Page 1

BB914

BB2016

OWNER'S MANUAL

MODELS BB914, BB2016 and BB1224

BURNISHERS

BLAKESLEE

1841 South Laramie Avenue

Chicago, IL 60650

Phone: (708) 656-0660

BB1224

BLAKESLEE

66 Crockford Boulevard

Scarborough Ontario. Canada M1 R 3C3

Phone: (416) 751-2625

Page 2

TABLE OF CONTENTS

SECTION 1 INTRODUCTION 1

1-1 General 1

1-2 Description 1

1-3 Specifications 1

SECTION 2 INSTALLATION 3

2-1 Unpacking the Unit 3

2-2 Installation 4

SECTION 3 OPERATION 7

3-1 General 7

3-2 Preparing Compound Solution 7

3-3 Operation 7

3-4 Draining and Cleaning the Unit 8

SECTION 4 MAINTENANCE 9

4-1 Daily 9

4-2 Monthly 9

4-3 Bi-Monthly 9

4-4 Replacing Tub Drain Screen 9

4-5 Media Replacement 10

4-6 Motor Belt Replacement and Adjustment 10

4-7 Converting "V" Belt Drive to "O- Ring" Drive 10

4-8 Eccentric Bearing Replacement 11

4-9 Media Tub Replacement 12

4-10 Compound Pump 13

4-11 Drive Motor Rotation 13

4-12 Wiring Diagrams and Schematics 13

4-13 Troubleshooting 14

SECTION 5 ILLUSTRATED PARTS LIST 15

Page 3

wx

1-1. GENERAL

This manual covers Installation, Operation, and Maintenance

Instructions and Illustrated Parts Lists for Blakeslee Burnishers Models BB914, BB2016 and BB1224.

1-2. DESCRIPTION

The Blakeslee Burnisher uses a special procelain ceramic

1-3. SPECIFICATIONS

SECTION 1

INTRODUCTION

burnishing media and chemical compound that restores luster to

stainless steel, silver, pewter, etc.

These procelain ceramic burnishing balls are 1/3 lighter than steel

balls, consequently all types of flat and hollow ware items can be

burnished without damage. Knives and other items are not dulled

no matter how long they remain in the machine.

Motor 1/2 H.P., 3450 RPM 1 H.P., 3450 RPM 1 H.P., 3450 RPM

Compound Pump P:AAA (Constant) 6 GPH P:AAA (Constant) 6 GPH* P:AAA (Constant) 6 GPH*

Media Capacity 40Lbs 160 Lbs 160 Lbs

Weight 140 Lbs, w/o media 265 Lbs, w/o media 265 Lbs, w/o media

Dimensions

Power Requirement 6 amp 115V 12amp 115V 12amp 115V

Tub Opening 9"x 14" 20"x 16" 12"x24"

*Compound pumps on later model burnishers operate in conjunction with a 1 minute timer. When the burnisher is initially turned on,

the pump will run for 2 minutes, then turn off.

BB914 BB2016 BB1224

20-3/4" 1 x 1 5-3/4"

35-5/8" h

20" 1 x 23" w x 35" h 37" 1 x 25" w x 30" h

1/2

Page 4

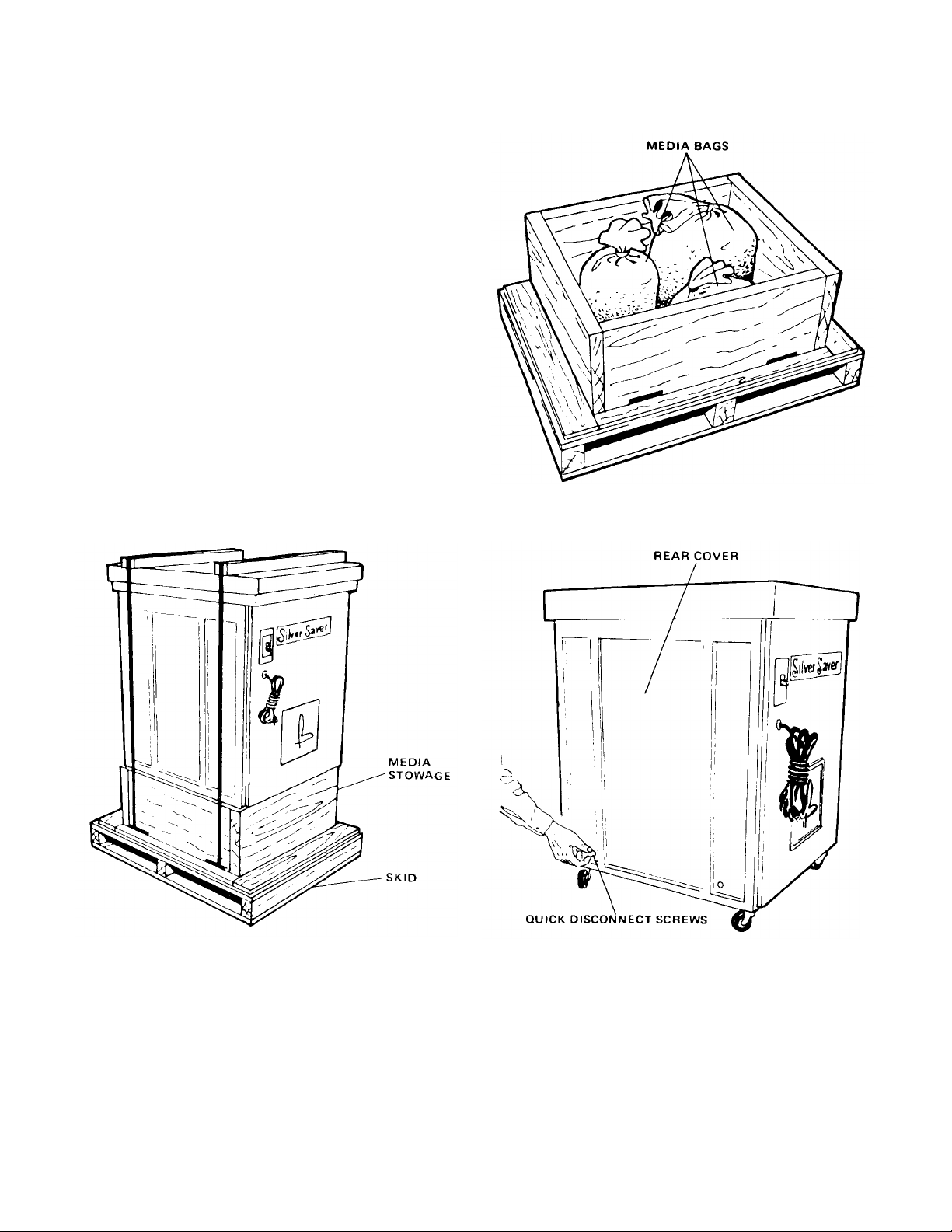

2-1. UNPACKING THE UNIT

1. Remove unit from shipping carton (See fig. 2-1.)

2. Lift unit from skid.

3. MODEL BB914. Remove media bags stowed in tub.

MODELS BB2016 and BB1224. Remove media bags stowed

inside skid. (See fig. 2-2.)

