Page 1

DD-40

DD-60

DD-80

1844 South Laramie Avenue

Chicago, IL 60804

Phone (708) 656-0660

Fax (708) 656-0017

ELECTRIC FOOD MIXER

www.blakesleeinc.com

service@blakesleeinc.com

1149 Bellamy Road North Unit 19

Scarborough, Ontario Canada M1H1H7

Phone (416) 751-2625

Fax (416) 751-8539

Page 2

INDEX

General Information

Installation Instructions

Design and Use Of Beaters, Whips and Other Accessories

Mixing Instructions

Mixing Bowl Capacity Chart

Available Beaters, Whips and Accessories

Operation

Parts Section:

Figure 1. Column Weldment 14

Figure 2. Bowl Support 16

Figure 3. Power Bowl Lift 18

Figure 4. Motor Mounting Bracket Assembly 20

Figure 5. Motor & Power Train 21

Figure 6. Auxiliary Hub Assembly 22

Figure 7. Lower Planetary 23

Figure 8. Planetary & Beater Shaft 24

Figure 9. Transmission Housing Assembly 25

Wiring Diagrams

Electrical Components

Service & Parts Distributors

Warranty

Page

1

2

3

5

7

9

12

13

30

34

35

37

Page 3

GENERAL INFORMATION

Your Blakeslee Mixer is just one piece of equipment that provides extra profit in your operation.

Consistency of performance will reduce waste and maintain better control over yield.

Your Blakeslee-built mixer has been designed and engineered to assist you in the quick and easy

preparation of fine tasting, quality foods. It is a valuable machine deserving the same maintenance and

attention your other kitchen equipment now receives. By following the suggestions in this booklet, your

mixer will operate for many trouble-free years.

This booklet has been prepared to give you the necessary knowledge for correct operation, load, and

lubrication of your mixer.

The food service operator will also be able to save you labor during the cleaning process due to the

smooth surfaces and design of the Blakeslee mixer. Each beater, whip and attachment is engineered to

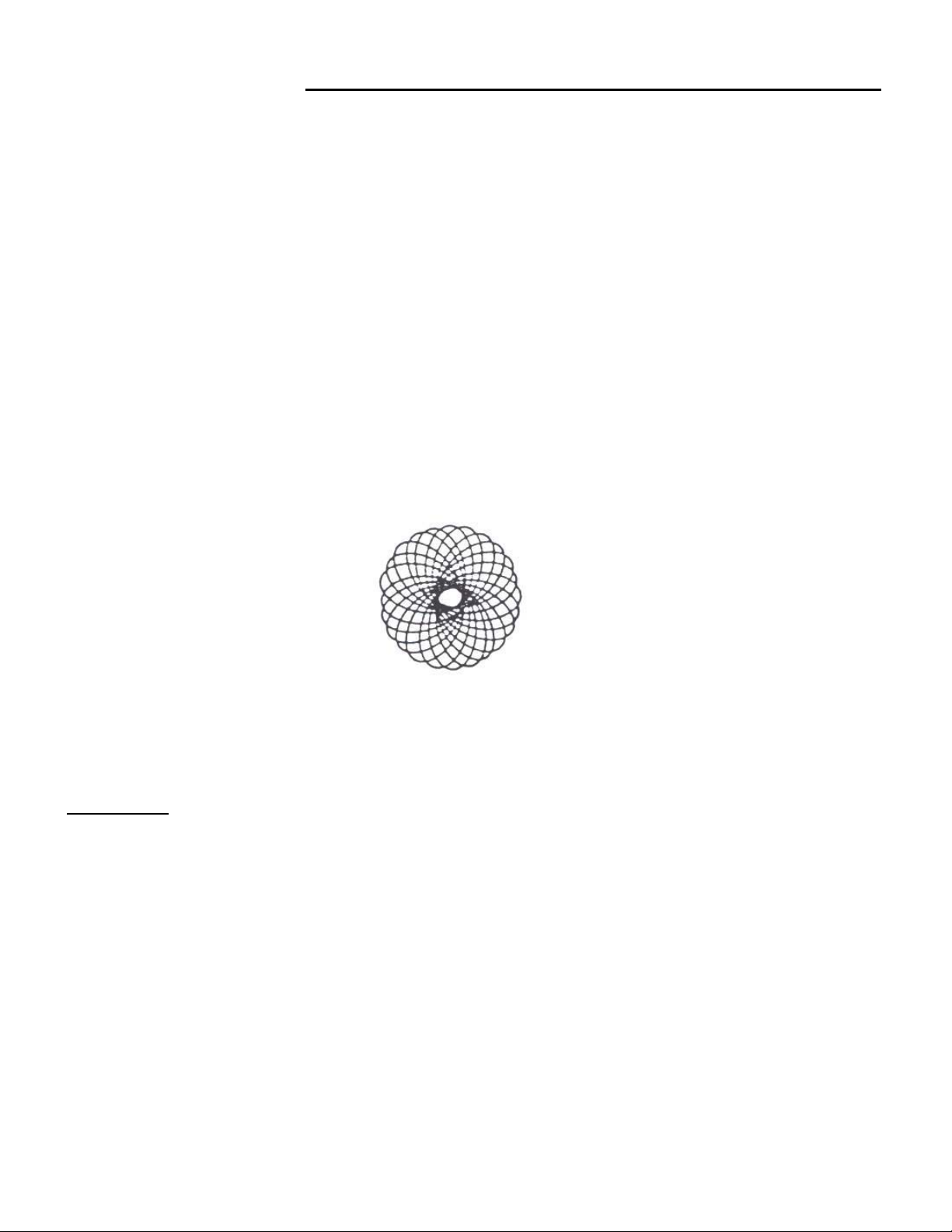

perform specific jobs for you. The planetary action of Blakeslee Mixers (beater travels around the

circumference of the bowl as it rotates) assures you of a perfectly blended mix every time.

Diagram shows complete coverage of

Bowl by planetary action of beaters

IMPORTANT - The mixer must be in gear for the mixer to start.

-1-

Page 4

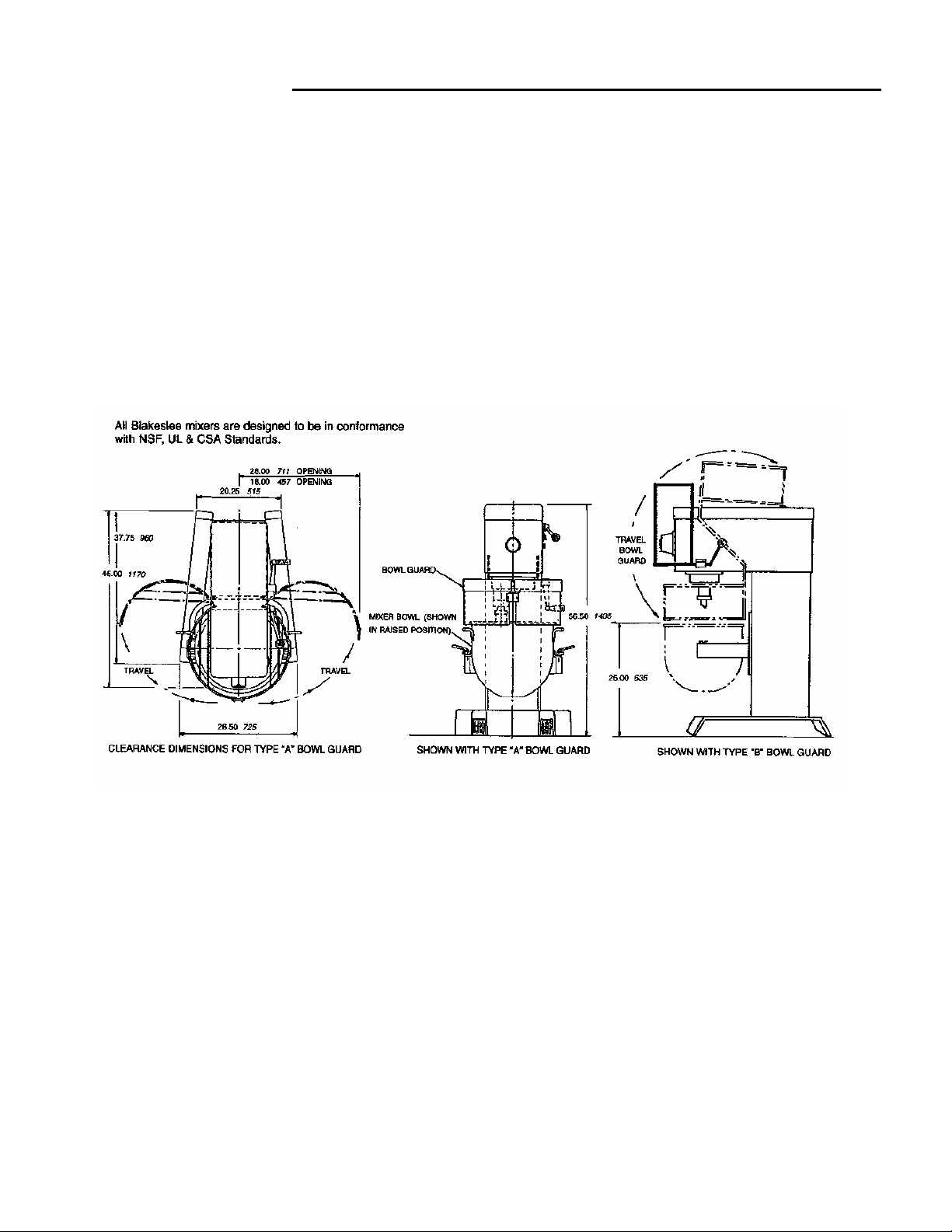

Installation Instructions

1. Place mixer in correct location with proper clearance between wall and / or adjacent equipment.

2. Level machine with shims.

3. No bolting to the floor is required.

4. Connect electrical conduit to left side of the machine. Check rotation of motor by arrow on planetary

cover. Planetary shaft should rotate as shown.

