Page 1

www.blackanddecker.ae

PW1400TDK

Page 2

ENGLISH

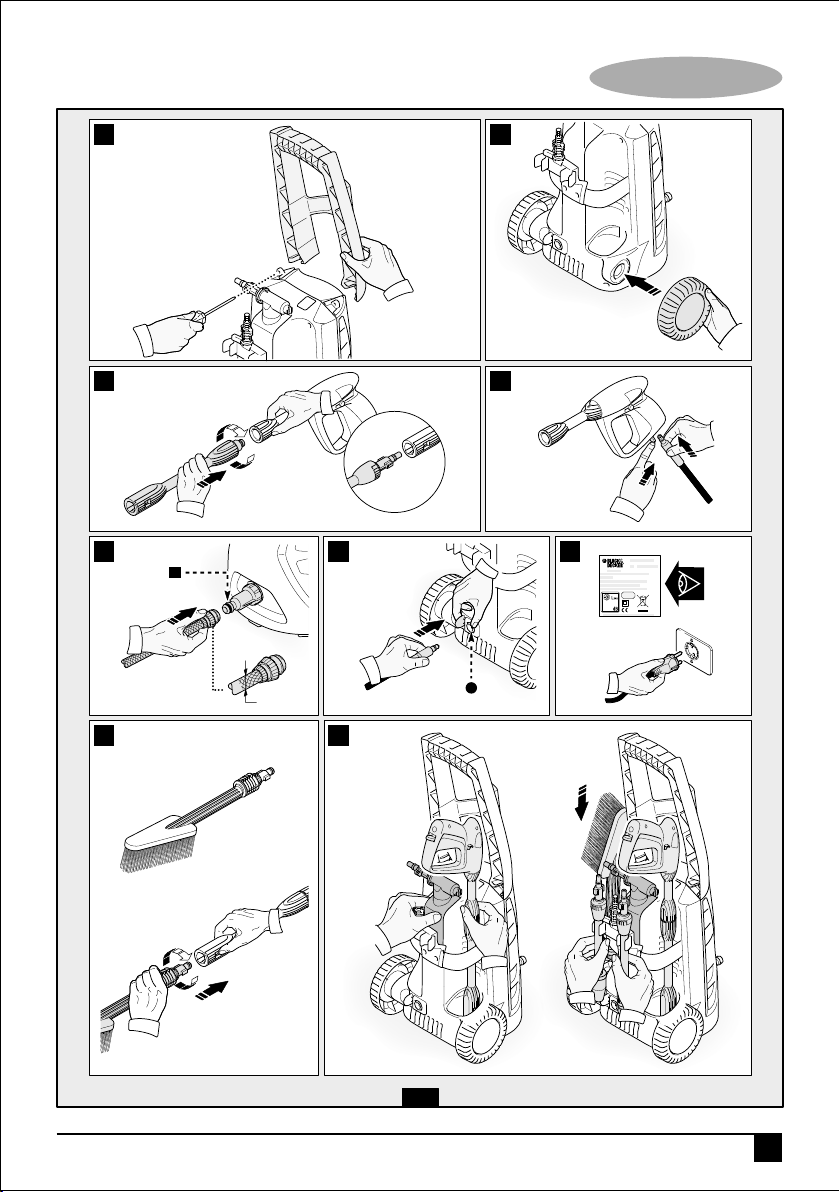

A1-A2-A3-A4

C4

C3

E3

B1

E1

B4

B5

C2

C1

B2

B3

B6

D

1

2

Page 3

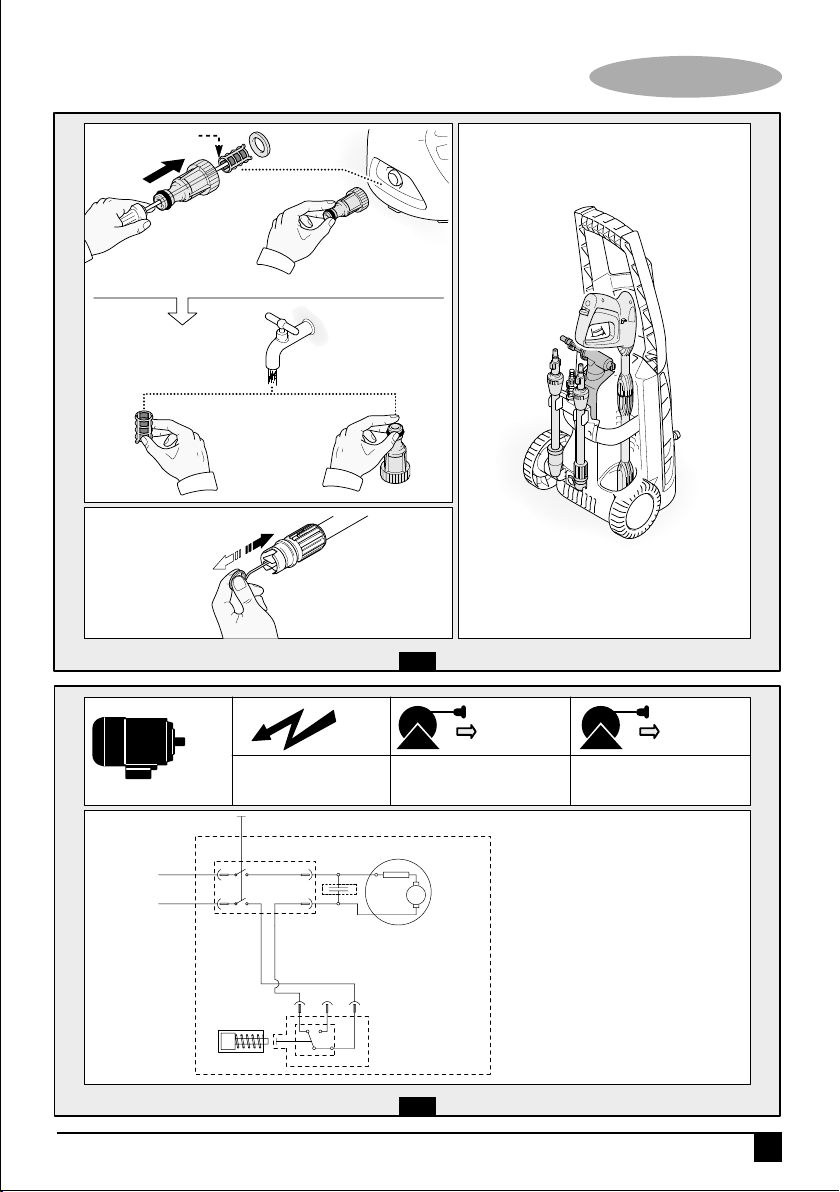

21

43

5 6 7

ENGLISH

Ø13

8 9

2

3

Page 4

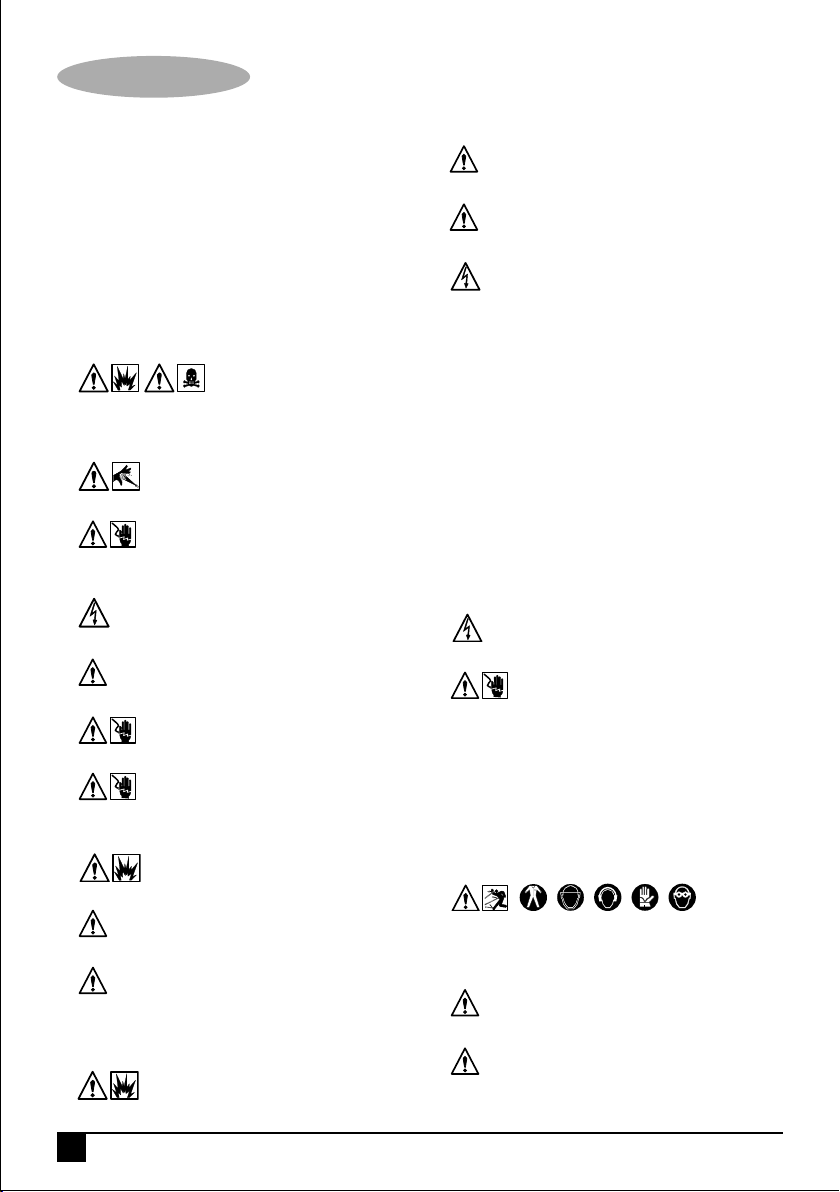

ENGLISH

E

3

D

H

1

I

2

H

4

H

4

Page 5

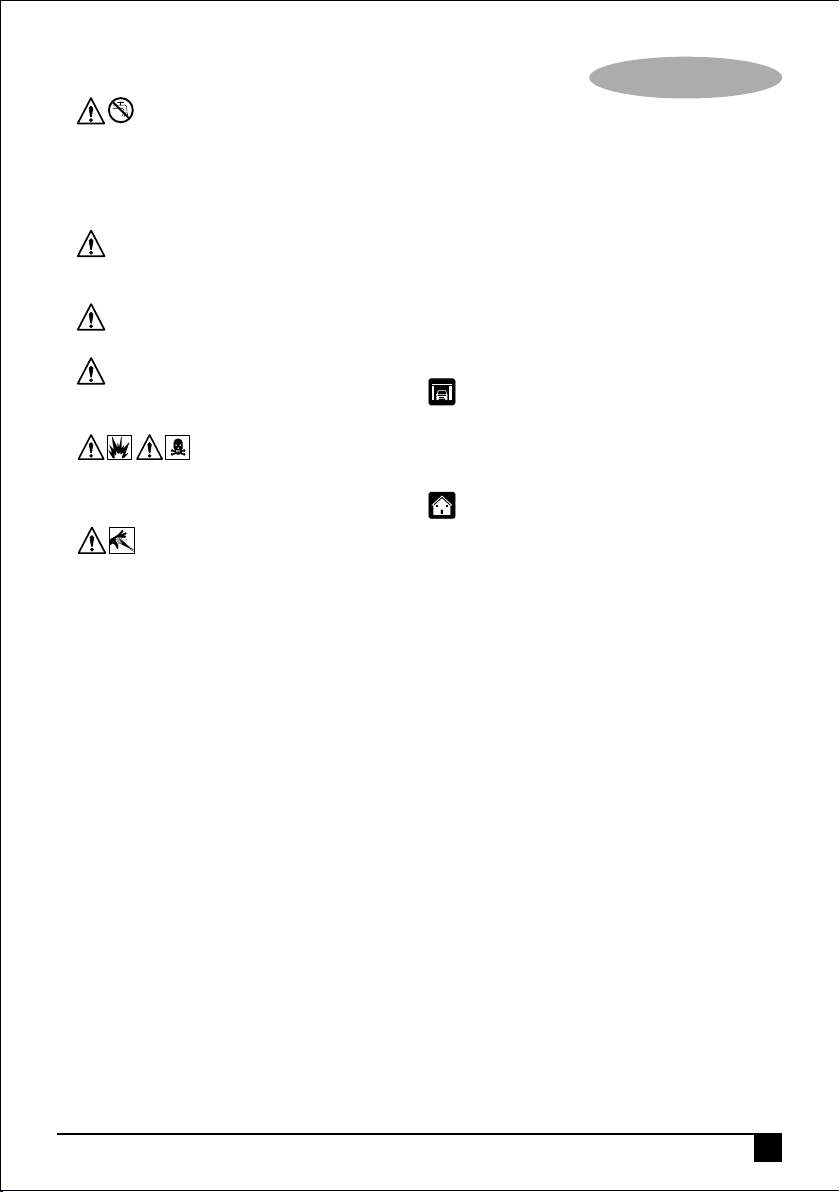

ENGLISH

L

5

25 ÷ 50 m

2 x 2,5 mm

2

M

1 ÷ 25 m

2

S = Switch

Z1 = Capacitor suppressor

T = Thermal protection

M = Motor

S1 = Pressure switch

Volt

230 2 x 1,5 mm

L1

N

S

Z1

T

1~

NCNOC

S1

I

5

Page 6

ENGLISH

Safety instructions

The appliance you have purchased is a technologically

advanced product designed by one of the leading European

manufacturers of high pressure pumps. To obtain the best

performance from your unit, read this booklet carefully and

follow the instructions each time you use it. We congratulate

you on your choice and wish you successful operation.

Safety rules/residual risks

Safety “must nots”

• Do not use the appliance with

inflammable or toxic liquids, or any products which are

not compatible with the correct operation of the

appliance. Explosion or poisoning hazard

• Do not direct the water jet towards people or

animals. Injury hazard

• Do not direct the water jet towards the unit

itself, electrical parts or towards other electrical

equipment. Electric shock hazard

• Do not use the appliance outdoors in case of rain.

Short circuit hazard

• Do not allow children or incompetent persons to

use the appliance. Injury hazard

• Do not touch the plug and/or socket with wet

hands. Electric shock hazard

• Do not use the appliance if the electrical

cable is damaged. Electric shock and short circuit

hazard

• Do not use the appliance if the high pressure

hose is damaged. Explosion hazard

the safety valve or the safety devices. Explosion hazard

• Do not alter the original diameter of the spray head

nozzle. Hazardous alteration of operating performance

• Do not leave the appliance unattended. Accident

hazard

• Do not move the appliance by pulling on the

electrical cable. Short circuit hazard

• Make sure that cars do not drive over the high pressure

hose.

• Do not move the appliance by pulling on the high

pressure hose.

Explosion hazard

• When directed towards tyres, tyre valves or other

pressurised components, the high pressure jet is

potentially dangerous. Do not use the rotating nozzle kit,

and always keep the jet at a distance of at least 30 cm

during cleaning. Explosion hazard

Safety “musts”

• All electrical conductors must be protected against

the water jet. Short circuit hazard

• The appliance MUST ONLY BE CONNECTED

to an adequate power supply in compliance with all

applicable regulations. Electric shock hazard

• Use of a safety residual current circuit-breaker

(R.C.C.B.) will provide additional protection for the

operator (30 mA). Models supplied without plug must be

installed by qualified staff. Use only authorized electrical

extension leads with suitable conductor gauge.

•

• Do not jam the trigger in the operating position.

