Page 1

G. S. BLAKESLEE

&

CO.

G. S. BLAKESLEE

&

CO.

TYPE "D" DRIVE

FIELD CONVERSION INSTRUCTIONS

W-O-95575

G. S. BLAKESLEE & CO.

1844 So. Laramie Avenue

Cicero, Illinois 60650

Scarborough, Ontario M1R3C3

of CANADA LTD.

66 Crockford Blvd.

Page 2

REMOVING EXISTING DRIVE 2

INSTALLING NEW DRIVE UNIT 2

ADJUSTMENTS 5

FINAL ASSEMBLY 6

PARTS LIST 7

REMOVING EXISTING DRIVE

CAUTION

MAKE SURE ELECTRICAL POWER IS TURNED OFF.

1. Disconnect electrical wiring to drive unit.

2. Refer to page 2-4 of Service Manual for Modular

Dishwashers, for instructions on removing existing drive

unit.

3. Remove bolts and nuts securing drive to table and lower

drive unit to floor. Remove existing drive unit.

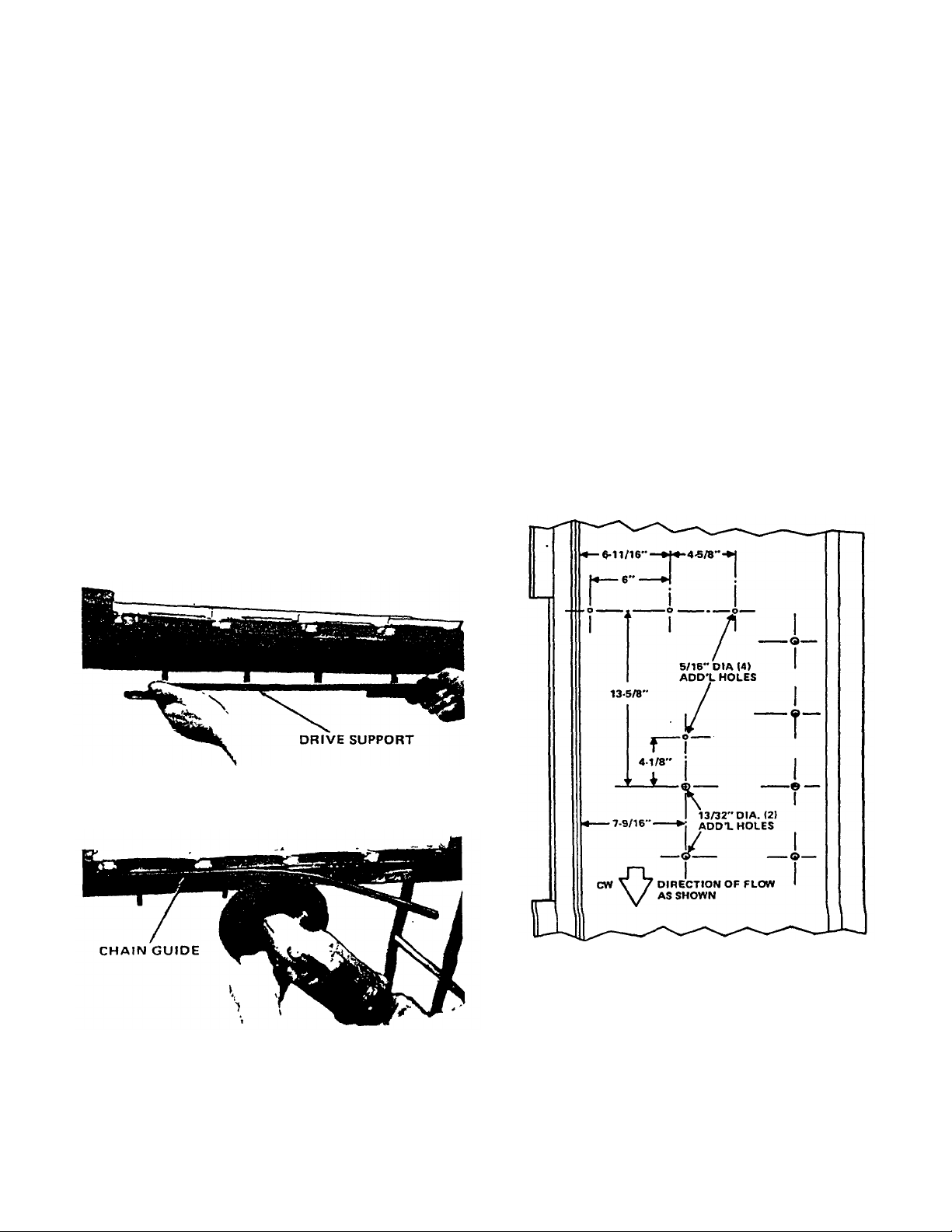

4. Remove both front and back drive supports (W-2-14148).

(See fig 1.)

INDEX

5. Using a grinder with a cutting disc remove the existing

chain guide (3/16" x 1/2" strip) welded outside the

tables. (See fig 2.)

INSTALLING NEW DRIVE UNIT

1. Determine if machine has clockwise or counter-clockwise

conveyor. Follow directions in fig 3 for drilling holes in

clockwise conveyor, fig 3A for counterclockwise conveyor.

