Page 1

D-8 & DD-8

DISHWASHERS

INSTALLATION &

OPERATION

(01-13)

Page 2

ELECTRICAL WARNINGS

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

ELECTRICAL EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR

PERFORMING MAINTENANCE ON THE EQUIPMENT.

WARNING: Failure to follow all the instructions in this manual can

cause property damage, injury or death.

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death.

WARNING: Electrical connections should be performed only by a certied

professional.

WARNING: Electrical and grounding connections must comply with the

applicable portions of the National Electric Code and/or all local electric codes.

Failure to comply with this procedure can cause property damage, injury or death.

WARNING: Before connecting the unit to the electrical supply, verify that

the electrical and grounding connections comply with the applicable portions of

the National Electric Code and/or all local electrical codes. Failure to comply with

this procedure can cause property damage, injury or death.

WARNING: Before connecting the unit to the electrical supply, verify that

the electrical connection agrees with the specications on the data plate. Failure to

comply with this procedure can cause property damage, injury or death.

WARNING: UL73 Grounding Instructions: This appliance must be connected

to a grounded, metal, permanent wiring system; or an equipment-grounding

conductor must be run with the circuit conductors and be connected to the

equipment-grounding terminal or lead on the appliance. Failure to comply with this

procedure can cause property damage, injury or death.

WARNING: Appliances equipped with a exible electric supply cord are

provided with a three-prong grounding plug. It is imperative that this plug be

connected into a properly grounded three-prong receptacle. Failure to comply with

this procedure can cause property damage, injury or death.

WARNING: If the receptacle is not the proper grounding type, contact an

electrician. Do not remove the grounding prong from the plug. Failure to comply

with this procedure can cause property damage, injury or death.

— 2 —

Page 3

WARNING: Before performing any service that involves electrical

connection or disconnection and/or exposure to electrical components, always

perform the Electrical LOCKOUT/TAGOUT Procedure. Disconnect all circuits. Failure

to comply with this procedure can cause property damage, injury or death.

WARNING: Before removing any sheet metal panels, always perform the

Electrical LOCKOUT/TAGOUT Procedure. Be sure all circuits are disconnected.

Failure to comply with this procedure can cause property damage, injury or death.

WARNING: Do not operate this equipment without properly placing and

securing all covers and access panels. Failure to comply with this procedure can

cause property damage, injury or death.

WARNING: Do not use or store gasoline or other ammable vapors or

liquids in the vicinity of this or any other appliance. Failure to comply can cause

property damage, injury or death.

WARNING: In the event of a power failure, do not attempt to operate this

appliance. Failure to comply can cause property damage, injury or death.

ELECTRICAL LOCKOUT/TAGOUT PROCEDURE

WARNING

Before performing any service that involves electrical

connection or disconnection and/or exposure to

electrical components, always follow the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all circuits.

Failure to comply with this procedure can cause

property damage, injury or death.

The Electrical LOCKOUT/TAGOUT Procedure is used to

protect personnel working on an electrical appliance.

Before performing any maintenance or service that

requires exposure to electrical components, follow these

steps:

1. In electrical box, place appliance circuit breaker into

OFF position.

2. Place a lock or other device on electrical box cover

to prevent someone from placing circuit breaker ON.

3. Place a tag on electrical box cover to indicate that

appliance has been disconnected for service and

power should not be restored until tag is removed

by maintenance personnel.

4. Disconnect appliance power cord from electrical

outlet.

5. Place a tag on the cord to indicate that unit has

been disconnected for service and power should

not be restored until tag is removed by maintenance

personnel.

— 3 —

Page 4

TABLE OF CONTENTS

GENERAL DESCRIPTION ..............................................................................................................................................................................................................5

Model D-8 ................................................................................................................................................................................................................................5

Model DD-8.............................................................................................................................................................................................................................5

Door Safety Switch ...............................................................................................................................................................................................................5

Pump Motor ............................................................................................................................................................................................................................5

Control Circuit ........................................................................................................................................................................................................................5

Vacuum Breaker ....................................................................................................................................................................................................................5

Heaters......................................................................................................................................................................................................................................5

Automatic Wash Tank Fill ...................................................................................................................................................................................................5

Final Rinse Boosters (Optional) ........................................................................................................................................................................................5

Heat and Voltage Field Changeover ..............................................................................................................................................................................5

INSTALLATION ..................................................................................................................................................................................................................................6

Visual Inspection ...................................................................................................................................................................................................................6

Unpacking the Dishwasher ...............................................................................................................................................................................................6

Leveling the Dishwasher ....................................................................................................................................................................................................6

Plumbing the Dishwasher .................................................................................................................................................................................................6

Dish Tables ..............................................................................................................................................................................................................................6

Electrical Connections ........................................................................................................................................................................................................7

Pump Motor Rotation .........................................................................................................................................................................................................8

Fill/Rinse ...................................................................................................................................................................................................................................8

Drains ........................................................................................................................................................................................................................................8

Electric Heater ........................................................................................................................................................................................................................9

Gas Heater ...............................................................................................................................................................................................................................9

Pilot Lighting ....................................................................................................................................................................................................................... 11

Pilot Flame Adjustment ................................................................................................................................................................................................... 12

Gas Vents............................................................................................................................................................................................................................... 12

Steam Injected Heaters ................................................................................................................................................................................................... 12

Steam Coil Heater .............................................................................................................................................................................................................. 12

Electrical Detergent and Rinse Additive Injector Connections ......................................................................................................................... 12

OPERATION ....................................................................................................................................................................................................................................14

Preparing the Dishwasher for Use ............................................................................................................................................................................... 14

Automatic Tank Fill (Standard) ...................................................................................................................................................................................... 14

Wash Cycle Selector .......................................................................................................................................................................................................... 14

Automatic Start (Optional) ............................................................................................................................................................................................. 15

Manual Start (Standard) .................................................................................................................................................................................................. 15

Tank Selection (Optional on DD-8 only) .................................................................................................................................................................... 15

Soiled Dishtable Operation ............................................................................................................................................................................................ 15

Loading the Dishwasher ................................................................................................................................................................................................. 15

Operating the Dishwasher ............................................................................................................................................................................................. 16

Shutdown and Cleaning ................................................................................................................................................................................................. 16

Maintenance ................................................................................................................................................................................................................................. 18

Motor...................................................................................................................................................................................................................................... 18

Pump ...................................................................................................................................................................................................................................... 18

Doors/Hood ......................................................................................................................................................................................................................... 18

Line Strainers ....................................................................................................................................................................................................................... 18

Wash Arms............................................................................................................................................................................................................................18

Final Rinse Arms and Nozzles ........................................................................................................................................................................................ 18

Pump Motor Overload Protection ............................................................................................................................................................................... 19

Water Treatment................................................................................................................................................................................................................. 19

Troubleshooting.................................................................................................................................................................................................................20

SCHEMATIC .................................................................................................................................................................................................................................... 22

WIRING DIAGRAM ....................................................................................................................................................................................................................... 24

WARRANTY .................................................................................................................................................................................................................................... 26

— 4 —

Page 5

GENERAL DESCRIPTION

Model D-8

The Model D-8 door-type commercial dishwasher has a

three-sided door or hood that is spring counterbalanced

and opens as one unit to provide access to the machine. The

machine can be easily modied from a straight- through to

a corner unit by simply moving one track rail. If the unit is

to be used in a corner, the right side should be positioned

toward the wall to allow access to the controls.

Model DD-8

The Model DD-8 door-type commercial dishwasher has a

three-sided door or hood that is spring counterbalanced

and opens as one unit to provide access to the machine.

The unit has two wash tanks and can wash two dish racks

at a time. The Model DD-8 can be specied as a straightthrough or corner unit when ordering. The side to be

used in the corner must be designated so the controls

are accessible.

