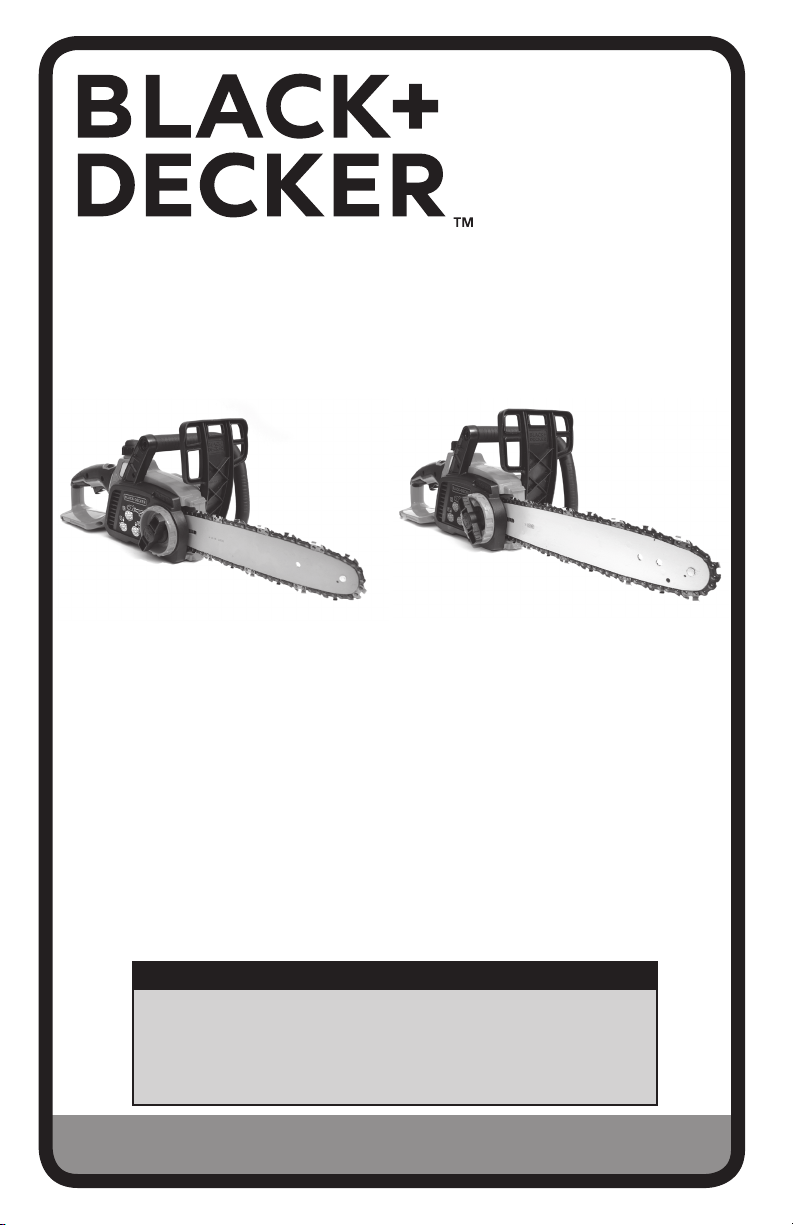

Black & Decker LCS1240, LCS1020 User Manual

20V MAX*, 40V MAX**

CORDLESS CHAIN SAW

INSTRUCTION MANUAL

CATALOG NUMBER

LCS1020 (20V MAX*)

*Maximum initial battery pack voltage (measured without

a workload) is 20 volts. The nominal voltage is 18.

LCS1240 (40V MAX**)

**Maximum initial battery pack voltage (measured without

a workload) is 40 volts. The nominal voltage is 36.

CATALOG NUMBER

Thank you for choosing BLACK+DECKER!

PLEASE READ BEFORE RETURNING THIS PRODUCT FOR ANY REASON.

If you have a question or experience a problem with your BLACK+DECKER

purchase, go to http://www.blackanddecker.com/instantanswers

If you can’t find the answer or do not have access to the Internet, call 1-800-5446986 from 8 a.m. to 5 p.m. EST Mon. - Fri. to speak with an agent. Please have the

catalog number available when you call.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

VEA EL E SPANOL EN LA CONTRAP ORTADA. INSTRUCTIVO DE OPE RACIÓN, CE NTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

KEY INFORMATION YOU SHOULD KNOW:

READ INSTRUCTIONS THOROUGHLY

BEFORE OPERATING!

• DO NOT OVER-TENSION CHAIN. Refer to “Adjusting Chain

Tension” for proper method of tensioning chain.

• Retighten chain frequently during first two hours of use.

To register your new product, visit

www.BlackandDecker.com/NewOwner

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains

relates to protecting YOUR SAFETY and PREVENTING PROBLEMS. The symbols

below are used to help you recognize this information.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially haz ard ous situation which, if not avoided,

may result in minor or mod er ate injury.

NOTICE: Used without the safety alert symbol indicates potentially hazardous

situation which, if not avoided, may result in property damage.

GENERAL POWER TOOL

SAFETY WARNINGS

WARNING:

and all instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

Read all safety warnings

SAVE ALL WARNINGS AND

INSTRUCTIONS FOR FUTURE

REFERENCE

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well

lit. Cluttered or dark areas invite

accidents.

b) Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases or dust. Power tools create

sparks which may ignite the dust or

fumes.

c) Keep children and bystanders

away while operating a power tool.

Distractions can cause you to lose

control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the

outlet. Never modify the plug in

any way. Do not use any adapter

plugs with earthed (grounded)

power tools. Unmodified plugs and

matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or

grounded.

c) Do not expose power tools to rain

or wet conditions. Water entering

a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp

edges or moving parts. Damaged or

entangled cords increase the risk of

electric shock.

e) When operating a power tool

outdoors, use an extension cord

suitable for outdoor use. Use of a

cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a

ground fault circuit interrupter

(GFCI) protected supply. Use of

a GFCI reduces the risk of electric

shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are

doing and use common sense

when operating a power tool. Do

not use a power tool while you

are tired or under the influence of

drugs, alcohol or medication. A

moment of inattention while operating

power tools may result in serious

personal injury.

b) Use personal protective equipment.

Always wear eye protection.

Protective equipment such as dust

mask, nonskid safety shoes, hard

hat, or hearing protection used for

appropriate conditions will reduce

personal injuries.

c) Prevent unintentional starting.

Ensure the switch is in the off

position before connecting to

power source and/ or battery pack,

picking up or carrying the tool.

Carrying power tools with your finger

on the switch or energizing power

tools that have the switch on invites

accidents.

d) Remove any adjusting key or

wrench before turning the power

tool on. A wrench or a key left

attached to a rotating part of the

power tool may result in personal

injury.

e) Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the

power tool in unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewelry. Keep your hair,

clothing and gloves away from

2

moving parts. Loose clothes, jewelry

or long hair can be caught in moving

parts.

g) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these

are connected and properly used.

Use of dust collection can reduce

dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use

the correct power tool for your

application. The correct power tool

will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the

switch does not turn it on and

off. Any power tool that cannot

be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the

power source and/or the battery

pack from the power tool before

making any adjustments, changing

accessories, or storing power

tools. Such preventive safety

measures reduce the risk of starting

the power tool accidentally.

d) Store idle power tools out of

the reach of children and do not

allow persons unfamiliar with the

power tool or these instructions

to operate the power tool. Power

tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any

other condition that may affect the

power tool’s operation. If damaged,

have the power tool repaired before

use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

g) Use the power tool, accessories

and tool bits, etc. in accordance

with these instructions, taking into

account the working conditions

and the work to be performed.

Use of the power tool for operations

different from those intended could

result in a hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Recharge only with the charger

specified by the manufacturer. A

charger that is suitable for one type of

battery pack may create a risk of fire

when used with another battery pack.

b) Use power tools only with

specifically designated battery

packs. Use of any other battery packs

may create a risk of injury and fire.

c) When battery pack is not in use,

keep it away from other metal

objects like paper clips, coins,

keys, nails, screws, or other small

metal objects that can make a

connection from one terminal

to another. Shorting the battery

terminals together may cause burns

or a fire.

d) Under abusive conditions, liquid

may be ejected from the battery,

avoid contact. If contact accidentally

occurs, flush with water. If liquid

contacts eyes, additionally seek

medical help. Liquid ejected from the

battery may cause irritation or burns.

6) SERVICE

a) Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This

will ensure at the safety of the power

tool is maintained.

READ ALL INSTRUCTIONS

CHAIN SAW SAFETY

WARNINGS:

• Keep all parts of the body away from

the saw chain when the chain saw is

operating. Before you start the chain

saw, make sure the saw chain is not

contacting anything. A moment of

inattention while operating chain saws

may cause entanglement of your clothing

or body with the saw chain.

• Always hold the chain saw with your

right hand on the rear handle and

your left hand on the front handle.

Holding the chain saw with a reversed

hand configuration increases the risk of

personal injury and should never be done.

• Hold the power tool by insulated

gripping surfaces only, because the

saw chain may contact hidden wiring.

Saw chains contacting a ″live″ wire may

make exposed metal parts of the power

tool ″live″ and could give the operator an

electric shock.

• Wear safety glasses and hearing

protection. Further protective

equipment for head, hands, legs

and feet is recommended. Adequate

protective clothing will reduce personal

injury by flying debris or accidental

contact with the saw chain.

• Do not operate a chain saw in a tree.

Operation of a chain saw while up in a

tree may result in personal injury.

• Always keep proper footing and

operate the chain saw only when

standing on fixed, secure and level

surface. Slippery or unstable surfaces

such as ladders may cause a loss of

balance or control of the chain saw.

• When cutting a limb that is under

tension be alert for spring back. When

the tension in the wood fibers is released

the spring loaded limb may strike the

operator and/or throw the chain saw out

3

of control.

• Use extreme caution when cutting

brush and saplings. The slender material

may catch the saw chain and be whipped

toward you or pull you off balance.