Figure 1. Removing Drive Supports

Figure 2. Removing Chain Guide Welded to Table

2

Figure 3. Drilling Locations for Clockwise Conveyor

Page 3

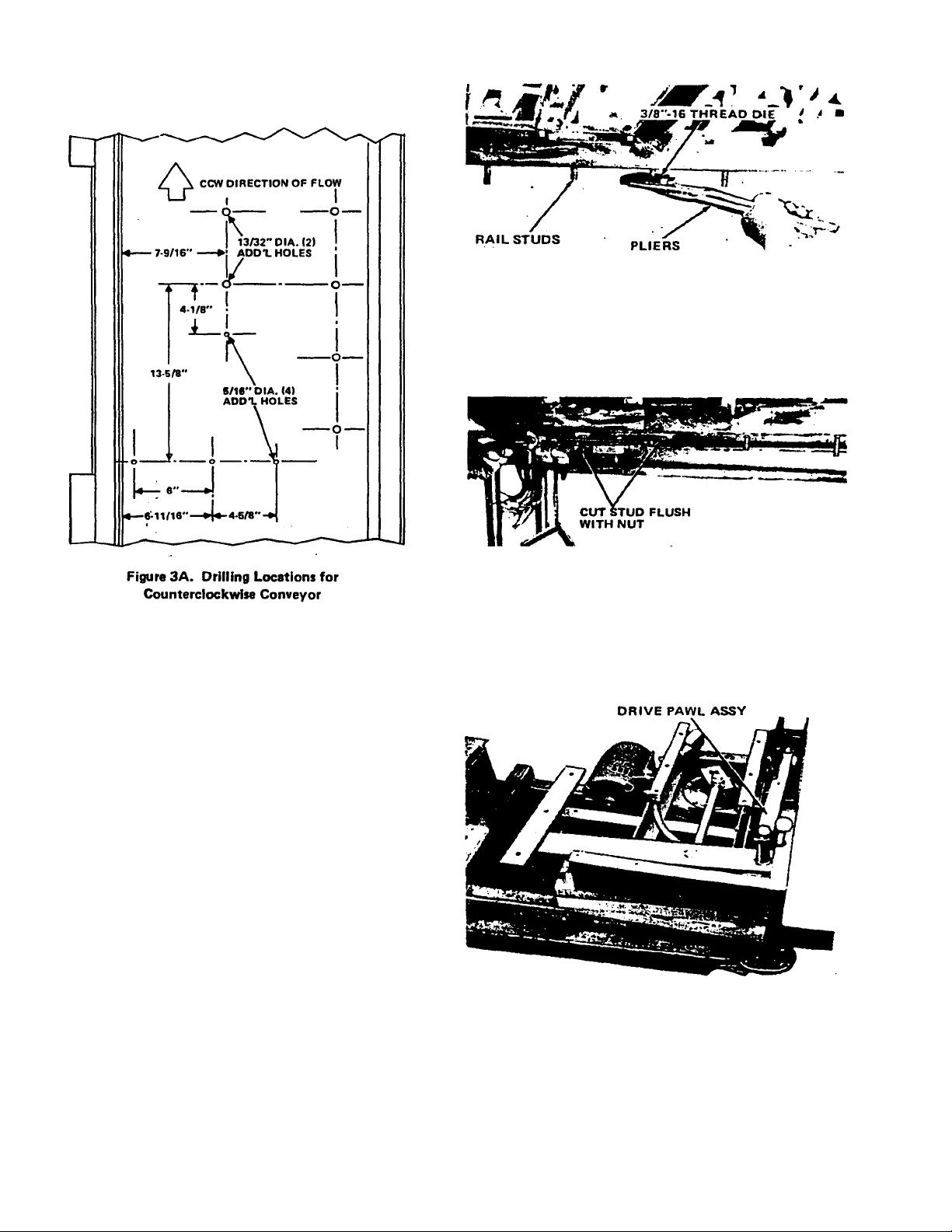

Figure 4. Threading Rail Studs

3. Cut off the excess amount of each stud flush with the

nut. (See fig 8.) This must be done to provide clearance

for drive arm assembly (Item 80 on attached exploded

view).

2. Run additional threads on all four of the existing rail

studs AS CLOSE as possible to the bottom of the

table. Use the 3/8"-16 thread die (W-0-95576) provided

in the kit. A large adjustable pliers or pipe wrench can

be used to run the thread die up the studs. (See fig 4.)

(A) CLOCKWISE MACHINE

Pack a large amount of silicons sealant around

the 2 studs on the left. Place a split lockwasher

and nut on each stud and securely tighten.

(B) COUNTERCLOCKWISE MACHINE

Pack a large amount of silicone sealant around

the 2 studs on the right. Place a split

lockwasher and nut on each stud and securely

tighten.

Figure 5. Cutting Off Studs on Clockwise Conveyor

4. Remove front and rear covers of type "D " drive and

place on lifting device. (See fig 6.)

5. Remove drive pawl assembly (Item 83 on attached

