Page 1

INSTRUCTION MANUAL

CHAIN SAW

Thank you for choosing BLACK+DECKER!

PLEASE READ BEFORE RETURNING THIS PRODUCT FOR

ANY REASON.

If you have a question or experience a problem with your BLACK+DECKER

purchase, go to http://www.blackanddecker.com/instantanswers

If you can’t find the answer or do not have access to the Internet, call

1-800-544-6986 from 8 a.m. to 5 p.m. EST Mon. - Fri. to speak with an agent.

Please have the catalog number available when you call.

SAVE THIS MANUAL FOR FUTURE REFERENCE.

VEA EL ESPANOL EN LA CONTRAPORTADA.

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

CATALOG NUMBER

CS1518

To register your new product, visit

www.BlackandDecker.com/NewOwner

KEY INFORMATION YOU SHOULD KNOW:

DO NOT OVER-TENSION CHAIN. Refer to “ADJUSTING CHAIN TENSION”

for proper method of tensioning chain.

Retighten chain frequently during first two hours of use.

Page 2

2

GENERAL POWER TOOL

SAFETY RULES

WARNING: Read all safety

warnings and all instructions. Failure to

follow the warnings and instructions may result

in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND

INSTRUCTIONS FOR FUTURE

REFERENCE

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in

explosive atmospheres, such as in the

presence of flammable liquids, gases

or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders

away while operating a power tool.

Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the

outlet. Never modify the plug in

any way. Do not use any adapter

plugs with earthed (grounded)

power tools. Unmodified plugs and

matching outlets will reduce risk of

electric shock.

b) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain

or wet conditions. Water entering

a power tool will increase the risk of

electric shock.

d) Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp

edges or moving parts. Damaged or

entangled cords increase the risk of

electric shock.

e)

When operating a power tool

outdoors, use an extension cord

suitable for outdoor use. Use of a

cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a damp

location is unavoidable, use a

ground fault circuit interrupter

(GFCI) protected supply. Use of a

GFCI reduces the risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are

doing and use common sense

when operating a power tool. Do

not use a power tool while you

are tired or under the influence of

drugs, alcohol or medication. A

moment of inattention while operating

power tools may result in serious

personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, nonskid

safety shoes, hard hat, or hearing

protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting.

Ensure the switch is in the off

position before connecting to power

source and/ or battery pack, picking

up or carrying the tool. Carrying

power tools with your finger on the

switch or energizing power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper

footing and balance at all times. This

enables better control of the power tool

in unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewelry. Keep your hair,

clothing and gloves away from

moving parts. Loose clothes, jewelry or

long hair can be caught in moving parts.

g) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains

relates to protecting YOUR SAFETY and PREVENTING PROBLEMS. The symbols

below are used to help you recognize this information.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially haz ard ous situation which, if not avoided,

may result in minor or mod er ate injury.

NOTICE: Used without the safety alert symbol indicates potentially hazardous

situation which, if not avoided, may result in property damage.

Page 3

3

are connected and properly used.

Use of dust collection can reduce dustrelated hazards.

4) POWER TOOL USE AND CARE

a)

Do not force the power tool. Use

the correct power tool for your

application. The correct power tool will

do the job better and safer at the rate

for which it was designed.

b) Do not use the power tool if the

switch does not turn it on and

off. Any power tool that cannot

be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories,

or storing power tools. Such preventive

safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of

the reach of children and do not

allow persons unfamiliar with the

power tool or these instructions

to operate the power tool. Power

tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any

other condition that may affect the

power tool’s operation. If damaged,

have the power tool repaired before

use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

g) Use the power tool, accessories

and tool bits, etc. in accordance

with these instructions, taking into

account the working conditions

and the work to be performed.

Use of the power tool for operations

different from those intended could

result in a hazardous situation.

5) SERVICE

a)

Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power

tool is maintained.

READ ALL INSTRUCTIONS

CHAIN SAW SAFETY WARNINGS:

• Keep all parts of the body away from

the saw chain when the chain saw is

operating. Before you start the chain

saw, make sure the saw chain is not

contacting anything. A moment of

inattention while operating chain saws

may cause entanglement of your clothing

or body with the saw chain.

• Always hold the chain saw with your

right hand on the rear handle and

your left hand on the front handle.

Holding the chain saw with a reversed

hand configuration increases the risk of

personal injury and should never be done.

• Hold the power tool by insulated

gripping surfaces only, because the

saw chain may contact hidden wiring

or its own cord. Saw chains contacting

a ″live″ wire may make exposed metal

parts of the power tool ″live″ and could

give the operator an electric shock.

• Wear safety glasses and hearing

protection. Further protective

equipment for head, hands, legs

and feet is recommended. Adequate

protective clothing will reduce personal

injury by flying debris or accidental

contact with the saw chain.

• Do not operate a chain saw in a tree.

Operation of a chain saw while up in a

tree may result in personal injury.

• Always keep proper footing and

operate the chain saw only when

standing on fixed, secure and level

surface. Slippery or unstable surfaces

such as ladders may cause a loss of

balance or control of the chain saw.

• When cutting a limb that is under tension

be alert for spring back. When the tension

in the wood fibres is released the spring

loaded limb may strike the operator and/or

throw the chain saw out of control.

• Use extreme caution when cutting

brush and saplings. The slender material

may catch the saw chain and be whipped

toward you or pull you off balance.

• Carry the chain saw by the front handle

with the chain saw switched off and away

from your body. When transporting or

storing the chain saw always fit the guide

bar cover. Proper handling of the chain

saw will reduce the likelihood of accidental

contact with the moving saw chain.

• Follow instructions for lubricating,

chain tensioning and changing

accessories. Improperly tensioned or

lubricated chain may either break or

increase the chance for kickback.

• Keep handles dry, clean, and free from

oil and grease. Greasy, oily handles are

slippery causing loss of control.

• Cut wood only. Do not use chain

saw for purposes not intended. For

example: do not use chain saw for

cutting plastic, masonry or non-wood

building materials. Use of the chain

saw for operations different than intended

could result in a hazardous situation.

CAUSES AND OPERATOR PREVENTION

OF KICKBACK:

Kickback may occur when the nose or tip

of the guide bar touches an object, or when

Page 4

the wood closes in and pinches the saw

chain in the cut.

Tip contact in some cases may cause a

sudden reverse reaction, kicking the guide

bar up and back towards the operator.

Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly

back towards the operator.

Either of these reactions may cause you

to lose control of the saw which could

result in serious personal injury. Do not

rely exclusively upon the safety devices

built into your saw. As a chain saw user,

you should take several steps to keep your

cutting jobs free from accident or injury.

Kickback is the result of tool misuse and/

or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below:

• Maintain a firm grip, with thumbs

and fingers encircling the chain saw

handles, with both hands on the saw

and position your body and arm to

allow you to resist kickback forces.

Kickback forces can be controlled by the

operator, if proper precautions are taken.

Do not let go of the chain saw.

• Do not overreach and do not cut

above shoulder height. This helps

prevent unintended tip contact and

enables better control of the chain saw in

unexpected situations.

• Only use replacement bars and chains

specified by the manufacturer. Incorrect

replacement bars and chains may cause

chain breakage and/or kickback.

• Follow the manufacturer’s sharpening

and maintenance instructions for the

saw chain. Decreasing the depth gauge

height can lead to increased kickback.

THE FOLLOWING PRECAUTIONS SHOULD

BE FOLLOWED TO MINIMIZE KICKBACK:

(1.) Grip Saw Firmly. Hold the chain saw firmly

with both hands when the motor is running.

Use a firm grip with thumbs and fingers

encircling the chain saw handles. Chain saw

will pull forward when cutting on the bottom

edge of the bar, and push backward when

cutting along the top edge of the bar.

(2.) Do not over reach.

(3.) Keep proper footing and balance at all times.

(4.) Don’t let the nose of the guide bar contact

a log, branch, ground or other obstruction.

(5.) Don’t cut above shoulder height.

(6.) Use devices such as low kickback

chain and reduced kickback guide bars that

reduce the risks associated with kickback.

(7.) Only use replacement bars and chains

specified by the manufacturer or the equivalent.

(8.) Never let the moving chain contact any

object at the tip of the guide bar.

(9.) Keep the working area free from

obstructions such as other trees, branches,

rocks, fences, stumps, etc. Eliminate or

avoid any obstruction that your saw chain

could hit while you are cutting through a

particular log or branch.

(10.) Keep your saw chain sharp and properly

tensioned. A loose or dull chain can increase

the chance of kickback. Check tension at

regular intervals with the motor stopped and

tool unpllugged, never with the motor running.

(11.) Begin and continue cutting only with

the chain moving at full speed. If the chain

is moving at a slower speed, there is a

greater chance for kickback to occur.

(12.) Cut one log at a time.

(13.) Use extreme caution when re-entering

a previous cut. Engage ribbed bumpers into

wood and allow chain to reach full speed

before proceeding with cut.

(14.) Do not attempt plunge cuts or bore cuts.

(15.) Watch for shifting logs or other forces that

could close a cut and pinch or fall into chain.

KICKBACK SAFETY FEATURES

WARNING: The following features are

included on your saw to help reduce the

hazard of kickback; however such features

will not totally eliminate this dangerous

reaction. As a chain saw user do not rely only

on safety devices. You must follow all safety

precautions, instructions, and maintenance in

this manual to help avoid kickback and other

forces which can result in serious injury.

•

Chain Brake, designed to immediately tun

the chain saw off if kickback is too great.

• Reduced-Kickback Guide Bar, designed

with a small radius tip which reduces the

size of the kickback danger zone on bar tip.

A reduced - kickback guide bar is one which

has been demonstrated to significantly

reduce the number and seriousness of

kickbacks when tested in accordance with

safety requirements for electric chain saws.

• Low-Kickback Chain, designed with a

contoured depth gauge and guard link

which deflect kickback force and allow

wood to gradually ride into the cutter. A

low-kickback chain is a chain which has

met kickback performance requirements

of ANSI B175.1-1991.

• Do not operate chain saw while in

a tree, on a ladder, on a scaffold, or

from any unstable surface.

• Hold tool by insulated gripping

surfaces when performing an

operation where the cutting tool may

contact hidden wiring. Contact with a

“live” wire will make exposed metal parts

of the tool “live” and shock the operator.

• Do not attempt operations beyond

your capacity or experience. Read

thoroughly and understand completely all

instructions in this manual.

• Before you start chain saw, make sure

saw chain is not contacting any object.

• Do not operate a chain saw with one

hand! Serious injury to the operator,

helpers, or bystanders may result

from one handed operation. A chain saw

4

Page 5

5

is intended for two-handed use only.