• Carry the chain saw by the front

handle with the chain saw switched

off and away from your body. When

transporting or storing the chain

saw always fit the scabbard. Proper

handling of the chain saw will reduce the

likelihood of accidental contact with the

moving saw chain.

• Follow instructions for lubricating,

chain tensioning and changing

accessories. Improperly tensioned or

lubricated chain may either break or

increase the chance for kickback.

• Keep handles dry, clean, and free from

oil and grease. Greasy, oily handles are

slippery causing loss of control.

• Cut wood only. Do not use chain

saw for purposes not intended. For

example: do not use chain saw for

cutting plastic, masonry or non-wood

building materials. Use of the chain

saw for operations different than intended

could result in a hazardous situation.

CAUSES AND OPERATOR

PREVENTION OF KICKBACK:

Kickback may occur when the nose or tip

of the guide bar touches an object, or when

the wood closes in and pinches the saw

chain in the cut.

Tip contact in some cases may cause a

sudden reverse reaction, kicking the guide

bar up and back towards the operator.

Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly

back towards the operator.

Either of these reactions may cause you

to lose control of the saw which could

result in serious personal injury. Do not

rely exclusively upon the safety devices

built into your saw. As a chain saw user,

you should take several steps to keep your

cutting jobs free from accident or injury.

Kickback is the result of tool misuse and/

or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below:

• Maintain a firm grip, with thumbs

and fingers encircling the chain saw

handles, with both hands on the saw

and position your body and arm to

allow you to resist kickback forces.

Kickback forces can be controlled by the

operator, if proper precautions are taken.

Do not let go of the chain saw.

• Do not overreach and do not cut above

chest height. This helps prevent unintended

tip contact and enables better control of the

chain saw in unexpected situations.

• Only use replacement bars and chains

specified by the manufacturer. Incorrect

replacement bars and chains may cause

chain breakage and/or kickback.

• Follow the manufacturer’s sharpening

and maintenance instructions for the

saw chain. Decreasing the depth gauge

height can lead to increased kickback.

THE FOLLOWING PRECAUTIONS

SHOULD BE FOLLOWED TO

MINIMIZE KICKBACK:

(1.) Grip Saw Firmly. Hold the chain saw firmly

with both hands when the motor is running.

Use a firm grip with thumbs and fingers

encircling the chain saw handles. Chain saw

will pull forward when cutting on the bottom

edge of the bar, and push backward when

cutting along the top edge of the bar.

(2.) Do not over reach.

(3.) Keep proper footing and balance at all times.

(4.) Don’t let the nose of the guide bar

contact a log, branch, ground or other

obstruction.

(5.) Don’t cut above shoulder height.

(6.) Use devices such as low kickback

chain and reduced kickback guide bars that

reduce the risks associated with kickback.

(7.) Only use replacement bars and chains

specified by the manufacturer or the

equivalent.

(8.) Never let the moving chain contact any

object at the tip of the guide bar.

(9.) Keep the working area free from

obstructions such as other trees, branches,

rocks, fences, stumps, etc. Eliminate or

avoid any obstruction that your saw chain

could hit while you are cutting through a

particular log or branch.

(10.) Keep your saw chain sharp and

properly tensioned. A loose or dull chain

can increase the chance of kickback.

Check tension at regular intervals with the

motor stopped and tool unplugged, never

with the motor running.

(11.) Begin and continue cutting only with

the chain moving at full speed. If the chain

is moving at a slower speed, there is a

greater chance for kickback to occur.

(12.) Cut one log at a time.

(13.) Use extreme caution when re-entering

a previous cut. Engage ribbed bumpers into

wood and allow chain to reach full speed

before proceeding with cut.

(14.) Do not attempt plunge cuts or bore cuts.

(15.) Watch for shifting logs or other forces that

could close a cut and pinch or fall into chain.

KICKBACK SAFETY FEATURES

WARNING: The following features

are included on your saw to help reduce the

hazard of kickback; however such features

will not totally eliminate this dangerous

reaction. As a chain saw user do not rely

only on safety devices. You must follow all

safety precautions, instructions, and

4

maintenance in this manual to help avoid

kickback and other forces which can result

in serious injury.

• Reduced-Kickback Guide Bar,

designed with a small radius tip which

reduces the size of the kickback danger

zone on bar tip. A reduced - kickback

guide bar is one which has been

demonstrated to significantly reduce the

number and seriousness of kickbacks

when tested in accordance with safety

requirements for electric chain saws.

• Low-Kickback Chain, designed with a

contoured depth gauge and guard link

which deflect kickback force and allow

wood to gradually ride into the cutter. A

low-kickback chain is a chain which has

met kickback performance requirements

of ANSI B175.1-2012.

• Do not operate chain saw while in

a tree, on a ladder, on a scaffold, or

from any unstable surface.

• Hold tool by insulated gripping

surfaces when performing an

operation where the cutting tool may

contact hidden wiring. Contact with a

“live” wire will make exposed metal parts

of the tool “live” and shock the operator.

• Do not attempt operations beyond

your capacity or experience. Read

thoroughly and understand completely all

instructions in this manual.

• Before you start chain saw, make sure

saw chain is not contacting any object.

• Do not operate a chain saw with one

hand! Serious injury to the operator,

helpers, or bystanders may result

from one handed operation. A chain

saw is intended for two-handed use only.

• Keep the handles dry, clean, and free

of oil or grease.

• Do not allow dirt, debris, or sawdust to

build up on the motor or outside air vents.

• Stop the chain saw before setting it down.

• Do not cut vines and/or small under brush.

• Use extreme caution when cutting

small size brush and saplings because

slender material may catch the saw chain

and be whipped toward you or pull you

off balance.

WARNING: Some dust created by

power sanding, sawing, grinding, drilling,

and other construction activities contains

chemicals known to the State of California

to cause cancer, birth defects or other

reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

•

crystalline silica from bricks and

cement and other masonry products, and

• arsenic and chromium from

chemically-treated lumber.

Your risk from these exposures varies,

depending on how often you do this type

of work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

5

such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust

from power sanding, sawing, grinding,

drilling, and other construction

activities. Wear protective clothing

and wash exposed areas with soap

and water. Allowing dust to get into

your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can

generate and/or disburse dust, which

may cause serious and permanent

respiratory or other injury. Always use

NIOSH/OSHA approved respiratory

protection appropriate for the dust

exposure. Direct particles away from face

and body.

CHAIN SAW NAMES AND TERMS

• Bucking - The process of cross cutting a

felled tree or log into lengths.

• Motor Brake - A device used to stop the

saw chain when the trigger is released.

• Chain Saw Powerhead - A chain saw

without the saw chain and guide bar.

• Drive Sprocket or Sprocket - The

toothed part that drives the saw chain.

•

Felling - The process of cutting down a tree.

• Felling Back Cut - The final cut in a tree

felling operation made on the opposite side

of the tree from the notching cut.

• Front Handle - The support handle located

at or toward the front of the chain saw.

• Front Hand Guard - A structural barrier

between the front handle of a chain saw

and the guide bar, typically located close

to the hand position on the front handle.

• Guide Bar - A solid railed structure that

supports and guides the saw chain.

• Guide Bar Scabbard - Enclosure fitted

over guide bar to prevent tooth contact

when saw is not in use.

• Kickback - The backward or upward

motion, or both of the guide bar occurring

when the saw chain near the nose of the

top area of the guide bar contacts any

object such as a log or branch, or when

the wood closes in and pinches the saw

chain in the cut.

•

Kickback, Pinch - The rapid pushback of

the saw which can occur when the wood

closes in and pinches the moving saw chain

in the cut along the top of the guide bar.

• Kickback, Rotational - The rapid upward

and backward motion of the saw which

can occur when the moving saw chain

near the upper portion of the tip of the

guide bar contacts an object, such as a

log or branch.

• Limbing - Removing the branches from a

fallen tree

• Low-Kickback Chain - A chain that

complies with the kickback

performance requirements of ANSI

B175.1-2012 (when tested on

a representative sample of chain saws.)

• Normal Cutting Position - Those

positions assumed in

performing the bucking and felling cuts.

• Notching Undercut - A notch cut in a

tree that directs the tree’s fall.

• Rear Handle - The support handle

located at or toward the rear of the saw.

• Reduced Kickback Guide Bar - A guide

bar which has been demonstrated to

reduce kickback significantly.

• Replacement Saw Chain - A chain that

complies with kickback performance

requirements of ANSI B175.1-2000 when

tested with specific chain saws. It may

not meet the ANSI performance

requirements when used with other saws.

• Saw Chain - A loop of chain having

cutting teeth, that cut the wood,and that is

driven by the motor and is supported by

the guide bar.

• Ribbed Bumper - The ribs used when

felling or bucking to pivot the saw and

maintain position while sawing.

• Switch - A device that when operated will

complete or interrupt an electrical power

circuit to the motor of the chain saw.

• Switch Linkage - The mechanism that

transmits motion from a trigger to the switch.

• Switch Lockout - A movable stop that

prevents the unintentional operation of

the switch until manually actuated.

INTENDED USE

Your BLACK+DECKER Chain Saw is ideal

for pruning applications and cutting small

logs up to 10 inches (254 mm) for the

LCS1020 and up to 12 inches (305 mm)

for the LCS1240 in diameter. This tool is

intended for consumer use only.