Door Safety Switch

All models are equipped with a door safety switch. The

machine will not operate when the door is open. If the

door is accidently opened during a cycle, the machine will

stop operating. Some models may be equipped with an

optional door safety lock which prevents the door from

opening during a cycle.

On manual start units, the door must be closed and the

operator must press the start button to initiate a cycle.

On machines equipped with the optional automatic

start feature, the operator need only close the door to

start a cycle.

Control Circuit

All units are supplied with a 110 VAC control circuit.

Vacuum Breaker

The ll line has a vacuum breaker installed in it to prevent

any backow of water into the fresh water supply line. If

a negative pressure develops in the supply line, the loss

of pressure permits a check valve inside the breaker to

drop, sealing the orice. At the same time, a vent opens

admitting air to the system to break the vacuum.

Heaters

Wash tank water is heated by electricity, steam coil, steam

injection or gas. Electrically heated machines are available

in 208, 240, 440, or 480 VAC only.

Automatic Wash Tank Fill

All machines are supplied with automatic wash tank ll.

Final Rinse Boosters (Optional)

Machines can be equipped with an optional built-in

electric booster, remote mounted booster or remote

mounted steam booster. These boosters are designed

to raise the rinse water temperature from 140°F to

180F°-185°F.

Heat and Voltage Field Changeover

Pump Motor

The unit is equipped with a 1½ HP motor. Model D-8 has

one motor; Model DD-8 has two motors.

When changing either to or from single- to three-phase

electrical power, the wash pump motor must be changed.

The motor overload relays must also be changed. See

parts description in the separate Illustrated Parts List and

wiring diagram.

When changing from 115 volts to 208, 230, 440 or 480 VACs,

single- or three-phase, a transformer must be added. The

motor overload relays must also be changed.

— 5 —

Page 6

INSTALLATION

Visual Inspection

Before installing the unit, inspect the shipping container

and machine for damage. A damaged container may

indicate there is damage to the machine. If there is

damage to both the container and machine, do not throw

away the container. The dishwasher has been inspected

and packed at the factory and is expected to arrive in

an undamaged condition. However, rough handling by

carriers or others may result in damage to the unit while

in transit. If such a situation occurs, do not return the unit

to Blakeslee; instead, contact the carrier and ask them to

send a representative to the site to inspect the damage

to the unit and to complete an inspection report. You

must contact the carrier within 48 hours of receiving the

machine. Also, contact the dealer where you purchased

the unit.

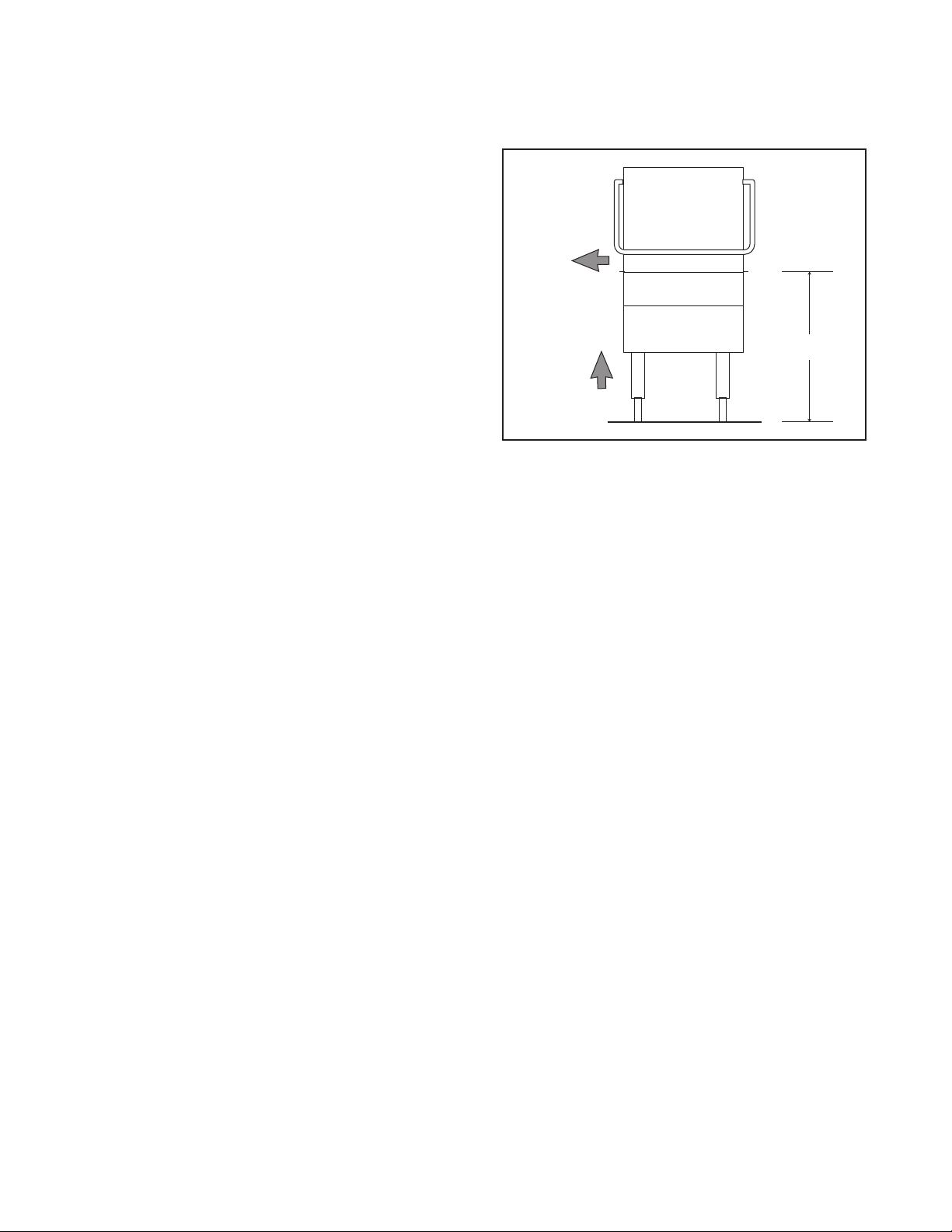

Unpacking the Dishwasher

Excessive gap

on left:

Raise left front

leg and door will

shift to the left

Excessive gap

on right:

Raise right front

leg and door will

shift to the right.

34-1/4" ± 3/4"

Leveling the Dishwasher

Once the machine has been removed from the container,

make sure that there are no parts missing from the

machine. This may not be obvious at rst. If an item is

missing, contact Blakeslee immediately to have the missing

item shipped to you.

Leveling the Dishwasher

The dishwasher must be level to operate correctly. This

allows the hood to open and close properly and ensures

the best results while washing. The unit comes with

adjustable bullet feet, which can be turned using a pair of

channel locks or by hand if the unit can be raised safely.

Ensure that the unit is level from side to side and from front

to back before making any service connections. Minor

adjustments to the feet may be necessary to eliminate

any door gaps once the unit has been leveled.

Plumbing the Dishwasher

All plumbing connections must comply with all applicable

local, state, and national plumbing codes. The installing

plumber must ush the incoming water line thoroughly

prior to connecting it to the dishwasher. Any valves that

are fouled as a result of foreign matter left in the water

line, and any expenses resulting from this fouling, are not

covered under the manufacturer’s warranty.

Various connections are labeled “180° Water”, “Steam”,

“Gas”, etc. Only connect the corresponding service to

these connections.

