Page 1

ENRUUA

www.blackanddecker.ru

CS1550

Page 2

ENGLISH

(Original instructions)

71311

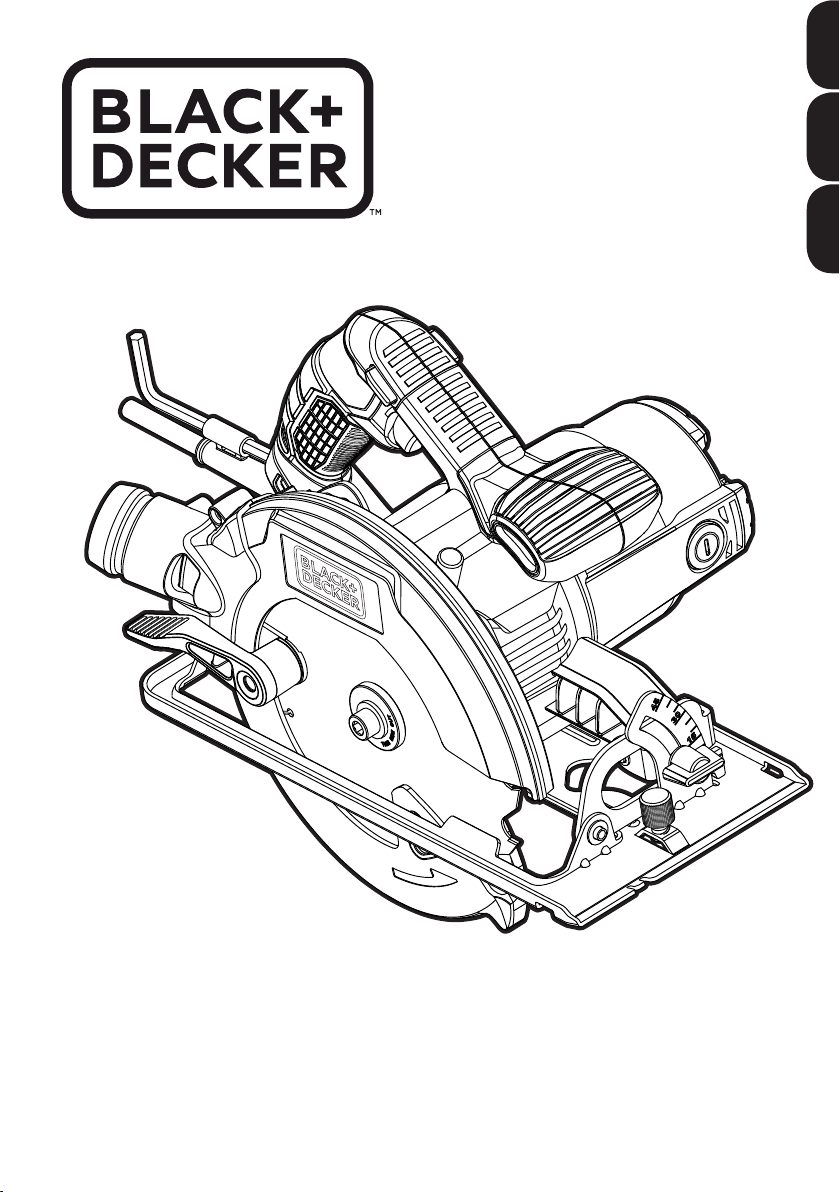

12 14

A

16

18

17

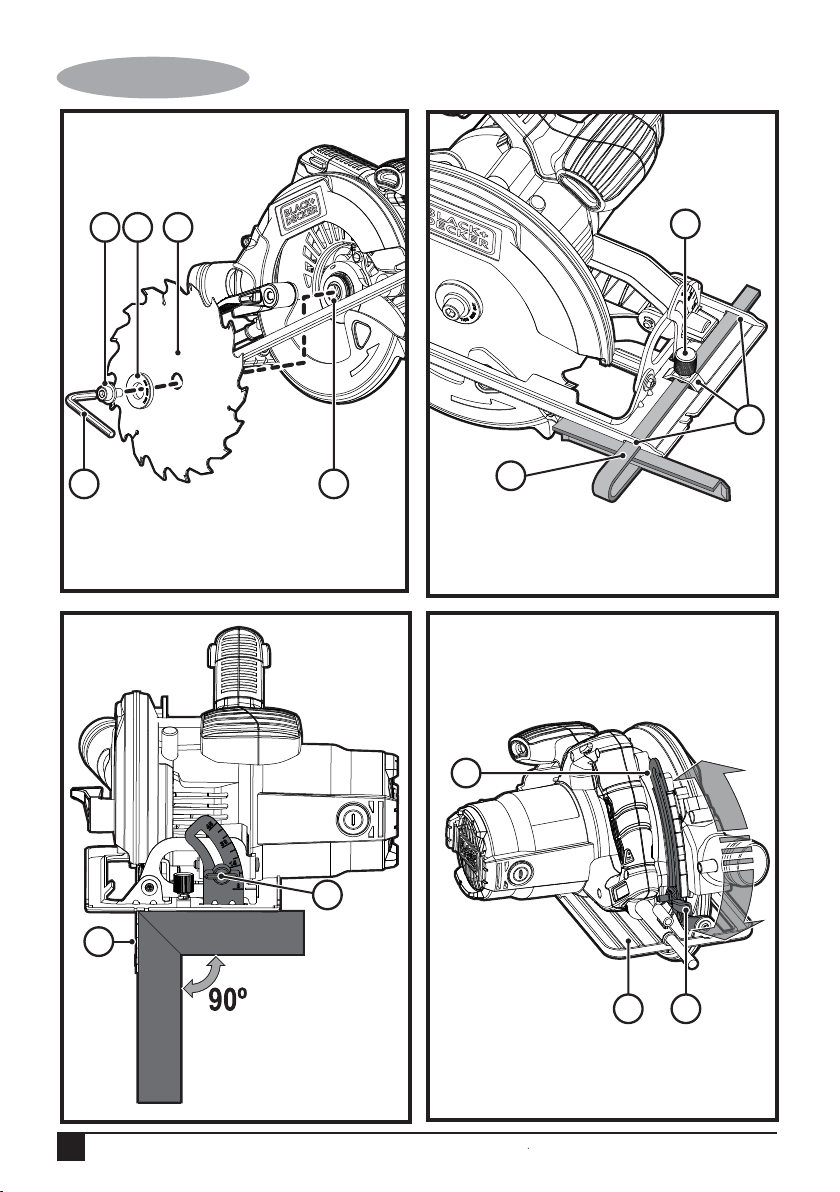

B

23

19

7

22

6

C

2

D

Page 3

(Original instructions)

ENGLISH

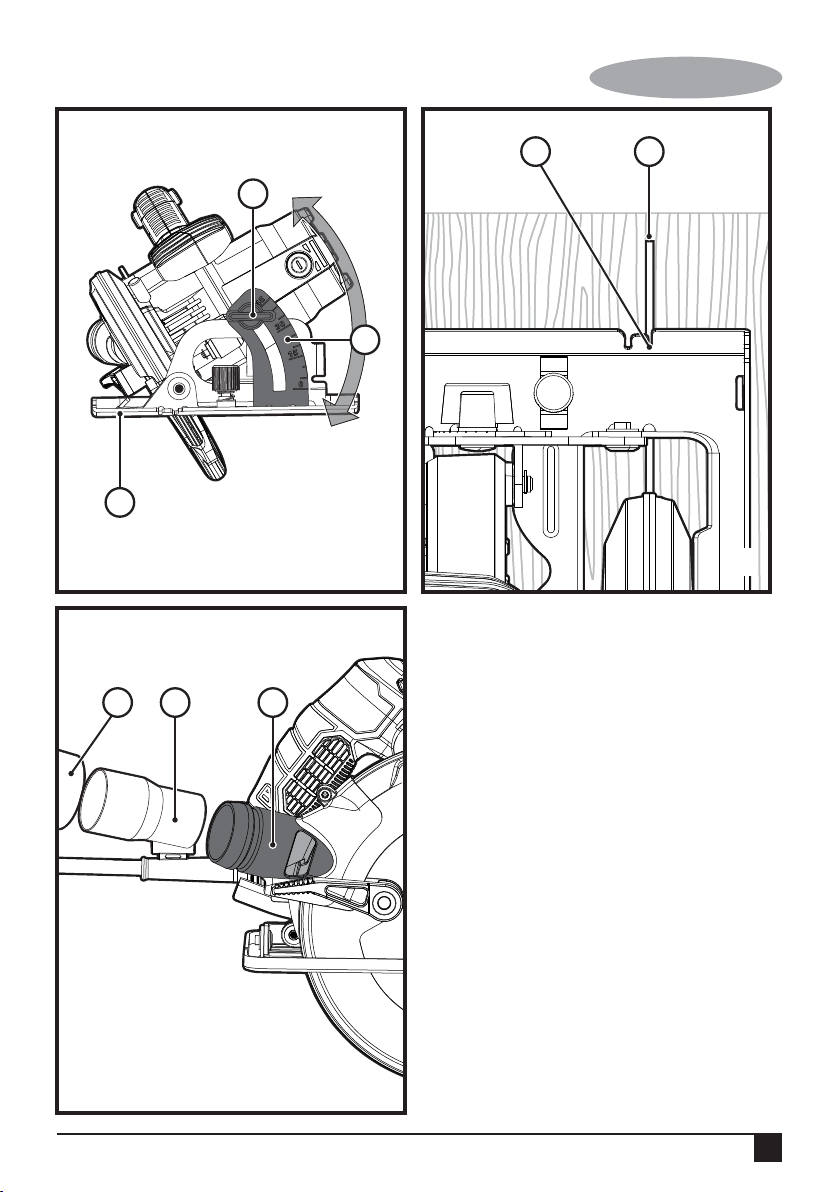

E

26

19

24

6

25

F

102728

G

3

Page 4

ENGLISH

(Original instructions)

Intended use

Your BLACK+DECKER™ CS1550 Circular saw

has been designed for sawing wood and

wood products. This tool is intended for

consumer use only.