• Keep the handles dry, clean, and free

of oil or grease.

• Do not allow dirt, debris, or sawdust to

build up on the motor or outside air vents.

• Stop the chain saw before setting it down.

• Do not cut vines and/or small under brush.

• Use extreme caution when cutting small

size brush and saplings because slender

material may catch the saw chain and be

whipped toward you or pull you off balance.

WARNING: Some dust created by power

sanding, sawing, grinding, drilling, and other

construction activities contains chemicals

known to the State of California to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and

cement and other masonry products, and

• arsenic and chromium from

chemically-treated lumber.

Your risk from these exposures varies,

depending on how often you do this type

of work. To reduce your exposure to these

chemicals: work in a well ventilated area,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust

from power sanding, sawing, grinding,

drilling, and other construction

activities. Wear protective clothing

and wash exposed areas with soap

and water. Allowing dust to get into

your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: Use of this tool can

generate and/or disburse dust, which may

cause serious and permanent respiratory

or other injury. Always use NIOSH/OSHA

approved respiratory protection appropriate

for the dust exposure. Direct particles away

from face and body.

CHAIN SAW NAMES AND TERMS

• Bucking - The process of cross cutting a

felled tree or log into lengths.

• Motor Brake - A device used to stop the

saw chain when the trigger is released.

• Chain Saw Powerhead - A chain saw

without the saw chain and guide bar.

• Drive Sprocket or Sprocket - The

toothed part that drives the saw chain.

• Felling - The process of cutting down a tree.

• Felling Back Cut - The final cut in a tree

felling operation made on the opposite

side of the tree from the notching cut.

• Front Handle - The support handle located

at or toward the front of the chain saw.

• Front Hand Guard - A structural barrier

between the front handle of a chain saw

and the guide bar, typically located close

to the hand position on the front handle

and sometimes employed as an activating

lever for a chain brake.

• Guide Bar - A solid railed structure that

supports and guides the saw chain.

• Guide Bar Scabbard - Enclosure fitted

over guide bar to prevent tooth contact

when saw is not in use.

• Kickback - The backward or upward motion,

or both of the guide bar occurring when the

saw chain near the nose of the top area of

the guide bar contacts any object such as a

log or branch, or when the wood closes in

and pinches the saw chain in the cut.

• Kickback, Pinch - The rapid pushback of

the saw which can occur when the wood

closes in and pinches the moving saw chain

in the cut along the top of the guide bar.

• Kickback, Rotational - The rapid upward

and backward motion of the saw which can

occur when the moving saw chain near

the upper portion of the tip of the guide bar

contacts an object, such as a log or branch.

• Limbing - Removing the branches from a

fallen tree

• Low-Kickback Chain - A chain that

complies with the kickback

performance requirements of ANSI

B175.1-1991 (when tested on

a representative sample of chain saws.)

• Normal Cutting Position - Those

positions assumed in

performing the bucking and felling cuts.

• Notching Undercut - A notch cut in a tree

that directs the tree’s fall.

• Rear Handle - The support handle

located at or toward the rear of the saw.

• Reduced Kickback Guide Bar - A guide

bar which has been demonstrated to

reduce kickback significantly.

• Replacement Saw Chain - A chain that

complies with kickback performance

requirements of ANSI B175.1-2000 when

tested with specific chain saws. It may

not meet the ANSI performance

requirements when used with other saws.

• Saw Chain - A loop of chain having

cutting teeth, that cut the wood,and that is

driven by the motor and is supported by

the guide bar.

• Ribbed Bumper - The ribs used when

felling or bucking to pivot the saw and

maintain position while sawing.

• Switch - A device that when operated will

complete or interrupt an electrical power

circuit to the motor of the chain saw.

• Switch Linkage - The mechanism that

transmits motion from a trigger to the switch.

• Switch Lockout - A movable stop that

prevents the unintentional operation of

the switch until manually actuated.

INTENDED USE

Your BLACK+DECKER Chain Saw is ideal

for pruning applications and cutting small

logs up to 16 inches (406 mm) in diameter.

This tool is intended for consumer use only.

SAVE THESE INSTRUCTIONS

Page 6

6

SYMBOLS

The label on your tool may include the

following symbols. The symbols and their

definitions are as follows:

V ..................volts

A ..................amperes

Hz ................ hertz

W .................watts

min ..............minutes

or AC ...... alternating current

or DC ...direct current

n

o ................ no load speed

................Class I Construction

(grounded)

PREPARING YOUR CHAIN SAW

FOR USE

WARNING: Read and understand all

instructions. Failure to follow all instructions

listed below may result in electric shock, fire

and/or serious personal injury.

ASSEMBLY

INSTALLING THE GUIDE BAR AND SAW CHAIN

CAUTION: Sharp chain. Always wear

protective gloves when handling the

chain. The chain is sharp and can cut you

when it is not running.

WARNING: Sharp moving chain. To

prevent accidental operation, insure that

tool is unplugged before performing the

following operations. Failure to do this

could result in serious personal injury.

The saw chain (5) and guide bar (4) are

packed separately in the carton. The chain

has to be attached to the bar, and both must

be attached to the body of the tool.

• Place the saw on a firm surface.

• Rotate the bar adjust locking knob (7)

counterclockwise as shown in figure A to

remove sprocket cover (6).

................earthing terminal

................safety alert symbol

................Class II Construction

(double insulated)

.../min or rpm...revolutions or

reciprocation per minute

...............Read instruction manual

before use

................ Use proper respiratory

protection

................ Use proper eye protection

................ Use proper hearing

protection

• Turn the tool-free tension assembly (16)

(attached to the bar) counterclockwise

until it stops as shown in figure B.

• Wearing protective gloves, grasp the saw

chain (5) and wrap it around the guide

bar (4), ensuring the teeth are facing the

correct direction (see figure F)