4. MODELS BB914 and BB2016. To remove rear cover, push

in and turn quick disconnect screws 1/4 turn

counterclockwise. (See fig. 2-3.)

MODEL BB1224. To open front doors, push in and turn quick

disconnect screws 1 /4 turn counter-clockwise. (See fig. 2-4.)

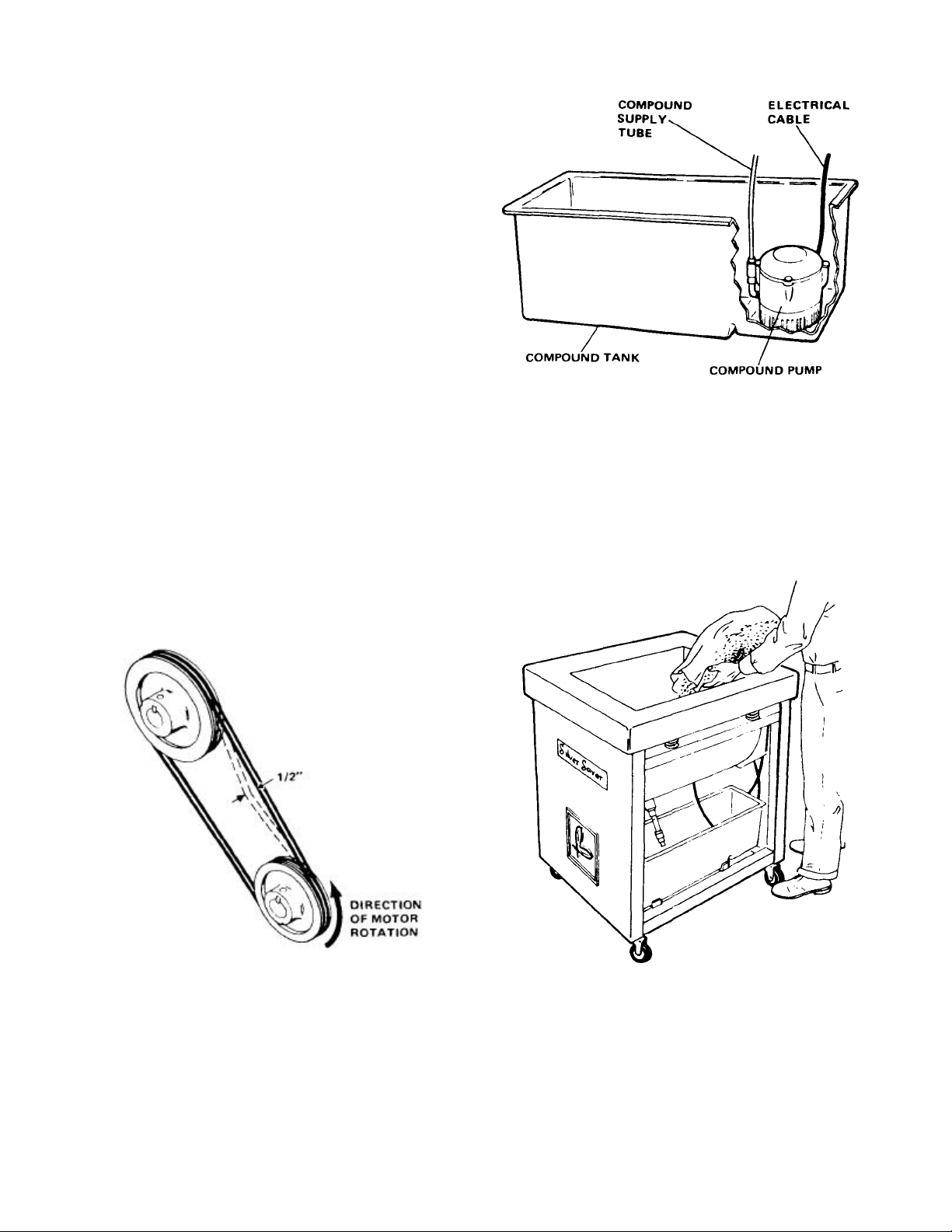

5. Remove compound tank from unit. (See fig. 2-5.) Remove

packing material and compound from tank.

SECTION 2

INSTALLATION

Figure 2-2. Location of Media Bags (Models BB2016 and

BB1224)

Figure 2-1. Model BB2016 with Shipping Carton Removed Figure 2-3. Removing Rear Cover (Model BB2016)

