Black & Decker PS310P Instruction Manual

GENERAL SAFETY RULES - FOR ALL BATTERY OPERATED TOOLS

WARNING: When using electric tools, basic safety precautions should always be followed

to reduce risk of fire, electric shock, and personal injury, including the following.

READ ALL INSTRUCTIONS

TO REDUCE RISK OF INJURY :

• Before any use, be sure everyone using this tool reads and understands all safety

instructions and other information contained in this manual.

• Save these instructions and review frequently prior to use and in instructing others.

General Safety Warnings and Instructions for All Tools

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

• CONSIDER WORK AREA ENVIRONMENT. Don’t expose power tools to rain. Don’t use

power tools in damp or wet locations. Keep work area well lit. Do not use in presence of

flammable liquids or gases. Motors in these tools normally spark, and the sparks may ignite

the fumes.

• GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded surfaces. For

example; pipes, radiators, ranges, refrigerator enclosures. Use extreme caution when

drilling, driving, or cutting into walls, floors, ceilings or other areas or wherever live electrical

wires may be contacted, do not touch any metal parts of the tool. Hold the tools only by the

plastic handle to prevent electric shock.

• KEEP CHILDREN AWAY. Do not let children and visitors contact tool or extension cord. All

children and visitors should be kept away from work area.

• STORE IDLE TOOLS. When not in use, tools should be stored in dry, and high or locked-up

place–out of reach of children.

• DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was

intended.

• USE RIGHT TOOL. Don’t force small tool or attachment to do the job of a heavy-duty tool.

Don’t use tool for purposes not intended.

• DRESS PROPERLY. Do not wear loose clothing or jewelry. They can be caught in moving

parts. Rubber gloves and non-skid footwear are recommended when working outdoors.

Wear protective hair covering to contain long hair.

• USE SAFETY GLASSES AND OTHER SAFETY EQUIPMENT. Use safety goggles or

safety glasses with side shields, complying with applicable safety standards and, when

needed, a face shield. Also use face or dust mask if cutting operation is dusty. This applies

to all persons in the work area. Also use a hard hat, hearing protection, gloves, safety shoes

and dust collection systems when specified or required.

• DON’T ABUSE CORD. Never carry tool by cord or yank it to disconnect from receptacle.

Keep cord from heat, oil, and sharp edges.

• SECURE WORK. Use clamps or a vise to hold work. It’s safer than using your hand and it

frees both hands to operate tool.

• DON’T OVERREACH. Keep proper footing and balance at all times.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect tool

cords periodically and if damaged, have repaired by authorized service facility. Inspect

extension cords periodically and replace if damaged. Keep handles dry, clean, and free

from oil and grease.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys

and adjusting wrenches are removed from tool before turning it on.

• STAY ALERT. Watch what you are doing. Use common sense. Do not operate tool when

you are tired or otherwise impaired.

• CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform

its intended function. Check for alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions that may affect its operation. Aguard

or other part that is damaged should be properly repaired or replaced by an authorized

service center. Do not use tool if switch does not turn it on and off.

• REPAIRS AND SERVICE. Repairs, maintenance and any adjustments not specified in this

manual should be performed by Black & Decker authorized service centers or other

qualified service organizations, always using identical replacement parts.

• USE OF ACCESSORIES AND ATTACHMENTS.The use of any accessory or attachment

1-800-54-HOW-TO

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON PLEASE CALL

IF YOU SHOULD EXPERIENCE A PROBLEM

WITH YOUR BLACK & DECKER PURCHASE,

CALL 1-800-54-HOW-TO (1-800-544-6986).

IN MOST CASES, A BLACK & DECKER REPRESENTATIVE

CAN RESOLVE YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT,

GIVE US A CALL. YOUR FEEDBACK IS VITAL

TO THE SUCCESS OF BLACK & DECKER’S QUALITY

IMPROVEMENT PROGRAM.

(544-6986)

VEA EL ESPAÑOL EN LA CONTRAPORTADA.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y

PÓLIZADE GARANTÍA. ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR ELPRODUCTO.

INSTRUCTION MANUAL

Catalog No. PS310P

9999....6666 VVVVoooolllltttt CCCCoooorrrrddddlllleeeessssssss DDDDrrrriiiillllll

ll

KEY INFORMATION YOU SHOULD KNOW :

• Battery pack must be charged for16 hours before initial use.