SAVE THESE INSTRUCTIONS

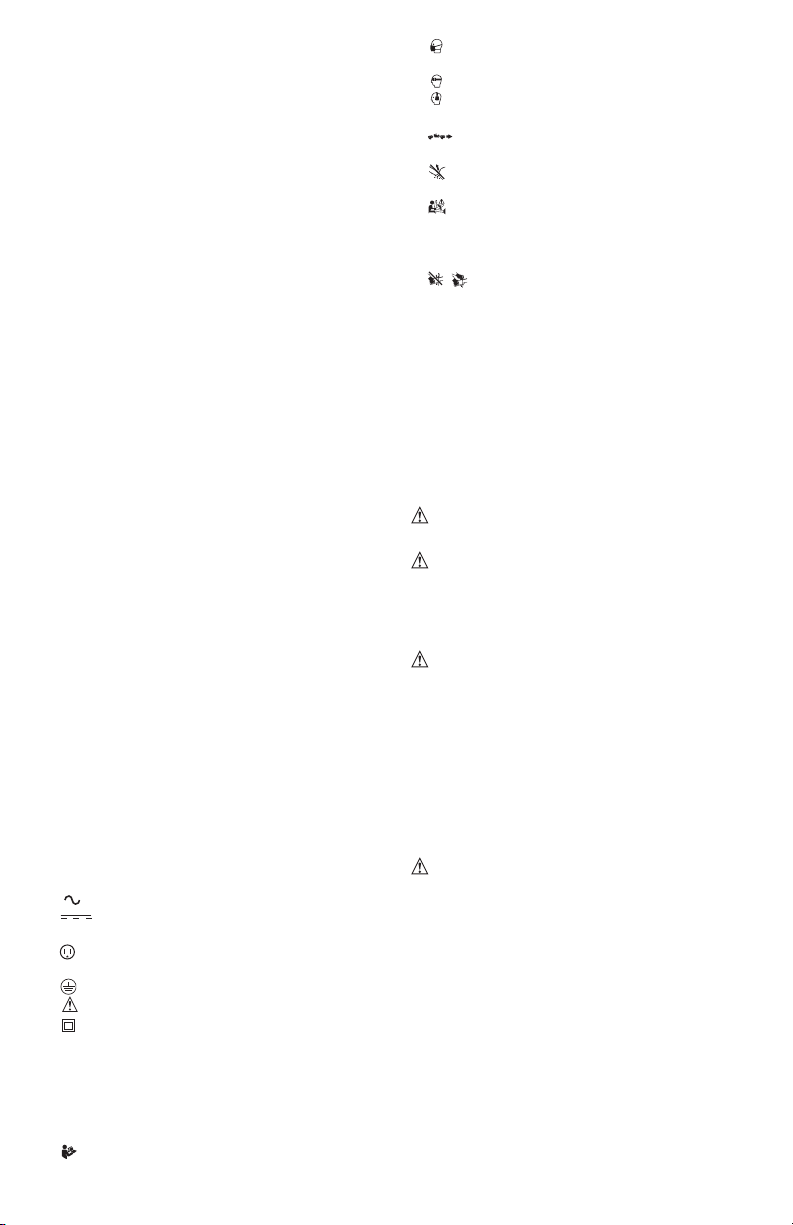

SYMBOLS

The label on your tool may include the

following symbols. The symbols and their

definitions are as follows:

V ..................volts

A ..................amperes

Hz ................hertz

W .................watts

min ..............minutes

or AC ......alternating current

or DC ...direct current

n

o ................no load speed

................Class I Construction

(grounded)

................earthing terminal

................safety alert symbol

................Class II Construction

(double insulated)

.../min or rpm...revolutions or

reciprocation per minute

m/s ..............meters per second

in .................inches

mm ..............millimeters

...............Read instruction manual

before use

................ Use proper respiratory

protection

................ Use proper eye protection

................ Use proper hearing

protection

..............Rotational direction of the

saw chain

...............

any object should be avoided

................

bar to move suddenly upward and

backward, which can cause

serious injury

...........Always use two hands when

operating the chain saw

Contact of the guide bar tip with

Tip contact can cause the guide

IMPORTANT SAFETY

INSTRUCTIONS FOR BATTERY

CHARGERS

SAVE THESE INSTRUCTIONS: THIS

MANUAL CONTAINS IMPORTANT

SAFETY INSTRUCTIONS FOR

BATTERY CHARGERS.

• Before using charger, read all instructions

and cautionary markings on charger, battery

pack, and product using battery pack.

WARNING: SHOCK HAZARD. Do

not allow any liquid to get inside charger.

WARNING: BURN HAZARD. To

reduce the risk of injury, charge only

designated BLACK+DECKER batteries.

Other types of batteries may burst causing

personal injury and damage.

CAUTION: Under certain conditions,

with the charger plugged in to the power

supply, the charger can be shorted by

foreign material. Foreign materials of a

conductive nature such as, but not limited

to, steel wool, aluminum foil, or any buildup

of metallic particles should be kept away

from charger cavities. Always unplug the

charger from the power supply when there

is no battery pack in the cavity. Unplug

charger before attempting to clean.

WARNING:

with this product is intended to be plugged

in such that it is correctly orientated in a

vertical or floor mount position.

• DO NOT attempt to charge the battery

pack with any chargers other than the

ones in this manual. The charger and

battery pack are specifically designed to

work together.

• These chargers are not intended

for any uses other than charging

designated Black+Decker rechargeable

batteries. Any other uses may result in

risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when

disconnecting charger. This will reduce

risk of damage to electric plug and cord.

6

The charger supplied

• Make sure that cord is located so that

it will not be stepped on, tripped over,

or otherwise subjected to damage or

stress.

• Do not use an extension cord unless

it is absolutely necessary. Use of

improper extension cord could result in

risk of fire, electric shock, or electrocution.

• An extension cord must have adequate

wire size (AWG or American Wire

Gauge) for safety. The smaller the

gauge number of the wire, the greater the

capacity of the cable, that is 16 gauge

has more capacity than 18 gauge. When

using more than one extension to make

up the total length, be sure each individual

extension contains at least the minimum

wire size.

Recommended Minimum Wire Size for

Extension Cords

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gauge

Than Than

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

• Do not place any object on top of

charger or place the charger on a soft

surface that might block the ventilation

slots and result in excessive internal

heat. Place the charger in a position

away from any heat source. The charger

is ventilated through slots in the top and

the bottom of the housing.

• Do not mount charger on wall or

permanently affix charger to any

surface. The charger is intended to use

on a flat, stable surface (i.e., table top,

bench top).

• Do not operate charger with damaged

cord or plug — have them replaced

immediately.

• Do not operate charger if it has

received a sharp blow, been dropped,

or otherwise damaged in any way. Take

it to an authorized service center.

• Do not disassemble charger; take it to

an authorized service center when service

or repair is required. Incorrect reassembly

may result in a risk of electric shock,

electrocution or fire.

• Disconnect the charger from the outlet

before attempting any cleaning. This

will reduce the risk of electric shock.

Removing the battery pack will not reduce

this risk.

• NEVER attempt to connect 2 chargers

together.

• The charger is designed to operate on

standard household electrical power

(120 Volts). Do not attempt to use it on

any other voltage.

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY WARNINGS

FOR BATTERY PACKS

WARNING:

this manual and manuals originally supplied

with tool before using the charger.

The battery pack is not fully charged out of

the carton. Before using the battery pack

and charger, read the safety instructions

below. Then follow charging procedures

outlined.

For safe operation, read

READ ALL INSTRUCTIONS

• Do not incinerate the battery pack

even if it is severely damaged or is

completely worn out. The battery pack

can explode in a fire. Toxic fumes and

materials are created when battery packs

are burned.

• Do not charge or use battery in

explosive atmospheres, such as in the

presence of flammable liquids, gases

or dust. Inserting or removing the battery

from the charger may ignite the dust or

fumes.

• If battery contents come into contact

with the skin, immediately wash area

with mild soap and water. If battery

liquid gets into the eye, rinse water over

the open eye for 15 minutes or until

irritation ceases. If medical attention is

needed, the battery electrolyte for Li-ion

batteries is composed of a mixture of

liquid organic carbonates and lithium

salts.

• Contents of opened battery cells may

cause respiratory irritation. Provide

fresh air. If symptoms persist, seek

medical attention.

WARNING:

BATTERY LIQUID MAY BE FLAMMABLE

IF EXPOSED TO SPARK OR FLAME.

• Charge the battery packs only in

Black+ Decker chargers.

• DO NOT splash or immerse in water or

other liquids. This may cause premature

cell failure.

• Do not store or use the tool and

battery pack in locations where the

temperature may reach or exceed

105°F (40˚C) (such as outside sheds or

metal buildings in summer).

WARNING:

the battery pack for any reason. If

battery pack case is cracked or

damaged, do not insert into charger. Do

not crush, drop or damage battery pack. Do

not use a battery pack or charger that has

received a sharp blow, been dropped, run

7

BURN HAZARD.

Never attempt to open

over or damaged in any way (i.e., pierced

with a nail, hit with a hammer, stepped on).

Damaged battery packs should be returned

to service center for recycling.

WARNING:

store or carry battery so that metal

objects can contact exposed battery

terminals. For example, do not place

battery in aprons, pockets, tool boxes,

product kit boxes, drawers, etc., with loose

nails, screws, keys, etc. Transporting

batteries can possibly cause fires if the

battery terminals inadvertently come in

contact with conductive materials such

as keys, coins, hand tools and the like.

The US Department of Transportation

Hazardous Material Regulations (HMR)

actually prohibit transporting batteries in

commerce or on airplanes (i.e., packed in

suitcases and carry-on luggage) UNLESS

they are properly protected from short

circuits. So when transporting individual

batteries, make sure that the battery

terminals are protected and well insulated

from materials that could contact them and

cause a short circuit. NOTE: LI-ION

batteries should not be put in checked

baggage.

Fire hazard. Do not

STORAGE

RECOMMENDATIONS

1. The best storage place is one that is

cool and dry away from direct sunlight and

excess heat or cold.

2. Long-term storage will not harm the

battery pack or charger, unless the battery

is depleted.

CHARGING PROCEDURE

The standard charger provided will charge

a fully depleted battery in about 4-5 hours.

1. Plug the charger into an appropriate

outlet before inserting the battery pack.

2. Insert the battery pack into the charger.

3. The green LED will flash indicating that

the battery is being charged.

4. The completion of charge is indicated by

the green LED remaining on continuously.

The pack is fully charged and may be used

at this time or left on the charger.

Recharge discharged batteries as soon as

possible after use or battery life may be

greatly diminished. It is recommended that

the batteries be recharged after each use.