Accident hazard

• Check that the data plates are affixed to the

appliance, if not, inform your dealer. Units without plates

must not be used as they are unidentifiable and

potentially dangerous. Accident hazard

• Do not tamper with or adjust the setting of

6

High pressure may cause parts to rebound: wear all the

protective clothing and equipment needed to ensure the

operator’s safety. Injury hazard

• Before doing work on the appliance, remov e the

plug. Accidental start-up hazard

• Before pressing the trigger, grip the gun firmly to

counteract the recoil. Injury hazard

Page 7

ENGLISH

• Comply with the requirements of the local

water supply company. According to EN 12729 (BA), the

appliance may only be connected to the mains drinking

water supply if a backflow preventer valve with drain

facility is installed in the supply hose. Contamination

hazard

• Maintenance and/or repair of electrical

components must be carried out by qualified staff.

Accident hazard

• DISCHARGE residual pressure before

disconnecting the unit hose. Injury hazard

• Before using the appliance, CHECK every time that

the screws are fully tightened and that there are no

broken or worn parts. Accident hazard

• Only use detergents which will not

corrode the coating materials of the high pressure

hose/electrical cable. Explosion and electric shock

hazard

• Ensure that all people or animals keep a

minimum distance of 16 yd. (15m) away. Injury hazard

General information (fig.1)

Use of the manual

This manual forms an integral part of the appliance and

should be kept for future reference. Please read it carefully

before installing/ using the unit. If the appliance is sold, the

Seller must pass on this manual to the new owner along

with the appliance.

Delivery

The appliance is delivered partially assembled in a

cardboard box. The supply package is illustrated in fig.1.

Documentation supplied with the appliance

• A1 Use and maintenance manual

• A2 Safety instructions

• A3 Declaration of conformity

• A4 Warranty regulations

Disposing of packaging

The packaging materials are not environmental pollutants

but must still be recycled or disposed of in compliance with

the relevant legislation in the country of use.

Safety signs

Comply with the instructions provided by the safety signs

fitted to the appliance.

Check that they are present and legible; otherwise, fit

replacements in the original positions.

E1 sign – Indicates that the appliance must not be disposed

of as municipal waste; it may be handed in to the dealer on

purchase of a new appliance. The appliance's electrical and

electronic parts must not be reused for improper uses since

they contain substances which constitute health hazards.

Symbols

E2 symbol – Indicates that the appliance is intended

for professional use, i.e. for experienced people informed

about the relative technical, regulatory and legislative

aspects and capable of performing the operations necessary

for the use and maintenance of the appliance.

E3 symbol – Indicates that the appliance is intended

for non-professional (domestic) use.

Technical information (fig.1)

Envisaged use

This appliance has been designed for individual use for the

cleaning of vehicles, machines, boats, masonry, etc, to

remove stubborn dirt using clean water and biodegradable

chemical detergents. Vehicle engines may be washed only if

the dirty water is disposed of as per regulations in force.

• Intake water temperature: see data plate on the

appliance.

• Intake water pressure: min. 0,1MPa-max 1MPa.

• Operating ambient temperature: above 0°C.

• The appliance is compliant with the EN 60335-2-79/A1

standard.

Operator

The symbol on the front cover identifies the appliance’s

intended operator (professional or non-professional).

Improper use

• Use by unskilled persons or those who have not read

and understood the instructions in the manual is

forbidden.

7

Page 8

ENGLISH

• The introduction of inflammable, explosive and toxic

liquids into the appliance is prohibited.

• Use of the appliance in a potentially inflammable or

explosive atmosphere is forbidden.

• The use of non-original spare parts and any other spare

parts not specifically intended for the model in question

is prohibited.

• All modifications to the appliance are prohibited. Any

modifications made to the appliance shall render the

Declaration of Conformity null and void and relieve the

manufacturer of all liability under civil and criminal law.

Main components

• B1 Adjustable spray nozzle

• B2 Lance

• B3 Gun with safety catch

• B4 Power supply cable with plug

• B5 High pressure hose

• B6 Detergent tank (on models with this feature)

Accessories (if included in the supply package –

see fig.1)

• C1 Nozzle cleaning tool

• C2 Rotating nozzle kit

• C3 Handle

• C4 Brush

• C5 Hose reel

Safety devices

Caution - Danger!

Do not tamper with or adjust the safety valve setting.

• Safety valve and/or pressure limiting valve. The safety

valve is also a pressure limiting valve. When the gun

trigger is released, the valve opens and the water

recirculates through the pump inlet or is discharged onto

the ground.

• Thermostat valve (D1 where fitted). If the water

temperature exceeds the temperature set by the

manufacturer, the thermostat valve discharges the hot

water and draws in an amount of cold water equal to the

amount of water discharged, until the correct

temperature is restored.

• Safety catch (D): prevents accidental spraying of water.

Installation (fig.2)

Assembly

Caution - Danger!

All installation and assembly operations must be

performed with the appliance disconnected from the mains

power supply.

The assembly sequence is illustrated in fig.2.

Assembling the rotating nozzle

(For models with this feature)

The rotating nozzle kit delivers greater washing power. Use

of the rotating nozzle may cause of reduction in pressure of

25% compared to the pressure obtained with the adjustable

nozzle. However, the rotating nozzle kit delivers greater

washing power due to the rotation of the water jet.

Electrical connection

Caution - Danger!

Check that the electrical supply voltage and frequency

(V-Hz) correspond to those specified on the appliance data

plate (fig.2). The appliance should only be connected to a

mains power supply equipped with an adequate earth

connection and a differential security breaker (30 mA) to cut

off the electricity supply in the instance of a short circuit.

Use of extension cables

Use cables featuring “IPX5” protection level. The

cross-section of the extension cable should be proportionate

to its length; the longer it is, the greater its cross-section

should be. See table I.

Water supply connection

Caution - Danger!

Only clean or filtered water should be used for intake. The

delivery of the water intake tap should be equal to that of

pump capacity.

Place the appliance as close to the water supply system as

possible.

Connection points

• Water outlet (OUTLET)

• Water inlet with filter (INLET)

8

Page 9

ENGLISH

Connection to the mains water supply

The appliance can be connected directly to the mains

drinking water supply only if the supply hose is fitted with a

backflow preventer valve as per current regulations in force.

Make sure that the hose is at least Ø 13 mm and that it is

reinforced.

Adjustment information (fig.3)

Adjusting the spray nozzle

(for models with this feature)

• Water flow is adjusted by regulating the nozzle (E).

Adjusting the detergent

(on models with this feature)

• Detergent flow is adjusted using the regulator (F).

Adjusting the detergent pressure

Set the adjustable nozzle (E) on " - " to deliver detergent at

the correct pressure (on models with this feature).

Adjusting the pressure

(on models with this feature)

• The regulator (G) is used to adjust the working pressure.

The pressure is shown on the pressure gauge (where

fitted).

Information on use of the appliance (fig.4)

Controls

• Starter device (H).

Set the starter switch on (ON/1) to:

a) Start the motor (in models without TSS device);

b) Set the motor ready to start (in models with TSS

device).

• If there is a pilot light on the starter device, it should light

up.

• If the “low/high” settings are available, use them as

follows:

• Low : low pressure washing

• High : high pressure washing

• Set the starter device switch on (OFF/0) to shut down

the appliance.

• If there is a pilot light on the starter device, it should go

out.

• Water jet control lever (I).

Caution - Danger!

During operation the appliance must be positioned as shown

in fig. 4 on a sturdy, stable surface.

Start-up

1) Turn on the water supply tap fully.

2) Release the safety catch (D).

3) Depress the gun trigger for a few seconds and start up

the appliance using the starter device (ON/1).

Caution - Danger!

Before starting up the appliance check that the water supply

hose is connected properly; use of the appliance without

water will damage it; do not cover the ventilation grilles when

the appliance is in use.

TSS models - In TSS models with automatic delivery flow

cut-off system:

• When the gun trigger is released the dynamic pressure

automatically cuts out the motor (see fig.4);

• When the gun trigger is depressed the automatic drop in

pressure starts the motor and the pressure is restored

after a very slight delay;

• If the TSS is to function correctly all gun releasing and

depressing operations must be performed at intervals of

less than 4-5 seconds.

• On three-phase models for professional use, at first use

start the appliance for a very short time to check that the

motor is running in the correct direction. If the motor fan

is turning anti-clockwise, exchange two of the three

phase wires (L1, L2, L3) in the electrical plug.

• To prevent damage to the appliance, do not allow it to

operate dry and when running do not stop the water jet

for more than 10 minutes at a time (for models without

TSS device).

Stopping the appliance

1) Set the starter device switch on (OFF/0).

2) Depress the gun trigger and discharge the residual

pressure inside the hoses.

3) Engage the gun safety catch (D).

9

Page 10

ENGLISH

Restarting

1) Release the safety catch (D).

2) Depress the gun trigger and discharge the residual air

inside the hoses.

3) Set the starter device on (ON/1).

Storage

1) Switch the appliance off (OFF/0).

2) Remove the plug from the socket.

3) Turn off the water supply tap.

4) Discharge the residual pressure from the gun until all

the water has come out of the nozzle.

5) Drain and wash out the detergent tank at the end of the

working session. To wash out the tank, use clean water

instead of the detergent.

6) Engage the gun safety catch (D).

Refilling and using detergent

When using detergent, the adjustable nozzle must be set on

"-" (on models with this feature).

Use of a high pressure hose longer than the one originally

supplied with the cleaner, or the use of an additional hose

extension, may reduce or completely halt the intake of

detergent.

Fill the tank with highly degradable detergent.

Recommended cleaning procedure

Dissolve dirt by applying the detergent mixed with water to

the surface while still dry.

When dealing with vertical surfaces work from the bottom

upwards.

Leave the detergent to act for 1-2 minutes but do not allow

the surface to dry. Starting from the bottom, use the high

pressure jet at a minimum distance of 30 cm. Do not allow

the rinse water to run onto unwashed surfaces.

In some cases, scrubbing with brushes is needed to remove

dirt.

High pressure is not always the best solution for good

washing results, since it may damage some surfaces. The

finest adjustable nozzle jet setting or the rotating nozzle

should not be used on delicate or painted parts, or on

pressurised components (e.g tyres, inflation valves, etc.).

Effective washing depends on both the pressure and volume

of the water used, to the same degree.

Maintenance (fig.5)

Any maintenance operations not covered by this chapter

should be carried out by an Authorized Sales and Service

Centre.

Caution - Danger!

Always disconnect the plug from the power socket before

carrying out any work on the appliance.

Cleaning the nozzle

1) Disconnect the lance from the nozzle.

2) Remove any dirt deposits from the nozzle hole using the

tool (C1).

Cleaning the filter

Inspect the intake filter (L) and detergent filter (if fitted)

before each use, and clean in accordance with the

instructions if necessary.

Unjamming the motor (on models with this feature)

In case of lengthy stoppages, limescale sediments may

cause the motor to seize. To unjam the motor, turn the drive

shaft with a tool (M).

End-of-season storage

Treat the appliance with non-corrosive, non-toxic antifreeze

before storing it away for winter.

Put the appliance in a dry place, protected from frost.

Mains plug replacement

(U.K. & Ireland only)

If a new mains plug needs to be fitted:

• Safely dispose of the old plug.

• Connect the brown lead to the live terminal in the new

plug.

• Connect the blue lead to the neutral terminal.

Warning! No connection is to be made to the earth terminal.

Follow the fitting instructions supplied with good quality

plugs. Recommended fuse: 5 A.

10

Page 11

ENGLISH

Troubleshooting

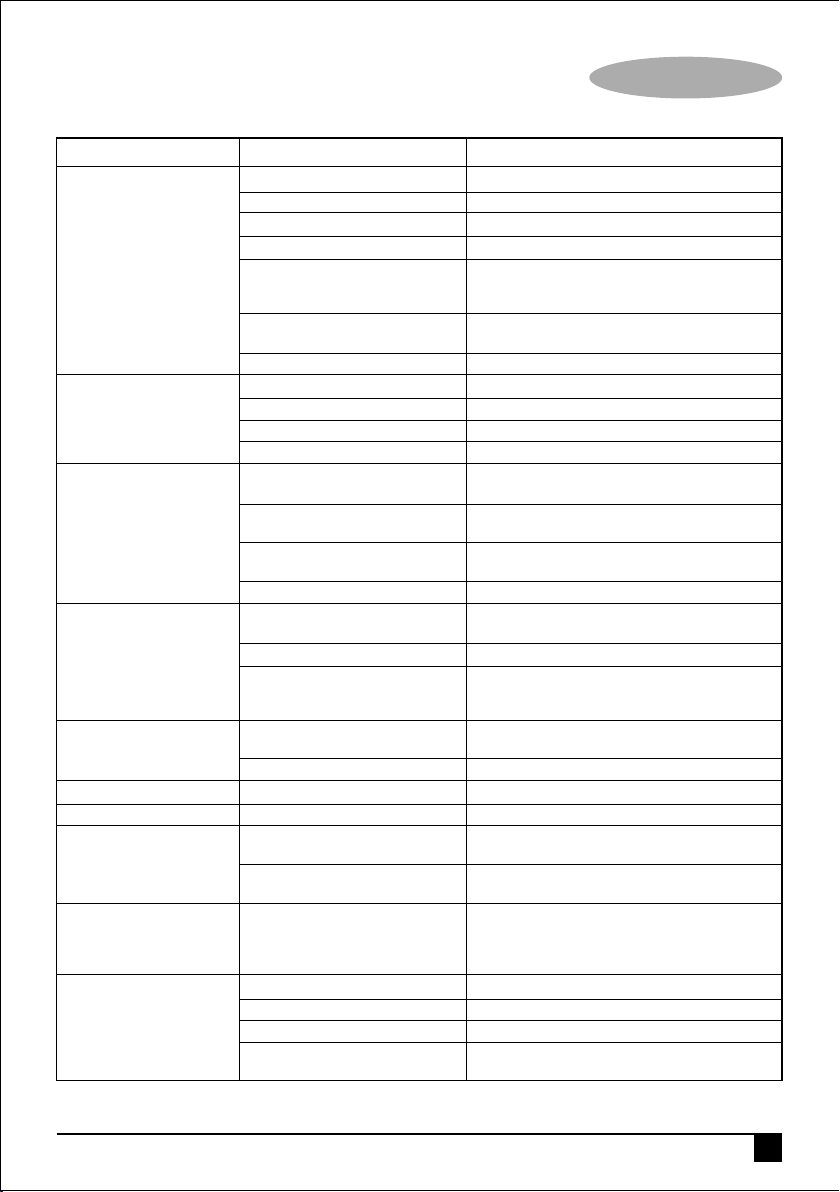

Problem Possible causes Remedy

Nozzle worn Replace nozzle

Water filter fouled Clean filter (fig.5)

Water supply pressure low Turn on water supply tap fully

Air being sucked into system Check tightness of hose fittings

Pump does not reach Air in pump Switch off the appliance and keep depressing and

working pressure releasing the gun trigger until the water comes out in

a steady flow. Switch the appliance back on again.