Safety instructions

General power tool safety warnings

Warning: Read all safety warnings

and all instructions. Failure to follow

the warnings and instructions listed

below may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions for

future reference. The term "power tool" in

all of the warnings listed below refers to

your mains operated (corded) power tool or

battery operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the

dust or fumes.

c. Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose

control.

2. Electrical safety

a. Power tool plugs must match the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce

risk of electric shock.

b. Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or

grounded.

c. Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric

shock.

d. Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

e. When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

f. If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

3. Personal safety

a. Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool

while you are tired or under the

influence of drugs, alcohol or

medication. A moment of inattention

while operating power tools may result in

serious personal injury.

b. Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate

conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure

the switch is in the o-position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your

finger on the switch or energising power

tools that have the switch on invites

accidents.

d. Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a

rotating part of the power tool may result

in personal injury.

e. Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

4

Page 5

(Original instructions)

ENGLISH

f. Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g. If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used. Use of

dust collection can reduce dust-related

hazards.

4. Power tool use and care

a. Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

b. Do not use the power tool if the switch

does not turn it on and o. Any power

tool that cannot be controlled with the

switch is dangerous and must be

repaired.

c. Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any

adjustments, changing accessories, or

storing power tools. Such preventive

safety measures reduce the risk of

starting the power tool accidentally.

d. Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

e. Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may aect the power

tools operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly

maintained power tools.

f. Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

g. Use the power tool, accessories and tool

bits etc. in accordance with these

instructions, taking into account the

working conditions and the work to be

performed. Use of the power tool for

operations dierent from those intended

could result in a hazardous situation.

5. Service

a. Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

Additional power tool safety

warnings

Warning! Additional safety warnings

for saws

a. Keep hands away from cutting area and

the blade. Keep your second hand on

auxiliary handle, or motor housing. If

both hands are holding the saw, they

cannot be cut by the blade.

b. Do not reach underneath the workpiece.

The guard cannot protect you from the

blade below the workpiece.

c. Adjust the cutting depth to the thickness

of the workpiece. Less than a full tooth of

the blade teeth should be visible below

the workpiece.

d. Never hold piece being cut in your hands

or across your leg. Secure the workpiece

to a stable platform. It is important to

support the work properly to minimize

body exposure, blade binding, or loss of

control.

e. Hold power tool by insulated gripping

surfaces when performing an operation

where the cutting tool may contact

hidden wiring or its own cord. Contact

with a "live" wire will also make exposed

metal parts of the power tool "live" and

shock the operator.

f. When ripping always use a rip fence or

straight edge guide. This improves the

accuracy of cut and reduces the chance

of blade binding.

g. Always use blades with correct size and

shape (diamond versus round) of arbour

holes. Blades that do not match the

mounting hardware of the saw will run

eccentrically, causing loss of control.

5

Page 6

ENGLISH

(Original instructions)

h. Never use damaged or incorrect blade

washers or bolt. The blade washers and

bolt were specially designed for your

saw, for optimum performance and

safety of operation.

Further safety instructions for all saws

Causes and operator prevention of

kickback:

• kickback is a sudden reaction to a

pinched, bound or misaligned saw blade,

causing an uncontrolled saw to lift up

and out of the workpiece toward the

operator;

• when the blade is pinched or bound

tightly by the kerf closing down, the

blade stalls and the motor reaction

drives the unit rapidly back toward the

operator;

• if the blade becomes twisted or

misaligned in the cut, the teeth at the

back edge of the blade can dig into the

top surface of the wood causing the

blade to climb out of the kerf and jump

back toward the operator.

Kickback is the result of saw misuse and/or

incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below.

a. Maintain a firm grip with both hands on

the saw and position your arms to resist

kickback forces. Position your body to

either side of the blade, but not in line

with the blade. Kickback could cause the

saw to jump backwards, but kickback

forces can be controlled by the operator,

if proper precautions are taken.

b. When the blade is binding, or when

interrupting a cut for any reason,

release the trigger and hold the saw

motionless in the material until the

blade comes to a complete stop. Never

attempt to remove the saw from the

work or pull the saw backward while the

blade is in motion or kickback may

occur. Investigate and take corrective

actions to eliminate the cause of blade

binding.

c. When restarting a saw in the workpiece,

centre the saw blade in the kerf and

check that saw teeth are not engaged

into the material. If saw blade is binding,

it may walk up or kickback from the

workpiece as the saw is restarted.

d. Support large panels to minimise the risk

of blade pinching and kickback. Large

panels tend to sag under their own

weight. Supports must be placed under

the panel on both sides, near the line of

cut and near the edge of the panel.

e. Do not use dull or damaged blades.

Unsharpened or improperly set blades

produce narrow kerf causing excessive

friction, blade binding and kickback.

f. Blade depth and bevel adjusting locking

levers must be tight and secure before

making cut. If blade adjustment shifts

while cutting, it may cause binding and

kickback.

g. Use extra caution when making a

"plunge cut" into existing walls or other

blind areas. The protruding blade may

cut objects that can cause kickback.

Safety instructions for circular saws with

outer or inner pendulum guards and with

tow guard

a. Check lower guard for proper closing

before each use. Do not operate the saw

if lower guard does not move freely and

close instantly. Never clamp or tie the

lower guard into the open position. If

saw is accidentally dropped, lower guard

may be bent. Raise the lower guard with

the retracting handle and make sure it

moves freely and does not touch the

blade or any other part, in all angles and

depths of cut.

b. Check the operation of the lower guard

spring. If the guard and the spring are

not operating properly, they must be

serviced before use. Lower guard may

operate sluggishly due to damaged parts,

gummy deposits, or a build-up of debris.

c. Lower guard should be retracted

manually only for special cuts such as

"plunge cuts" and "compound cuts".

Raise lower guard by retracting handle

and as soon as blade enters the material,

the lower guard must be released. For all

other sawing, the lower guard should

operate automatically.

6

Page 7

(Original instructions)

ENGLISH

d. Always observe that the lower guard is

covering the blade before placing saw

down on bench or floor. An unprotected,

coasting blade will cause the saw to walk

backwards, cutting whatever is in its

path. Be aware of the time it takes for

the blade to stop after switch is released.

Residual risks

The following risks are inherent to the use of

saws:

- Injuries caused by touching the rotating

parts.

Even with the application of the relevant

safety regulations and the implementation

of safety devices, certain residual risks

cannot be avoided. These are:

- Impairment of hearing.

- Risk of accidents caused by the

uncovered parts of the rotating saw

blade.

- Risk of injury when changing the blade.

- Risk of squeezing fingers when opening

the guards.

- Health hazards caused by breathing dust

developed when sawing wood, especially

oak, beech and MDF.

Saw blades

• Do not use blades of larger or smaller

diameter than recommended. For the

proper blade rating refer to the technical

data. Use only the blades specified in this

manual, complying with EN 847-1.

• Warning! Never use abrasive wheels.

Safety of others

• This appliance is not intended for use by

persons (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning use

of the appliance by a person responsible

for their safety.

• Children should be supervised to ensure

that they do not play with the appliance.

Vibration

The declared vibration emission values

stated in the technical data and the

declaration of conformity have been

measured in accordance with a standard test

method provided by EN 60745 and may be

used for comparing one tool with another.

The declared vibration emission value may

also be used in a preliminary assessment of

exposure.

Warning! The vibration emission value

during actual use of the power tool can

dier from the declared value depending on

the ways in which the tool is used. The

vibration level may increase above the level

stated.

When assessing vibration exposure to

determine safety measures required by

2002/44/EC to protect persons regularly

using power tools in employment, an

estimation of vibration exposure should

consider, the actual conditions of use and

the way the tool is used, including taking

account of all parts of the operating cycle

such as the times when the tool is switched

o and when it is running idle in addition to

the trigger time.

Labels on tool

The label on your tool may include the

following symbols

Hz .......

Read

Instructions

Manual

Use Eye

Protection

Use Ear

Protection

V ........ Volts

A ........ Amperes

Hertz

W ........ Watts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n0 ....... No-Load

Speed

Position of date barcode

The Date Code, which also includes the year

of manufacture, is printed into the housing.

Example:

2017 XX JN

Year of manufacturing

...... Class II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Reciprocation per

minute

7

Page 8

ENGLISH

(Original instructions)

Electrical safety

This tool is double insulated;

therefore no earth wire is required.

Always check that the power supply

corresponds to the voltage on the

rating plate.

• If the supply cord is damaged, it must be

replaced by the manufacturer or an

authorised BLACK+DECKER Service

Centre in order to avoid a hazard.

Features

1. On/o switch

2. Lock-o button

3. Main handle

4. Secondary handle

5. Spindle lock button

6. Shoe

7. Saw blade

8. Saw blade guard

9. Guard handle

10. Saw dust outlet

Assembly

Warning! Before attempting any of the

following operations, make sure that the

tool is switched o and unplugged and that

the saw blade has stopped.

Removing and fitting a saw blade

(fig. A)

Removing

• Keep the spindle lock button (5)

depressed and rotate the blade until the

spindle lock engages.

• Loosen and remove the blade retaining

screw (11) by turning it counterclockwise

using the spanner (12) supplied.