3

Page 5

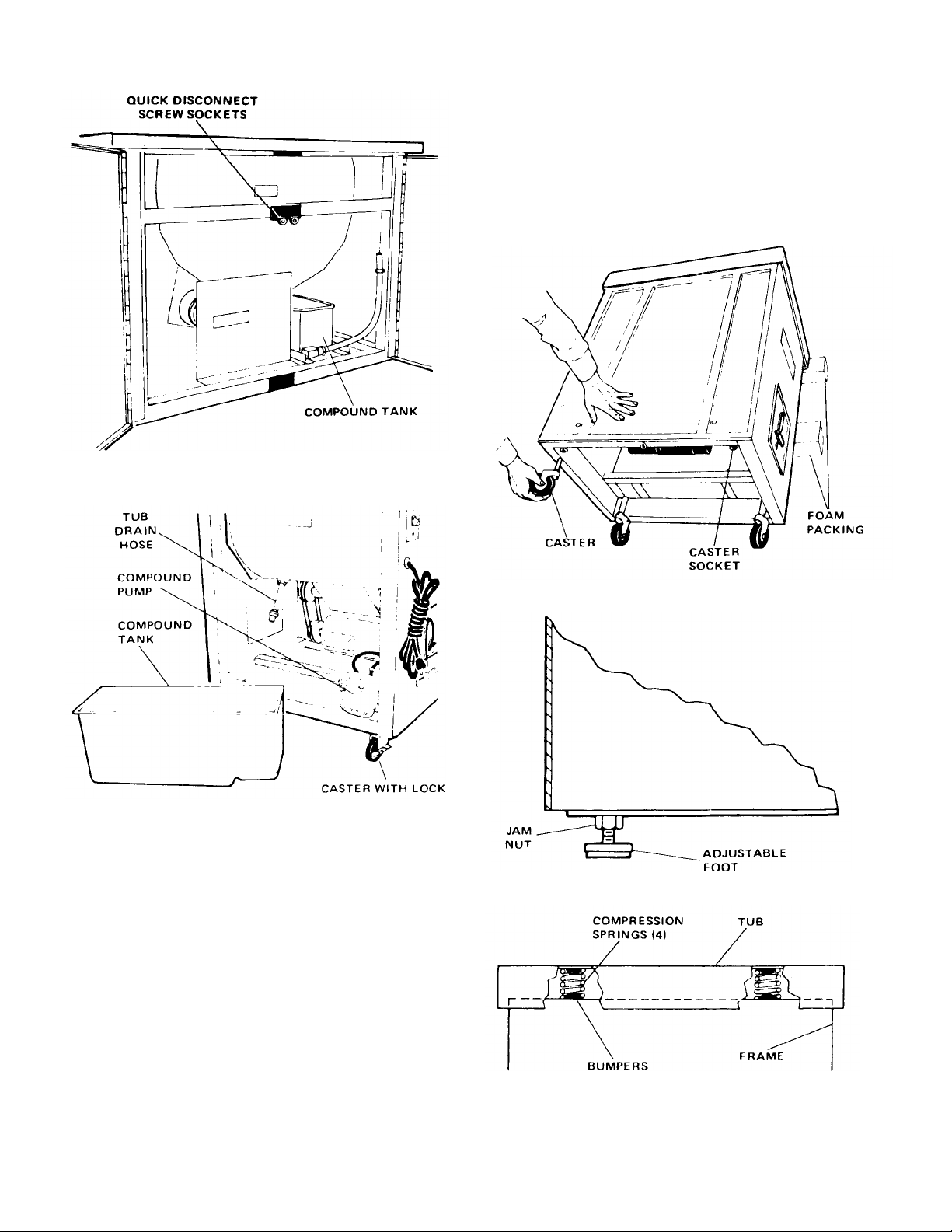

MODEL BB1224. Place unit in desired operating location

(near floor drain if possible). Level machine by loosening

jam nut on adjustable feet and screwing feet in or out until

unit is level. (See fig. 2-7.)

Figure 2-4. Model BB1224 with Front Doors Open

2. Be sure that compression springs are positioned

correctly between upper and lower bumpers. (See fig. 2-

8.)

Figure 2-6. Installing Casters (Model BB2016)

Figure 2-5. Compound Tank Removed (Model 2016)

2-2. INSTALLATION

1. MODELS BB914 and BB2016. Lay unit on its side on

some of the foam packaging (to prevent scratching the

finish) and install casters to bottom of unit. (See fig. 2-6.)

NOTE: One of the casters has a brake (large wing type nut

on side of wheel). The most convenient location for

the brake caster is the corner directly under the motor

starting switch. (See fig. 2-5.)

4

Figure 2-7. Adjustable Foot (Model BB1224)

Figure 2-8. Compression Springs Properly Positioned

Page 6

3. Check the following to make sure nothing has come loose

during shipment:

A. Drain hose assembly attached to tub.

B. Compound hose connected to compound pump and

tub.

C. Cords, hoses clear of motor belts.

4. Check Motor 0-ring belts for correct installation and

tension (see fig. 2-9). If belt deflection is not approximately

1/2 inch, adjust as described in MOTOR BELT

REPLACEMENT AND ADJUSTMENT (paragraph 4-6).

5. Uncoil motor cable and place on floor next to unit.

6. Install compound tank in unit and place compound pump

in recess in bottom of tank. (See fig. 2-10.)

7. Place end of tub drain hose in compound tank.

8. Clean inside of media tub with a cloth dampened in

menthal alcohol.

Figure 2-10. Compound Pump Installed In Tank

9. Open bag(s) and empty media into tub (approximately

two level inches below compound inlet to tub). (See fig. 2-

11.)

10. If unit is to be put into service immediately, refer to

operating instructions. If unit is not to be put into service

immediately, replace cover.

Figure 2-9. Checking Belt Tension Figure 2-11. Emptying Media Bags Into Tub

5/6

Page 7

3-1. GENERAL

Before putting unit in operation, be sure all steps outlined in

installation instructions have been covered.

NOTE: On initial start-up, it is desirable to flush media

before initial use. This is accomplished by going

thru steps described in paragraph 3-2 and

running unit for approximately 1/2 hour, then

draining the unit by following steps

described in paragraph 3-4.

IMPORTANT

USE ONLY BLAKESLEE SPECIAL COMPOUND. USE OF

OTHER COMPOUND MAY GIVE INCOMPLETE OR

UNSATISFACTORY RESULTS. IN SOME CASES

DAMAGE TO FINE SILVER COULD OCCUR.

UNDER NO CIRCUMSTANCES SHOULD ITEMS BE

PLACED OR SOAKED IN DETAR-NISHING SOLUTION

BEFORE BEING PLACED IN BURNISHER.

SECTION 3

OPERATION

3-2. PREPARING COMPOUND SOLUTION

(See fig. 3-1.)

1. MODEL BB914. Remove rear cover and add one oz. of

compound to compound tank.

MODEL BB2016. Remove rear cover and add two oz. of

compound to compound tank.

MODEL BB1224. Open front door and add two oz. of

compound to compound tank.

2. Be sure end of tub drain hose is in compound tank and

external drain hose is held in vertical position by the clip

(BB1224 only).

3. Fill compound tank with water to full line (approximately

1 -1/2 inch from top of tank).

3-3. OPERATION

1. MODELS BB914 and BB2016. Replace rear cover. Place

unit in desired operating position and lock brake on caster

located under ON-OFF switch.

Figure 3-1. Adding Special Blakeslee Compound to Tank

(Models 914 & 2016)

2. Plug power supply cord into any convenient 115V outlet.

NOTE: Model BB914 requires 6 amp 115V circuit.

Models BB2016 and BB1224 require 12 amp

115V circuit.

3. MODEL BB914 and EARLY MODELS BB2016.

Turn unit on. Motor and compound pump will continue to

run as long as switch is in the ON position.

MODEL BB1224 and LATE MODELS BB2016.