Adjustable nozzle not Turn the adjustable

positioned correctly nozzle (E) (+) (fig.3)

Thermostatic valve tripped Wait for correct water temperature to be restored

Water intake from external tank Connect appliance to the mains water supply

Pressure drops during use Intake water too hot Reduce temperature

Nozzle clogged Clean nozzle (fig.5)

Intake filter (L) dirty Clean filter (L) (fig.5)

Insufficient power supply Check that the voltage of the mains power

supply line is the same as that on the plate (fig.2)

Voltage loss due to use of Check characteristics of extension cable

Motor “sounds” but fails to start extension cable

Appliance not used for a Contact your nearest Authorized Service Centre

long period of time

Problems with TSS device Contact your nearest Authorized Service Centre

No electrical power Check that the plug is firmly in the socket

and that the mains voltage supply is present (*)

Motor fails to start Problems with TSS device Contact your nearest Authorized Service Centre

Appliance not used for a Using the tool (L) unjam the motor

long period of time from the hole at the rear of the appliance

(in models with this feature) (fig.5)

Seals worn Have the seals replaced at your nearest

Water leakage Authorized Service Centre

Safety valve tripped and discharging Contact an Authorized Service Centre

Appliance noisy Water too hot Reduce temperature (see technical data

Oil leakage Seals worn Contact your nearest Authorized Service Centre

Nozzle clogged Clean nozzle (fig.5)

TSS versions only: motor starts

even with gun trigger is released High pressure system or pump Contact your nearest Authorized Service Centre

hydraulic circuit not watertight

TSS versions only: no water

delivery when gun trigger is Nozzle clogged Clean nozzle (fig.5)

depressed (with supply hose

connected)

Adjustable nozzle on high pressure setting Set nozzle on "-" setting (fig.5)

Detergent too dense Dilute with water

No detergent taken in High pressure hose extension being used Fit original hose

Deposits or restriction in detergent circuit Flush with clean water and eliminate any restrictions.

If the problem persists, contact an Authorized Service Centre

(*) If the motor starts and does not restart during operation, wait 2-3 minutes before repeating the start-up procedure (overload cutout has

been tripped). If the problem recurs more than once, contact your nearest Authorized Service Centre.

11

Page 12

ENGLISH

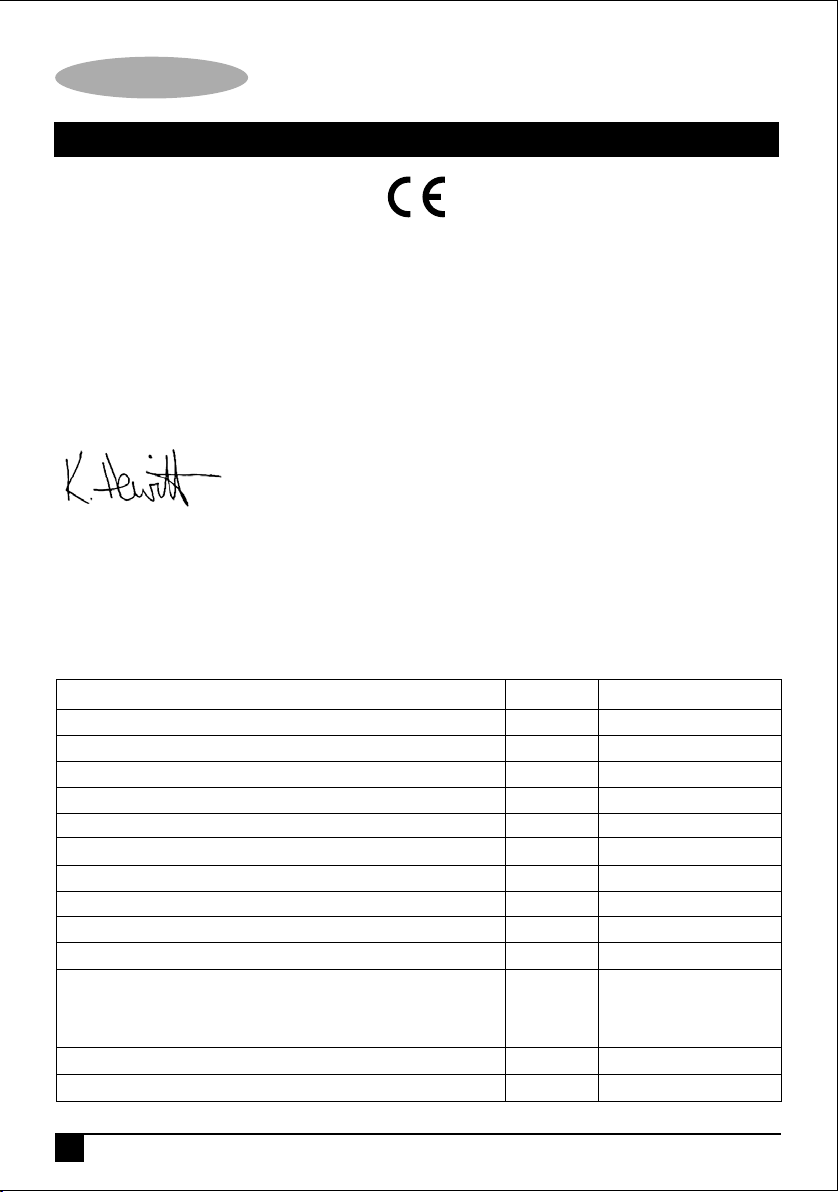

Declaration of conformity

We declare under our sole responsibility that this product is in conformity with the following standards or standardized

EN 60335-1 - EN 60335-2-79; EN 55014-1; EN 55014-2;

EN 61000-3-2;EN 61000-3-3; EN 61000-3-11; EN 60704-1

2006/42/CE, 2006/95/CE, 2002/95/CE, 2002/96/CE, 2004/108/CE, 2000/14/CE

F

or more information, please contact Black & Decker at the following address or refer to the back of the manual. The

undersigned is responsible for compilation of the technical file and makes this declaration on behalf of Black & Decker.

Kevin Hewitt

Vice-President Global Engineering

Black & Decker Europe, 210 Bath Road, Slough,

Berkshire, SL1 3YD

United Kingdom

04/02/2013

In accordance with the regulations:

documents

Technical Data

Unit PW1400TDK

Output L/min 6,2

Pressure MPa 8

Maximum pressure MPa 11

Power kW 1,4

T° input °C 50

Maximum input pressure MPa 1

Repulsive force of the gun to the maximum pressure N 9,3

Motor Insulation - Class F

Motor Protection - IPX5

Voltage V/Hz 230/50

Sound level (K=3 dB(A)) :

LPA (EN 60704-1) dB (A) 75,8

LWA (EN 60704-1) dB (A) 84

Unit vibrations (K=1,5M/s2) M/s2 2,74

Weight kg 6,4

12

Page 13

ENGLISH

Protecting the environment

Separate collection. This product must not be

disposed of with normal household waste.

Should you find one day that your Black & Decker product

needs replacement, or if it is of no further use to you, do not

dispose of it with other household waste. Make this product

available for separate collection.

• Black & Decker provides a facility for recycling Black &

Decker products once they have reached the end of their

working life. This service is provided free of charge. To

take advantage of this service please return your product

to any authorised repair agent who will collect them on

our behalf.

• You can check the location of your nearest authorised

repair agent by contacting your local Black & Decker

office at the address indicated in this manual.

Alternatively, a list of authorized Black & Decker repair

agents and full details of our after-sales service and

contact are available on the Internet at:

www.2helpU.com.

Warranty

Black & Decker is confident of the quality of its products and

offers an outstanding warranty.

This warranty statement is in addition to and in no way

prejudices your statutory rights.

If a Black & Decker product becomes defective due to faulty

materials, workmanship or lack of conformity, within 24

months from the date of purchase, Black & Decker warranty

to replace defective parts, repair products subjected to fair

wear and tear or replace such products to ensure minimum

inconvenience to the customer unless:

• T

he product has been used for trade, professional or hire

purposes;

• The product has been subjected to misuse or neglect;

• The product has sustained damage through foreign

objects, substances or accidents;

• Repairs have been attempted by persons other than

authorised repair agents or Black & Dec

To claim on the warranty, you will need to submit proof of

purchase to the seller or an authorised repair agent. You can

check the location of your nearest authorised repair agent by

contacting your local Black & Decker office at the address

indicated in this manual.

ker service staff.

Alternatively, a list of authorised Black & Decker repair agents

and full details of our after-sales service and contacts are

available on the Internet at: www.2helpU.com.

13

Page 14

FRANÇAIS

A1-A2-A3-A4

C4

C3

E3

B1

E1

B4

14

B6

B5

B2

B3

1

C2

C1

D

Page 15

21

43

5 6 7

FRANÇAIS

Ø13

8 9

2

15

Page 16

FRANÇAIS

E

3

D

16

H

1

I

2

H

4

H

Page 17

FRANÇAIS

L

5

25 ÷ 50 m

2 x 2,5 mm

2

M

1 ÷ 25 m

2

S = Switch

Z1 = Capacitor suppressor

T = Thermal protection

M = Motor

S1 = Pressure switch

Volt

230 2 x 1,5 mm

L1

N

S

Z1

T

1~

NCNOC

S1

I

17

Page 18

FRANÇAIS

Instructions pour la sécurité

L’appareil que vous venez d’acheter est un produit de très

haut niveau technologique réalisé par l’une des entreprises

européennes les plus expertes en la fabrication de pompes

à haute pression. Pour obtenir des performances optimales,

veuillez lire et observer scrupuleusement les instructions

que nous avons formulées à chaque fois que vous utiliserez

cet appareil. Nous vous félicitons de votre choix et vous

souhaitons un bon travail.

Règles de sécurité/risques résiduels

Avertissements: à ne pas faire

• N’utilisez jamais l’appareil avec

des fluides inflammables, toxiques ou dont les

caractéristiques ne sont pas compatibles avec le

fonctionnment correct de l'appareil. danger d’explosion

et d’empoisonnement

• Ne dirigez jamais le jet d’eau contre des

personnes ou des animaux. danger de lesions

• Ne dirigez jamais le jet d’eau contre

l’appareil, les parties électriques ou tout autre appareil

électrique. Danger de choc électrique

• N’utilisez jamais l’appareil en plein air en cas de

pluie. danger de court-circuit

• Ne laissez jamais la machine entre les mains

d’enfants ou de personnel non formé. danger d’accident

• Ne prenez jamais la fiche ou la prise avec les

mains mouillées. Danger de choc électrique

• N’utilisez jamais l’appareil si son câble

électrique est endommagé. danger de choc électrique et

court-circuit

• N’utilisez jamais l’appareil si son tube à

haute pression est endommagé. danger d’explosion

• Ne bloquez pas le levier du pistolet si l’appareil est

en marche. Danger d’accident

• Vérifiez la présence de la plaquette des

caractéristiques sur l’appareil; dans le cas contraire

contactez immédiatement le revendeur. N’utilisez en

aucun cas un appareil dépourvu de plaquette car il

pourrait être dangereux. Danger d’accident

18

• N’altérez jamais ni modifiez le tarage de la

soupape de réglage et des dispositifs de sécurité.

Danger d’explosion

• Ne modifiez pas le diamètre d’origine du jet de la

tête. Danger! Le fonctionnement risque d’être compromis

• Ne laissez jamais l’appareil sans surveillance.

Danger d’accident

• Ne déplacez jamais l’appareil en le tirant par le

CABLE ELECTRIQUE. Danger de court-circuit

• Évitez le passage de véhicules sur le tuyau haute

pression.

• Ne déplacez pas l’appareil en tirant le tuyau haute

pression. Danger d’explosion

• Le jet haute pression sur pneumatiques, valves de

pneumatiques et autres composants sous pression est

potentiellement dangereux. Évitez l' utilisation du kit buse

rotative et maintenir une distance du jet d’au moins 30

cm pendant le lavage. Danger d’explosion

Avertissements: à faire

• Toutes les parties conductrices de courant

DOIVENT ÊTRE PROTÉ GÉES contre le jet d’eau.

Danger de court-circuit

• Branc hez l’appareil uniquement sur une

source d’électricité appropriée et conforme aux normes

en vigueur. Danger de choc électrique

• Dans ce cas, le fonctionnement avec un disjoncteur

différentiel de sécurité offre une protection personnelle

supplémentaire (30 mA). Sur les modèles sans fiche,

l'installation doit être effectuée par du personnel qualifié.

N’utilisez que des rallonges électriques autorisées et

avec une section appropriée.

•

La haute pression peut faire rebondir les pièces;

PORTEZ toujours des vêtements et des lunettes de

protection. danger de lesions

• Avant d’exécuter toute opération sur l’appareil,

DÉBRA NCHEZ -le l’appareil. Danger de démarrage

accidentel

• A cause du recul, saisissez bien le pistolet lorsque

vous tirez le levier. Danger de lesions

Page 19

FRANÇAIS

• Respectez les règles de la société des eaux

potables de la région. Suivant EN 12729 (BA), il est

possible de connecter l’appareil directement au réseau

d’eau potable uniquement si la tuyauterie d’alimentation

comporte un dispositif anti-reflux avec vidange. Danger

de pollution

• L’entretien et/ou la réparation des composants

électriques DOIVENT/do it être effectué(s) par du

personnel qualifié. Danger d’accident

• RE LÂCHEZ la pression résiduelle avant de

déconnecter le tube de l’appareil. Danger de lesions

• CONTR ÔLEZ avant toute utilisation et de temps à

autre le serrage des vis et le bon état des composants

de l’appareil. Vérifiez s’il y a des pièces cassées ou

usagées. Danger d’accident

• N’utilisez que des détergents

compatibles avec les matériaux de revêtement du

flexible haute pression/câble électrique. Danger

d’explosion et de choc électrique

• Les personnes ou les animaux DOIVENT

ÊTRE à la distance minimale de 15 m. Danger de

lesions

Informations générales (fig.1)

Utilisation du manuel

Ce manuel fait partie intégrante de l’appareil, le conserver

pour des consultations futures. Le lire attentivement avant

l’installation/ utilisation. En cas de cessions, remettre le

manuel au nouveau propriétaire.

Livraison

L’appareil est livré partiellement démonté, dans un

emballage en carton. La composition de la fourniture est

représentée sur la fig.1

Documentation fournie

• A1 Manuel d’utilisation et d’entretien

• A2 Instructions pour la sécurité

• A3 Déclaration de conformité

• A4 Règles de garantie

Élimination des emballages

Les matériaux de l’emballage ne sont pas polluants pour

l’environnement, toutefois ils doivent être recyclés ou

éliminés conformément aux normes en vigueur dans le pays

d’utilisation.

Signalisations d’information

Respecter les signalisations des plaques appliquées sur

l’appareil.

Vérifier qu’elles soient toujours présentes et lisibles ; dans le

cas contraire, les remplacer en les appliquant dans la

position d’origine.

Plaque E1 – Elle indique l’obligation de ne pas éliminer

l’appareil comme déchet urbain ; il peut être redonné au

distributeur au moment de l’achat d’un appareil neuf. Les

parties électriques et électroniques de l’appareil ne doivent

pas être réutilisées pour usages impropres car elles

contiennent des substances dangereuses pour la santé.

Symboles

Icône E2 – Elle indique que l’appareil est conçu pour

un usage professionnel, c’est-à-dire pour les personnes qui

ont de l’expérience, une connaissance technique, normative,

législative et qui sont en mesure d’exécuter les opérations

nécessaires à l’utilisation et l’entretien de l’appareil.

Icône E3 – Elle indique que l’appareil est conçu pour

une usage non professionnel (domestique).

Informations techniques (fig.1)

Utilisation prévue

Cet appareil a été conçu pour une utilisation individuelle

pour le lavage de véhicules, voitures, navires, façades, etc.,

pour enlever la saleté tenace avec de l’eau propre et des

détergents chimiques biodégradables. Le lavage de moteurs

de véhicules n’est consenti que si l’eau sale est évacuée

selon les normes en vigueur.

• Température de l’eau en entrée : voir plaquette des

caractéristiques techniques sur l’appareil.

• Pression de l’eau en entrée : 0,1MPa mini. - 1MPa maxi.

• Température ambiante de fonctionnement : supérieure à

0°C. L’appareil est conforme à la norme EN

60335-2-79/A1.