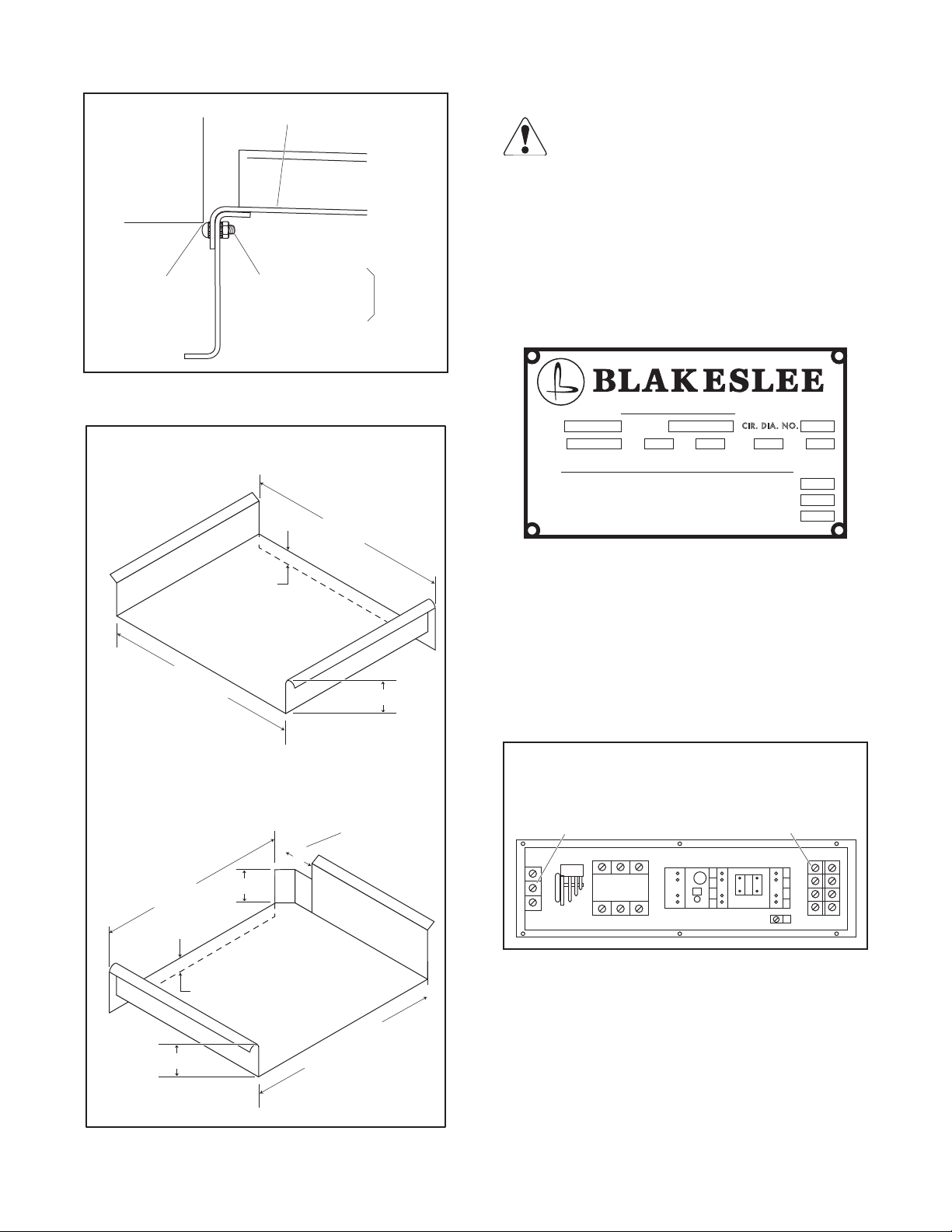

Dish Tables

Dish tables must be lipped into and slope slightly toward

the dishwasher. Use silicone sealant between the dish

table and the dishwasher. Secure with stainless steel

truss head screws.

— 6 —

Page 7

Washer

Hood

Gap

Table

Truss head screws,

lockwashers and nuts

S/S

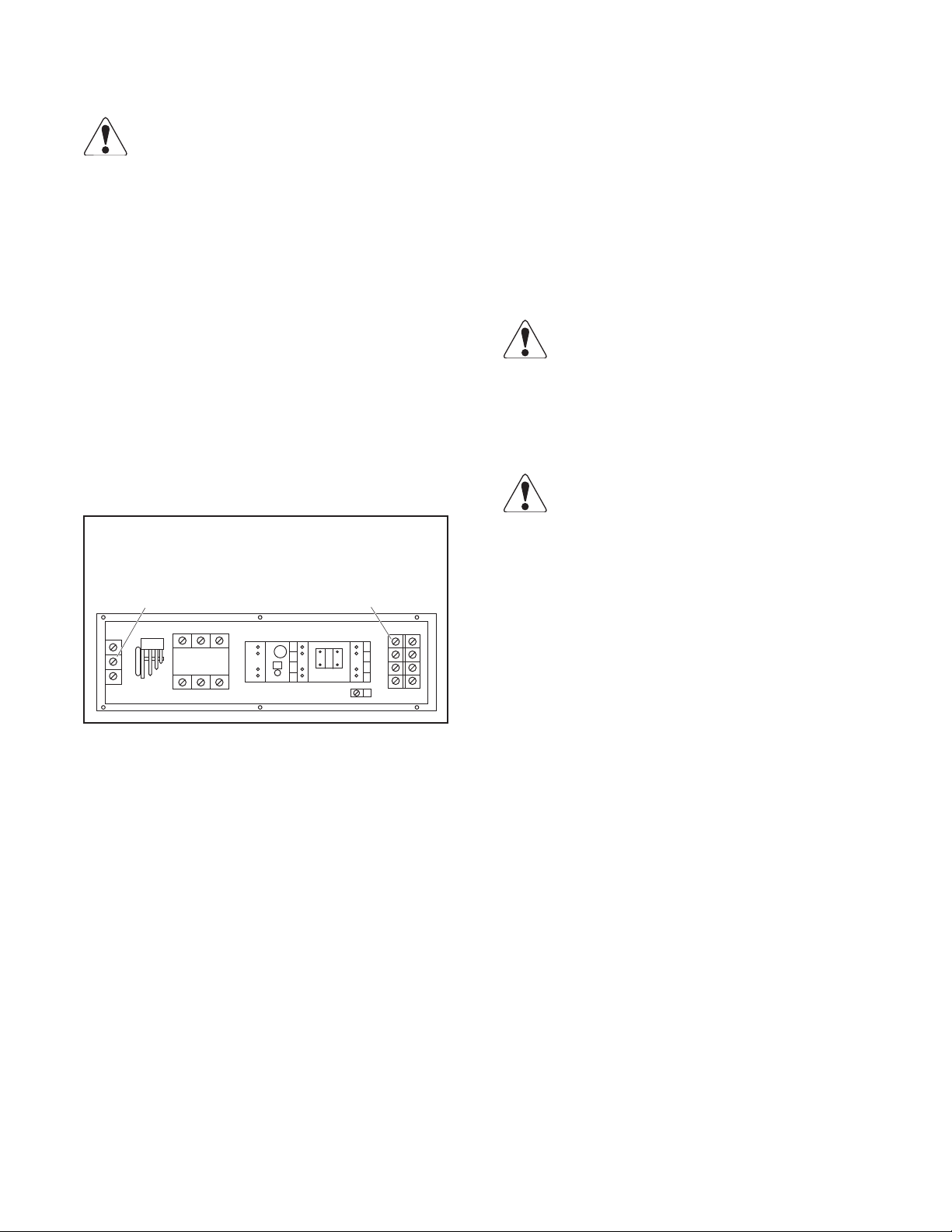

Electrical Connections

WARNING

Before performing any service that involves electrical

connection or disconnection and/or exposure to

electrical components, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all circuits.

Failure to comply with this procedure can cause

property damage, injury or death.

Refer to the unit’s data plate before making any

connections.

Attach Table to Tank

DISHTABLE DIMENSION INFORMATION

1"

22" MIN.

LEFT SIDE TABLE

Right side table (not shown) –

dimensions are same but reversed

6"

23-3/8"

4" MAX.

Notch for

Hood Handle

POWER REQUIREMENT

MOD.

VOLTS

BRANCH CIRCUIT PROTECTION REQUIREMENT

SUPPLY CIRCUIT CONDUCTORS (MINIMUM AMPACITY)

W-2-20878

SER. NO.

