" Ig.

7 97698 PLANETARY 1

24

Page 27

WIRING DIAGRAM FOR 208-240/440-480 VOLT THREE PHASE 60 HZ.

NOTES: 1. ALL CONTROL CIRCUIT WIRING IS #16 AWG. "RED" TYPE "A.W.M." OR "M.T.W." WIRE 600 VOLT.

105)C. RATED. U/L & C.S.A. LISTED.

2. REFER TO SHOP NOTES #4 AND #5 ALSO.

WIRI NG DIAGRAM FOR 115/230 VOLT SINGLE PHASE 60 HZ.

NOTE: ALL CONTROL CIRCUIT WIRING IS, #16 AWG. "RED" TYPE: "M.T.W." OR "AWM"

WIRE, 600 VOLT, 105'C. RATED. U/L & C.S.A. LISTED.

25

Page 28

93

TRANSMISSION

Page 29

TRANSMISSION HOUSING ASSEMBLY

Item Number Part Number DESCRIPTION

1 - Set - Spiral Bevel Gear & Pinion,

2 97733 Gear - Spiral Bevel

3 97734 Pinion - Spiral Bevel Gear

4 73230 Seal

5 98402 Key

6 97838 Ring - Retaining

7 97702 Support - Bevel Gear

8 7524 Lockwasher, 3/8 In. (8 Req.)

9 97858 Screw - Hex Hd. Mach., 3/8-24 X 1 In. (8 Req.)

10 98402 Key (2 Req.)

11 97816 Shaft - Main Drive

12 97824 Set - Bearing, Includes Items 13 & 14

13 99191 Cone - Timken

14 99190 Cup - Timken

15 73863 Support - Transmission

16 74170 Transmission - 93

17 15317 Lockwasher, 1/2 In. (4 Req.)

18 74216 Screw - Hex Hd. Cap, 1/2-13 X 2 In.

19 97826 Knob - Gear Shift

20 97810 Handle - Gear Shift

21 97813 Hub - Gear Shift

22 70404 Roller (2 Req.)

23 99730 Screw - Shoulder (2 Req.)

24 97836 Pin - Spring

25 97281 Wheel - Gear

26 97284 Hub

27 98398 Key

28 12122 Screw - Rd. Hd. Mach., 6/32 X 3/4. In. (4 Req.)

29 70152 Switch - Limited (2 Req.)

30 - Switch Mounting Assembly

31 74215 Nut, 5/8 In. (4 Req.)

32 74214 Lockwasher, 5/8 In. (4 Req.)

33 74213 Screw - Hex Hd. Cap, 5/8-11 X 2-1/4 In. (4 Req.)

34 97831 Gear - Planetary

35 3574 Screw - Socket Hd. Cap, 3/8-16 X 1-1/4 In. (4 Req.)

36 97809 Spacer

37 97898 Planetary

38 98399 Key. 1/4 X 1/4 X 4 In.

39 97807 Plug - Retainer

40 97849 Screw - Stainless StI. Hex Hd. Cap,

- Lockwasher, 5/16 In. (3 Req.)

- Screw - Long Hex Hd. Cap, 5/16-18 X 2 In. (3 Req.)

- Setscrew, 1/4-20

70409 Plate - Switch Mtg.

70411 Weldment - Switch Mtg. Bracket

14784 Screw - Hex Hd. Cap. 5/16 X 3/4 In. (2 Req.)

10019 Flatwasher, 5/16 In. (2 Req.)

5996 Lockwasher, 5/16 In. (2 Req.)

14786 Nut - Hex. 5/16 In. (2 Req.)

70403 Flatwasher (4 Req.)

14082 Roller (4 Req.)

8523 Washer - Seal (2 Req.)

41 97832 Cover - Planetary

42 15310 Screw - Pan Hd., 8/32 X 3/8 In.

43 98349 Arrow - Direction

44 97835 Ring - Retaining

45 97842 Pinion

46 98402 Key

47 97851 Bearing - Ball

48 97850 Bearing - Ball

49 97830 Shaft - Beater

50 97857 Pin

51 97852 Seal

52 98094 Setscrew, 1/2-20 X 1/2 In. (2 Req.)

53 98095 Screw - Stainless StI. Hex Hd. Cap

1/2-20 X 1 In.

includes items 2 & 3

5/8-18 X 1-1/4 In.

Loading...

Loading...