Turn unit on. Compound pump will run for approximately

two minutes then stop automatically. This charge is

adequate for 6 hours of operation under normal operating

conditions.

NOTE: If unit is turned off for any reason, wait 10

minutes before restarting.

4. Deposit washed items in Burnisher tub.

7

Page 8

Figure

3-2.

Draining Compound Tank (Model

BB1224)

5. MODEL BB914 will hold approximately 144 pieces of

mixed flatware.

MODELS BB2016 and BB1224 will hold approximately

576 pieces (4 gross) of mixed flatware.

Burnishing a large amount of similar items (all knives, all

forks, etc.) at one time is not recommended. Normal

burnishing time is 10 minutes. Naturally this will depend on

the condition of the ware. Items that have not been

burnished for a long period will require more time. A weekly

burnishing program will decrease the amount of burnishing

time and keep all items looking like new.

NOTE: Items need not be detarnished. If you choose to

detarnish, items MUST be run through

dishwasher again before being placed in

Burnisher (all items must be dishwasher clean

before processing in Burnisher System).

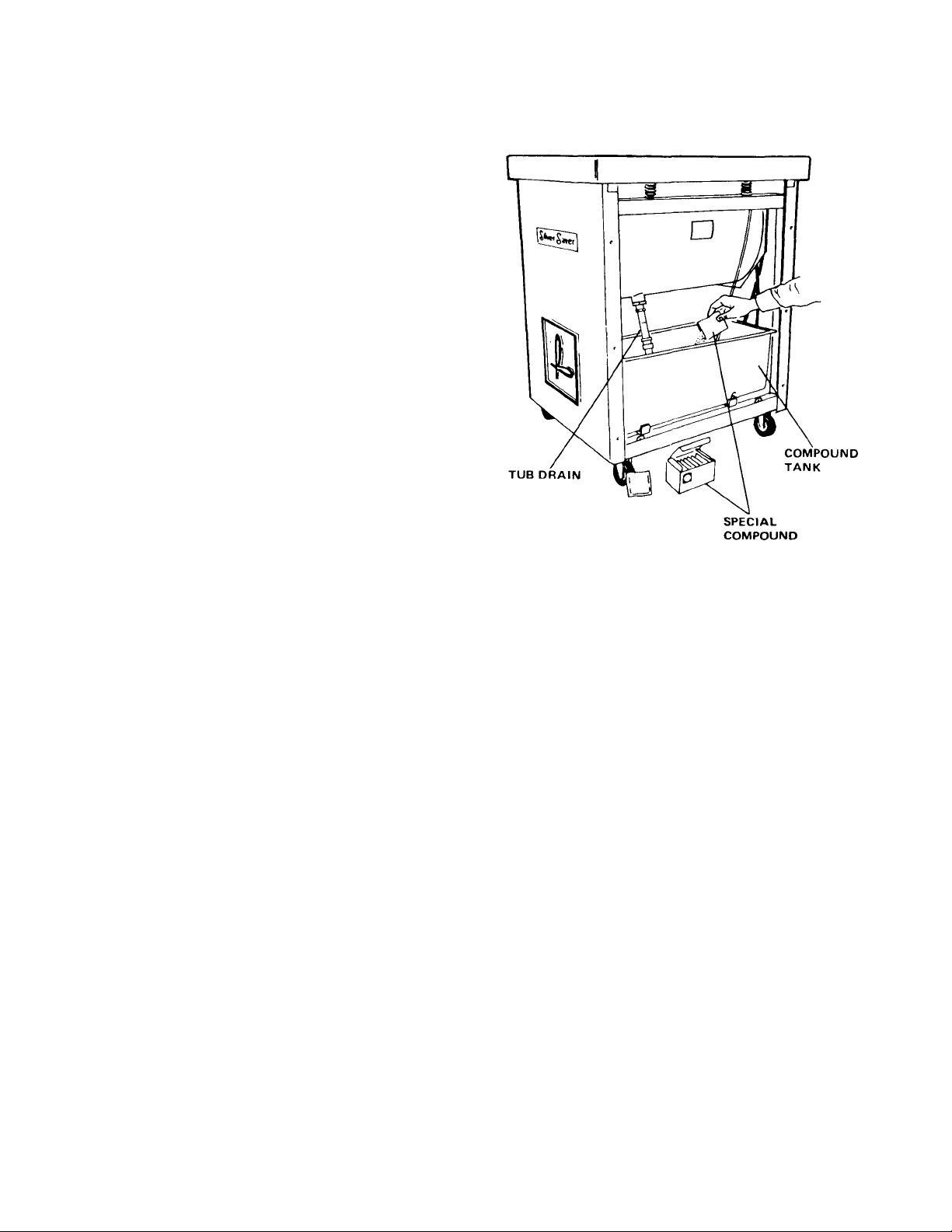

2. MODELS BB914 and BB2016. Remove rear cover.

Remove compound tank from unit and discard compound

solution. Clean tank with fresh water and reinstall in unit.

MODEL BB1224. Open doors and drain compound

solution by removing external drain hose from clip and

allowing solution to drain into a suitable receptacle or floor

drain. (See fig. 3-2.) Flush and clean compound tank with

fresh water.

NOTE: Compound must be replaced daily for best results.

3. No cleaning of media is necessary.

6. Condition of flatware can be checked while the

7. After desired burnishing results have been obtained,

8. Burnished items must then be processed through your

9. If more items are to be burnished, repeat steps 4 thru 8.

unit is in operation by observing the items as they rotate in

the tub or they can be removed for closer visual

inspection.

remove all items from tub. It is best to remove items from

the machine while it is in operation.

NOTE: Do not remove the media (porcelain ceramic

balls).

dishwashing system in the normal fashion.

3-4. DRAINING AND CLEANING THE UNIT

1. If Burnisher will not be used for the remainder of the day,

turn off the switch and allow system to drain for a few

minutes.

8

Page 9

4-1. DAILY

1. Empty and clean compound tank using fresh water and

soap.

2. Clean inside and outside of unit with a soft damp cloth.

Stainless steel components should be cleaned with

stainless steel cleaner and polish.

3. Check to be sure screen in media tub drain is clear of

foreign objects. On later model BB2016 and BB1224

Burnishers this screen is located on the end of the drain

hose inside the faucet aerator. Remove the aerator and

clear or dislodge foreign objects using a wooden toothpick

or similar item. (See fig 4-1.)

NOTE: Grasping the tubing tightly or bending the tubing

up will prevent any media from falling out when

the aerator is removed. (See fig 4-2.) A small

cork or rubber stopper can then be inserted in

the coupling until the aerator is reinstalled.

