Page 1

20V MAX* LiTHiUM CORDLESS

CHAIN SAW iNSTRUCTiON MANUAL

IVlodel Number LCS120

Model # LCS120

PLEASE READ BEFORE RETURNING

THiS PRODUCT FOR ANY REASON:

If you have a question or experience a problem with your

WWW.BLACKAND DECKER.COM/INSTANTANSWERS

If you can't find the answer or do not have access to the intemet,

call 1-800-544-6986 from 8 a.m. to 5 p.m. EST Mon.- Fri

Please have the catalog number available when you call.

SAVE THiS MANUAL FOR FUTURE REFERENCE.

VEA EL ESPA_IOL EN LA CONTRAPORTADA.

POUR LE FRAN(_,AIS, VOIR LA COUVERTURE ARRII_RE.

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO

Y POLIZA DE GARANTIA. ADVERTENClA: LEASE ESTE

INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Black & Decker purchase, go to

for instant answers 24 hours a day.

to speak with an agent.

KEY iNFORMATION YOU SHOULD KNOW:

- DO NOT OVER-TENSION CHAIN. Refer to "ADJUSTING

CHAIN TENSION" for proper method of tensioning

chain.

- Retighten chain frequently during first two hours of use.

*Maximum initial battery pack voltage [

(measured without a workload) is 20

volts. Measured under a workload,

nom na votage s 18.

Page 2

Safety Guidelines - Definitions ................................................. 2

Chain Saw Terms ..................................................................... 2

Important Safety Instructions ................................................... 3

Components ............................................................................. 6

Important Safety Instructions for Battery Chargers .................. 6

Important Safety Instructions for Battery Packs ....................... 7

Charging Procedure ................................................................. 8

Preparing Chain Saw for Use .................................................. 10

Assembly ................................................................................. 10

Operating the Chain Saw ......................................................... 12

Maintenance ............................................................................ 15

Service Information .................................................................. 16

Full Two-Year Home Use Warranty ......................................... 16

Troubleshooting ....................................................................... 17

SAFETY GUIDELINES =DEFINITIONS

It is important for you to read and understand this manual. The

information it contains relates to protecting YOUR SAFETY and

PREVENTING PROBLEMS. The symbols below are used to help

you recognize this information.

z_DANGER: Indicates an imminent!y hazardous situation which

if not avoided, will result in death or serious tnjury.

z_WARNING- Indicates a potentially hazardous situation which,

not avoided, could result in death or serious injury.

z_CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

NOTICE: Used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may result in

property damage.

Your Black & Decker Cordless Chain Saw is ideal for pruning

applications and cutting small logs up to 8 inches (203 mm) in

diameter. This tool isintended for consumer use only.

Bucking - The process of cross cutting a felled tree or log into

lengths.

Motor Brake = A device used to stop the saw chain when the

trigger is released.

Chain Saw Powerhead - A chain saw without the saw chain and

guide bar.

Drive Sprocket or Sprocket - The toothed part that drives the

saw chain.

Felling =The process of cutting down a tree.

Felling Back Cut = The final cut in a tree felling operation made

on the opposite side of the tree from the notching cut.

Front Handle =The support handle located at or toward the front

of the chain saw.

Front Hand Guard - A structural barrier between the front handle

of a chain saw and the guide bar, typically located close to the

hand position on the front handle and sometimes employed as an

activating lever for a chain brake.

Guide Bar - A solid railed structure that supports and guides the

saw chain.

Guide Bar Scabbard = Enclosure fitted over guide bar to prevent

tooth contact when saw is not in use.

Kickback =The backward or upward motion, or both of the guide

bar occurring when the saw chain near the nose of the top area

of the guide bar contacts any object such as a log or branch, or

when the wood closes in and pinches the saw chain in the cut.

Kickback, Pinch - The rapid pushback of the saw which can

occur when the wood closes in and pinches the moving saw chain

in the cut along the top of the guide bar.

Page 3

Kickback,Rotational-Therapidupwardandbackwardmotion

ofthesawwhichcanoccurwhenthemovingsawchainnearthe

upperportionofthetipoftheguidebarcontactsanobject,such

asalogorbranch.

Limbing- Removingthebranchesfromafallentree

Low-KickbackChain-Achainthatcomplieswiththekickback

performancerequirementsofANSIB175.1-1991(whentestedon

arepresentativesampleofchainsaws.)

NormalCuttingPosition - Those positions assumed in

performing the bucking and felling cuts.

Notching Undercut - A notch cut in a tree that directs the tree's fall.

Rear Handle - The support handle located at or toward the rear

of the saw.

Reduced Kickback Guide Bar - A guide bar which has been

demonstrated to reduce kickback significantly.

Replacement Saw Chain - A chain that complies with kickback

performance requirements of ANSI B175.1-2000 when tested

with specific chain saws. It may not meet the ANSI performance

requirements when used with other saws.

Saw Chain - A loop of chain having cutting teeth, that cut the

wood,and that is driven by the motor and is supported by the

guide bar.

Ribbed Bumper - The ribs used when felling or bucking to pivot

the saw and maintain position while sawing.

Switch - A device that when operated will complete or interrupt

an electrical power circuit to the motor of the chain saw.

Switch Linkage - The mechanism that transmits motion from a

trigger to the switch.

Switch Lockout - A movable stop that prevents the unintentional

operation of the switch until manually actuated.

safety precau to reduce risk of fire,

electric shock, and personal injury, including the following:

When usmc 3erated chain saw, basic

READ ALL INSTRUCTIONS

• Keep all parts of the body away from the saw chain when the

chain saw is operating. Before you start the chain saw, make

sure the saw chain is not contacting anything. A moment of

inattention while operating chain saws may cause entanglement

of your clothing or body with the saw chain.

• Hold the power tool by insulated gripping surfaces only,

because the saw chain may contact hidden wiring or its own

cord. Saw chains contacting a "live" wire may make exposed

metal parts of the power tool "live" and could give the operator an

electric shock:

• Wear safety glasses and hearing protection. Further

protective equipment for head, hands, legs and feet is

recommended. Adequate protective clothing wifl reduce personal

injury by flying debris or accidental contact with the saw chain.

• Do not operate a chain saw in a tree. Operation of a chain saw

while up in a tree may result in personal injury.

• Always keep proper footing and operate the chain saw only

when standing on fixed, secure and level surface. Slippery or

unstable surfaces such as ladders may cause a loss of balance or

control of the chain saw.

• When cutting a limb that is under tension be alert for spring

back. When the tension in the wood fibres is released the spring

loaded limb may strike the operator and/or throw the chain saw

out of control.

• Use extreme caution when cutting brush and saplings. The

slender material may catch the saw chain and be whipped toward

you or pull you off balance.

• Carry the chain saw by the front handle with the chain saw

switched off and away from your body. When transporting or

storing the chain saw always fit the guide bar cover. Proper

handling of the chain saw will reduce the fikelihood of accidental

contact with the moving saw chain.

• Follow instructions for lubricating, chain tensioning and

changing accessories. Improperly tensioned or lubricated chain

may either break or increase the chance for kickback:

Page 4

o

Keep handles dry, clean, and free from oil and grease.

Greasy, oily handles are slippery causing loss of control.

o

Cut wood only. Do not use chain saw for purposes not

intended. For example: do not use chain saw for cutting

plastic, masonry or non-wood building materials. Use of the

chain saw for operations different than intended could result in a

hazardous situation.

Causes and operator prevention of kickback:

Kickback may occur when the nose or tip of the guide bar touches

an object, or when the wood closes in and pinches the saw chain in

the cut.

Tip contact in some cases may cause a sudden reverse reaction,

kicking the guide bar up and back towards the operator.

Pinching the saw chain along the top of the guide bar may push the

guide bar rapidly back towards the operator.

Either of these reactions may cause you to lose control of the saw

which could result in serious personal injury. Do not rely exclusively

upon the safety devices built into your saw. As a chain saw user,

you should take several steps to keep your cutting jobs free from

accident or injury.

Kickback is the result of tool misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below:

• Maintain a firm grip, with thumbs and fingers encircling the

chain saw handles, with both hands on the saw and position

your body and arm to allow you to resist kickback forces.

Kickback forces can be controlled by the operator, if proper

precautions are taken. Do not let go of the chain saw.

• Do not overreach and do not cut above shoulder height. This

helps prevent unintended tip contact and enables better control of

the chain saw in unexpected situations.

• Only use replacement bars and chains specified by the

manufacturer. Incorrect replacement bars and chains may cause

chain breakage and/or kickback:

• Follow the manufacturer's sharpening and maintenance

instructions for the saw chain. Decreasing the depth gauge

height can lead to increased kickback:

The following precautions should be followed to minimize

kickback:

(1.) Grip Saw Firmly. Hold the chain saw firmly with both hands

when the motor is running. Use a firm grip with thumbs and fingers

encircling the chain saw handles. Chain saw will pull forward when

cutting on the bottom edge of the bar, and push backward when

cutting along the top edge of the bar.

(2.) Do not over reach.

(3.) Keep proper footing and balance at all times.

(4.) Don't let the nose of the guide bar contact a log, branch, ground

or other obstruction.

(5.) Don't cut above shoulder height.

(6.) Use devices such as low kickback chain and reduced kickback

uide bars that reduce the risks associated with kickback.

.) Only use replacement bars and chains specified by the

manufacturer or the equivalent.

(8.) Never let the moving chain contact any object at the tip of the

uide bar.

.) Keep the working area free from obstructions such as other

trees, branches, rocks, fences, stumps, etc. Eliminate or avoid

any obstruction that your saw chain could hit while you are cutting

through a particular log or branch.

(10.) Keep your saw chain sharp and properly tensioned. A loose

or dull chain can increase the chance of kickback. Check tension at

regular intervals with the motor stopped and battery removed, never

with the motor running.

(11.) Begin and continue cutting only with the chain moving at full

speed. If the chain is moving at a slower speed, there is a greater

chance for kickback to occur.

(12.) Cut one log at a time.

(13.) Use extreme caution when re-entering a previous cut. Engage

ribbed bumpers into wood and allow chain to reach full speed before

roceeding with cut.

14.) Do not attempt plunge cuts or bore cuts.

(15.) Watch for shifting logs or other forces that could close a cut

and pinch or fall into chain.

• Power Supply - Connect chain saw battery charger to correct

voltage, that is, be sure that the voltage supplied is the same as that

specified on the nameplate of the tool

Page 5

ckbackSafety Features

WARNING: The following features are included on your saw

to help reduce the hazard of kickback; however such features

wilt not totally eliminate this dangerous reaction. As a chain saw user

do not rely only on safety devices. You must follow all safety

precautions, instructions, and maintenance in this manual to help

avoid kickback and other forces which can result in serious injury.

• Reduced-Kickback Guide Bar, designed with a small radius tip

which reduces the size of the kickback danger zone on bar tip. A

reduced - kickback guide bar is one which has been demonstrated to

significantly reduce the number and seriousness of kickbacks when

tested in accordance with safety requirements for electric chain saws.

• Low=Kickback Chain, designed with a contoured depth gauge and

guard link which deflect kickback force and allow wood to gradually

ride into the cutter. A low-kickback chain is a chain which has met

kickback performance requirements of ANSI B175.1-1991.

• Do not operate chain saw while in a tree, on a ladder, on a

scaffold, or from any unstable surface.

• Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring.

Contact with a "live" wire will make exposed metal parts of the tool

"live" and shock the operator.

• Do not attempt operations beyond your capacity or

experience. Read thoroughly and understandcompletely all

instructions in this manual.

• Before you start chain saw, make sure saw chain is not

contacting any object.

• Do not operate a chain saw with one hand! Serious injury

to the operator, helpers, or bystanders may result from one

handed operation. A chain saw is intended for two-handed use only.

• Keep the handles dry, clean, and free of oil or grease.

Do not allow dirt, debris, or sawdust to build up on the motor

or outside air vents.

• Stop the chain saw before setting it down.

• Do not cut vines and/or small under brush.

• Use extreme caution when cutting smatl size brush and

saplings because slender material may catch the saw chain and

!_be whipped toward you or pull you off balance.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals

known to the State of California to cause cancer, birth defects or

other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with approved

safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction activities.

Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth, eyes, or lay on the

_Nkin maypromote absorption of harmful chemicals.

ARNING: Use of this tool can generate and/or disburse dust,

which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate for

the dust exposure. Direct particles away from face and body.

SAVE THESE INSTRUCTIONS

Symbols

The label on your tool may include the following symbols.