exploded view). (See fig 6.)

Figure 6. Drive Assy Mounted on Lifting Device

3

Page 4

Figure

8.

Fastening Dri

ve to Table

Figure

10.

Checking Drive Arm to Slide Clearance

6. Lift new drive part way into place. (See fig 7.)

7. Reconnect safety limit switch (Item 10 of attached

exploded view). Connect to COMMON and N.O.

terminals. If flexible conduit is not long enough. you may

need a new section of 3/8" flexible waterproof conduit.

CAUTION

9. Attach drive arm pivot weldment (Item 7 of attached

exploded view) to front of table. Be sure Item 46 of

attached exploded view is placed under Item 7 before

attaching lockwashers and nuts. Apply liberal amount of

silicone sealant around top of hole before inserting bolts.

10. Plug unused hole with 3/8" x 16 truss head bolt. Apply

silicone sealant around hole before inserting.

BE SURE FLEXIBLE CONDUIT IS RETAINED BY BOTH

CLAMPS (ITEM 19 ON EXPLODED VIEW). THIS HOLDS

CONDUIT AWAY FROM GEAR REDUCER CRANK.

Figure 7. Lifting New Drive Into Place

8. Lift drive up to the table and fasten, using 3/8"-16 and

1/4"-20 S/S truss head screws as shown. Always apply a

liberal amount of silicone sealant around the hole before

inserting the truss head bolt. (See fig 8.)