• Remove the outer washer (13).

• Remove the saw blade (7).

Fitting

• Place the saw blade onto the inner flange

(14), making sure that the arrow on the

blade points in the same direction as the

arrow on the tool.

• Fit the outer washer (13) on the spindle,

with the raised part pointing away from

the saw blade.

• Insert the blade retaining screw (11) into

the hole.

• Keep the spindle lock button (5)

depressed.

• Securely tighten the blade retaining

screw by turning it clockwise using the

spanner (12) supplied.

• Adjust the riving knife as described

below.

Fitting and removing the parallel

fence (fig. B)

• The parallel fence is used to saw in a

straight line parellel to the edge of the

workpiece.

Fitting

• Loosen the locking knob (16).

• Insert the parallel fence (17) through the

openings (18).

• Slide the parallel fence into the desired

position.

• Tighten the locking knob.

Removing

• Loosen the locking knob.

• Pull the parallel fence off the tool.

Use

Warning! Let the tool work at its own pace.

Do not overload.

Note: This tool can be used in the right hand

or the left hand.

Adjusting the sawing angle (fig. C)

The default angle between the saw blade

and the shoe is 90°.

8

Page 9

(Original instructions)

ENGLISH

• Use a square to check that the angle

between the saw blade and the shoe is

90°. If the angle does not measure 90°

adjust as follows:

• Loosen the locking knob (19) to unlock

the saw shoe.

• Loosen the locknut (20) on the adjusting

screw (21).

• Screw the adjusting screw in or out to

achieve a 90° angle.

• Retighten the locknut.

• Tighten the locking knob to lock the saw

shoe in place.

Adjusting the depth of cut (fig. D)

The depth of cut should be set according to

the thickness of the workpiece. It should

exceed the thickness by approx. 2 mm.

• Loosen the knob (22) to unlock the saw

shoe.

• Move the saw shoe (6) into the desired

position.

The corresponding depth of cut can be read

from the scale (23).

• Tighten the knob to lock the saw shoe in

place.

Adjusting the bevel angle (fig. E)

This tool can be set to bevel angles between

0° and 45°.

• Loosen the locking knob (19) to unlock

the saw shoe.

• Move the saw shoe (8) into the desired

position. The corresponding bevel angle

can be read from the scale (24).

• Tighten the locking knob to lock the saw

shoe in place.

Switching on and o

• To switch the tool on, move the lock-off

button (2) into the unlock position and

squeeze the on/off switch (1).

• To switch the tool off, release the on/off

switch.

Sawing

Always hold the tool with both hands.

• Let the blade run freely for a few seconds

before starting the cut.

• Apply only a gentle pressure to the tool

while performing the cut.

• Work with the shoe pressed against the

workpiece.

Hints for optimum use

• As some splintering along the line of cut

on the top side of the workpiece cannot

be avoided, cut on the side where

splintering is acceptable.

• Where splintering is to be minimised, e.g.

when cutting laminates, clamp a piece of

plywood onto the top of the workpiece.

Using the sight guide (fig. F)

The tool is equipped with a sight guide for

straight cutting.

• Align the left edge of the guides (26)

with the cutting line (25).

• Keep the sight guide aligned with the

cutting line while sawing.

• Work with the shoe pressed against the

workpiece.

Dust extraction (fig. G)

An adaptor is required to connect a vacuum

cleaner or dust extractor to the tool.

• Insert the dust extraction adaptor (27)

into the saw dust outlet (10).

• Connect the vacuum cleaner hose (28) to

the adaptor.

Maintenance

Your BLACK+DECKER corded/cordless

appliance/tool has been designed to operate

over a long period of time with a minimum

of maintenance. Continuous satisfactory

operation depends upon proper tool care

and regular cleaning.

Warning! Before performing any

maintenance on corded/cordless power

tools:

9

Page 10

ENGLISH

(Original instructions)

• Switch off and unplug the appliance/tool.

• Or switch off and remove the battery

from the appliance/tool if the

appliance/tool has a separate battery

pack.

• Or run the battery down completely if it

is integral and then switch o.

• Unplug the charger before cleaning it.

Your charger does not require any

maintenance apart from regular cleaning.

• Regularly clean the ventilation slots in

your appliance/tool/charger using a soft

brush or dry cloth.

• Regularly clean the motor housing using

a damp cloth. Do not use any abrasive or

solvent-based cleaner.

• Regularly open the chuck and tap it to

remove any dust from the interior (when

fitted).

Protecting the environment

Separate collection. This product

must not be disposed of with normal

household waste.

Should you find one day that your

BLACK+DECKER product needs replace-

ment, or if it is of no further use to you, do

not dispose of it with household waste.

Make this product available for separate

collection.

Separate collection of used products

and packaging allows materials to be

recycled and used again. Reuse of

recycled materials helps prevent environmental pollution and reduces the demand

for raw materials.

Local regulations may provide for separate

collection of electrical products from the

household, at municipal waste sites or by

the retailer when you purchase a new

product.

BLACK+DECKER provides a facility for the

collection and recycling of BLACK+DECKER

products once they have reached the end of

their working life. To take advantage of this

service please return your product to any

authorised repair agent who will collect

them on our behalf.

You can check the location of your nearest

authorised repair agent by contacting your

local BLACK+DECKER oce at the address

indicated in this manual. Alternatively, a list

of authorised BLACK+DECKER repair agents

and full details of our after-sales service and

contacts are available on the Internet at:

www.2helpU.com.

TECHNICAL DATA

CS1550

Input voltage

Power input W 1500

No-load speed

Max. depth of cut mm 66

Blade diameter mm 190

Blade bore mm 16

Blade tip width mm 1.8

Weight kg 3.9

(4.31 with blade)

Level of sound pressure according to EN 60745:

Sound pressure (LpA) 89,0 dB(A), uncertainty (K) 3 dB(A)

Sound power (L

Vibration total values (triax vector sum)

according to EN 60745:

Vibration emission value (a

uncertainty (K) 1.5m/s

WA

VAC

220-240

min-1 5500

) 100 dB(A), uncertainty (K) 3 dB(A)

) 2.6m/s2,

h,w

2

(cutting wood)

10

Page 11

(Original instructions)

ENGLISH

EC declaration of conformity

MACHINERY DIRECTIVE

CS1550-Circular saw

BLACK+DECKER declares that these

products described under "Technical data"

are in compliance with: 2006/42/EC,

EN60745-1:2010, EN60745-2-5:2010

These products also comply with Directive

2014/30/EU and 2011/65/EU.

For more information, please contact

BLACK+DECKER at the following address or

refer to the back of the manual.

The undersigned is responsible for

compilation of the technical fi le and makes

this declaration on behalf of

BLACK+DECKER.

R. Laverick

Engineering Manager

BLACK+DECKER Europe, 210 Bath Road,

Slough,

Berkshire, SL1 3YD

United Kingdom

01.2017

Guarantee

BLACK+DECKER is confident of the quality

of its products and oers an outstanding

guarantee. This guarantee statement is in

addition to and in no way prejudices your

statutory rights.

If a BLACK+DECKER product becomes

defective due to faulty materials,

workmanship or lack of conformity, within

24 months from the date of purchase,

BLACK+DECKER guarantees to replace

defective parts, repair products subjected

to fair wear and tear or replace such

products to make sure of the minimum

inconvenience to the customer unless:

• The product has been used for trade,

professional or hire purposes.

• The product has been subjected to

misuse or neglect.

• The product has sustained damage

through foreign objects, substances or

accidents.

• Repairs have been attempted by persons

other than authorised repair agents or

BLACK+DECKER service sta.

To claim on the guarantee, you will need to

submit proof of purchase to the seller or an

authorised repair agent. You can check the

location of your nearest authorised repair

agent by contacting your local

BLACK+DECKER oce at the address

indicated in this manual. Alternatively, a list

of authorised BLACK+DECKER repair

agents and full details of our aftersales

service and contacts are available on the

Internet at: www.2helpU.com

11

Page 12

РУССКИЙ

(Перевод с оригинала инструкции)

Назначение

Ваша дисковая пила BLACK+DECKER™ CS1550

предназначена для пиления древесины и изделий

из дерева. Данный инструмент предназначен

только для бытового использования.

Инструкции по технике безопасности

Общие правила безопасности при работе с

электроинструментами

Внимание! Внимательно прочтите все

инструкции по безопасности и руко-

Несоблюдение всех перечисленных ниже правил

безопасности и инструкций может привести к

поражению электрическим током,

возникновению пожара и/или получению

тяжелой травмы.

Сохраните все инструкции по безопасности и

руководство по эксплуатации для их

дальнейшего использования. Термин

«Электроинструмент» во всех приведенных ниже

указаниях относится к Вашему сетевому (с

кабелем) электроинструменту или аккумуляторному (беспроводному) электроинструменту.

1. Безопасность рабочего места

a. Содержите рабочее место в чистоте и

b. Не используйте электроинструменты, если

c. Во время работы с электроинструментом

2. Электробезопасность

a. Вилка кабеля электроинструмента должна

водство по эксплуатации.

обеспечьте хорошее освещение. Плохое

освещение или беспорядок на рабочем месте

может привести к несчастному случаю.

есть опасность возгорания или взрыва,

например, вблизи легко

воспламеняющихся жидкостей, газов или

пыли. В процессе работы

электроинструменты создают искровые

разряды, которые могут воспламенить пыль

или горючие пары.

не подпускайте близко детей или

посторонних лиц. Отвлечение внимания

может вызвать у Вас потерю контроля над

рабочим процессом.