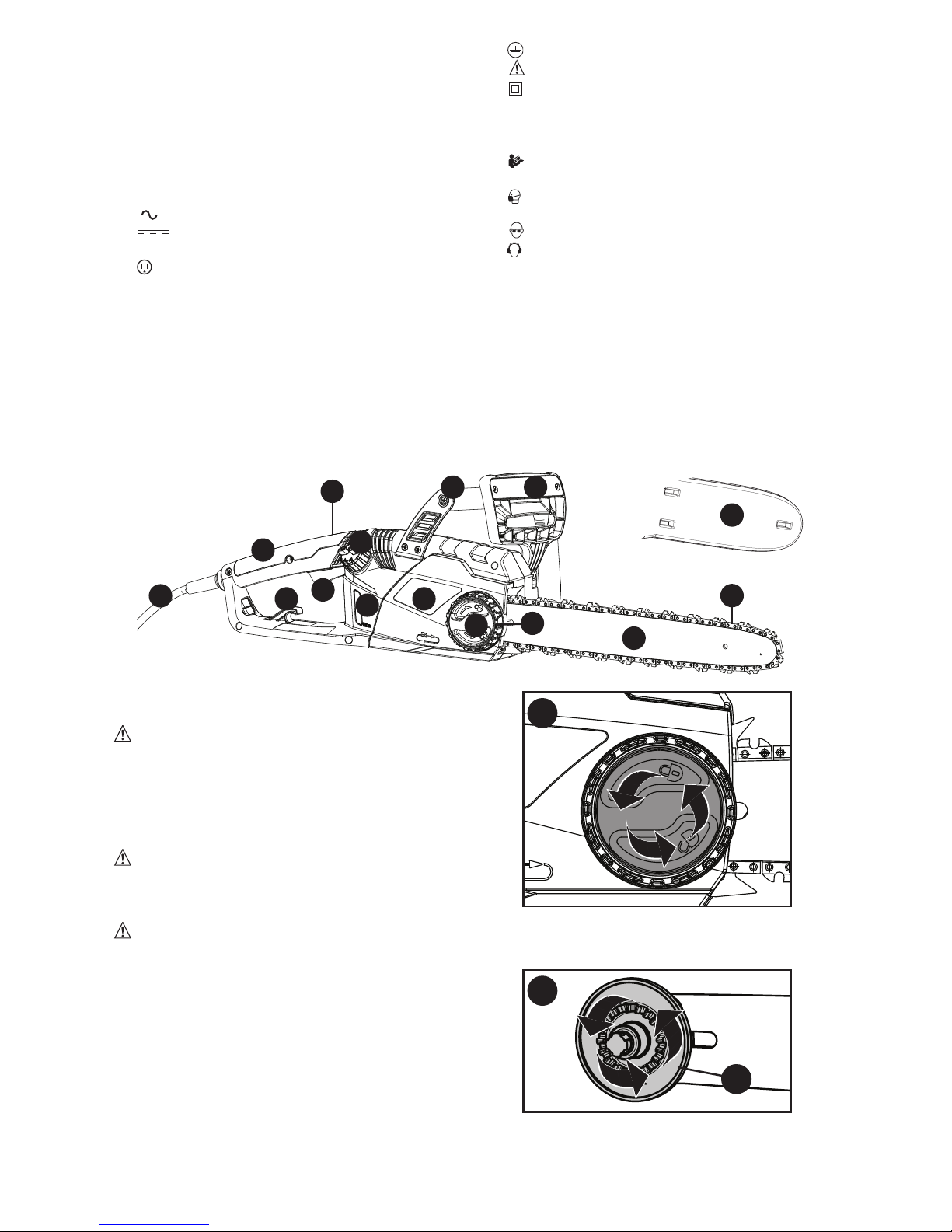

FUNCTIONAL DESCRIPTION

1. Trigger switch

2. Lock-off button (not shown)

3. Chain brake / front hand guard

4. Guide bar

5. Saw chain

6. Sprocket cover

7. Bar adjust locking knob

8. Chain tensioning wheel

9. Guide bar scabbard

10. Rear handle

11. Front handle

12. Cord

13. Extention cord retainer

14. Oil cap

15. Oil level indicator

A

1

3

6

7

4

2

5

9

11

10

12

13

14

8

15

B

16

Page 7

7

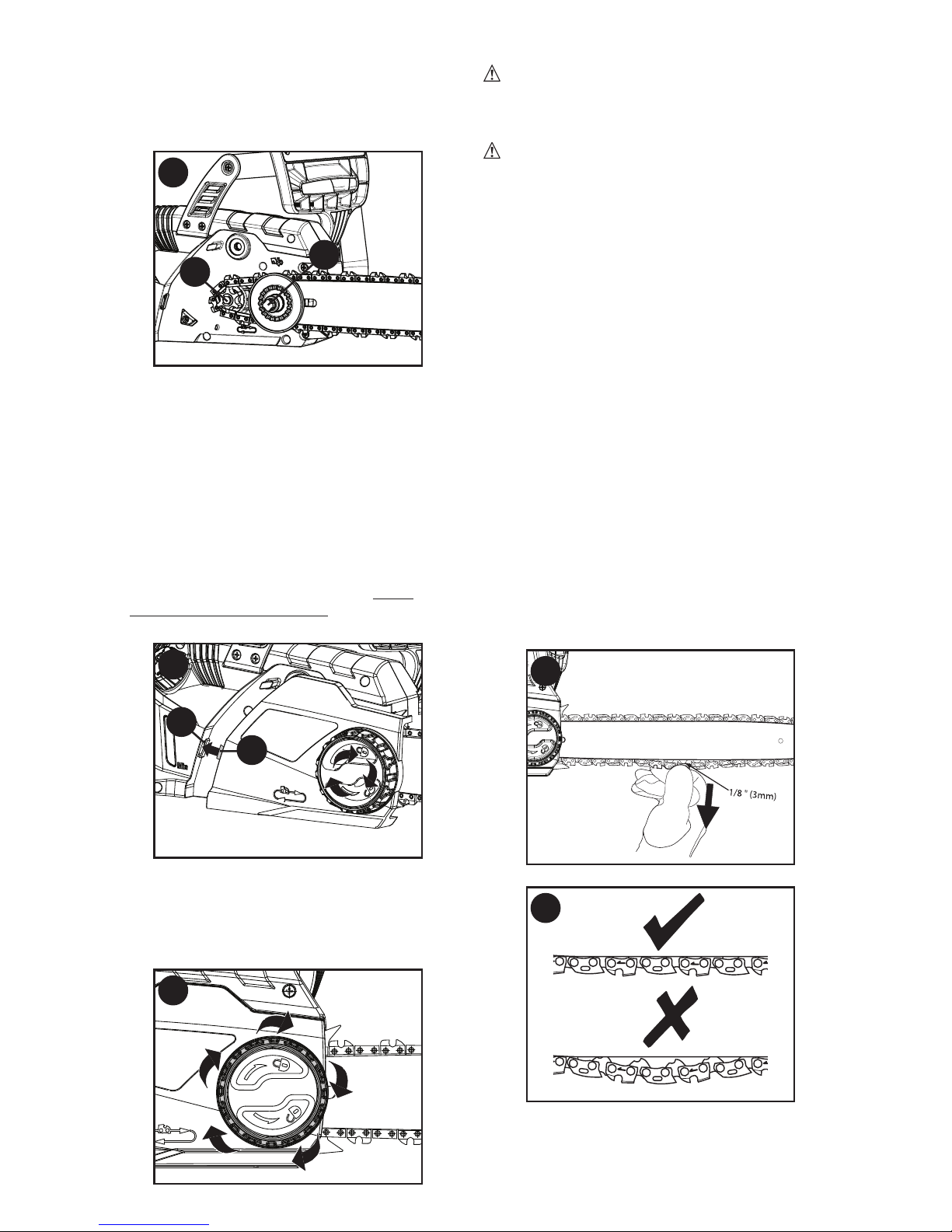

• Ensure the chain is properly set in the slot

around the entire guide bar.

• Place the saw chain around the sprocket

(17) while lining up the hole in the tool-free

tension assembly with the bolt (18) in the

base of the tool as shown in figure C.

• Rotate bar until it engages the two pins

underneath and no longer easily rotates

up and down.

• Once in place, turn the tool-free tension

assembly (16) clockwise by hand to

preliminarily tighten the assembly to hold

it in place.

• While holding the bar in still, replace

sprocket cover (6). Make sure the nub

(19) on the cover lines up with the slot

(20) in the main housing as shown in

figure D. Rotate the bar adjust locking

knob (7) clockwise until snug, then

loosen knob one full turn, so the saw

chain can be properly tensioned.

• While holding the bar adjust locking knob

(7), rotate the chain tensioning wheel (8)

clockwise to increase tension as shown

in figure E. Make sure the saw chain (5)

is snug around the guide bar (4).

ADJUSTING CHAIN TENSION

CAUTION: Sharp chain. Always wear

protective gloves when handling the

chain. The chain is sharp and can cut you

when it is not running.

WARNING: Sharp moving chain. To

prevent accidental operation, insure that

the tool is unplugged before performing

the following operations. Failure to do this

could result in serious personal injury.

• With the saw on a firm surface, check

the saw chain (5) tension. The tension is

correct when the chain snaps back after

being pulled 1/8 inch (3mm) away from

the guide bar (4) with light force from

the middle finger and thumb as shown

in figure F. There should be no “sag”

between the guide bar and the chain on

the underside as shown in figure G.

• To adjust saw chain tension, loosen

bar adjust locking knob (7) and follow

instructions for “Installing the Guide Bar

and Saw Chain.”

• Do not over-tension the chain as this will

lead to excessive wear and will reduce

the life of the bar and chain.

• Once chain tension is correct, tighten bar

adjust locking knob.

• When the chain is new, check the tension

frequently (after unplugging tool) during

the first 2 hours of use as a new chain

stretches slightly.

E

D

20

19

C

17

18

F

G

Page 8

8

AUTO OILING SYSTEM

This chain saw is equipped with an auto

oiling system that keeps the saw chain and

guide bar constantly lubricated.

The oil level indicator (15) shows the level

of the oil in the chain saw. If the oil level is

less than a quarter full, unplug the chain

saw and refill with the proper oil.

NOTE: Use a high quality bar and chain

oil for proper chain and bar lubrication. As

a temporary substitute, a non-detergent

SAE30 weight motor oil can be used.The

use of a vegetable based bar and chain oil is

recommended when pruning trees. Mineral

oil is not recommended because it may harm

trees. Never use waste oil or very thick oil.

These may damage your chain saw.

Filling the oil reservoir

• Remove the oil cap (14) and fill the

reservoir with the recommended chain oil

until the oil level has reached the top of

the oil level indicator (15).

• Refit the oil cap.

• Periodically switch the chain saw off and

check the oil level indicator to insure the

bar and chain are being properly oiled.

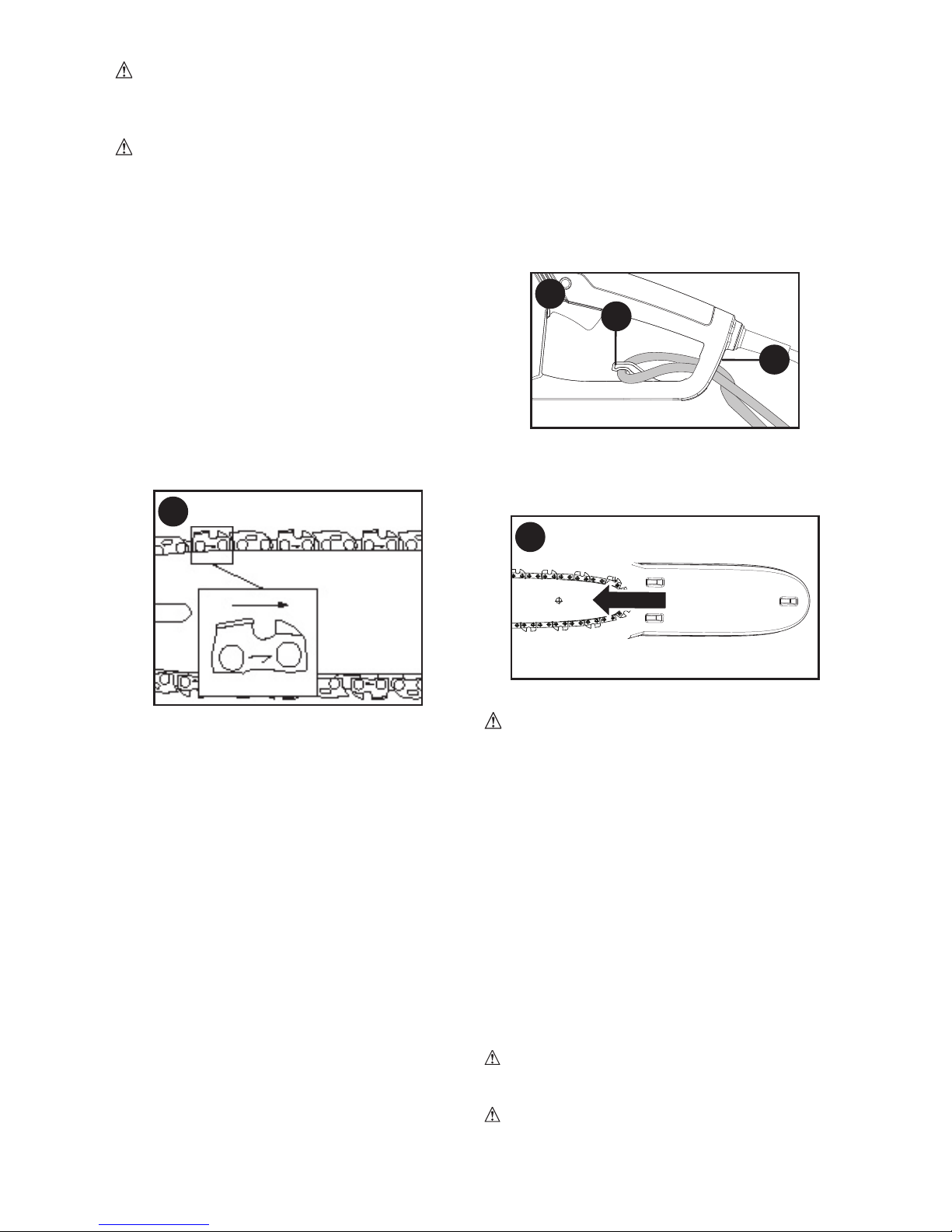

ATTACHING EXTENSION CORD

An extension cord retainer (13) is built into

the switch handle. It prevents the extention

cord from coming unplugged.

• Double the extension cord and insert it

into the slot (20) in the end of the handle

area as shown in figure I. Hook the loop

formed by doubling the cord over the

cord retainer (13). Gently tug on the cord

to insure that it is firmly retained in the

handle. Plug the receptacle end of the

extension cord into the power cord (12)

of the chain saw.

TRANSPORTING SAW

• Always cover the guide bar (4) with the

scabbard (9) (figure J) when transporting

the saw.

OPERATING THE CHAIN SAW

WARNING: Read and understand all

instructions. Failure to follow all instructions

listed below may result in electric shock, fire

and/or serious personal injury.

• Guard Against Kickback which can result

in severe injury or death. See Important

Safety Instructions “Guard Against

Kickback”, to avoid the risk of kickback.

• Do not overreach. Do not cut above

chest height. Make sure your footing is

firm. Keep feet apart. Divide your weight

evenly on both feet.