V. ................................volts

Hz..............................herlz

min.............................minutes

- - -. ........................directcurrent

@ ..............................ClassIConstructbn

(grounded)

[] ..............................ClassIIConstructbn

(doubleinsulated)

........................Readinstruction

manualbeforeuse

..............................Usepropereyeprotedion

A..............amperes

W.............watts

,_..........attemabhgcurrent

no............noloadspeed

8. ...........earthingterminal

z_..........safetyalertsymbd

.../minorrpm...revduiionsor

recfprocationperminute

............Useproper

respiratoryprotectlbn

0 ...........Useproper

heatingprotection

Page 6

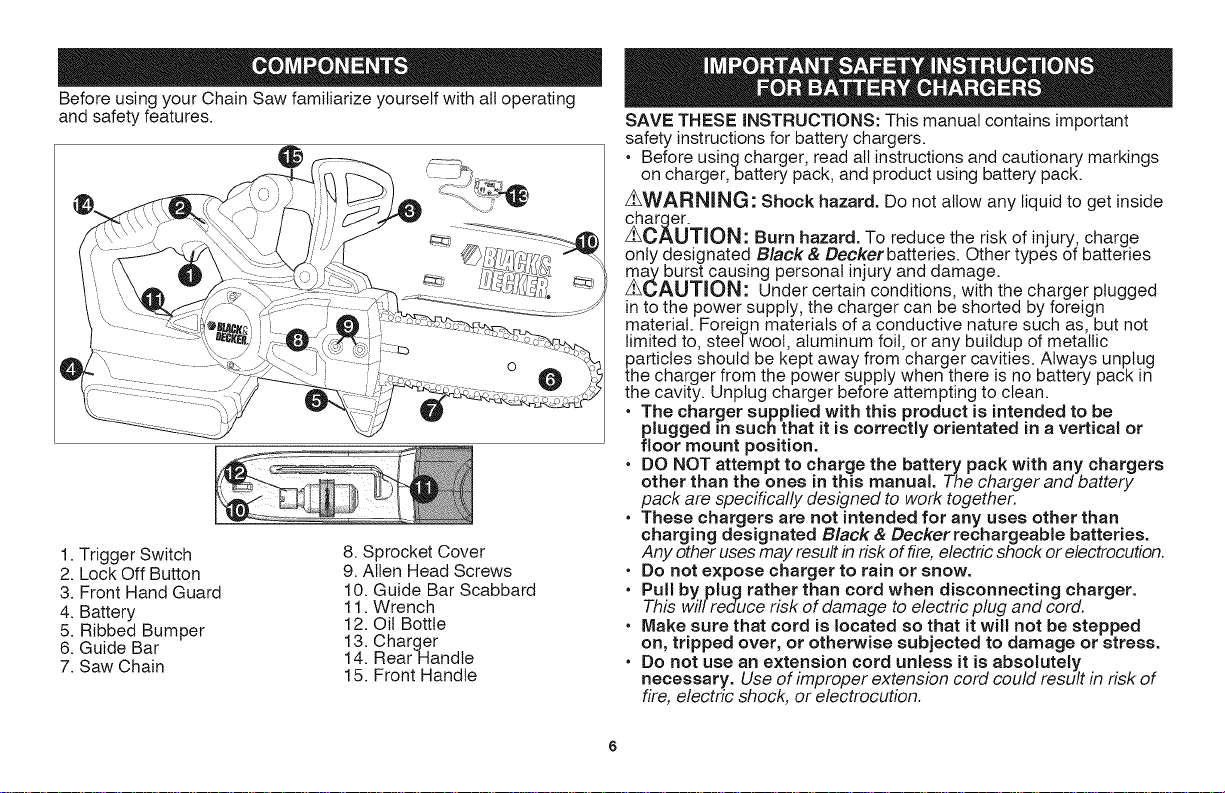

Before using your Chain Saw familiarize yourself with all operating

and safety features.

1. Trigger Switch

2. Lock Off Button

3. Front Hand Guard

4. Battery

5. Ribbed Bumper

6. Guide Bar

7. Saw Chain

8. Sprocket Cover

9. Allen Head Screws

10. Guide Bar Scabbard

11. Wrench

12. Oil Bottle

13. Charger

14. Rear Handle

15. Front Handle

SAVE THESE INSTRUCTIONS: This manual contains important

safety instructions for battery chargers.

• Before usingcharger, read all instructions and cautionary markings

on charger,battery pack, and product using battery pack.

Z_WARNING: Shock hazard. Do not allow any liquid to get inside

charqer.

z_CAUTION: Burn hazard. To reduce the risk of injury, charge

only designated Black & Decker batteries. Other types of batteries

may burst causing personal injury and damage.

_CAUTION: Under certain conditions, with the charger plugged

in to the power supply, the charger can be shorted by foreign

material. Foreign materials of a conductive nature such as, but not

limited to, stee/woot, aluminum foil, or any buildup of metallic

particles should be kept away from charger cavities. Always unplug

the charger from the power supply when there is no battery pack in

the cavity. Unplug charger before attempting to clean.

• The charger supplied with this product is intended to be

plugged in suchthat it is correctly orientated in a vertical or

floor mount position.

• DO NOT attempt to charge the battery pack with any chargers

other than the ones in this manual. The charger and battery

pack are specifically designed to work together.

• These chargers are not intended for any uses other than

charging designated Black & Decker rechargeable batteries.

Any other uses may result in risk of fire, electric shock or electrocution.

• Do not expose charger to rain or snow.

• Pull byplug rather than cord when disconnecting charger.

This will reduce risk of damage to electric plug and cord.

• Make sure that cord is located so that it will not be stepped

on, tripped over, or otherwise subjected to damage or stress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result in risk of

fire, electric shock; or electrocution.

Page 7

• An extension cord must have adequate wire size (AWG or

American Wire Gauge) for safety. The smaller the gauge number

of the wire, the greater the capacity of the cable, that is 16 gauge

has more capacity than 18 gauge. When using more than one

extension to make up the total length, be sure each individual

extension contains at least the minimum wire size.

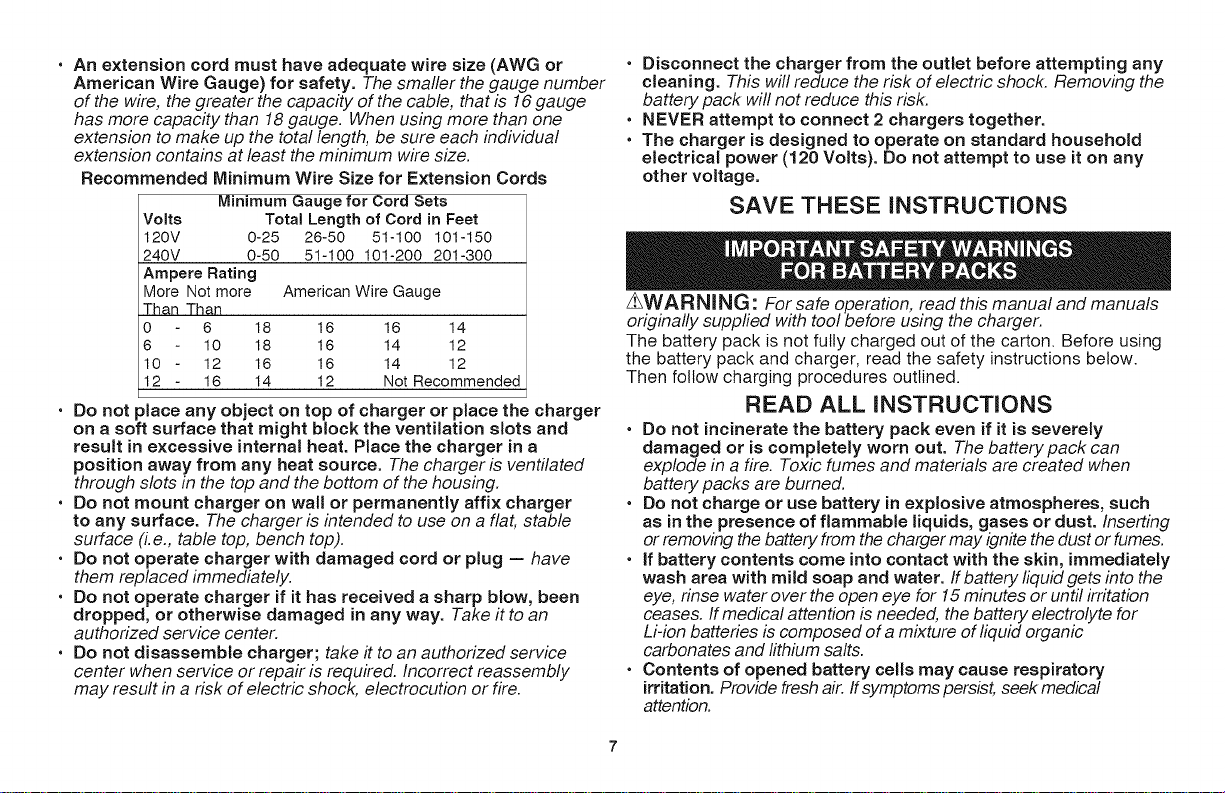

Recommended Minimum Wire Size for Extension Cords

MinimumGauge for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more American Wire Gauge

Than Than

0 6 18 16 16 14

6 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

• Do not place any object on top of charger or place the charger

on a soft surface that might block the ventilation slots and

result in excessive internal heat. Place the charger in a

position away from any heat source. The charger is ventilated

through slots in the top and the bottom of the housing.

• Do not mount charger on wall or permanently affix charger

to any surface. The charger is intended to use on a flat, stable

surface (i.e., table top, bench top).

• Do not operate charger with damaged cord or plug = have

them replaced immediately.

• Do not operate charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way. Take it to an

authorized service center.

• Do not disassemble charger; take it to an authorized service

center when service or repair is required. Incorrect reassembly

may result in a risk of electric shock, electrocution or fire.

• Disconnect the charger from the outlet before attempting any

cleaning. This will reduce the risk of electric shock: Removing the

battery pack will not reduce this risk:

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard household

electrical power (120 Volts). Do not attempt to use it on any

other voltage.

SAVE THESE INSTRUCTIONS

z_WARNING: For safe operation, read this manual and manuals

originally supplied with tool before using the charger.

The battery pack is not fully charged out of the carton. Before using

the battery pack and charger, read the safety instructions below.

Then follow charging procedures outlined.

READ ALL INSTRUCTIONS

• Do not incinerate the battery pack even if it is severely

damaged or is completely worn out. The battery pack can

explode in a fire. Toxic fumes and materials are created when

battery packs are burned.

• Do not charge or use battery in explosive atmospheres, such

as in the presence of flammable liquids, gases or dust. Inserting

or removing the battery from the charger may ignite the dust or fumes.

• If battery contents come into contact with the skin, immediately

wash area with mild soap and water, ff battery liquid gets into the

eye, rinse water over the open eye for 15 minutes or until irritation

ceases. If medical attention is needed, the battery electrolyte for

Li-ion batteries is composed of a mixture of liquid organic

carbonates and fithium salts.

• Contents of opened battery cells may cause respiratory

irritation. Provide fresh air. If symptoms persist, seek medical

attention.

Page 8

ZLWARNING:Burnhazard.Batteryliquidmaybeflammableif

exposedtosparkorflame.

• Charge the batterypacks only in Black & Decker chargers.

• DO NOT splash or immerse in water or other liquids. This may

cause premature ceil failure.

• Do not store or use the tool and battery pack in locations where

the temperature may reach or exceed 105°F (40°C) (such as

outside sheds or metal buildings in summer).

Z_WARNING: Never attempt to open the battery pack for any

reason. If battery pack case is cracked or damaged, do not insert into

charger. Do not crush, drop or damage battery pack. Do not use a

battery pack or charger that has received asharp blow, been

dropped, run over or damaged in any way (i.e., pierced with a nail, hit

with a hammer, stepped on). Damaged battery packs should be

returned to service center for recycling.

Z_WARNING: Fire hazard. Do not store or carry battery so that

metal objects can contact exposed battery terminals. For

example, do not place battery in aprons, pockets, tool boxes, product

kit boxes, drawers, etc., with loose nails, screws, keys, etc.

Transporting batteries can possibly cause fires ff the battery

terminals inadvertently come in contact with conductive materials

such as keys, coins, hand tools and the like. The US Department

of Transportation Hazardous Material Regulations (HMR) actually

prohibit transporting batteries in commerce or on airplanes (Le.,

packed in suitcases and carry-on luggage) UNLESSthey are properly

protected from short circuits. So when transporting individual batteries,

make sure that the battery terminals are protected and well insulated

from materials that could contact them and cause a short circuit.