Opérateur

Pour identifier l’opérateur chargé de l’utilisation de l’appareil

(professionnel ou non professionnel), voir l’icône

représentée sur la couverture.

Utilisations non consenties

• L’utilisation est interdite aux personnes inexpérimentées

ou qui n’ont pas lu et compris les instructions données

dans ce manuel.

19

Page 20

FRANÇAIS

• Il est interdit d’alimenter l’appareil avec des liquides

inflammables, explosifs et toxiques.

• Il est interdit de faire fonctionner l’appareil en

atmosphère potentiellement inflammable ou explosive.

• Il est interdit d’utiliser des accessoires qui ne sont pas

d’origine et non spécifiques pour le modèle.

• Il est interdit de modifier l’appareil ; toute modification

entraîne l’invalidation de la déclaration de conformité et

exonère le fabricant de toute responsabilité civile et

pénale.

Parties principales

• B1 Tête réglable

• B2 Lance

• B3 Pistolet avec sécurité

• B4 Câble électrique avec fiche

• B5 Tuyau haute pression

• B6 Réservoir à détergent (s’il est prévu)

Accessoires (s’ils sont prévus dans la fourniture -

voir fig.1)

• C1 Outil de nettoyage de la tête

• C2 Kit buse rotative

• C3 Manche

• C4 Brosse

• C5 Enrouleur de flexible

Dispositifs de sécurité

Attention – danger !

Ne pas modifier le tarage de la soupape de sûreté.

• Soupape de sûreté et/ou de limitation de pression. La

soupape de sûreté est aussi une soupape de limitation

de pression. Quand le pistolet se ferme, la soupape

s’ouvre et l’eau recircule par l’aspiration de la pompe ou

est évacuée au sol.

• Soupape thermostatique (D1 si prévue) Si la

température de l’eau dépasse la température prévue par

le fabricant, la soupape thermostatique évacue l’eau

chaude et aspire une quantité d’eau froide égale à l’eau

évacuée jusqu’au rétablissement de la température

correcte.

• Dispositif de sécurité (D) : il évite le jet d’eau accidentel.

Installation (fig.2)

Montage

Attention – danger !

Toutes les opérations d’installation et de montage

doivent être effectuées avec l’appareil débranché.

Pour la séquence de montage voir fig.2.

Montage de la buse rotative

(Pour les modèles qui en sont équipés).

Le kit buse rotative permet une plus grande puissance de

lavage. L'utilisation de la buse rotative peut coïncider avec

une baisse de la pression égale à 25% par rapport à la

pression obtenue avec la tête réglable. Son utilisation

permet une plus grande puissance de lavage grâce à l'effet

rotatif transmis au jet d’eau.

Branchement électrique

Attention – danger !

Vérifier que le voltage et la fréquence (V-Hz) du réseau

électrique correspondent à ceux reportés sur la plaque

d’identification (fig.2). Brancher l’appareil au réseau

électrique ayant une mise à la terre efficace et une

protection différentielle (30 mA) qui interrompt l’alimentation

électrique en cas de court-circuit.

Utilisation des câbles de rallonge Les câbles doivent avoir

un degré de protection « I PX5 ». La section des câbles de

rallonge doit être proportionnée à leur longueur. Plus ils sont

longs et plus la section doit être grande. Voir tableau I.

Raccordement au réseau d’eau

Attention – danger !

Aspirer uniquement de l’eau filtrée ou propre. Le robinet de

prélèvement de l’eau doit garantir une arrivée égale au débit

de la pompe.

Mettre l’appareil le plus près possible du réseau d’eau.

Raccords

• Sortie de l’eau (OUTLET )

• Entrée de l’eau avec filtre (INLET )

20

Page 21

FRANÇAIS

Raccordement au réseau d’alimentation en eau public

L’appareil ne peut être raccordé directement au réseau

public de distribution de l’eau potable que si, dans la

tuyauterie d’alimentation, se trouve un dispositif anti-reflux

avec vidange conforme aux normes en vigueur. S’assurer

que le tuyau ait un diamètre d’au moins 13 mm et qu’il soit

renforcé.

Réglages (fig.3)

Réglage de la tête (si prévu)

• Agir sur la tête (E) pour régler le jet d’eau

Réglage du détergent (si prévu)

• Agir sur le régulateur (F) pour doser la quantité de

détergent nécessaire.

Réglage de la distribution de détergent

Mettre la tête réglable (E) en position « » pour distribuer le

détergent à la pression correcte (si prévu).

Réglage de la pression (si prévu)

• Agir sur le régulateur (G) pour changer la pression de

travail. La pression est indiquée par le manomètre (si

présent).

Utilisation (fig.4)

Commandes

• Dispositif de mise en marche (H).

Mettre le dispositif de mise en marche en pos. (ON/1) pour :

a) Faire démarrer le moteur (dans les modèles sans

dispositif TSS )

b) Préparer le moteur pour son fonctionnement (dans les

modèles avec dispositif TSS ).

• Si le dispositif de mise en marche est doté de voyant,

celui-ci doit s’allumer.

• Si les positions « low/high » sont présentes, elles

indiquent :

• Low : nettoyage à basse pression

• High : nettoyage à haute pression

• Mettre le dispositif de mise en marche en pos. (OFF/0)

pour arrêter le fonctionnement de l’appareil.

• Si le dispositif de mise en marche est doté de voyant,

celui-ci doit s’éteindre.

• Levier de commande du jet d’eau (I).

Attention – danger !

L’appareil doit fonctionner posé sur un plan sûr et stable,

positionné comme indiqué sur la fig.4.

Mise en marche

1) Ouvrir complètement le robinet d’arrivée d’eau ;

2) Débloquer la sécurité (D) ;

3) Tenir le pistolet ouvert pendant quelques secondes et

mettre en marche l’appareil avec le dispositif de mise en

marche (ON/1).

Attention – danger !

Avant de mettre en marche l’appareil, vérifier s’il est bien

alimenté en eau ; l’utilisation à sec provoque

l’endommagement de l’appareil. Pendant le fonctionnement,

ne pas couvrir les grilles de ventilation.

Modèles TSS - Dans les modèles TSS , avec interruption

automatique du refoulement :

• en fermant le pistolet, la pression dynamique éteint

automatiquement le moteur électrique (voir fig. 4) ;

• en ouvrant le pistolet, la chute de pression fait partir

automatiquement le moteur et la pression se reforme

avec un tout petit retard ;

• pour un fonctionnement correct du TSS , les opérations

de fermeture et d’ouverture du pistolet ne doivent pas

être effectuées dans un intervalle de temps inférieur à

4÷5 secondes.

• À la première utilisation, dans les modèles triphasés

pour usage professionnel, mettre en marche un bref

instant pour vérifier le sens de rotation du moteur. Si la

rotation du ventilateur du moteur est antihoraire, invertir

deux des trois phases (L1, L2, L3) dans la fiche

électrique.

• Évitez le fonctionnement à sec pour ne pas

endommager l’appareil et pendant son fonctionnement

ne pas interrompre le jet d’eau pour plus de 10 minutes

(pour les modèles sans dispositif TSS).

Arrêt

1) Mettre le dispositif de mise en marche en pos. (OFF/0).

2) Ouvrir le pistolet et décharger la pression à l’intérieur

des tuyauteries.

3) Mettre la sécurité (D).

21

Page 22

FRANÇAIS

Remise en marche

1) Débloquer la sécurité (D).

2) Ouvrir le pistolet et laisser sortir l’air prèsent à l’intérieur

des tuyauteries..

3) Mettre le dispositif de mise en marche en pos. (ON/1).

Mise hors service

1) Éteindre l’appareil (OFF/0).

2) Enlever la fiche de la prise.

3) Fermer le robinet de l’eau.

4) Décharger la pression résiduelle du pistolet jusqu’à ce

que l’eau soit complètement sortie de la tête.

5) Videz et nettoyez le réservoir à détergent à la fin du

travail. Pour le nettoyage du réservoir, utilisez de l’eau

propre au lieu du détergent.

6) Remettre la sécurité (D) du pistolet.

Utilisation du détergent

Le détergent doit être pulvérisé avec la tête réglable en

position «-» (si prévu).

L'utilisation d’un tuyau haute pression plus long que celui

fourni avec l’appareil ou l’utilisation d’une rallonge de tuyau

supplémentaire peut diminuer ou arrêter complètement

l'aspiration du détergent.

Remplir le réservoir de détergent à haute biodégrabilité.

Conseils pour un bon lavage

Pulvériser la surface sèche à nettoyer de détergent mélangé

à l’eau pour dissoudre la saleté.

Sur les surfaces verticales, partir du bas vers le haut.

Laisser agir pendant

1÷2 minutes, sans laisser sécher la surface. Pulvériser un

jet à haute pression à une distance de plus de 30 cm, en

commençant par le bas. Éviter que l’eau de rinçage coule

sur les surfaces non lavées.

Dans certains cas, pour enlever la saleté, l’action

mécanique des brosses est nécessaire.

La pression élevée n’est pas toujours la meilleure solution

pour un bon lavage, car elle peut endommager certaines

surfaces. Il est conseillé d’éviter l’utilisation du jet fin de la

tête réglable et de la buse rotative sur des parties délicates

et peintes et sur des composants sous pression (ex.

pneumatiques, valves de gonflage..).

Un bon lavage dépend, en mesure égale, de la pression et

du volume d’eau.

Entretien (fig.5)

Tous les entretiens dont on ne parle pas dans ce chapitre

doivent être effectués auprès d’un revendeur agréé avec

service après-vente.

Attention – danger !

Avant toute intervention sur l’appareil, le débrancher.

Nettoyage de la tête

1) Démonter la lance du pistolet.

2) Enlever la saleté du trou de la tête avec l’outil (C1).

Nettoyage du filtre

Vérifiez le filtre d’aspiration (L) et le filtre du détergent (si

prévu) avant chaque utilisation et, si nécessaire,

nettoyez-les comme indiqué.

Déblocage du moteur (si prévu)

En cas d’arrêts prolongés, des sédiments calcaires peuvent

provoquer le blocage du moteur. Pour débloquer le moteur,

tourner l’arbre moteur avec l’outil (M).

Remisage d’hiver

Avant ce remisage, faire fonctionner l’appareil avec du

liquide antigel non agressif et non toxique.

Rangez l' appareil dans un endroit sec et à l’abri du gel.

Remplacement des prises secteur (RU et

Irlande uniquement)

Si une nouvelle prise secteur doit être installée :

• Mettez au rebut la vieille prise.

• Branchez le fil brun dans la borne de la nouvelle prise.

• Branchez le fil bleu à la borne neutre.

Attention ! Aucune connexion ne doit être faite à la borne

de terre. Suivez les instructions de montage fournies avec

les prises de bonne qualité. Fusibles recommandés : 13 A.

22

Page 23

FRANÇAIS

Anomalies de fonctionnement

Anomalies Causes probables Solutions

Buse usée Remplacer la buse

Filtre de l’eau sale Nettoyer le filtre (fig.5)

Alimentation en eau insuffisante Ouvrir complètement le robinet

La pompe n’atteint pas la Aspiration d’air Contrôler les raccords

pression prescrite Air dans la pompe Éteindre l’appareil et actionner le pistolet jusqu’à la sortie

d’un jet continu. Rallumer.

Mauvais réglage de la tête Tourner la tête (E) (+) (fig.3)

Intervention de la soupape thermostatique Attendre le rétablissement de la température correcte de l’eau

Aspiration d’eau du réservoir extérieur Raccorder l’appareil au réseau d’alimentation en eau

La pompe a des sautes de Température de l’eau en entrée trop élevée Baisser la température

pression Buse obstruée Nettoyer la buse (fig.5)

Filtre d’aspiration (L) sale Nettoyer le filtre (L) (fig.5)

Tension de réseau insuffisante Contrôler que la tension de réseau corresponde à celle de

la plaque (fig.2)

Le moteur « ronfle » mais ne Perte de tension causée par la rallonge Vérifier les caractéristiques de la rallonge

démarre pas Arrêt prolongé de l’appareil Contacter le Centre d’assistance technique agréé

Problèmes au dispositif TSS Contacter le Centre d’assistance technique agréé

Manque de tension Vérifier la présence de tension dans le réseau et contrôler

si la fiche est bien introduite dans la prise (*)

Le moteur électrique ne démarre Problèmes au dispositif TSS Contacter le Centre d’assistance technique agréé

pas Appareil qui n’est plus utilisé Par le trou arrière, débloquer le moteur avec l’outil (L)

depuis longtemps (pour les modèles qui le prévoient) (fig.5)

Joints d’étanchéité usés Remplacer les joints auprès d’un Centre d’assistance

Fuites d’eau technique agréé

Intervention soupape de sûreté à Contacter le Centre d’assistance technique agréé

décharge libre

Bruit Température de l’eau trop élevée Baisser la température (voir données techniques)

Fuites d’huile Joints d’étanchéité usés Contacter le Centre d’assistance technique agréé

Seulement pour TSS : l’appareil Buse obstruée Nettoyer la buse (fig.5)

se met en marche bien que le

pistolet soit fermé Mauvaise étanchéité du système haute

pression ou dans le circuit de la pompe Contacter le Centre d’assistance technique agréé

Seulement pour TSS : en tirant le

levier du pistolet, l’eau ne sort Buse obstruée Nettoyer la buse (fig.5)

pas (avec tuyau d’alimentation

introduit)

Position de la tête réglable en haute pression Mettre la tête en position «-» (fig.3)

Détergent trop dense Diluer avec de l’eau

Le détergent n’est pas aspiré Utilisation de rallonges tuyau haute pression Remettre le tuyau d’origine

Rincer avec de l’eau propre et éliminer les étranglements

Circuit du détergent encrassé ou étranglé éventuels. Si le problème persiste consulter un Centre

d’assistance technique agréé

(*) Si, au cours du fonctionnement, le moteur s’arrête et ne repart pas, attendre 2-3 minutes avant de tenter de nouveau la mise en marche

(Intervention de la protection thermique). Si l’inconvénient se répète plus d’une fois, contacter le Centre d’assistance technique agréé.

23

Page 24

FRANÇAIS

Déclaration de conformité

Nous déclarons, en assumant la pleine responsabilité de cette déclaration, que le produit est conforme aux

2006/42/CE, 2006/95/CE, 2002/95/CE, 2002/96/CE, 2004/108/CE, 2000/14/CE

Pour plus de renseignements, veuillez contacter Black & Decker à l’adresse suivante ou reportez-vous au dos du manuel. Le

soussigné est responsable des données de la fiche technique et fait cette déclaration au nom de Black & Decker

Kevin Hewitt

Vice-President Global Engineering

Black & Decker Europe, 210 Bath Road, Slough,

Berkshire, SL1 3YD

Royaume-Uni

04/02/2013

normes suivantes et aux documents correspondants

EN 60335-1 - EN 60335-2-79; EN 55014-1; EN 55014-2;

EN 61000-3-2;EN 61000-3-3; EN 61000-3-11; EN 60704-1

Selon les prescriptions des directives :

Données Techniques

Unité PW1400TDK

Débit L/min 6,2

Pression MPa 8

Pression maximale MPa 11

Puissance kW 1,4

T° Alimentation °C 50

Pression d’alimentation maximale MPa 1

Force répulsive du pistolet à la pression maximale N 9,3

Isolation du moteur - Classe F

Protection du moteur - IPX5

Tension V/Hz 230/50

Niveau de pression sonore (K=3 dB(A)) :

LPA (EN 60704-1) dB (A) 75,8

LWA (EN 60704-1) dB (A) 84

Vibrations de l’appareil (K=1.5M/s2 ) M/s2 2,74

Poids kg 6,4

24

Page 25

FRANÇAIS

Protection de l'environnement

Collecte séparée. Ce produit ne doit pas être jeté

avec les déchets domestiques normaux.