11. Reinstall drive pawl assembly. (See fig 9.)

Figure 9. Reinstalling Drive Pawl Assy

12. Check for clearance between drive arm assembly (Item 80

of exploded view) and drive arm slide (Item 53 of exploded

view). You should be able to pass a business card (0.020

shim) between the arm and slide. (See fig 10.) To adjust,

place a shim on one side or the other of the drive arm pivot

weldment. (See fig 11.) Placing a shim as shown in fig. 11

will increase the clearance. Placing a shim on the other side

will decrease the clear-ance (hack saw blade(s) work very

well as shims).

4

Page 5

13. Make motor connections. Change motor overloads to

Figure

11.

Adjusting Drive Arm to Slide Clearanc

e

Figure

14.

Location of Overload Compression Springs

accomodate heavier 1/2 H.P. motor of type "D" drive.

The kit contains overloads for both old and new style

control boxes and for both 208-230V and 460-480V, 3

Phase, power connections. Old style control boxes used

2 overloads, new style use 3. Select and change the

proper overload from the chart listed below. Use the

extra overloads for other service work.

Figure 12. Checking Drive Pawl to Roller Clearance

208-230 Volts Use 2 E34 Overloads

OLD STYLE CONTROL BOX

440-480 Volts Use 2 E26 Overloads

NEW STYLE CONTROL BOX

208-230 Volts Use 3 N-17 Overloads

440-480 Volts Use 3 N-11 Overloads

ADJUSTMENTS

1. Operate conveyor. When fully retracted, drive pawl

assembly (Item 83) wilt be approximately 1/2 inch in

back of roller. (See fig 12.)

The stroke of the drive is fixed at 6 inches. The

connecting rod (item 64, page 7) should be adjust ed so

that the drive arm assembly (item 80, page 7) clears

both sides of the drive equally. (See fig. 13.)

2. Setting Conveyor Overload Switch.

The following test should be performed on every

Flight-A-Round dishwasher service call, even when

there is no apparent conveyor problem. Machine

damage due to improper setting of the overload safety

switch adjustment nut is not covered under warranty.

Misaligned tracks or other binds in the track wilt make

the overload switch ineffective. Be sure conveyor

flows freely around the table before setting the

switch. Usually, conveyor misalignments or binds can

be easily located. In the event that they cannot,

remove the entire conveyor from the machine. Then

manually push a 4 foot section of conveyor around

the table to locate the obstruction. Fig 14 shows the

side of the drive with the cover removed, exposing the

compression springs.

5

Page 6

Use a testing scale for conveyor overload safety

Figure

15.

Testing Conveyor Overload Switch Setting

switch (Pan No. W-0-18410) or a 50 pound fish scale.

To hold the testing scale. Insert a 9-inch piece of 1/2

inch pipe or thinwall through the eyelet of the scale.

Test and adjust the overload safety switch setting as

follows:

(A) Press conveyor START switch.

(B) Position yourself at a curved section of the

Flight-A-Round table, preferably the curve

farthest from the conveyor drive assembly.

nut or loosen the spring compression nuts

until the conveyor stops. (Loosen both

nuts evenly.) Turn clockwise to increase

tension.

(F) Recheck overload safety switch setting and

repeat adjustment until conveyor stops

within the 40 to 50 pound ran ge. Lock the

adjustment nuts in position with the

lockouts. Recheck safety switch setting

after the locknuts have been tight-ened and

readjust if necessary.

(C) With conveyor running, insert hook end of

the scale around the last outboard spacer of

a carrier as shown in fig 15.

(CW Shown)

(D) Pull back on scale, noting scale reading.

Conveyor must stop when scale reading is

between 40 and 50 pounds with conveyor

empty.

FINAL ASSEMBLY

1. Install all covers and check all screws for proper

tightness.