NOTE: LI=ION batteries should not be put in checked baggage.

STORAGE RECOMMENDATIONS

1. The best storage place is one that is cool and dry away from

direct sunlight and excess heat or cold.

2. Long storage will not harm the battery pack or charger.

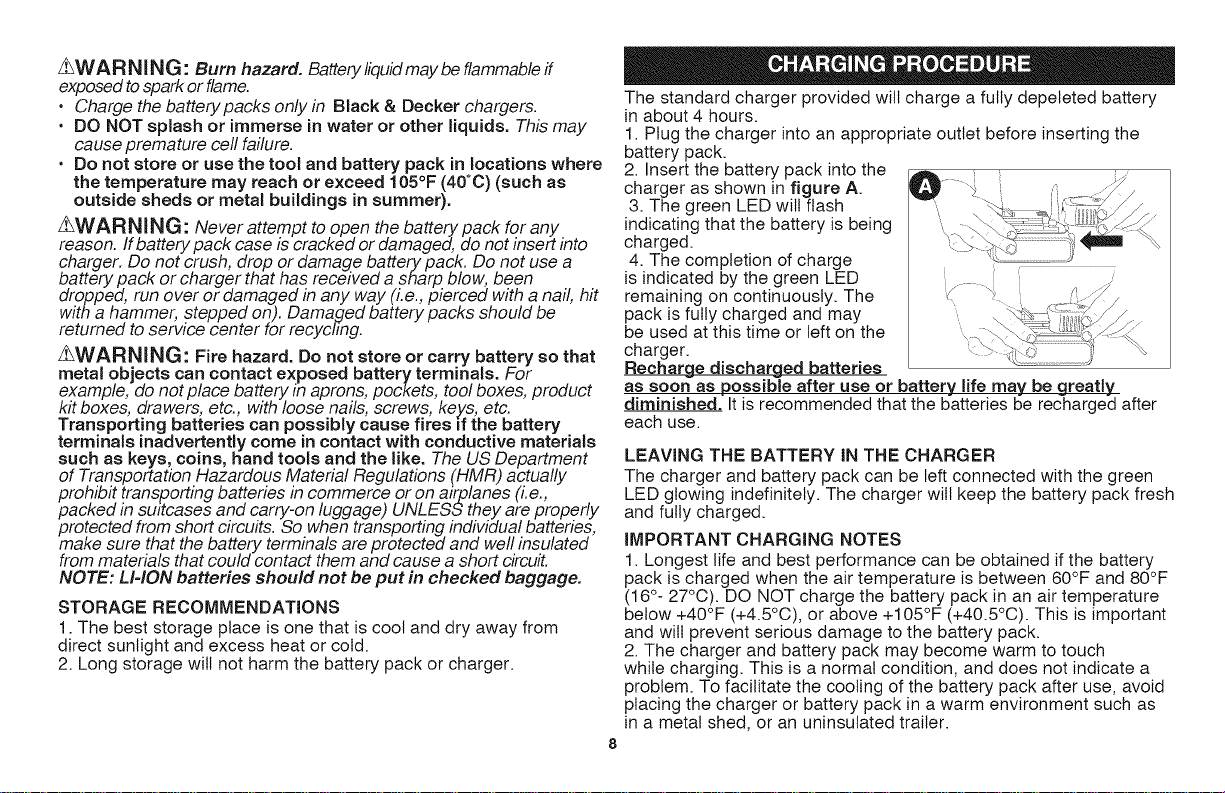

The standard charger provided will charge a fully depeleted battery

in about 4 hours.

1. Plug the charger into an appropriate outlet before inserting the

battery pack.

2. Insert the battery pack into the

charger as shown in figure A.

3. The green LED will flash

indicating that the battery is being

charged.

4. The completion of charge

is indicated by the green LED

remaining on continuously. The

pack is fully charged and may

be used at this time or left on the

charger.

Recharge discharged batteries

as soon as possible after use or battery life may be

diminished. It is recommended that the batteries be recharged after

each use.

LEAVING THE BATTERY IN THE CHARGER

The charger and battery pack can be left connected with the green

LED glowing indefinitely. The charger will keep the battery pack fresh

and fully charged.

IMPORTANT CHARGING NOTES

1. Longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 60°F and 80°F

(16°- 27°C). DO NOT charge the battery pack in an air temperature

below +40°F (+4.5°C), or above +105°F (+40.5°C). This is important

and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch

while charging. This is a normal condition, and does not indicate a

problem. To facilitate the cooling of the battery pack after use, avoid

placing the charger or battery pack in a warm environment such as

in a metal shed, or an uninsulated trailer.

Page 9

3.Ifthebatterypackdoesnotchargeproperly:

a.Checkcurrentatreceptaclebyplugginginalamporother

appliance.

b.Checktoseeifreceptacleisconnectedtoalightswitch

whichturnspoweroffwhenyouturnoutthelights.

c.Movechargerandbatterypacktoalocationwherethe

surroundingairtemperatureisapproximately60°Fand80°F

(16°-27°C).

d.Ifchargingproblemspersist,takethetool,batterypackand

chargertoyourlocalservicecenter.

4.Thebatterypackshouldberechargedwhenitfailstoproduce

sufficientpoweronjobswhichwereeasilydonepreviously.DO

NOTCONTINUEtouseundertheseconditions.Followthecharging

procedure.Youmayalsochargeapartiallyusedpackwhenever

youdesirewithnoadverseaffectonthebatterypack.

5.Foreignmaterialsofaconductivenaturesuchas,butnotlimited

to,steelwool,aluminumfoil,oranybuildupofmetallicparticles

shouldbekeptawayfromchargercavities.Alwaysunplugthe

chargerfromthepowersupplywhenthereisnobatterypackinthe

cavity.Unplugchargerbeforeattemptingtoclean.

6.Donotfreezeorimmersechargerinwateroranyotherliquid.

ZhWARNING: Shock hazard. Do not allow any liquid to get inside

charger. Never attempt to open the battery pack for any reason. If the

plastic housing of the battery pack breaks or cracks, return to a service

center for recycling.

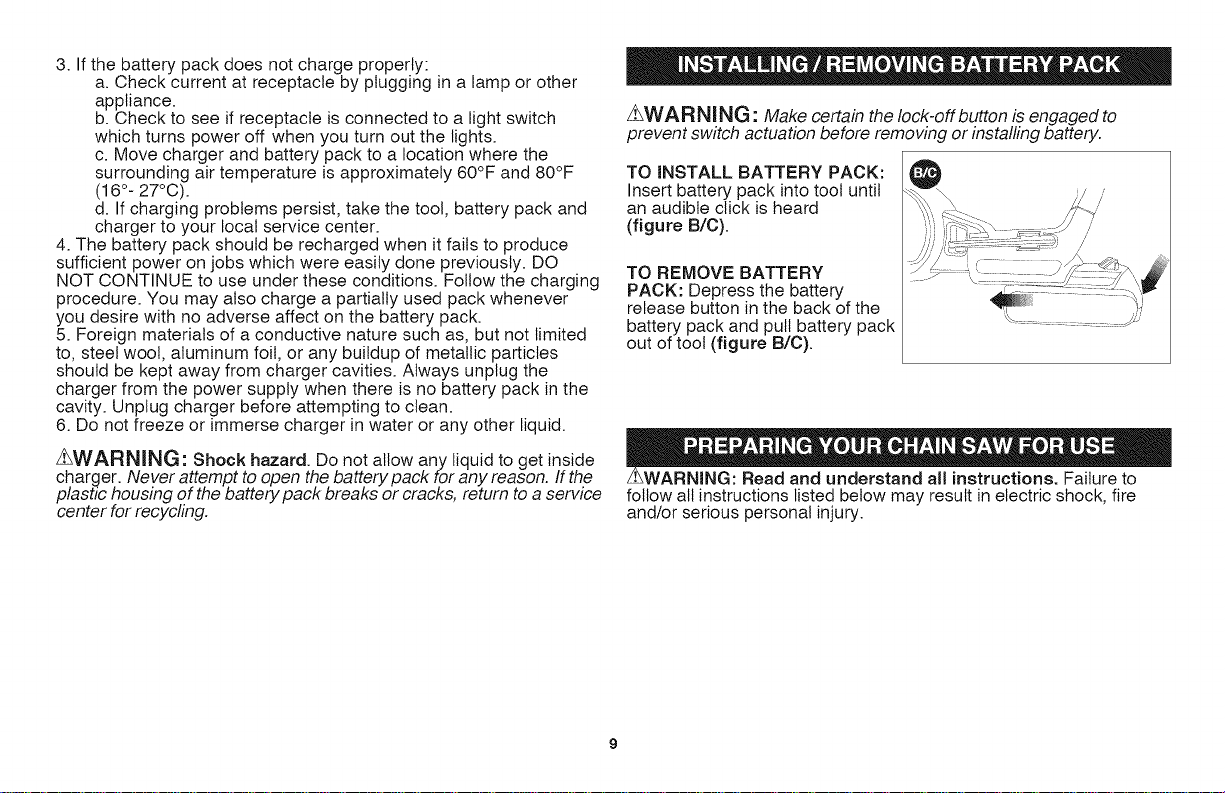

zLWARNING- Make certain the lock-off button is engaged to

prevent switch actuation before removing or installing battery.

TO INSTALL BATTERY PACK:

Insert battery pack into tool until

an audible click is heard

(figure B/C).

TO REMOVE BATTERY

PACK: Depress the battery

release button in the back of the

battery pack and pull battery pack

out of tool (figure B/C).

Read and understand atl instructions. Failure to

follow all instructions listed below may result in electric shock, fire

and/or serious personal injury.

Page 10

_stallingthe Guide Bar and Saw Chain

CAUTION: Sharp chain. Always wear protective gloves when

handling the chain. The chain is sharp and can cut you when it is not

running.

_WARNING: Sharp moving chain. To prevent accidental

operation, insure that battery is disconnected from the tool

before performing the following operations. Failure to do this

could result in serious personal injury.

The saw chain and guide bar are packed separately in the carton

inside the scabbard. The chain has been placed on the guide bar at

the factory to insure that the teeth are facing in the proper direction

when you first attach it. Should the chain come off of the guide bar,

refer to the section "Replacing the Chain" for proper tooth orientation.

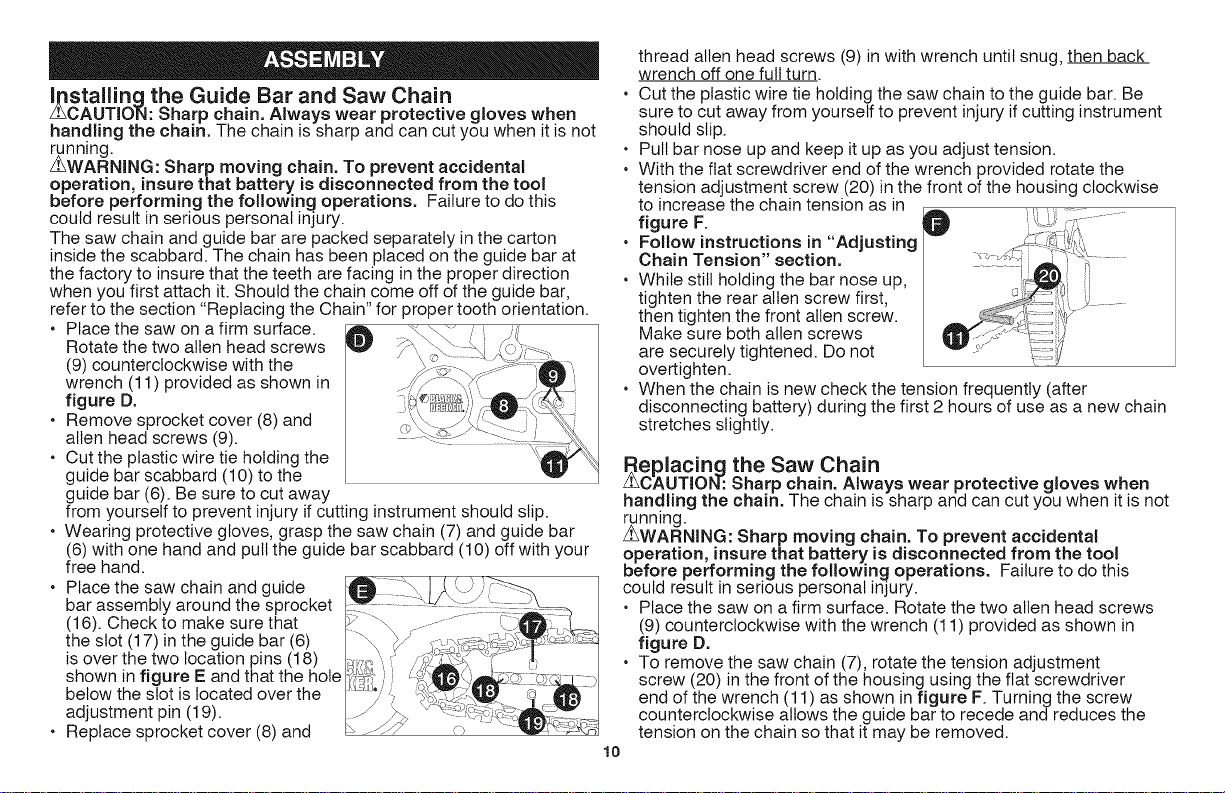

• Place the saw on a firm surface.