Si vous décidez de remplacer ce produit Black & Decker, ou

si vous n'en avez plus l'utilité, ne le jetez pas avec vos

déchets domestiques Rendez-le disponible pour une collecte

séparée.

• Black & De

collecter et de recycler les produits Black & Decker

lorsqu'ils ont atteint la fin de leur cycle de vie. Pour

pouvoir profiter de ce service, veuillez retourner votre

produit à un réparateur agréé qui se chargera de le

collecter pour nous.

• Pour connaître l'adresse du réparateur agréé le plus

proche de chez vous, contactez le bureau Black &

Decker à l'adresse indiquée dans ce manuel. Vous

pourrez aussi trouvez un liste des réparateurs agréés de

Black & Decker et de plus amples détails sur notre

service après-vente sur le site Internet à l'adresse

suivante : www

cker fournit un dispositif permettant de

.2helpU.com

Garantie

Black & Decker vous assure la qualité de ses produits et vous

offre une garantie très étendue.

Ce certificat de garantie est un document supplémentaire et

ne peut en aucun cas se substituer à vos droits légaux.

Si un produit Black & Decker s'avère défectueux en raison de

matériaux en mauvais état, d'une erreur humaine, ou d'un

manque de conformité dans les 24 mois suivant la date

d'achat, Black & Decker garantit le remplacement des pièces

défectueuses, la réparation des produits usés ou cassés ou

remplace ces produits à la convenance du client, sauf dans

les circonstances suivantes :

•

Le produit a été utilisé dans un but commercial,

professionnel, ou a été loué.

• Le produit a été mal utilisé ou avec négligence.

• Le produit a subi des dommages à cause de corps

étrangers, de substances ou d'accidents.

• Des réparations on

faisant pas partie du servic

Decker.

Pour avoir recours à la garantie, il est nécessaire de fournir

une preuve d'achat au vendeur ou à un réparateur agréé.

t été tentées par des techniciens ne

e technique de Black &

Pour connaître l'adresse du réparateur agréé le plus proche

de chez vous, contactez le bureau Black & Decker à

l'adresse indiquée dans ce manuel.

Vous pourrez aussi trouver une liste de réparateurs agréés

de Black & Decker et de plus amples détails sur notre service

après-vente sur le site Internet à l'adresse suivante :

www.2helpU.com

25

Page 26

ARABIC

¿Éª°†dG

.kGõ«‡ kÉfɪ°V Ωó≤Jh É¡JÉéàæe IOƒéH ôµjO ófBG ∑ÓH ≥ãJ

∫GƒMC’G øe ∫ÉM …CÉH πîj ’h áaÉ°VE’ÉH Gòg ¿Éª°†dG ¿É«H ¿ƒµjh

.á«fƒfÉ≤dG ¥ƒ≤◊ÉH

áYÉæ°üdGh OGƒŸG ܃«Y ÖÑ°ùH kÉÑ«©e ôµjO ófBG ∑ÓH èàæe íÑ°UCG GPEG

ïjQÉJ øe kGô¡°T 24 ¿ƒ°†Z ‘ ôµjO ófBG ∑ÓH øª°†J ,á≤HÉ£ŸG ΩóYh

»∏СdG IЙYGфe ™e дЙйажŸG мУ°UEGh бС«©ŸG AGхLC’G ∫GуСа°SG AGцыdG

AУª©dG Й°VQ шe уcCЙа∏d дЙйажŸG √тg ∫GуСа°SG hCG …OЙ©dG ΩGуоа°S’ЙH

:⁄ Ée

.ÒLCÉà∏d hCG á«æ¡e hCG ájQÉŒ ¢VGôZC’ èàæŸG ΩGóîà°SG ” •

.èàæŸG ΩGóîà°SG IAÉ°SEG hCG ∫ɪgEG •

.çOGƒ◊G hCG á«HôZ ¢VGôZCG hCG OGƒe ÖÑ°ùH ∞∏àd èàæŸG ¢Vô©J •

øjôNB’G ¢UÉî°TC’G πÑb øe ìÓ°UE’G äÉ«∏ªY AGôLEG ádhÉfi •

∑ÓÑd ™HÉàdG áeóÿG ≥jôa hCG º¡H ìöüŸG ìÓ°UE’G AÓch ±ÓîH

.ôµjO ófBG

™«ÑdG π«ch hCG ™FÉÑ∏d AGöûdG äÉÑKEG Ëó≤J Öéj ,¿Éª°†dÉH áÑdÉ£ª∏d

Öàµe á©LGôà óªà©e ìÓ°UEG π«ch ÜôbCG ¿Éµe áaô©e ∂æµÁh .óªà©ŸG

.π«dódG ‘ ¬«dEG QÉ°ûŸG ¿Gƒæ©dG ‘ »∏ëŸG ôµjO ófBG ∑ÓH

ôµjO ófBG ∑ÓH iód øjóªà©ŸG ìÓ°UE’G AÓcƒH áªFÉb ôaƒàJ ɪc

:ÊhεdE’G ™bƒŸG ≈∏Y ∫É°üJ’Gh ™«ÑdG ó©H Ée äÉeóN äÉfÉ«Hh

.www.2helpU.com

áÄ«ÑdG ájɪM

™e èàæŸG Gòg øe ¢ü∏îàdG ΩóY Ωõ∏j .π°üØæŸG ™ª÷G

.ájOÉ©dG á«dõæŸG áeɪ≤dG

hCG ,∂H ¢UÉÿG ôµjO ófBG ∑ÓH èàæe ∫GóÑà°SG ΩÉjC’G øe Ωƒj ‘ Ωõd GPEG

πH ,iôNC’G á«dõæŸG áeɪ≤dG ™e ¬æe ¢ü∏îàJ Óa ,¬eóîà°ùJ ó©J ⁄ GPEG

.π°üØæŸG ™ªé∏d èàæŸG Gòg áMÉJEG øe ócCÉJ

уfBG ∑УH дЙйажe фjhуJ IOЙYE’ ≥aфe фµjO уfBG ∑УH бcцT фaƒJ •

.πª©∏d É¡à«MÓ°U ΩóYh ÉgôªY ájÉ¡f ¤EG É¡dƒ°Uh Oôéà ôµjO

≈Lôj ,áeóÿG √òg øe IOÉØà°SÓd .ÉkfÉ› áeóÿG √òg Ëó≤J ºàjh

√QhóH ¤ƒàj ±ƒ°S …òdGh óªà©e áfÉ«°U π«ch …CG ¤EG èàæŸG IOÉYEG

.ЙжY бHЙ«f дЙйажŸG ™ªL

∫ÓN øe óªà©e áfÉ«°U π«ch ÜôbCG ™bƒe ≈∏Y ±ô©àdG ∂æµÁ •

‘ í°VƒŸG ¿Gƒæ©dG ‘ »∏ëŸG ôµjO ófBG ∑ÓH Öàµe ≈∏Y ∫É°üJ’G

øjóªà©ŸG áfÉ«°üdG AÓcƒH áªFÉb óLƒJ ,∂dP øe k’óHh .π«dódG Gòg

ó©H Ée äÉeóÿ á∏eɵdG π«°UÉØàdGh ôµjO ófBG ∑ÓH ácöûd Ú©HÉàdG

™bƒŸG ≈∏Y âfÎfE’G ≈∏Y ÉæH á°UÉÿG ∫É°üJ’G πFÉ°Shh ™«ÑdG

.www.2helpU.com :ÊhεdE’G

26

Page 27

ARABIC

≥```````aGƒ``````à``````dG QGô```````bEG

hCG ÒjÉ©ŸG ™e ≥aGƒàj èàæŸG Gòg ¿CÉH á°UÉÿG Éæà«dhDƒ°ùe ≈∏Y ô≤of

:á«dÉàdG á«°SÉ«≤dG ≥FÉKƒdG

EN 55014-2h EN 55014-1h EN 60335-1 - EN 60335-2-79

EN 60704-1h EN 61000-3-11h EN 61000-3-3h EN 61000-3-2h

:äÉ¡«LƒàdG ÖLƒÃ

CE/2000/14h CE/2004/108h CE/2002/96h CE/2002/95h CE/2006/95h CE/2006/42

™bƒŸG πªëàjh .π«dódG ájÉ¡f ‘ OQGƒdG hCG ‹ÉàdG ¿Gƒæ©dG ≈∏Y ôµjO ófBG ∑ÓÑH ∫É°üJ’G ≈Lôj ,äÉeƒ∏©ŸG øe ójõª∏d

.ôµjO ófBG ∑ÓH øY áHÉ«f QGôbE’G Gòg Ëó≤Jh »æØdG ∞∏ŸG ™ªL øY á«dhDƒ°ùŸG √ÉfOCG

á«ŸÉ©dG á°Sóæ¡dG ¢ù«FQ ÖFÉf

ƒ∏°S ,OhQ çÉH 210 ,ÉHQhCG ôµjO ófBG ∑ÓH

SL1 3YD ,ôjÉ°ûcÒH

âjƒ«g øØ«c

IóëàŸG áµ∏ªŸG

04/02/2013

á«æØdG äÉfÉ«ÑdG

PW1400TDK IóMƒdG

6.2 á≤«bO/Îd êÉàfE’G

8 ∫ɵ°SÉH Éé«e §¨°†dG

11 ∫ɵ°SÉH Éé«e §¨°V ≈°übCG

1.4 äGh ƒ∏«c ábÉ£dG

50 ¢Sƒjõ∏«°S ∫ÉNOE’G IQGôM áLQO

1 ∫ɵ°SÉH Éé«e ∫ÉNOEÓd §¨°V ≈°übCG

9.3 øJƒ«f §¨°V ≈°übCG óæY ¢TôdG ¢Só°ùŸ ôaÉæàdG Iƒb

áÄa - ∑ôëŸG ∫õY

IPX5 - ∑ôëŸG ájɪM

230 / 50 õJÒg/âdƒa »FÉHô¡µdG ó¡÷G

:(A) πÑ«°ùjO 3 = ºé◊G πeÉY) 䃰üdG iƒà°ùe

75.8 (A) πÑ«°ùjO LPA (EN 60704-1)

84 (A) πÑ«°ùjO LWA (EN 60704-1)

2.74

6.4 ºéc ¿RƒdG

2

á«fÉK/Ω (2á«fÉK/Ω 1.5 =ºé◊G πeÉY) IóMƒdG RGõàgG

27

Page 28

ARABIC

É¡MÓ°UEGh AÉ£NC’G ±É°ûµà°SG

π◊G á∏ªàëŸG ÜÉÑ°SC’G á∏µ°ûŸG

ágƒØdG ∫GóÑà°SG ágƒØdG ∞∏J

(5 πµ°T) í°TôŸG ∞«¶æJ √É«ŸG í°Tôe OGó°ùfG

ΩÉJ πµ°ûH √É«ŸG Qó°üe QƒÑæ°U íàa √É«ŸG Qó°üe §¨°V ¢VÉØîfG

ΩƒWôÿG äÉÑ«côJ ΩɵMEG øe ≥≤– ΩɶædG πNGO AGƒ¡dG ÜöùJ ¤EG áî°†ŸG ∫ƒ°Uh ΩóY

¢Só°ùe π¨°ûe ôjô–h ≈∏Y §¨°†dG ‘ QGôªà°S’Gh RÉ¡÷G ¥ÓZEG .܃∏£ŸG πª©dG §¨°V

𫨰ûJ IOÉYEG ºK .åHÉK ≥aóàH √É«ŸG êôîJ ≈àM ¢TôdG áî°†ŸG ‘ AGƒg OƒLh

¢ù«FôdG √É«ŸG Qó°üà RÉ¡÷G π«°UƒJ »LQÉN ¿GõN øe √É«ŸG ∫ÉNOEG ΩGóîà°S’G AÉæKCG §¨°†dG ¢VÉØîfG

πKɇ ¢ù«FôdG ábÉ£dG Qó°üe §ÿ »FÉHô¡µdG ó¡÷G ¿CG øe ócCÉàdG ±Éc ÒZ ábÉW Qó°üe

.(2 πµ°T) ‘ áæ«ÑŸG áMƒ∏dG ≈∏Y ÚÑŸG ó¡é∏d

π«°UƒàdG πHÉc ¢üFÉ°üN øe ócCÉàdG π«°UƒJ πHÉc ΩGóîà°SG ÖÑ°ùH »FÉHô¡µdG ó¡÷G ó≤a ¬æµdh kÉJƒ°U ∑ôëŸG QGó°UEG

óªà©e áeóN õcôe ÜôbCÉH ∫É°üJ’G á∏jƒW IóŸ RÉ¡÷G ΩGóîà°SG ΩóY 𫨰ûàdG CGóÑj ’

óªà©e áeóN õcôe ÜôbCÉH ∫É°üJ’G TSS RÉ¡éH á°UÉN πcÉ°ûe

QÉ«àdG òNCÉe ‘ ¢ùHÉ≤dG ™°Vh ΩɵMEG øe ócCÉàdG á«FÉHô¡c ábÉW OƒLh ΩóY

(*) ¢ù«FôdG »FÉHô¡µdG Qó°üe OƒLhh

óªà©e áeóN õcôe ÜôbCÉH ∫É°üJ’G TSS RÉ¡éH á°UÉN πcÉ°ûe 𫨰ûàdG AóH ‘ ∑ôëŸG π°ûa

≈∏Y IOƒLƒŸG áëàØdG øe ∑ôëŸG ∞«¶æàd (L) IGOC’G ΩGóîà°SG á∏jƒW IóŸ RÉ¡÷G ΩGóîà°SG ΩóY

(5 πµ°T) (á«°UÉÿG √ò¡H IOhõŸG äGRGô£dG ‘) RÉ¡÷G ô¡X

óªà©e áeóN õcôe ÜôbCG øe ÜöùàdG ™fGƒe ∫GóÑà°SG ÜöùàdG ™fGƒe ∞∏J √É«ŸG ÜöùJ

óªà©e áeóN õcôe ÜôbCÉH ∫É°üJ’G √É«ª∏d ¬ØjöüJh ¿ÉeC’G Ωɪ°U π£©J

(á«æØdG äÉfÉ«ÑdG ™LGQ) IQGô◊G áLQO ¢†«ØîJ kGóL √É«ŸG IQGôM áLQO ´ÉØJQG RÉ¡÷G 䃰U ´ÉØJQG

óªà©e áeóN õcôe ÜôbCÉH ∫É°üJ’G ÜöùàdG ™fGƒe ∞∏J âjõdG ÜöùJ

óªà©e áeóN õcôe ÜôbCÉH ∫É°üJ’G ᫵«dhQó«¡dG IôFGódG hCG ™ØJôŸG §¨°†dG Ωɶf ¢TôdG ¢Só°ùe π¨°ûe

(5 πµ°T) "-" OGóYE’G ≈∏Y ágƒØdG §Ñ°VG ™ØJôe §¨°V OGóYE’G

äôªà°SG GPEGh .≥FGƒY ájCG ádGREGh áØ«¶f √É«e ™aO ÈY ∞«¶æàdG ∞¶æŸG IôFGO ‘ ≥FGƒY hCG äÉÑ°SôJ OƒLh

óªà©e áeóN õcôe ÜôbCÉH ∫É°üJ’G ≈LÒa ,á∏µ°ûŸG ∂∏J

AGôLEG π£©J) iôNCG Iôe 𫨰ûàdG AGôLEG IOÉYEG πÑb ≥FÉbO 3 ¤EG 2 øe Qɶàf’G ∂«∏Y ,𫨰ûàdG IÎa AÉæKCG 𫨰ûàdG IOÉYEÉH º≤j ⁄h ∑ôëŸG CGóH GPEG (*)