5. Checking the oil level is not required due to the permanent lubrication used (See Page 27).

Dimensions are shown in both inches and millimeters Specifications are subject to change with out notice

-2-

Page 5

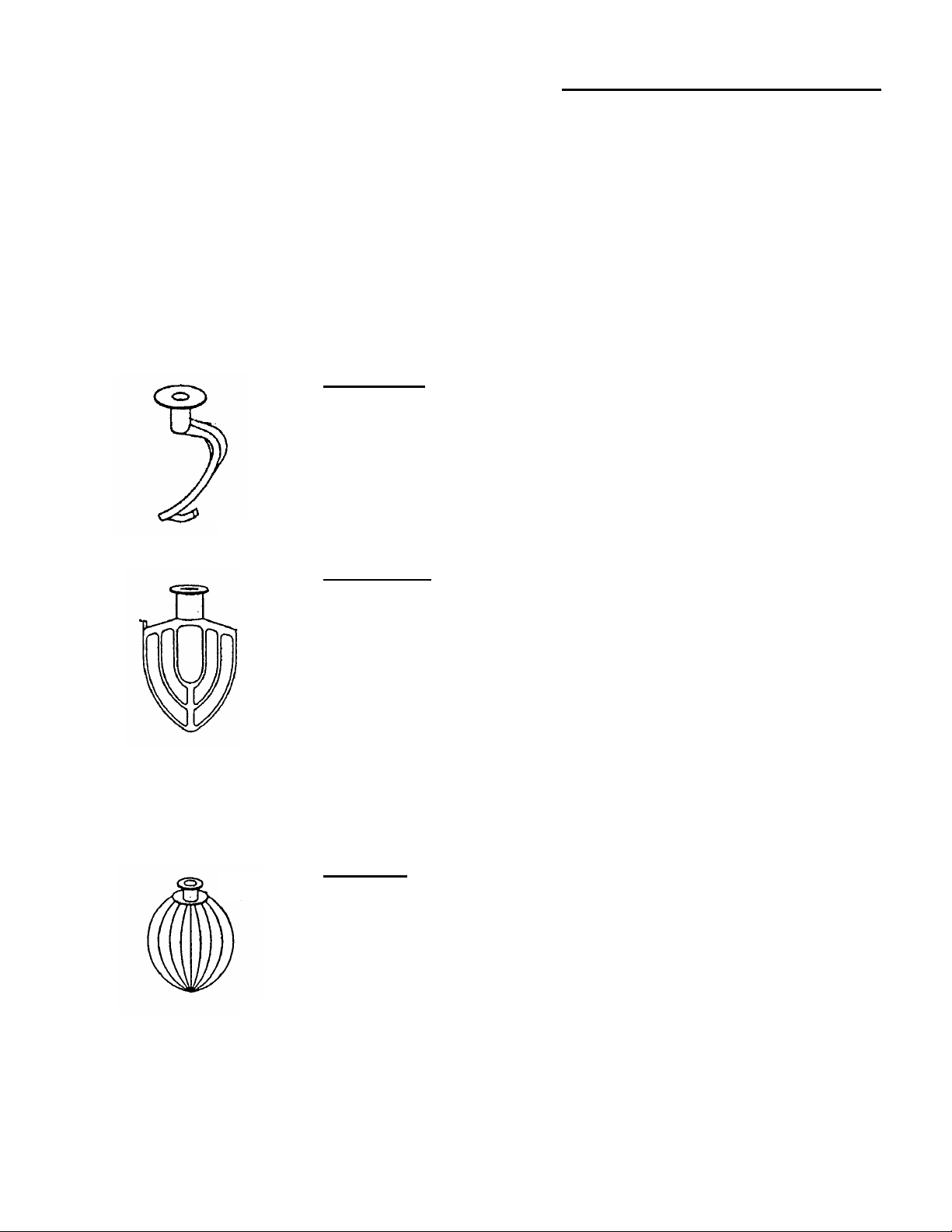

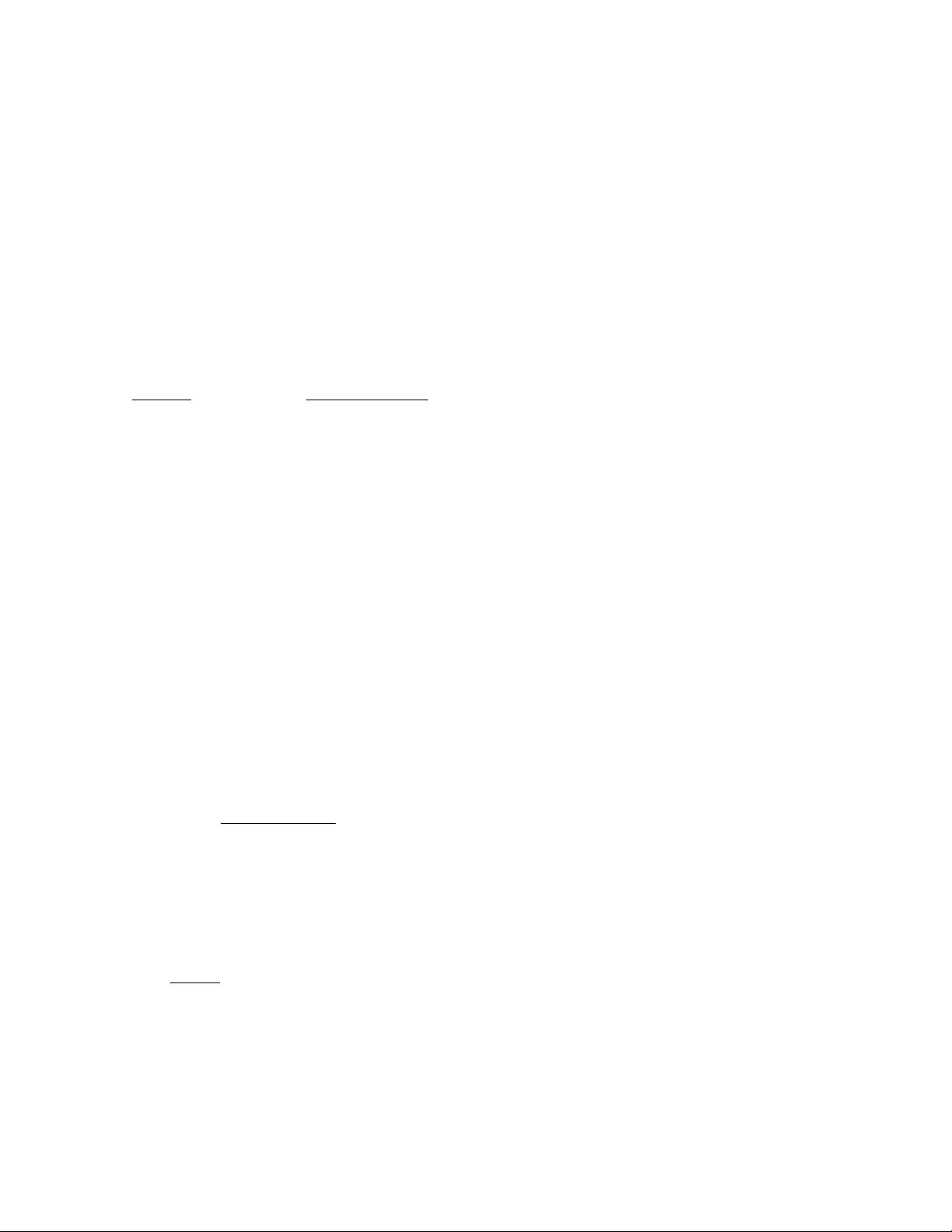

Design and use of Beaters Whips & Other Accessories

Each beater and whip has been designed to do a particular type of work. Use only that beater or whip for

the work for which it was designed. For example: never use a batter beater for mixing heavy dough’s.

Always use a dough hook for dough work.

Following are illustrations of the different types of beaters and whips with an explanation of the work and

use for which they were designed.

Dough Hook

Used for mixing bread or roll dough of standard consistency, biscuits,

meat loaf, etc. Dough hooks should always be operated at low speeds

only. Do not use other types of beaters for dough work; doing so will

result in damage to either the beaters or the mixer proper.

Batter Beater

Used for mixing batters such as cake and muffin batters, creaming

butter, mashing potatoes and vegetables, light cakes, icings and the

average run of light work. Never use this beater for heavy dough work.

When mashing potatoes, etc. it is advisable to start with the bowl at its

lowest position and as the potatoes or other ingredients break up, the

bowl should be raised to its working position. This procedure eliminates

severe strain to the beater and to the mixer proper and consequently

adds to their life and efficiency.

Wire Whip

Used for whipping, creaming, beating eggs, meringues, small amounts

of mayonnaise, icings and for whipping milk or cream into mashed

potatoes after they have been broken up with a batter beater

-3-

Page 6

“PK” Pastry Knife

Used for cutting flour and shortening together in a pie dough, pastry

shells and for cutting lard or shortening into flour. The “PK” pastry

knife should always be used for such work so that pie crusts, etc, are

mixed with as little rubbing as possible and so that the shortening will

be in small pieces to produce a flaky product.

The true capacity of a mixer is not the amount of material that can be put in the bowl or the amount of

the total batch which can be mixed with in the power of the motor. The true capacities and the most

efficient (therefore the best money makers) are the ideal loads which permit a Mixer to operate at

peak efficiency, so far as development, yield or aeration have their effect on the mixing operation.

recommended maximum. They are convenience items, not capacity increasers. The best functioning

of Blakeslee mixers depends on leaving room for proper material aeration or manipulation. Use

splash covers or extenders only for containing ingredients. They are efficient for their intended use,

but if a mixer is overloaded and a Splash Cover is used, aeration is reduced due to restriction in the

area where air enters the mix. The capacity chart located on the column of the mixer is a good guide

for maximum efficient use for the Mixer. Experience will have to dictate exact top capacity and Splash

Cover use under your own needs.

Bowl Extension

Extension Rims are merely vertical sided splash covers. They are

not covers in form but do provide higher side walls to prevent throwout of ingredients. Usually they are not recommended because they

are invitations to overloading a machine beyond its point of maximum

efficiency. Extension rims permit more air to enter the bowl and

prevents splash of light ingredients.

Splash Covers

These items provide means for providing splash of throw-out on

certain mixers when, for reasons of speed, the operator prefers to

start in a higher speed or progress quickly to a high speed in order to

complete a batch. These are valuable accessories but would not be

used to increase the mixing capacity of any particular machine,

beyond its

-4-

Page 7

Mixing Instructions

FOR BEST

RESULTS

Operators have their own particular ways of operating their

mixing machines, so no attempt will be made to set up iron

clad instructions, but there are certain general principles that

should be followed in the various operations. These general

principles as listed below should be helpful to old and new

operators.

General Points for Proper Operation

Refer to Mixing Chart before filling bowl.