2. Install 4-Inch section of carrier link shield over spot

vacated by type "C" drive cover. You will probably have

to customize here. Usually the carrier shields on both

sides of the drive must be removed, cut back and new

mounting holes drilled. This will provide a mounting

surface for the new shield. BE SURE TO RADIUS ALL

SHARP CORNERS. (See fig 16.)

3. If machine is equipped with one man cost control, it will

probably be necessary to reset the cost control timer.

Refer to Section 13-37 of your Service Manual for

Modular Dishwashers for complete recalibration

instructions.

Figure 16. New Carrier Link Shield Installed

(E) If conveyor does not stop, turn off the conveyor

6

and adjust tension of overload arm extension

springs. Loosen the lock-

Page 7

PARTS LIST

(CLOCKWISE DIRECTION - - - COUNTERCLOCKWISE DIRECTION)

FLIGHT-A-ROUND DRIVE ASSEMBLY TYPE "D"

7

Page 8

Motor Mount Weldment

Single Groo

ve

"V"

Pulley,

3/8"

Bore,

4.25"

O.D. for

5

FPM (Optional

Single Groove

"V"

Pulley,

5/8"

Bore,

2.25"

O.D. for

6.6

PPM (Standard

44B W -1-10985

Single Groove

"V"

Pulley,

5/8"

Bore,

2.5"

O.D. for

8.5

FPM (Optional

1

Single Groove

"V"

Pulley.

5/8"

Bore,

3.0"

O.D. for

10.5

FPM (Optional

PARTS LIST

(CLOCKWISE DIRECTION - - - COUNTERCLOCKWISE DIRECTION)

ITEM

PART NO. DESCRIPTION QTY

NO.