• Drill is shipped with switch locked off.

Cat #PS310P Form # 606046-00 (APR-01-1) Copyright © 2001 Black & Decker Printed in China

not recommended for use with the tool could be hazardous. Note: Refer to the accessory

section of this manual for further details.

SPECIFIC SAFETY RULES

• Hold tool by insulated gripping surfaces when performing an operation where the

cutting tool may contact hidden wiring or its own cord. Contact with a "live" wire will also

make exposed metal parts of the tool "live" and shock the operator.

The label on your tool may include the following symbols.

V ..........................volts A..........................amperes

Hz ........................hertz W ........................watts

min ........................minutes ......................alternating current

......................direct current

n

o........................no load speed

..........................

Class II Construction

........................earthing terminal

........................safety alert symbol .../min ..................revolutions or

reciprocations

per minute

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber. (CCA)

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter out

microscopic particles.

Charging the Drill

Before attempting to charge your drill, thoroughly read ALL of the safety instructions. To

charge your drill, follow the steps below.

The 12-16 hour charger is designed to use standard household 120 volt 60 Hz power.

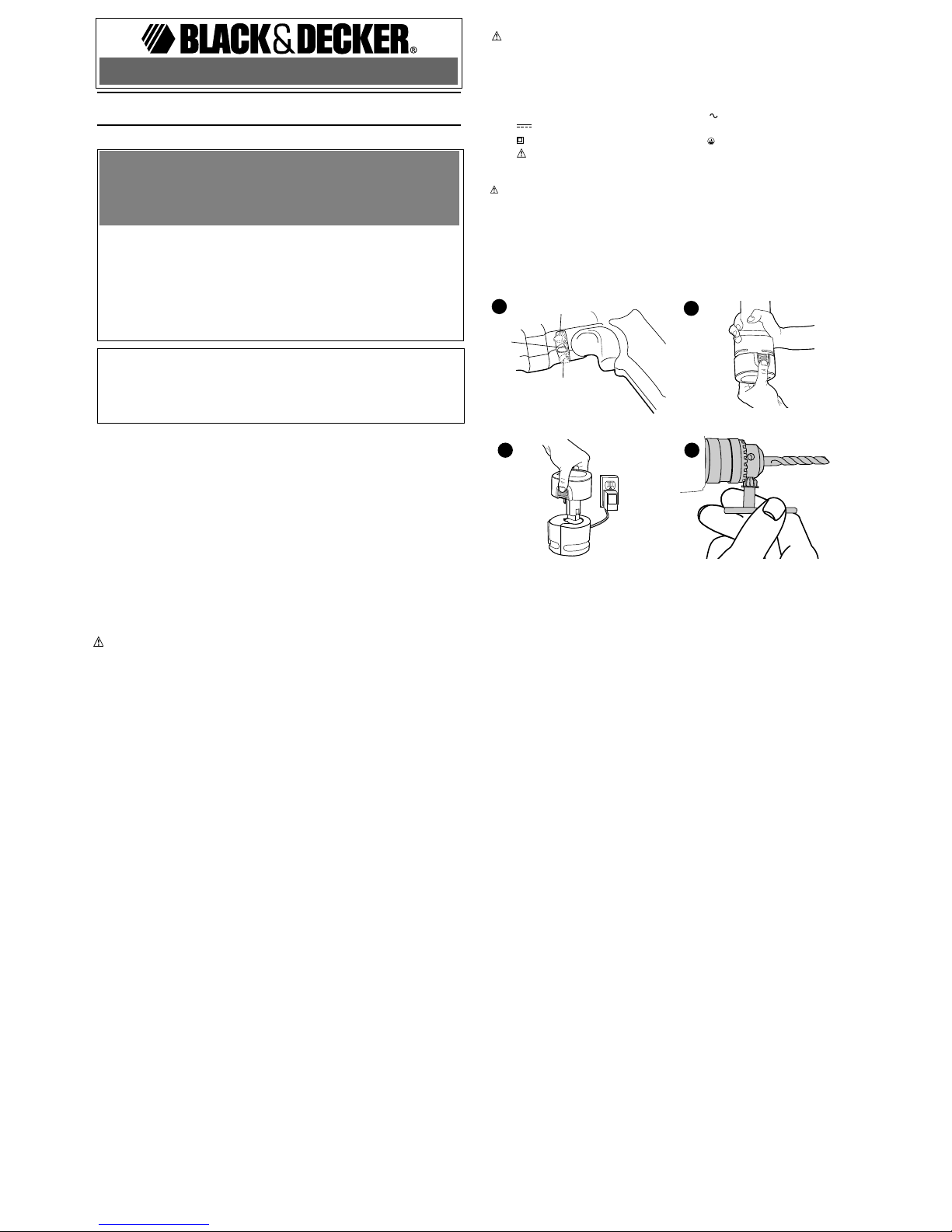

1. Put the switch control lever in the center OFF position (Fig. 1) and remove the power pack

from the tool (Fig. 2).