1. In general, start all mixing at slow speed.

2. Always return to neutral position when

finished with a mix.

3. Gradually raise bowl and its contents to

the working position.

4. Bowl should be filled to at least half

capacity to achieve best results.

5. Make sure that bowl-to-beater clearance

is about 1/8”. Place a 1/8” layer of paper

on bottom of bowl to check bowl-to-beater

clearance.

Electrical

“Start-Stop” Push buttons are used to operate the

mixer. There is a thermal overload device with

automatic resetting for protection, internally

mounted. On all machines over 250 volts primary,

a transformer is supplied to reduce voltage to the

pilot circuit.

A timer shuts off the machine in any speed after

the pre-set time has expired. Normal operation is

obtained by setting the timer to “Hold” position.

When the timer is set at “O”, the start button

becomes a jog button, permitting intermittent

operation at the push of a button.

NOTE

Whipping Cream

The wire whip (refer to Beaters and Whip chart)

should be used for whipping cream. Cream to be

whipped should be 24 hours old, should contain

30% butter fat and should be well chilled, in fact

near freezing temperature is desirable, since the

cooler the cream the better the whipping. Warm

cream may turn into butter instead of whipped

cream. To prevent splashing out of the bowl,

start whipping the cream at low speed and

increase the speed as the cream thickens.

Egg Whites

Use the wire whip and be sure the eggs are at

room temperature and that both the mixing bowl

and wire whip are free from all traces of fat or oil,

or egg whites won’t whip. In some installations

one bowl will be kept and used exclusively for

beating egg whites. Another bowl will be kept

and used exclusively for the oily type mixes.

Start beating the eggs at low speeds and

gradually increase the speed.

Meringues

Use the wire whip. Meringues can be made

perfect by the gradual addition of sugar to egg

whites which have not been too stiffly beaten.

5

Page 8

Mashing Potatoes

Use the batter beater and pre-heat the bowl and

beater. Lower the mixing bowl before putting in

the potatoes to be mashed then gradually raise

the bowl to its working position.

Start the operation on low speed. When the

potatoes have been broken up, stop the mixer

and add milk or cream, butter and seasoning.

Many operators like to change to the wire whip for

whipping in the milk or cream since more of a

whipping action is obtained to produce a fluffier

mashed potato.

Cake Batters and Cookie Dough

Use the batter beater. Butter or shortening can

be thoroughly creamed in about 10 minutes. The

butter or shortening should be at room

temperature. Always lower the mixing bowl

before putting in the ingredients then gradually

raise the bowl to its working position.

Sugar should be added to recipes at a medium

speed. When all of the sugar has been added,

stop the mixer and scrape down the sides of the

mixing bowl with a spatula to insure a smooth

mix. Be careful not to add sugar until the butter

or shortening has been thoroughly creamed.

When adding dry ingredients, stop the mixer

occasionally and scrape the upper part of the

bowl with a spatula to make sure that every

portion will be efficiently mixed into the recipe.

Always operate the mixer on slow speed while

adding dry ingredients. Add dry ingredients

alternately with liquid, starting and ending with dry

ingredients. Do most of the beating before the

flour and milk are added. Over beating after

these two ingredients causes a sub-standard

mixture.

Mixing Dough

Always use the dough hook for mixing heavy

doughs. Do not overload the mixer with too large

batches. (See the capacity chart on page 7.)

When using the dough hook, the mixing should

be started at low speed only. The bowl should be

in its lowest position gradually raised to working

position. Remember – an increased mixing time

means a decreased fermentation time. Weighing

materials each mix time will insure a standard

product. Stop the mixer occasionally to lower the

dough mass from the hook and to scrape the

bowl.

Important – In mixing heavy doughs be sure to

use the dough hook, be sure not to overload the

mixer (see capacity chart on page 7,) and be sure

to start the mixer on low speed with the bowl in

operating position.

Biscuit Mix

Use “W” wire whip and bowl extension ring (to

confine ingredients to bowl). Mix shortening and

dry ingredients until shortening is blended and

mixture is granular in appearance. Turn off

mixer. Scrape bowl down with bowl knife. Store

in covered can until ready for use. Use beater or

dough hook when adding liquid; start mixing on

slow speed and bowl in lowest position, then

gradually rise to the working position. Do not

over mix.

Pastries

Use the “PK” pastry knife, as pastries should be

mixed with as little “rubbing” as possible. The

“PK” pastry knife leaves the shortening in small

pieces to produce a flaky product. Remember,

over-worked dough makes tough pastry, and

working in too much flour tends to toughen

pastry.

Sweet Dough

For best results use the “SD” sweet dough

beater.

6

Page 9

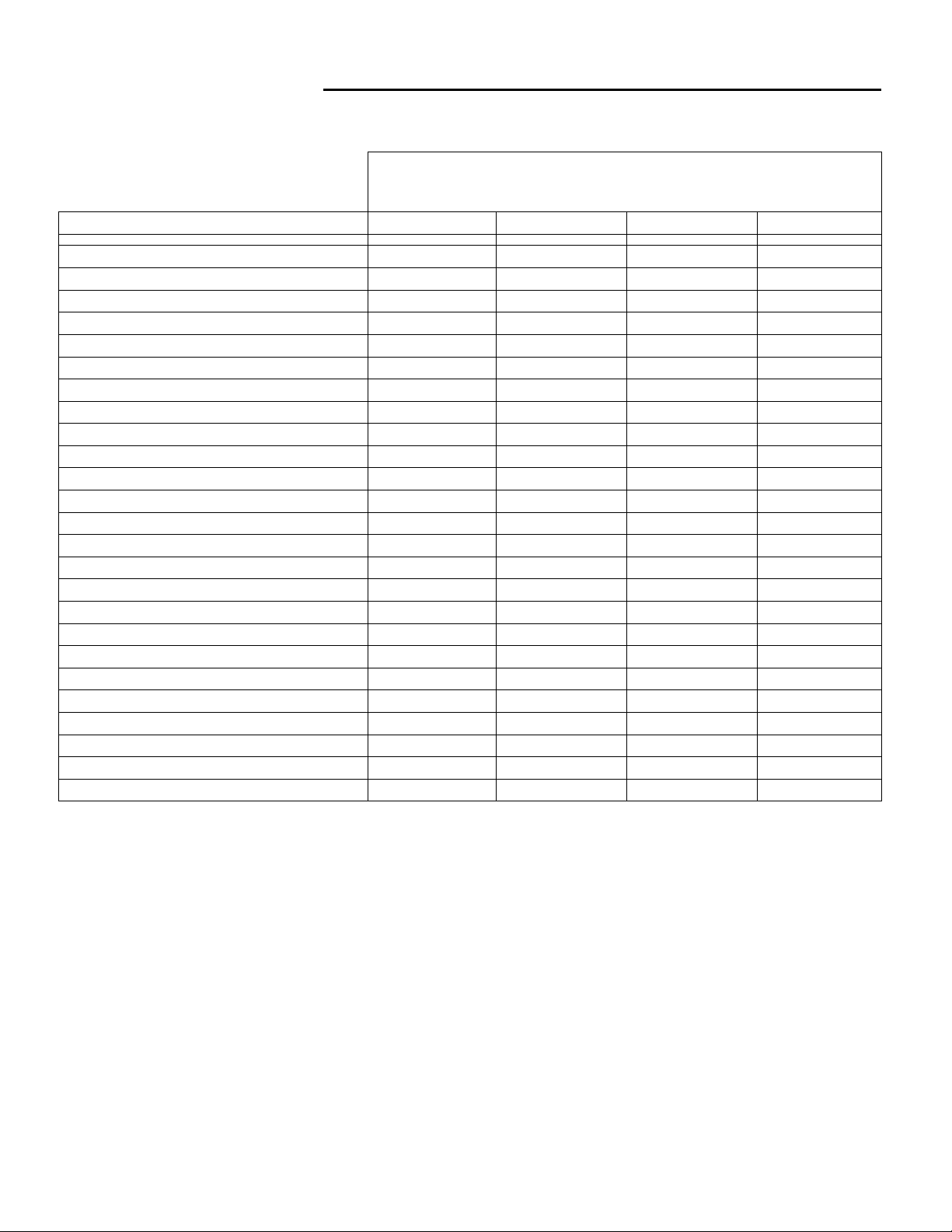

Mixing Bowl Capacity Chart

CAPACITY OF BOWL

(Finished Material)

KITCHEN MATERIALS 30 Qt. 40 QT. 60 QT. 80 QT.

Egg whites 1 1/2qt. 1 1/2qt. 2qts. 21/2qts.

Mashed potatoes 23 lbs. 26 lbs 42 lbs 55 lbs

Mayonnaise (qts. Of oil) 12 qts 13 qts 18 qts 24 qts

Meringue (pts. Of water) 2 Pts. 2 ¼ pts. 3 pts. 6 pts.

Waffle or Hot cake batter 12 qts. 13 qts 24 qts 32 qts

Whipped cream 6 qts. 6 ½ qts 12 qts 16 qts

BAKE SHOP MATERIALS

Angle Food (8 to 10 oz. cake) 22 24 lbs. 45 lbs. 60 lbs.

Box or Slab Cake 30 lbs. 33 lbs. 52 lbs. 80 lbs.

Cup cakes 33 doz. 34 doz. 65 doz. 90 doz.

Layer cakes 30 lbs. 34 lbs. 60 lbs. 82 lbs.

Pound cake 30 lbs. 34 lbs. 52 lbs. 80 lbs.

Short sponge cake 23 lbs. 25 lbs. 45 lbs. 70 lbs.

Sponge cake batter 18 lbs. 20 lbs. 36 lbs. 54 lbs.

Sugar cookies 50 doz. 55 doz. 100 doz. 115 doz.

Bread or roll dough (60%AR) 45 lbs. (1) 50 lbs. (1) 70 lbs. (1) 105 lbs. (2)

Heavy bread dough (55%AR) 30 lbs. (1) 40 lbs. (1) 60 lbs. (1) 80 lbs. (2)

Noodle dough 10 lbs. 11 lbs. 15 lbs. 35 lbs.

Pie dough (50%AR) 27 lbs. 30 lbs. 50 lbs. 62 lbs.

Pizza dough (65%AR) 21 lbs. (1) 18 lbs. (1) 40 lbs. (1) 55 lbs. (1)

Raised donut dough 15 lbs. (2) 17 lbs. (2) 30 lbs. (3) 40 lbs. (3)

Eggs & sugar (for sponge cake) 12lbs. 13 lbs. 24 lbs. 24 lbs.