соответствовать штепсельной розетке. Ни в

коем случае не видоизменяйте вилку

электрического кабеля. Не используйте

соединительные штепсели-переходники, если

в силовом кабеле электроинструмента есть

провод заземления. Использование

оригинальной вилки кабеля и

соответствующей ей штепсельной розетки

уменьшает риск поражения электрическим

током.

b. Во время работы с электроинструментом

избегайте физического контакта с

заземлёнными объектами, такими как

трубопроводы, радиаторы отопления,

электроплиты и холодильники. Риск

поражения электрическим током

увеличивается, если Ваше тело заземлено.

c. Не используйте электроинструмент под

дождём или во влажной среде. Попадание

воды в электроинструмент увеличивает риск

поражения электрическим током.

d. Бережно обращайтесь с электрическим

кабелем. Ни в коем случае не используйте

кабель для переноски электроинструмента

или для вытягивания его вилки из

штепсельной розетки. Не подвергайте

электрический кабель воздействию

высоких температур и смазочных веществ;

держите его в стороне от острых кромок и

движущихся частей электроинструмента.

Повреждённый или запутанный кабель

увеличивает риск поражения электрическим

током.

e. При работе с электроинструментом на

открытом воздухе используйте

удлинительный кабель, предназначенный

для наружных работ. Использование кабеля,

пригодного для работы на открытом воздухе,

снижает риск поражения электрическим током.

f. При необходимости работы с

электроинструментом во влажной среде

используйте источник питания,

оборудованный устройством защитного

отключения (УЗО). Использование УЗО

снижает риск поражения электрическим током.

3. Личная безопасность

a. При работе с электроинструментами будьте

внимательны, следите за тем, что Вы

делаете, и руководствуйтесь здравым

смыслом. Не используйте

электроинструмент, если Вы устали, а также

находясь под действием алкоголя или

понижающих реакцию лекарственных

препаратов и других средств. Малейшая

неосторожность при работе с

электроинструментами может привести к

серьёзной травме.

b. При работе используйте средства

индивидуальной защиты. Всегда надевайте

защитные очки. Своевременное

использование защитного снаряжения, а

именно: пылезащитной маски, ботинок на

нескользящей подошве, защитного шлема или

противошумовых наушников, значительно

снизит риск получения травмы.

12

Page 13

(Перевод с оригинала инструкции)

РУССКИЙ

c. Не допускайте непреднамеренного

запуска. Перед тем, как подключить

электроинструмент к сети и/или

аккумулятору, поднять или перенести его,

убедитесь, что выключатель находится в

положении «выключено». Не переносите

электроинструмент с нажатым курковым

выключателем и не подключайте к сетевой

розетке электроинструмент, выключатель

которого установлен в положение «включено»,

это может привести к несчастному случаю.

d. Перед включением электроинструмента

снимите с него все регулировочные или

гаечные ключи. Регулировочный или

гаечный ключ, оставленный закреплённым на

вращающейся части электроинструмента,

может стать причиной получения тяжёлой

травмы.

e. Работайте в устойчивой позе. Всегда

твёрдо стойте на ногах, сохраняя

равновесие. Это позволит Вам не потерять

контроль при работе электроинструментом в

непредвиденной ситуации.

f. Одевайтесь соответствующим образом. Во

время работы не надевайте свободную

одежду или украшения. Следите за тем,

чтобы Ваши волосы, одежда или перчатки

находились в постоянном отдалении от

движущихся частей инструмента.

Свободная одежда, украшения или длинные

волосы могут попасть в движущиеся части

инструмента.

g. Если электроинструмент снабжён

устройством сбора и удаления пыли,

убедитесь, что данное устройство

подключено и используется надлежащим

образом. Использование устройства

пылеудаления значительно снижает риск

возникновения несчастного случая,

связанного с запылённостью рабочего

пространства.

4. Использование электроинструментов и

технический уход

a. Не перегружайте электроинструмент.

Используйте Ваш инструмент по

назначению. Электроинструмент работает

надёжно и безопасно только при соблюдении

параметров, указанных в его технических

характеристиках.

b. Не используйте электроинструмент, если

его выключатель не устанавливается в

положение включения или выключения.

Электроинструмент с неисправным

выключателем представляет опасность и

подлежит ремонту.

c. Отключайте электроинструмент от сетевой

розетки и/или извлекайте аккумулятор

перед регулировкой, заменой

принадлежностей или при хранении

электроинструмента. Такие меры

предосторожности снижают риск случайного

включения электроинструмента.

d. Храните неиспользуемые

электроинструменты в недоступном для

детей месте и не позволяйте лицам, не

знакомым с электроинструментом или

данными инструкциями, работать с

электроинструментом. Электроинструменты

представляют опасность в руках неопытных

пользователей.

e. Регулярно проверяйте исправность

электроинструмента. Проверяйте точность

совмещения и легкость перемещения

подвижных частей, целостность деталей и

любых других элементов

электроинструмента, воздействующих на

его работу. Не используйте неисправный

электроинструмент, пока он не будет

полностью отремонтирован. Большинство

несчастных случаев являются следствием

недостаточного технического ухода за

электроинструментом.

f. Следите за остротой заточки и чистотой

режущих принадлежностей.

Принадлежности с острыми кромками

позволяют избежать заклинивания и делают

работу менее утомительной.

g. Используйте электроинструмент,

аксессуары и насадки в соответствии с

данным Руководством и с учетом рабочих

условий и характера будущей работы.

Использование электроинструмента не по

назначению может создать опасную ситуацию.

5. Техническое обслуживание

a. Ремонт Вашего электроинструмента должен

производиться только

квалифицированными специалистами с

использованием идентичных запасных

частей. Это обеспечит безопасность Вашего

электроинструмента в дальнейшей

эксплуатации.

Дополнительные меры безопасности

при работе с электроинструментами

Внимание! Дополнительные меры без- опасности

при работе пилами

a. Держите руки на расстоянии от области

распила и диска. Держите вторую руку на

дополнительной рукоятке или на корпусе

двигателя. Если пила удержива- ется обеими

руками, исключается вероят- ность их пореза

диском.

b. Не держите руки под обрабатываемой

деталью. Защитный кожух не защищает руки

от касания диска под обрабатывае- мой

деталью.

13

Page 14

РУССКИЙ

(Перевод с оригинала инструкции)

c. Отрегулируйте глубину пропила в соот-

ветствии с толщиной обрабатываемой

детали. Зуб диска не должен выступать с

нижней стороны обрабатываемой детали

полностью.

d. Никогда не удерживайте разрезаемую

деталь в руках или прижав ее к ноге.

Зафиксируйте обрабатываемую деталь на

неподвижной опоре. Необходимо

надлежащим образом закрепить обрабатываемую деталь для снижения риска

получения травмы, заклинивания диска или

потери управления.

e. Держите электроинструмент за

изолированные ручки при выполнении

операций, во время которых режущий

инструмент может задеть скрытую

проводку или собственный кабель. Контакт

с находящимся под напряжением проводом

делает непокрытые изоляцией металлические

части электроинструмента также «живыми»,

что создает опасность поражения

электрическим током.

f. Во время продольной распиловки всегда

используйте направляющую планку или

прямой направитель детали. Это повышает

точность распила и снижает вероятность

заклинивания диска.

g. Всегда используйте диски с посадочными

отверстиями соответствующего размера и

формы (ромбовидные или круглые). Диски,

не совпадающие с крепежными

приспособлениями пилы, будут вращаться

эксцентрически, что приведет к потере

контроля.

h. Ни в коем случае не используйте

поврежденные или несоответствующие

зажимные кольца или болты для дисков.

Зажимные кольца и болты для дисков были

разработаны специально для данной пилы с

целью обеспечения оптимальной

производительности и безопасности во время

работы.

Дополнительные меры безопасности для всех

типов пил

Причины обратного удара и действия оператора

по его предупреждению:

• Обратный удар является внезапной реакцией

на защемление, зажимание или смещение

пильного диска, что приводит к

неконтролируемому подъему пилы из

обрабатываемой детали в направлении

оператора.

• При зажатии или защемлении диска в

пропиле, он останавливается, и реакция

электродвигателя приводит к внезапному

смещению инструмента в направлении или в

сторону от оператора.

• Если диск перекашивается или смещается в

пропиле, зубья на его задней кромке могут

войти в верхнюю часть деревянной детали, что

приведет к выходу диска из пропила и его

скачку в направлении опе- ратора.

Обратный удар является результатом

использования пилы не по назначению и/или

неправильных действий оператора и условий

работы, и его можно избежать, соблюдая

следующие меры безопасности:

a. Крепко держите пилу обеими руками и

следите за положением рук, чтобы

эффективно противостоять воздействию

обратного удара. Стойте сбоку от пилы, но

не на одной линии с ней. Обратный удар

может привести к скачку пилы назад, но

оператор может гасить его энергию при

условии соблюдения надле- жащих мер.

b. В случае заклинивания диска или в случае

прекращения процесса резки по любой

причине, отпустите курковый выключатель

и удерживайте пилу не- подвижно в

обрабатываемой детали до полной

остановки диска. Никогда не пытайтесь

извлечь пилу из обрабатываемой детали

или вытянуть ее назад, пока вращается диск

- это может привести к обратному удару.