2. Plug the charger into any standard 120 Volts 60 Hz electrical outlet.

3. Insert the power pack into the charger (Fig. 3) and let it charge for 12-16 hours.

4. Remove pack from the charger and replace in tool.

Important Charging Notes

1. After normal usage, your drill should be fully charged in 12-16 hours or less. Your drill

was sent from the factory in an uncharged condition. Before attempting to use it, it must

be charged for at least 16 hours.

2. DO NOT charge the batteries in an air temperature below +40°F or above +105°F. This

is important and will prevent serious damage to the batteries.

3. While charging, the charger may hum and become warm to touch. This is a normal condition and does not indicate a problem.

4. If the batteries do not charge properly –

(1) Check current at receptacle by plugging in a lamp or other appliance.

(2) Check to see if the receptacle is connected to a light switch which turns power off

when you turn out the lights.

(3) Move charger and drill to a surrounding air temperature of +40°F to +105°F.

(4) If the receptacle and temperature are OK, and you do not get proper charging, take

or send the tool and charger to your local Black & Decker service center. See "Tools

Electric"’ in yellow pages.

5. The drill should be recharged when it fails to produce sufficient power on the jobs which

previously were done easily. DO NOT CONTINUE to use the drill with its battery in a

depleted condition.

6. To prolong battery life, avoid leaving the tool on charge for more than 2 days. Although

overcharging is not a safety concern, it can significantly reduce overall battery life.

7. Since the unit is designed for cordless applications, use of the unit while plugged in is of

no benefit. Batteries will still become depleted.

8. Unplug your tool’s charger from the power supply before disconnecting the charger from

the tool. Under certain conditions, with the charger plugged in to the power supply, the

exposed charging plug can be shorted by foreign material and may create a fire hazard.

Foreign materials of a conductive nature, such as but not limited to, steel wool, aluminum

foil, or any build up of metallic particles should be kept away from the charging plug.

Unplug charger before attempting to clean.

Operating Instructions

SWITCH AND CONTROL LEVER

Your drill is equipped with a variable speed reversing switch . To turn the tool ON, move the

control lever to the left or right and squeeze the trigger switch. The control lever is a three

position lever located over the trigger switch (Fig. 1). To drill holes or drive screws, slide the

control lever to the left and squeeze the trigger. To turn the tool OFF release the trigger

switch. To back out jammed drill bits or to remove screws, slide the control lever to the right

and squeeze the trigger. To lock the tool OFF for storage or when not being used, slide the

control lever to the center position.

TORQUE CONTROL

To set the tool’s torque, rotate the adjustable torque collar clockwise as required. Six

positions are marked around the collar and the higher the number, the higher the torque.

Each click in a clockwise direction means an increase in the torque produced. Position 6 is

the drill mode. In this position the clutch will not operate. This permits heavy duty drilling.

CHUCK & KEY

Turn chuck key counterclockwise to open chuck jaws, place bit in chuck as far as it will go and

then pull it out far enough so that the chuck jaws do not touch the flutes of the bit. Tighten

chuck collar by hand. Place chuck key in each of the three holes, and tighten in clockwise

direction (Figure 4). It’s important to tighten the chuck with all three holes to prevent bit

slippage. To release bit, turn chuck key counterclockwise in just one hole, then continue to

loosen chuck by hand.

1

2

3 4

Forward

Marche avant

Hacia adelante

Reverse

Aarche arrière

Reversa

Off

Arrêt

Apagado

étincelles générées par le moteur des outils électriques peuvent enflammer les poussières ou

les vapeurs.

• Éloigner les curieux, les enfants et les visiteurs de la zone de travail lorsqu’on utilise

un outil électrique. Une distraction peut entraîner la perte de maîtrise de l’outil.