Rotate the two allen head screws

(9) counterclockwise with the

wrench (11) provided as shown in

figure O.

• Remove sprocket cover (8) and

allen head screws (9).

• Cut the plastic wire tie holding the

guide bar scabbard (10) to the

guide bar (6). Be sure to cut away

from yourself to prevent injury if cutting instrument should slip.

• Wearing protective gloves, grasp the saw chain (7) and guide bar

(6) with one hand and pull the guide bar scabbard (10) off with your

free hand.

• Place the saw chain and guide

bar assembly around the sprocket

(16). Check to make sure that

the slot (17) in the guide bar (6)

is over the two location pins (18)

shown in figure E and that the hole

below the slot is located over the

adjustment pin (19).

• Replace sprocket cover (8) and

thread allen head screws (9) in with wrench until snug, then back

wrench off one full turn.

Cut the plastic wire tie holding the saw chain to the guide bar. Be

sure to cut away from yourself to prevent injury if cutting instrument

should slip.

Pull bar nose up and keep it up as you adjust tension.

With the flat screwdriver end of the wrench provided rotate the

tension adjustment screw (20) in the front of the housing clockwise

to increase the chain tension as in

figure F. O

o

Follow instructions in "Adjusting

Chain Tension" section.

o

While still holding the bar nose up,

tighten the rear allen screw first,

then tighten the front allen screw. _-_.......

Make sure both allen screws

are securely tightened. Do not

overtighten. _'_

When the chain is new check the tension frequently (after

disconnecting battery) during the first 2 hours of use as a new chain

stretches slightly.

lacing the Saw Chain

AUTION: Sharp chain. Always wear protective gloves when

handling the chain. The chain is sharp and can cut you when it is not

running.

_WARNING: Sharp moving chain. To prevent accidental

operation, insure that battery is disconnected from the tool

before performing the following operations. Failure to do this

could result in serious personal injury.

• Place the saw on a firm surface. Rotate the two allen head screws

(9) counterclockwise with the wrench (11) provided as shown in

figure D.

• To remove the saw chain (7), rotate the tension adjustment

screw (20) in the front of the housing using the flat screwdriver

end of the wrench (11 ) as shown in figure F. Turning the screw

counterclockwise allows the guide bar to recede and reduces the

tension on the chain so that it may be removed.

10

Page 11

• Removesprocketcover(8)andallenheadscrews(9).

• Liftthewornsawchain(7)outofthegrooveintheguidebar(6).

o

Place new chain in groove of

guide bar making sure saw teeth

are facing correct direction by

matching arrow on chain with

graphic on housing shown in

figure G.

Place the saw chain and guide

bar assembly around the sprocket

(16). Check to make sure that the

slot (17) in the guide bar (6) is

over the two location pins (18) shown in figure E and that the hole

below the slot is located over the adjustment pin (19).

o

Replace sprocket cover (8) and thread allen head screws (9) in

with wrench until snug, then back wrench off one full turn.

o

Pull bar nose up and keep it up as you adjust

tension Figure G1.

o

Rotate the tension adjustment screw (20) in the

front of the housing clockwise to increase the

chain tension as in Figure F.

o

Follow instructions in "Adjusting Chain

Tension" section.

o

While still holding the bar nose up, securely

tighten the rear allen screw (9) first, then tighten

the front allen screw.

When the chain is new check the tension

frequently (after disconnecting battery) during the first 2 hours of

use as a new chain stretches slightly.

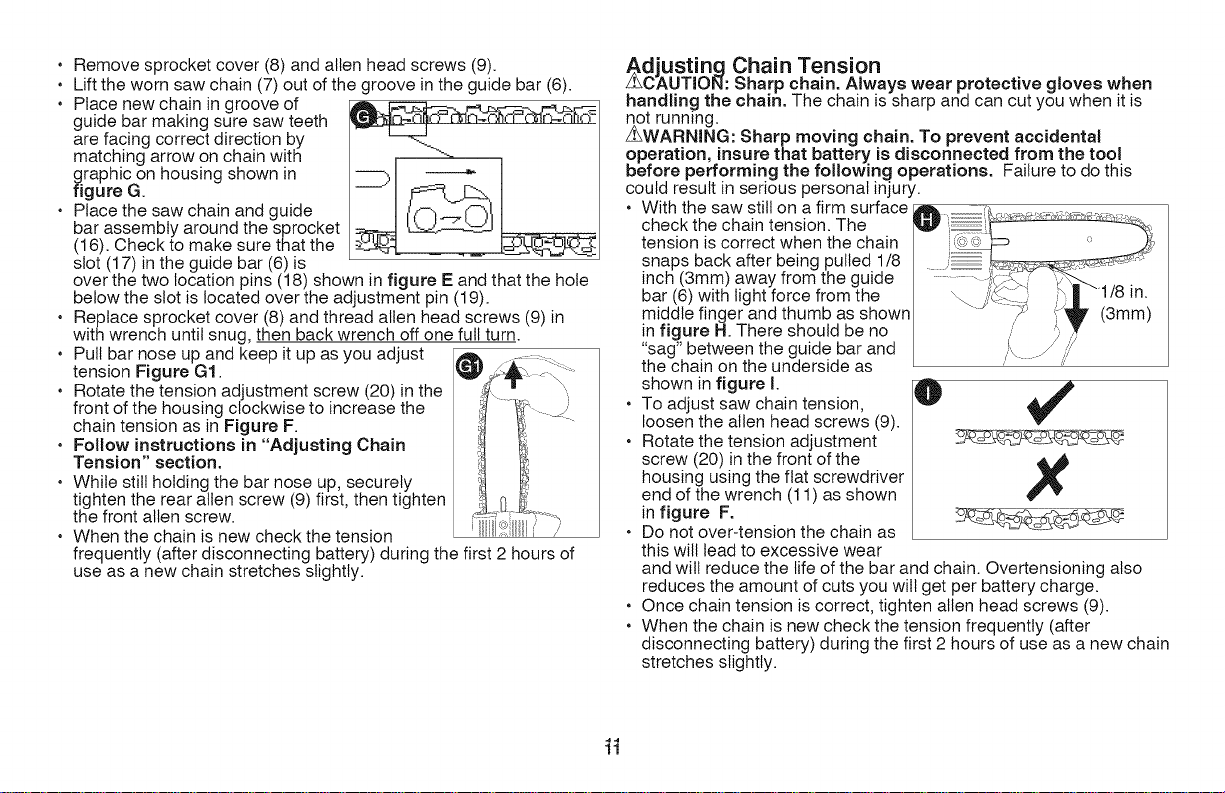

_dcJUSting Chain Tension

AUTION: Sharp chain. Always wear protective gloves when

handling the chain. The chain is sharp and can cut you when it is

z_t running.

WARNING: Sharp moving chain. To prevent accidental

operation, insure that battery is disconnected from the tool

before performing the following operations. Failure to do this

could result in serious personal injury.

• With the saw still on a firm surface

check the chain tension. The

tension is correct when the chain

snaps back after being pulled 1/8

inch (3mm) away from the guide

bar (6) with light force from the

middle finger and thumb as shown

in figure H. There should be no

"sag" between the guide bar and

the chain on the underside as

shown in figure I. A

• To adjust saw chain tension,

loosen the allen head screws (9).

• Rotate the tension adjustment

screw (20) in the front of the

housing using the flat screwdriver

end of the wrench (11) as shown

in figure F.

• Do not over-tension the chain as

this will lead to excessive wear

and will reduce the life of the bar and chain. Overtensioning also

reduces the amount of cuts you wilt get per battery charge.

Once chain tension is correct, tighten allen head screws (9).

When the chain is new check the tension frequently (after

disconnecting battery) during the first 2 hours of use as a new chain

stretches slightly.

_o_

v'

X

ii

Page 12

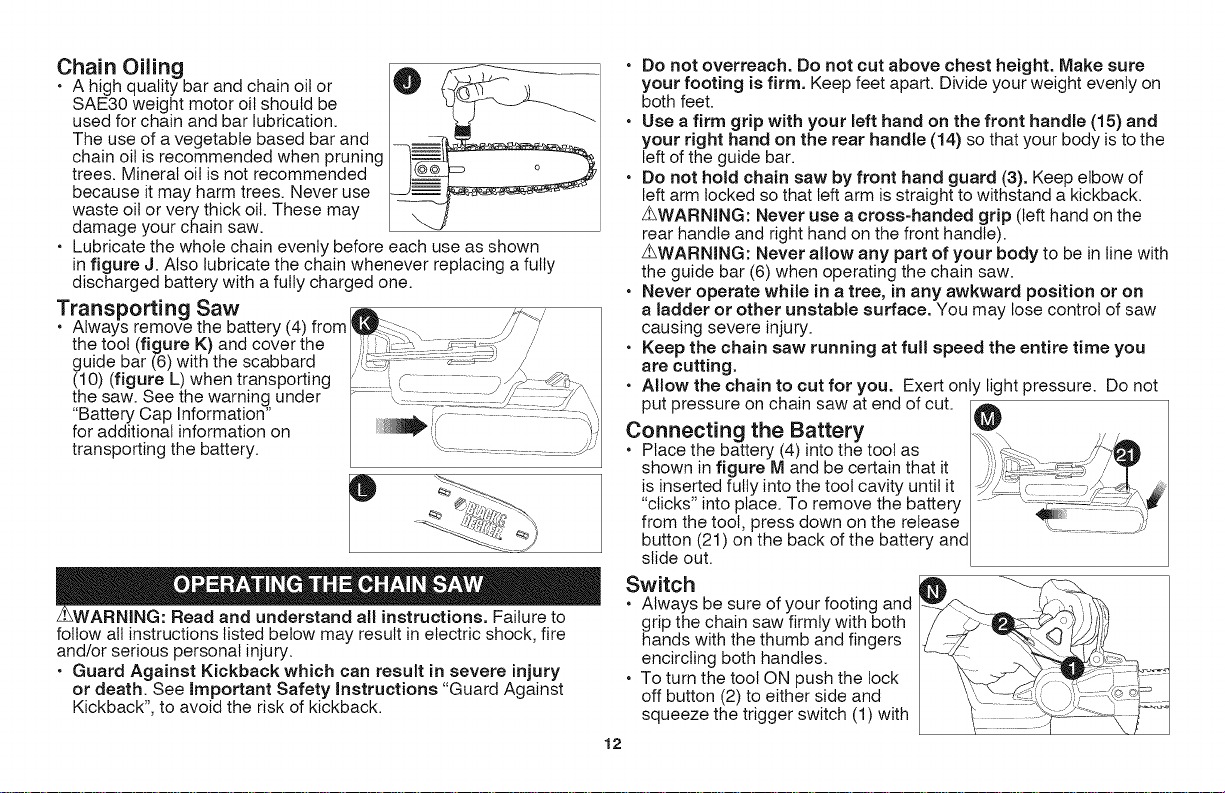

Chain Oiling

• A high quality bar and chain oil or

SAE30 weight motor oil should be

used for chain and bar lubrication.

The use of a vegetable based bar and

chain oil is recommended when pruning

trees. Mineral oil is not recommended

because it may harm trees. Never use

waste oil or very thick oil. These may

damage your chain saw.

• Lubricate the whole chain evenly before each use as shown

in figure J. Also lubricate the chain whenever replacing a fully

discharged battery with a fully charged one.