Выясните причину заклинивания диска и

примите надлежащие меры по ее устранению.

c. При перезапуске пилы в детали отцентруйте

пильный диск в пропиле и убедитесь в том,

что зубья пилы не касаются материала. Если

пильный диск заклинен, то при повторном

запуске пилы он может подскочить вверх из

детали или ударить назад.

d. Для сведения к минимуму риска

заклинивания диска и возникновения

обратного удара, поддерживайте заготовки

большого размера. Большие заготовки

провисают под собственным весом. Разместите

опоры под заготовку с обеих сторон, в

непосредственной близости от линии распила

и краев заготовки.

e. Не используйте затупившиеся или

поврежденные диски. Тупые или

неправильно разведенные диски образуют

узкий пропил, что приводит к повышенному

трению, заклиниванию диска и образованию

обратного удара.

f. Рычаги настройки глубины пропила и угла

резки на конус перед началом работы

должны быть затянуты и зафиксированы. В

случае сбоя настроек диска, во время работы

может произойти заклинивание и обратный

удар.

g. Соблюдайте повышенную осторожность

при выполнении врезного пиления стен или

в других слепых зонах. Выдвигаемый диск

может встречаться с предметами, которые

могут привести к образованию обратного

удара.

14

Page 15

(Перевод с оригинала инструкции)

РУССКИЙ

Инструкции по технике безопасности при

работе дисковыми пилами с внешним и

внутренним маятниковыми защитными

кожухами и буксирным защитным кожухом

a. Перед каждым использованием проверяй-

те, правильно ли закрыт нижний защитный

кожух. Не используйте пилу, если нижний

защитный кожух не перемещается

свободно и не закрывает диск постоянно.

Никогда не зажимайте и не подвязывайте

нижний защитный кожух в открытом

положении. При случайном падении пилы

нижний защитный кожух может погнуться.

Поднимите нижний защитный кожух при

помощи втягива- ющей рукоятки и убедитесь в

том, что кожух перемещается свободно и не

прикасается к диску или другим деталям при

любых углах и глубине пиления.

b. Проверьте функционирование и состояние

возвратной пружины нижнего защитного

кожуха. Если защитный кожух и пружина

не работают нормально, перед

использованием необходимо выполнить

их текущий ремонт. Нижний защитный кожух

может перемещаться замедленно из-за

повреждения деталей, отложения клейких

веществ или скопле- ния мусора.

c. Нижний защитный кожух следует втя-

гивать вручную только при выполне- нии

специальных разрезов, например, врезных

и комбинированных распилов.

Поднимайте нижний защитный кожух при

помощи втягивающей рукоятки, а когда

диск прикоснется к материалу нижний

кожух следует опустить. Для всех других

типов пиления нижний защитный кожух

должен работать в автоматическом режиме.

d. Всегда следите за тем, чтобы нижний

защитный кожух закрывал диск, прежде

чем класть пилу на верстак или на пол.

Незащищенный диск во время выбега

приведет к смещению пилы назад и

разрезанию всех находящихся на траектории

его движения предметов. Помните о том, что

после отпускания выключателя требуется

некоторое время для полной остановки диска.

Остаточные риски

Следующие риски являются характерными при

использовании пил:

- Травмы в результате касания вращающихся

частей.

Несмотря на соблюдение соответствующих

инструкций по технике безопасности и

использование предохранительных устройств,

некоторые остаточные риски невозможно

полностью исключить. К ним относятся:

- Ухудшение слуха.

- Риск несчастных случаев, вызванных

незакрытыми частями вращающегося

режущего диска.

- Риск получения травмы при смене диска.

- Риск защемления пальцев при снятии защитных кожухов.

- Ущерб здоровью в результате вдыхания пыли

от распила древесины, в особенно- сти, дуба,

бука и ДВП.

Пильные диски

• Не используйте диски меньшего или большего

диаметра, чем рекомендовано. См. скорость

вращения дисков в технических

характеристиках. Используйте только

указанные в данном руководстве диски,

соответствующие стандарту EN 847-1.

• Внимание! Никогда не используйте

абразивные диски.

Безопасность посторонних лиц

• Использование инструмента физически или

умственно неполноценными людьми, а также

детьми и неопытными лицами допускается

только под контролем ответственного за их

безопасность лица.

• Не позволяйте детям играть с электроин-

струментом.

Вибрация

Значения уровня вибрации, указанные в

технических характеристиках инструмента и

декларации соответствия, были измерены в

соответствии со стандартным методом

определения вибрационного воздействия

согласно EN60745 и могут использоваться при

сравнении характеристик различных

инструментов. Приведенные значения уровня

вибрации могут также использоваться для

предварительной оценки величины

вибрационного воздействия.

Внимание! Значения вибрационного воздействия

при работе с электроинструментом зависят от

вида работ, выполняемых данным инструментом, и

могут отличаться от заявленных значений.

Уровень вибрации может превышать заявленное

значение.

15

Page 16

РУССКИЙ

(Перевод с оригинала инструкции)

При оценке степени вибрационного воздействия

для определения необходимых защитных мер

(2002/44/EC) для людей, использующих в

процессе работы электроинструменты,

необходимо принимать во внимание

действительные условия использования

электроинструмента, учитывая все составляющие

рабочего цикла, в том числе время, когда

инструмент находится в выключенном состоянии,

и время, когда он работает без нагрузки, а также

время его запуска и отключения.

Маркировка инструмента

Наравне с кодом даты на инструменте могут

находиться следующие знаки:

Прочтите

руководство

по эксплуатации.

Используйте

защитные очки.

Используйте

средства защиты

органов слуха.

V ........ Вольт

A ........ Ампер

Hz .......

Герц

W ........ Ватт

min ..... минут

..... Переменный

ток

..... Постоянный

ток

n0 ....... Скорость без

нагрузки

...... Конс трукция

.... К лемма

.... Симво л

.../min.. Кол-во оборотов

Класса II

заземления

опасности

или шагов в

минуту

Местоположение кода даты

Код даты, который также включает в себя год

изготовления, отштампован на поверхности

корпуса инструмента.

Пример:

2017 XX JN

Год изготовления

Электробезопасность

Данный электроинструмент защищен

двойной изоляцией, исключающей потребность в заземляющем проводе.

Следите за напряжением электрической

сети, оно должно соответствовать

величине, обозначенной на

информационной табличке

электроинструмента.

• Во избежание несчастного случая,

заменаповрежденного кабеля питания должна

производиться только на заводе-изготовителе

или в авторизованном сервисном центре

BLACK+DECKER.

Составные части

1. Клавиша пускового выключателя

2. Кнопка защиты от непреднамеренного пуска

3. Основная рукоятка

4. Вспомогательная рукоятка

5. Кнопка блокировки шпинделя

6. Подошва

7. Пильный диск

8. Защитный кожух пильного диска

9. Рычаг защитного кожуха

10. Выпускное отверстие пылеотвода

Сборка

Внимание! Перед выполнением любой из

последующих операций убедитесь, что

электроинструмент выключен и отсоединен от

электросети, а пильный диск остановлен.

Снятие и установка пильного диска

(Рис. А)

Снятие

• Нажимайте на кнопку блокировки шпинделя (5)

и одновременно поворачивайте пильный диск,

пока не включится блокировка шпинделя.

• Используя ключ (12), входящий в комплект

поставки, отвинтите и удалите стопорный винт

(11), поворачивая его против часовой стрелки.

• Удалите внешнюю шайбу (13).

• Снимите пильный диск (7).

Установка

• Установите пильный диск на внутренний

фланец (14), убедившись, что стрелки на диске

и инструменте указывают в одном

направлении.

• Установите внешнюю шайбу (13) на шпиндель,

чтобы выпуклая сторона была направлена в

сторону от диска.

• Вставьте в отверстие стопорный винт (11)

диска.

• Нажмите и удерживайте кнопку блокировки

шпинделя (5).

• Используя ключ (12), входящий в комплект

поставки, крепко затяните стопорный винт

диска, поворачивая его по часовой стрелке.

• Отрегулируйте расклинивающий нож, как

описано ниже.

Установка и снятие параллельной

направляющей (Рис. В)

Параллельная направляющая предназначена для

выполнения прямого реза параллельно краю

заготовки.

16

Page 17

(Перевод с оригинала инструкции)

РУССКИЙ

Установка

• Ослабьте зажимную рукоятку (16).

• Вставьте направляющую (17) через отверстия

(18).

• Передвиньте параллельную направляющую в

необходимое положение.

• Затяните зажимную рукоятку.

Снятие

• Ослабьте зажимную рукоятку.

• Снимите параллельную направляющую с

инструмента.

Эксплуатация

Внимание! Не форсируйте рабочий процесс.

Избегайте перегрузки электроинструмента.

Примечание: Данный инструмент может

управляться пользователями как с правой, так и с

левой рабочей рукой.

Регулировка угла реза (Рис. С)

• По умолчанию угол между пильным диском и

подошвой составляет 90°.

• Проверьте по угольнику, равен ли угол между

пильным диском и подошвой 90°. Если нет,

отрегулируйте угол следующим образом:

• Ослабьте зажимную рукоятку (19) для

разблокировки подошвы.

• Открутите стопорную гайку (20) на

регулировочном винте (21).

• Вкручивайте/выкручивайте регулировочный

винт для установки угла 90°.

• Затяните стопорную гайку.

• Затяните зажимную рукоятку, фиксируя

подошву на месте.

Настройка глубины пропила (Рис. D)

Глубина пропила устанавливается в соответствии

с толщиной заготовки. Глубина пропила должна

превышать толщину заготовки примерно на 2 мм.

• Поднимите рычаг настройки (22) для

разблокировки подошвы.

• Установите подошву (6) в желаемое

положение.

Глубину пропила можно проверить по шкале (23).

• Затяните зажимную рукоятку, фиксируя

подошву на месте.

Регулировка угла наклона подошвы

(Рис. Е)

На данном инструменте может устанавливаться

угол наклона от 0° до 45°.

• Ослабьте зажимную рукоятку (19) для

разблокировки подошвы.

• Установите подошву (8) в желаемое положение.