MESURES DE SÉCURITÉ RELATIVES À L’ÉLECTRICITÉ

• Manipuler le cordon avec soin. Ne jamais se servir du cordon afin de transporter

l’outil ni tirer sur le cordon pour débrancher l’outil. Éloigner le cordon des sources de

chaleur, des flaques d’huile, des arêtes tranchantes et des pièces mobiles.

Remplacer immédiatement les cordons endommagés. Les cordons endommagés

augmentent les risques de secousses électriques.

• Il faut charger un outil à piles intégrées ou un ensemble de piles seulement dans le

chargeur conçu à cet effet. Un chargeur convenant pour un type de piles peut présenter

un risque d’incendie lorsqu’on s’en sert avec un autre type de piles.

• Utiliser un outil alimenté par piles seulement avec la pile appropriée. L’utilisation de

toute autre pile présente des risques d’incendie.

SÉCURITÉ PERSONNELLE

• Demeurer vigilant, prendre soin et faire preuve de jugement lorsqu’on utilise un outil

électrique. Ne pas s’en servir lorsqu’on est fatigué ou affaibli par des drogues, de

l’alcool ou des médicaments. De graves blessures peuvent résulter d’un moment

d’inattention lors de l’utilisation d’un outil électrique.

• Porter des vêtements appropriés. Éviter de porter des vêtements amples ou des

bijoux. Recouvrir la chevelure si elle est longue. Éloigner les cheveux, les vêtements

et les gants des pièces en mouvement qui peuvent les happer.

• Éviter les démarrages accidentels. S’assurer que l’interrupteur est en position hors

tension avant d’insérer la pile. Afin d’éviter les risques de blessures, ne pas transporter

l’outil avec le doigt sur l’interrupteur ni insérer la pile dans un outil dont l’interrupteur est en

position sous tension.

• Enlever les clés de réglage avant de mettre l’outil sous tension. Une clé qui est laissée

sur une pièce rotative de l’outil présente des risques de blessures.

• Ne pas dépasser sa portée. Garder son équilibre en tout temps. On s’assure d’une

meilleure maîtrise de l’outil dans des situations imprévues grâce à une position stable et un

bon équilibre.

• Porter de l’équipement de sécurité. Toujours porter des lunettes de sécurité. Dans

certaines conditions, il faut porter des masques respiratoires, des chaussures

antidérapantes, un casque de sécurité ou des protège-tympans.

UTILISATION ET ENTRETIEN DE L’OUTIL

• Utiliser des pinces de serrage ou de tout autre moyen pratique afin de fixer et de

soutenir la pièce à ouvrer sur une plate-forme stable. La pièce est instable lorsqu’elle

est retenue par la main ou le corps de l’utilisateur. Cela présente des risques de perte de

maîtrise de l’outil.

• Ne pas forcer l’outil. Utiliser l’outil approprié à la tâche. L’outil approprié fonctionne

mieux et sûrement lorsqu’on s’en sert à son rendement nominal.

• Ne pas se servir de l’outil lorsque l’interrupteur est défectueux. Le cas échéant, l’outil

est dangereux et il faut le réparer.

• Enlever la pile de l’outil ou placer celui-ci en position hors tension avant de le régler,

d’en remplacer les accessoires ou de le ranger. On minimise de la sorte le risque de

démarrage accidentel de l’outil.

• Ranger l’outil hors de portée des enfants et de toute autre personne qui n’en connaît

pas le fonctionnement. L’outil est dangereux entre les mains de ces personnes.

• Lorsque la pile ne sert pas, l’éloigner de tout objet métallique (comme des trombones,

des pièces de monnaie, des clés, des clous, des vis ou tout autre petit objets

métalliques qui peut créer une connexion d’une borne à l’autre). Lorsque les bornes

sont court-circuitées, cela peut générer des étincelles, des brûlures ou un incendie.

• Prendre soin des outils. S’assurer que les outils de coupe sont tranchants et propres.

Des outils bien entretenus à arêtes tranchantes ont moins tendance à se coincer et ils se

maîtrisent mieux.

• Vérifier l’alignement et les attaches des pièces mobiles, le degré d’usure des pièces

ainsi que tout autre facteur susceptible de nuire au bon fonctionnement de l’outil.

Faire réparer un outil endommagé avant de s’en servir. Des outils mal entretenus sont la

cause de nombreux accidents.