IMPORTANT CHARGING NOTES

1. Longest life and best performance can

be obtained if the battery pack is charged

when the air temperature is between 60°F

and 80°F (16°- 27°C). DO NOT charge

the battery pack in an air temperature

below +40°F (+4.5°C), or above +105°F

(+40.5°C). This is important and will

prevent serious damage to the battery

pack.

2. The charger and battery pack may

become warm to touch while charging.

This is a normal condition, and does not

indicate a problem. To facilitate the cooling

of the battery pack after use, avoid placing

the charger or battery pack in a warm

environment such as in a metal shed, or an

uninsulated trailer.

3. If the battery pack does not charge

properly:

a. Check current at receptacle by

plugging in a lamp or other appliance

b. Check to see if receptacle is

connected to a light switch which turns

power off when you turn out the lights.

c. Move charger and battery pack to

a location where the surrounding air

temperature is approximately 60°F and

80°F (16°- 27°C)

d. If charging problems persist, take the

tool, battery pack and charger to your

local service center.

4. The battery pack should be recharged

when it fails to produce sufficient power on

jobs which were easily done previously.

DO NOT CONTINUE to use under these

conditions. Follow the charging procedure.

You may also charge a partially used pack

whenever you desire with no adverse affect

on the battery pack.

5. Foreign materials of a conductive nature

such as, but not limited to, steel wool,

aluminum foil, or any buildup of metallic

particles should be kept away from charger

cavities. Always unplug the charger from

the power supply when there is no battery

pack in the cavity. Unplug charger before

attempting to clean.

6. Do not freeze or immerse charger in

water or any other liquid.

WARNING:

not allow any liquid to get inside charger.

Never attempt to open the battery pack

for any reason. If the plastic housing of

the battery pack breaks or cracks, return

to a service center for recycling.

8

SHOCK HAZARD. Do

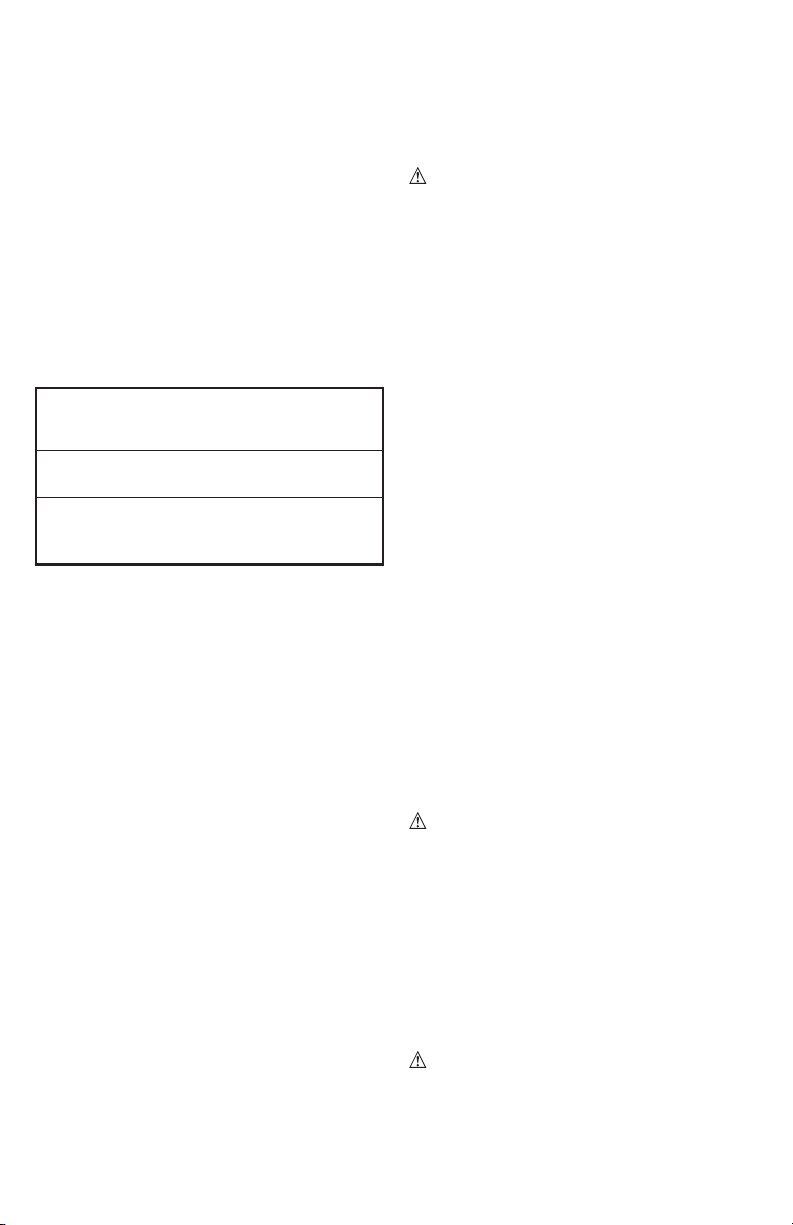

FUNCTIONAL DESCRIPTION

LCS1020

15

2

10

1

16

LCS1240

2

10

1

1. Trigger switch

2. Lock-off button

3. Front hand guard

4. Guide bar

5. Saw chain

6. Sprocket cover

7. Bar adjust locking knob

8. Chain tensioning knob

14

16

14

6

6

11

3

7

11

7 4

8

3

8

9

5

4

9

5

9. Guide bar scabbard

10. Rear handle

11. Front handle

12. 20V Battery (not shown)

13. 40V Battery (not shown)

14. Oil cap

15. Oil primer bulb

16. Oil level indicator

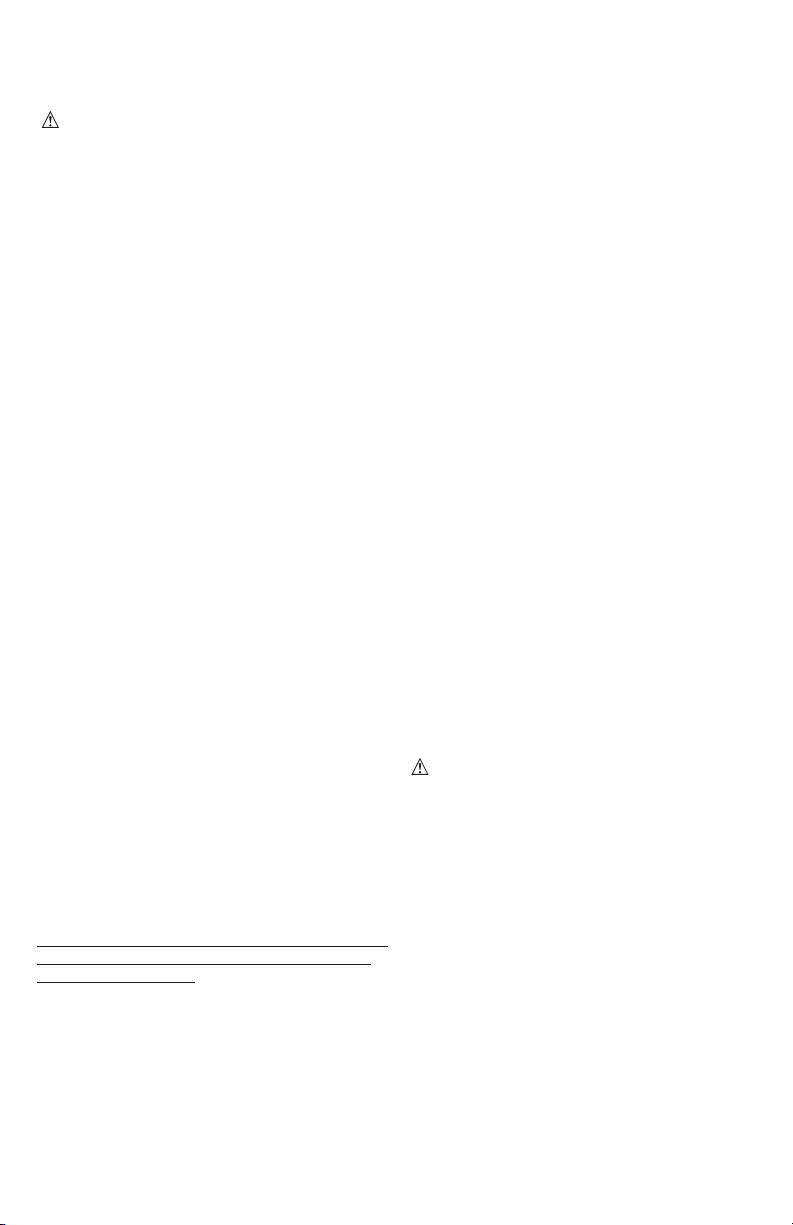

INSTALLING / REMOVING

BATTERY PACK

WARNING:

button is engaged to prevent switch actuation

before removing or installing battery.

TO INSTALL BATTERY PACK: Insert

battery pack into tool until an audible click

is heard, as shown in Figure A. Ensure

battery pack is fully seated and fully latched

into position.

TO REMOVE BATTERY PACK:

Depress the battery release button in the

back of the battery pack and pull battery

pack out of tool (figure A).

Make certain the lock-off

PREPARING YOUR CHAIN

SAW FOR USE

WARNING:

all instructions. Failure to follow all

instructions listed below may result in electric

shock, fire and/or serious personal injury.