SECTION 4

MAINTENANCE

Figure 4-2. Grasping Drain Tube to Prevent Media from Falling

Out

Figure 4-1. Cleaning Tub Drain Screen

4-2. MONTHLY

Check condition of motor belts and hoses. Replace as necessary.

See MOTOR BELT REPLACEMENT AND ADJUSTMENT

(paragraph 4-6).

4-3. BI-MONTHLY

Lubricate both vibrator bearings through grease fittings provided on

flanged bearing assy. Use good grade (E.P.O.) of bearing grease.

4-4. REPLACING TUB DRAIN SCREEN (Early Models)

On model BB914 and older models BB2016 and BB1224 the tub

drain screen is located inside the media tub in the tub drain inlet.

The redesigned hose assy. can be retrofitted on models BB2016

and BB1224 (except some very early models) by simply prying the

old screen out of the tub drain inlet (see fig 4-3) and installing the

new drain hose assy. (part no. W-0-95016).

Figure 4-3. Removing Tub Drain Screen From Early

Models BB2016 and BB1224

9

Page 10

4-5. MEDIA REPLACEMENT

The best burnishing results are obtained when both 1/8" and 1/4"

porcelain-ceramic media (balls) are mixed. Proper mixture is 3 parts

1/8" media (white color) to one part 1/4" media (blue color) by weight.

The burnishing media supplied with your machine has been premixed as described above. When replacement media is ordered, it

also will be mixed as shown above.

ALL MODELS USING "V" BELT DRIVE

1. Removal and replacement is the same as for O-ring belts

except that the motor mount bolts must be loosened in

order to remove or replace the belt.

2. Adjustment is the same as O-ring belts.

4-7. CONVERTING "V" BELT DRIVE TO "O-

RING" DRIVE

MODEL BB914. Parts needed for conversion are as follows:

4-6. MOTOR BELT REPLACEMENT AND

ADJUSTMENT

MODELS BB914 and BB2016. Remove rear covers by

turning quick disconnect screws 1/4 turn counterclockwise.

MODEL BB1224. Open front doors by turning quick

disconnect screws 1/4 turn counterclockwise.

CAUTION

MAKE SURE SWITCH IS OFF AND POWER CORD IS

DISCONNECTED FROM WALL OUTLET.

ALL MODELS USING DOUBLE "O-RING" TYPE BELTS.

1. Because these belts have more "stretch" than ordinary

"V" belts they can be removed and replaced without

loosening the motor mounts. Simply pull the belt to the top

of the pulley groove and rotate pulley by hand until belt

pops off. These belts should be replaced in sets.

2. Install new belts making sure belts are seated properly

in grooves and are not twisted.

3. Check belt tension for approximately 1/2-inch deflection

when moderate pressure is applied to belts as shown in

fig. 2-9. If adjustment is required, loosen motor mount

bolts and slide motor until proper tension is obtained.

NOTE: Media tub should be filled with proper amount of

media before checking or adjusting belt tension.

Double groove driven pulley ..……….... W-0-20456

Double groove drive pulley .....………... W-0-20458

Special "O-ring" belt (2 required) . . ….. W-0-20459

1/2 hp, 3450 rpm motor ......………….... W-0-95057

CAUTION

MAKE SURE SWITCH IS OFF AND POWER CORD IS

DISCONNECTED FROM WALL OUTLET.

1. Disconnect electrical wires from motor.

2. Remove bolts securing motor to motor mount plate.

3. Remove "V" belt and motor.

4. Remove driven pulley from eccentric shaft.

5. Install new 3450 rpm motor with the same bolts used on

the old motor.

6. Connect electrical wires to motor terminals.

7. Install driven pulley (large diameter) on eccentric shaft with

setscrew side of hub facing out.

8. Install drive pulley (small diameter) on motor shaft with

setscrew side of hub facing out.

9. Using a straight edge or ruler, adjust the pulleys so they

are exactly in line (see fig. 4-4) then tighten setscrews.

10. Install new belts as described in MOTOR BELT

REPLACEMENT AND ADJUSTMENT (paragraph 4-6).

10

Page 11

Figure 4-4. Checking Pulley Alignment

MODEL BB2016. Parts needed for conversion are as follows:

Double groove driven pulley ..……... W-0-20456

Double groove drive pulley ..……..... W-0-20457

Special "O-ring" belt (2 required) . . . W-0-20459

1 hp, 3450 rpm motor .....………….... W-0-95058

CAUTION

MAKE SURE SWITCH IS OFF AND POWER CORD IS

DISCONNECTED FROM WALL OUTLET.

1. Disconnect electrical wires from motor.

2. Remove the entire motor and motor mount assy. (see fig.

5-3). These parts will not be reused.

9. Using a straightedge or ruler, adjust the pulleys so they

are exactly in line (see fig. 4-4) then tighten setscrews.

10. Install new belts as described in MOTOR BELT

REPLACEMENT AND ADJUSTMENT (paragraph 4-6).

4-8. ECCENTRIC BEARING REPLACEMENT

1. Remove front cover, rear cover, and guards as necessary

to gain access to both flange bearings.

2. Remove drive belts.

3. Remove driven pulley from eccentric shaft.

4. Model BB914 refer to insert in fig. 5-1. Models BB2016

and BB1224 refer to fig. 5-4. Remove three bearing

bolts, nuts, and lockwashers.

5. Remove flange bearings and eccentric shaft assy. from

housing.

NOTE: If the unit is still equipped with the old style 2

piece lead weight it should be converted at this

time to the one piece steel weight. Refer to parts

list for parts required for conversion.

6. Reinstall eccentric shaft assy. in housing.

7. Install flange bearings on eccentric shaft and line up bolt

holes with grease fittings positioned for easiest access for

servicing.

8. Install and tighten three flange bolts, nuts and washers.

3. Remove motor mount plate. Layout and drill two new holes

in the plate as shown in fig. 4-5.

4. Reinstall motor mount plate.

5. Install new 3450 rpm motor.

6. Connect electrical wires to motor terminals.

7. Install drive pulley (small diameter) on motor shaft with

setscrew side of hub facing out.

8. Remove old driven pulley from eccentric shaft and replace

with new double groove pulley (large diameter). Setscrew

side of hub should face out.

9. Install pulley on eccentric shaft and line up pulleys as

shown in fig. 4-4. Tighten setscrew.

10. Install belts and check for proper tension as described in

MOTOR REPLACEMENT AND ADJUSTMENT

(paragraph 4-6).