PH. HZ. AMP. H P.

CIRCUIT-BREAKERS (MAZIMUM AMPACITY)

TIME-DELAY FUSES (MAZIMUM AMPACITY)

Any connections must correspond to the information

specied on the data plate. A fused disconnect switch

or circuit breaker (not supplied) MUST be installed in

the electrical supply line for the dishwasher. This service

connection must meet all local and national electrical code

requirements. All connections are made at one common

location in the control box. The control box cover is hinged

and can be opened by removing six (6) ¼ -20 screws and

swinging the cover to the right.

Thermostat –

Turn screw clockwise to

increase temperature;

Turn counterclockwise to

decrease temperature

Incoming

power

connection

4" MAX.

25-3/4"

1"

4" MAX.

FRONT TABLE

(Corner installation only)

26-3/4" MIN.

Thermostat & Power Connection Locations

Note: If the unit has the optional electrical booster,

refer to section on Boosters for separate electrical

connection information.

— 7 —

Page 8

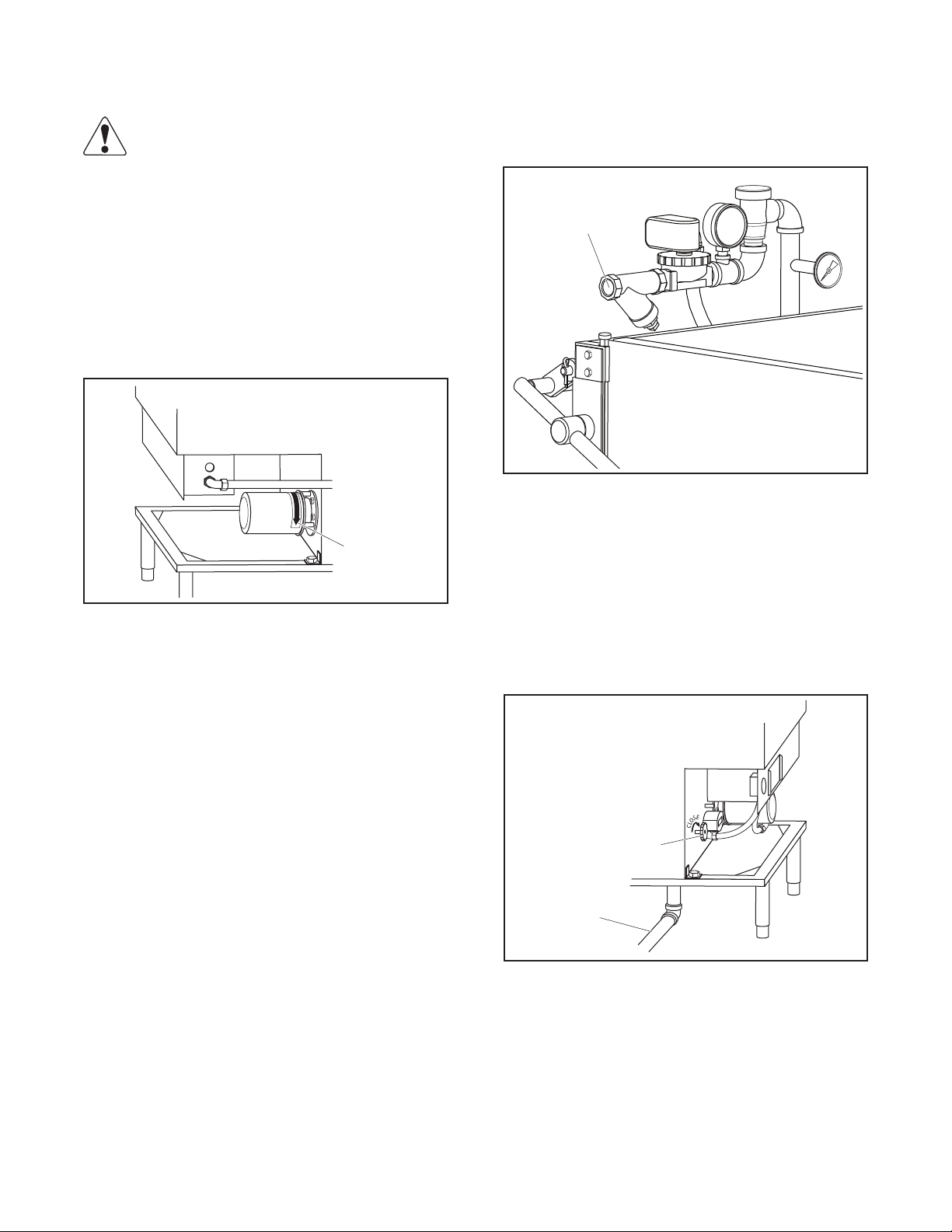

Pump Motor Rotation

WARNING

Before performing any service that involves electrical

connection or disconnection and/or exposure to

electrical components, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all circuits.

Failure to comply with this procedure can cause

property damage, injury or death.

The pump motor(s) must rotate in a clockwise direction

as viewed from the front of the dishwasher. An arrow

on the side of the pump motor(s) indicates the correct

motor direction.

Connect a ¾" pipe to the line strainer.

For a piping run greater than 20 ft, increase the pipe size

to insure proper ow pressure at the dishwasher.

Line Strainer

Line Strainer

Motor rotation

arrow

Pump Motor Rotation

This rotation was checked at the factory but must be

rechecked before putting the dishwasher into service.

Note: There may be more than one pump motor

depending on the model.

Fill/Rinse

Final Rinse water is used to ll the dishwasher’s wash

tank(s). The water supply must have a water temperature

of 180°-195° F with a dynamic ow pressure of 15 to 25

PSI at the dishwasher.

Note: If the dishwasher has been supplied with either a

machine mounted booster or a remote booster, the

water supply temperature must be 140° F minimum.

Drains

Drain connections must comply with all local and national

code requirements.

Connect the tank drain(s) to the building drain connection

using 2” pipe.

Drain Valve Handle

Drain line

to sewer

Drain Installation

If the incoming water supply pressure is below the required

15 PSI, an optional pressure booster pump will be required.

If the incoming water supply pressure is greater than 25

PSI, a pressure reducing valve (optional) will be needed.

The unit requires 72 gal/hr of 140°F water.

If a grease trap is required, it must be installed below the

drain line and have a capacity of 40 gallons per minute.

— 8 —

Page 9

Electric Heater

WARNING

Before performing any service that involves electrical

connection or disconnection and/or exposure to

electrical components, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all circuits.

Failure to comply with this procedure can cause

property damage, injury or death.

Electrically heated machines are available in 208, 240,

or 440-480 volts, single- or three-phase only. They are

prewired at the factory and only one common connection

is required. Use L1 and L2 for single-phase units and L1,

L2 and L3 for three-phase units.

Additional instructions are located inside the control

box. Make sure the wire size is adequate to carry the

amperage load.

The temperature is controlled by the thermostat located

in the control box.

Thermostat –

Turn screw clockwise to

increase temperature;

Turn counterclockwise to

decrease temperature

Incoming

power

connection

Gas Heater

Before making a gas connection, verify the gas type. A tag

is attached to the gas valve that will indicate the correct

gas type (L.P. or Natural) to be supplied to the unit.

Note: If the tag is missing, the gas type can be determined

by inspecting the gas valve. A Natural gas valve will

have a pressure regulator where a L.P. gas valve will

not.

WARNING

Instructions to be followed in the event the operator

smells gas or otherwise detects a gas leak must be

posted in a prominent location. This information

can be obtained from the local gas company or gas

supplier.

WARNING

All connections must be sealed with a joint compound

suitable for the gas being used and all connections

must be tested with a solution of soapy water before

lighting any pilots.

Never use matches, candles, or any other ignition

source to check for leaks. If gas odors are detected,

shut o the gas supply to the appliance at the main

shuto valve and immediately contact the local gas

company or an authorized service agency for service.