• Use a firm grip with your left hand on

the front handle (11) and your right

hand on the rear handle (10) so that

your body is to the left of the guide bar.

• Do not hold chain saw by front hand guard

(3). Keep elbow of left arm locked so that left

arm is straight to withstand a kickback.

WARNING: Never use a cross-handed

grip (left hand on the rear handle and right

hand on the front handle).

WARNING: Never allow any part of

your body to be in line with the guide bar

(4) when operating the chain saw.

• Never operate while in a tree, in any

awkward position or on a ladder or

J

I

20

13

REPLACING THE SAW CHAIN

CAUTION: Sharp chain. Always wear

protective gloves when handling the

chain. The chain is sharp and can cut you

when it is not running.

WARNING: Sharp moving chain. To

prevent accidental operation, insure that

the tool is unplugged before performing

the following operations. Failure to do this

could result in serious personal injury.

• Rotate the bar adjust locking knob (7)

counterclockwise to lessen chain tension.

• Remove sprocket cover (6) as described

in “Installing the Guide Bar and Saw

Chain” section.

• Lift the worn saw chain (5) out of the

groove in the guide bar (4).

• Place the new chain in the slot of the

guide bar, making sure the saw teeth are

facing the correct direction by matching

the arrow on the chain with the graphic on

the sprocket cover (6) shown in figure H.

• Follow instructions for “Installing the

Guide Bar and Saw Chain.”

H

Page 9

9

other unstable surface. You may lose

control of saw causing severe injury.

• Keep the chain saw running at full

speed the entire time you are cutting.

• Allow the chain to cut for you. Exert

only light pressure. Do not put pressure

on chain saw at end of cut.

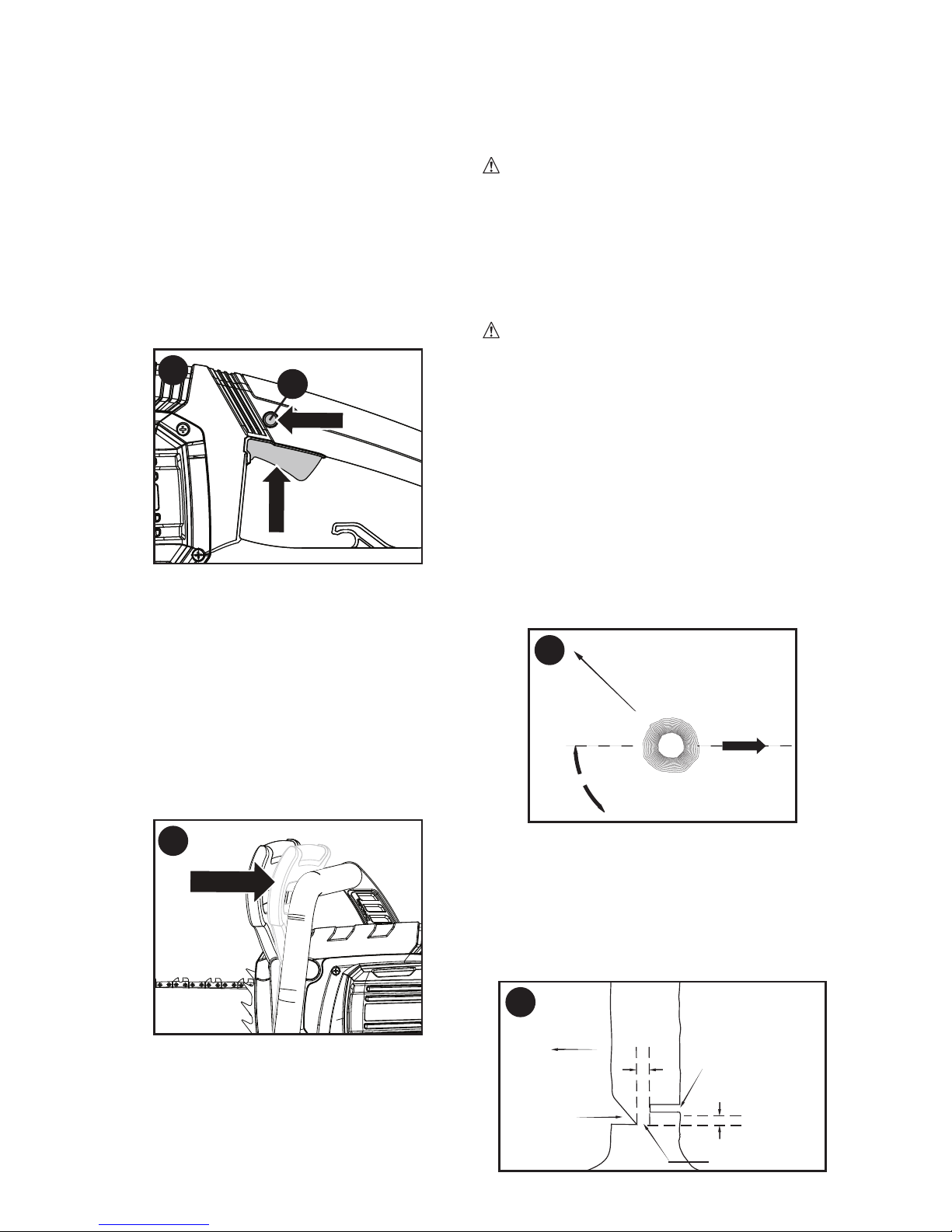

ON / OFF

• Always be sure of your footing and grip the

chain saw firmly with both hands with the

thumb and fingers encircling both handles.

• To turn the tool ON, depress the lock off

button (2) and squeeze the trigger switch

(1) as shown in figure K. (Once the tool is

running you can release the lock off button.)

• To turn the tool OFF, release the trigger switch.

SETTING THE CHAIN BRAKE

Your chain saw is equipped with a motor

chain braking system which will stop the

chain quickly in case of kickback.

• Make sure the tool is unplugged.

• Pull the chain brake / front hand guard

(3) back into the “set” position as shown

in figure L.

• The tool is now ready to use.

NOTE: In the event of kickback, your left

hand will come in contact with the front

guard, pushing it forward, toward the

workpiece. This will stop the tool immediately.

TESTING THE CHAIN BRAKE

Test the chain brake before every use to

make sure it operates correctly.

• Place the tool on a firm surface. Make sure

the saw chain (5) is clear of the ground.

• Grip the tool firmly with both hands and

turn the chain saw on .

• Rotate your left hand forward around the

front handle so the back of your hand

comes in contact with the Chain brake /

front hand guard (3) and push it forward,

toward the workpiece. The saw chain

should stop immediately.

NOTE: If saw does not stop immediately,

stop use of tool and bring it to a service

center nearest you.

WARNING:

Make sure to set chain brake

before cutting.

COMMON CUTTING TECHNIQUES

Felling

Felling is the process of cutting down a tree.

Be sure battery is fully charged before felling

a tree so you can finish on a single charge.

Do not fell trees in high wind conditions.

WARNING: Felling can result in injury. It

should only be performed by a trained person.

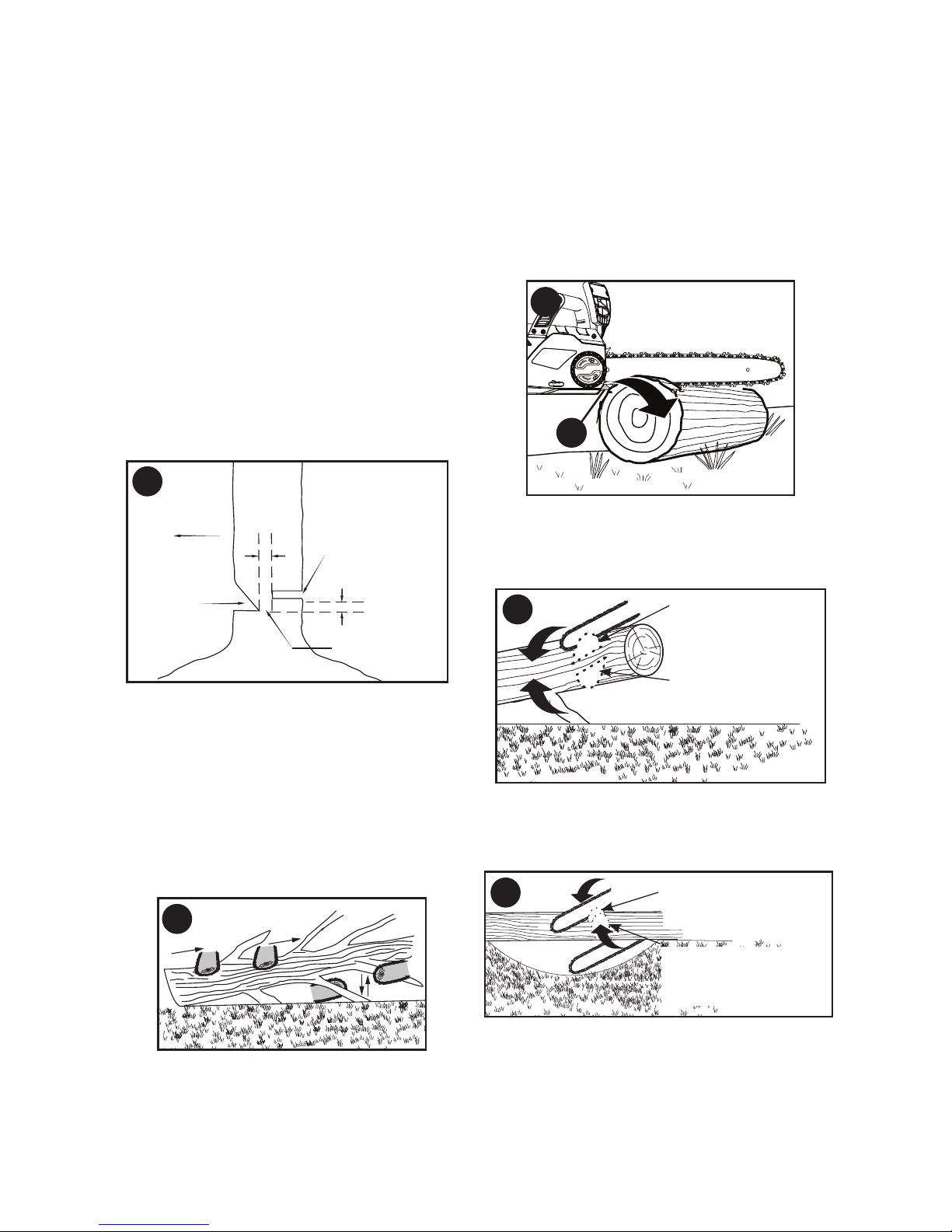

• (Figure M) A retreat path should be

planned and cleared as necessary before

cuts are started. The retreat path should

extend back and diagonally to the rear of

the expected line of fall.