.iôNCG Iôe RÉ¡÷G

áLQO IOÉ©à°SG ≈àM Qɶàf’G º¶æŸG Ωɪ°üdG ábÉYEG

áë«ë°üdG √É«ŸG IQGôM

IQGô◊G áLQO ¢†«ØîJ kGóL áæNÉ°S √É«e ∫ÉNOEG

(5 πµ°T) ágƒØdG ∞«¶æJ ágƒØdG OGó°ùfG

(5 πµ°T) (L) í°TôŸG ∞«¶æJ (L) ∫ÉNOE’G í°Tôe ñÉ°ùJG

(5 πµ°T) ágƒØdG ∞«¶æJ ágƒØdG OGó°ùfG AóH :§≤a TSS äGQGó°UEÉH ¢UÉN

ôjô– ∫ÉM ‘ ≈àM ∑ôëŸG 𫨰ûJ

√É«ª∏d á©fÉe â°ù«d áî°†ª∏d

ΩóY :§≤a TSS äGQGó°UEÉH ¢UÉN

(5 πµ°T) ágƒØdG ∞«¶æJ ágƒØdG OGó°ùfG π¨°ûe ≈∏Y §¨°†dG óæY √É«ŸG ∫ƒ°Uh

¢TôdG ¢Só°ùe

(Qó°üŸG ΩƒWôN π«°UƒJ ™e)

≈∏Y πjó©à∏d á∏HÉ≤dG ágƒØdG §Ñ°V

AÉŸÉH ∞¶æŸG ∞«ØîJ kGóL ∞«ãc ∞¶æŸG ∞¶æŸG Öë°S ΩóY

»∏°UC’G ΩƒWôÿG Ö«côJ ™ØJôe §¨°V ΩƒWôN á∏°Uh ΩGóîà°SG

.óªà©e áeóN õcôe ÜôbCÉH ∫É°üJ’G ≈Lôj ,Iôe øe ÌcCG á∏µ°ûŸG äQôµJ GPEGh .(óFGõdG πª◊G óæY ™£≤dG

28

Page 29

ARABIC

(5 πµ°T) áfÉ«°üdG

õcôe ‘ É¡FGôLEG »¨Ñæj π°üØdG √òg ‘ IQƒcòe ÒZ áfÉ«°U äÉ«∏ªY ájCG

.óªà©ŸG äÉ©«ÑŸGh áeóÿG

!ô£N – ôjò–

≈∏Y πªY …CG IöTÉÑe πÑb QÉ«àdG òNCÉe øe ¢ùHÉ≤dG π°üØH kɪFGO ºb

.RÉ¡÷G

ágƒØdG ∞«¶æJ

.ágƒØdG øe ´GQòdG π°üØH ºb 1

IGOC’G kÉeóîà°ùe ágƒØdG ΩƒWôN øe IQòb äÉÑ°SôJ ájCG ádGREÉH ºb 2

.(C1)

í°TôŸG ∞«¶æJ

πc πÑb (¬à«ÑãJ ∫ÉM ‘) ∞¶æŸG í°Tôeh (L) πNóŸG í°Tôe ¢üëØH ºb

.∂dòd áLÉ◊G óæY äɪ«∏©à∏d kÉ≤ah ɪ¡Ø«¶æàH ºbh ,ΩGóîà°SG

(á«°UÉÿG √ò¡H IOhõŸG äGRGô£dG ‘) ∑ôëŸG ∞«¶æJ

Ö°SGhôdG ÖÑ°ùàJ ¿CG øµÁ ,á∏jƒW äGÎØd RÉ¡÷G ΩGóîà°SG ΩóY ∫ÉM ‘

∂∏J øe ∑ôëŸG ∞«¶æJ øµÁ ≈àMh .∑ôëŸG 샪L ‘ á«°ù∏µdG

.(M) IGOC’G ΩGóîà°SÉH IOÉ«≤dG É°üY 𫨰ûJ ≈Lôj ,Ö°SGhôdG

»ª°SƒŸG øjõîàdG

πcBÉà∏d OÉ°†eh Ωƒª°ù∏d OÉ°†eh ó«ªéà∏d OÉ°†Ã RÉ¡÷G á÷É©e ≈Lôj

.ô£ŸG ÖÑ°ùH êQÉÿÉH ¬æjõîJ πÑb

.™«≤°üdG øe ¬àjɪ◊ ±ÉL ¿Éµe ‘ RÉ¡÷G ™°VƒH í°üæj

¢ù«FôdG ¢ùHÉ≤dG ∫GóÑà°SG

(§≤a GóædôjCGh IóëàŸG áµ∏ªŸÉH ¢UÉN)

:»∏j Éà ºb ójóL ¢ù«FQ ¢ùHÉb â«ÑãJ ¤EG áLÉ◊G óæY

.øeCG πµ°ûH Ëó≤dG ¢ùHÉ≤dG øe ¢ü∏îàdG •

.ójó÷G ¢ùHÉ≤dG ‘ π°UƒŸG ±ô£dG ™e »æÑdG ∂∏°ùdG π«°UƒJ •

.ójó÷G ¢ùHÉ≤dG ‘ ójÉëŸG ±ô£dG ™e ¥QRC’G ∂∏°ùdG π«°UƒJ •

äɪ«∏©J ´ÉÑJG ≈Lôjh .»°VQC’G ±ô£dÉH π«°UƒJ …CG AGôLEG ô¶ëj !ôjò–

ΩGóîà°SÉH í°üæj ɪc ,IOƒ÷G á«dÉY ¢ùHGƒ≤dG ™e á≤aôŸG â«ÑãàdG

.A 5 :AÉHô¡µdG ᪰UÉa

øjõîàdG

.(OFF/0) RÉ¡÷G 𫨰ûJ ±É≤jEÉH ºb 1

.QÉ«àdG òNCÉe øe ¢ùHÉ≤dG ádGREÉH ºb 2

.√É«ŸG Qó°üe QƒÑæ°U ¥ÓZEÉH ºb 3

ôNCG êôîJ ≈àM ¢TôdG ¢Só°ùe øe »≤ÑàŸG §¨°†dG ∞jöüàH ºb 4

.√É«ŸG øe Iô£b

‘ ¬∏°ù¨H ºbh ∞¶æŸG ¿GõN ‘ OƒLƒŸG πFÉ°ùdG ∞jöüàH ºb 5

á«∏ªY ‘ ∞«¶ædG AÉŸG ΩGóîà°SÉH í°üæjh .𫨰ûàdG á«∏ªY ájÉ¡f

.∞¶æŸG øe k’óH ¿GõÿG ∞«¶æJ

.(D) ¢TôdG ¢Só°ùe ¿ÉeCG ¢†Ñ≤e 𫨰ûàH ºb 6

∞¶æŸG ΩGóîà°SGh áÄÑ©àdG IOÉYEG

™°VƒdG ≈∏Y πjó©à∏d á∏HÉ≤dG ágƒØdG §Ñ°V Öéj ,∞¶æŸG ΩGóîà°SG óæY

(á«°UÉÿG √ò¡H IOhõŸG äGRGô£dG ‘) "-"

RÉ¡L ™e Ωó≤ŸG »∏°UC’G ΩƒWôÿG ÒZ ™ØJôe §¨°V ΩƒWôN ΩGóîà°SG

∞¶æŸG ∫ƒNO øe π∏≤j ób á«aÉ°VEG ΩƒWôN á∏°Uh ΩGóîà°SG hCG ∞«¶æàdG

.»∏c πµ°ûH ¬dƒNO ™æÁ hCG

.∑

Qnó

àdG oπr¡n°S ∞¶æà ¿GõÿG Aπà í°üæj

n

q

o

q

πãeC’G ∞«¶æàdG AGôLEG

í£°ùdG ≈∏Y AÉŸÉH êhõªŸG ∞¶æŸG ™°Vh ÈY ñÉ°ShC’G áHGPEÉH ºb

.±É÷G

.πØ°SC’ ≈∏YCG øe πª©dÉH í°üæj ,á«°SCGôdG í£°SC’G ™e πeÉ©àdG óæY

´óJ ’h ,á≤«bO 2 ¤EG 1 øe ìhGÎJ IóŸ í£°ùdG ≈∏Y πª©j ∞¶æŸG ∑ôJG

§¨°V ¢TÉ°TQ kÉeóîà°ùe πØ°SCG øe ∞«¶æàdG á«∏ªY CGóHGh ,∞éj í£°ùdG

π«°ù¨dG √É«e ´óJ ’h ,πbC’G ≈∏Y º°S 30 QGó≤Ã í£°ùdG øY ó©Ñj ™ØJôe

.ó©H É¡∏°ùZ ºàj ⁄ »àdG í£°SC’G ≈∏Y §bÉ°ùàJ

.ñÉ°ShC’G ádGRE’ ä’É◊G ¢†©H ‘ ∂dO IÉ°Tôa ΩGóîà°SG Ωõ∏j ób

∞«¶æJ èFÉàf ≈∏Y ∫ƒ°üë∏d πãeC’G π◊G ƒg kɪFGO ¢ù«d ™ØJôŸG §¨°†dG

ΩGóîà°SG ΩóY »¨Ñæjh .í£°SC’G ¢†©H ∞∏J ‘ ÖÑ°ùàj ób ¬fEG å«M ,Ió«L

AGõLC’G ™e IQGhódG ágƒØ∏d hCG πjó©à∏d á∏HÉ≤dG ágƒØ∏d ¢TQ OGóYEG π°†aCG

hCG äGQÉWE’G πãe) §¨°†∏d ¢Vô©àJ »àdG AGõLC’G hCG á°SÉ°ù◊G hCG á«∏£ŸG

.(ÉgÒZh íØædG äÉeɪ°U

᫪ch §¨°†dG ɪg ÚæKG Ú∏eÉY ≈∏Y ∫É©ØdG π«°ù¨dG á«∏ªY óªà©J

.…hÉ°ùàdÉH áeóîà°ùŸG √É«ŸG

29

Page 30

ARABIC

𫨰ûàdG AóH

.ΩÉJ πµ°ûH √É«ŸG Qó°üe QƒÑæ°U íàaG 1

.(D) ¿ÉeC’G ¢†Ñ≤e QôM 2

RÉ¡÷G 𫨰ûJ CGóHGh á∏«∏b ÊGƒãd ¢TôdG ¢Só°ùe π¨°ûe ≈∏Y §¨°VG 3

.(ON/1) 𫨰ûàdG AóH ìÉàØe kÉeóîà°ùe

!ô£N – ôjò–

,í«ë°U πµ°ûH √É«ŸG Qó°üe ΩƒWôN π«°UƒJ øe ócCÉJ ,𫨰ûàdG AóH πÑb

ΩÉ«≤dG ô¶ëjh ,¬Ø∏J ‘ ÖÑ°ùàj √É«e ¿hO RÉ¡÷G ΩGóîà°SG ¿EG å«M

.RÉ¡÷G ΩGóîà°SG AÉæKCG ájƒ¡àdG äɵѰT á«£¨àH

QÉ«àdG ™£b ΩɶæH IOhõŸG TSS äGRGô£dG ‘ – TSS äGRGô£dG

:»FÉ≤∏àdG

±É≤jEÉH »µ«eÉæjódG §¨°†dG Ωƒ≤j ,¢TôdG ¢Só°ùe π¨°ûe ôjô– óæY •

.(4 πµ°T ™LGQ) kÉ«FÉ≤∏J ∑ôëŸG

»FÉ≤∏àdG ¢VÉØîf’G ÖÑ°ùàj ,¢TôdG ¢Só°ùe π¨°ûe ≈∏Y §¨°†dG óæY •

‘ ≥HÉ°ùdG √Gƒà°ùŸ §¨°†dG Oƒ©j ºK ,∑ôëŸG 𫨰ûJ ‘ §¨°†dG ‘

.á¶◊ øe πbCG

ò«ØæJ ºàj ¿CG Öé«a ,í«ë°U πµ°ûH πª©j TSS Ωɶf ¿Éc GPEG •

4 øe πbCG á«æeR äGÎa ≈∏Y ¢TôdG ¢Só°ùe §¨°Vh ôjô– äÉ«∏ªY

.ÊGƒK 5 ¤EG

óæY ,»æ¡ŸG ΩGóîà°S’ÉH á°UÉÿG QGƒWC’G á«KÓK äGRGô£dG ‘ •

ócCÉà∏d IÒ°üb IÎØd RÉ¡÷G 𫨰ûJ CGóHG ,¤hC’G Iôª∏d ΩGóîà°S’G

áMhôe âfÉc GPEGh .í«ë°üdG √ÉŒ’G ‘ Qhój ∑ôëŸG ¿CG øe

áKÓãdG øe ÚæKG π«HóàH ºb ,áYÉ°ùdG ÜQÉ≤Y ¢ùµY QhóJ ∑ôëŸG

.»FÉHô¡µdG ¢ùHÉ≤dG ‘ (L1, L2, L3) ∑Ó°SCG

AÉæKCGh .√É«e ¿hO RÉ¡÷G 𫨰ûàH º≤J ’ ,RÉ¡÷G ∞∏J Öæéàd •

‘ ≥FÉbO 10 øY ójõJ IóŸ √É«ŸG ¢TÉ°TQ ±É≤jEÉH º≤J ’ ,𫨰ûàdG

(TSS RÉ¡L É¡H ôaGƒàj ’ »àdG äGRGô£dÉH ¢UÉN) IóMGƒdG IôŸG

RÉ¡÷G 𫨰ûJ ±É≤jEG

.(OFF/0) ™°VƒdG ≈∏Y 𫨰ûàdG AóH ìÉàØe §Ñ°VG 1

»≤ÑàŸG §¨°†dG ∞jöüàH ºbh ¢TôdG ¢Só°ùe π¨°ûe ≈∏Y §¨°VG 2

.º«WGôÿG πNGO

.(D) ¢TôdG ¢Só°ùe ¿ÉeCG ¢†Ñ≤e π¨°T 3

𫨰ûàdG IOÉYEG

.(D) ¿ÉeC’G ¢†Ñ≤e QôM 1

»≤ÑàŸG AGƒ¡dG ∞jöüàH ºbh ¢TôdG ¢Só°ùe π¨°ûe ≈∏Y §¨°VG 2

.º«WGôÿG πNGO

.(ON/1) ™°VƒdG ≈∏Y 𫨰ûJ AóH ìÉàØe §Ñ°VG 3

(3 πµ°T) §Ñ°†dG äÉeƒ∏©e

¢TôdG ágƒa §Ñ°V

(á«°UÉÿG √ò¡H IOhõŸG äGRGô£dÉH ¢UÉN)

.(E) ágƒØdG πjó©J ÈY √É«ŸG ≥aóJ §Ñ°V ºàj •

∞¶æŸG §Ñ°V

(á«°UÉÿG √ò¡H IOhõŸG äGRGô£dÉH ¢UÉN)

.(F) º¶æŸG ΩGóîà°SÉH ∞¶æŸG ≥aóJ §Ñ°V ºàj •

∞¶æŸG §¨°V §Ñ°V

≈∏Y ∫ƒ°üë∏d " - " ™°VƒdG ≈∏Y (E) πjó©à∏d á∏HÉ≤dG ágƒØdG §Ñ°VG

(á«°UÉÿG √ò¡H IOhõŸG äGRGô£dÉH ¢UÉN) Ö°SÉæŸG §¨°†dÉH ∞¶æŸG

§¨°†dG §Ñ°V

(á«°UÉÿG √ò¡H IOhõŸG äGRGô£dÉH ¢UÉN)