• Utiliser seulement les accessoires recommandés par le fabricant. Des accessoires qui

conviennent à un outil peuvent présenter des risques avec un autre outil.

ENTRETIEN

• Confier l’entretien de l’outil seulement à du personnel qualifié. Le non-respect de la

présente directive présente des risques de blessures.

• Lors de l’entretien de l’outil, utiliser seulement des pièces de rechange identiques.

Respecter les consignes relatives à l’entretien du présent guide d’utilisation. Il y a

risque de secousses électriques ou de blessures lorsqu’on utilise des pièces non autorisées

ou lorsqu’on ne respecte pas les consignes relatives à l’entretien

MESURES DE SÉCURITÉ SPÉCIFIQUES

• Saisir l’outil par ses surfaces de prises isolées lorsque l’outil peut entrer en contact

avec des fils cachés. En cas de contact avec un fil sous tension, les pièces métalliques de

l’outil seront sous tension et l’utilisateur subira des secousses électriques.

L’étiquette de l’outil peut comporter les symboles suivants.

V ....................................volts A..........................ampères

Hz ..................................hertz W ........................watts

min ..................................minutes ......................courant alternatif

................................courant continu

n

o........................sous vide

....................................

Construction de classe II

........................borne de mise à la

minute

..................................symbole d´avertissement .../min ..................tours ou courses

à la minute

CONSERVER CES MESURES.

Chargement de la perceuse

Les perceuses décrites dans le présent guide utilisent le même chargeur.

Faire ce qui suit pour charger l’ensemble de piles.

Le chargeur en 12-16 heures est conçu pour utiliser une alimentation standard de

120 volts, 60 Hz.

1. Placer le levier de commande de l’interrupteur à la position centrale (arrêt), comme le

montre la figure 1, et retirer l’ensemble de piles de l’outil de la façon illustrée à la

figure 2

2. Brancher le chargeur dans une prise standard de 120 volts.

3. Insérer l’ensemble de piles dans le chargeur, comme le montre la figure 3, et l’y laisser

pendant 12-16 heures.

4. Retirer l’ensemble de piles du chargeur et le remettre dans l’outil.

Notes importantes relatives au chargement

1. Après une utilisation normale, le chargement complet de la perceuse se fait en moins de

16 heures. La perceuse n'est pas chargée à sa sortie de l'usine. Il faut la charger pendant au moins 16 heures avant de s'en servir.

2. NE PAS charger l'ensemble de piles lorsque la température ambiante est inférieure à

4,5 °C (40 °F) ou supérieure à 40,5 °C (105 °F). Cette mesure est importante et aide à

prévenir les risques de graves dommages à l'ensemble de piles.

3. Le chargeur peut émettre des sons et les piles ainsi que le chargeur peuvent devenir

chauds au toucher pendant le chargement. Cette situation est normale et ne pose

aucun problème.

4. Lorsque la pile n’est pas bien chargée (1) vérifier l’alimentation de la prise en y bran-

RENSEIGNEMENTS IMPORT ANTS

• Il faut charger l’ensemble de piles pendant trois heures avant de s’en servir.

•À la sortie de l’usine, l’interrupteur de l’outil est verrouillé en position d’arrêt.

• Examiner l’intérieur du mandrin sans clé lorsqu’on le serre afin d’observer le

mouvement des mâchoires.

WARNING: Do not attempt to tighten drill bits (or any other accessory) by gripping the

front part of the chuck and turning the tool on. Damage to the chuck and personal injury may

occur when changing accessories.

SCREW DRIVING

For driving fasteners, the reversing button should be pushed to the left. Use reverse (button

pushed to the right) for removing fasteners. When moving from forward to reverse, or vice

versa, always release the trigger switch first.

DRILLING

• Use sharp drill bits only.

• Support and secure work properly, as instructed in the Safety Instructions.

• Use appropriate and required safety equipment, as instructed in the Safety Instructions.

• Secure and maintain work area, as instructed in the Safety Instructions.

• Run the drill very slowly, using light pressure, until the hole is started enough to keep the

drill bit from slipping out of it.

• Apply pressure in a straight line with the bit. Use enough pressure to keep the bit biting but

not so much as to stall the motor or deflect the bit.

• Hold the drill firmly to control its twisting action.

• DO NOT CLICK THE TRIGGER OF ASTALLED DRILLOFF AND ON IN AN ATTEMPT TO

STARTIT. DAMAGE TO THE DRILL CAN RESULT.