• Before felling is started, consider the

natural lean of the tree, the location of

larger branches and the wind direction to

judge which way the tree will fall. Have

wedges (wood, plastic or aluminum)

and a heavy mallet handy.

Remove dirt, stones, loose bark, nails,

staples, and wire from the tree where the

felling cuts are to be made.

• (Figure N) Notching Undercut - Make

the notch 1/3 of the diameter of the tree,

perpendicular to the direction of the fall.

Make the lower horizontal notching cut

first. This will help to avoid pinching of

either the saw chain or the guide bar

when the second notch is being made.

L

1

2

K

2

DIRECTION

OF

FALL

RETREAT

45°

TREE

M

2 (5cm)

INCHES

DIRECTION

OF FALL

2 (5cm)

INCHES

HINGE

NOTCH

FELLING BACK

CUT

N

Page 10

10

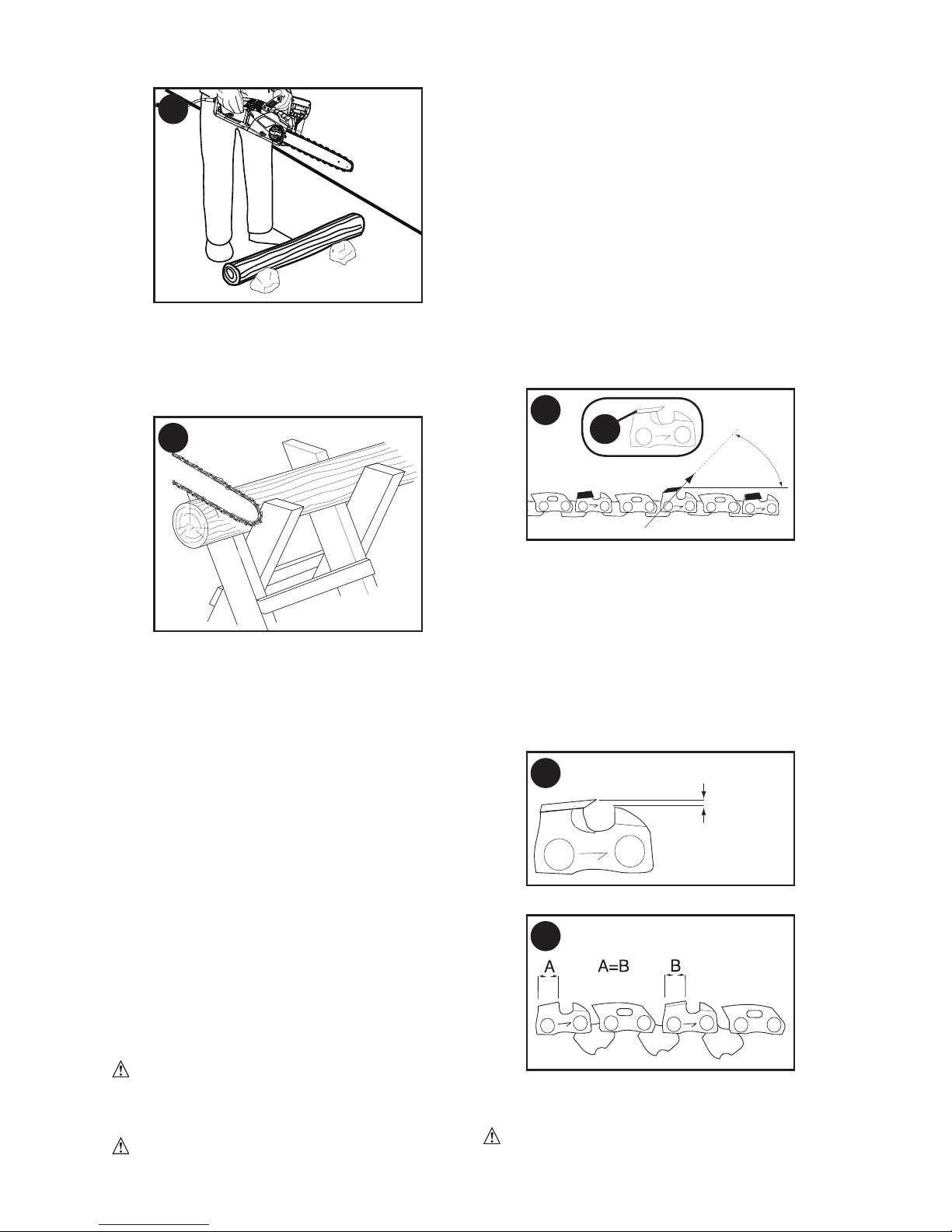

Limbing

Limbing is removing the branches from a

fallen tree. When limbing, leave larger lower

limbs to support the log off the ground.

Remove the small limbs in one cut. Branches

under tension should be cut from the bottom

up to avoid binding the chain saw as shown

in figure P. Trim limbs from opposite side

keeping tree stem between you and saw.

Never make cuts with saw between your legs

or straddle the limb to be cut.

P

Q

21

CUT FROM TOP

(OVERBUCK)

AVOID CUTTING EARTH

1

1

2

2nd CUT OVERBUCK

(2/3DIAMETER)

TO MEET 1st CUT

(TO AVOID PINCHING)

1st CUT UNDERBUCK

(1/3 DIAMETER)

AVOID SPLINTERING

R

1

2

S

2nd CUT UNDERBUCK

(2/3 DIAMETER)

TO MEET 1st CUT

(TO AVOID PINCHING)

1st CUT OVERBUCK

(1/3 DIAMETER)

TO AVOID SPLINTERING

Bucking

Bucking is cutting a felled tree or log into

lengths. How you should cut depends on

how the log is supported. Use a saw horse

(figure U) whenever possible.

Always start a cut with the chain running at

full speed.

• Place the bottom spike (21) of the chain

saw behind the area of the initial cut as

shown in figure Q.

• Turn the chain saw on then rotate the chain

and bar down into the tree, using the spike

as a hinge.

•

Once the chain saw gets to a 45 degree

angle, level the chain saw again and

repeat steps until you cut fully through.

• When the tree is supported along its

entire length, make a cut from the top

(overbuck), but avoid cutting the earth as

this will dull your saw quickly.

• (Figure O) Felling Back Cut - Make the

felling back cut at least

2 inches (51mm) higher than the

horizontal notching cut. Keep the felling

back cut parallel to the horizontal

notching cut. Make the felling back cut

so enough wood is left to act as a hinge.

The hinge wood keeps the tree from

twisting and falling in the wrong direction.

Do not cut through the hinge.

• (Figure O) As the felling cut gets close to

the hinge the tree should begin to fall. If

there is any chance that the tree may not

fall in the desired direction or it may rock

back and bind the saw chain, stop cutting

before the felling cut is complete and use

wedges to open the cut and drop the

tree along the desired line of fall. When

the tree begins to fall remove the chain

saw from the cut, stop the motor, put the

chain saw down, then use the retreat

path planned. Be alert for overhead limbs

falling and watch your footing.

• (Figure R) When supported at one end

First, cut 1/3 the diameter from the underside

(underbuck). Then make the finished cut by

overbucking to meet the first cut.

• (Figure S) When supported at both ends

First, cut 1/3 down from the top overbuck.

Then make the finished cut by underbucking

the lower 2/3 to meet the first cut.

• (Figure T) When on a slope

Always stand on the uphill side of the

log. When “cutting through”, to maintain

complete control release the cutting

pressure near the end of the cut without

relaxing your grip on the chain saw

handles. Don’t let the chain contact the

ground. After completing the cut, wait for

the saw chain to stop before you move

2 (5cm)

INCHES

DIRECTION

OF FALL

2 (5cm)

INCHES

HINGE

NOTCH

FELLING BACK

CUT

O

Page 11

11

X

T

U

60°

V

22

W

.025 in.

.635mm

• (Figure U) When using a saw horse

This is strongly recommended whenever

possible. Position the log in a stable

position. Always cut on the outside of the

saw horse arms.

the chain saw. Always stop the motor

before moving from tree to tree.

CARE AND MAINTENANCE

Use only mild soap and damp cloth to clean

the tool. Do not use solvents to clean the

plastic housing of the saw. Never let any

liquid get inside the tool; never immerse any

part of the tool into a liquid.

IMPORTANT: To assure product SAFETY

and RELIABILITY, repairs, maintenance

and adjustment should be performed by

authorized service centers or other qualified

service organizations, always using identical

replacement parts.

Regular maintenance ensures a long

effective life for your chain saw. We

recommend you make the following checks

on a regular basis:

CHAIN AND BAR

After every few hours of use, remove the

guide bar and chain and

clean thoroughly.

SAW CHAIN SHARPENING

CAUTION: Sharp chain. Always wear

protective gloves when handling the

chain. The chain is sharp and can cut you

when it is not running.

WARNING: Sharp moving chain. To

prevent accidental operation, insure that

the tool is unplugged before performing

the following operations. Failure to do

this could result in serious personal injury.

NOTE: The cutters will dull immediately if

they touch the ground or a nail while cutting.

To get the best possible performance from

your chain saw it is important to keep the

teeth of the chain sharp. Follow these

helpful tips for proper saw chain sharpening:

1. For best results use a 4.5mm file and

a file holder or filing guide to sharpen

your chain. This will ensure you always

get the correct sharpening angles.

2. Place the file holder flat on the top

plate and depth gauge of the cutter.

3. (Figure V) Keep the correct top plate

(22) filing angle line of 30° on your file

guide parallel with your chain (file at

60° from chain viewed from above).

4. Sharpen cutters on one side of the

chain first. File from the inside of

each cutter to the outside. Then turn

your saw around and repeat the

processes (2,3,4) for cutters on the

other side of the chain.

NOTE: Use a flat file to file the tops of the

rakers (portion of chain link in front of the

cutter) so they are about .025 inch (.635

mm) below the tips of the cutters as shown

in Figure W.

5. (Figure X) Keep all cutter lengths equal.

6. If damage is present on the chrome

surface of the top plates or side plates,

file back until such damage is removed.

CAUTION: After filing, the cutter will be

sharp, use extra caution during this process.

NOTE: Each time the chain is sharpened,

Page 12

12

it loses some of the low kickback qualities

and extra caution should be used. It is

recommended that a chain be sharpened

no more than four times.

ACCESSORIES

WARNING: The use of accessories not

recommended in this manual may be hazardous.

Accessories are available from your local retailer

or nearest BLACK+DECKER service center.

•

This chain saw is compatible with the

BLACK+DECKER chain RC1800

• Replace bar with a corresponding 18-inch

Oregon low-kickback bar.