Fondant icing 18 lbs 20 lbs. 36 lbs. 45 lbs.

Marshmallow icing 3 lbs, 3 lbs. 5 lbs. 7 lbs.

Sponge cake batter 18 lbs. 36 lbs. 48 lbs. 55 lbs.

(1) – First speed

(2) – Second speed

(3) –Third speed

-7-

Page 10

Mixer Capacity

The mixer capacity chart is provided as a guide for

controlling the batch sizes. The capacities listed

take into account the amount of product which can

be contained in a particular size bowl and the type

of dough or product to be mixed and it’s own unique

properties which affect mixer performance.

Also considered and noted on the chart is the batch

absorption rate, the ratio of the weight of water to

the weight of flour expressed as a percentage. The

absorption rate (AR) measures how heavy a batch

is or the density of the batch. In fact, the capacities

listed on the capacity chart for the products listed

below are based on the following absorption rates:

Product

Heavy bread dough

Medium bread dough

Light bread dough

Pizza dough

Raised donut dough

Absorption Rate

55%

60%

65%

50%

65%

When mixing any of the above products with an

absorption rate lower than listed, the batch size

should be decreased proportionately to insure

efficient mixing of the product and eliminate the

possibility of over-loading your mixer. For example:

A DD-60 mixer has a pizza dough capacity of 40

pounds at first speed based on AR of 50%

according to the capacity chart. If the batch to be

mixed has an AR of 45%, the batch size must be

reduced to compensate for the difference. The size

of the reduction is computed as follows:

1. Divide the AR of the batch to be mixed by

the AR listed on the capacity chart.

45% Actual AR

50% Rated AR

= 90%

2. Multiply the rated batch size by the

percentage obtained in step 1. The result is

the maximum batch size of the DD-60 mixer

for pizza dough with a 40% AR.

40 Lbs Rated Batch size

X 90%

36 lbs. Max Capacity @ 45% AR

-8-

Another factor often overlooked is the ability of your

mixer to operate at a higher speed. For example,

the DD-60 has a 60 pound capacity of heavy bread

dough with an AR of 50% in second speed. The

batch could be mixed in third speed but the batch

must be reduced by half to 30 pounds. Conversely

a batch may be increased by half to 90 pounds if

first speed were used provided the bowl is large

enough to hold another 30 pounds of dough.

However, while the mixer is capable of handling a

larger batch, a change in speed will affect

development of the product and may result in

quality being sacrificed for quantity.

Your Blakeslee mixer is designed and intended to

mix your products in the most efficient way possible.

There is no need for you to sacrifice individual

characteristics when using your Blakeslee mixer.

Care should be taken during your batch mixing.

When results are exactly to your liking, note

carefully the time of operation and speed setting.

Under the same conditions your Blakeslee mixer

will perform exactly the same, day after day,

providing uniformity of your product. A word of

caution: Do not over-mix. Over mixing can

adversely affect the texture of the product you are

mixing. You will also discover there is often a

savings in the time required for each mixing

operation, and that even delicate products usually

mixed by hand can be adapted to your mixer.

Page 11

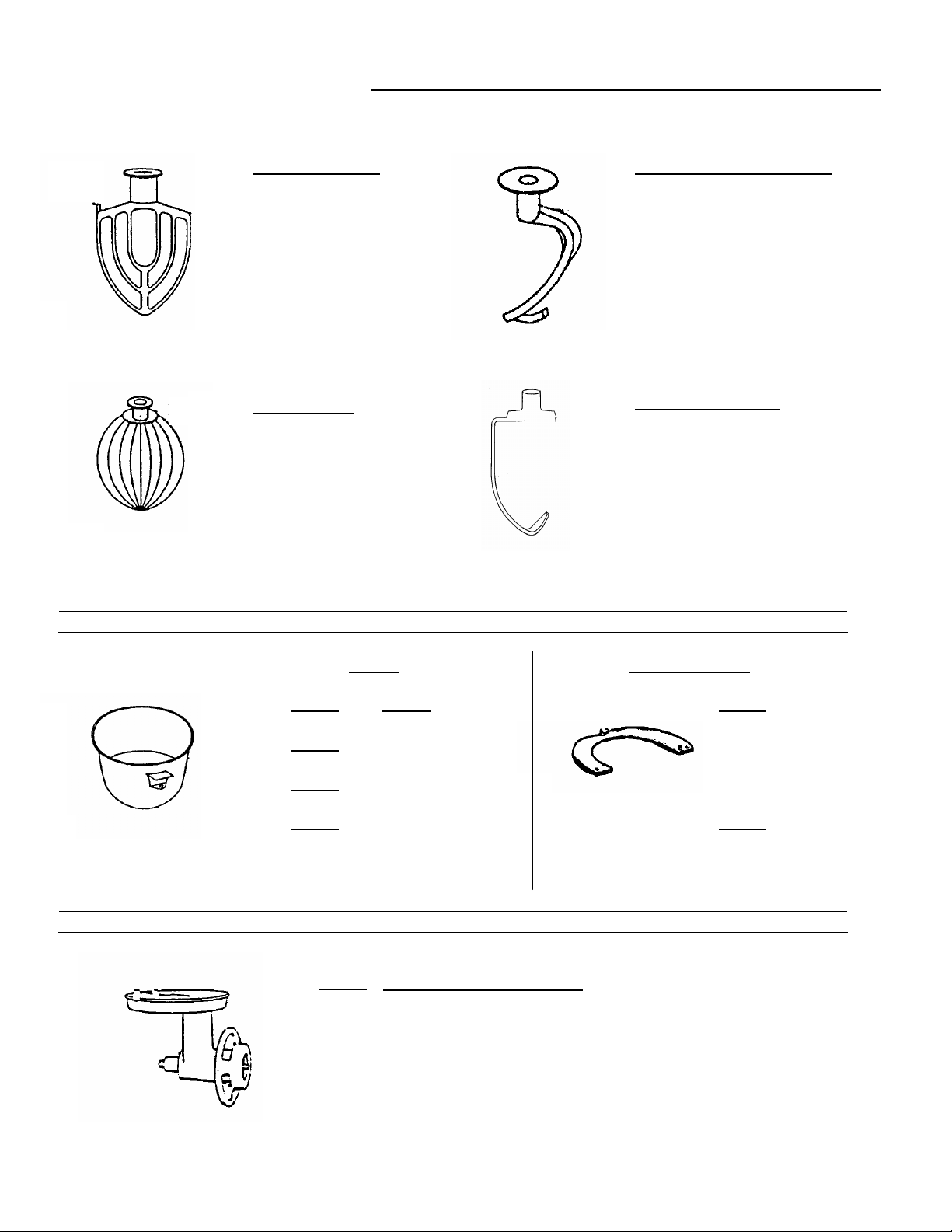

Beaters, Whips and Accessories

Batter Beaters

30 QT. 98521

40 QT. 98515

60 QT. 98268

80 QT. 98019

60Qt used on

80 Qt. 98268

Wire Whips

30 QT. 98501

40 QT. 98506

60 QT. 98271

80 QT. 98021

30 QT.

40 QT.

60 QT.

80 QT.

20447

98513

98508

98108

98023

WHIPS & BEATERS

“Spiral” Dough Hooks

60 QT. 98269

80 QT. 98020

BOWLS

Bowls Bowl Adaptors

99059

60 QT Used on

80 Qt

MEAT CHOPPER

Meat Chopper Assembly

Includes Knife and 1/8” Plate and Pusher

-9-

“H” Dough Hooks

30 QT. 98517

40 QT. 98522

99040

30QT & 40 Qt

Used on 60 QT

99100

30QT & 40 Qt

Used on 80 QT

Page 12

1

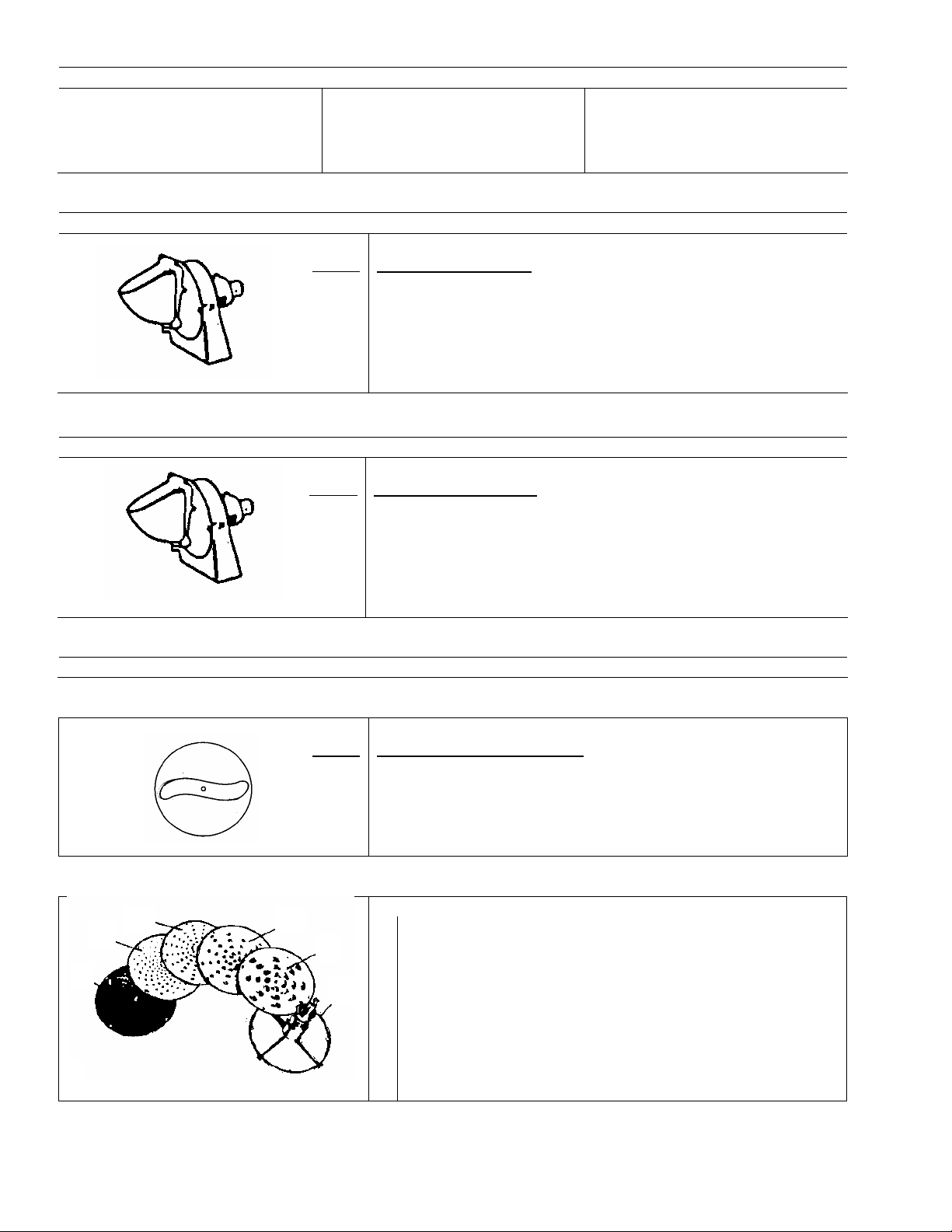

ACCESSORIES FOR MEAT CHOPPER

1901 Knife 1903 End Plate, 3/16”

1902 End Plate, 1/8” Perforations

Perforations 1904 End Plate, 1/4”

Perforations

VEGETABLE SLICER

20581

9” Vegetable Slicer

Complete with Slicer Plate & Hopper Front

CHEESE SHREDDER

99731

9” Cheese Shredder

Complete with Hub & Shaft, 5/16” Shredder Plate and

Hopper Front.