Read and understand

9

A

ASSEMBLY

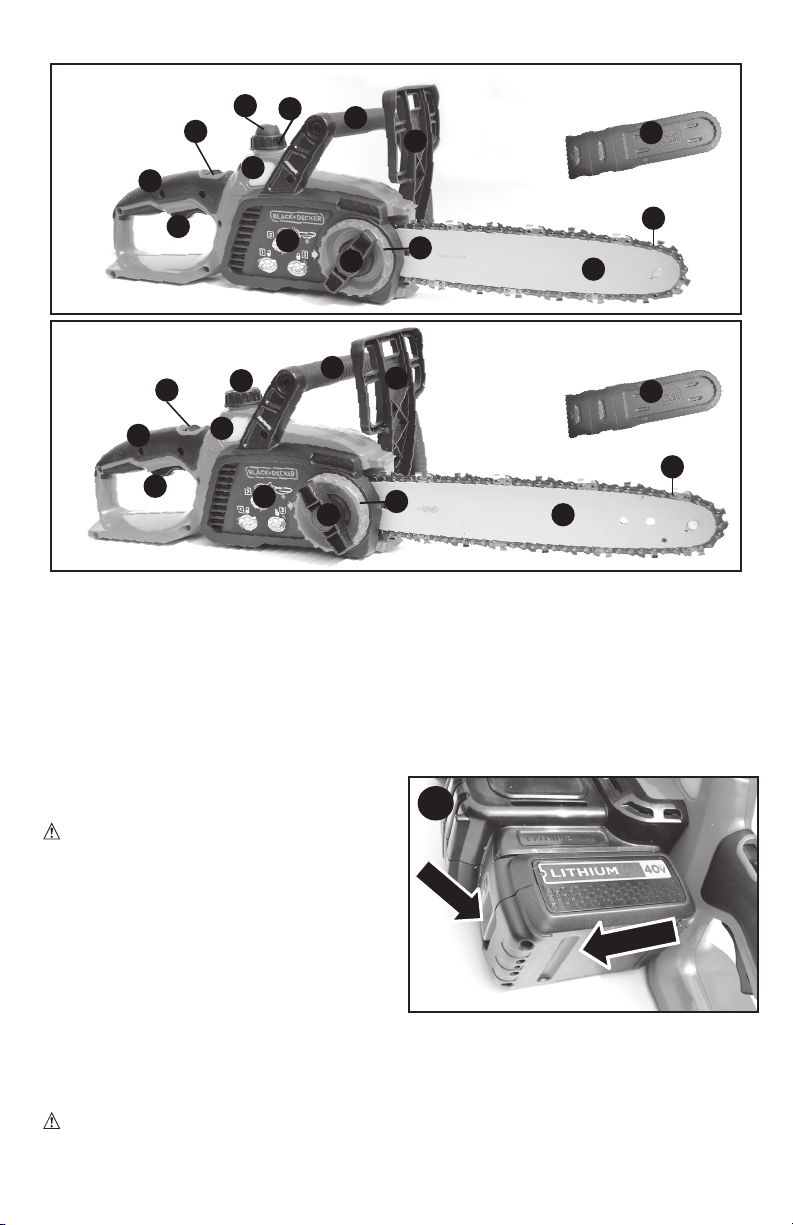

INSTALLING THE GUIDE BAR AND

SAW CHAIN

CAUTION:

wear protective gloves when handling

the chain. The chain is sharp and can cut

you when it is not running.

WARNING:

To prevent accidental operation, ensure

that battery is removed from the tool

before performing the following

operations. Failure to do this could result in

serious personal injury.

The saw chain (5) and guide bar (4) are

packed separately in the carton. The chain

has to be attached to the bar, and both must

be attached to the body of the tool.

• Place the saw on a firm surface.

• Rotate the bar adjust locking knob (7)

counterclockwise as shown in Figure B

to remove sprocket cover (6).

Sharp chain. Always

Sharp moving chain.

B

until snug, then loosen knob one full

turn, so the saw chain can be properly

tensioned.

Note:

check that the tab for the tool free tensioner

on the bar aligns with the slot on the inside

of the sprocket cover.

If the cover does not fit correctly,

D

• While holding the bar adjust locking knob

(7), rotate the chain tensioning knob (8)

clockwise to increase tension as shown

in Figure E. Make sure the saw chain (5)

is snug around the guide bar (4).

E

• Wearing protective gloves, grasp the saw

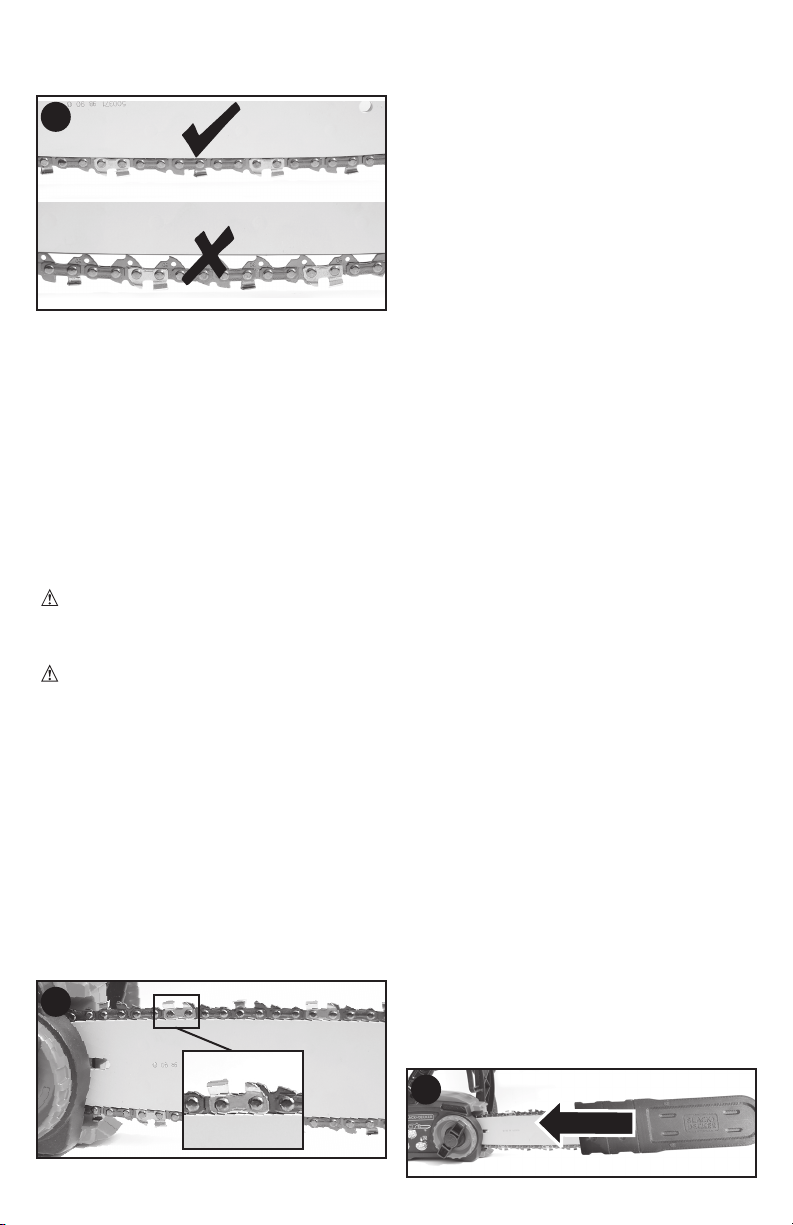

chain (5) and wrap it around the guide

bar (4), ensuring the teeth are facing the

correct direction (see figure F)

• Ensure the chain is properly set in the slot

around the entire guide bar.

• Place the saw chain around the sprocket

(17) while lining up the slot on the guide

bar with the bolt (18) in the base of the

tool as shown in Figure C.

C

17

• The tensioning knob must be rotated

counterclockwise to its stop. Arrows on

the sprocket cover and tensioning knob

must align before the cover is replaced.

Once in place, hold the bar still, replace

sprocket cover (6).

tension assembly bolt hole on the cover

lines up with the bolt (18) in the main

housing as shown in Figure D. Rotate

the bar adjust locking knob (7) clockwise

18

Make sure tool-free

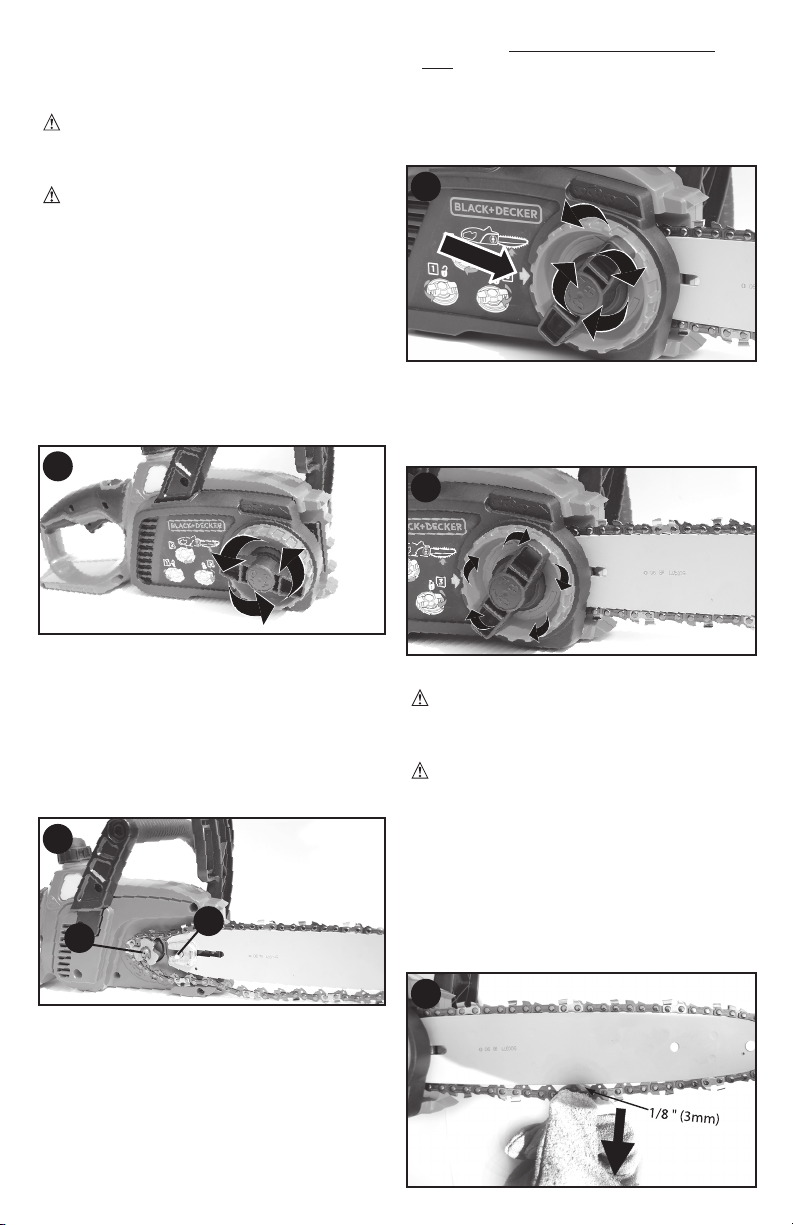

ADJUSTING CHAIN TENSION

CAUTION:

wear protective gloves when handling

the chain. The chain is sharp and can cut

you when it is not running.