• Minimize stalling on breakthrough by reducing pressure and slowly drilling through the last

part of the hole.

• Keep the motor running while pulling the bit out of a drilled hole. This will help reduce

jamming.

• Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which

should be drilled dry. The lubricants that work best are sulphurized cutting oil or lard oil.

Bacon grease will also serve.

• When using twist drill bits to drill holes in wood, it will be necessary to pull the bits out

frequently to clear chips from the flutes.

• Make sure switch turns drill on and off.

WARNING: It is important to support the work properly and to hold the drill firmly to

prevent loss of control which could cause personal injury. If you have any questions on how

to properly operate tool, call: 1-800-54-HOW-TO (544-6986).

DRILLING IN WOOD

Holes in wood can be made with the same twist drill bits used for metal or with spade bits.

These bits should be sharp and should be pulled out frequently when drilling to clear chips

from the flutes.

DRILLING IN METAL

Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which

should be drilled dry. The cutting lubricants that work best are sulfurized cutting oil or lard oil;

bacon grease will also serve the purpose.

DRILLING IN MASONRY

Use carbide tipped masonry bits. Refer to Drilling section. Keep even force on the drill but not

so much that you crack the brittle material. Asmooth, even flow of dust indicates the proper

drilling rate.

Maintenance

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be performed by authorized service

centers or other qualified service organizations, always using identical replacement parts.

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling Corporation)

Seal on the nickel-cadmium battery (or battery pack) indicates that the costs to

recycle the battery (or battery pack) at the end of its useful life have already been

paid by Black & Decker. In some areas, it is illegal to place spent nickel-cadmium

batteries in the trash or municipal solid waste stream and the RBRC program

provides an environmentally conscious alternative.

RBRC in cooperation with Black & Decker and other battery users, has established programs

in the United States and Canada to facilitate the collection of spent nickel-cadmium batteries.

Help protect our environment and conserve natural resources by returning the spent nickelcadmium battery to an authorized Black & Decker service center or to your local retailer for

recycling. You may also contact your local recycling center for information on where to drop

off the spent battery, or call 1-800-8-BATTERY.

Accessories

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call:

1-800-54-HOW-TO (544-6986).

WARNING:The use of any accessory not recommended for use with this tool could be

hazardous.

The following accessories should be used only in the sizes specified below:

BITS, METALDRILLING – Up to 3/8" (9.5mm); BITS, MASONRY DRILLING – Up to 3/8"

(9.5mm); WOOD DRILLING – Up to 1/2" (12.7mm).

Service Information

All Black & Decker Service Centers are staffed with trained personnel to provide customers

with efficient and reliable power tool service. Whether you need technical advice, repair, or

genuine factory replacement parts, contact the Black & Decker location nearest you. To find

your local service location, refer to the yellow page directory under "Tools—Electric" or call:

1-800-54-HOW TO. (544-6986)

Full Two-Year Home Use Warranty

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in material

or workmanship. The defective product will be replaced or repaired at no charge in either of

two ways.

The first, which will result in exchanges only, is to return the product to the retailer from whom

it was purchased (provided that the store is a participating retailer). Returns should be made

within the time period of the retailer’s policy for exchanges (usually 30 to 90 days after the

sale). Proof of purchase may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned or

authorized Service Center for repair or replacement at our option. Proof of purchase may be

required. Black & Decker owned and authorized Service Centers are listed under "ToolsElectric" in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights and

you may have other rights which vary from state to state. Should you have any questions,

contact the manager of your nearest Black & Decker Service Center.

This product is not intended for commercial use.

See ‘Tools-Electric’

– Yellow Pages –

for Service & Sales

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

IMPORTANTES MESURES DE SÉCURITÉ - POUR TOUS LES OUTILS

ALIMENTÉS PAR PILES

AVERTISSEMENT! Lire et comprendre toutes les directives. Le non-respect de toutes

les directives suivantes présente des risques de secousses électriques, d’incendie ou de

blessures graves.

CONSERVER CES MESURES.

ZONE DE TRAVAIL

• S’assurer que la zone de travail est propre et bien éclairée. Des établis encombrés et

des endroits sombres présentent des risques d’accidents.

• Ne pas utiliser des outils électriques en présence de vapeurs explosives (comme

celles dégagées par des liquides, des gaz ou des poussières inflammables). Les

Loading...

Loading...