11. Replace all guards and covers.

12. After unit has run approximately 30 minutes, lubricate

both flange bearings through grease fittings on housings.

11

Page 12

NOTE:

1. DRILL 2 HOLES 11/32 DIA. TO INSTALL ITEMS 2, 3 & 4

FOR BOLTING MOTOR TO MOUNT PLATE.

2. USE OLD 5/16 BOLTS FOR CONVERSION.

Figure 4-5. Layout Drawing for Modifying BB2016 Motor

4-9. MEDIA TUB REPLACEMENT

CAUTION

MAKE SURE SWITCH IS OFF AND POWER CORD IS

DISCONNECTED FROM WALL OUTLET:

1. Remove all media from tub.

2. Remove drive belts.

3. Disconnect compound supply tube from compound

pump.

4. Lift media tub out of unit.

4 A/R

3 2

2 4

1 1

ITEM

Mount Plate

5. Transfer eccentric assy. from old tub to new tub. Refer to

6. Transfer rubber bumpers, compound supply tube and tub

7. Insert new tub into unit making sure springs are properly

8. Reconnect compound supply tube to compound pump.

9. Reinstall drive belts.

10. Remove any foreign objects from tub and wash tub lining

11. Fill tub to proper level with media.

5/16 WASHER

5/16-18 HEX NUT

5/16-18 x 1/2 LG H.H.C.S. PLATED

11 GA C.R. STL 7-15/16 x 22-3/4

QTY. PART NO. DESCRIPTION

ECCENTRIC BEARING REPLACEMENT (paragraph 4-

8).

drain hose assy. to new tub.

positioned (see fig 2-8.)

with methol alcohol.

12

Page 13

4-10. COMPOUND PUMP

The compound pump is the same for all units, however its operation

varies between units. On model BB914 and early model BB2016

the pump continues to run as long as the switch is on. On model

BB1224 and later model BB2016 a timing relay is used to

automatically turn the pump off 2 minutes after the unit is started.

This 2 minute charge is sufficient for approximately 6 hours or until

the unit is turned off. Once the unit is turned off it must remain off

for 10 minutes to allow the compound solution to drain into the

compound tank.

The compound pump is a sealed unit and requires no service or

maintenance. If the pump fails to operate it can easily be replaced

by disconnecting the compound supply tube and wires from the

switch or timing relay.

4-11. DRIVE MOTOR ROTATION

reversed by changing the internal wiring of the motor. Instructions

are usually provided on the motor data plate. When the motor is

rotating properly the media will be pitched as shown in fig 4-6.

The electric drive motor should rotate in a counterclockwise

direction (see fig 2-9). The direction of rotation can be

4-12. WIRING DIAGRAMS AND SCHEMATICS

Figure 4-7. Wiring Diagram, Model BB1224 and

Late Model BB2016

Figure 4-6. Pitch of Media as Viewed from Pulley Side of Tub

Figure 4-9. Schematic, Model BB1224 and Late Model

BB2016

Figure 4-8. Wiring Diagram, Model BB914 and Early

Model BB2016

Figure 4-10. Schematic, Model BB914 and

Early Model BB2016

13

Page 14

4-13. TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Unit fails to operate. Unit not plugged in. Plug in power cord.

Blown fuse or circuit breaker. Replace fuse or reset circuit breaker.

Defective switch. Replace switch.

Drive motor overheats. Eccentric bearings seizing due to lack of lubrication. Lubricate or replace bearings as necessary.

Broken wire in power supply cord. Repair or replace.

Low supply voltage to motor. Check voltage at wall outlet. Possibly too much load

on that circuit. Reduce load on circuit or use

different circuit.

Internal defect in motor. Have motor tested by qualified technician.

Excessive noise. Media tub spring(s) broken or out of position. Replace spring or reposition. See fig. 2-8.

Eccentric bearings worn. Replace eccentric bearings.

Pulleys loose on motor or eccentric shaft. Tighten setscrew in pulley hub.

Media tub fails to maintain proper

level of compound solution.

Eccentric bearings need lubrication. Lubricate bearings through grease fittings.

Drive belts worn or frayed. Replace belts.

Loose covers or panels. Tighten screws.

Compound pump inlet plugged. Compound pump

inoperative.

Timing relay improperly adjusted or inoperative. Late

Model 2016 and Model 1224 only.

Drive motor rotating in wrong direction (new unit or

new motor only).

Clean pump inlet. Replace pump.

Readjust or replace as necessary.

Check that motor rotates counterclock-wise when

facing front of pulley. Have wiring checked by

qualified technician.

14

Page 15

5

ILLUSTRATED PARTS LIST

A

Ib. cartons

18020

To expedite delivery, all parts must be ordered by name and number listed in this parts list.

All orders must include Serial Number of the machine. Place your order with your local

Blakeslee Parts Distributor or Service Agency. Their name and address can be found in the

Service Agency Booklet which accompanies this manual. If you need further assistance,

contact:

BLAKESLEE

1844 So. Laramie Avenue

Chicago, Illinois 60650

Telephone: (312)

REPLACEMENT BURNISHING MEDIA AND CHEMICAL COMPOUND

SECTION

PART

NO.

W-0-18021W-0-18026-A

W-0W-0-18757

DESCRIPTION

Consisting of 1/8" x 1/4" diameter balls mixed, 3 parts 1/8" balls and 1 part 1/4"

balls BY WEIGHT.

8 carton case of 5

1 - 40 Ib. carton

Case of 4 Gallons

Case of 360 - 1 oz. packets

BURNISHING MEDIA

CHEMICAL COMPOUND

15

Page 16

16

Figure 5-1. Model BB914 Main Assembly

Page 17

17

FIG. 5-1. MODEL BB914 MAIN ASSEMBLY

ITEM

NO.