Угол наклона можно проверить по шкале (24).

• Затяните зажимную рукоятку, фиксируя

подошву на месте.

Включение и выключение

• Для включения инструмента, переведите

кнопку защиты от непреднамеренного пуска (2)

в положение разблокировки и нажмите на

клавишу пускового выключателя (1).

• Чтобы выключить инструмент, отпустите

клавишу пускового выключателя

Пиление

Всегда удерживайте инструмент обеими руками.

• Перед выполнением реза дайте пильному

полотну поработать без нагрузки в течение

нескольких секунд.

• При распиле прилагайте к инструменту только

лёгкое усилие.

• В ходе работы прижимайте подошву к

поверхности заготовки.

Рекомендации по оптимальному

использованию

• Поскольку невозможно полностью избежать

откалывания мелких частиц вдоль линии реза,

выбирайте для работы ту сторону заготовки,

где это допустимо.

• Если необходимо свести количество сколов к

минимуму (например, при распиле ламината),

закрепите поверх заготовки лист фанеры

Использование направляющей

пластины (Рис. F)

Инструмент оснащен направляющей пластиной

для выполнения точных прямых резов.

• Совместите левую кромку направляющей

пластины (26) с линией реза (25).

• Выполняйте рез, удерживая кромку

направляющей по линии реза.

• В ходе работы прижимайте подошву к

поверхности заготовки.

17

Page 18

РУССКИЙ

(Перевод с оригинала инструкции)

Пылеудаление (Рис. G)

Для подключения к инструменту пылесоса или

пылеудаляющего устройства необходим

переходник.

• Вставьте переходник (27) в выпускное

отверстие пылеотвода (10).

• Подключите шланг пылесоса (28) к

переходнику.

Техническое обслуживание

Ваш электрический/аккумуляторный инструмент

BLACK+DECKER рассчитан на работу в течение

продолжительного времени при минимальном

техническом обслуживании. Срок службы и

надёжность инструмента увеличивается при

правильном уходе и регулярной чистке.

Внимание! Перед проведением технического

обслуживания электрического/аккумуляторного

инструмента:

• Выключите инструмент и отключите его от

источника питания.

• Или выключите инструмент и извлеките из

него аккумулятор, если инструмент оснащён

съёмным аккумулятором.

• В случае наличия встроенного аккумулятора,

полностью разгрузите аккумулятор и

выключите инструмент.

• Перед чисткой зарядного устройства

отключите его от источника питания. Ваше

зарядное устройство не требует никакого

дополнительного технического обслуживания,

кроме регулярной чистки.

• Регулярно очищайте вентиляционные

отверстия инструмента/зарядного устройства

мягкой щёткой или сухой тканью.

• Регулярно очищайте корпус двигателя

влажной тканью. Не используйте абразивные

чистящие средства, а также чистящие средства

на основе растворителей.

• Регулярно раскрывайте патрон (при наличии)

и вытряхивайте из него всю накопившуюся

пыль.

Защита окружающей среды

Раздельный сбор отходов. Запрещается

утилизировать этот продукт вместе с

обычными бытовыми отходами.

Если вы решите, что ваше изделие BLACK+DECKER

необходимо заменить, или если вы не будете его

больше использовать, не утилизируйте его вместе

с бытовыми отходами. Этот продукт подлежит

раздельному сбору отходов.

Раздельный сбор использованных

продуктов и упаковочных материалов

позволяет производить их вторичную

переработку с дальнейшим повторным

использованием. Повторное использование

материалов, прошедших вторичную переработку,

снижает загрязнение окружающей среды и

уменьшает потребность в сырьевых материалах.

Нормативные акты местных органов власти могут

предусматривать сбор использованных

электрических изделий отдельно от бытовых

отходов, в муниципальных пунктах сбора отходов

или в магазине при покупке нового изделия.

BLACK+DECKER предоставляет возможность для

сбора и повторной переработки продуктов

BLACK+DECKER после окончания срока их службы.

Чтобы воспользоваться преимуществом этого

сервиса, пожалуйста, отправьте ваш продукт

любому уполномоченному представителю по

ремонту, который собирает такие изделия от

нашего имени.

Вы можете узнать адрес нашего ближайшего

уполномоченного представителя по ремонту,

позвонив в региональное представительство

BLACK+DECKER, указанное в этой инструкции.

Кроме того, список уполномоченных

представителей по ремонту BLACK+DECKER,

подробная информация о послепродажном

обслуживании и контактные данные можно найти

на сайте www.2helpU.com.

18

Page 19

(Перевод с оригинала инструкции)

РУССКИЙ

Технические характеристики

CS1550

Входное В

напряжение

Потребляемая мощность Вт 1500

Число оборотов без

нагрузки об/мин. 5500

Макс. глубина пропила мм 66

Диаметр пильного диска мм 190

Диаметр посадочного

отверстия мм 16

Ширина шага зубьев мм 1,8

Вес кг 3,9

(4,31 вместе с

диском)

Уровень звукового давления в

соответствии с EN 60745:

Звуковое давление (LpA) 89,0 дБ(А),

погрешность (K) 3 дБ(А)

Акустическая мощность (LwA) 100 дБ(А),

погрешность (K) 3 дБ(А)

Сумма величин вибрации (сумма векторов по трём осям), измеренных в соответствии со стандартом EN 60745:

Значения вибрационного воздействия

(a

) 2,6м/с,

h,w

Погрешность (K) 1,5м/с (пиление древесины)

перем. тока

220-240

Декларация соответствия ЕС

ДИРЕКТИВА ПО МЕХАНИЧЕСКОМУ

ОБОРУДОВАНИЮ

CS1550-дисковая пила

BLACK+DECKER заявляет, что продукты,

обозначенные в разделе «Технические

характеристики», полностью соответствуют

стандартам: 2006/42/EC, EN60745-1:2010,

EN60745-2-5:2010

Данные продукты также соответствуют

Директивам 2014/30/EU и 2011/65/EU.

За дополнительной информацией обращайтесь в

BLACK+DECKER по указанному ниже адресу или

по адресу, указанному на последней странице

руководства.

Нижеподписавшееся лицо полностью отвечает за

соответствие технических данных и делает это

заявление от имени фирмы BLACK+DECKER.

R. Laverick

Руководитель отдела технических разработок

BLACK+DECKER Europe, 210 Bath Road,

Slough,

Berkshire, SL1 3YD

United Kingdom

01.2017

19

Page 20

РУССКИЙ

(Перевод с оригинала инструкции)

Гарантийные условия

Уважаемый покупатель!

1. Поздравляем Вас с покупкой высококачественного

изделия Black + Decker и выражаем признательность за

Ваш выбор.

2. При покупке изделия требуйте проверки его комплектности

и исправности в Вашем присутствии, инструкцию по

эксплуатации и заполненный гарантийный талон на

русском языке.

В гарантийном талоне должны быть внесены: модель,

дата продажи, серийный номер, дата производства

инструмента; название, печать и подпись торговой

организации. При отсутствии у Вас правильно

заполненного гарантийного талона мы будем вынуждены

отклонить Ваши претензии по качеству данного изделия.

3. Во избежание недоразумений убедительно просим Вас

перед началом работы с изделием внимательно

ознакомиться с инструкцией по его эксплуатации.

Правовой основой настоящих гарантийных условий

является действующее Законодательство.

Гарантийный срок на данное изделие составляет 24

месяца и исчисляется со дня продажи. В случае

устранения недостатков изделия, гарантийный срок

продлевается на период его нахождения в ремонте.

Срок службы изделия - 5 лет со дня продажи.

4. В случае возникновения каких-либо проблем в процессе

эксплуатации изделия рекомендуем Вам обращаться

только в уполномоченные сервисные центры Black +

Decker, адреса и телефоны которых Вы сможете найти в

гарантийном талоне, на сайте www.2helpU.com или узнать

в магазине. Наши сервисные станции - это не только

квалифицированный ремонт, но и широкий ассортимент

запчастей и принадлежностей.

5. Производитель рекомендует проводить периодическую

проверку и техническое обслуживание изделия в

уполномоченных сервисных центрах.

Изготовитель

Блэк энд Деккер Холдингс ГмбХ

Германия, 65510, Идштайн,

ул. Блэк энд Деккер, 40

6. Наши гарантийные обязательства распространяются

только на неисправности, выявленные в течение

гарантийного срока и вызванные дефектами производства

и \ или материалов.

7. Гарантийные обязательства не распространяются на

неисправности изделия, возникшие в результате:

7.1. Несоблюдения пользователем предписаний инструкции по

эксплуатации изделия, применения изделия не по

назначению, неправильном хранении, использования

принадлежностей, расходных материалов и запчастей, не

предусмотренных производителем.

7.2. Механического повреждения (сколы, трещины и

разрушения) внутренних и внешних деталей изделия,

основных и вспомогательных рукояток, сетевого

электрического кабеля, вызванного внешним ударным или

любым иным воздействием.

7.3. Попадания в вентиляционные отверстия и проникновение

внутрь изделия посторонних предметов, материалов или

веществ, не являющихся отходами, сопровождающими

применение изделия по назначению, такими как: стружка,

опилки, песок, и пр.

7.4. Воздействие на изделие неблагоприятных атмосферных и

иных внешних факторов, таких как дождь, снег,

повышенная влажность, нагрев, агрессивные среды,

несоответствие параметров питающей электросети,

указанным на инструменте.

7.5. Стихийного бедствия. Повреждение или утрата изделия,

связанное с непредвиденными бедствиями, стихийными

явлениями, в том числе вследствие действия

непреодолимой силы (пожар, молния, потоп и другие

природные явления), а так же вследствие перепадов

напряжения в электросети и другими причинами, которые

находятся вне контроля производителя.