Transporting Saw

• Always remove the battery (4) from

the tool (figure K) and cover the

guide bar (6) with the scabbard

(10) (figure L) when transporting

the saw. See the warning under

"Battery Cap Information"

for additional information on

transporting the battery.

Read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire

and/or serious personal injury.

• Guard Against Kickback which can result in severe injury

or death. See important Safety instructions "Guard Against

Kickback", to avoid the risk of kickback.

• Do not overreach. Do not cut above chest height. Make sure

your footing is firm. Keep feet apart. Divide your weight evenly on

both feet.

• Use a firm grip with your left hand on the front handle (15) and

your right hand on the rear handle (14) so that your body is to the

left of the guide bar.

• Do not hold chain saw by front hand guard (3). Keep elbow of

left arm locked so that left arm is straight to withstand a kickback.

z_WARNING: Never use a cross-handed grip (left hand on the

rear handle and right hand on the front handle).

z_WARNING: Never allow any part of your body to be in line with

the guide bar (6) when operating the chain saw.

• Never operate while in a tree, in any awkward position or on

a ladder or other unstable surface. You may lose control of saw

causing severe injury.

• Keep the chain saw running at full speed the entire time you

are cutting.

• Allow the chain to cut for you. Exert only light pressure. Do not

put pressure on chain saw at end of cut.

Connecting the Battery

• Place the battery (4) into the tool as

shown in figure M and be certain that it

is inserted fully into the tool cavity until it

"clicks" into place. To remove the battery

from the tool, press down on the release

button (21) on the back of the battery and

slide out.

Switch

• Always be sure of your footing and

grip the chain saw firmly with both

hands with the thumb and fingers

encircling both handles.

• To turn the tool ON push the lock

off button (2) to either side and

squeeze the trigger switch (1) with

12

Page 13

yourfingersasshownin figureN.(Oncethetoolisrunningyou

canreleasethelockoffbutton.)

• ToturnthetoolOFF,releasethetriggerswitch.

Chain Braking System

Your chain saw is equipped with a motor chain braking system which

wilt stop the chain quickly each time you release the trigger. This

system should be tested before every use.

Saw Chain Sharpness

The cutters wilt dull immediately if they touch the ground or a nail

while cutting. Refer to "Sharpening the Chain".

Saw Chain Tension

This should be done regularly. Refer to "Adjusting Chain Tension".

Common Cutting Techniques

Felling

Felling is the process of cutting down a tree. Be sure battery is

fully charged before felling a tree so you can finish on a single

charge. Do not fell trees in high wind conditions.

Bucking is the process of cutting a felled tree or log into lengths.

When bucking and felling operations are being performed by two

or more persons, at the same time, the felling operation should

be separated from the bucking operation by a distance of at least

twice the height of the tree being felled. Trees should not be felled

in a manner that would endanger any person, strike any utility line

or cause any property damage. If the tree does make contact with

any utility line, the utility company should be notified immediately.

Scrutinize the surrounding overhead for dead or broken limbs or

branches which may fall during the felling process.

The chain saw operator should keep on the uphill side of the

terrain as the tree is likely to roll or slide downhill after it is felled.

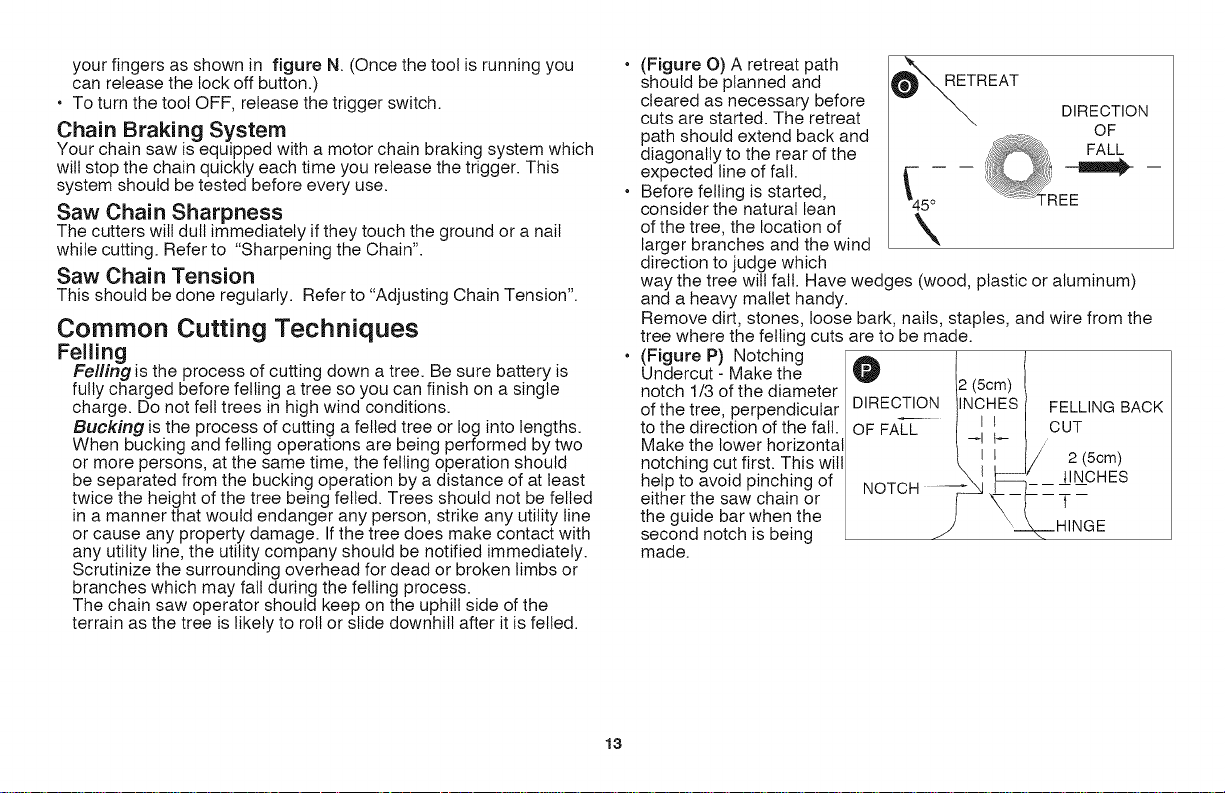

• (Figure O) A retreat path

should be planned and

cleared as necessary before

cuts are started. The retreat

path should extend back and

diagonally to the rear of the

expected line of fall.

• Before felling is started,

consider the natural lean

of the tree, the location of

larger branches and the wind

direction to judge which

way the tree will fall. Have wedges (wood, plastic or aluminum)

and a heavy mallet handy.

Remove dirt, stones, loose bark, nails, staples, and wire from the

tree where the felling cuts are to be made.

(Figure P) Notching

Undercut - Make the

notch 1/3 of the diameter

of the tree, perpendicular

to the direction of the fall.

Make the lower horizonta

notching cut first. This will

help to avoid pinching of

either the saw chain or

the guide bar when the

second notch is being

made.

_TREAT DIRECTION

5° _" _q-REE

\

DI_DRECTION2 (5cm) /

OFFAL_- ..... / J L / ,CUT

NOTCH .... XI I I- -- _ --

/INCHES/ FELLING BACK

L,y/ 2( cm)

_1 _ IINCHES

OF

FALL

13

Page 14

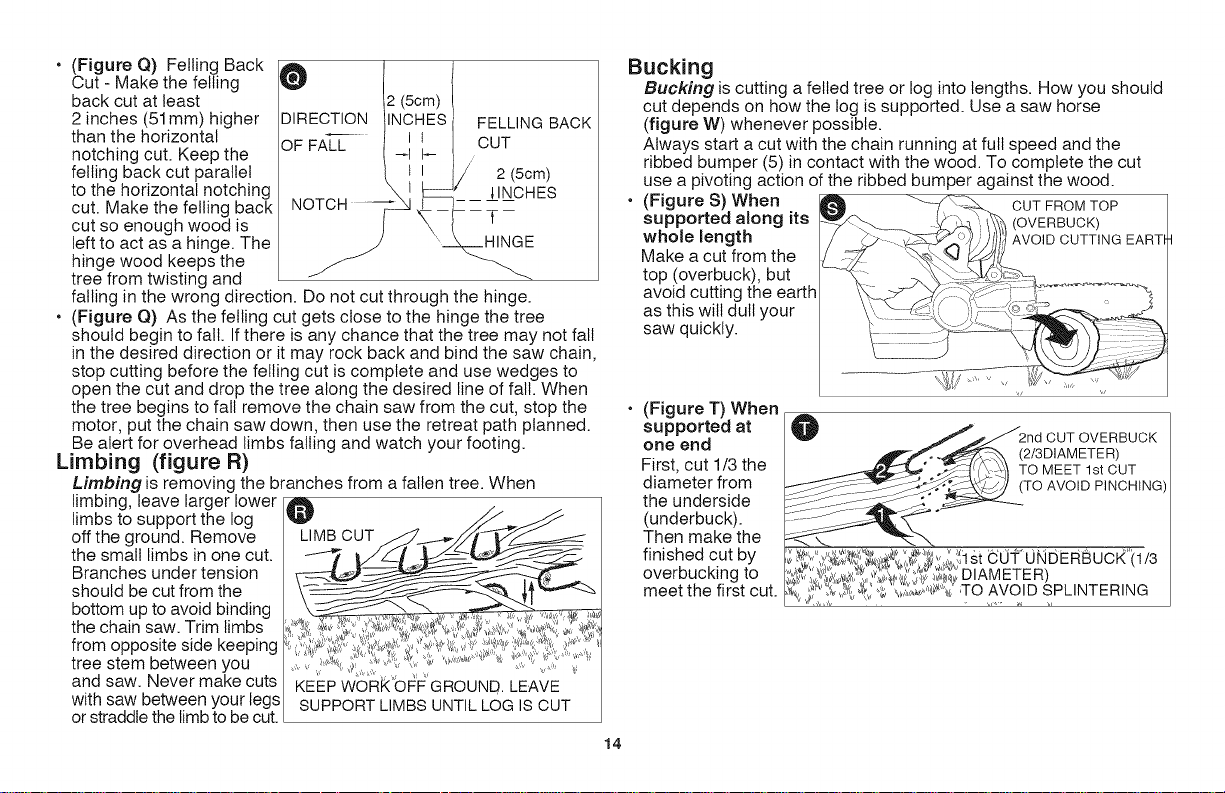

• (Figure Q) Felling Back

Cut - Make the felling

back cut at least

2 inches (51 ram) higher

than the horizontal

notching cut. Keep the

felling back cut parallel

to the horizontal notching

cut. Make the felling back

cut so enough wood is

left to act as a hinge. The

hinge wood keeps the

tree from twisting and

falling in the wrong direction. Do not cut through the hinge.

• (Figure Q) As the felling cut gets close to the hinge the tree

should begin to fall. Ifthere is any chance that the tree may not fall

in the desired direction or it may rock back and bind the saw chain,

stop cutting before the felling cut is complete and use wedges to

open the cut and drop the tree along the desired line of fall. When

the tree begins to fall remove the chain saw from the cut, stop the

motor, put the chain saw down, then use the retreat path planned.

Be alert for overhead limbs falling and watch your footing.

OFFA ........

N

FELLING BACK

CUT

/ 2 (5cm)

_ IINCHES

-T-

__HINGE

Limbing (figure R)

Limbing is removing the branches from a fallen tree. When

limbing, leave larger lower

limbs to support the log

off the ground. Remove

the small limbs in one cut.

Branches under tension

should be cut from the

bottom up to avoid binding

the chain saw. Trim limbs

from opposite side keeping

tree stem between you

and saw. Never make cuts

with saw between your legs SUPPORT LIMBS UNTILLOG IS CUT

or straddle the limb to be cut.

Bucking

Bucking is cutting a felled tree or log into lengths. How you should

cut depends on how the log is supported. Use a saw horse

(figure W) whenever possible.

Always start a cut with the chain running at full speed and the

ribbed bumper (5) in contact with the wood. To complete the cut

use a pivoting action of the ribbed bumper against the wood.

• (Figure S) When

supported along its

whole length

Make a cut from the

top (overbuck), but

avoid cutting the earth

as this will dull your

saw quickly.

(Figure T) When

supported at

one end

First, cut 1/3 the

diameter from

the underside

(underbuck).

Then make the

finished cut by

overbucking to

meet the first cut.