NOTE:

Ensure the new bar is equipped with

a tool-free tension assembly (16).

SERVICE INFORMATION

All BLACK+DECKER Service Centers

are staffed with trained personnel to

provide customers with efficient and

reliable power tool service. Whether you

need technical advice, repair, or genuine

factory replacement parts, contact the

BLACK+DECKER location nearest you. To

find your local service location, call:

1-800-544-6986, or visit

www.blackanddecker.com

FULL TWO-YEAR HOME USE

WARRANTY

BLACK+DECKER warrants this product for

two years against any defects in material or

workmanship. The defective product will be

replaced or repaired at no charge in either of

two ways.

The first, which will result in exchanges

only, is to return the product to the retailer

from whom it was purchased (provided

that the store is a participating retailer).

Returns should be made within the time

period of the retailer’s policy for exchanges

(usually 30 to 90 days after the sale). Proof

of purchase may be required. Please check

with the retailer for their specific return policy

regarding returns that are beyond the time

set for exchanges.

The second option is to take or send the

product (prepaid) to a BLACK+DECKER

owned or authorized Service Center for

repair or replacement at our option. Proof of

purchase may be required.

This warranty does not apply to accessories.

This warranty gives you specific legal rights

and you may have other rights which vary

from state to state or province to province.

Should you have any questions, contact the

manager of your nearest BLACK+DECKER

Service Center. This product is not intended

for commercial use.

FREE WARNING LABEL REPLACEMENT:

If your warning labels become illegible or

are missing, call 1-800-544-6986 for a free

replacement.

LATIN AMERICA: This warranty does not

apply to products sold in Latin America. For

products sold in Latin America, check country

specific warranty information contained in the

packaging, call the local company or see the

website for warranty information.

Page 13

13

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Chain saw will not start. • Cord not plugged in.

• Plug chain saw into a working outlet.

• Circuit fuse is blown. • Replace circuit fuse. (If the

product repeatedly causes the

circuit fuse to blow, discontinue use

immediately and have it serviced

at a BLACK+DECKER service center

or authorized servicer.)

• Circuit breaker is tripped.

• Reset circuit breaker. (If the product

repeatedly causes the circuit

breaker to trip, discontinue use

immediately and have it serviced

at a BLACK+DECKER service

center or authorized servicer.)

• Cord or switch is • Have cord or switch replaced at

damaged. BLACK+DECKER Service Center or

Authorized Servicer.

• Lock-off button not • Push lock off button and then

actuated. depress the trigger switch.

• Bar / chain overheated.

• Chain too tight. • Refer to “adjusting chain

tension” section.

• Lubrication needed.

• Refer to “filling the oil reservoir”

section.

• Chain is loose. • Chain tension set • Refer to “adjusting chain

incorrectly. tension” section.

• Poor cut quality. • Chain tension set • Refer to “adjusting chain

incorrectly. tension” section.

• Chain needs to be • Refer to “saw chain sharpening”

sharpened. section.

• Chain needs Note: Excessive tension leads to

replacement. excessive wear and reduction in

life of bar & chain. Ensure too is

always adequately filled with

proper oil.

Refer to “replacing the saw chain”

section.

• Unit runs but does • Chain installed • Refer to sections for installing

not cut. backwards. and removing chain.

For assistance with your product, visit our website www.blackanddecker.com for the location

of the service center nearest you or call the BLACK+DECKER help line at 1-800-544-6986.

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.

Page 14

14

MODE D’EMPLOI

SCIE À CHAÎNE

Merci d’avoir choisi BLACK+DECKER! Consulter le site Web

www.BlackandDecker.com/NewOwner pour enregistrer votre nouveau produit.

ÀLIRE AVANT DE RETOURNER CE PRODUIT POUR QUELQUE

RAISON QUE CE SOIT :

Si des questions ou des problèmes surgissent après l’achat d’un produit

BLACK+DECKER, consulter le site Web www.blackanddecker.com/instantanswers

pour obtenir des réponses instantanément 24 heures par jour. Si la réponse est

introuvable ou en l’absence d’accès à l’Internet, composer le 1 800 544-6986 de 8 h à

17 h HNE, du lundi au vendredi, pour parler avec un agent. Prière d’avoir le numéro de

catalogue sous la main lors de l’appel.

Pour l´achat d´un filtre de rechange composer le 1-888-678-7278

CONSERVER CE MODE D’EMPLOI POUR UN USAGE ULTÉRIEUR.

VOICI DES RENSEIGNEMENTS IMPORTANTS À CONNAÎTRE :

NE PAS EXERCER DE TENSION TROP FORTE SUR LA CHAÎNE. Se

reporter à la rubrique « RÉGLAGE DE LA TENSION DE LA CHAÎNE »

pour savoir comment tendre la chaîne correctement.

Retendre la chaîne fréquemment durant les deux premières heures

d’utilisation.

NUMERO DE CATALOGUE

CS1518

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ - DÉFINITIONS

Il est important que vous lisiez et compreniez ce mode d’emploi. Les informations qu’il

contient concernent VOTRE SÉCURITÉ et visent à ÉVITER TOUT PROBLÈME. Les

symboles ci-dessous servent à vous aider à reconnaître cette information.

DANGER : Indique une situation dangereuse imminente qui, si elle n’est pas

évitée, causera la mort ou des graves blessures.

AVERTISSEMENT : Indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, pourrait causer la mort ou de graves blessures.

MISE EN GARDE : Indique une situation potentiellement dangereuse

qui, si elle n’est pas évitée, pourrait causer des blessures mineures ou modérées.

MISE EN GARDE : Utilisé sans le symbole d’alerte à la sécurité,

indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, peut résulter

en des dommages à la propriété.

Page 15

15

Avertissements de sécurité

généraux pour les outils

électriques

AVERTISSEMENT : Lire tous les

avertissements de sécurité et

toutes les directives. Le non-respect

des avertissements et des directives

pourrait se solder par un choc

électrique, un incendie et/ou une

blessure grave.

Conserver tous les

avertissements et toutes les

directives pour un usage

ultérieur.

Le terme «outil électrique» cité dans

les avertissements se rapporte à votre

outil électrique à alimentation sur

secteur (avec fil) ou par piles (sans fil).

1) Sécurité du lieu de travail

a) Tenir la zone de travail propre et

bien éclairée. Les endroits sombres

sont souvent des causes d’accidents.

b) Ne pas faire fonctionner d’outils

électriques dans un milieu

déflagrant, soit en présence de

liquides inflammables, de gaz ou

de poussière. Les outils électriques

produisent des étincelles qui peuvent

enflammer la poussière ou les vapeurs.

c) Éloigner les enfants et les curieux

au moment d’utiliser un outil

électrique. Une distraction pourrait

vous en faire perdre la maîtrise.

2) Sécurité en matière d’électricité

a) Les fiches des outils électriques

doivent correspondre à la prise. Ne

jamais modifier la fiche en aucune

façon. Ne jamais utiliser de fiche

d’adaptation avec un outil électrique mis

à la terre. Le risque de choc électrique

sera réduit par l’utilisation de fiches non

modifiées correspondant à la prise.

b) Éviter tout contact physique

avec des surfaces mises à la

terre comme des tuyaux, des

radiateurs, des cuisinières et des

réfrigérateurs. Le risque de choc

électrique est plus élevé si votre corps

est mis à la terre.

c) Ne pas exposer les outils

électriques à la pluie ou à d’autres

conditions où il pourrait être

mouillé. La pénétration de l’eau dans

un outil électrique augmente le risque

de choc électrique.

d) Ne pas utiliser abusivement le cordon

d’alimentation. Ne jamais utiliser

le cordon pour transporter, tirer ou

débrancher un outil électrique. Tenir

le cordon éloigné de la chaleur, de

l’huile, des bords tranchants ou

des pièces mobiles. Les cordons

endommagés ou emmêlés augmentent

les risques de choc électrique.

e) Pour l’utilisation d’un outil

électrique à l’extérieur, se servir

d’une rallonge convenant à une telle

utilisation. L’utilisation d’une rallonge

conçue pour l’extérieur réduit les

risques de choc électrique.

f) S’il est impossible d’éviter

l’utilisation d’un outil électrique

dans un endroit humide, brancher

l’outil dans une prise ou sur un

circuit d’alimentation dotés d’un

disjoncteur de fuite à la terre (GFCI).

L’utilisation de ce type de disjoncteur

réduit les risques de choc électrique.

3) Sécurité personnelle

a) Ê

tre vigilant, surveiller le travail

effectué et faire preuve de jugement

lorsqu’un outil électrique est utilisé.

Ne pas utiliser d’outil électrique en

cas de fatigue ou sous l’influence de

drogues, d’alcool ou de médicaments.

Un simple moment d’inattention en

utilisant un outil électrique peut entraîner

des blessures corporelles graves.

b) Utiliser des équipements de

protection individuelle. Toujours

porter une protection oculaire.

L’utilisation d’équipements de protection

comme un masque antipoussière, des

chaussures antidérapantes, un casque

de sécurité ou des protecteurs auditifs

lorsque la situation le requiert réduira les

risques de blessures corporelles.

c) Empêcher les démarrages

intempestifs. S’assurer que

l’interrupteur se trouve à la position

d’arrêt avant de relier l’outil à une

source d’alimentation et/ou d’insérer

un bloc-piles, de ramasser ou de

transporter l’outil. Transporter un

outil électrique alors que le doigt

repose sur l’interrupteur ou brancher

un outil électrique dont l’interrupteur

est à la position de marche risque de

provoquer un accident.

d) Retirer toute clé de réglage ou

clé standard avant de démarrer

l’outil. Une clé standard ou une clé

de réglage attachée à une partie

pivotante peut causer des blessures.

e) Ne pas trop tendre les bras.

Conserver son équilibre en tout

temps. Cela permet de mieux

maîtriser l’outil électrique dans les

situations imprévues.

f) S’habiller de manière appropriée.

Ne pas porter de vêtements amples

ni de bijoux. Garder les cheveux,

les vêtements et les gants à l’écart

des pièces mobiles. Les vêtements

amples, les bijoux ou les cheveux

Page 16

16

longs risquent de rester coincés dans

les pièces mobiles.

g) Si des composants sont fournis

pour le raccordement de dispositifs

de dépoussiérage et de ramassage,

s’assurer que ceux-ci sont bien

raccordés et utilisés. L’utilisation

d’un dispositif de dépoussiérage peut

réduire les dangers

engendrés par les poussières.

4) Utilisation et entretien d’un outil

électrique

a) Ne pas forcer un outil électrique.