᪫b ¢VôY ºàjh .§¨°†dG §Ñ°†d (G) º¶æŸG ΩGóîà°SG ºàj •

.(¬à«ÑãJ ∫ÉM ‘) §¨°†dG ¢SÉ«≤e ≈∏Y §¨°†dG

(4 πµ°T) RÉ¡÷G Ωóîà°SG ∫ƒM äÉeƒ∏©e

ºµëàdG öUÉæY

.(H) 𫨰ûàdG AóH ìÉàØe •

:πLCG øe (ON/1) ™°VƒdG ≈∏Y 𫨰ûàdG AóH ìÉàØe §Ñ°VG

(TSS RÉ¡L É¡H ôaGƒàj ’ »àdG äGRGô£dG ‘) ∑ôëŸG 𫨰ûJ AóH (a

É¡H ôaGƒàj »àdG äGRGô£dG ‘) 𫨰ûàdG AóÑd √OGóYEGh ∑ôëŸG §Ñ°V (b

(TSS RÉ¡L

¿CG »¨Ñæ«a ,𫨰ûàdG AóH ìÉàØe ≈∏Y »∏«dO Qƒf ∑Éæg ¿Éc GPEG •

.Å°†j

É¡eGóîà°SÉH º≤a ,IôaGƒàe "™ØJôe/¢†Øîæe" äGOGóYE’G âfÉc GPEG •

:»∏j ɪc

¢†Øîæe §¨°V π«°ùZ :¢†Øîæe •

™ØJôe §¨°V π«°ùZ :™ØJôe •

𫨰ûJ ±É≤jE’ (OFF/0) ™°VƒdG ≈∏Y 𫨰ûàdG AóH ìÉàØe §Ñ°VG •

.RÉ¡÷G

¿CG »¨Ñæ«a ,𫨰ûàdG AóH ìÉàØe ≈∏Y »∏«dO Qƒf ∑Éæg ¿Éc GPEG •

.»Øàîj

.(I) √É«ŸG ¢TÉ°TQ ‘ ºµëàdG ´GQP •

!ô£N – ôjò–

ÚÑe ƒg ɪc Úàeh âHÉK í£°S ≈∏Y RÉ¡÷G ™°Vh Öéj ,𫨰ûàdG AÉæKCG

.4 πµ°ûdG ‘

30

Page 31

ARABIC

.¢ù«FôdG ábÉ£dG Qó°üe

.2 πµ°ûdG ‘ ™«ªéàdG á«∏ªY π°ù∏°ùJ ô¡¶j

IQGhódG ágƒØdG ™«ªŒ

(á«°UÉÿG √ò¡H IOhõŸG äGRGô£dÉH ¢UÉN)

ágƒØdG ΩGóîà°SG ¿CG ’EG .ÈcCG π«°ùZ Iƒb IQGhódG ágƒØdG á©£b ôaƒJ

§¨°†dÉH áfQÉ≤ŸÉH 25% áÑ°ùæH §¨°†dG ¢†«ØîJ ‘ ÖÑ°ùàj ób IQGhódG

IQGhódG ágƒØdG á©£b ôaƒJ ∂dP ™eh ,πjó©à∏d á∏HÉ≤dG ágƒØdG øe QOÉ°üdG

.√É«ŸG ¢TÉ°Tôd á«fGQhódG ácô◊G ÖÑ°ùH ÈcCG π«°ùZ Iƒb

»FÉHô¡µdG π«°UƒàdG

!ô£N – ôjò–

™e »FÉHô¡µdG QÉ«àdG Qó°üe (õJôg-âdƒa) OOôJh ó¡L ≥HÉ£J øe ócCÉJ

»¨Ñæjh .(2 πµ°T) RÉ¡÷G äÉfÉ«H áMƒd ≈∏Y OóëŸG OOÎdGh ó¡÷G

»°VQCG π«°UƒàH OhõŸG ¢ù«FôdG ábÉ£dG Qó°üe ™e §≤a RÉ¡÷G π«°UƒJ

AÉHô¡µdG Qó°üe ™£≤d (ÒÑeCG »∏∏«e 30) »∏°VÉØJ ¿ÉeCG ™WÉbh Ö°SÉæe

.»FÉHô¡c ¢SÉ“ çhóM ∫ÉM ‘

π«°UƒàdG äÓHÉc ΩGóîà°SG

,“IPX5” ájɪ◊G iƒà°ùà ∞°üàJ »àdG äÓHɵdG ΩGóîà°SG ≈Lôj

ɪ∏c …CG ,¬dƒW ™e π«°UƒàdG πHɵd »°Vô©dG ™£≤ŸG Ö°SÉæàj ¿CG »¨Ñæjh

.1 ∫hó÷G ™LGQ .»°Vô©dG ¬©£≤e ójõj ¿CG »¨Ñæj ,¬dƒW OGR

√É«ŸG Qó°üe π«°UƒJ

!ô£N – ôjò–

.áî°†ŸG πNóe ™e §≤a áë°TôŸGh áØ«¶ædG √É«ŸG ΩGóîà°SG Öéj

™e √É«ŸG ∫ÉNOEG QƒÑæ°U øe IOQGƒdG √É«ŸG ᫪c ihÉ°ùàJ ¿CG »¨Ñæjh

.áî°†ŸG á©°S

.¿ÉµeE’G Qób √É«ŸG Qó°üe Ωɶf øe Üô≤dÉH RÉ¡÷G ™°Vh »¨Ñæj

π«°UƒàdG •É≤f

(êôîŸG) √É«ŸG êôfl •

(πNóŸG) í°Tôe ™e √É«ŸG πNóe •

¢ù«FôdG √É«ŸG Qó°üà π«°UƒàdG

â«ÑãJ •öûH IöTÉÑe ¢ù«FôdG √É«ŸG Qó°üà RÉ¡÷G π«°UƒJ øµÁ

᫪«¶æàdG íFGƒ∏d kÉ≤ah »Ø∏ÿG ≥aódG ™fÉe Ωɪ°U ™e Qó°üŸG ΩƒWôN

º∏e 13 øY π≤j ’ ΩƒWôÿG ∂ª°S ¿CG øe ócCÉàdG ≈Lôjh .á≤Ñ£ŸG á«dÉ◊G

.iƒ≤e ¬fCGh

ájCG AGôLEG Èà©jh .RÉ¡÷G ≈∏Y äÓjó©àdG ™«ªL AGôLEG ô¶ëj •

áeP AGôHEGh ≥aGƒàdG QGôbEG AɨdEG ‘ kÉÑÑ°S RÉ¡÷G ≈∏Y äÓjó©J

.»FÉæ÷Gh ÊóŸG ¿ƒfÉ≤dG ÖLƒÃ äÉ«dhDƒ°ùŸG ™«ªL øe ™pæn°üoŸG

á°ù«FôdG äÉfƒµŸG

πjó©à∏d á∏HÉ≤dG ¢TÉ°TôdG ágƒa B1 •

´GQP B2 •

¿ÉeCG ¢†Ñ≤e ™e ¢TQ ¢Só°ùe B3 •

¢ùHÉb ™e ábÉ£dG Qó°üe πHÉc B4 •

™ØJôŸG §¨°†dG ΩƒWôN B5 •

(á«°UÉÿG √ò¡H IOhõŸG äÓjOƒŸG ‘) ∞¶æŸG ¿GõN B6 •

ô¶fG – ójQƒàdG IƒÑY ‘ IOƒLƒe âfÉc GPEG) äÉ≤ë∏ŸG

(1 πµ°T

ágƒØdG ∞«¶æJ IGOCG C1 •

IQGhódG ágƒØdG á©£b C2 •

¢†Ñ≤ŸG C3 •

IÉ°TôØdG C4 •

ΩƒWôÿG IôµH C5 •

¿ÉeC’G Iõ¡LCG

!ô£N – ôjò–

.¿ÉeC’G Ωɪ°U OGóYEG πjó©àH hCG åÑ©dÉH º≤J ’

ƒg ¿ÉeC’G Ωɪ°U Èà©j .§¨°†dG ójó– Ωɪ°U hCG/h ¿ÉeC’G Ωɪ°U •

íàa ºàj ,¢TôdG ¢Só°ùe π¨°ûe ôjô– óæYh ,§¨°†dG ójó– Ωɪ°U

É¡ØjöüJ ºàj hCG áî°†ŸG πNóe ÈY É¡JQhO √É«ŸG ó«©Jh Ωɪ°üdG

.¢VQC’G ≈∏Y

áLQO äRhÉŒ ∫ÉM ‘ .(¬à«ÑãJ ∫ÉM ‘ D1) º¶æe Ωɪ°U •

Ωɪ°üdG Ωƒ≤j ,™mæn°üoŸG πÑb øe IOóëŸG áLQódG √É«ŸG IQGôM

IOQÉÑdG √É«ŸG øe ᫪c Öë°Sh áæNÉ°ùdG √É«ŸG ∞jöüàH º¶æŸG

¤EG ∫ƒ°UƒdG ºàj ≈àM ,É¡ØjöüJ ” »àdG √É«ŸG ᫪µd ájhÉ°ùe

.áë«ë°üdG IQGô◊G áLQO

.√É«ª∏d »p°Vnôn©dG ¢TôdG ™æÁ :(D) ¿ÉeC’G ¢†Ñ≤e •

(2 πµ°T) Ö«cÎdG

™«ªéàdG

!ô£N – ôjò–

øe RÉ¡÷G π°üa ™e ™«ªéàdGh Ö«cÎdG äÉ«∏ªY ™«ªéH ΩÉ«≤dG Öéj

31

Page 32

ARABIC

äÉjÉØædG óMCG √QÉÑàYÉH RÉ¡÷G øe ¢ü∏îàdG ô¶M ¤EG Ò°ûJ E1- áeÓY

ô¶ëjh .ójóL RÉ¡L AGöT óæY ôLÉà∏d ¬ª«∏°ùJ øµÁ ɉEG ,á«dõæŸG

ÒZ ¢VGôZCG ‘ RÉ¡é∏d á«FÉHô¡µdGh á«fhεdE’G AGõLC’G ΩGóîà°SG

.á«ë°U ôWÉfl ≈∏Y …ƒ£æJ OGƒe ≈∏Y …ƒà– É¡fEG å«M áÑ°SÉæe

RƒeôdG

ΩGóîà°SÓd kÉ°ü«°üN ºª°üe RÉ¡÷G ¿CG ¤EG Ò°ûj – E2 õeôdG

á«æØdG ÖfGƒ÷G ≈∏Y Ú©∏£ŸG IÈÿG …hP ¢UÉî°TCÓd …CG ,»æ¡ŸG

äÉ«∏ª©dG ò«ØæJ ≈∏Y øjQOÉ≤dGh ,á∏°üdG äGP á«©jöûàdGh ᫪«¶æàdGh

.RÉ¡÷G áfÉ«°Uh ΩGóîà°S’ áeRÓdG

πLCG øe kÉ°ü«°üN ºª°üe RÉ¡÷G ¿CG ¤EG Ò°ûj – E3 õeôdG

.(‹õæŸG) »æ¡ŸG ÒZ ΩGóîà°S’G

(1 πµ°T) á«æØdG äÉeƒ∏©ŸG

Qƒ°üàŸG ΩGóîà°S’G

∞«¶æJ πLCG øe »°üî°ûdG ΩGóîà°SÓd kÉ°ü«°üN RÉ¡÷G Gòg º«ª°üJ ”

ñÉ°ShC’G ádGREG Gòch ,ÉgÒZh AÉæÑdG IQÉéMh ÜQGƒ≤dGh ä’B’Gh äÉÑcôŸG

á«FÉ«ª«µdG äÉضæŸGh áØ«¶ædG √É«ŸG ΩGóîà°SG ÈY á«°ü©à°ùŸG

äÉcôfi ∞«¶æJ ‘ RÉ¡÷G ΩGóîà°SG øµÁ ɪc . ∑

᫪«¶æàdG íFGƒ∏d kÉ≤ah áî°ùàŸG √É«ŸG øe ¢ü∏îàdG •öûH áÑcôŸG

RÉ¡÷G ≈∏Y áàÑãŸG äÉfÉ«ÑdG ìƒd ô¶fG :πNGódG AÉŸG §¨°V •

ó◊G - ∫ɵ°SÉH Éé«e 0.1 ≈fOC’G ó◊G :πNGódG AÉŸG §¨°V •

∫ɵ°SÉH Éé«e 1 ≈°übC’G

.rΩ 0¥ƒa :𫨰ûàdG §«fi IQGôM áLQO •

.EN 60335-2-79/A1 QÉ«©ŸG ™e ≥aGƒàe RÉ¡÷G •

RÉ¡÷G Gò¡d Ö°SÉæŸG π¨°ûŸG Oóëj »eÉeC’G AÉ£¨dG ≈∏Y OƒLƒŸG õeôdG

í«ë°üdG ÒZ ΩGóîà°S’G

∂dP ≈∏Y ÚHQóŸG ÒZ ¢UÉî°TC’G πÑb øe RÉ¡÷G ΩGóîà°SG ô¶ëj •

IOQGƒdG äɪ«∏©àdG Gƒª¡Øjh GhDhô≤j ⁄ øjòdG ¢UÉî°TC’G πÑb øe hCG

πNGO áeÉ°ùdG hCG IôéØàŸG hCG ∫É©à°TÓd á∏HÉ≤dG πFGƒ°ùdG ™°Vh ô¶ëj •

á°VôY hCG kɪª°ùe ¬fƒc πªàëj §«fi ‘ RÉ¡÷G ΩGóîà°SG ô¶ëj •

iôNCG QÉ«Z ™£b ájCG Gòch á«∏°UC’G ÒZ QÉ«¨dG ™£b ΩGóîà°SG ô¶ëj •

.ÉæjójCG ÚH OƒLƒŸG RGô£dG Gò¡d á°ü°üfl ÒZ

Qnó

àdG á«Lƒdƒ«H

n

q

o

q

.á≤Ñ£ŸG

π¨°ûŸG

.(»æ¡e ÒZ hCG »æ¡e)