OPTIONAL EQUIPMENT FOR USE WITH SLICERS

20595

3 4

2

9” Adjustable Slicer Plate

Furnished with Vegetable Slicer

1 15071 Grater Disc

5

2 15021 3/16” Shredder Disc.

3 15088 3/32” Shredder Disc.

6

4 15019 5/16” Shredder Disc.

5 15072 1/2” Shredder Disc.

6 20599 Hub & Shaft Assembly - Optional for 20581

(only one required for all sizes of shredder plates and

grater plates)

-10-

1905 End Plate, 3/8”

Perforations

1906 End Plate, 1/2”

Perforations

Page 13

Part No. Includes

Spindle

Part No. Includes

Spindle

Part No. Includes

Spindle

“SD” Sweet Dough

Beaters

30 QT

40QT

60QT

80 QT

98520

98516

98504

97681

CAP PART

30 Qt

40 Qt

60 QT

80 QT

“PK” Pastry Knife

30 QT

40QT

60QT

80 QT

99481

99479

99472

99470

CAP PART

30 QT

40 QT 99474 Stainless Steel

60 QT 96003 Stainless Steel

80 QT 3439 Stainless Steel

“M” Four Wing Whip Bowl Truck

Allows bowl to be transported without carrying

30 QT

40QT

60QT

80 QT

98500

98505

98502

97674

Splash Covers

DESCRIPTION

NO.

99491

99477

99119

99120

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Bowl Extensions

DESCRIPTION

NO.

99493 Stainless Steel

CAP PART NO. DESCRIPTION

30 QT 07125 Painted Steel

30Qt on 40 Qt 77156 Painted Steel

40 QT 76729 Painted Steel

60 QT 15094 Painted Steel

80 QT 15094 Painted Steel

-11-

Page 14

Operation

In Order for your mixer to perform at top efficiency at all times, it is necessary that you follow the

recommendations as laid down by the designing engineers. Give your mixer the same attention you

would give your automobile and your Blakeslee-Built Mixer will give you many years of satisfactory

service.

SPEED SELECTION

Speed for the beater and auxiliary attachments are varied by the use of a four speed transmission. When

changing speeds one must first push the “stop” button and allow the mixer to come to a complete stop

before changing. NOTE: the mixer must be in gear in order for the mixer to start.

PULL OUT NEUTRAL PUSH IN

CAUTION: DO NOT SHIFT GEARS

WITH MOTOR RUNNING

SHIFT LEVER IS IN NEUTRAL WHEN IN

HORIZONTAL POSITION

There is an exclusive locking gear feature to prevent damage to the transmission and planetary gears if

inadvertently changed while in operation.

The available speeds are as such:

SPEEDS AGITATOR AUX. DRIVE SPEED

Second 100 190

Third 175 300

Fourth 310 575

First 55 105

The bowl is raised to working position by means of a power switch or crank handle

located on the right side of the machine. The bowl lift is adjusted to stop at the

proper working position before the mixer is shipped from the factory and therefore no

further adjustment should be necessary.

(RPM) (RPM)

-12-

Page 15

Parts Section

-13-

Page 16

FIGURE 1. COLUMN WELDMENT, UPPER HOUSING, MAIN SHAFT

AND ELECTRICAL COMPONENTS

-14-

Page 17

FIGURE 1. COLUMN WELDMENT, UPPER HOUSING, MAIN SHAFT

AND ELECTRICAL COMPONENTS

ITEM PART

NO.

1 97763 Column Weldment (80 & 60Qt.) 1 31 98075 Cover for Controller 1

1A 75804 Column Weldment (40Qt) 1 32 * Screw - Included with 98075 4

2 97793 Mixer Foot 4 33 70192 Contactor-25 Amp with 120V Coil 1

3 97803 Column Panel Front 1 33 A 97289 Contactor- 22 Amp with 240V Coil 1

4 07580 ¼-20 S/S Right Hand Screw 3 33B 76619 Contactor-35 Amp with 240V Coil 1

5

97849

Large Hex Head Cap Screw 5/8-18

N.F. X I-1/4

6 97807 Flat Washer 5/8” 1

7 97700 Housing-Bearing Weldment

8 97843 Label Instruction 1

9 97278 Label On-Off with Timer

97315 Label On-Off without Timer 1

10 96858 Label, Blakeslee Logo 1

11 97779 Housing-Transmission Weldment 35 N/A

11A 75850

12 97846

Housing-Transmission Weldment

(40Qt)

Large Head SHCS 5/8-11 NC x 1-1/2”

Long

13 98399 Key ¼ x ¼ x 4” 1 40 98082 Cover 1

14 97816 Shaft Main Drive 1 41 97276 Contact Block-Normally Open 1

15 98402 Key 2 42 97275 “Start” Push Button 1

16 07858

Large Hex Head Machine Screw

3/8-24 x 1”

17 07524 Lock Washer 3/8” 1 43B 15258 Timer – 30 Minute w/hold circuit 1

18 97702 Bevel Gear Support 1 44 97275 “Stop” Push Button 1

19 97838 Ring Retaining 1 45 97277 Contact Block-Normally Closed 1

20 74840 Spiral Bevel Gear Set 1 46 97668 Bracket for Timer 1

21 97833 Transmission Cover 1 47 97699 Screw 6-40x1/2” Lg. R.H. for timer 2

21A 71629 Stainless Steel Transmission Cover 1 48 98081 Hold Down Bracket 1

21B 75853 Transmission Cover (40 Qt.) 1 49 08132 10-32 Nut 2

22 07564 Locknut ½” 1

23 97307 Handy Electrical Box & Cover Ass’y 1

24 Handy Electrical Box 1 Not Shown

25 Handy Electrical Bo x Cover 1 76429 Knob - For Timer 76426 1

26 13965 Nipple-Close ½” NPT-1-1/2 Long 1 77380 Screw for above Knob 1

95645 Knob – For timers 98083 & 15258 1

27 Screw 18-32 x 3/8” Long 1

29 03584 ¾ Lock Washer 4

30 03484 ¾ Lock Washer 4

* Not available separately included with

Not Shown P/N 98075

77178 8 Pin Socket 1

77177 Reverse Phase Relay 1

07957 Transformer A/R

DESCRIPTION QTY ITEM PART

1

34

34A 71603

34B 71604

34C 71606

36 08132 10-32 Nut 2

1

37 97709 Bracket for Controller 1

38 8132 Nut Hex 10- 32 1

4

39 7285 Lock Washer 1

43 76426 Timer Electric 1

1

43A 98083 Timer – 15 Minute w/hold circuit 1

NO.

71600

Overload Thermal Relay, Range 2.5-3.9

amp

Overload Thermal Relay, Range 7-10

amp

Overload Thermal Relay, Range 10-13

amp

Overload Thermal Relay, Range 18-25

amp

DESCRIPTION QTY

1

1

1

1

-15-

Page 18

39

FIGURE 2. BOWL SUPPORT, BOWL SUPPORT CRANK AND

BOWL LOCKDOWN ASSEMBLY

-16-

Page 19

FIGURE 2. BOWL SUPPORT, BOWL SUPPORT CRANK AND

BOWL LOCKDOWN ASSEMBLY

ITEM PART NO. DESCRIPTION QTY NOTES

1 97799 Post (For 60 & 80 Qt) 1

1A 75823 Post (For 40 Qt) 1

1B 98578 Post (For 60 & 80 Qt Tall)

2 97798 Retainer, Post 1

3 97819 Plate, Backup 1

4 97846 Cap Screw, Socket Head - 5/18-11 NC X 1-1/2” Long 1

5 97837 Bearing “Rulon” 2

6 97769 Bowl, Support Elevator Weldment (For 80 Qt.) 1

6A 98152 Bowl, Support Elevator Weldment (For 60 Qt.) 1

6B 75870 Bowl, Support Elevator Weldment (For 40 Qt.) 1

7 98154 Bowl, Support Rear Shield (For 80 Qt.) 1

7A 98156 Bowl, Support Rear Shield (For 60 & 40 Qt.) 1

8 97800 Bowl, Rear Retainer (For 80 Qt.) 1

8A 98158 Bowl, Rear Upper Retainer (For 60 & 40 Qt.) 1

9 97761 Bowl, Clamp Stud 1

10 97822 Spring, Pressure Die 1

11 07115 Nut, Hex 3/8 X 16 1

12 07524 Lock Washer 1

13 98155 Bowl, Support Side Shield (For 80 Qt.) 1

13A 98157 Bowl, Support Side Shield (For 60 & 40 Qt.) 1

14 98963 Pin (For 60 & 80 Qt)

14A 75825 Pin (For 40 Qt) 1

15 98290 Washer 1

16 97818 Bowl Hub (For 60 & 80 Qt.)