1 W-0-17916 FRAME ASSY, w/electrical box and casters, epoxy painted 1

2 W-0-17917 TUB WELDMENT, Complete w/urethane lining and epoxy paint 1

3 W-0-17919 RUBBER BUMPER 8

4 W-0-17920 SPRING, Painted 4

5 W-0-17921 CASTER, w/brake, w/o bracket 1

6 W-0-18018 CASTER, w/o brake, w/o bracket 3

7 W-0-17922 BRACKET, For casters, unpainted 4

8 W-0-17923 ABS GUARD, Left side switch opening, w/double coated tape and rivets 1

9 W-0-17924 ABS GUARD, Right side, w/tape and rivets 1

10 W-0-17925 ABS GUARD, Front and/or rear, w/o fasteners 1

11 W-0-17926 FASTENER KIT, Quick disconnect, for front and rear guards,

12 W-0-17942 TOGGLE SWITCH 1

13 W-0-17929 COMPOUND PUMP 110 V 60 Cycle 1

13A W-0-95556 COMPOUND PUMP 230 V 50 Cycle (Export only)

14 W-0-17930 HOSE ASSY, Compound supply, 1/4", w/connectors 1

15 W-0-17931 DRAIN HOSE ASSY, Complete with 5/8" hose 1

16 W-0-17932 COMPOUND TANK 1

17 W-0-17933 FLANGED BEARING ASSY, Painted 2

18 W-0-17935 BEARING BOLT KIT 1

19 W-0-17934 SHAFT, Eccentric 1

20 W-0-20766 ECCENTRIC WEIGHT ASSY, Consists of: 1

21 W-0-20765

22 W-0-20460

23 W-0-7023

24 W-0-20313

25 W-0-20456 PULLEY, Driven, double groove, serial no. 77-001 and up 1

25A W-0-17936 PULLEY, Driven, single groove, serial no. 77-000 and below 1

26 W-0-20458 PULLEY, Drive, double groove, serial no. 77-001 and up 1

26A W-0-17938 PULLEY, Drive, single groove, serial no. 77-000 and below 1

27 W-0-20459 BELT, "O"-Ring type, serial no. 77-001 and up 2

27A W-0-16907 BELT, "V" type, serial no. 77-000 and below 1

28 W-0-95057 MOTOR, 1/2 hp, 3450 rpm, 110/220V, 1 phase, 60 cycle

serial no. 77-001 and up 1

28A P-1-5280 MOTOR, 1/3 hp, 1725 rpm, 110/220V, 1 phase, 60 cycle

serial no. 77-000 and below 1

28 B W-0-95554 MOTOR, 1/2 hp, 3450 rpm, 115/230V, 1 phase, 50 cycle,

serial no. 77-001 and up (Export only)

29 W-0-17940 CABLE, Electrical, between switch and motor 1

30 W-0-17941 CABLE KIT, Electrical, supply, 12 ft 1

31 W-0-17943 COVER, s/s toggle switch 1

32 W-0-17945 FASTENER KIT, Motor mount 1

33 W-0-17927 MEDIA RETURN TOP DECK, w/decal and chrome fastener 1

34 W-0-17928 TUB COVER, Can be used only with media return top deck 1

35 W-0-18618 DECAL, Silver Saver 1

36 W-0-20340 DECAL - Serial no 1

PART NO. DESCRIPTION

3 piece assy 2

i ECCENTRIC WEIGHT

i SCREW, Socket head, 1/4"-28 x 1-1/2" Ig

i LOCKWASHER, 1/4"

i NUT, Hex, 1/4"-28

QTY.

REQD.

1

1

1

1

Page 18

18

Figure 5-2. Model BB2016 Main Assembly

Page 19

FIG. 5-2. MODEL BB2016 MAIN ASSEMBLY

19

ITEM PART

NO. NO DESCRIPTION REQD.

1 W-0-18675 FRAME ASSY, w/electrical box and casters 1

2 W-0-18676 TUB WELDMENT, Complete w/urethane lining 1

3 W-0-17919 RUBBER BUMPER KIT, Consists of (4) rubber bumpers,

4 W-0-17920 SPRING 1

5 W-0-17921 CASTER, w/brake, w/o bracket 1

6 W-0-18017 CASTER, w/o brake, w/o bracket, consists of (3) swivel casters 1

7 W-0-17922 CASTER BRACKET, Consists of (4) brackets 1

8 W-0-18678 COVER, Left side w/switch opening, includes double

9 W-0-18678 COVER, Right side, includes double coated tape and screws 1

10 W-0-18680 COVER, Front and/or rear 2

11 W-0-17926 FASTENER KIT, Quick disconnect, 3 piece assy 4

12 W-0-17942 TOGGLE SWITCH 1

13 W-0-17929 COMPOUND PUMP, 110V 60 cycle 1

13A W-0-95556 COMPOUND PUMP, 220V 50 cycle (export only) 1

14 W-0-17930 HOSE ASSY, Compound supply, 1/4" w/connectors 1

15 W-0-95016 DRAIN HOSE ASSY, Consists of the following parts 1

16 W-0-18681 COMPOUND TANK 1

17 W-0-20459 BELT. "O-ring" type, serial no. 20S-77-001 and up 2

17A W-0-17937 BELT, "V" type, serial no. 20S-77-000 and below 1

18 W-0-20457 PULLEY, Drive, double groove, serial no. 20S-77-001 and up 1

18A W-0-18690 PULLEY, Drive, single groove, serial no. 20S-77-000 and below 1

19 W-0-20456 PULLEY, Driven, double groove, serial no. 20S-77-001 and up 1

19A W-0-18689 PULLEY, Driven, single groove, serial no. 20S-77-000 and below 1

20 W-0-95058 MOTOR, 1 hp, 3450 rpm, 110/220V, 1 phase, 60 cycle

20A W-0-18684 MOTOR, 3/4 hp, 1725 rpm, 110/220V, 1 phase, 60 cycle

20B W-0-95555 MOTOR, 1 hp, 3450 rpm, 110/220V, 1 phase, 50 cycle,

21 W-0-17940 CABLE, Electrical, v//connectors, motor to switch 1

22 W-0-17941 CABLE, Electrical, w/connectors, power supply 1

23 W-0-17943 COVER, s/s toggle switch 1

24 W-0-20336 RELAY, Timing (late production models) 110V, 60 cycle 1

24A W-0-95557 RELAY, Timing (late production models) 220V, 50 cycle (export only) 1

25 W-0-20335 SOCKET. Timing relay (late production models) 1

26 W-0-15971 TIE WRAP. Timing relay (late production models) 1

27 W-0-17945 FASTENER KIT, Motor mount 1

28 W-0-18687 TUB EXTENSION 1

29 W-0-18618 DECAL, Silver Saver 1

30 W-0-18688 TUB COVER 1

31 W-0-18691 HOSE KIT, Compound tank drain, includes connector and

32 W-0-20347 ECCENTRIC SHAFT ASSY (See fig. 5-4 for detail parts) 1

33 W-0-20338 DECAL Pump warning 1

34 W-0-20340 DECAL, Serial No. 1

W-0-20325

(4) 10-24 hex nuts and (4) no. 10 lockwashers 1

coated tape and screws 1

i FAUCET AERATOR

i ADAPTER, Hose connector to aerator

i HOSE CONNECTOR, 1/2" male

i POLYVINYL TUBING. 5/8" x 1/2" x 6-1/2" Ig

i COUPLING Reusable

serial no. 20S-77-001 and up 1

serial no. 20S-77-000 and below 1

serial no. 20S-77-001 and up (export only) 1

spring clip (Early Models Only) 1

QTY.