Thermostat & Power Connection Locations

The natural gas valve has a pressure regulator

for minor adjustments to the gas pressure. L.P.

gas pressure must be adjusted by the customer’s

regulator.

— 9 —

Page 10

Rough-in Diagrams – Model D-8

STRAIGHT-THROUGH INSTALLATION

WALL

6-1/2"

165mm

7-1/8" min.**

180mm

30-1/2"

Model D-8

15-1/4"

Tank

inside

23-1/2"

595mm

Hood

outside

Tank

inside

25-3/16" 640mm

26" 660mm

30-1/2" 775mm

CORNER INSTALLATION

RIGHT SIDE OF UNIT ALWAYS FACES WALL

WALL

Between

tracks

20"

510mm

3"

75mm

Splash guard recommended

3" min. 75mm

Tank

inside

Tank

side

to rear

track

23-3/4"

600mm

26"

660mm

58"

“Blakeslee”

Electric

Booster

25-3/4"

655mm

4" min.**

100mm

TOP VIEW OF DISHWASHER

A

A

2

10

13-3/16"

335mm

WALL

5

1 3

9

17"

430mm

FITTING POINTED DOWN

DIRECTION OF FITTING

4

8

16"

410mm

Front of

machine

6

7

WALL

BB

ELECTRIC

BOOSTER

(OPTIONAL)

2-1/2"

65mm

4-3/8" 110mm

26-3/16"

665mm

tank outside

2-1/2"

65mm

6"

150

mm

Drain

Handle

17"

430mm

vert.

work

clear.

33-5/8"

855mm

76"

1930mm

min.

clear.

to

raise

hood

34-1/4"

± 3/4"

870mm

± 20mm

height

of

table

— 10 —

Page 11

Rough-in Diagrams – Model DD-8

6-1/2"

165mm

WALL

7-1/8" min.**

180mm

Tank

inside

23-1/2"

595mm

Hood

outside

Tank

inside

25-3/4"

655mm

2-1/2"

65mm

4-3/8" 110mm

25-3/16" 640mm

52-1/4" 1327mm

6"

150

mm

2-1/2"

65mm

430mm

56" 1422mm

Model DD-8

33-5/8"

855mm

1930mm

17"

vert.

work

clear.

25-3/16" 640mm

76"

min.

clear.

to

raise

hood

Between

tracks

20"

510mm

3"

75mm

Pilot Lighting

To light the pilot burner:

1. Press the control knob and rotate it clockwise to the

OFF position. Allow ve (5) minutes to pass to allow

any unburned gas to dissipate.

WARNING

L.P. Gas is heavier than air and does not dissipate

easily. Venting the area with a fan or equivalent

is recommended before attempting to relight the

pilot burner.

2. Rotate the control knob to the PILOT position, press

the knob fully and light the pilot burner.

26-3/16"

665mm

tank outside

Drain

Handle

34-1/4"

± 3/4"

870mm

± 20mm

height

of

table

3. Continue to hold the control knob down for about

one minute to allow the pilot sensor enough time to

heat up and sense the ame.

4. Release the knob and the pilot should remain lit.

5. Rotate the knob to the ON position, set the thermostat

located in the control box to the desired wash tank

temperature (150° - 160° F).

The main burner should ignite when the thermostat calls

for heat.

CAUTION

Do not turn on gas heat until the wash tank is lled

with water.

Note: The main burner is equipped with a non adjustable

orice (0.052 for L.P. gas and 0.078 for Natural gas).

— 11 —

Page 12

Pilot Flame Adjustment

Steam Injected Heaters

The pilot ame should engulf the tip of the pilot sensing

thermocouple.

Correct ame adjustment

3/8" to 1/2"

Thermocouple

Correct Pilot Flame

To adjust the pilot ame:

1. Remove the pilot adjustment cover screw.

Lite-Rite Gas Cock

manual knob

Wrench

Boss

Gas

Inlet

Pressure Regulator

Adjustment

(beneath screw)

NATURAL GAS

V5306

Pressure

Regulator

”A” Model

LP GAS

V5307

”C” Model

with step

opening

Incoming steam supply line must be connected to the

steam connection (line strainer) labeled “incoming

steam”. Blakeslee recommends installing a steam shutoff

valve and steam regulator (not supplied) close to the

dishwasher to aid in servicing. The wash tank water

temperature is controlled by the thermostat located

inside the control box.

Steam Coil Heater

Incoming steam supply line must be connected to the

steam connection (line strainer) labeled “Steam Supply”.

Blakeslee recommends installing a steam shutoff

valve and steam regulator (not supplied) close to the

dishwasher to aid in servicing. The wash tank water

temperature is controlled by the thermostat located

inside the control box.

Connect the condensate return line or drain (depending

on local codes) to the steam trap.

CAUTION

The condensate return line must run parallel or

on a downward slope from the dishwasher. If the

condensate must be run vertically, a condensate

pump system (not supplied) must be installed.

Pilotstat

Power Unit

Pilot Flow Adjusting Screw

(beneath Cover Screw)

Pilot Gas Outlet

(pressure tapping

directly beneath)

Gas Control Valve

2. Turn the inner adjustment screw clockwise to decrease

or counter-clockwise to increase the pilot ame.

3. Replace the cover screw when nished to prevent

possible gas leakage.

Gas Vents

Gas heated machines are supplied with ues. These ues

do not need to be connected to any external vents. The

ue temperature is controlled by the thermostat located

inside the control box.

Electrical Detergent and Rinse Additive

Injector Connections

WARNING

Before performing any service that involves electrical

connection or disconnection and/or exposure to

electrical components, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all circuits.

Failure to comply with this procedure can cause

property damage, injury or death.

Note: The dishwasher will supply a switch signal only. A

relay must be installed. The switched signal is used

to energize the relay coil. The Normally Open (NO)

contacts on the relay can be powered by L1 and

ground. Normally this would be a neutral if available.

— 12 —

Page 13

DISPENSER

TRANSFORMER

K1

N.O.

FUSE

L1

Ground

K1

5*

2

The designated wire connections for the dispensers are

found in the control box. #2 is common; the switched side

connection is determined by the serial number sux.

Connections for machines manufactured after September

2005 with a sux ABB and up:

Detergent – 8 & 2

Rinse – 6 & 2

Detergent

L1 L2 2 6 8

Rinse

— 13 —

Page 14

OPERATION

Preparing the Dishwasher for Use

1. Close the drain by turning the drain valve handle

clockwise as far as it will go.

Drain Valve Handle

Drain line

to sewer

2. Make sure standpipe guide is in position.

Standpipe

4. Make sure all wash and rinse arms are in position and

spin freely. Tighten the lower spindle (turn clockwise)

and upper wash rotor nut by hand.

5. Scatter initial charge of detergent into scrap screens.

Replenish as needed. This may not be necessary on

dishwashers that have an external chemical dispenser.

6. Close the counterbalanced three-way hood.

7. Place the power switch in ON (up) position. The tank

will begin to ll and the tank heat will initiate when

the water reaches the appropriate level.

8. When the wash tank thermometer reads between 150°F

and 160°F, the dishwasher is ready for use. If after a short

period of time this temperature is not attained, adjust

the thermostat located in the control box.

WARNING

Before performing any service that involves electrical

connection or disconnection and/or exposure to

electrical components, always perform the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all circuits.

Failure to comply with this procedure can cause

property damage, injury or death.

Standpipe

Guide

Standpipe

Screen

3. Install scrap screens into position.

Scrap

Screens

Note: Adjusting the thermostat is a user function and is

not covered under the warranty.

Automatic Tank Fill (Standard)

The dishwasher is equipped with an automatic tank ll

system that utilizes a liquid level control. The unit will ll

automatically when the power switch is placed in the ON

(up) position. The tank takes approximately 3 minutes to

ll completely.