Utiliser l’outil électrique approprié

à l’application. L’outil électrique

approprié effectuera un meilleur travail,

de façon plus sûre et à la vitesse pour

laquelle il a été conçu.

b) Ne pas utiliser un outil électrique

dont l’interrupteur est défectueux.

Tout outil électrique dont l’interrupteur

est défectueux est dangereux et doit

être réparé.

c) Débrancher la fiche du secteur ou le

bloc-piles de l’outil électrique avant

de faire tout réglage ou changement

d’accessoire, ou avant de ranger

l’outil électrique. Ces mesures

préventives réduisent les risques de

démarrage accidentel de l’outil électrique.

d) Ranger les outils électriques

hors de la portée des enfants, et

ne permettre à aucune personne

n’étant pas familière avec un

outil électrique (ou son manuel

d’instruction) d’utiliser ce dernier.

Les outils électriques deviennent

dangereux entre les mains

d’utilisateurs inexpérimentés.

e) Entretenir les outils électriques.

Vérifier les pièces mobiles pour

s’assurer qu’elles sont bien

alignées et tournent librement,

qu’elles sont en bon état et ne

sont affectées par aucun trouble

susceptible de nuire au bon

fonctionnement de l’outil électrique.

En cas de dommage, faire réparer

l’outil électrique avant toute

nouvelle utilisation. Beaucoup

d’accidents sont causés par des outils

électriques mal entretenus.

f) S’assurer que les outils de coupe sont

aiguisés et propres. Les outils de coupe

bien entretenus et affûtés sont moins

susceptibles de se coincer et sont plus

faciles à contrôler.

g) Utiliser l’outil électrique, les

accessoires, les forets, etc.

conformément aux présentes

directives en tenant compte des

conditions de travail et du travail

à effectuer. L’utilisation d’un outil

électrique pour toute opération autre

que celle pour laquelle il a été conçu

est dangereuse.

5) Réparation

a) Faire réparer l’outil électrique

par un réparateur professionnel

en n’utilisant que des pièces de

rechange identiques. Cela permettra

de maintenir une utilisation sécuritaire

de l’outil électrique.

LIRE TOUTES CES DIRECTIVES.

CONSIGNES DE SÉCURITÉ ET

AVERTISSEMENTS POUR LES

SCIES Á CHAÍNE

• Éloigner toute partie du corps de

la chaîne de l’outil lorsque la scie

à chaîne est en marche. Avant de

démarrer la scie à chaîne, s’assurer

que la chaîne est dégagée, sans

aucun contact avec des objets. Un

moment d’inattention, durant l’utilisation

d’une scie à chaîne, peut résulter dans

l’enchevêtrement des vêtements ou d’une

partie du corps dans la chaîne.

• Toujours tenir la tronçonneuse avec

votre ISO sur la poignée arrière et la

main gauche sur la poignée avant. Tenir

la tronçonneuse avec une configuration

inversée main augmente le risque de

blessure et ne devrait jamais être fait.

• Tenir l’outil électrique par ses surfaces

de prise isolées seulement, car la

chaîne peut entrer en contact avec un

câblage caché ou le cordon de la scie.

Tout contact entre une chaîne de scie et

un fil « sous tension » risque de mettre

« sous tension » les pièces métalliques

exposées de l’outil et de donner un choc

électrique à l’opérateur.

• Porter des lunettes de sécurité et

une protection auditive. Le port

d’un équipement de protection

supplémentaire pour la tête, les

mains, les jambes et les pieds est

recommandé. Les vêtements de

protection appropriés réduisent les

blessures corporelles causées par les

débris projetés ou un contact accidentel

avec la chaîne de scie.

• Ne pas grimper dans un arbre pour

utiliser la scie à chaîne. L’utilisation d’une

scie à chaîne en hauteur dans un arbre peut

se solder par des blessures corporelles.

• Conserver toujours un pas sûr et

utiliser uniquement la scie à chaîne

debout sur une surface fixe, sécuritaire

et de niveau. Les surfaces glissantes ou

instables comme les échelles peuvent

entraîner une perte de l’équilibre ou du

contrôle de la scie à chaîne.

• Lors de la coupe d’une branche

maîtresse sous tension, prendre

Page 17

17

garde au redressement de la branche.

Lorsque la tension contenue dans les

fibres de bois se relâche, la branche

maîtresse pendant la détente risque

de frapper l’utilisateur et/ou de lui faire

perdre le contrôle de la scie à chaîne.

• Être extrêmement prudent lors de la

coupe de broussailles ou de jeunes

arbres. Les branches élancées peuvent

se coincer dans la chaîne et être projetées

vers vous ou vous déséquilibrer.

• Transporter la scie à chaîne par la

poignée avant avec l’outil hors tension

et à l’écart du corps. Toujours mettre

la gaine du guide-chaîne avant de

transporter ou d’entreposer la scie à

chaîne. La manipulation adéquate de la

scie à chaîne réduit le risque de contact

accidentel avec la chaîne en mouvement.

• Suivre les consignes de graissage, de

tension de la chaîne et de changement

d’accessoires. Une chaîne mal tendue

ou graissée risque de se briser ou accroît

la probabilité d’un effet de rebond.

• Maintenir les poignées sèches,

propres et exemptes d’huile et de

graisse. Des poignées pleines de graisse

sont glissantes et peuvent vous faire

perdre le contrôle de votre outil.

• Ne couper que le bois. Ne pas utiliser

la scie à chaîne pour des applications

pour lesquelles l’outil n’est pas

conçu, comme la coupe des matières

plastiques, de la maçonnerie ou des

matériaux de constructions qui ne

sont pas en bois. L’utilisation de la scie

à chaîne pour toutes opérations autres

que celles pour lesquelles elle a été

conçue est dangereuse.

Causes de l’effet de rebond et

prévention par l’opérateur :

L’effet de rebond se produit lorsque

l’extrémité ou la partie supérieure du guidechaîne frappe un objet ou lorsque la chaîne

se coince dans une entaille.

Le contact de l’extrémité pourrait provoquer

une réaction inverse soudaine qui

projetterait le guide-chaîne vers le haut et

l’arrière en direction de l’opérateur.

Un coincement de la chaîne de la scie

sur le dessus du guide-chaîne pourrait

repousser rapidement le guide-chaîne vers

l’arrière en direction de l’opérateur.

L’un ou l’autre de ces mouvements

brusques pourrait vous faire perdre la

maîtrise de la scie et se solder par une

grave blessure corporelle. Il ne faut pas

se fier exclusivement aux dispositifs de

sécurité intégrés à votre scie. L’utilisateur

de scie à chaîne doit prendre plusieurs

mesures pour éviter tout accident ou toute

blessure lors des travaux de coupe.

Un effet de rebond est le résultat

d’une mauvaise utilisation de l’outil et/

ou de procédures ou conditions de

fonctionnement incorrectes. Il peut

être évité en prenant les précautions

nécessaires telles que décrites ci-dessous :

• Saisir fermement la scie à chaîne

des deux mains, avec les pouces et

les doigts autour des poignées, et

positionner le corps et les bras de

sorte à résister à la force de l’effet de

rebond. Il est possible de maîtriser

les forces de l’effet de rebond avec de

telles mesures de précaution. Ne pas

lâcher la scie à chaîne.

• Ne pas trop tendre les bras et ne

pas couper au-dessus du niveau des

épaules. Cela aide à éviter un contact

accidentel de l’extrémité et permet de

mieux maîtriser la scie à chaîne dans les

situations imprévues.

• Utiliser uniquement les guide-chaînes

et les chaînes de remplacement

spécifiés par le fabricant. Les guide-

chaînes et les chaînes de remplacement

inadéquats peuvent entraîner un bris de

la chaîne et/ou un effet de rebond.

• Suivre les directives du fabricant pour

l’affûtage et l’entretien de la chaîne

de scie. Le fait de baisser le guide de

profondeur peut accroître l’effet de rebond.

Suivre les précautions qui suivent pour

réduire l’effet de rebond notamment :

(1.) Saisir fermement la scie à chaîne. Tenir

fermement la scie à chaîne avec les deux

mains lorsque le moteur est en marche.

Utiliser une prise ferme avec les pouces et

les doigts et encercler les poignées de la

scie à chaîne. La scie à chaîne imprimera

un mouvement avant lors de la coupe avec

la partie inférieure du guide-chaîne et un

mouvement arrière lors de coupe avec la

partie supérieure du guide-chaîne.

(2.) Ne pas trop se pencher.

(3.) Conserver son équilibre en tout temps.

(4.) Ne pas laisser l’extrémité du guidechaîne frapper un billot, une branche, le sol

ou tout autre obstruction.

(5.) Ne pas couper au-dessus de la hauteur

des épaules.

(6.) Utiliser des dispositifs comme des chaînes

à faible effet de rebond et des guides-chaîne à

faible effet de rebond pour réduire les risques

associés à l’effet de rebond.

(7.) Utiliser uniquement des guides-chaîne

et des chaînes de rechange précisés par le

fabricant ou son équivalent.

(8.) Ne pas mettre en contact la chaîne et tout

objet se trouvant à l’extrémité du guide-chaîne.

(9.) Tenir la zone de travail dégagée et

exempte d’obstructions comme d’autres

arbres, branches, roches, clôtures,

souches, etc. Éliminer ou éviter toute

obstruction que la scie à chaîne pourrait

Page 18

18

frapper lors d’une coupe d’un billot ou

d’une branche en particulier.

(10.) Maintenir la chaîne de la scie bien

affûtée et tendue correctement. Une chaîne

lâche ou émoussée peut augmenter le

risque d’effet de rebond. Vérifier la tension

à intervalles réguliers, avec le moteur hors

tension et sans le bloc-piles, jamais avec le

moteur en marche.

(11.) Commencer et poursuivre la coupe

uniquement lorsque la chaîne fonctionne

à plein régime. Si la chaîne tourne à un

régime plus lent, le risque d’un effet de

rebond est plus élevé.

(12.) Tronçonner un seul billot à la fois.

(13.) Faire très attention lorsque vous

recommencez à scier à partir d’une

entaille déjà entamée. Appuyer les butées

cannelées contre le tronc et laisser la

chaîne atteindre son plein régime avant de

poursuivre la coupe.

(14.) Ne pas essayer de coupes en

plongée ou le perçage de trous.

(15.) Prendre garde au déplacement des

billots ou à d’autres forces qui pourraient

faire refermer une entaille et pincer la

chaîne ou qui pourraient tomber sur celle-ci.