WARNING:

prevent accidental operation, ensure that

battery is removed from the tool before

performing the following operations. Failure

to do this could result in serious personal injury

• With the saw on a firm surface, check

the saw chain (5) tension. The tension is

correct when the chain snaps back after

being pulled 1/8 inch (3mm) away from

the guide bar (4) with light force from

the middle finger and thumb as shown

Sharp chain. Always

Sharp moving chain. To

F

10

.

in figure F. There should be no “sag”

between the guide bar and the chain on

the underside as shown in figure G.

G

• To adjust saw chain tension, loosen bar

adjust locking knob (7) one full turn and

follow instructions for “Installing the Guide

Bar and Saw Chain.”

• Do not over-tension the chain as this will

lead to excessive wear and will reduce the

life of the bar and chain.

• Once chain tension is correct, securely

tighten bar adjust locking knob.

• When the chain is new, check the tension

frequently (after removing battery) during

the first 2 hours of use as a new chain

stretches slightly.

REPLACING THE SAW CHAIN

CAUTION:

wear protective gloves when handling

the chain. The chain is sharp and can cut

you when it is not running.

WARNING:

prevent accidental operation, ensure that

battery is removed from the tool before

performing the following operations. Failure

to do this could result in serious personal injury

• Rotate the bar adjust locking knob (7)

counte

• Remove sprocket cover (6) as described

• Lift the worn saw chain (5) out of the

• Place the new chain in the slot of the

rclockwise to release chain tension.

in “Installing the Guide Bar and Saw

Chain” section.

groove in the guide bar (4).

guide bar, making sure the saw teeth are

facing the correct direction by matching

the arrow on the chain with the graphic on

the sprocket cover (6) shown in figure H.

Sharp chain. Always

Sharp moving chain. To

.

H

• Follow instructions for “Installing the

Guide Bar and Saw Chain.”

Replacement chain and bar are available from

your nearest Black+Decker service center.

• LCS1020 requires replacement chain #

RC1000, service part number 90609782.

Replacement 10” bar, service part number

90609787.

• LCS1240 requires replacement chain #

RC1200, service part number 90609781.

Replacement 12” bar, service part number

90609786.

Saw chain and guide bar Oiling

MANUAL OILING SYSTEM (20V ONLY)

This chain saw is equipped with a manual

oiling system that keeps the saw chain and

guide bar lubricated. Slowly press the primer

bulb (15) on the oil cap (14) three times

before making each cut. Hold the primer bulb

down for 1 second each time. The oil level

indicator (16) shows the level of the oil in

the chain saw. If the oil level is less than a

quarter full, remove the battery from the chain

saw and refill with the correct type of oil.

AUTO OILING SYSTEM (40V ONLY)

This chain saw is equipped with an auto

oiling system that keeps the saw chain and

guide bar constantly lubricated. The oil level

indicator (16) shows the level of the oil in

the chain saw. If the oil level is less than a

quarter full, remove the battery from the chain

saw and refill with the correct type of oil.

NOTE: Use a high quality bar and chain

oil for proper chain and bar lubrication. As

a temporary substitute, a non-detergent

SAE30 weight motor oil can be used. The

use of a vegetable based bar and chain

oil is recommended when pruning trees.

Mineral oil is not recommended because it

may harm trees. Never use waste oil or very

thick oil. These may damage your chain saw.

FILLING THE OIL RESERVOIR

• Remove the oil cap (14) and fill the

reservoir with the recommended chain oil

until the oil level has reached the top of

the oil level indicator (16).

• Refit the oil cap.

• Periodically switch the chain saw off and

check the oil level indicator to ensure the

bar and chain are being properly oiled.

TRANSPORTING SAW

• Always remove the battery from the tool

and cover the guide bar (4) with the

scabbard (9) (figure I) when transporting

the saw.

11

I

OPERATING THE CHAIN SAW

WARNING: Read and understand

all instructions. Failure to follow all

instructions listed below may result in

electric shock, fire and/or serious personal

injury.

• Guard Against Kickback which can

result in severe injury or death. See

Important Safety Instructions “Guard

Against Kickback”, to avoid the risk of

kickback.

• Do not overreach. Do not cut above

chest height. Make sure your footing

is firm. Keep feet apart. Divide your

weight evenly on both feet.

• Use a firm grip with your left hand on

the front handle (11) and your right

hand on the rear handle (10) so that

your body is to the left of the guide bar.

• Do not hold chain saw by front hand

guard (3). Keep elbow of left arm locked

so that left arm is straight to withstand a

kickback.

WARNING: Never use a cross-

handed grip (left hand on the rear handle

and right hand on the front handle).

WARNING: Never allow any part

of your body to be in line with the guide

bar (4) when operating the chain saw.

• Never operate while in a tree, in any

awkward position or on a ladder or

other unstable surface. You may lose

control of saw causing severe injury.

• Keep the chain saw running at full

speed the entire time you are cutting.

• Allow the chain to cut for you. Exert

only light pressure. Do not put pressure

on chain saw at end of cut.

ON / OFF

• Always be sure of your footing and grip

the chain saw firmly with both hands with

the thumb and fingers encircling both

handles.

• To turn the tool ON, depress the lock off

button (2) and squeeze the trigger switch

(1) as shown in figure J. (Once the tool

is running you can release the lock off

button.)

• To turn the tool OFF, release the trigger

switch.

J

2

COMMON CUTTING

TECHNIQUES

FELLING

The process of cutting down a tree. Be

sure battery is fully charged before felling a

tree so you can finish on a single charge.

Do not fell trees in high wind conditions.

WARNING: Felling can result in

injury. It should only be performed by a

trained person.

• (Figure K) A retreat path should be

planned and cleared as necessary before

cuts are started. The retreat path should

extend back and diagonally to the rear of

the expected line of fall.

K

• Before felling is started, consider the

natural lean of the tree, the location of

larger branches and the wind direction to

judge which way the tree will fall. Have

wedges (wood, plastic or aluminum)

and a heavy mallet handy.

Remove dirt, stones, loose bark, nails,

staples, and wire from the tree where the

felling cuts are to be made.

• Figure

the notch 1/3 of the diameter of the tree,

perpendicular to the direction of the fall.

Make the lower horizontal notching cut

first. This will help to avoid pinching of

either the saw chain or the guide bar

when the second notch cut is being made.

• (Figure L) Felling Back Cut - Make the

felling back cut at least 2 inches (51mm)

higher than the horizontal notching cut.

Keep the felling back cut parallel to the

horizontal notching cut. Make the felling

back cut so enough wood is left to act

as a hinge. The hinge wood keeps the

tree from twisting and falling in the wrong

L

DIRECTION

OF FALL

NOTCH

RETREAT

45°

L- Notching Undercut - Make

TREE

2 (5cm)

INCHES

DIRECTION

OF

FALL

FELLING BACK

CUT

2 (5cm)

INCHES

12

HINGE

direction. Do not cut through the hinge.

• (Figure L) As the felling cut gets close to

the hinge the tree should begin to fall. If

there is any chance that the tree may not

fall in the desired direction or it may rock

back and bind the saw chain, stop cutting

before the felling cut is complete and

use wedges to open the cut and drop the

tree along the desired line of fall. When

the tree begins to fall remove the chain

saw from the cut, stop the motor, put the

chain saw down, then use the retreat

path planned. Be alert for overhead limbs

falling and watch your footing.

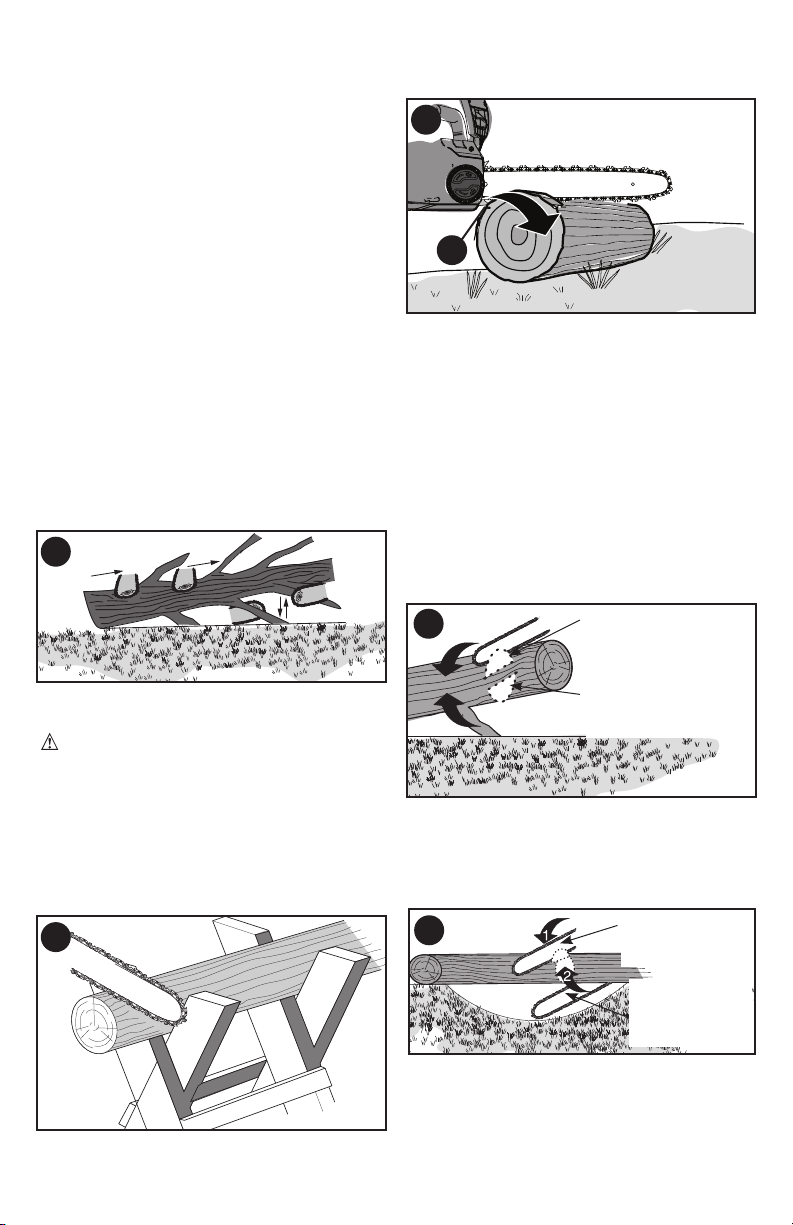

LIMBING

Removing the branches from a fallen tree.