16A 75824 Bowl Hub (For 40 Qt) 1

17 97811 Bowl, Clamp Handle 1

18 97795 Screw, Elevator 1

18A 98569 Screw, Elevator (for Tall Mixer) 1

19 15328 Setscrew, 5/16 – 18 X 5/16 Long 4

20 03181 Collar 1

21 98639 Thrust Bearing 1

22 15323 Nut, 3/8” 2

23 15095 Bolt 1

24 97797 Plate, Post Support 1

25 98170 Lock Washer, 5/8” 4

26 97846 Cap Screw, Socket Head - 5/18-11 NC X1-1/2” Long 1

27 17224 Timken Cup 1

28 17225 Bearing 1

29 97802 Collar 2

30 97827 Gear 2

31 98400 Key 1

32 97796 Bowl, Rising Shaft 1

33 * Setscrew,1/4-27 X1/4” Long 4

34 97825 Flange Bearing 2

35 05996 Lockwasher,5/16” 4

36 10660 Bolt 4

37 97845 Pin, Grooved 1

38 97760 Crank Handle, Complete 1

39 97794 Nut Assembly, for Elevator Screw 1

40 97836 Roll Pin 1

* Not available separately Included with P/N 97825 Flange Bearing, P/N 03181

Collar and P/N 97827 Gear

8B 98159 Bowl, Rear Lower Retainer (For 60 & 40 Qt.)

# 7 is Welded on,

on Current Models

# 8 Not Used On

Current Models

-17-

Page 20

6,8,10 23

21,22 3 12,13

19

1

2

16 17 18 5 7,8

9,25 20

4 11,24 6,8

1 3 12,13

9,25

2

19

4 6,8 12,24 14

FIGURE 3. POWER BOWL LIFT COMPONENTS

-18-

15

6,8,10

16

15

7,8

5

17 8,24

Page 21

FIGURE 3. POWER BOWL LIFT COMPONENTS

ITEM PART NO. DESCRIPTION QTY

1 72023 Brake Motor 1

2 72025 Gear Reducer 1

3 72085 Reducer Mounting Plate 1

4 72006 Reducer Mounting Bracket 1

5 72150 Switch Actuator Bracket 1

6 13091 Weld Stud ¼-20 x 1” 10

7 05643 Weld Stud ¼-20 x ½” 2

8 16732 Nylock Hex Nut ¼-20 12

9 07111 Hex Head Bolt 5/16-18 x ¾” 4

10 10019 Flat Washer 5/16 ID 4

11 08148 Hex Head Bolt 3/8-16 x ¾” 2

12 09548 Hex Head Bolt 3/8-16 x 1 ¾ 2

13 05998 Hex Nut 3/8-16 2

14 07584 Flat Washer 3/8 ID 2

15 14084 Guide Roller 4

16 72034 Switch Mounting Bracket 2

17 07235 Micro Switch 2

18 85891 Machine Screw 6-32 x 1 ½” 4

19 98064 Sprocket 1

20 98068 Sprocket 1

21 72086 Roller Chain 1

22 98653 Connecting Link 1

23 05990 Elastic Stop Nut 6-32 4

24 05994 Lock Washer 3/8 I.D. 2

25 07598 Lock Washer 5/16 I.D. 4

NOT SHOWN

72024 Baldor SP 5001 Instant Rev. Switch 1

98477 3 Pole Rocker Switch 1

71451 Circuit Breaker 1

71942 Power Lift Switch Plate 1

-19-

Page 22

FIGURE 4. MOTOR MOUNTING BRACKET ASSEMBLY

ITEM PART No. DESCRIPTION QTY

1 97777 Motor Base Weldment 1

2 98006 Support Bracket Weldment 2

3 98011 Screw, Hex Head ½-13 X 1” long 3

4 12836 Washer, Flat 9/16 I.D. X 1 ¼ O.D. 3

5 98012 Screw, Hex Head ½-13 X 3” Long 1

6 98004 Stop Bracket 1

-20-

Page 23

14 A,B,C,D,E & F

FIGURE 5. MOTOR AND POWER TRAIN ASSEMBLY

ITEM PART

NO.

DESCRIPTION

QTY

ITEM

PART

NO.

DESCRIPTON

QTY

1 97714 Transmission 1 17 08532 Sealing Washer 2

2 97281 Gear Wheel 1 18 14082 Roller 4

3 97284 Hub 1 19 70409 Switch Mounting Plate 1

4 * Set Screw 1 20 70411 Switch Mounting Plate 1

5 98398 Key 1 21 70403 Flat Washer 1

6 * Lock Washer 5/16” 1 22 97836 Roll Pin 1

7 * Bolt, 5/16” -18 x 2” Long 1 23 12122 6-32 Rnd Hd Machine Screw 4

8 97282 Flex Gear 1 24 70152 Limit Switch 2

9 + Bolt, 3/16” -24 x 1” Long 1 25 05587 Flat Washer 4

10 + Lock Washer, 3/16” 1 26 14784 Bolt 5/16” x 3/8” 2

11 97283 Hub, 7/8” Dia. With 1/4 “ Keyway 1 27 05996 Lock Washer 5/16 2

12 98400 Key 1 28 14786 Hex Nut 5/16”-18 2

13 97280 Gear Wheel 1 29 97813 Hub 1

DD 40 Motors

30 97810 Shaft 1

14 75795 1 ½ HP Motor 115/230 V 1PH. 1 31 97826 Knob 1

14A 75796 1 ½ HP Motor 208/230/460 V 3PH. 1

DD 60 & DD 80 Motors

14B 97298 2 HP Motor 115/230 V 1PH. 1

14C 97660 2 HP Motor 208/230/460 V 3PH 1

14D 15126 2 HP Motor 220/440 V 3PH 1

14E 98543 3 HP Motor 208/230/460 V 3PH for

1 * Included in P/N 97284 Assembly

XT300

14F 72184 5 HP Motor208/230/460 V 3PH for

1 + Included in P/N 97283 Assembly

XT500

15 99730 Shoulder Screw 2

16 70404 Roller 2

-21-

Page 24

15

FIGURE 6. AUXILIARY HUB ASSEMBLY

ITEM PART

NO.

1 98483 Adaptor, for Attachment 1 10 98379 Adaptor, Bearing Attachment 1

2 14784 Bolt,5/16-18 x ¾” Long 1 11 98377 Hub Attachment 1

3 05996 Lock Washer 1 12 18751 Drive Cap, Auxiliary 1

4 97817 Lock Washer, 5/16 1 13 98015 Screw Ass’y, Wing Nut 1

5 97734 Gear Pinion, Spiral Bevel 1 14 97815 Retaining Plate 1

6 97804 Connector, for Attachment Drive 1

7 97738 Pin, Spring 2

8 98484 Adaptor, for Attachment 1

9 98378 Sleeve, Bearing “Rulon” 1

DESCRIPTION

QTY

ITEM PART

NO.

15 74742 Drive Rod Assembly

DESCRIPTON QTY

Includes 1,6,7,8

1

-22-

Page 25

FIGURE 7. LOWER PLANETARY & BEARING HOUSING ASSEMBLY

Used prior to Serial Number Suffix EDD Changed 5/1993

ITEM PART

NO.

1 98349 Label Direction Arrow 1 8 99190 Cup *

2 97832 Cover 1 9 97700 Bearing Housing 1

3 97831 Gear Planetary 1 Weldment

4 97842 Pinion 1 10 97779 Transmission Housing 1

5 97809 Spacer 1 Weldment

6 97824 Bearing Roller (Includes # 7&8) 2* 11 97848 Cap Screw, Soc. Head 4

7 99191 * 5/8-11 NC X 1 ½” Long

DESCRIPTION

Cone

QTY

ITEM PART

NO.

-23-

DESCRIPTON QTY

Page 26

NOTES

FIGURE 8. PLANETARY & BEATER SHAFT ASSEMBLY

ITEM PART

NO.

1 97849

2 98904 Set Screw 2 8 97851 Ball Bearing 1

2A 74922 Set Screw 1 9 97842 Pinion 1

3 97852 Seal 1 10 98402 Key, ¼ x1/4 x 1 ¼ 1

4 97857 Pin 1 11 97835 Ring, Retaining 1

5 97830 Shaft Agitator 1

DESCRIPTION

Cap Screw, Hex Head

5/8-18 N.D. x 1 ¼” Long

QTY

1

ITEM PART

NO.

6 98750 Ball Bearing 1

7 97698 Planetary 1

DESCRIPTON QTY

-24-

2A

Page 27

NOTES

Lubrication

The planetary and spiral-beveled gears are self-lubricated for life. The lubrication used is micromly grease

and must be re-applied if gears are replaced. The transmission uses Mobil “delvic 1” synthetic oil which

should last the normal life of the mixer. No lubrication is required for the auxiliary drive hub.

If lubrication is applied to the auxiliary hub a grease-like substance will possibly leak out causing damage

to the product.

Applications of any lubrication will Void Warranty.