Directives de sécurité concernant l’effet

de rebond

AVERTISSEMENT : la scie à chaîne est

dotée des caractéristiques suivantes afin

d’aider à réduire les risques liés à l’effet de

rebond; toutefois, ces caractéristiques

n’élimineront pas totalement cette

dangereuse réaction. En tant qu’utilisateur

de scie à chaîne, ne pas se fier uniquement

aux dispositifs de sécurité. Vous devez

respecter toutes les précautions, directives

et consignes d’entretien et de sécurité

contenues dans ce manuel afin d’essayer

d’éviter l’effet de rebond et autres forces qui

pourraient entraîner de graves blessures.

• Frein de chaîne, conçu pour éteindre

immédiatement la scie à chaîne si le

rebond est trop grand.

• Guide-chaîne à faible effet de rebond,

conçu avec une extrémité de faible rayon

qui réduit la taille de la zone dangereuse

d’effet de rebond sur l’extrémité de la

barre. Un guide-chaîne à faible effet

de rebond est l’un des dispositifs qui

réduit de manière significative le nombre

et l’ampleur des effets de rebond

lors d’essais en conformité avec les

exigences de sécurité pour les scies à

chaîne électriques.

• Chaîne à effet de rebond réduit, conçue

avec un guide de profondeur profilé et un

lien de pare-main qui dévie la force de

l’effet de rebond et permet à la chaîne de

s’enfoncer progressivement dans le bois.

Une chaîne à faible effet de rebond est

une chaîne conforme aux exigences de

performance ANSI B175.1-1991.

• Ne pas utiliser la scie à chaîne lorsque

vous êtes dans un arbre, sur une

échelle ou un échafaudage ou sur

toute autre surface instable.

• Tenir l’outil par sa surface de prise

isolée dans une situation où l’outil de

coupe peut entrer en contact avec un

câblage dissimulé. Tout contact avec un

fil « sous tension » mettra « sous tension

» les pièces métalliques exposées de

l’outil et électrocutera l’opérateur.

• Ne pas effectuer d’opérations au-delà de

sa capacité ou de son expérience. Lire

attentivement et comprendre parfaitement

les directives de ce mode d’emploi.

• Avant de démarrer la scie à chaîne,

s’assurer que la chaîne est dégagée,

sans aucun contact avec des objets.

• Ne pas utiliser la scie à chaîne d’une

seule main! Une telle pratique risque

de blesser gravement l’opérateur,

les aides ou les curieux. Une scie à

chaîne est conçue uniquement pour une

utilisation à deux mains.

• Garder les poignées sèches, propres

et exemptes d’huile ou de graisse.

• Ne pas laisser la saleté, les débris ou

la sciure s’accumuler sur le moteur ou

les évents externes.

• Arrêter la scie à chaîne avant de la

déposer sur le sol.

• Ne pas couper de vignes, de petites

broussailles ou du sous-bois.

• Être extrêmement prudent lors de la

coupe de broussailles ou de jeunes

arbres, car les branches élancées

peuvent se coincer dans la chaîne et être

projetées vers vous ou vous déséquilibrer.

AVERTISSEMENT : certains outils

électriques, tels que les sableuses, les scies,

les meules, les perceuses ou certains autres

outils de construction, peuvent produire de

la poussière contenant des produits

chimiques reconnus par l’État de la

Californie comme étant susceptibles

d’entraîner le cancer, des malformations

congénitales ou pouvant être nocifs pour le

système reproductif. Parmi ces produits

chimiques, on retrouve :

• le plomb contenu dans les peintures à

base de plomb,

• la silice cristalline de la brique, du

ciment et d’autres

produits de maçonnerie, et

• l’arsenic et chrome provenant de bois

traité chimiquement

Les risques reliés à l’exposition à ces

poussières varient selon la fréquence à

laquelle l’utilisateur travaille avec ce type

de matériaux. Pour réduire l’exposition à

ces produits chimiques, travailler dans un

endroit bien ventilé et porter un équipement

Page 19

19

de sécurité approuvé comme un masque

antipoussières conçu spécialement pour

filtrer les particules microscopiques.

• Éviter le contact prolongé avec les

poussières produites par les activités

de ponçage, sciage, meulage, perçage

et autres activités de construction.

Porter des vêtements de protection et

laver les parties du corps exposées

avec une solution d’eau et de savon.

Laisser la poussière pénétrer dans

la bouche et les yeux ou la laisser

reposer sur la peau, pourrait promouvoir

l’absorption de produits chimiques nocifs.

AVERTISSEMENT : Utilisation de cet

outil peut générer ou débourser de

poussière, ce qui peut causer des

blessures graves et permanentes

respiratoires ou autres. Toujours utiliser

une protection respiratoire approuvé par

NIOSH/OSHA approprié pour l’exposition à

la poussière. Particules directs loin du

visage et du corps.

TERMINOLOGIE ET

NOMENCLATURE RELATIVES Á

SCIES Á CHAÍNE

• Tronçonnage - le processus de coupe

transversale d’un arbre abattu ou d’un

billot en morceaux.

• Frein moteur - un dispositif utilisé pour

immobiliser la chaîne de la scie dès

que la détente est relâchée.

• Tête motorisée de la scie à chaîne -

une scie sans chaîne et guide-chaîne.

• Pignon d’entraînement ou pignon -

la pièce dentée qui entraîne la chaîne

de l’outil.

• Abattage - le processus de coupe d’un arbre.

• Trait d’abattage - la dernière entaille

pratiquée au côté opposé à l’entaille

d’abattage sur le tronc d’un arbre.

• Poignée avant - la poignée d’appui

logée à l’avant ou vers l’avant de la

scie à chaîne.

• Protège-main avant - une barrière

physique entre la poignée avant de

la scie à chaîne et le guide-chaîne

normalement positionné près de la

main sur la poignée avant et parfois

utilisé comme levier d’actionnement du

frein de chaîne.

• Guide-chaîne - une solide structure

sur rail qui supporte et guide la chaîne

de l’outil.

• Fourreau du guide-chaîne - boîtier

qui s’adapte sur le guide-chaîne pour

prévenir le contact des dents lorsque la

scie n’est pas en utilisation.

• Effet de rebond - le mouvement

vertical ou arrière, ou les deux

simultanément, du guide-chaîne, se

produit lorsque la chaîne près de

l’extrémité supérieure du guide-chaîne

frappe un objet tel un billot ou une

branche ou lorsque la chaîne est prise

dans une entaille du tronc.

• Effet de rebond par pincement - le

refoulement rapide de la scie peut

se produire lorsque l’entaille dans le

tronc se referme et pince la chaîne

en mouvement et la bloque près de

l’extrémité du guide-chaîne.

• Effet de rebond par rotation - le

mouvement vertical ou arrière rapide de

la scie peut se produire lorsque la chaîne

en mouvement près de l’extrémité

supérieure du guide-chaîne frappe un

objet tel un billot ou une branche.

• Ébranchage - la coupe des branches

d’un arbre abattu

• Chaîne à faible effet de rebond - une

chaîne conforme aux exigences de

performance de rebond de la norme

ANSI B175.1-1991 (lors d’essais sur un

échantillon représentatif de scies à chaîne).

• Position normale de coupe - ces

positions sont utilisées lors du

tronçonnage et des entailles d’abattage.

• Entaille d’abattage - une entaille dans

le tronc qui dirige la chute de l’arbre.

• Poignée arrière - la poignée d’appui

logée à l’arrière ou vers l’arrière de la scie.

• Guide-chaîne à faible effet de rebond

- un guide-chaîne qui réduit de façon

significative et prouvée l’effet de rebond.

• Chaîne de rechange - une chaîne

conforme aux exigences de

performance d’effet de rebond de la

norme ANSI B175.1-1991 lors d’essais

avec des modèles spécifiques de

scies à chaîne. Il est possible que

cette chaîne ne soit pas conforme aux

exigences de performance ANSI si

utilisée sur d’autres modèles d’outils.

• Chaîne pour scies à chaîne - une

chaîne dentée en boucle, qui coupe le

bois, et qui est entraînée par le moteur

et supportée par le guide-chaîne.

• Butée cannelée - le point d’appui utilisé

en cours d’abattage ou de tronçonnage

pour faire pivoter la scie et maintenir la

position lors de la coupe.

• Interrupteur - un dispositif qui, lorsque

actionné, complètera ou interrompra un circuit

électrique du moteur de la scie à chaîne.

• Bielle - un mécanisme qui transmet le

mouvement d’une détente à l’interrupteur.

• Verrou d’interrupteur - une butée

qui se déplace pour empêcher le

fonctionnement non intentionnel

de l’interrupteur à moins d’un

actionnement manuel.

UTILISATION PRÉVUE

La scie à chaîne sans fil BLACK+DECKER

est parfaite pour l’élagage et le tronçonnage

de petits billots jusqu’à 406 mm (16 po) de

diamètre. Cet outil se destine uniquement à

être utilisé par les consommateurs.

Page 20

20

SYMBOLES

• L’étiquette apposée sur votre outil pourrait

comprendre les symboles suivants. Les

symboles et leurs définitions sont indiqués

ci-après :

V ................. volts

A ................. ampères

Hz ............... hertz

W ................ watts

min ..............minutes

ou AC ....courant alternatif

ou DC ..courant continu

n

o ...............sous vide

................ Construction de classe I

PRÉPARATION POUR L’UTILISATION DE

LA SCIE À CHAÎNE

AVERTISSEMENT : Lire et assimiler toutes

les directives. Le non-respect des directives

indiquées ci-dessous peut entraîner des

risques de choc électrique, d’incendie ou de

blessures corporelles graves.

ASSEMBLAGE

INSTALLATION DU GUIDE-CHAÎNE ET

DE LA CHAÎNE

MISE EN GARDE :

Chaîne affûtée.

Toujours porter des gants protecteurs lors

de la manipulation de la chaîne. La chaîne

est tranchante et peut vous couper même

lorsqu’elle est au repos.

AVERTISSEMENT :

Chaîne affûtée en

mouvement. Pour prévenir tout

fonctionnement accidentel, s’assurer de

débrancher l’outil avant d’effectuer les

opérations suivantes. Le non-respect de

cette directive risque d’entraîner des

blessures corporelles graves.

................borne de mise à la minute

(mis à la terre)

...............

Construction de classe II

.............. symbole d´avertissement

.../min ..........tours à la minute

.............. Lire le mode d’emploi avant

l’utilisation

............Utiliser une protection

respiratoire adéquate.

...........Utiliser une protection oculaire

adéquate.

............Utiliser une protection auditive

adéquate.

La chaîne (5) et le guide-chaîne (4) sont

emballés individuellement dans la boîte. La

chaîne doit être attachée au guide-chaîne,

et l’ensemble doit être monté sur le corps

de l’outil.

• Déposer la scie sur une surface ferme.

• Tourner le bouton de réglage du guide-

chaîne (7) dans le sens antihoraire

comme le montre la figure A pour

enlever le couvercle du pignon (6).