When limbing, leave larger lower limbs to

support the log off the ground. Remove

the small limbs in one cut. Branches under

tension should be cut from the bottom of

the branch towards the top to avoid binding

the chain saw as shown in figure M.

Trim limbs from opposite side keeping

tree stem between you and saw. Never

make cuts with saw between your legs or

straddle the limb to be cut.

M

BUCKING

WARNING: Recommend that first

time users should practice cutting on a

saw horse.

Cutting a felled tree or log into lengths.

How you should cut depends on how the

log is supported. Use a saw horse

(figure N) whenever possible.

Always start a cut with the chain running at

full speed.

N

• Place the bottom spike (19) of the chain

saw behind the area of the initial cut as

shown in figure O.

O

CUT FROM TOP (OVERBUCK)

AVOID CUTTING EARTH

19

• Turn the chain saw on then rotate the

chain and bar down into the tree, using

the spike as a hinge.

• Once the chain saw gets to a 45 degree

angle, level the chain saw again and

repeat steps until you cut fully through.

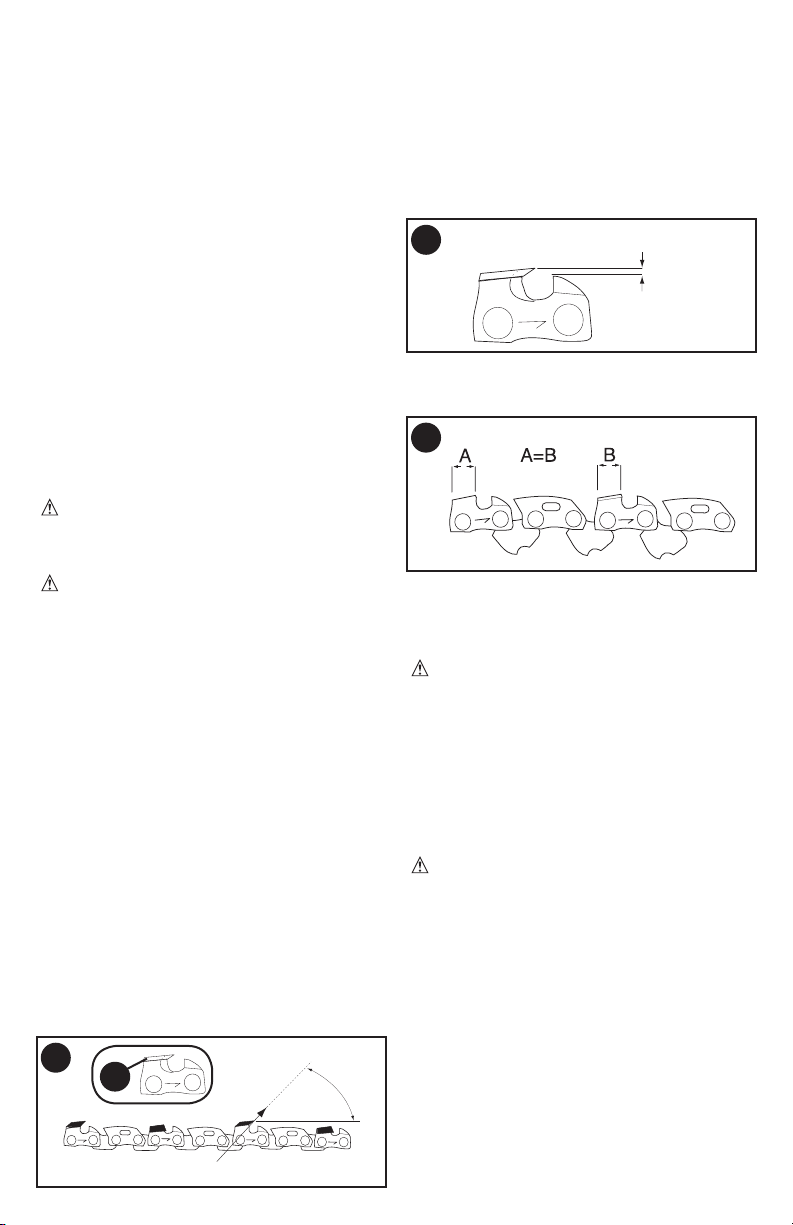

• When the tree is supported along its

entire length, make a cut from the top

(overbuck), but avoid cutting the earth as

this will dull your saw quickly.

• Figure P- When supported at one end

First, cut 1/3 the diameter from the

underside (underbuck). Then make the

finished cut by overbucking to meet the

first cut.

P

2nd CUT OVERBUCK

(2/3DIAMETER) TO MEET 1st

CUT (TO AVOID PINCHING)

2

1

1

1st CUT UNDERBUCK

(1/3 DIAMETER)

AVOID SPLINTERING

• Figure Q- When supported at both ends

First, cut 1/3 down from the top

overbuck. Then make the finished cut by

underbucking the lower 2/3 to meet the

first cut.

Q

1st CUT OVERBUCK

(1/3 DIAMETER)

TO AVOID SPLINTERING

2nd CUT UNDERBUCK

(2/3 DIAMETER)

TO MEET 1st CUT

(TO AVOID PINCHING)

• When on a slope

Always stand on the uphill side of the

log. When “cutting through”, to maintain

complete control release the cutting

pressure near the end of the cut without

relaxing your grip on the chain saw

handles. Don’t let the chain contact the

13

ground. After completing the cut, wait for

60°

the saw chain to stop before you move

the chain saw. Always stop the motor

before moving from cut to cut.

CARE AND MAINTENANCE

Use only mild soap and damp cloth to clean

the tool. Do not use solvents to clean the

plastic housing of the saw. Never let any

liquid get inside the tool; never immerse any

part of the tool into a liquid.

IMPORTANT: To assure product

SAFETY and RELIABILITY, repairs,

maintenance and adjustment should be

performed by authorized service centers or

other qualified service organizations, always

using identical replacement parts.

Regular maintenance ensures a long

effective life for your chain saw.

CHAIN AND BAR

After every few hours of use, remove the

guide bar and chain and clean thoroughly

using a soft bristle brush. Ensure oiling

hole on bar is clear of debris.

SAW CHAIN SHARPENING

CAUTION: Sharp chain. Always

wear protective gloves when handling

the chain. The chain is sharp and can cut

you when it is not running.

WARNING:

To prevent accidental operation, ensure

that battery is removed from the tool

before performing the following

operations. Failure to do this could result in

serious personal injury.

Sharp moving chain.

NOTE: The cutters will dull immediately if

they touch the ground or a nail while cutting.

To get the best possible performance from

your chain saw it is important to keep the

teeth of the chain sharp. Follow these

helpful tips for proper saw chain sharpening:

1. For best results use a 4.5mm file and

a file holder or filing guide to sharpen

your chain. This will ensure you always

get the correct sharpening angles.

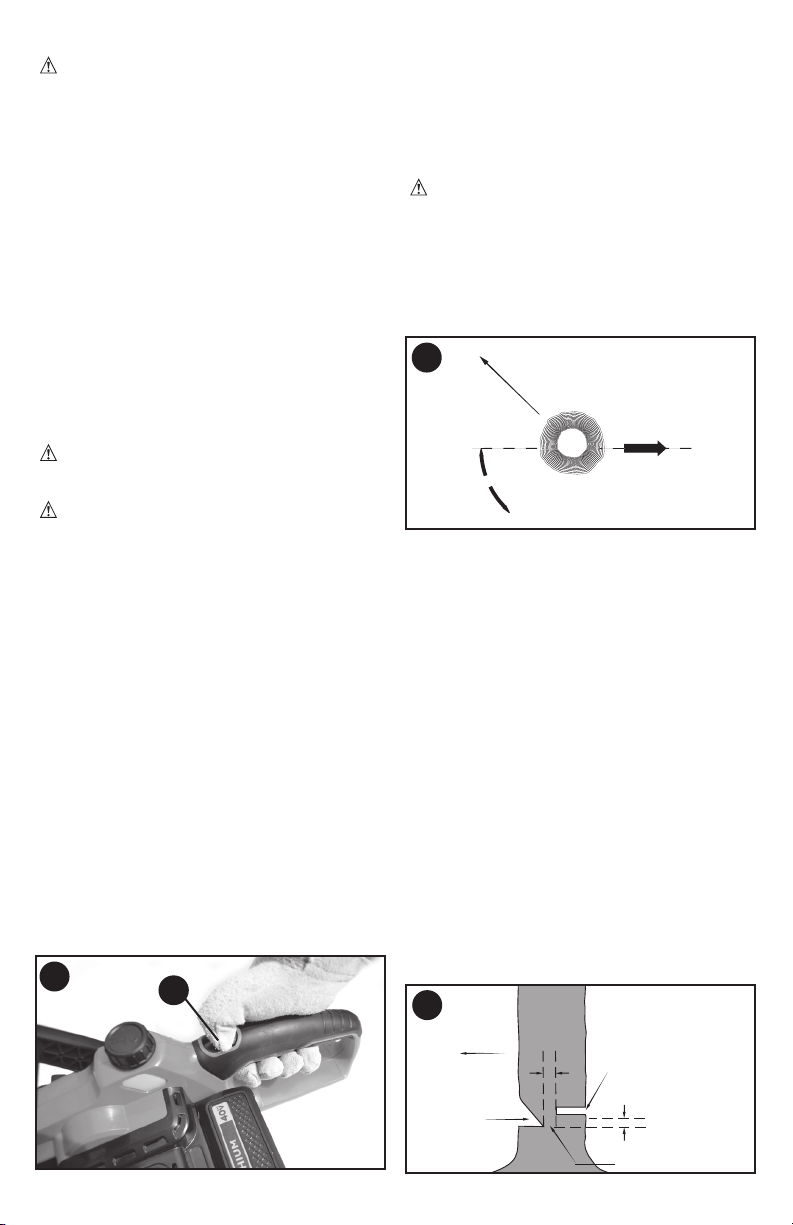

2. Place the file holder flat on the top

plate and depth gauge of the cutter.