-25-

Page 28

FIGURE 9. TRANSMISSION HOUSING ASSEMBLY

-26-

Page 29

FIGURE 9. TRANSMISSION HOUSING ASSEMBLY

ITEM PART NO. DESCRIPTION QTY

1 74840 Set, Spiral Bevel Gear & Pinion Gear 1

2 NLA Gear, Spiral Bevel

3 NLA Pinion, Spiral Bevel

4 73230 Seal 1

5 98402 Key 1

6 97838 Ring, Retaining 1

7 97702 Support, Bevel Gear 1

8 07524 Lock Washer, 3/8 8

9 97858 Screw Hex Head1/2-13 x 2” 8

10 98402 Key 2

11 97816 Shaft, Main Drive 1

12 97824 Bearing, Set – includes items 13 & 14 1

13 99191 Cone, Timken 1

14 99190 Cup, Timken 1

15 73863 Support, Transmission

16 74170 Transmission 1

17 15317 Lock Washer, ½” 4

18 74216 Screw, Hex Head, ½-13 x 2” 4

19 97826 Knob, Gear Shift A/R

20 97810 Handle, Gear Shift 1

21 97813 Hub, Gear Shift 1

22 70404 Roller 2

23 99730 Screw, Shoulder 2

24 97836 Spring Pin 1

25 97281 Wheel Gear 1

26 97284 Hub 1

- Lock Washer, 5/16” 3

- Screw, Long Hex Head, 5/16-18 x2” 3

- Setscrew, ¼-20 1

27 98398 Key 1

28 12122 Screw, Rd. Head Machine, 6/32 x ¾” 4

29 70152 Switch, Limit 2

30 - Switch Mounting Assembly

70409 Plate, Switch Mounting 1

70411 Weldment, Switch Mtg. Bracket 1

14784 Screw, Hex Head 5/16 x ¾” 1

10019 Flat Washer, 5/16” 2

05996 Lock Washer, 5/16” 2

14786 Nut, Hex, 5/16” 2

70403 Flat Washer 4

14082 Roller 4

08523 Washer, Seal 2

31 74215 Nut, 5/8” 4

32 74214 Lock Washer, 5/8” 4

33 74213 Screw, Hex Head, 5/8-11 x 2 ¼” 4

34 97831 Gear, Planetary 1

35 03574 Screw, Socket Head, 3/8-16 x 1 1/4 “ 4

36 97809 Spacer 1

37 97898 Planetary 1

38 98399 Key, ¼ x1/4 x 4” 1

39 97807 Plug, Retainer 1

40 97849 Screw, Stainless Steel Hex Head, 5/8-18 x 1 ¼” 1

-27-

Page 30

FIGURE 9. TRANSMISSION HOUSING ASSEMBLY

-28-

Page 31

FIGURE 9. TRANSMISSION HOUSING ASSEMBLY

ITEM PART NO. DESCRIPTION QTY

41 97832 Cover Planetary 1

42 15310 Screw, Pan Head, 8/32 x 3/8” 1

43 98349 Arrow, Direction 1

44 97835 Ring, Retaining 1

45 97842 Pinion 1

46 98402 Key 1

47 97851 Bearing, Ball 1

48 97850 Bearing, Ball 1

49 97830 Shaft, Beater 1

50 97857 Pin 1

51 97852 Seal 1

52 98094 Setscrew 1

53 98094 Screw, Stainless Steel Hex Head ½-20 x 1” 1

54 97738 Pin, Spring, 3/16 x1 ¼” 1

-29

Page 32

FIGURE 1

WIRING DIAGRAM FOR 208-204/440-480 VOLTS THREE PHASE 60HZ

-30-

NOTES: 1. THE CONTROL CIRCUIT WIRING IS #16GA. 2&3 COND NEOPREME CORD, 600 VOLT RATED, U\L & C.S.A. LISTED.

Page 33

FIGURE 2

WIRES 83 & 81 ATTACH TO 1 & 3

TERMINALS OF CONTACTOR “C1”

CABLE ITEM # 9 CONNECT TO X2 *X1

WIRES 1 & 3 FROM CONTROL CIRCUIT

-31-

Page 34

FIGURE 3

-32-

WIRING DIAGRAM FOR 208-204/440-480 VOLTS THREE PHASE 60HZ

NOTES: 1. THE CONTROL CIRCUIT WIRING IS #16GA. 2&3 COND NEOPREME CORD, 600 VOLT RATED, U\L & C.S.A. LISTED.

Page 35

FIGURE 4

-33-

Page 36

ELECTRICAL COMPONENTS

FIGURE 5

MOTOR TABLE

ITEM

22 M1 2 208-220 3 7.0 60 T1,T7 T2,T8 T3,T9 T4,T5,T6

22 M1 2 440-480 3 3.5 60 T1 T2 T3 (T4,T7)(T5,T8)

23 M2 2 115 1 23.0 60 T1,T3,T8 T2,T4,T5 -------- ---------23 M2 2 208-240 1 11.5 60 T1 T4,T5 -------- T2,T3,T8

MOTOR HP VOLTAGE PHASE F.L.

AMPS

CYCLE

MOTOR LEAD CONNECTION

SUPPLY LINE LEADS

L1 L2 L3

TOGETHER

TIE-

(T6,T9)

-34-

Page 37

PARTS & SERVICE

USA

Blakeslee Authorized Parts & service Distributors and Preferred Service Agents are the focal point for service and are responsible for all warranty/repair work

and for maintaining a complete stock of replacement parts.

They have factory-trained servicemen and are kept informed by the factory on the latest servicing procedures.

To receive service and/or parts, call the Blakeslee Distributor nearest you. If you happen to be in an area not covered by a distributor, phone the Blakeslee Serv ice

Department in Chicago at 708-656-0660 for the name and location of one of over 300 strategically-located Blakeslee Authorized Service Agencies, which is nearest

you.

ALABAMA FLORIDA (Cont.) LOUISIANNA NEW YORK TENNESSEE

Jones McLeod Appliance Co. Nass Service Co. Inc. Chandler’s Parts & Service Acme American Repairs Inc. A-Tech Inc

1616 Seventh Ave. North 1108 S. Woods Ave. 11656 Darryl Drive 99 Scott Ave. 424 Sixth Avenue South

Birmingham, AL 35203 Orlando, FL 32805 Baton Rouge, LA 70815 Brooklyn, NY 112237 Nashville, TN 37203

205-251-0159 407-425-2681 225-272-6620 718-456-6544 615-255-2002

ARIZONA GEORGIA MARYLAND

3138 Oneida Street 1209 S. Watkins

Byassee Equipment TWC Electric Motor Repair CO. Sauquoit (Utica), NY 13456 Chattanooga, TN 37404

1939 E. Washington 5080 Highlands Pkwy S. A150 700 East 25

Phoenix, AZ 85034 Smyrna, GA 20082 Baltimore, MD 21218

602-252-0402 770-438-9797 410-467-8080

3717 Cherry Road

ARKANSAS HAWAII MASSACHUSETTS

1020 Tuckaseegee Road 901-366-4587

Bromley Parts & Service Commercial Appliance Ace Service Co. Inc. Charlotte, NC 28208

10th & Ringo Street Parts & Service Co. 95 Hampton Ave. 704/377-4501

Little Rock, AR 72202 1623 Democratic St. Needham (Boston), MA 02194

501-374-0281 Honolulu, HI 96819 617-449-4220

808-841-4545 1377 N. Bravos

CALIFORNIA

Acme Pacific Repairs, Inc. E & G Appliance Service Co. Akron, OH 44314

1347 Fulton Place Boise Appliance 1435 Lawndale Ave. 330/753-6635 Kenco Service

Fremont, CA 94539 1503 Main Street Detroit, MI 48209 26 Lyerly – Suite 1

510-252-2070 Boise, ID 83702 313-842-2252 Commercial Parts & Service Houston, TX 77022

208-343-0102 6940 Plainfield Road 713-691-2935

Barker’s Food Machinery Ser. Midwest Food Equipment Serv. Cincinnati, OH 45236

5367 Second Street

Irwindale, CA 91706 Grandville, MI 49418 2120 Solana

626-960-9390 Eichenauer Food Equipment 616-261-2000 Electrical Appliance Repair Fort Worth, TX 76117

130 S. Oakland Ave. 5805 Valley Belt Road 817-831-0381

Chapman Appliance Service Decatur, IL 62522

1784 San Diego Ave. 217-429-4229 216-459-8700

San Diego, CA 92126 GCS

619-298-7106 General Parts Inc 2854 Louisiana Ave. North

248 James Street Minneapolis, MN 55427 Equipment Service

Sterling Service Bensenville, IL 60106 763-546-4221 Krueger Electric Service Inc. 6182 South Stratler

644 W. Hawthorn Street 630-595-3300 100 N.E. 24

Irwindale, CA

818-243-1234 Rescor 405-528-8883

5344 East Ave. Camp Service & Parts Inc.

COLORADO

708-352-3155 Jackson MS 39201 Authorized Appliance

Metro Appliance Service 601-353-9700 Ron’s Service Inc. 74

1640 S. Broadway

Denver, CO 80210

303-778-1126 GCS 503-624-0890

5310 East 25

CONNECTICUT

317-545-9655 St. Louis, MO 63105 Daubers Inc.

A-Tech Service, Inc. 314-535-2222 American Kitchen Mach. Corp. 7645 Dynatech Court

161 Sanrico Drive

Manchester, CT 06040

860-649-6627 Goodwin-Tucker 215-627-7760

2900 Delaware Ave Goodwin-Tucker Group

DISTRICT OF COLUMBIA

515-262-9308 Omaha, NE 68124 210 Vista Park Dr. Walsh Equipment Repair

Electric Motor Repair 402-397-2880 Pittsburg, PA 15205 1519 128

700 East 25

Baltimore, MD 21218

410-467-8080 General Parts, Inc. K & D Parts

1101 E. 13

FLORIDA

816-421-5400 Las Vegas, NV 89103 717-236-9039 Authorized Factory Service

Commercial Appliance Service 702-736-0006 Edens Fork Exit I 77

8416 Laurel Fair Circle

Tampa, FL 33610

813-663-0313 GCS Whaley Foodservice Repairs

4204 S. Brook Street R & B Service 2544D Morningside Dr.

Dade Restaurant Repair Louisville, KY 40214 4412 Towner N.E. West Columbia, SC 29169

2001 W. 27

Hihleah, FL 33010 505-889-4090 W223 N. 735 Saratoga Dr.

305-887-0783 GCS Waukesha, WI 53186

533 A Codell Drive 262-650-6666

GCS Lexington, KY

3373 Northwest 168

Miami, FL 33056

305-623-7001

th

Street

th

Street 502-367-1788 Albuquerque, NM 87110 803-926-5252 General Parts Inc.

th

Street 859-269-7484

IDAHO

ILLINOIS

Countryside, IL 60525 328 B Oakdale Street

INDIANA

th

Indianapolis, IN 46218 2728 Locust Street

Street Kaemmerlen Parts & Service

IOWA

Des Moines, IA 50137 7535 D Street GCS

KANSAS

th

Kansas City, MO 64101 4480 Aldebaran Ave. Harrisburg, PA 17103

Street Burney’s Commercial Service 1833-41 N. Cameron Street

KENTUCKY

MICHIGAN

1169 W. Waterloo Road 210-735-2811

3055 Dixie 513-984-1900 Stove Parts Supply Co.

MINNESOTA

MISSISSIPPI

16364 S.W. 72

MISSOURI

204 Quarry Street Springfield, VA 22153

NEBRASKA

412-787-1970 Bellevue, WA 98005

NEVADA

NEW MEXICO

th

Street 315/737-9401 423-624-3381

Duffys Rest. Equip. Service FESCO

NORTH CAROLINA

GCS

Authorized Appliance Service Memphis, TN 38118

TEXAS

OHIO

Commercial Kitchen Repair

Akron Restaurant Equipment San Antonio, TX 78207

Cleveland, OH 44131

OKLAHOMA

th

Oklahoma City, OK 73105 801-263-3221

Street Murray, UT 84107

OREGON

nd

Portland, OR 97224 802-775-5588

Ave. Rutland, VT 05701

PENNESYLVANIA

UTAH

LaMonicas Restaurant

VERMONT

th

River Street

VIRGINIA

Philadelphia, PA 19106 703-866-3600

WASHINGTON

th

Place N.E.