Note: The liquid level control will automatically maintain

the water level in the wash tank to within 3 inches

of the top of the standpipe when the unit is ON.

When the dishwasher is cycled, the nal rinse will

bring the water level up to the top of the standpipe.

Wash Cycle Selector (Optional)

This feature allows the user to choose between wash cycle

times. Choices are 1, 2, 4 and 6 minutes. The rinse cycle

is a set time of 12 seconds and cannot be changed. On

double units, each side will operate on the same cycle time.

— 14 —

Page 15

Automatic Start (Optional)

When the dishwasher is equipped with this feature, a cycle

is initiated automatically when the door closes.

Manual Start (Standard)

To start a cycle on a unit equipped with the manual start

feature, the operator must close the door and press the

start button to initiate a cycle.

Tank Selection

(Optional on DD-8 only)

On two tank units, this feature allows the operator to

choose either the left, right of both tanks to operate

during each cycle. A choice of one of the single tanks can

be cycled during non-rush periods. It also wil allow the

use of one side if the other side is disabled.

POWER CYCLE FUSE

1.6 AMP

TANK SELECTION

RIGHT

LEFT

ON

ON

OFF

OFF

• Stackableware,suchasdishesandtrays,shouldhave

food debris removed and be placed in manageable

stacks. A “buildup” area should be designated for

these stacks until dish racks are lled.

• Itemssuchascoeecups,glassesandbowls,donot

stack well and should be placed directly into racks

for transport.

• Whenracksarelled,theyshouldbekeptinthe

buildup area until they can be washed.

• Goodorganizationiskeytospeedandeciencyin

dish room operation, as well as reduced breakage.

• Silverwareshouldbepresoakedinasinkorother

container to keep food particles from drying out.

Silverware should then be placed in an appropriate

rack and sent through the dishwasher.

Tank Selection Switches

Soiled Dishtable Operation

To increase speed and eciency and reduce breakage,

a few simple rules need to be observed:

• Allfoodmustberemovedfromdishwarebefore

placing them in stacks. This will maintain cleaner

wash water and reduce detergent usage.

Note: When placing silverware in at racks, it is important

not to overload. The silverware should be spread

out evenly in the rack so the surfaces are exposed

and can be cleaned by the spray of the dishwasher.

Note: As much as possible, keep soil from entering the

dishwasher. This will help maintain cleaner wash

water and reduce detergent usage.

Loading the Dishwasher

As much as possible, wash similar dishes at the same time.

This reduces sorting once the dishes have been cleaned.

When several racks in the buildup area have been lled,

run them through the dishwasher one after the other.

This will allow the loading operator to return to scrapping

and stacking.

For optimum results from a DD-8, two-tank dishwasher,

consider using one side exclusively for glasses and

silverware and the other side for more soiled ware, such

as plates and bowls.

— 15 —

Page 16

Operating the Dishwasher

Once the wash tank has been lled and the detergent

added (for units with optional Wash Cycle Timer, set the

wash cycle time to 1, 2, 4 or 6 minutes), raise the hood

and slide the rack (or racks for DD-8) into the dishwasher.

Lower the hood. The dishwasher has a safety switch that will

prevent the machine from operating if the hood is open.

For units with standard timer, when the hood is opened,

the cycle will stop. The cycle will resume at the stopping

point when the hood is closed.

For units with the automatic start feature, if the hood is

opened during a cycle, another complete cycle will be

initiated when the hood is closed. This provides a complete

cycle to assure proper cleaning and rinsing.

Door Interlock

Switch

Door Interlock Safety Switch

Door closed

Door open

WARNING

To avoid being splashed, allow at least 5 seconds

before opening the hood after the cycle is completed.

Shutdown and Cleaning

An important part of maintaining the dishwasher is

keeping it clean. A thorough cleaning before shutting the

unit down will help keep it working at peak performance.

Shutdown

1. Place the main power switch in the OFF (down)

position.

2. Drain the wash tank(s) by turning the drain valve

handle(s) counter-clockwise until it stops.

Cleaning

1. With the hood fully open, and the scrap screen still

in place, wash down and thoroughly rinse the dish

tables.

For machines with the optional automatic start feature,

the cycle will start when the hood is closed. For machines

with manual start, close the hood and momentarily press

the Start button to initiate a cycle. The cycle light will

illuminate and remain on during the cycle. When the cycle

iscomplete,thelightwillturnoandthehood can be

opened and the dish racks removed.

Cycle Light

POWER CYCLE FUSE

1.6 AMP

TANK SELECTION

RIGHT

LEFT

ON

ON

OFF

OFF

Cycle Light Location

2. Remove the scrap screens and empty them. Take them

to a sink and clean them using a suitable brush. Make

sure all debris is removed. Rinse thoroughly and place

them on a dish table

Note: Do not hit the sides of the scrap screens on a trash

container. Damage to the anges will not allow

them to seat properly in the dishwasher, permitting

food debris to pass into the wash tank.

3. Inspect the rotating wash arms for blockage of any

opening and free rotation. Remove and clean as

needed. (See MAINTENANCE section of this manual.)

4. Lift the retainer on the standpipe guide. Remove

standpipe and screen and clean thoroughly with an

appropriate brush.

— 16 —

Page 17

Standpipe

Standpipe

Guide

Standpipe

Screen

Standpipe Guide

5. Thoroughly wash and rinse the interior of the

dishwasher. Pay special attention to the hood guides

and remove any residue.

6. Leave the hood open to allow the interior to dry.

7. If your dishwasher is equipped with an external

chemical dispenser, wipe it clean and rell. Follow

the instructions from your chemical supplier.

8. Reinstall the standpipe and screen; ip standpipe

retainer back in place.

— 17 —

Page 18

MAINTENANCE

Motor

No lubrication required.

Pump

No lubrication required.

Doors/Hood

No lubrication required.

Line Strainers

Water inlet (and steam line, if supplied) line strainers

protect solenoids and pressure reducing valves from

sediment in the water (or steam) supply. The line strainer

must be cleaned on a regular basis.

Line Strainer

Wash Arms

Upper and lower wash arms must turn freely and continue

to turn for a few seconds when spun by hand.

Wash arm openings may become clogged by food debris

if scrap screens are not in place. The wash arms are easily

removed for cleaning.

Rinse

Arm

Spindle

Bearing Pin

Wash

Arm

Spindle

Wash Arm

Line Strainer

Tocleanalinestrainer,turnowaterorsteamsupplyand

perform a lockout-tagout procedure. Unscrew the plug

and clean the screen thoroughly. Reinsert the screen into

the strainer body and tighten the plug.

To remove the lower wash arm, rst remove the rinse arm

and unscrew the spindle bearing pin. The wash arm can

thenbeliftedothespindle.

To remove the upper wash arm, unscrew the rotor nut

and remove the wash arm.

Final Rinse Arms and Nozzles

The rinse nozzles will need frequent cleaning if the water

supply is considered “hard” and contains dissolved solids

such as calcium and magnesium.

Obstructions in the lower rinse arm nozzles can be cleared

using an opened paper clip or similar object. Push the

obstruction into the rinse arm, then remove the end caps

and ush out the tube.

Thelowerrinsearmcanbeliftedstraightothebearing

pin and thrust washer assembly.

The upper rinse nozzles can be cleared by using an opened

paper clip or similar object. Push the obstruction into the

rinse arm. Remove the rinse nozzle closest to the end and

ush out the line. Reinstall the rinse nozzle when nished.

— 18 —

Page 19

Pump Motor Overload Protection

Water Treatment

Wash pump motor protection is provided by thermal

overload relay(s) located in the control box. In the event

the pump becomes jammed, the motor will draw a higher

current and trip the overload relay. Once any jam has been

cleared and the impeller turns freely, the overload must

be manually reset before the motor will operate.