8. Гарантийные условия не распространяются:

8.1. На инструменты, подвергавшиеся вскрытию, ремонту или

модификации вне уполномоченной сервисного центра.

8.2. На детали и узлы, имеющие следы естественного износа,

такие как: приводные ремни и колеса, угольные щетки,

смазка, подшипники, зубчатое зацепление редукторов,

резиновые уплотнения, сальники, направляющие ролики,

муфты, выключатели, бойки, толкатели, стволы и т.п.

8.3. на сменные части: патроны, цанги, зажимные гайки и

фланцы, фильтры, аккумуляторные батареи, ножи,

шлифовальные подошвы, цепи, звездочки, пильные шины,

защитные кожухи, пилки, абразивы, пильные и

абразивные диски, фрезы, сверла, буры и т.п.

8.4. На неисправности, возникшие в результате перегрузки

инструмента (как механической, так и электрической),

повлекшей выход из строя одновременно двух и более

деталей и узлов, таких как: ротора и статора, обеих

обмоток статора, ведомой и ведущей шестерни редуктора

и других узлов и деталей. К безусловным признакам

перегрузки изделия относятся, помимо прочих: появление

цветов побежалости, деформация или оплавление

деталей и узлов изделия, потемнение или обугливание

изоляции проводов электродвигателя под воздействием

высокой температуры.

20

Page 21

(Перевод с оригинала инструкции)

Приложение к руководству по эксплуатации электроинструмента

Пилы дисковые

CS1250*, CS1550*, FME301*, CS1004*, KS1300* - Сделано в Китае.

Где символ “*” - различные варианты исполнения изделия.

РУССКИЙ

Сертификат №: RU C-DE.АЯ46.B.77535

Действителен до: 24 ноября 2019 г.

Выдан: Орган по сертификации "РОСТЕСТ- Москва“ ЗАО

“Региональный орган по сертификации и тестированию” ,

Адрес: 119049,г. Москва, улица Житная, д. 14, стр. 1;

117418,Москва, Нахимовский просп., 31 (фактический),

Телефон: (499) 1292311, (495) 6682893;, Факс: (495) 6682893,

E-mail: office@rostest.ru,

Изготовитель: Блэк энд Деккер Холдингс ГмбХ

Германия, 65510, Идштайн,

ул. Блэк энд Деккер, 40a

Хранение.

Необходимо хранить в сухом месте, вдали от источников

повышенных температур и воздействия солнечных лучей. При

хранении необходимо избегать резкого перепада температур.

Хранение без упаковки не допускается

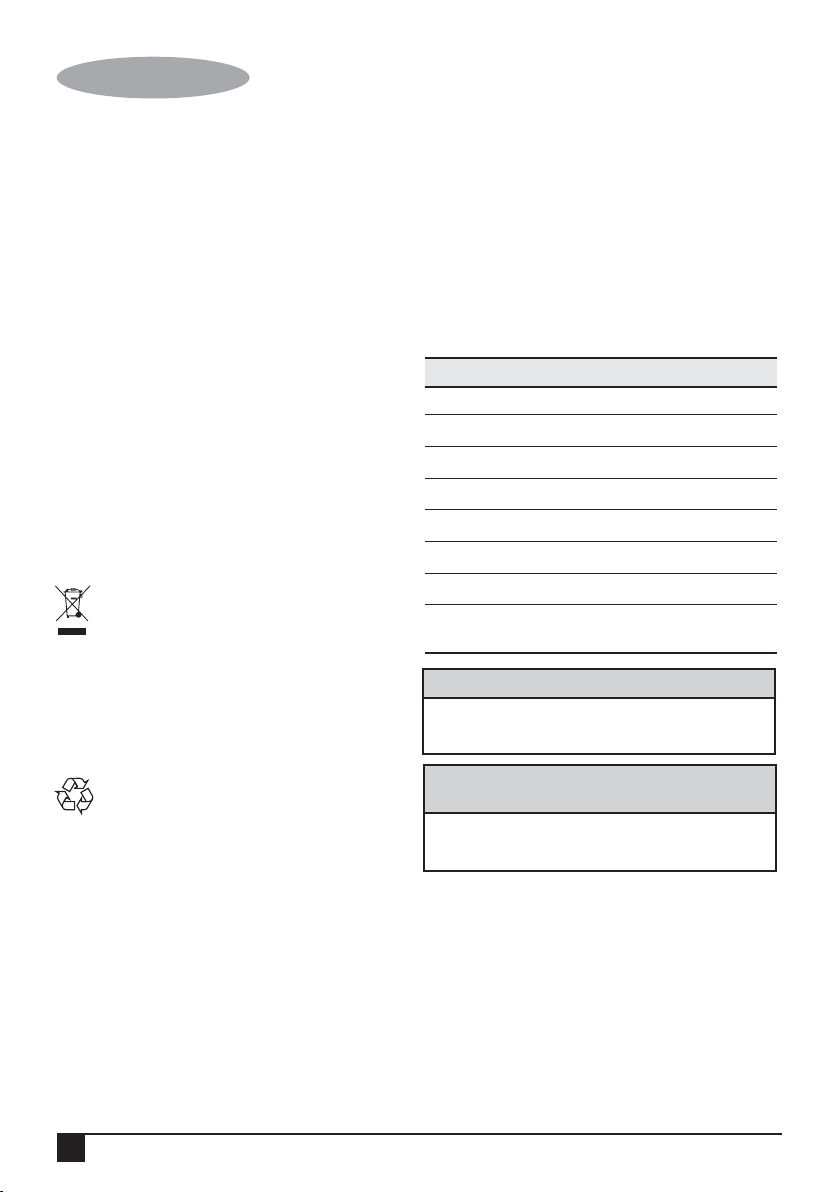

Срок службы.

Срок службы изделия составляет 5 лет. Не рекомендуется к

эксплуатации по истечении 5 лет хранения с даты

изготовления без предварительной проверки.

Дата изготовления (код даты) указана на корпусе инструмента.

Код даты, который также включает год изготовления,

отштампован на поверхности корпуса изделия.

Пример:

2014 46 XX, где 2014 –год изготовления, 46-неделя

изготовления.

Определить месяц изготовления по указанной неделе

изготовления можно согласно приведенной ниже таблице.

Месяц Январь Февраль Март Апрель Май Июнь Июль Август Сентябрь Октябрь Ноябрь Декабрь Год производства

01 05 09 14 18 22 27 31 36 40 44 49

02 06 10 15 19 23 28 32 37 41 45 50

03 07 11 16 20 24 29 33 38 42 46 51 2014

04 08 12 17 21 25 30 34 39 43 47 52

Неделя

05 09 13 18 22 26 31 35 40 44 48

14 27

01 05 09 14 18 23 27 31 36 40 44 49

02 06 10 15 19 24 28 32 37 41 45 50

03 07 11 16 20 25 29 33 38 42 46 51 2015

04 08 12 17 21 26 30 34 39 43 47 52

Неделя

09 13 18 22 27 31 35 40 44 48 53

14 36 49

01 05 09 13 17 22 26 31 35 39 44 48

02 06 10 14 18 23 27 32 36 40 45 49

03 07 11 15 19 24 28 33 37 41 46 50 2016

04 08 12 16 20 25 29 34 38 42 47 51

Неделя

09 13 17 21 26 30 35 39 43 48 52

22 44

01 05 09 13 18 22 26 31 35 39 44 48

02 06 10 14 19 23 27 32 36 40 45 49

03 07 11 15 20 24 28 33 37 41 46 50 2017

04 08 12 16 21 25 29 34 38 42 47 51

Неделя

05 09 13 17 22 26 30 35 39 43 48 52

31 44

Уполномоченное изготовителем юр.лицо:

ООО "Стэнли Блэк энд Деккер",117485, город Москва, улица

Обручева, дом 30/1, строение 2

Телефон: + 7 (495) 258-3981, факс: + 7 (495) 258-3984, E-mail:

inbox@dewalt.com

Сведения о импортере указаны в сопроводительной

документации и/или на упаковке

Транспортировка.

Категорически не допускается падение и любые механические

воздействия на упаковку при транспортировке.

При разгрузке/погрузке не допускается использование любого

вида техники, работающей по принципу зажима упаковки.

Перечень критических отказов, возможные ошибочные

действия персонала.

Не допускается эксплуатация изделия:

-При появлении дыма из корпуса изделия

-При поврежденном и/ или оголенном сетевом кабеле

-при повреждении корпуса изделия, защитного кожуха, рукоятки

-при попадании жидкости в корпус

-при возникновении сильной вибрации

-при возникновении сильного искрения внутри корпуса

Критерии предельных состояний

-При поврежденном и/или оголенном сетевом кабеле

-при повреждении корпуса изделия

21

Page 22

УКРАЇНСЬКА

(Переклад оригінальних інструкцій)

Призначення

Ваша циркулярна пилка виробництва

BLACK + DECKER™ CS1550 призначена для пиляння

дерева та лісоматеріалів. Цей інструмент

призначений тільки для побутового використання

Вказівки з техніки безпеки

Загальні попередження з техніки безпеки

Увага! Уважно прочитайте всі

попереджувальні написи та вказівки з

техніки безпеки. Порушення наведених

нижче попереджувальних написів і вказівок може

призвести до ураження електричним струмом,

пожежі та (або) серйозних травм

Збережіть усі застереження та вказівки з

техніки безпеки для подальшого

використання. Термін «електричний інструмент»,

що використовується в усіх наведених нижче

застереженнях та вказівках з техніки безпеки,

стосується цього електричного інструмента з

живленням від мережі (через шнур живлення) чи

від акумуляторної батареї (без шнура живлення).