425-462-1645

WEST VIRGINIA

SOUTH CAROLINA

304-344-8225

Charleston, WV 53186

WISCONSIN

-35-

Page 38

PARTS & SERVICE Canada

ALBERTA MANITOBA NOVA SCOTIA Continued

Great West Comm. Kit. Rep. Grand Valley Mechanical Buddens Appliance Service Blanchfield Comm. Kit. Serv. Electro Ref. Service Ent.

5664 Burleigh Cresc. S.E. 360 Park Avenue E., 164 Nichols Avenue 770 Industrial Ave., Unit 13 161 Pere Divet

Calgary, AB T2H 1Z8 Brandon, MB R7A 6N2 Kentville, NS B4N 2H6 Ottawa, ON K1G 4H3 Sept-lles, QC G4R 3P8

Tel: 403-276-7832 Tel: 204-728-3898 Tel: 902-678-7895 Tel: 613-737-6632 Tel: 418-962-9186

L.D.I. Technical Services Commercial Kitchen Equip. J.R. Mahone y Ltd. McNabb Appliances Kitchen Equipment Services

4 – 3600 21

Calgary, AB T2E 6V6 Winnipeg, MB R3G 2T6 Sydney, NS B1L 1C5 Peterborough, ON K9H 1T6 Sherbrooke, QC J1H 1R9

Tel: 403-299-9591 Tel: 204-586-8273 Tel: 902-564-8775 Tel: 705-743-5350 Tel: 819-821-2153

Res Tech Service Ltd. Syd Tech Appliances Erlmar Plumbing Ltd. Choquette CKS

North Star Repair 593 Sherburne Street Box 1907 795 Batory Avenue 900 Pierre Bertrand, #220

11518 119

Edmonton, AB T5G 2X7 Tel: 204-228-5399 Tel: 902-561-0156 Tel: 905-420-5252

Tel: 780-453-6213

Robertshaw Refrigeration

P.O. Box 840 D & L Electric Tel: 902-897-0479 St. Catharines’s ON L2R 3X8 Comfort Mechanical

Cold Lake, AB T9M 1P2 83 Sister Green Road

Tel: 780-594-3488 Campbellton, NB E3N 3Y5

Tel: 506-753-5076

Re-Nu Mechanical Ltd. OFS Restaurant Appl. Serv. 116 Talford Street

1710 Bay F – 31

Lethbridge, AB T1H 5H1 88 Beaverbrook Street Barrie, ON L4M 4S4 Tel: 519-332-1770 1327 Hamilton Street

Tel: 403-327-7368 Moncton, NB E1C 8H7 Tel: 705-728-5289 Regina, SK S4R 2B6

Tel: 506-857-2232 Sault Rapid Repair Tel: 306-525-1979

Medicine Hat Refrigeration ChemMark 1496 Wellington St. E.

666 17

Medicine Hat, AB T1A 4X7 122 Driscoll Avenue Chalk River, ON K0J 1J0 Tel: 705-759-3311 410 Lauriston Street

Satellite Mechanical Ltd. Tel: 506-855-4228 Tisdale Plumbing & Heating Tel: 306-653-2772

#1 – 5571 45

Red Deer, AB T4N 1L2 I Line Electric Ltd. R.R. #5, 823974 Massie Rd.

Tel: 403-343-6122 280 Dalton Avenue Chatsworth, ON N0H 1G0 Tel: 705-235-4045 Oscar’s Electric

Miramichi, NB E1V 3N9 Tel: 519-794-3633 310 Alexander St.

BRITISH COLUMBIA

Key Food Equip. Services Fundy Gas & Electric 39 Regal Road Chelmsford, ON P0M 1L0

180 – 3700 North Fraser 45 Glen Road Guelph, ON N1K 1B6 Tel: 705-671-6477 Yukon Appliance Sales & Serv.

Burnaby, BC V5J 5H4 Saint John, NB E2H 2C9 Tel: 519-836-1090 9041 Quartz Road

Tel: 604-433-4484 Jemm Service White Horse, YK Y A 4Z5 1

Marsh & Sons Ventures

10411 – 95

Fort St. John, BC V1J 5Z4 14 Cooks Avenue Tel: 905-527-2525

Tel: 250-787-9733 Cornerbrook, NF A2H 1P1 R.G. Henderson & Son Ltd.

Tel: 709-634-7588 J.I.K.S. Ind. Kitchen Serv. 100 Thorncliff Park Dr.

J.D. Appliance Repairs 42 Groff Place, #4 Toronto, ON M4H 1G9

1965 Moss Crt. Domestic Service Centre Kitchener, ON N2E 2L6 Tel: 416-423-4357

Kelowna, BC V1Y 9L3 27 McCurdy Drive,

Tel: 250-860-5057 Gander, NF A1V 1W5

Jemco Food Equip. Service 660A Justus Drive Waites Enterprises

7431 Industrial Road Harold Snow & Son Ltd. Kingston, ON K7M 4H4 626 South Drive

Lantzville, BC V0R 2H0 451 Kenmount Road Tel: 613-384-1718 Summerside, PEI C1N 3Z7

Tel: 250-390-3244 St-John’s, NF A1B 3P9 Tel: 902-436-7509

Tel: 709-754-0330 A-1 Plumbing & Heating

Sheridan Appliances P.O. Box 414

764 Chaparral Place

Kamloops, BC V2C 5W4

Tel: 250-314-1722 Jerome Cameron 8487 19

R.R. #5, Salt Springs Action Rest. & Serv. Equip. Montreal, QC H1Z 4J2

Mark’s Rest. Services Antigonish, NS B2G 2L3 151 Bentley Street, #9 Tel: 514-723-5000

515 Dupplin Road, #3 Tel: 902-863-4528 Markham, ON L3R 3L1

Victoria, BC V8Z 1C2 Tel: 905-475-1499 L. Chasse Inc.

Tel: 250-475-6275 Harry Rhyno Refrigeration 448 Richelieu

233 North Street Stell Mechanical Pointe au Pic, QC G5M 1C9

Key Food Services Bridgewater, Lun. Co. NS 25 Iron Street Tel: 418-723-9100

2740 Bridge St., #105 B4A 2V7 Etobicoke, ON M9W 5E3

Victoria, BC V8T 5C5 Tel: 902-543-4737 Tel: 905-569-8270 Majella Vaillancourt

Tel: 250-920-4888 82 St. Cyrille

Walker’s Electric Repco Restaurant Equip.

Triumph Food Equip. Service 2608 Windsor Street 9208 Lundy’s Lane Tel: 418-862-2503

4671 Slocan Street Halifax, NS B3K 5C8 Niagara Falls, ON L2E 6S4

Vancouver, BC V5R 1Z8 Tel: 902-454-0291 Tel: 905-358-9071

Tel: 604-454-9326

Gas Repair Equipment

7 St. N.E. #322 Puerto Nuevo

San Juan, PR 00920

787-749-8044

st

St. N.E. 731 Wall Street 1810 Kings Road 370 Burnham Street 893 King Street W.

th

Street Winnipeg, MB R3G 2K8 Sydney, NS B1P 6W4 Pickering, ON L1W 2W5 Ville Vanier, QC G M 3K2 1

st

St. N. Electrical & Refrigeration Serv. 16 Lennox Dr., R.R. #2 Sarnia, ON N7T 7J2 Northcote Sales & Serv. Co.

th

Street S.W. EMR 52 Highway 17, P.O. Box 371

th

Street

th

Avenue Bob’s Electric Hamilton, ON L8L 3C4 Tel: 807-623-7851

NEW BRUNSWICK

Moncton, NB E1E 3R8 Tel: 613-584-2988 Saskatoon, SK S7K 0R5

Tel: 506-622-2214 Sudbury Rapid Service Whitehorse, YK Y1A 2L6

G.R. Garrity 23 Main Street Tel: 867-667-2330

NEWFOUNDLAND

Tel: 709-256-7738 R.G. Henderson & Son Ltd.

NOVA SCOTIA

P.O. Box 83 Tel: 519-748-5361

Fundy Appliance Service Sure-Fix Food Equip. Serv.

Truro, NS B2N 5B3 52 Vine Street S.

ONTARIO

Kitchenworks Rest. Equip. Sup 40 Golden Avenue

Barbers Rest. Eq. & Repairs 1211 Ford Street

927 Barton Street E. Thunder Bay, ON P3A 4R8

Ilderton, ON N0M 2A0

Tel: 519-455-6559 Choquette CKS

ONTARIO

Tel: 905-685-0480 1355 11th Avenue

Regina, SK S4P 0G8

W.J. Barnes & Son Tel: 306-352-0544

Sault Ste. Marie, ON P6A 2R1

South Porcupine, ON P0N 1H0

P.E.I.

QUEBEC

Riviere de Loup, QC G5R 2G8

Continued

th

Avenue

-36-

QUEBEC

Tel: 418-681-3944

SASKATCHEWAN

Evan’s Restaurant Serv.

YUKON

Tel: 867-668-4844

Puerto Rico

Page 39

Date of Installation

Serial

No.

Model

No.

Your new Blakeslee mixer is warranted for one year from date of installation shown above

against defective materials and workmanship. If any defects are found within the warranty

period; parts, and labor involved with their replacement will be covered free of charge.

Service must be performed by a Blakeslee authorized service agency. All labor to be

performed during regular working hours. Overtime premium will be charged to the

customer. All warranty parts are shipped by surface transportation. If other means of

transportation is requested the customer is required to pay the premium. This warranty

does not apply to damages resulting from errors in installation on the part of other

contractors, nor does it apply to machines which have been subject to accident, misuse, or

abuse. It is understood that Blakeslee’s warranty obligation with respect to machines

located outside of the United States or located in the state of Alaska is limited to the

furnishing of replacement parts only. In the state of Hawaii, repair labor is provided free of

charge; travel time and expenses paid by the customer. On the island of Oahu, repair labor,

travel time and expenses are provided free of charge. This is the entire and only warranty

of Blakeslee. We neither assume nor authorize anyone else to assume for us any other

obligation or liability in connection with Blakeslee Machines.

Limited Warranty

Note: In no case can this warranty exceed eighteen (18) months from the date of shipment from our

Plant at Chicago, Illinois.

-37-

Page 40

Revised 4/2005

Loading...

Loading...