Thermal Overload Relay

Thermal Overload Relay Location

CAUTION

Any open (blown) fuse must be replaced with the

same size and type fuse. Increasing the size or

rating of the replacement fuse will eliminate the

circuit protection and void the warranty. The control

panel uses a 1.6 amp – slow blow fuse. Blakeslee

recommends that spare fuses of the correct rating and

type be kept on hand. These fuses can be obtained

from the Blakeslee parts distributor or authorized

service agency.

The quality of the water supplied to the dishwasher will

greatlyaectthemaintenancerequirements,detergent

usage and end results.

Water quality is typically referred to as water hardness.

The higher the mineral content, the harder the water.

Some water supplies are only slightly hard, while others

are considered very hard. Water hardness is measured in

grains per gallon (gpg).

Water Quality Categories

1–3 gpg – slightly hard

3–7 gpg – moderately hard

7–10 gpg – hard

10+ gpg – very hard

Left untreated, hard water will leave behind deposits,

called scale, that can build up on machine surfaces. Hard

water requires the use of more detergent to achieve the

same cleaning results and may leave visible spots on

glasses and atware.

Water that is only slightly hard may not need treatment

to achieve good results; however, if moderately hard to

very hard water is being supplied to the unit, a water

treatment system is recommended.

There are various water treatment systems available. Speak

to a water treatment specialist or chemical supplier for

water treatment options.

— 19 —

Water Treatment System Maintenance

Depending on the type of water treatment system, regular

maintenance may be required.

Water hardness may dictate the type and frequency of

maintenance. Make sure to follow the manufacturer’s or

water treatment specialist’s recommendations.

Equipment failures caused by water quality issues (scale

or lime buildup, for example) are not covered under the

manufacturer’s warranty.

Page 20

TROUBLESHOOTING

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

Pump motor will not start Overload tripped

Unit not turned ON Place power switch in ON position.

Machine will not start

No Tank Heat

Wash tank foaming

Poor wash results

Unit not plugged in

Power not being supplied to unit Check building circuit breaker or fuses.

No power to unit

Main gas valve, steam supply valve or

circuitbreakerturnedo

Thermostat set too low

Steam supply pressure too low

Thermostat defective

Faulty gas valve

Faulty contactor

Faulty steam solenoid

Faulty steam trap

Dirty wash water Drain wash tank and rell.

Too much food debris in wash water Improve pre-scrapping.

Incorrect detergent Use only approved detergents.

Too much food debris in wash water Improve pre-scrapping.

Scrap screens clogged Unclog screens.

Dirty wash water Drain wash tank and rell.

Wash tank temperature too low

No detergent

Pump impeller clogged

Pump running backwards

Wash arms clogged or not turning. Clean and free wash arms.

Improper racking Improve racking technique.

Clear pump impeller.

Reset relay.

Plug unit in to an appropriate power

receptacle.

Place power switch in ON position.

If power indicator lamp lights, unit is

receiving power.

Check each and return to on position.

Open control box and turn thermostat

knob clockwise until heat comes on.

Contact your authorized service

provider.

Contact your authorized service

provider.

Contact your authorized service

provider.

Contact your authorized service

provider.

Contact your authorized service

provider.

Contact your authorized service

provider

Open control box.

Turn thermostat knob clockwise and set

temperature between 150° - 160°F.

Rell detergent dispenser.

Add detergent manually.

Turnopower.

Drain wash tank.

Clear impeller.

Check pump rotation.

If incorrect, contact your authorized

service provider.

— 20 —

Page 21

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

Poor rinse results

Wash tank not holding water

Wash tank will not drain

Rinse nozzles clogged Clear rinse nozzles.

Line strainer clogged

Clogged solenoid valve

Faulty solenoid

Final rinse booster turned OFF Turn booster ON.

Power supply to booster OFF Restore power to booster.

Booster thermostat set too low

Water supply temperature too low

Water supply pressure to booster too

low. Must be 15-25 psi ow pressure.

Water supply line too small.

Water quality causing spotting.

Drain not fully closed

Drain seat dirty

Worn or damaged drain plug Replace drain plug.

Clogged drain screen Empty wash tank. Clean screen.

Drain line clogged or too small

Mineral deposits on seat

Turnowatersupply.

Clean line strainer screen.

Contact your authorized service

provider.

Contact your authorized service

provider.

Increase temperature setting on

booster.

Water supply temperature must be

140° F min.

Contact your authorized service

provider.

Contact your authorized service

provider.

Contact your detergent supplier for

remedies.

Turn drain valve handle clockwise until

it stops.

Turnounit.

Drain tank.

Remove and clean standpipe drain plug

and seat.

Contact your authorized service

provider.

Contact your authorized service

provider.

— 21 —

Page 22

SCHEMATIC

OL

T 2

HTR

T 1

T 3

HTR

T 1

SW-1 TAS-2 FU

7

7

7

7

4

4

4

7

DS

4

13

4

(3 PHASE)

53

MCA

MCA

T3

(1 PHASE)

3

CR1

13

9

LWC

TAS-1

7

1516 1

7

PB-1

PB-2

5

TR-1

COM

5

54

TR-2

COM

L3

6

1

2 3

11

7

TM

12

6

13

7 4

23

CR1

TR

HC

HCOL

5

NC

NO

NC

NO

L 3

L 2T 2

L 1

8

5

MC

10 8

13

14

2LT

EQUIPMENT

GROUND

G L

L 2

L 2

L 1

L 1

CT

EQUIPMENT

GROUND

G L

L 3

L 2

L 1

CT

2

7

2

1LT

A2 A1

NC

14 96 95

SOL

BA

CR1

HC

S SOL

GC

208 / 240 VAC

1 PHASE 60 HZ

SUPPLY LINES

208 / 240 / 480 VAC

3 PHASE 60 HZ

SUPPLY LINES

2

CYCLE LIGHT

(AMBER)

2

TIMER MOTOR

2

WASH PUMP

2

RINSE SOLENOID

2

AUTO FILL

2

TANK HEAT

2

POWER ON LIGHT

(RED)

BOOSTER

CONTROL

HTR

OL

T 1

TRANSFORMER

DISPENSER POWER & CONTROL CONNECTIONS

208 - 240 VAC 3KV

ELECTRIC TANK HEATER

H C

DISPENSER

NO

(PARTS & WIRING BY OTHERS)

H2

L2

HTR

H1

L1

BLACK

L1

WHITE

K1

RINSE CONTROL

EQUIPMENT

GROUND

G L

L 1

FUSE

L1

L2

K1

8

2

6

2

HTR

H1

H2

440 - 480 VAC 3KV

ELECTRIC TANK HEATER

120 VAC

1 PHASE 60 HZ

SUPPLY LINES

L2

L1

— 22 —

Page 23

SYM. DESCRIPTION

TB Terminal Block

GL Ground Lug

MC 25A Motor Contactor

OL Overload Relay

MTR 1.5 HP Motor 208-240/480V, 3 PH, 60Hz

1.5 HP Motor 115/230V, 1 PH, 60Hz

CT .150 KVA Transformer

MC-A Auxiliary Contact Block (3-phase only)

FH Fuse Holder

FU 1.6A Fuse

SW-2 Toggle Switch

DS Door Switch

PB Pushbutton (Start)

TR Timer (60-Sec.)

1LT Cycle Light (Amber)

2LT Power Light (Red)

TAS-1 Thermostat

SOL Solenoid Valve

HC Contactor (Elec. Tank Heat)

HTR 3KV Immersion Heater

GC Gas Control (LP or Nat.)

SSOL Solenoid Valve (Steam)

LWC LowWaterCuto

TAS-2 Thermostat (High Limit)

TM Auto Fill Timer (3-Min.)

CR1 Relay

1. All wires are identied with wire markers.

2. Line, motor circuit and immersion heater wires are

#12 AWG Black, type MTW, 105 C, 600 V.

3. Control circuit wires are 16 AWG Red, type MTW,

105 C, 600 V.

4, TR-1 is a cam switch located next to the Timer

Motor TR.