1. Безпека на робочому місці

a. Робоче місце має бути прибране й добре

освітлене. Безлад або погане освітлення на

робочому місці може призвести до нещасного

випадку.

b. Забороняється використання електричного

інструмента у вибухонебезпечному

середовищі, наприклад, в умовах наявності

легкозаймистих рідин, газів або пилу. Іскри,

що виникають під час роботи електричного

інструмента, можуть призвести до займання

пилу чи випарів.

c. Дітям та стороннім особам забороняється

перебувати в місцях виконання робіт із

використанням електричного інструмента.

Відволікання може призвести до втрати

контролю за роботою інструмента.

2. Електрична безпека

a. Вилка шнура живлення інструмента

повинна відповідати мережевій розетці.

Забороняється вносити будь-які зміни у

вилку шнура живлення. Не використовуйте

жодних вилок-перехідників із заземленими

(зануленими) електроінструментами.

Відсутність змін у вилках шнурів живлення та

відповідність електричних вилок і розеток

знижує ризик ураження електричним струмом.

b. Не торкайтеся поверхонь заземлених чи

занулених предметів, наприклад труб,

радіаторів, електроплит або

холодильників. Заземлення чи занулення тіла

22

підвищує ризик ураження електричним

струмом.

c. Забороняється піддавати електричні

інструменти впливу дощу чи підвищеної

вологості. При попаданні вологи всередину

електричного інструмента підвищується ризик

ураження електричним струмом.

d. Забороняється пошкоджувати шнур

живлення. У жодному разі не

використовуйте шнур живлення для

перенесення чи зміни положення

інструмента; не тягніть за шнур, виймаючи

вилку з розетки. Не прокладайте шнур

живлення поруч із гарячими предметами,

мастилом, гострими краями і рухомими

деталями. Пошкодження й заплутування

шнурів живлення підвищує ризик ураження

електричним струмом.

e. Під час роботи з електричним інструментом

за межами приміщень використовуйте

відповідний подовжувач. Використання

подовжувача, призначеного для роботи поза

приміщеннями, знижує ризик ураження

електричним струмом.

f. Якщо електричним інструментом необхідно

користуватись у вологому місці, слід

використовувати пристрій захисного

відключення (ПЗВ) електричної мережі.

Використання ПЗВ знижує ризик ураження

електричним струмом

3. Безпека персоналу

a. Під час роботи з електричним інструментом

необхідно бути обачним, слідкувати за

виконуваною роботою та керуватися

здоровим глуздом. Забороняється працювати

з електричним інструментом у стані втоми чи

під впливом наркотиків, алкоголю й лікарських

препаратів. Ослаблення уваги навіть на мить

може призвести до серйозної травми.

b. Використовуйте засоби індивідуального

захисту. Завжди надягайте засоби захисту

очей. Використання у відповідних умовах

засобів індивідуального захисту, наприклад

пилозахисної маски, протиковзного захисного

взуття, захисної каски або засобів захисту

органів слуху, завжди знижує ризик отримання

травми.

c. Не допускайте ненавмисного вмикання

інструмента. Перш ніж підключити джерело

живлення або акумулятор, піднімаючи або

несучи інструмент, перевірте, щоб його

вимикач знаходився у вимкненому

положенні. Якщо тримати палець на вимикачі

під час перенесення інструмента чи

підключення увімкненого інструмента до

мережі, це підвищує ризик нещасного випадку.

Page 23

(Переклад оригінальних інструкцій)

УКРАЇНСЬКА

d. Перш ніж увімкнути електричний

інструмент, обов’язково вийміть із нього

регулювальний чи гайковий ключ. Ключ,

залишений ключ на обертальній деталі

інструмента, може призвести до травмування.

e. Не намагайтеся дотягнутися до

важкодоступних місць. Завжди міцно

тримайтеся на ногах і зберігайте рівновагу

під час роботи. Це дозволяє краще

контролювати електричний інструмент у

непередбачуваних ситуаціях.

f. Одягайте відповідний одяг. Забороняється

одягати вільний одяг або прикраси.

Волосся, одяг та рукавиці повинні знаходитися

на максимальній відстані від рухомих деталей

інструмента. Вільний одяг, прикраси або довге

волосся можуть бути захоплені рухомими

деталями.

g. Якщо встановлені пристрої підключення

засобів пиловловлювання та

пилозбірників, необхідно перевіряти, щоб

вони були підключені та

використовувалися належним чином.

Використання засобів пиловловлювання

знижує рівень ризику, пов'язаного з наявністю

пилу в повітрі.

4. Використання та догляд за електричним

інструментом

a. Не застосовуйте надмірне зусилля до

електричного інструмента. Використовуйте

електричний інструмент тільки за

призначенням. Правильно підібраний

електроінструмент дозволить виконати

роботу краще і безпечніше при швидкості, для

якої він був розроблений.

b. Не використовуйте інструмент із

несправним вимикачем. Будь-який

електричний інструмент, роботою якого не

можна керувати за допомогою його вимикача,

являє собою небезпеку та підлягає

обов’язковому ремонту.

c. Перед виконанням регулювання

електричного інструмента, заміною його

приладдя та постановкою на зберігання

необхідно вийняти вилку його шнура

живлення з розетки та/або дістати з нього

акумулятор. Така превентивна міра безпеки

знижує ризик випадкового ввімкнення

інструмента.

d. Зберігайте електричний інструмент, який в

даний момент не використовується, в

недоступному для дітей місці та не

дозволяйте працювати з інструментом

особам, які не знайомі з ним або з цими

вказівками. Електричний інструмент є

небезпечним в руках ненавченої людини.

e. Підтримуйте інструмент в робочому стані.

Перевіряйте центровку та з’єднання

рухомих деталей, наявність пошкоджених

деталей та будь-які фактори, які можуть

негативно позначитися на роботі

електричного інструмента. У разі виявлення

пошкодження електричний інструмент

необхідно відремонтувати перед

використанням. Багато нещасних випадків

трапляється через неналежне технічне

обслуговування електричних інструментів.

f. Ріжучі інструменти повинні бути

нагостреними й чистими. Підтримуваний у

належному робочому стані ріжучий інструмент

з гострими лезами менше застряє, ним легше

керувати.

g. Використовуйте електричний інструмент,

приладдя, вставні різці тощо відповідно до

цієї інструкції, враховуючи умови

експлуатації та роботу, яку потрібно

виконати. Використання електричного

інструмента всупереч призначенню може

призвести до виникнення небезпечної ситуації.

5. Обслуговування

a. Обслуговувати електричний інструмент

повинен тільки кваліфікований ремонтний

персонал, і при цьому повинні

використовуватися тільки оригінальні

запасні деталі. Це забезпечить утримання

електричного інструмента у безпечному стані.

Додаткові застереження з техніки

безпеки роботи з електричним

інструментом

Увага! Додаткові застереження щодо безпечної

роботи пилок

a. Руки не повинні знаходитися поблизу

ділянки різання і пильного диску. Другою

рукою ви повинні тримати допоміжну ручку

або підтримувати корпус двигуна. Якщо

обидві руки будуть тримати пилку, диск не

зможе їх порізати.

b. Не доводьте пилку до нижнього краю

оброблюваної деталі. Захисний щиток не

може захистити вас від диска під робочою

деталлю.

c. Відрегулюйте глибину різу відповідно до

товщини робочої деталі. Під робочою

деталлю має бути видно менше повної довжини

зуба диска.

23

Page 24

УКРАЇНСЬКА

(Переклад оригінальних інструкцій)

d. Ніколи не тримайте розрізувану деталь в

руках або на ногах. Закріпіть робочу деталь

на стійкій основі. Щоб звести до мінімуму

небезпеку отримання пошкоджень, ризик

заклинювання диска і втрати контролю над

інструментом, важливо належним чином

підтримувати робочу деталь.

e. Під час виконання робіт, коли ріжуча

деталь електричного інструмента може

контактувати з прихованою

електропроводкою або зі своїм шнуром,

інструмент необхідно тримати за

діелектричну поверхню. При контакті

ріжучої деталі з проводом, що під напругою,

під напругу можуть потрапити металеві деталі

електричного інструмента, внаслідок чого

виникає небезпека ураження оператора

електричним струмом.

f. При поздовжньому пилянні завжди

використовуйте направляючу планку або

лінійку. Це підвищить точність різу та

зменшить ризик заклинювання диска.

g. Завжди використовуйте диски з точним

розміром і формою (ромб проти кола)

осьового отвору. Диски, що не відповідають

елементам кріплення пили, будуть обертатися

ексцентрично, що призведе до втрати

контролю над інструментом.

h. Ніколи не використовуйте пошкоджені або

невідповідні шайби чи болт для диска.

Шайби та болт для диска були спеціально

розроблені для вашої пилки для досягнення

оптимальних робочих характеристик і

безпечної роботи.

Додаткові вказівки з безпеки для всіх

пилок

Причини віддачі та запобігання її оператором:

• віддача є миттєвою реакцією на защемлення,

заїдання або розцентровку пильного диска,

коли пилка неконтрольовано піднімається

вгору та виходить з робочої деталі в напрямку

до оператора;

• коли диск защемлюється або щільно застрягає

в пропилі, він зупиняється і реакція двигуна

швидко відводить пилку назад до оператора;

• якщо диск викривляється або втрачає

співвісність у пропилі, зуби в задній кромці

диска можуть зайти у верхню поверхню

дерева, внаслідок чого диск піде з пропила і

відскочить на оператора.

Віддача є результатом неправильного

використання інструмента та/або неправильної