14

O j_,l_"2nd CUT OVERBUCK

A_I_-j_..1_d_'X (2/3DIAMETER)

_J .-_(_-Z_,_ TO MEET 1st CUT

TO AVOID PINCHING'

_, _)?''_:_t,_,_, I_,' _,,;_>"_'_/,_TO AVOID SPLINTERING

Page 15

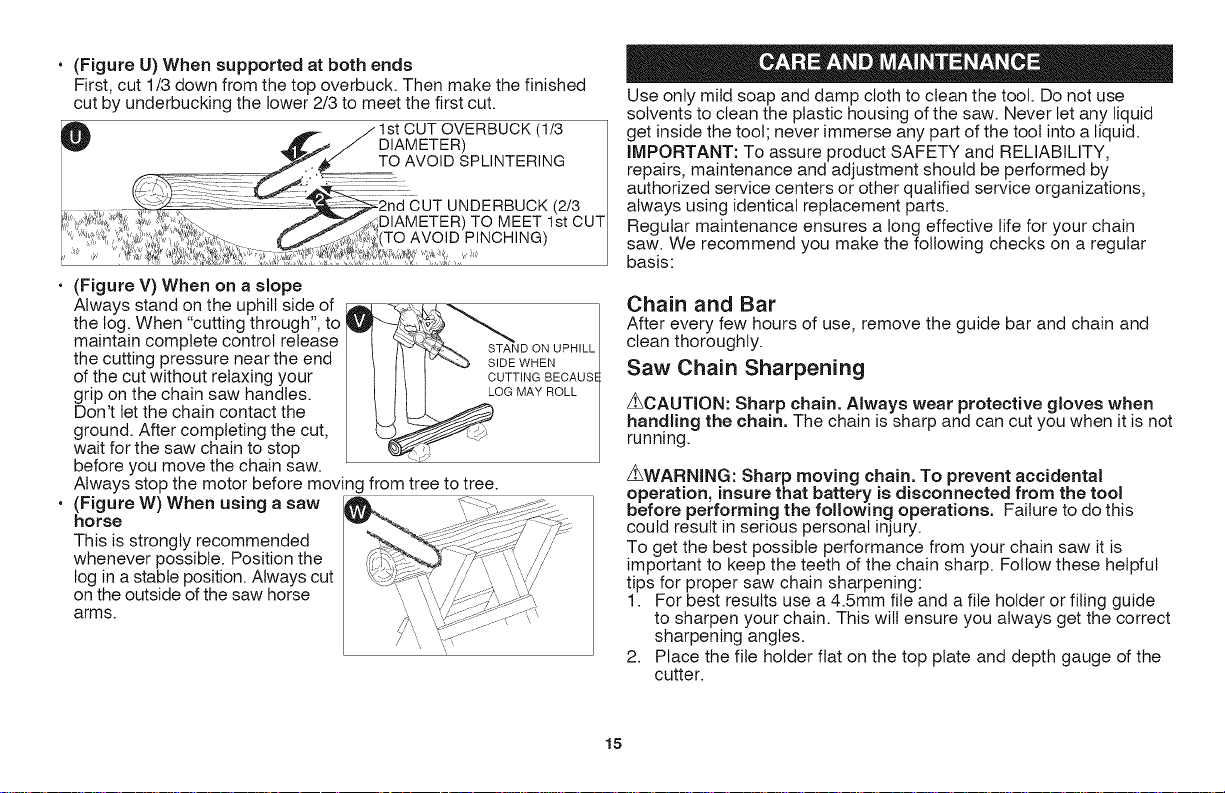

• (Figure U) When supported at both ends

First, cut 1/3 down from the top overbuck. Then make the finished

cut by underbucking the bower2/3 to meet the first cut.

CUTOVERBUCK (1/3

PINCHING)

• (Figure V) When on a slope

Always stand on the uphill side of

the log. When "cutting through", to

maintain complete control release

the cutting pressure near the end

of the cut without relaxing your

% _ STAND ON UPHILL

/ [/ _ _4._ SIDE WHEN

I I / CUTTING BECAUSI

grip on the chain saw handles.

Don't let the chain contact the

__.] l LOG MAY ROLL

ground. After completing the cut,

wait for the saw chain to stop

before you move the chain saw.

Always stop the motor before moving from tree to tree.

• (Figure W) When using a saw

horse

This is strongly recommended

whenever possible. Position the

log in a stable position. Always cut

on the outside of the saw horse

arms.

Use only mild soap and damp cloth to clean the tool. Do not use

solvents to clean the plastic housing of the saw. Never let any liquid

get inside the tool; never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY,

repairs, maintenance and adjustment should be performed by

authorized service centers or other qualified service organizations,

always using identical replacement parts.

Regular maintenance ensures a long effective life for your chain

saw. We recommend you make the following checks on a regular

basis:

Chain and Bar

After every few hours of use, remove the guide bar and chain and

clean thoroughly.

Saw Chain Sharpening

z_CAUTION: Sharp chain. Always wear protective gloves when

handling the chain. The chain is sharp and can cut you when it is not

running.

Z_WARNING: Sharp moving chain. To prevent accidental

operation, insure that battery is disconnected from the tool

before performing the following operations. Failure to do this

could result in serious personal injury.

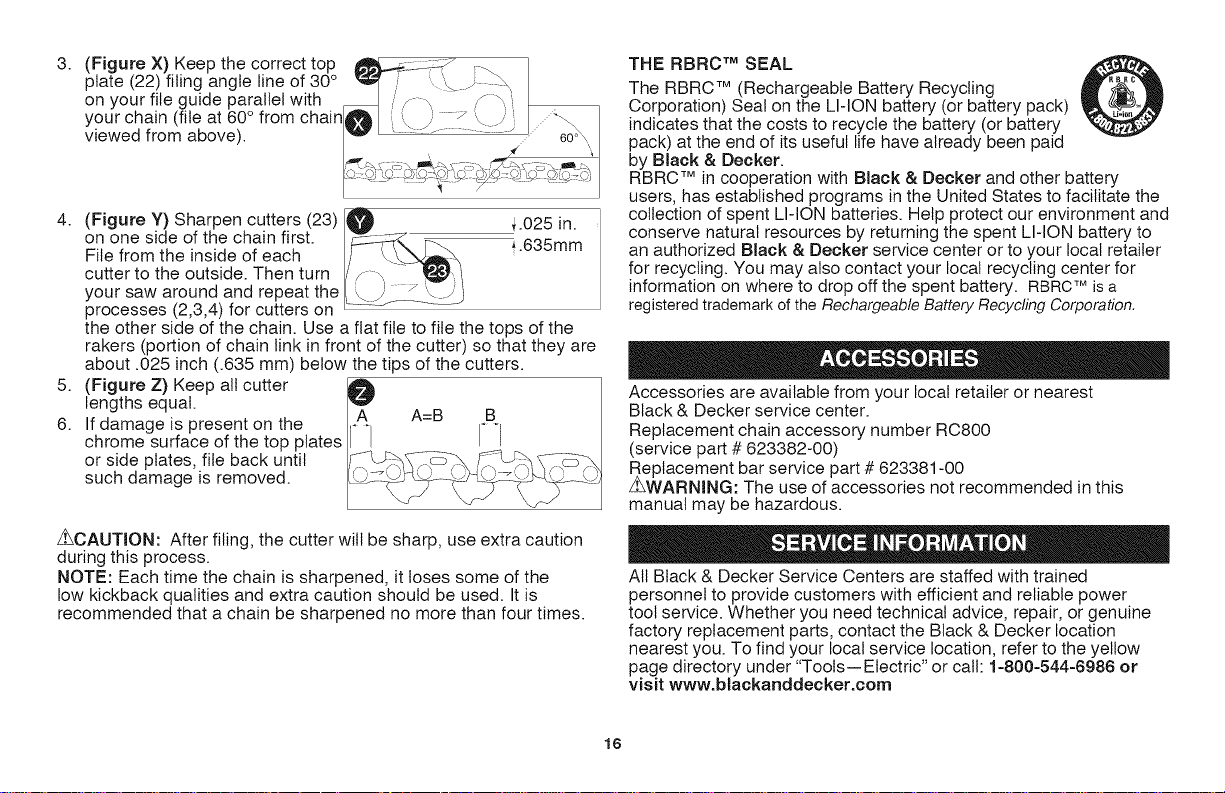

To get the best possible performance from your chain saw it is

important to keep the teeth of the chain sharp. Follow these helpful

tips for proper saw chain sharpening:

1. For best results use a 4.5mm file and a file holder or filing guide

to sharpen your chain. This will ensure you always get the correct

sharpening angles.

2. Place the file holder flat on the top plate and depth gauge of the

cutter.

15

Page 16

3. (Figure X) Keep the correct top _j___:_:J_u _ I

plate (22) filing angle line of 30° _ .; ",_ S .... I

on your file guide parallel with _ _.'-, /\.'

your chain (file at 60° from chain_ ._ / _ s "-_

viewed from above). _' ' .........._: _ ...... 60Q

on one side of the chain first. ÷.635mm

File from the inside of each

cutter to the outside. Then turn \.

4. (Figure Y) Sharpen cutters (23) _[_ _-_'_i_--- ¢.025 in.

your saw around and repeat the _.

processes (2,3,4) for cutters on

the other side of the chain. Use a flat file to file the tops of the

rakers (portion of chain link in front of the cutter) so that they are

about .025 inch (.635 mm) below the tips of the cutters.

5. (Figure Z) Keep all cutter

lengths equal.

6. If damage is present on the

chrome surface of the top plates

or side plates, file back until

such damage is removed.

z_CAUTION: After filing, the cutter will be sharp, use extra caution

during this process.

NOTE: Each time the chain is sharpened, it loses some of the

low kickback qualities and extra caution should be used. It is

recommended that a chain be sharpened no more than four times.

THE RBRC TM SEAL

The RBRC TM (Rechargeable Battery Recycling

Corporation) Seal on the M-ION battery (or battery pack)

indicates that the costs to recycle the battery (or battery

pack) at the end of its useful life have already been paid

by Black & Decker.

RBRC TM in cooperation with Black & Decker and other battery

users, has established programs in the United States to facilitate the

collection of spent M-ION batteries. Help protect our environment and

conserve natural resources by returning the spent M-ION battery to

an authorized Black & Decker service center or to your local retailer

for recycling. You may also contact your local recycling center for

information on where to drop off the spent battery. RBROTM isa

registeredtrademark ofthe Rechargeable Battery RecyclingCorporation.

Accessories are available from your local retailer or nearest

Black & Decker service center.

Replacement chain accessory number RC800

(service part # 623382-00)

eplacement bar service part # 623381-00

WARNING: The use of accessories not recommended in this

manual may be hazardous.

All Black & Decker Service Centers are staffed with trained

personnel to provide customers with efficient and reliable power

tool service. Whether you need technical advice, repair, or genuine

factory replacement parts, contact the Black & Decker location

nearest you. To find your local service location, refer to the yellow

page directory under "Tools--Electric" or call: 1=800=544-6986 or

visit www.blackanddecker.com

16

Page 17

Black & Decker (U.S.) Inc. warrants this product for two years against

any defects in material or workmanship. The defective product will be

replaced or repaired at no charge in either of two ways.

The first, is to return the product to the retailer from whom it was

purchased (provided that the store is a participating retailer). Returns

should be made within the time period of the retailer's policy for

exchanges (usually 30 to 90 days after the sale). Proof of purchase

may be required. Please check with the retailer for their specific

return policy regarding returns that are beyond the time set for

exchanges.

The second option is to take or send the product (prepaid) to a

Black & Decker owned or authorized Service Center for repair or

replacement at our option. Proof of purchase may be required.Black

& Decker owned and authorized Service Centers are listed under

"Tools-Electric" in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives

you specific legal rights and you may have other rights which vary

from state to state or province to province. Should you have any

questions, contact the manager of your nearest Black & Decker

Service Center. This product is not intended for commercial use.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, check country

specific warranty information contained in the packaging, call the

local company or see the website for warranty information.FREE

WARNING LABEL REPLACEMENT: If your warning labels become

illegible or are missing, call 1=800=544-6986 for a free replacement.

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

See 'Tools=Electric'

- Yellow Pages -

for Service & Sales

Ifyour Chain Saw does not operate correctly check the following:

Problem Possible Cause Possible Solution

• Toot will not • Battery not •

Check battery installation.

start, installed properly.

• Battery not •

charged.

• Lock-out button not •

actuated.

• Unit will not • Battery not inserted"

charge, into charger.

Check battery charging

requirements.

Push lock off button/

actuate triqger.

Insert battery into charger

until green LED appears.