1

1

1

1

1

Page 20

Figure 5-3. Motor Mount Assembly, Model BB2016 (Serial No. 20S-

QTY.

20

77-000 and Below)

ITEM

NO.

1

PART

NO.

W-0-18806

DESCRIPTION

SUPPORT, Motor bearing

2 W-0-18807 SHAFT, Extension 1

3 W-0-18808 BEARING, Flanged 1

4 W-1-7657 BOLT, Hex head, 3/8-16 x 1-1/4" Ig 3

5 W-1-15334 LOCKWASHER,3/8" 3

6 W-1-7115 NUT, Hex, 3/8"-16 3

7 P-1-17243 SETSCREW. 1/4-10x3/8" lg 1

NOTE: These parts are no longer used starting with serial number 20S-77-001 and up.

When either the motor or flanged bearing need replacing on older models, the

system should be changed to the new style. Refer to Section 4 for instructions on

converting to the new system.

REQD.

1

Page 21

Figure 5-4. Eccentric Shaft Assembly

Models BB2016 and BB1224

ITEM

NO.

1

PART

NO.

W-0-17933

FLANGED BEARING ASSY

DESCRIPTION

2 W-0-20314 GREASE FITTING 2

3 W-0-18683 BEARING BOLT KIT 1

4 W-0-18682 ECCENTRIC SHAFT 1

W-0-20767 ECCENTRIC WEIGHT ASSY, Consists of: 1

6 W-0-20432

7 W-0-20460

8 W-0-20313

9 W-0-7023

i ECCENTRIC WEIGHT

i SCREW, Socket head, 1/4-28 x 1-1/2" Ig

i NUT, Hex, 1/4"-28

i LOCKWASHER. 1/4"

NOTE: When replacing old style 3 piece eccentric weight order item 5, Eccentric

Weight Assy.

QTY.

REQD.

2

1

2

2

2

21

Page 22

22 Figure 5-5. Model BB1224 Main Assembly

Page 23

NO.

NO

REQD.

FAUCET AERATOR

ADAPTER, Hose connector to aerator

COUPLING, Reusable

23

ITEM

PART

FIG. 5-5. MODEL BB1224 MAIN ASSEMBLY

DESCRIPTION QTY.

1 W-0-20315 FRAME WELDMENT

2 W-0-20316 TUB WELDMENT, Complete w/urethane lining

3 W-0-20317 DOOR, Front, RH

4 W-0-20318 COVER, Side, RH

5 W-0-20319 COVER, Back

6 W-0-20320 COVER, Frame, top

7 W-0-20321 TANK, Compound

8 W-0-20322 COVER, Tub

9 W-0-17920 SPRING, Compression 4

10 W-0-20347 ECCENTRIC SHAFT ASSY (See fig. 5-4 for detail parts)

11 W-0-20345 DOOR, Front, LH

12 W-0-17929 PUMP, Compound, 110V, 60 cycle

12A W-0-95556 PUMP, Compound, 220V, 50 cycle (export only) 1

13 W-0-20323 GROMMET 1

14 W-0-17919 RUBBER BUMPER 8

15 W-0-17931 HOSE, Compound supply, w/connectors 1

16 W-0-95016 DRAIN HOSE ASSY, Consists of the following parts 1

17 W-0-95058 MOTOR, 1 hp, 3450 rpm, 110/220V, 1 phase, 60 cycle 1

17A W-0-95555 MOTOR, 1 hp, 3450 rpm, 110/220V, 1 phase, 50 cycle (export only) 1

18 W-0-17941 CABLE ASSY, Electrical, power supply, 12 ft Ig 1

19 W-0-27942 SWITCH, Toggle 1

20 W-0-17943 COVER, Toggle switch, s/s 1

21 W-0-20346 COVER, Side, LH 1

22 W-0-20459 BELT, "O-ring" type 2

23 W-0-20456 PULLEY, Driven, 2 groove 1

24 W-0-20457 PULLEY, Drive, 2 groove 1

25 W-0-20326 FEET, Level mount 4

26 W-0-17926 FASTENER, Quick disconnect, 3 piece assy 2

27 W-0-20327 RIVET, Aluminum 4

28 W-1-5999 SCREW, Rd hd, s/s. 10-32 x 1-1/2" Ig 36

29 W-1-7285 LOCKWASHER, s/s, no. 10 36

30 W-1-7680 NUT, Hex, no.10-24 8

31 W-1-7647 LOCKWASHER,No.10 14

32 W-1-7291 SCREW. Cap, hex hd, 5/16-18 x 1"lg 4

33 W-1-5996 LOCKWASHER. Split, 5/16" 4

34 W-1-5587 WASHER, Flat 5/16"-10 4

35 W-0-18618 DECAL, Silver Saver 1

36 W-0-20328 SCREW, Self tapping washer hd, Rollex, 6-32 x 1/2" Ig

37 W-0-30329 TUBING, Polyvinyl. 5/8" OD x 1/2" ID x 30" Ig

38 W-0-20330 CLIP, Spring

39 W-2-16380 NAMEPLATE, Blakeslee (horizontal)

40

41 W-0-20333 PAN, Frame cover

42 W-0-20334 SPACER. Cover 14

43 W-0-20335 SOCKET, Relay 1

44 W-0-20336 RELAY, Timing, 110V, 60 cycle 1

44A W-0-95557 RELAY, Timing, 220V, 50 cycle (export only) 1

45 W-0-20337 SMITH SHAFT LOCK 1

46 W-0-20338 DECAL, Pump warning 1

47 W-0-15971 TIE WRAP, Timing relay 1

48 W-0-20339 TAPE, Scotch foam, 16 ft. 1

49 W-0-20340 DECAL, Serial no. 1

50 W-2-16380 NAMEPLATE, Blakeslee (vertical) 1

51 W-1-74 76 SCREW 4

52 W-1-7104 NUT 4

53 W-1-8839 LOCKWASHER 4

W-0-20325

i

i

i HOSE CONNECTOR, 1/2" male

i POLYVINYL TUBING, 5/8" x 1/2" x 6-1/2" Ig

i

GUARD, Drive belt

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Loading...

Loading...