.ΩGóîà°S’G π«dO ‘

.RÉ¡÷G

.QÉéØfÓd

äÉfƒµŸG ìÓ°UEG hCG/h áfÉ«°U á«∏ªY ò«ØæJ Öéj •

çOGƒ◊G ô£N .πgDƒe πªY ≥jôa ᣰSGƒH á«FÉHô¡µdG

.IóMƒdG ΩƒWôN π°üa πÑb »≤ÑàŸG §¨°†dG ∞jöüJ Öéj •

áHÉ°UE’G ô£N

AGõLCG OƒLh ΩóYh »ZGÈdG ΩɵMEG øe kɪFGO ócCÉàdG ≈Lôj •

çOGƒ◊G ô£N .RÉ¡÷G ΩGóîà°SG πÑb IQƒ°ùµe hCG áØdÉJ

ÖÑ°ùàJ ’ »àdG äÉضæŸG ΩGóîà°SG Öéj •

πѵdG/™ØJôŸG §¨°†dG ΩƒWôîH á°UÉÿG AÓ£dG OGƒe πcBÉJ ‘

»FÉHô¡µdG

øY äÉfGƒ«◊G hCG ¢UÉî°TC’G ™«ªL OÉ©àHG øe ócCÉJ •

.(Îe 15) IOQÉj 16 øY π≤j ’ Éà RÉ¡÷G

(1 πµ°T) áeÉY äÉeƒ∏©e

ΩGóîà°S’G π«dO ΩGóîà°SG

´ƒLô∏d ¬H ®ÉØàM’G »¨Ñæjh ,RÉ¡÷G øe CGõéàj ’ kAõL π«dódG Gòg ó©j

ΩGóîà°SG/Ö«côJ πÑb kGó«L π«dódG Gòg IAGôb ≈Lôjh .kÓÑ≤à°ùe ¬«dEG

π«dódG Gòg Ëó≤J ™FÉÑdG ≈∏Y Öéj ,RÉ¡÷G √òg ™«H ∫ÉM ‘h .IóMƒdG

.ójó÷G ∂dÉŸG ¤EG RÉ¡÷G ™e

º«∏°ùàdG

IƒÑY .ʃJôc ¥hóæ°U ‘ »FõL πµ°ûH Öcôe ƒgh RÉ¡÷G Gòg º∏°ùj

.1 πµ°ûdG ‘ áë°VƒŸG ójQƒàdG

RÉ¡÷G ™e áeó≤ŸG ≥FÉKƒdG

.ΩGóîà°S’Gh áfÉ«°üdG π«dO A1 •

.áeÓ°ùdG äɪ«∏©J A2 •

.≥aGƒàdG QGôbEG A3 •

¿Éª°†∏d ᪶æŸG íFGƒ∏dG A4 •

IƒÑ©dG øe ¢ü∏îàdG

IOÉYEG Öéj ¬fCG ’EG ,áÄ«Ñ∏d çƒ∏ŸG ´ƒædG øe â°ù«d IƒÑ©∏d áfƒµŸG OGƒŸG

ádhO ‘ Ö°SÉæŸG ™jöûàdG ™e ≥aGƒàj Éà ɡæe ¢ü∏îàdG hCG ÉgôjhóJ

.ΩGóîà°S’G

áeÓ°ùdG äÉeÓY

áàÑãŸG áeÓ°ùdG äÉeÓY É¡«dEG Ò°ûJ »àdG äɪ«∏©àdÉH ΩGõàd’G »¨Ñæj

.RÉ¡÷G ≈∏Y

∫ÉM ‘h ,IAhô≤eh IOƒLƒe áeÓ°ùdG äÉeÓY ™«ªL ¿CG øe ócCÉJ

É¡©°Vƒe ¢ùØf ‘ á∏jóÑdG äÉeÓ©dG âÑãàH ºb ,∂dP ÒZ ±É°ûàcG

.»∏°UC’G

32

Page 33

ARABIC

QÉéØf’G ô£N .¿ÉeC’G

ô£N Ò«¨J .¢TÉ°TôdG ¢SCGQ ágƒØd »∏°UC’G ô£≤dG Ò«¨J ô¶ëj •

𫨰ûàdG AGOC’

çOGƒ◊G ô£N .áHÉbQ ¿hO RÉ¡÷G ∑ôJ ô¶ëj •

ô£N .»FÉHô¡µdG πѵdG Öë°S ÈY RÉ¡÷G ∂jô– ô¶ëj •

»FÉHô¡c ¢SÉ“

™ØJôŸG §¨°†dG ΩƒWôN ≈∏Y äGQÉ«°ùdG Qhôe ΩóY øe ócCÉJ •

ô£N .™ØJôŸG §¨°†dG ΩƒWôN Öë°S ÈY RÉ¡÷G ∂jô– ô¶ëj •

QÉéØf’G

øe ÉgÒZ hCG QÉWE’G äÉeɪ°U hCG äGQÉWE’G ¤EG ¢TÉ°TôdG ¬«LƒJ óæY •

™ØJôŸG §¨°†dG ¢TÉ°TQ ΩGóîà°SG …ƒ£æj ,§¨°†∏d á°Vô©àŸG AGõLC’G

Öéjh ,IQGhódG ágƒØdG á©£b ΩGóîà°SG ô¶ëjh .kÉÑdÉZ ôWÉfl ≈∏Y

á«∏ªY AÉæKCG πbC’G ≈∏Y Ϊ«àæ°S 30 ó©H ≈∏Y kɪFGO ¢TÉ°TôdG π©L

QÉéØf’G ô£N .∞«¶æàdG

áeÓ°ùdG "äÉjQhöV"

.√É«ŸG ¢TÉ°TQ øe AÉHô¡µdG äÓ°Uƒe ™«ªL ájɪM Öéj •

»FÉHô¡c ¢SÉ“ ô£N

kÉ«°TÉ“ Ö°SÉæe ábÉW Qó°üà §≤a RÉ¡÷G π«°UƒJ Öéj •

á«FÉHô¡µdG áeó°üdG ô£N .á≤Ñ£ŸG ᫪«¶æàdG íFGƒ∏dG áaÉc ™e

ájɪ◊G øe ójõe ôaƒj »≤ÑàŸG QÉ«àdÉH πª©j IôFGO ™WÉb ΩGóîà°SG •

,¢ùHÉb ¿hóH áeó≤ŸG äGRGô£dG ÉeCG .(ÒÑeCG »∏∏«e 30) π¨°ûª∏d

∑Ó°SCG ΩGóîà°SG Öéjh .πgDƒe πªY ≥jôa ᣰSGƒH É¡Ñ«côJ Öé«a

.Ö°SÉæŸG π°UƒŸG ¢SÉ«≤e ™e Ióª©àŸG »FÉHô¡µdG π«°UƒàdG

AGóJQG Ωõ∏j Gòd ,AGõLC’G ¢†©H OGóJQG ‘ ‹É©dG §¨°†dG ÖÑ°ùàj ób

.π¨°ûŸG áeÓ°S ¿Éª°†d áeRÓdG á«bGƒdG äGó©ŸGh ¢ùHÓŸG ™«ªL

áHÉ°UE’G ô£N

áeÓ°ùdG äɪ«∏©J

kÉ«LƒdƒæµJ Ωó≤àe èàæe ƒg ¬FGöûH âªb …òdG RÉ¡÷G ¿CÉH º∏©dG ≈Lôj

‘ Ú°ü°üîàŸG Ú«HhQhC’G ™«æ°üàdG OGhQ óMCG πÑb øe ¬ª«ª°üJ ”

,IóMƒdG √ò¡d AGOCG π°†aCG ≈∏Y ∫ƒ°üë∏dh .™ØJôŸG §¨°†dG äÉî°†e

kÉehO É¡«a IOQGƒdG äɪ«∏©àdG ´ÉÑJGh ,ájÉæ©H IöûædG √òg IAGôb ≈Lôj

∂d ≈æªàfh ≥aƒŸG ∑QÉ«àNG ≈∏Y ∂Äæ¡f øëfh .RÉ¡÷G ΩGóîà°SG óæY

.áëLÉf 𫨰ûJ á«∏ªY

áæeɵdG ôWÉîŸG/áeÓ°ùdG óYGƒb

áeÓ°ùdG "äGQƒ¶fi"

πFGƒ°ùdG ™e RÉ¡÷G ΩGóîà°SG ô¶ëj •

™e ≈°TЙªаJ ’ дЙйажe бjCG hCG бeЙ°щdG πFGƒ°щdG hCG ∫Й©а°T’G б©jцS

.ºª°ùàdG hCG QÉéØf’G ô£N .RÉ¡é∏d í«ë°üdG 𫨰ûàdG

hCG ¢UÉî°TC’G ¤EG √É«ŸG ¢TÉ°TQ ¬«LƒJ ô¶ëj •

¥GÎM’G ô£N .äÉfGƒ«◊G

¤EG hCG É¡JGP IóMƒdG ¤EG √É«ŸG ¢TÉ°TQ ¬«LƒJ ô¶ëj •

ô£N .iôNC’G á«FÉHô¡µdG äGó©ŸG ¤EG hCG á«FÉHô¡µdG AGõLC’G

á«FÉHô¡µdG áeó°üdG

ô£N .ô£ŸG ádÉM ‘ ∫õæŸG êQÉN RÉ¡÷G ΩGóîà°SG ô¶ëj •

»FÉHô¡µdG ¢SɪàdG

Ú∏gDƒŸG ÒZ ¢UÉî°TC’G hCG ∫ÉØWCÓd ìɪ°ùdG ô¶ëj •

áHÉ°UE’G ô£N .RÉ¡÷G ΩGóîà°SÉH

.AÉŸÉH á∏àÑŸG ó«dÉH ¢ùÑ≤ŸG hCG/h ¢ùHÉ≤dG ¢ùŸ ô¶ëj •

á«FÉHô¡µdG áeó°üdG ô£N

•

πHɵdG ∞∏J ∫ÉM ‘ RÉ¡÷G ΩGóîà°SG ô¶ëj •

»FÉHô¡µdG ¢SɪàdGh á«FÉHô¡µdG áeó°üdG ô£N .»FÉHô¡µdG

§¨°†dG ΩƒWôN ∞∏J ∫ÉM ‘ RÉ¡÷G ΩGóîà°SG ô¶ëj •

QÉéØf’G ô£N .‹É©dG

ô£N .¢ùHÉ≤dG ádGREG ≈Lôj ,RÉ¡÷G ≈∏Y πª©dG IöTÉÑe πÑb •

á«°Vô©dG ájGóÑdG

¢Só°ùe ∑É°ùeEG ≈Lôj ,¢TôdG ¢Só°ùe π¨°ûe ≈∏Y §¨°†dG πÑb •

áHÉ°UE’G ô£N .√OGóJQ’ kÉÑ°ù– ΩɵMEÉH ¢TôdG

.á«∏ëŸG √É«ŸG ójQƒJ ácöT äÉÑ∏£àà ΩGõàd’G ≈Lôj •

™e §≤a RÉ¡÷G π«°UƒJ øµÁ ,EN 12729 (BA) QÉ«©ª∏d kÉ≤aƒa

≥aódG ™fÉe Ωɪ°U â«ÑãJ ∫ÉM ‘ ¢ù«FôdG ÜöûdG √É«e Qó°üe

çƒ∏àdG ô£N .Qó°üŸG ΩƒWôN ‘ ±öüdG IGOCG ™e »Ø∏ÿG

.QGôªà°SÉH 𫨰ûàdG ™°Vh ‘ ¢TôdG ¢Só°ùe π¨°ûe π©Œ ’ •

çOGƒ◊G ô£N

∫ÉM ‘h ,RÉ¡÷G ≈∏Y äÉfÉ«ÑdG äÉMƒd âÑãJ øe ≥≤– •

ô¶ëjh .∂dòH ´RƒŸG ÆÓHEG ≈Lôj ,äÉMƒ∏dG ∂∏J OƒLh ΩóY

Qò©àj å«M ,äÉMƒ∏dG ∂∏J É¡H óLƒj ’ »àdG äGóMƒdG ΩGóîà°SG

çOGƒ◊G ô£N .kÉÑdÉZ IQƒ£N ≈∏Y É¡eGóîà°SG iƒ£æjh É¡Øjô©J

Iõ¡LCG hCG ¿ÉeC’G Ωɪ°U OGóYEG πjó©J hCG åÑ©dG ô¶ëj •

33

Page 34

ARABIC

L

34

5

25 ÷ 50 m

2 x 2,5 mm

S ìÉàØe

T ájQGô◊G ájÉbƒdG

2

M

1 ÷ 25 m

2

Z1 ¢ûjƒ°ûàdG ™fÉe ∞ãµe

M ∑ôëŸG

S1 §¨°†dG ìÉàØe

Volt

230 2 x 1,5 mm

L1

N

S

Z1

T

1~

NCNOC

S1

I

Page 35

ARABIC

E

3

D

H

1

I

2

H

4

H

35

Page 36

ARABIC

21

43

5 6 7

8 9

36

Ø13

2

Page 37

ARABIC

A1-A2-A3-A4

C3

E3

PW1300TDW

B4

E1

B6

B5

B2

B3

B1

C2

C1

D

37

Page 38

N a m e s & A dd re ss es f o r B la ck & D ec ke r S er vi ce C on ce ss io na ri es

ALGERIA: SARL Outillage Corporation, After Sale Service Center-08, Rue Mohamed Boudiaf - Cheraga, Algiers, Algeria,

Tel: +213 21 375131, Fax: +213-0-369667. BAHRAIN: Alfouz Services Co. WLL, P.O. Box 26562, Tubli, Manama, Tel:

+973-17783562 / 17879987, Fax: +973-17783479. EGYPT: Anasia Egypt for Trading S.A.E, P.O. Box 2443, 9, Mostafa

Refaat Street, Sheraton Heliopolis 11361, Cairo, Tel: +202-22684159, Fax: +202-22684169. ETHIOPIA: Seif Sherif Trade

PLC -Arada Sub City, Kebele 01-02, Global Insurance Bldg., 2nd Flr. Room 43, P.O.Box 2525, Addis Ababa, Ethiopia, Tel:

00-251-11-1563968/ 1563969, Fax: 00-251-11-1558009. IRAQ: Financial Links, Kazzaz Building Arasat Al-Hindia Block No:

629 Street: 31Building No: 1 Baghdad – Iraq, Tel: +964 (0)780 195 2223 /+ 964 (0)781 3763044. JORDAN: Bashiti

Hardware, 93 King Abdullah 2nd St., Opp ELBA House, P.O. Box 3005, Tel: +962-6-5349098 ext.11, Fax: +962-6-5330731.

KENYA: Leading Concepts, P.O. Box: 40877-00100, Nairobi, Kenya. Tel: +254 20 690 5000, Fax: +254 20 690 5111.

KUWAIT: Al Omar Technical Co., P.O. Box 4062, Safat 13041, Kuwait, Tel: +965-24848595 / 24840039, Fax:

+965-24845652. LEBANON: Aces Service Centre, P.O. Box 90-102, Nahr El Mot, Seaside Highway, Pharaon Building,

Beirut. Tel: 00961-1-898989, Fax: 00961-1-245880. LIBYA: Homeworld Co., Building No.5, Senidal St., Amr Ibn Elaas Road,

Benghazi, Libya. Tel: 00218-61-9094183. Service Center1 - Benghazi: Tel: +218-061-3383994, Fax: +218-092-7640688,

Service Center2 - Tripoli: Tel: +218-021-3606430, Fax: +218-092-6514813. MALTA: John G Cassar Ltd. 36-Victory Street,

Qormi QRM 06, Malta. Tel: +356-21493251, Fax: +356-21483231. MAURITIUS: J.M. Goupille & Co. Ltd., Rogers Industrial

Park 1, Riche Terre, Mauritius, Tel: +230 206 9450/ +230 207 1700, Fax: +230 206 9474/ +230 248 3188. MOROCCO:

UATS, No. 37, Lotissement KADIRIA, km 10 Route Eljadida - LISASSFA, Casablanca, Morocco, Tel: +212 522652602, Fax:

+212522652603. NIGERIA: Dana Electronics Ltd. (Lagos) 116/ 120, Apapa Oshodi Express Way, Isolo, Lagos, Nigeria. Tel:

+234-17431818/ +234-8037767774/ +234-8057445477. (Abuja) 18, A.E. Ekukinam Street, Off Obsfemi Awolowo Road,

Utako, Abuja, Nigeria. Tel: +234-8032276101/ +234-8037767774. (Kano) 9A - Mai Malari Road, Bompai, Kano, Nigeria. Tel:

+234-8053294947/ +234-8037767774. OMAN: Oman Marketing & Service Co. (Omasco), P.O. Box 2734, Behind Honda

Showroom, Wattayah, Oman, Tel: +968-24560232/ 24560255, Fax: +968-24560993. Oman Marketing & Service Co.

(Omasco), Al Ohi, Sohar, Oman, Tel: +968-26846379, Fax: +968-26846379. Oman Marketing & Service Co. (Omasco) Sanaya, Salalah, Oman, Tel: 00968-23212290, Fax: +968-23210936. PAKISTAN: Ammar Service & Spares - 60-Bank