Charge up to 8 hours if

• Chain too tight, battery totally drained.

• Bar / chain • Lubrication • Refer to "adjusting chain

overheated, needed, tension" section.

• Refer to "chain oiling"

section.

• Chain is loose. • Chain tension set • Refer to"adjusting chain

incorrectly, tension" section.

• Poor cut • Chain tension set • Refer to"adjusting chain

quality, incorrectly, tension" section.

• Chain needs Note: Excessive tension

replacement, leads to excessive wear

and reduction in life of bar

& chain. Lubricate before

each cut.

Refer to "replacing the

chain" section.

• Unit runs but • Chain installed • Refer to sections for

does not cut. backwards, installing and removing

chain.

For assistance, visit our website www.btackanddecker.corn for

the location of the service center nearestyou or call the

BLACK & DECKER help line at 1=800=544-6986.

17

Page 18

MUUP_.. U'l:::NIPLUI PUUH LA _Uli::: A

CHAiNE SANS FIL, A PILE AU LITHIUM

DE 20 V MAX.*

Numero de catalogue LCS120

A LIRE AVANT DE RETOURNER CE PRODUIT

POUR QUELQUE RAISON QUE CE SOIT :

SidesquestionsoudesproblemessurgissentapresI'achatd'unproduit

Black&Decker,consulterlesiteWeb

HTTP://WWW.BLACKANDDECKER.COM/INSTANTANSWERS

_ourobtenirdesr@onsesinstantanement24heuresparjour.

lar@onseestintrouvableouenI'absenced'ac@saI'lnternet,

composerle1800544-6986de8ha17hHNE,dulundiauvendredi,

pourparleravecunagent.

P@red'avoirlenumerodecataloguesouslamainIorsdeI'appel.

18

Numero de modele LCS120

VOICI DES RENSEIGNEIVlENTS IMPORTANTS

QU'IL VOUS FAUT CONNAJTRE •

• NE PAS EXERCER DE TENSION TROP FORTE SUR LA

CHA'iNE. Se reporter #.la rubrique ,, Reglage de la tension

de la chafne _,pour savoir comment tendre la chafne

correctement.

• Retendre la chafne frequemment durant les deux

premieres heures d'utilisation.

La tension initiale maximale du bloc-piles

mesur6e sans charge de travail) est de 20 volts.

a tension nominale, mesur6e avec une charge

e travail, est de 18 volts.

Page 19

Lignes directrices de s6curit_ - D6finitions .............................. 19

Terminologie portant sur la scie & chat

ne ............................................................................................. 20

Importantes directives de s6curit6 ........................................... 21

Composantes ........................................................................... 24

Importantes directives de s6curit6 pour les chargeurs

de piles ..................................................................................... 25

Importantes directives de s6curit6 pour les blocs-piles .......... 26

Proc6dures en mati@e de charge ............................................ 27

Pr6parer la scie & chafne en vue de son utitisation ................. 29

Assemblage ............................................................................. 29

Utitiser la scie & chafne ............................................................ 31

Entretien ................................................................................... 35

Information en mati@e de r6paration ....................................... 36

Garantie complete de deux ans pour une utitisation

domestique .............................................................................. 36

D6pannage .............................................................................. 37

LIGNES DJRECTRICES EN IVIATIERE DE

SECURITE = DEFiNiTiONS

Itest important que vous lisiez et compreniez ce mode d'emp!oi.

Les informations qu'it contient concernent VOTRE SECURITE et

visent & EVITER TOUT PROBLEME. Les symboles ci-dessous

servent & vous aider & reconnattre cette information.

Z_DANGER " Indique une situation dangereuse imminente

qui, si elle n'est pas evit6e, causera la mort ou des graves

blessures.

Z_AVERTISSEMENT : Indique une situation potentiellement

dangereuse qui, si elle n'est pas evit6e, pourrait causer la mort

ou de graves blessures.

Z_MISE EN GARDE : Indique une situation potentiellement

dangereuse qui, si elle n'est pas evit6e, pourrait causer des

blessures mineures ou moder6es.

AVIS : Utilise sans le symbole d'alerte & la securit6, indique

une situation potentiellement dangereuse qui, si elle n'est pas

evit6e, peut resulter en des dommages &la propriet&

19

Page 20

La scie &chafne sans fil Black & Decker est parfaite pour 1'61agage

et le tron£;onnage de petits bitlots jusqu'& 203 mm (8 po) de diam_tre.

Cet outit se destine uniquement &@re utitis6 par les consommateurs.

Trongonnage - le processus de coupe transversale d'un arbre

abattu ou d'un billot en morceaux.

Frein rnoteur - un dispositif utilis6 pour immobiliser la chafne de

la scie d_s que la d6tente est rel&ch6e.

Tete rnotorisee de JascJe a cha'ine - une scie sans chafne et

guide-chafne.

PJgnon d'entraTnement ou pJgnon - la piece dent6e qui

entrafne la chafne de I'outil.

Abattage - le processus de coupe d'un arbre.

Trait d'abattage - la derni@e entaille pratiqu6e au c6t6 oppos6 &

I'entaille d'abattage sur le tronc d'un arbre.

Poignee avant - la poi_n6e d'appui Iog_e & I'avant ou vers

I'avant de la scie & chaine.

Protege-main avant - une barri_re physique entre la poign_e

avant de la scie &chafne et le guide-chafne normatement

positionn_ pres de la main surta poign6e avant et parfois utilis6

comme levier d'actionnement du frein de chafne.

Guide-chaine - une sotide structure sur rail qui supporte et guide

la chafne de I'outit.

Fourreau du guide-cha'_ne - boftier qui s'adapte sur le guide-

chafne pour pr6venir le contact des dents Iorsque la scie n'est

L_?fsen utitisation.

et de rebond - le mouvement vertical ou arriere, ou les deux

simuttan_ment, du guide-chafne, se produit torsque la chatne

pres de I'extr6mit_ sup@ieure du guide-chafne frappe un objet tel

un billot ou une branche ou Iorsque la chafne est prise dans une

entaitle du tronc.

Effet de rebond par pJncement - le refoutement rapide de la

scie peut se produire Iorsque I'entailte dans le tronc se referme et

pince la chafne en mouvement et la bloque pr6s de I'extr6mit6 du

guide-chafne.

Effet de rebond par rotation - le mouvement vertical ou

arri_re rapide de la scie peut se produire Iorsque la chafne en

mouvement pres de I'extr_mit6 sup@ieure du guide-chafne

f.rappe un objet tel un bitlot ou une branche.

Ebranchage - la coupe des branches d'un arbre abattu

Chaine a faible effet de rebond - une chafne conforme aux

exigences de performance de rebond de la norme

ANSI B175.1-1991 (Iors d'essais sur un _chantitlon repr6sentatif

de scies & chafne).

Position normale de coupe - ces positions sont utilis6es lors du

trongonnage et des entailles d'abattage.

EntaiHe d'abattage - une entailte dans le tronc qui dirige la

chute de t'arbre.

Poignee arriere - la poign6e d'appui Iog_e & I'arri@e ou vers

I'arri_re de la scie.

GuJde-chaTne a faibJe effet de rebond - un guide-chafne qui

r6duit de fa(_on significative et prouv6e I'effet de rebond.

ChaTne de rechange - une chafne conforme aux exigences de

performance d'effet de rebond de la norme ANSI B175.1-1991

Iors d'essais avec des modules sp6cifiques de scies & chafne. II

est possible que cette chafne ne soit pas conforme aux exigences

de performance ANSI si utilis6e sur d'autres modules d'outils.

ChaTne pour scies a cha'_ne - une chafne dent6e en boucle, qui

coupe le bois, et qui est entrafn6e par le moteur et support6e par

le guide-chafne.

Butee cannelee - le point d'appui utitis6 en cours d'abattage ou

de trongonnage pour faire pivoter la scie et maintenir la position

Iors dela coupe.

Interrupteur - un dispositif qui, Iorsque actionn6, comptetera ou

interrompra un circuit 61ectrique du moteur de la scie &chafne.

Bielle - un m6canisme qui transmet le mouvement d'une d_tente

& I'interrupteur.

Verrou d'interrupteur - une butte qui se d6ptace pour

emp6cher le fonctionnement non intentionnel de I'interrupteur

moins d'un actionnement manuel.

20

Page 21

z_AVERTISSEMENT : Iors de I'utilisation d'une scie A chafne A

piles des pr6cautions de base en mati_re de s6curit6 doivent 6tre

suivies afin de r6duire le risque d'incendie de choc _lectrique et de

b essure corpore e, notamment es su vantes :

LIRE TOUTES CES DIRECTIVES.

• Eloigner toute pattie du corps de la chaine de I'outil Iorsque

la scie a chaine est en marche. Avant de d6marrer la scie

chaine, s'assurer que la chaine est d6gag6e, sans aucun

contact avec des objets. Un moment d'inattention, durant

I'utilisation d'une scie _ chafne, peut r6sulter dans I'enchev_trement

des v_tements ou d'une partie du corps clans la chafne.

• Tenir I'outil 61ectrique par ses surfaces de prise isol6es

seulement, car la chaine peut entrer en contact avec un

c_blage cach6 ou le cordon de la scie. Tout contact entre une

chafne de scie et un fil ,, sous tension >>risque de mettre ,_sous

tension >>les pieces m_talliques expos_es de I outil et de donner un

choc _lectrique _ Ibp_rateur.

• Porter des lunettes de s6curit6 et une protection auditive.

Le port d'un 6quipement de protection suppl6mentaire pour

la t6te, les mains, les jambes et les pieds est recommand6.

Les v_tements de protection appropries r6duisent les blessures

corporelles caus_es par les debris projet_s ou un contact accidentel

avec la chafne de scie.

• Ne pas grimper darts un arbre pour utiliser la scie a chaine.

L'utilisation d'une scie _ chafne en hauteur dans un arbre peut se

solder par des blessures corporelles.

• Conserver toujours un pas sQr et utiliser uniquement la scie

chaine debout sur une surface fi×e, s6curitaire et de niveau.

Les surfaces glissantes ou instables comme les _chelles peuvent

entrafner une perte de I'_quilibre ou du contrSle de la scie D chafne.

• Lots de la coupe d'une branche maitresse sous tension,

prendre garde au redressement de la branche. Lorsque la

tension contenue dans les fibres de bois se relgche, la branche

maftresse pendant la d_tente risque de frapper I'utilisateur et/ou de

lui faire perdre le contrSle de la scie _ chafne.

• Etre extr6mement prudent lots de la coupe de broussailtes ou

de jeunes arbres. Les branches _lanc6es peuvent se coincer dans

la chafne et _tre projet_es vers vous ou vous d_s_quilibrer.

• Transporter ta scie a chaine par la poign6e avant avec I'outil

hors tension et a 1'6cart du corps. Toujours mettre la gaine du

guide-chaine avant de transporter ou d'entreposer la scie

chaine. La manipulation ad6quate de ta scie achaine r6duit le

risque de contact accidentel avec la chaine en mouvement.

• Suivre les consignes de graissage, de tension de la chaine

et de changement d'accessoires. Une chafne mal tendue ou

graiss_e risque de se briser ou accroft la probabifit_ d'un effet de

rebond.

• Maintenir les poign6es seches, propres et exemptes d'huile

et de graisse. Des poign_es pleines de graisse sont glissantes et

peuvent vous faire perdre le contrSle de votre outiL

• Ne couper que le bois. Ne pas utiliser la scie a chaine pour

des applications pour lesquelles I'outil n'est pas congu,

comme la coupe des matieres plastiques, de la ma?onnerie

ou des mat6riaux de constructions qui ne sont pas en bois.

L'utilisation de la scie Dchafne pour toutes operations autres que

celles pour lesquelles elle a _t_ congue est dangereuse.

Causes de reffet de rebond et pr6vention par I'op6rateur :

L'effet de rebond se produit Iorsque I'extr6mit_ ou la pattie

sup_rieure du guide-chafne frappe un objet ou Iorsque la chafne se

coince dans une entaille.

Le contact de I'extr6mit_ pourrait provoquer une r_action inverse

soudaine qui projetterait le guide-chafne vers le haut et I'arri_re en

direction de I'operateur.

Un coincement de la chafne de la scie sur le dessus du guide-

chafne pourrait repousser rapidement le guide-chafne vers I'arriere

en direction de I'op_rateur.