1 W -2-95461 Rail Weldment Assy (Includes Items 2 thru 4) 1

2 W-1-7118 Screw. SS Hex Hd Mach., 1/4-20 x 1/2" Ig. 8

3 W-1-7007 Lockwasher, SS Split. 1/4" 15

4 W-1-7905 Stat-0-Seal, 1/4" 2

5 W-1-5998 Nut, SS Hex, 3/8-16 5

6 W-1-7524 Lockwasher. SS Split, 3/8" 5

7 W-2-95173 Drive Arm Pivot Weldment 1

8 W-0-14146 Screw, SS Truss Hd Slotted Mach., 3/8-16 x 1-1/2" Ig 2

9 W-0-14185 Screw, SS Truss Hd Slotted Mach., 3/8.16 x 1" Ig. 3

10 W-1-7235 Micro Switch 1

11 W-1-7654 Connector, Straight Liquid Tight, 3/8" 1

12 W-1-95453 Overload Switch Bracket 1

13 W-1-7023 Lockwasher, Plated Split. 1/4" 10

14 M -1-3571 Screw, Hex Hd Plated Steel Cap. 1/4-20 x 1/2" Ig. 5

15 W-2-95158 Drive Base Support, R.H. 1

16 W-0-14784 Bolt. Hex Hd Plated Steel. 5/16-18 x 3/4" 9

17 W-1-8491 Screw. SS Truss Hd Slotted Mach., 1/4-20 x 5/8" Ig. 3

18 W-1-7146 Nut, SS Hex. 1/4-20 9

19 W-1-12977 Conduit Clamp. One Hole, 1/2" 2

20 W-1-7012 Nut, Hex, Plated Steel, 1/4-20 6

21 W-1-8348 Screw. Hex Hd Steel, 1/4-20 x 3/4" Ig. 2

22 W-1-7657 Bolt. Hex Hd, Plated Steel, 3/8-16 x 1-1/4" Ig. 2

23 W-1-7584 Washer, 16 Ga, SS Plat, 13/32" I.D.x 1" O.D. 2

24 W-1-16493 Washer, Nylon Pivot 4

25 W-1-16492 Sleeve, Driven Base Pivot 2

26 P -1-17245 Lockwasher, Plated Split, 3/8" 5

27 W -0-14785 Nut, Hex, Plated Steel. 3/8-16 7

28 W-1-95I62 Overload Spring Bar 1

29 1-9268 Compression Spring (.177 Dia. Wire) 1-1/32" I.D. x 2" high 2

30 W-1-95191 Spring Washer 4

31 M -1-15062 Bolt. Hex Hd Steel. 3/8-16 x 3-1/2" Ig. 2

32 W-1-95199 Drive Base End Panel 1

33 W-1-95193 Drive Belt Tightener Assy (Consists of Items 34 thru 38) 4

34 W-0-95192 Flat Plate 1

35 P -1-17235- Lockwasher, Plated Split, 5/16" 18

36 W-0-14786 Nut, Hex Plated Steel, 5/16-18 18

37 M -1-15069 Screw, Hex Hd Steel. Fully Threaded, 5/16-18 x 2-1/2" Ig 1

38 W-0-14099 Bolt. Carriage, Plated Steel, 5/16-18 x 3/4" Ig. 4

39 W-1-11312 Motor, 1/2 HP 115/230V Single Phase, Type 56-4 Frame 1

39A W-1-11314 Motor, 1/2 HP 208/230/460V Three Phase. Type 56-4 Frame 1

40 W-1-14945

41 W -1-9859 Washer. 16 Ga. SS Flat, .337" I.D. x 7/8" O.D. 2

42 W -1-95163 Motor Mount Hanger 1

43 W -0-95465 Bolt, Sq. Hd Plated Steel, 3/8-16 x 7" Ig. 1

44 W -1-11328

44A W -0-14753

FLIGHT-A-ROUND DRIVE ASSEMBLY TYPE "D"

REQ.

1

1

1

8

44C W -0-10984

1

Page 9

ITEM PART

QTY

46 W-1-95450

-A

Motor Cover Mount

1

50 W-1-95156

Drive Bas

e Weldment

1

53 W-1-95190

Drive Arm Slide

1

6.6

(Standard) FPM Speeds

1

56 W-0-14097

Speed Reducer,

60:1

1

58 W-1-95167

Crank Weldment w/Setscrew

1

65 W-0-95455

Rod End

2

68 W-2-95468

-A

Drive Pawl Guard Assy (Consists of One Item

3,

One Item

18,

and Items

69

thru

74) . 1

72 W-1-14198

Delrin Roller,

15/16"

O.D. 2

74 W-1-95462

Drive Pawl Guard Base

1

77 W-2-95177

-A

Drive Enclosure

1

PARTS LIST

FLIGHT-A.ROUND DRIVE ASSEMBLY TYPE "D"

(CLOCKWISE DIRECTION - - - COUNTERCLOCKWISE DIRECTION)

NO. NO. DESCRIPTION REQ.

45 W-0-16891 "V" Belt, 25" OAL for Clockwise Drive 5 and 8.5 FPM Speeds 1

45A W-1-11331 "V" Belt, 26" OAL for Clockwise Drive 6.6 and 10.5 FPM Speeds 1

45B W-0-95456 "V" Belt, 35.2" OAL for Counterclockwise Drive 5 and 8.5 FPM Speeds 1

45C W-0-95457 "V" Belt. 36.2" OAL for Counterclockwise Drive 6.6 and 10.5 FPM Speeds 1