5. Numbers in the square boxes

Control circuit connection points.

are Booster

— 23 —

Page 24

WIRING DIAGRAM

MCOL

T 3

HTR

T 1

T 3

HTR

T 1

L 3

L 2T 2

L1

EQUIPMENT

GROUND

MCOL

L 3

L 2T 2

G L

L 3

L 2

208 / 240 / 480 VAC

3 PHASE 60 HZ

SUPPLY LINES

L1

L 1

TB

CT

TAS-2

TAS-2 FUSE

18

17 1 2

4

L3

53 54

L3 T3

AUTO

4

(3 PHASE)

MC-1-A

MC-1

(1 PHASE)

(3 PHASE)

MC-2-A

MC-2

(1 PHASE)

FILL

4

P B-2

7

P B–1

P B–1–1

5

CR–1

5453

5

T3

TR–2

TR–2

12

13

TR–1

COM

6

5

14

TR

NC

NO

5

NC

NO

4

7

2

TO LINE OR L1 SIDE OF

HEATER CONTACTOR

IN BOOSTER

CR

1

8

1 LT

5

MC

10 21 9

13

MC

SW-3-2

SW-4-2

S W–3–1 (TANK #2)

S W–4–1 (TANK #1)

A1

MC

14

A1 A2

MC

1412

SOL #1

SOL #2

TM

A2

9

95 96

2

2

OL

2

OL

2

2

2

2

BOOSTER

CONTROL

THERMAL CYCLE

EXTENSION

CYCLE LIGHT

(AMBER)

TIMER MOTOR

WASH PUMP – TANK #1

WASH PUMP – TANK #2

RINSE-FILL

SOLENOID – TANK #1

RINSE-FILL

SOLENOID – TANK #2

19

ON

S W-2

7

FILL

DOOR SW

3

ON

S W-2

7

4

OFF

FILL

4

6

6 6

#1

WASH TANK

HEATER

H1

H2

#2

WASH TANK

HEATER

H3

H4

208 - 240 VAC SINGLE-PHASE

IMMERSION HEATER WIRING

#1

WASH TANK

HEATER

H1

H2

#2

WASH TANK

HEATER

H3

H4

208 - 240 VAC 3-PHASE

IMMERSION HEATER WIRING

TRANSFORMER

HC1

1L1

L1

1L2

L2

HC2

HC1

1L1

L1

1L2

1L3

L2

L3

K-1

NO

440 - 480 VAC 3KV

ELECTRIC TANK HEATER

FUSE

K

L1

L2

5

HC2

DISPENSER

2

RINSE CONTROL

DISPENSER POWER & CONTROL CONNECTIONS

(PARTS & WIRING BY OTHERS)

6

2

HTR

HC

H1

H2

L2

L1

HTR

HC

H1

H2

L2

L1

T A S

T A S

7

L W C

13 147

LWC

15 167

HC

S SOL

GC

HC

S SOL

GC

2LT

2

TANK HEAT – TANK #1

2

TANK HEAT – TANK #2

2

POWER ON LIGHT

(RED)

— 24 —

Page 25

SYM. DESCRIPTION

TB Terminal Block

GL Ground Lug

MC 25A Motor Contactor

OL Overload Relay

MTR 1.5 HP Motor 208-240/480V, 3 PH, 60Hz

1.5 HP Motor 115/230V, 1 PH, 60Hz

CT .150 KVA Transformer

MC-A Auxiliary Contact Block (3-phase only)

FH Fuse Holder

FU 1.6A Fuse

SW-2 ToggleSwitch(On-O-Momentary)

DS Door Switch

PB Pushbutton (Start)

TR Timer, 60-Sec. (3 cams)

1LT Cycle Light (Amber)

2LT Power Light (Red)

TAS-1 Thermostat

SOL Solenoid Valve

HC Contactor (Elec. Tank Heat)

HTR 3KV Immersion Heater

GC Gas Control (LP or Nat.)

SSOL Solenoid Valve (Steam)

LWC LowWaterCuto

TAS-2 Thermostat (High Limit)

TM Auto Fill Timer, 3-Min.

SW3&4 ToggleSwitch(On-O)

CR1 Relay

1. All wires are identied with wire markers.

2. Line, motor circuit and immersion heater wires are

#12 AWG Black, type MTW, 105 C, 600 V.

3. Control circuit wires are 16 AWG Red, type MTW,

105 C, 600 V.

4, TR-1 is a cam switch located next to the Timer

Motor TR.

5. Numbers in the square boxes

Control circuit connection points.

6.

indicates optional feature.

are Booster

— 25 —

Page 26

USA

Date of Installation ________________________________

Serial No. Model No.

_____________________ _____________________

Limited Warranty

Your new Blakeslee dishwashing machine is warranted for one year from date of installation shown above

against defective materials and workmanship. If any defects are found within the warranty period, parts, and

labor involved with their replacement will be covered free of charge. Service must be performed by a Blakeslee

authorized service agency. All labor to be performed during regular working hours. Overtime premium will be

charged to the customer. All warranty parts are shipped by surface transportation. If other means of transportation is requested the customer is required to pay the premium. This warranty does not apply to damages

resulting from errors in installation on the part of other contractors, nor does it apply to machines which have

been subject to accident, misuse, or abuse. It is understood that Blakeslee’s warranty obligation with respect

to machines located outside of the United States and Canada or located in the state of Alaska is limited to

the furnishing of replacement parts only. In the state of Hawaii, repair labor is provided free of charge; travel

time and expenses paid by the customer. On the island of Oahu, repair labor, travel time and expenses are

provided free of charge. This is the entire and only warranty of Blakeslee. We neither assume nor authorize

anyone else to assume for us any other obligation or liability in connection with Blakeslee Machines.

In no case can this warranty exceed eighteen (18) months from the date of shipment from our plant at Addison, Illinois.

Items NOT Covered Under Warranty:

1. Lighting of Gas Pilots

At the time of installation the gas pilots and burners should

be adjusted. Continued failures of pilot lights would

indicate dirty gas lines, improper original adjustment or

intermittent drafts blowing out the ume.

2. Replacing Fuses or resetting Overloads

Replacing a blown fuse or resetting an open overload

breaker is a very simple procedure and is the owner’s

responsibility. If the machine continues to blow fuses

or open the overload breaker, contact your nearest

authorized Blakeslee Service Center.

3. Adjusting Tank Heats

Heat adjustments are covered in the INSTALLATION &

OPERATION manual and must be adjusted depending

upon desired results.

4. Proper Loading of Dishes

It is important that the machine owner’s personnel

observe the instructions outlined in the INSTALLATION

& OPERATION manual.

5. Cleaning Drain Valves

Foreign articles lodged in the drain valve seat should be

removed as a part of the normal daily cleaning.

6. Cleaning Rinse or Wash Nozzles and Line Strainers

Keeping a dishwasher clean and removing obstructions

from the nozzles and line strainers will be a periodic

function of the machine owner’s personnel. The cleaning

periods will vary depending upon impurities in the water

supply and cleanliness of the washing operation.

7. Final Rinse Water

Most frequent of all complaints in any dishwashing

machine is that of poor nal rinse. It is the responsibility

of the owner to provide 180to 195 degree (plus) water at

15-25 lb. ow pressure through clean unobstructed water

lines. If the machine has a factory equipped nal rinse

water booster, the owner must supply the booster with

a minimum of 140 degree temperature water.

8. Electric Boosters and Garbage Disposals

Although these units may have been purchased with

the machine, they are warranted by the individual

manufacturer. Consult the nearest factory authorized

representatives for these particular items.

— 26 —

Page 27

Notes

— 27 —

Page 28

1228 Capitol Drive

Addison, IL 60101

Phone: 630-532-5021

Fax: 630-532-5020

www.blakesleeinc.com

service@blakesleeinc.com

Loading...

Loading...