L'un ou I'autre de ces mouvements brusques pourrait vous faire

perdre la maftrise de la scie et se solder par une grave blessure

corporelle. It ne faut passe tier exclusivement aux dispositifs de

s_curit_ int6gr_s & votre scie. L'utitisateur de scie & chafne doit

prendre plusieurs mesures pour _viter tout accident ou toute

21

Page 22

btessuretorsdestravauxdecoupe.

Uneffetderebondestler6sultatd'unemauvaiseutilisationdel'outit

et/oudeproc6duresouconditionsdefonctionnementincorrectes.

I1peut_tre6vit6enprenantlespr6cautionsn6cessairestellesque

decritesci-dessous:

• Saisir fermement la scie a chaTne des deu× mains, avec les

pouces et les doigts autour des poignees, et positionner le

corps et les bras de sorte a resister a la force de I'effet de

rebond. II estpossible de maTtriser les forces de I'effet de

rebond avec de relies mesures de precaution. Ne pas Igcher la

scie 9 chafne.

• Ne pas trop tendre les bras et ne pas couper au-dessus du

niveau des epaules. Cela aide _ _viter un contact accidentel de

I'extr_mit6 et permet de mieux maffriser la scie _ chafne dans les

situations impr6vues.

• Utiliser uniquement les guide-chaines et les chaTnes de

remplacement specifi6s par le fabricant. Les guide-chafnes et les

chafnes de remplacement inad_quats peuvent entrafner un bris de

la chafne et/ou un effet de rebond.

• Suivre les directives du fabricant pour I'aff0tage et I'entretien

de la chaTne de scie. Le fait de baisser le guide de profondeur peut

accroffre I'effet de rebond.

Suivre les precautions qui suivent pour reduire I'effet de

rebond notamment :

(1.) Saisir fermement la scie & cha_ne. Tenir fermement la scie

&cha_ne avec les deux mains Iorsque le moteur est en marche.

Utiliser une prise ferme avec les pouces et tes doigts et encercler

les poign6es de la scie & cha_ne. La scie &cha_ne imprimera un

mouvement avant Iors de la coupe avec la partie inf6rieure du

guide-cha_ne et un mouvement arriere Iors de coupe avec la partie

sup6rieure du guide-chatne.

(2.) Ne pas trop se pencher.

(3.) Conserver son 6quitibre en tout temps.

(4.) Ne pas laisser I'extr6mit6 du guide-cha_ne frapper un billot, une

branche, le sol ou tout autre obstruction.

(5.) Ne pas couper au-dessus de la hauteur des 6paules.

(6.) Utiliser des dispositifs comme des chafnes #.faible effet de

rebond et des guides-chatne b.faibte effet de rebond pour r6duire

les risques associ6s & I'effet de rebond.

(7.) Utiliser uniquement des guides-chafne et des chafnes de

rechange pr6cis6s par le fabricant ou son 6quivalent.

(8.) Ne pas mettre en contact la chafne et tout objet se trouvant &

I'extr6mit6 du guide-chafne.

(9.) Tenir la zone de travail d6gag6e et exempte d'obstructions

comme d'autres arbres, branches, roches, cl6tures, souches, etc.

Eliminer ou _viter toute obstruction que la scie &chafne pourrait

frapper tors d'une coupe d'un billot ou d'une branche en particutier.

(10.) Maintenir la chafne de la scie bien affQt6e et tendue

correctement. Une chatne I&che ou 6mouss6e peut augmenter le

risque d'effet de rebond. V6rifier la tension _. intervalles r6guliers,

avec le moteur hors tension et sans le bloc-piles, jamais avec le

moteur en marche.

(11.) Commencer et poursuivre la coupe uniquement Iorsque la

chafne fonctionne & plein r6gime. Si la chafne tourne & un r6gime

plus lent, te risque d'un effet de rebond est plus 61ev_.

(12.) Tron(;onner un seul biltot & la fois.

(13.) Faire tres attention Iorsque vous recommencez & scier & partir

d'une entaille d6j& entam6e. Appuyer les but6es cannel6es contre

le tronc et laisser la chafne atteindre son plein r_gime avant de

poursuivre la coupe.

(14.) Ne pas essayer de coupes en plong6e ou le per(;age de trous.

(15.) Prendre garde au d6ptacement des bittots ou & d'autres forces

qui pourraient faire refermer une entailte et pincer la chafne ou qui

pourraient tomber sur celte-ci.

• Bloc d'aHmentation

Brancher le bloc-piles de la scie & chatne & la tension appropri6e,

c'est-&-dire, s'assurer que I'alimentation en tension est la m_me

que celle indiqu6e sur la plaque signat6tique de I'outil.

Directives de securit6 concernant I'effet de rebond

22

Page 23

Z_AVERTISSEMENT : la scie & chafne est dot6e des

caract6ristiques suivantes afin d'aider & r6duire les risques li6s &

I'effet de rebond; toutefois, ces caract6ristiques n'_limineront pas

totalement cette dangereuse r6action. En tant qu'utilisateur de scie

&chafne, ne pas se tier uniquement aux dispositifs de s6curit&

Vous devez respecter toutes les pr6cautions, directives et consignes

d'entretien et de s6curit6 contenues dans ce manuel afin d'essayer

d'6viter l'effet de rebond et autres forces qui pourraient entrafner de

graves blessures.

• Guide-chaTne a faible effet de rebond, congu avec une

extr6mit6 de faible rayon qui r6duit la taille de la zone dangereuse

d'effet de rebond sur I'extr6mit6 de la barre. Un guide-chafne &

faibte effet de rebond est Fun des dispositifs qui r6duit de mani_re

significative le nombre et I'ampteur des effets de rebond tors

d'essais en conformit6 avec les exigences de s6curit6 pour les

scies & chafne 61ectriques.

• ChaTne a effet de rebond reduit, congue avec un guide de

profondeur profil6 et un lien de pare-main qui d6vie la force

de I'effet de rebond et permet & la chafne de s'enfoncer

progressivement dans le bois. Une chafne a faibte effet de rebond

est une chafne conforme aux exigences de performance ANSI

B175.1-1991.

• Ne pas utiliser la scie a chaine Iorsque vous _tes darts un

arbre, sur une echelle ou un echafaudage ou sur route autre

surface instable.

• Tenir I'outil par sa surface de prise isolee darts une situation

o_ I'outil de coupe peut entrer en contact avec un c_blage

dissimul& Tout contact avec un fit <<sous tension _>mettra <<

sous tension >>les pi_ces m6talliques expos6es de I'outil et

6tectrocutera I'op6rateur.

• Ne pas effectuer d'operations au=dela de sa capacite ou de

son experience. Lire attentivement et comprendre parfaitement

les directives de ce mode d'emploi.

• Avant de demarrer la scie a chafne, s'assurer que la chafne est

d6gag6e, sans aucun contact avec des objets.

• Ne pas utiliser la scie a chaTne d'une seule main! Une relic

pratique risque de blesser gravernent I'operateur, les aides

ou les curieux. Une scie & chafne est congue uniquement pour

une utilisation & deux mains.

• Garder les poignees seches, propres et exemptes d"huile ou

de graisse.

• Ne pas laisser la salete, les debris ou la sciure s'accumuler

sur le moteur ou les events externes.

• Arr_ter la scie a cha'ine avant de la deposer sur le sol.

• Ne pas couper de vignes, de petites broussailles ou du sous=

bois.

• Etre extr6rnernent prudent lots de la coupe de broussailles ou

de jeunes arbres, car les branches 6lanc6es peuvent se coincer

dans la chafne et _tre projet6es vers vous ou vous d6s6quitibrer.

Z_AVERTISSEMENT : certains outils 61ectriques, tels que les

sableuses, les scies, les meutes, les perceuses ou certains autres

outits de construction, peuvent produire, de la poussi_re contenant

des produits chimiques reconnus par I'Etat de la Californie comme

6tant susceptibtes d'entrafner le cancer, des malformations

cong6nitales ou pouvant _tre nocifs pour le syst_me reproductif.

Parmi ces produits chimiques, on retrouve :

• le plomb contenu darts les peintures & base de plomb,

• la sitice cristalline de la brique, du ciment et d'autres

produits de magonnerie, et

• I'arsenic et chrome provenant de bois trait6 chimiquement

Les risques reli6s & I'exposition & ces poussi_res varient selon la

fr6quence & laquelte I'utilisateur travailte avec ce type de mat6riaux.

Pour r6duire I'exposition & ces produits chimiques, travailler dans un

endroit bien ventil6 et porter un _quipement de s6curit6 approuv6

comme un masque antipoussi_res congu sp6cialement pour filtrer

les particules microscopiques.

• Eviter le contact prolonge avec les poussieres produites par

les activites de port,age, sciage, meulage, per£age et autres

activites de construction. Porter des v6tements de protection

et laver les parties du corps exposees avec une solution

d'eau et de savon. Laisser la poussi_re p6n_trer dans la bouche

et les yeux ou ta laisser reposer sur la peau, pourrait promouvoir

I'absorption de produits chimiques nocifs.

23

Page 24

_AVERTISSEMENT : life et cornprendre toutes les directives. Le

non-respect des directives indiqu6es ci-dessous peut entrafner des

risques de choc _lectrique, d'incendie ou de blessures graves.

Symboles

L'_tiquette appos_e sur votre outil pourrait comprendre les

symboles suivants.

V............... volts A .................... amperes

Hz ............. hertz W ................... watts

min ............ minutes _ .................. courant altematif

- - -. ......... courant continue no................... r6gime _ vide

[] .............. Construction classe II _ .................... borne de terre

Avant d'utiliser la scie & chafne, se famitiariser avec toutes les

fonctions d'utitisation et de s6curit6.

............. symbole d'alerte

la s#curit#

.../min ............. r#volutions par

minute

1. D6tente

2. Bouton de verrouitlage

3. Protege-main avant

4. Bloc-piles

5. But6e cannel6e

6. Guide-chafne

7. Chafne de scie

8. Couvercle du pignon

24

9. Vis Allen

10. Fourreau du guide-chafne

11. Cl6

12. Flacon d'huile

13. Chargeur

14. Poign6e arri_re

15. Poign6e avant

Page 25

CONSERVER CES DIRECTIVES : ce mode d'emptoi comprend

d'importantes directives de s6curit6 pour les chargeurs de piles.

• Avant d'utiliser le chargeur, lire toutes les directives et tous les

avertissements figurant sur le chargeur, le bloc-piles et le produit °

utilis6 avec le bloc-piles.

z._AVERTISSEMENT : risque de choc electrique. Eviter la

p.l_6n_trationde tout liquide dans le chargeur.

MISE EN GARDE : risque de brl31ure. Pour r6duire le risque de

blessures, charger uniquement des piles Black & Deckerconseilt6es.

D'autres types de piles peuvent exptoser et provoquer des btessures

corporeltes et des dommages.

_l MISE EN GARDE : dans certaines circonstances, Iorsque le

chargeur est branch6 au bloc d'alimentation, le chargeur peut _tre

court-circuit6 par des corps 6trangers conducteurs tels que, mais

sans s'y limiter, la laine d'acier, le papier d'aluminium ou toute

accumulation de particutes m6talliques. IIs doivent @re maintenus &

distance des ouvertures du chargeur. D6brancher syst6matiquement

cetui-ci si aucun bloc-piles n'y est ins@& D6brancher lechargeur

avant tout nettoyage.

• Le chargeur fourni avec ce produit est correctement branche

s'it est oriente en position verticale ou au ptancher.

• NE PAS tenter de charger le bloc-piles avec autre chose qu'un

chargeur de marque. Les chargeurs et blocs-piles sont congus

sp4cialement pour fonctionner ensemble.

• Ces chargeurs ne sont pas destines a 6tre utilises a d'autres

fins que celles de charger les piles rechargeables conseillees

Black & Decker. Toute autre utilisation risque de provoquer un

incendie, un choc 41ectrique ou une 41ectrocution. •

• Proteger le chargeur de la pluJe et de la neige.

• Tirer la fiche plut6t que le cordon pour debrancher le chargeur

ou pour debrancher les cordons a I'aide de la fonction de

guirlande. Cela permet de r4duire le risque d'endommager la fiche

ou le cordon d'alimentation.

S'assurer que le cordon est situe en lieu s_r de manJere ace

que personne ne marche ni ne trebuche dessus ou ace qu'it ne

soit pas endommage ni soumis a une tension.

Ne pas utiliser de rallonge a moins que cela ne soit absolument

necessaire. L'utilisation d'une rallonge inad4quate risque

d'entrafner un incendie, un choc 41ectfique ou une 41ectrocution.