3. (Figure R) Keep the correct top plate

(20) filing angle line of 30° on your file

guide parallel with your chain (file at

60° from chain viewed from above).

4. Sharpen cutters on one side of the

chain first. File from the inside of

R

20

each cutter to the outside. Then turn

your saw around and repeat the

processes (2,3,4) for cutters on the

other side of the chain.

NOTE: Use a flat file to file the tops of

the rakers (portion of chain link in front of

the cutter) so they are about .025 inch (.635

mm) below the tips of the cutters as shown

in Figure S.

S

.025 in.

.635mm

5. Figure T- Keep all cutter lengths

equal.

T

6. If damage is present on the chrome

surface of the top plates or side

plates, file back until such damage is

removed.

CAUTION:

be sharp, use extra caution during this

process.

After filing, the cutter will

NOTE: Each time the chain is

sharpened, it loses some of the low

kickback qualities and extra caution should

be used. It is recommended that a chain be

sharpened no more than four times.

ACCESSORIES

WARNING: The use of accessories

not recommended in this manual may be

hazardous.

Replacement chain and bar are available from

your nearest Black+Decker service center.

• LCS1020 requires replacement chain #

RC1000, service part number 90609782.

Replacement 10” bar, service part number

90609787.

• LCS1240 requires replacement chain #

RC1200, service part number 90609781.

Replacement 12” bar, service part number

90609786.

The use of accessories not recommended

in this manual may be hazardous.

14

TROUBLESHOOTING

If your Chain Saw does not operate correctly check the following:

Problem Possible Cause Possible Solution

• Tool will not start.

• Unit will not charge.

• Bar / chain

overheated.

• Chain is loose.

• Poor cut quality.

• Unit runs but does

not cut.

• Unit stops while

cutting.

• Unit does not oil. • Oil reservoir emptied.

• Battery not installed

properly.

• Battery not charged.

• Lock-out button not

actuated.

• Battery not inserted into

charger.

• Chain too tight.

• Lubrication needed.

• Chain tension set

incorrectly.

• Chain tension set

incorrectly.

• Chain needs

replacement.

• Chain installed backwards. • Refer to sections for installing and

• Lithium battery depleted.

• Voltage limit protection

exceeded.

• Battery too hot.

• Oiling hole on guide bar

clogged.

• Check battery installation.

• Check battery charging

requirements.

• Push lock off button/actuate trigger.

• Insert battery into charger until green

LED appears. Charge up to 5 hours if

battery totally drained.

• Refer to “adjusting chain

tension” section.

• Refer to “chain oiling” section.

• Refer to “adjusting chain

tension” section.

• Refer to “adjusting chain

tension” section.

Note: Excessive tension leads to

excessive wear and reduction in life

of bar & chain. Lubricate before each

cut. Refer to “replacing the chain”

section.

removing chain.

• Charge battery.

• Unit is being forced. Restart and

apply less pressure.

• Allow battery to cool for 30 minutes

before proceeding.

• Refill reservoir.

• Clean guide bar, sprocket and

sprocket cover. Refer to “care and

maintenance” section.

For assistance with your product, visit our website www.blackanddecker.com for the location

of the service center nearest you or call the BLACK+DECKER help line at 1-800-544-6986.

15

SERVICE INFORMATION

All BLACK+DECKER Service Centers

are staffed with trained personnel to

provide customers with efficient and

reliable power tool service. Whether you

need technical advice, repair, or genuine

factory replacement parts, contact the

BLACK+DECKER location nearest you. To

find your local service location, call:

1-800-544-6986, or visit

www.blackanddecker.com

THE RBRC™ SEAL

The RBRC™ (Rechargeable

Battery Recycling Corporation)

Seal on the Li-Ion battery (or

battery pack) indicates that the

costs to recycle the battery (or battery pack)

at the end of its useful life have already

been paid by Black+Decker. RBRC™ in

cooperation with Black+Decker and other

battery users, has established programs in

the United States to facilitate the collection

of spent Li-Ion batteries. Help protect

our environment and conserve natural

resources by returning the spent Li-Ion

battery to an authorized Black+Decker

service center or to your local retailer for

recycling. You may also contact your local

recycling center for information on where

to drop off the spent battery. RBRC™ is a

registered trademark of the Rechargeable

Battery Recycling Corporation.

This Class B digital apparatus complies with

Canadian ICES-003.

This device complies with part 15 of the

FCC rules. Operation is subject to the

following two conditions: (1) This device

may not cause harmful interference, and

(2) this device must accept any interference

received, including interference that may

cause undesired operation.

NOTE: This equipment has been tested

and found to comply with the limits for a

Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are

designed to provide reasonable protection

against harmful interference in a residential

installation. This equipment generates, uses

and can radiate radio frequency energy

and, if not installed and used in accordance

with the instructions, may cause harmful

interference to radio communications.

However, there is no guarantee that

interference will not occur in a particular

installation.

If this equipment does cause harmful

interference to radio or television reception,

which can be determined by turning

the equipment off and on, the user is

encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the

equipment and receiver.

• Connect the equipment into an outlet on

a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/

TV technician for help.

Changes or modifications to this unit not

expressly approved by the party responsible

for compliance could void the user’s

authority to operate the equipment. This

Class B digital apparatus complies with

Canadian ICES-003.

16

LIMITED WARRANTY

TWO-YEAR (LCS1020 ONLY)

THREE-YEAR (LCS1240 ONLY)

Black+Decker (U.S.) Inc. warranties this

product to be free from defects in material

or workmanship for a period of two (2)

years for LCS1020 and three (3) years for

LCS1240 following the date of purchase,

provided that the product is used in a home

environment. This limited warranty does

not cover failures due to abuse, accidental

damage or when repairs have been

made or attempted by anyone other than

Black+Decker and its Authorized Service

Centers. A defective product meeting the

warranty conditions set forth herein will be

replaced or repaired at no charge in either

of two ways:

The first, which will result in exchanges

only, is to return the product to the retailer

from whom it was purchased (provided

that the store is a participating retailer).

Returns should be made within the time

period of the retailer’s policy for exchanges.

Proof of purchase may be required. Please

check with the retailer for its specific

return policy regarding time limits for

returns or exchanges. The second option

is to take or send the product (prepaid)

to a Black+Decker owned or authorized

Service Center for repair or replacement at

Black+Decker’s option. Proof of purchase

may be required. Black+Decker owned and

authorized service centers are listed online

at www.blackanddecker.com.

This warranty does not apply to

accessories. This warranty gives you

specific legal rights and you may have

other rights which vary from state to state.

Should you have any questions, contact

the manager of your nearest Black+Decker

Service Center. This product is not intended

for commercial use, and accordingly, such

commercial use of this product will void this

warranty. All other guarentees, express or

implied, are hereby disclaimed.

LATIN AMERICA: This warranty does not

apply to products sold in Latin America.

For products sold in Latin America, check

country specific warranty information

contained in the packaging, call the local

company or see the website for such

information.

Imported by

Black+Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

17

20 V MAX.*, 40 V MAX.**

SCIE À CHAÎNE SANS FIL

MODE D’EMPLOI

NUMERO DE CATALOGUE

LCS1020 (20V MAX*)

*La tension initiale maximale du bloc-piles (mesurée sans

charge de travail) est de 20 volts. La tension nominale,

mesurée avec une charge de travail, est de 18 volts.

NUMERO DE CATALOGUE

LCS1240 (40V MAX**)

**La tension initiale maximale du bloc-piles (mesurée sans

charge de travail) est de 40 volts. La tension nominale,

mesurée avec une charge de travail, est de 36 volts.

MERCI D’AVOIR CHOISI BLACK+DECKER!

ÀLIRE AVANT DE RETOURNER CE PRODUIT POUR

QUELQUE RAISON QUE CE SOIT:

Si des questions ou des problèmes surgissent après l’achat d’un produit

Black+Decker, consulter le site Web www.blackanddecker.com/instantanswers

pour obtenir des réponses instantanément 24 heures par jour. Si la réponse est

introuvable ou en l’absence d’accès à l’Internet, composer le 1 800 544-6986 de 8 h

à 17 h HNE, du lundi au vendredi, pour parler avec un agent. Prière d’avoir le numéro

de catalogue sous la main lors de l’appel.

CONSERVER CE MODE D’EMPLOI POUR UN USAGE ULTÉRIEUR.

RENSEIGNEMENTS IMPORTANTS

LIRE LES INSTRUCTIONS AVANT D’UTILISER!

• NE PAS SUR TENDRE LA CHAÎNE. Se reporter à la section

« RÉGLAGE DE LA TENSION DE LA CHAÎNE » pour savoir

comment tendre correctement la chaîne.

• Retendre la chaîne fréquemment pendant les deux premières

heures d’utilisation.

Visite www.BlackandDecker.com/NewOwner

para registrar su nuevo producto.

18

Loading...

Loading...