47 W-1-95451 Drive Motor Cover 1

48 W-1-95452 Motor Cover Lower Bracket 1

49 W-2-95178 Pulley and Belt Cover 1

51 W-2-95161 Drive Mount Rear Support 1

52 W-2-95159 Drive Base Support, L.H. 1

54 W-1-11335 Screw, Hex Hd SS Fully Threaded, 1/4-20 x 1.1/4" Ig. 3

55 W-1-11331 Single Groove "V" Pulley, 5/8" Bore, 5.0 O.D. for 5 (Optional) and

55A W.O-14281 Single Groove "V" Pulley. 5/8" Bore, 4.25" O.D. for 8.5 and

10.5 FPM (Optional Speeds) 1

57 W-1-8067 Bolt, Hex Hd Plated Steel. 5/16-18 x 1" Ig. 4

59 W-0-14192 Jam Nut, Hex Plated Steel. 1/2-13 1

60 M -1-15317 Lockwasher, Plated Split, 1/2" 2

61 M -1-15151 Washer. Plated Steel Flat, 17/32" I.D. x 1-1/16" O.D. x 3/32" thick 6

62 W-0-95466 Bolt, Hex Hd Plated Steel 1-1/4" Ig. thread) 1/2-13 x 2" Ig. 2

63 P -1-17237 Nut, Hex Plated Steel, 1/2-13 . 1

64 W-1-954 54 Connecting Rod Assy (Consists of Items 65 thru 67) 1

66 W-0-95459 Jam Nut. Hex 1/4-20 2

67 W-1-95164 Connecting Rod 1

69 W-0-95485 Bolt, Hex Hd SS. 1/4-20 x 3" Ig. 1

70 W-1-8622 Washer. Flat, 18 Ga. SS, 17/64" I.D. x 5/8" O.D. 3

71 W-1-14517 Tubular Spacer, 3/4" Ig. 1

73 W-1-95458 Tubular Spacer, 1-3/4" Ig. 1

75 W-1-95170 Drive Enclosure Mounting Bracket 1

76 W-1-967 7 Screw, Hex Hd Mach., SS, 1/4-20 x 3/4" Ig 5

78 W-0-18190 Pin, SS Roll, 1/4"Dia.x 1-3/4"lg. 1

79 M -1-15208 Set Collar, w/setscrew, plain steel, 1"I.D.x 1-5/8" x 5/8" thick 1

80 W-2-95176 Drive Arm Assy (Consists of Items 81 and 82) 1

81 W-2-95175 Drive Arm Weldment 1

82 W-1-9868 Oilite Flange Bearing 1

83 W-3-95197 Drive Pawl Assy (for CCW Drive) (Consists of One Item 73 and Items 84 thru 89) 1

83A W-3-95196 Drive Pawl Assy (for CW Drive) (Consists of One Item 73 and Items 84A thru 89) 1

84 W-3-95195 Drive Pawl Weldment (CCW Drive) 1

84A W-3-95194 Drive Pawl Weldment (CW Drive) 1

9

Page 10

PARTS LIST

FLIGHT-A-ROUND DRIVE ASSEMBLY TYPE "D"

(CLOCKWISE DIRECTION - - - COUNTERCLOCKWISE DIRECTION)

ITEM

NO.

85 W-0-14392 Screw. Hex Hd Mach., SS. 3/8-16 x 2" 1

86 W-1-95189 Drive Pawl Roller 1

87 W-1-95187 Pawl Roller Sleeve 1

88 W-0-16161 Nut, SS Hex Acom, 3/8-16 1

89 W-0-95460 Oilite Flange Bearing 2

90 P-1-17237 Nut. Plated Steel. 1/2 -13 1

91 M-1-15317 Lockwasher. Split Plated, 1/2" 1

92 W-1-12836 Washer, Flat, 16 Ga. SS, 17/32" I.D. x 1-1/4" O.D 1

93 W-1-95198 Pawl Driving Arm Stud 1

94 W-1-95372 Pawl Cam Cover 1

95 W-1-95374 Drive Pawl Cam 1

96 W-1-95458 Cam Spring Spacer 1

97 1-8879 Compression Spring, 9/16" O.D. x 1-3/4" lg. 1

98 W-1-7145 Screw, Hex Hd Mach., SS, 1/4-20 x 2-1/4" lg. 1

99 W-2-95371 Drive Pawl Guide 1

100 W-2-95179 Pawl Support Assy 1

PART NO. DESCRIPTION

NOTE: The drive assembly pictured is for counterclockwise direction. When a

clockwise direction is required, the complete unit is turned 180°.

QTY

REQ.

10

Loading...

Loading...